S&A CW-3000 Series, CW-3000AG, CW-3000DG, CW-3000DF, CW-3000AK User Manual

...

CW-3000 USER MANUAL

1

CW-3000

INDUSTRIAL CHILLER

USER MANUAL

CW-3000 USER MANUAL

2

<1> INTRODUCTION

CW-3000 Series is professional cooling machine referring to international

advanced thermolysis cooling system design, suitable for small

water-cooled cooling devices requested machinery.

1. Specific disconnection alarm security protection.

2. Hermetic type water tank, water is available for a long time used.

3. Real-time temperature monitoring, accurate knowledge of heating devices

working condition.

4. Professional air-cooled forced radiator with strong heat dissipating

capacity and difficult to be blocked up.

5. Equipped with alarm output port to protect sensitive components quickly.

6. High cost performance, low failure rate.

7. There are several options of power supply, complete in specifications.

<2> CAUTION

1. It is strictly forbidden to plug and run the cooler without feeding water.

2. Cooler should be placed in a well-ventilated, dry environment place and

away from heat sources. Please keep at least 30cm from obstructions to the

air outlet which is in the back of the cooler, and should leave at least 10cm

between obstructions and air inlets of two sides.

3. The cooling water must be drained if the cooler is out of use for long time or

before being transported.

4. To protect laser tubes , the radiator fan of cooler will suspend to work when

water temperature is lower ( about 10℃ ) , and it will restart to run when

water temperature rises to higher ( about 20 ℃).

CW-3000 USER MANUAL

3

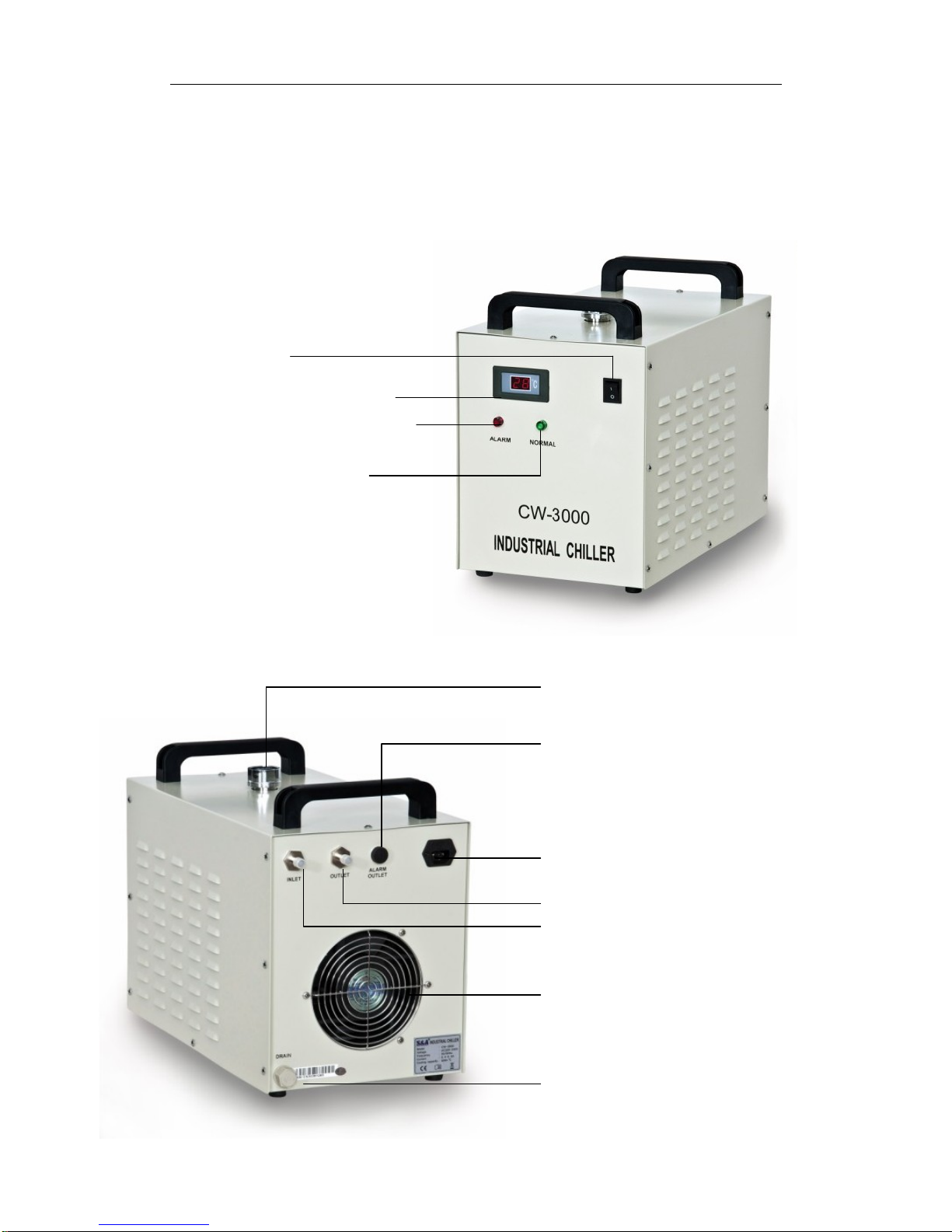

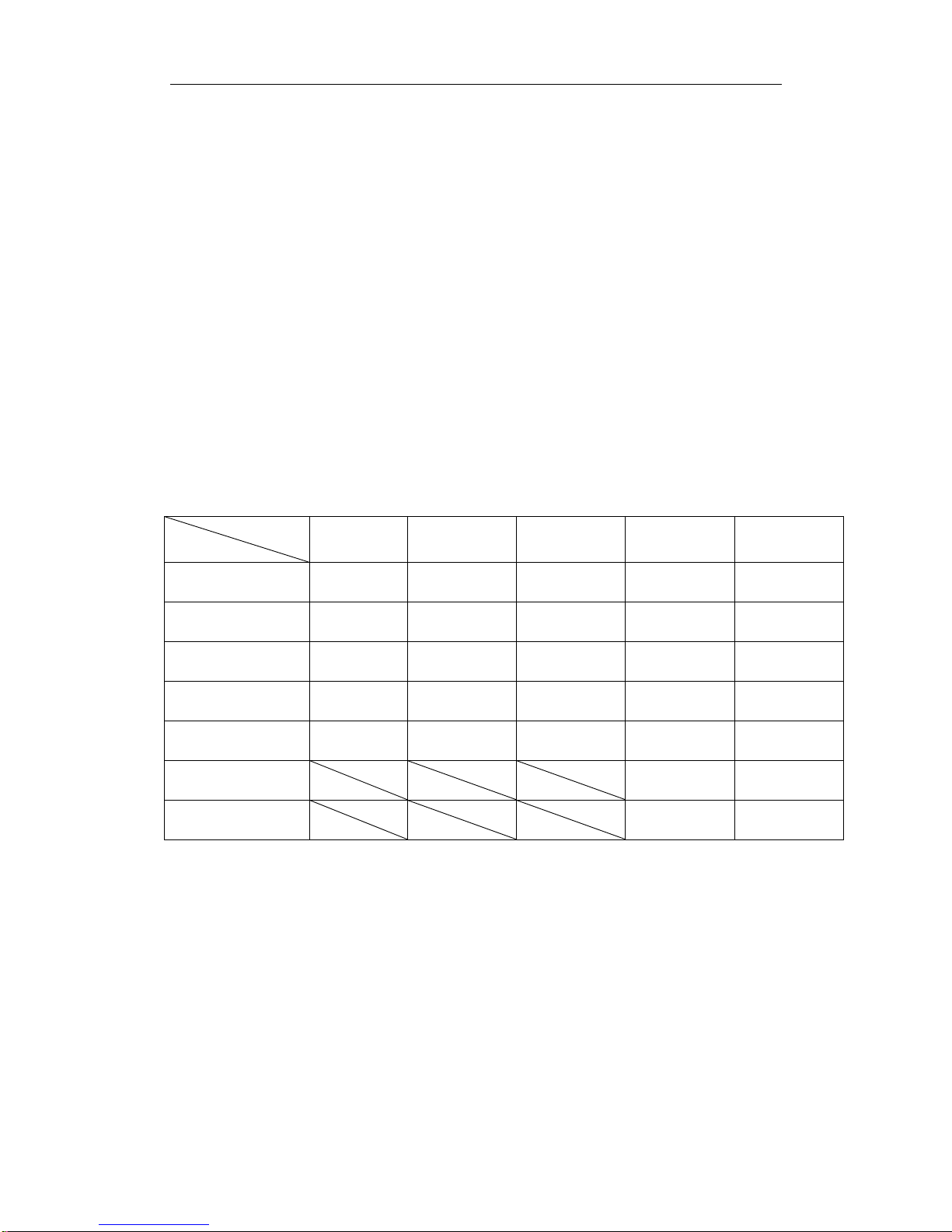

<3> Details

1.Shape and parts name

FRONT

BACK

POWER SW

TEMPERATURE DISPLAY

SYSTEM ALARM INDICATOR

RUNNING INDICATOR

WATER SUPPLY INLET

ALARM SIGNAL OUTPUT TERMINAL

POWER SOCKET (WITH FUSE)

OUTLET

INLET

WATER DRAIN

RADIATOR FAN

CW-3000 USER MANUAL

4

2. The first installation

It is very simple to install this industrial cooling machine. The first time

installation of the new machine can be carried out by following steps.

1. Open the package to check if the machine is intact and all the necessary

accessories are completed.

2. Open the injection port, then add cooling water.

3. According to system conditions, connect the water inlet and outlet pipe

well.

4. Plug in power, turn on the power switch. (Do not allow the water overflow)

5. Check the w ater level of the water tank again. (It should be 80-150cm from

the surface of water to the injection port)

3. Alarm description

Causes of the cooling water circulation loop alarm and the working condition

table.

Display

Condition

Green

light

Red

light

Buzzer

out

H1、H2

out

H1、H3

Normal On Off No voice Off On

Water stops up Off On Voice On Off

Surpasses 60℃

Off On Voice On Off

Pump breakdown Off On Voice On Off

Water alarm Off On Voice On Off

Faulted circuit On Off

Power outage On Off

Note: The flow alarm port connects to the normally open relay and normally closed

relay contacts, requiring operating current to be less than 5A, working voltage less

than 300V.

Loading...

Loading...