Page 1

CW-3000 USER MANUAL

1

CW-3000

INDUSTRIAL CHILLER

USER MANUAL

Page 2

CW-3000 USER MANUAL

2

<1> INTRODUCTION

CW-3000 Series is professional cooling machine referring to international

advanced thermolysis cooling system design, suitable for small

water-cooled cooling devices requested machinery.

1. Specific disconnection alarm security protection.

2. Hermetic type water tank, water is available for a long time used.

3. Real-time temperature monitoring, accurate knowledge of heating devices

working condition.

4. Professional air-cooled forced radiator with strong heat dissipating

capacity and difficult to be blocked up.

5. Equipped with alarm output port to protect sensitive components quickly.

6. High cost performance, low failure rate.

7. There are several options of power supply, complete in specifications.

<2> CAUTION

1. It is strictly forbidden to plug and run the cooler without feeding water.

2. Cooler should be placed in a well-ventilated, dry environment place and

away from heat sources. Please keep at least 30cm from obstructions to the

air outlet which is in the back of the cooler, and should leave at least 10cm

between obstructions and air inlets of two sides.

3. The cooling water must be drained if the cooler is out of use for long time or

before being transported.

4. To protect laser tubes , the radiator fan of cooler will suspend to work when

water temperature is lower ( about 10℃ ) , and it will restart to run when

water temperature rises to higher ( about 20 ℃).

Page 3

CW-3000 USER MANUAL

3

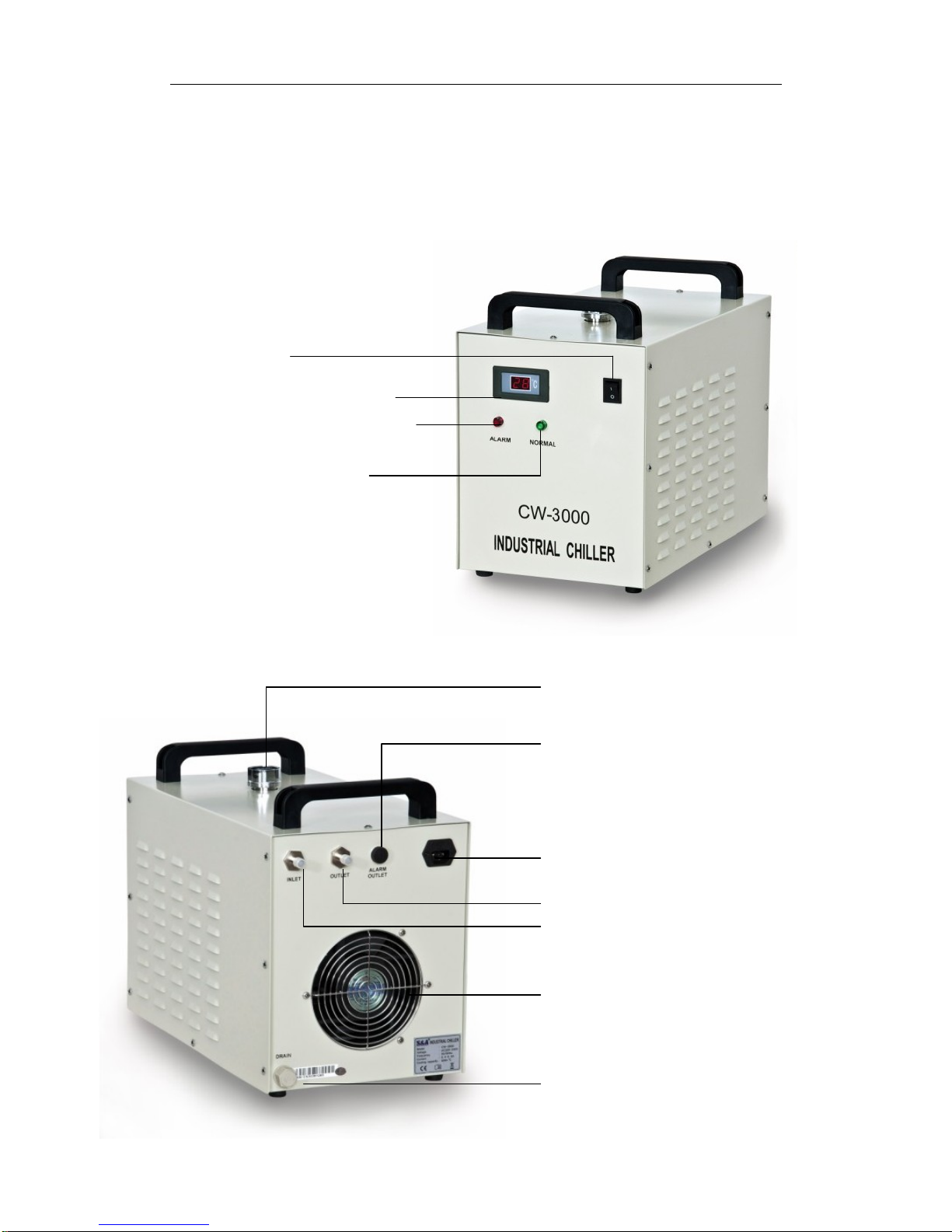

<3> Details

1.Shape and parts name

FRONT

BACK

POWER SW

TEMPERATURE DISPLAY

SYSTEM ALARM INDICATOR

RUNNING INDICATOR

WATER SUPPLY INLET

ALARM SIGNAL OUTPUT TERMINAL

POWER SOCKET (WITH FUSE)

OUTLET

INLET

WATER DRAIN

RADIATOR FAN

Page 4

CW-3000 USER MANUAL

4

2. The first installation

It is very simple to install this industrial cooling machine. The first time

installation of the new machine can be carried out by following steps.

1. Open the package to check if the machine is intact and all the necessary

accessories are completed.

2. Open the injection port, then add cooling water.

3. According to system conditions, connect the water inlet and outlet pipe

well.

4. Plug in power, turn on the power switch. (Do not allow the water overflow)

5. Check the w ater level of the water tank again. (It should be 80-150cm from

the surface of water to the injection port)

3. Alarm description

Causes of the cooling water circulation loop alarm and the working condition

table.

Display

Condition

Green

light

Red

light

Buzzer

out

H1、H2

out

H1、H3

Normal On Off No voice Off On

Water stops up Off On Voice On Off

Surpasses 60℃

Off On Voice On Off

Pump breakdown Off On Voice On Off

Water alarm Off On Voice On Off

Faulted circuit On Off

Power outage On Off

Note: The flow alarm port connects to the normally open relay and normally closed

relay contacts, requiring operating current to be less than 5A, working voltage less

than 300V.

Page 5

CW-3000 USER MANUAL

5

4. Maintenance

1. To ensure good heat dissipating, please open the lid to clean the dirt after the

cooler used in long-term.

2. Working in cold north area, it is better to use noncorrosive antifreeze fluid.

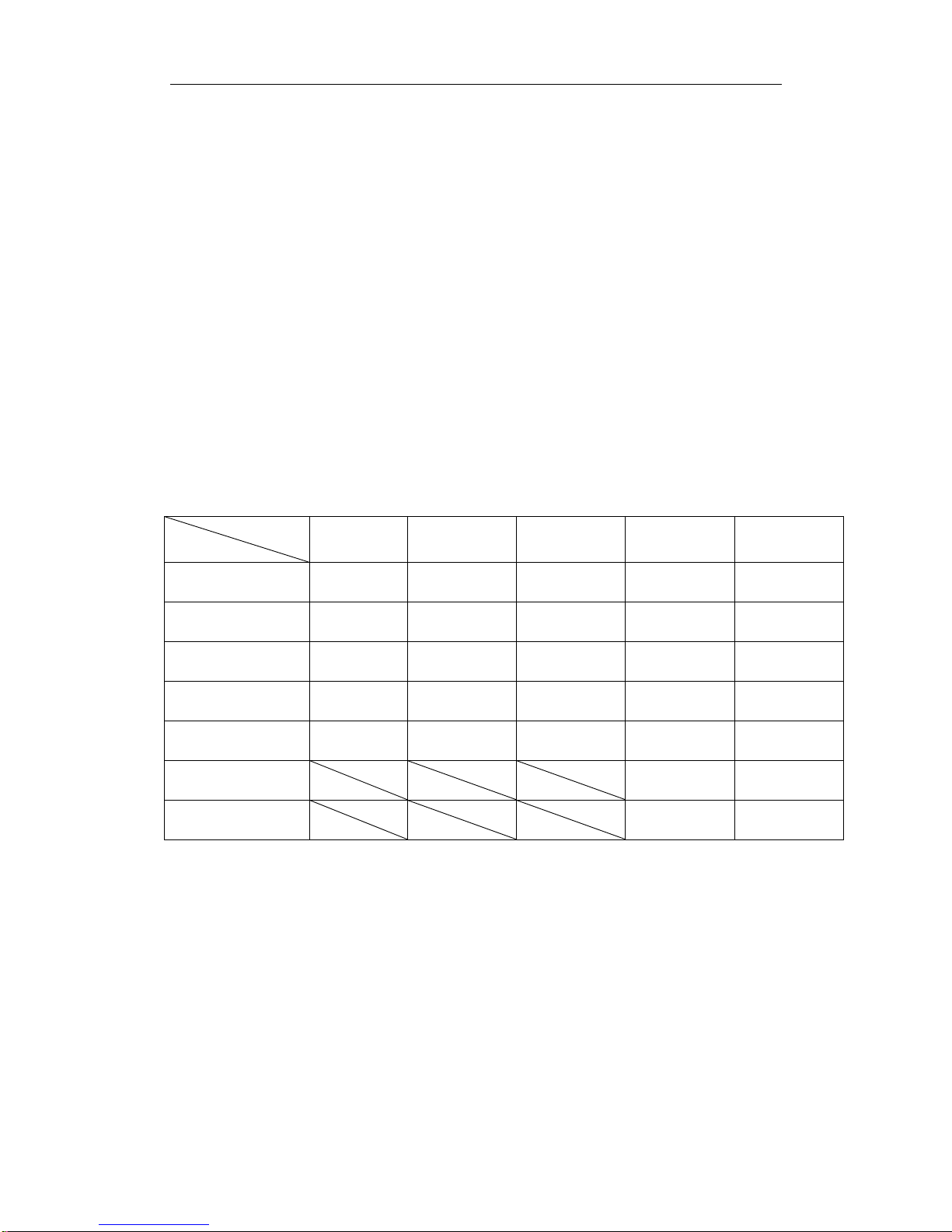

<4> SPECIFICATIONS

Model CW-3000AG CW-3000DG CW-3000AF CW-3000DF CW-3000AK CW-3000DK

Voltages AC220~240V AC100~120V AC220~240V AC100~120V AC220~240V AC100~120V

Frequency 50/60Hz

Current 0.45A 0.9A 0.45A 0.9A 0.5A 1.0A

Cooling 50W/ °C 60W/ °C

capacity 9 L

Inlet and

outlet hold

Outside dimensions

10mm brass connector

Inside dimensions

8mm speedy connector

Inside dimensions

6mm speedy connector

Max. pumping

lift

10 M 70 M

N.W 9.5Kg 12Kg

G.W 12Kg 14.5Kg

Dimensions 47X27X37cm (L X W X H)

Packing

dimensions

59X39X48cm (L X W X H)

Page 6

CW-3000 USER MANUAL

6

<5> SIMPIE TROUBLESHOOTING

Failure Fault cause Approach

Machine turned on

but unelectrified

Power cord is not

plugged in place

Plug the power

cord in place

fuse burnt-out

Replace the fuse inside the

power interface which is in

the back of machine

Flow alarm (panel red light)

with water pipe directly

connect to the outlet,

inlet, there is no water flow

Water level in

water tank is

too low

Feed water and check the

pipe leakage

When used with the device,

flow alarm (panel red light),

but a direct connection with

the pipe outlet and inlet,

there is water flowing but

not alarming

Blockage in

circulating water

pipeline

Check circulating

water pipeline

Ultra-high temperature

Chiller of poor

ventilation

To improve the ventilation

Excessive heat load

Reduce the heat load or

to use other models

A normal boot, but the

fan does not work

The water temperature

below 20 degrees

A normal phenomenon,

no processing

Switch on with alarming

after adding water or

changing water

Water drop in

electric circuit

Natural drying or

drying off cap

Damaged pumps

dry transfer

To replace or repair water

pumps,prohibited

anhydrous boot

Slow outfall drainage

The injection port

is not open

Open the injection port

<6> PACKING LIST

1. Machine 1pc,user manual 1pc.

2. Power cord 1pc, connection hose 1pc,sealed hoop 2pcs.

3. Spare fuse for 250V/2A 1pc. (Held in the spare fuseholder of power socket.)

4. An alarm signal output plug.

CAUTION: The appliance is not to be used by children or persons with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction,children

being supervised not to play with the appliance!

Page 7

CW-3000 USER MANUAL

7

CW-3000 工业循环冷却机

使用安装说明书

Page 8

CW-3000 USER MANUAL

8

一、 功能特点简介

CW-3000 系列是参照国际先进散热型冷却系统设计制造的

专业冷却机,适用于小型水冷散热设备。

( 1) 特有断流报警安全保护功能。

( 2) 密闭式水箱,一次加水长期使用。

( 3) 实时温度监控,准确掌握发热器件工作状态。

( 4) 专业散热器强制风冷,散热量大,不易堵塞。

( 5) 设有报警输出端口,可快速保护敏感元件。

( 6) 性能价格比高,故障率低。

( 7) 有多种电源的机型,规格齐全。

二、使用注意事项

(1)冷却机在没有加水的情况下严禁通电开机!

(2)冷却机的安放位置应尽量选择通风良好、干燥的环境,远离其它

热源。机器后面的出风口距离障碍物 30cm 以上,两侧的入风口

距离障碍物 10cm 以上。

(3)冷却机在长期不用或运输时必须排空冷却水。

(4)为保护发热器件,冷却机在水温较低时(约 10℃),散热风扇会

暂停工作,而当水温回升到较高时(约 20℃),散热风扇将继续

工作。

Page 9

CW-3000 USER MANUAL

9

三、使用说明

1、外形及部件名称

机身正面

机身背面

电源开关

温度显示

系统报警指示灯

正常运行指示灯

注水口

报警信号输出端口

电源接口(带保险管)

出水口

回水口

散热风扇

排水口

Page 10

CW-3000 USER MANUAL

10

2、首次安装

工业冷却机安装使用非常简单,新机首次使用可以按以下步骤

进行。

(1)打开包装,检查机器是否完好,附件是否齐备。

(2)拧开机器顶部注水口,加入冷却水。(严禁无水开机)

(3)根据系统情况把出、入水管接好。

(4)接上电源,打开电源开关。(注意不要让水溢出)

(5)再次检查水箱水位。(以水面距注水口距离 80-150mm 为 宜 )

3、报警功能说明

冷却水循环回路报警原因与工作状态表。

系统指示

工作状态

绿色

指示灯

红色

指示灯

蜂鸣器

输出端口

H1、H2

输出端口

H1、H3

系统工作正常 发光 熄灭 不发声 断路 导通

冷却水循环回路堵塞 熄灭 发光 发声 导通 断路

冷却水温度超过 60 度 熄灭 发光 发声 导通 断路

循环水泵故障 熄灭 发光 发声 导通 断路

缺水报警 熄灭 发光 发声 导通 断路

电路故障

导通 断路

供电中断

导通 断路

注:流量报警端口连接机内继电器一组常开、常闭触点。要求工作电流小于 5A,

工作电压小于 300V。

Page 11

CW-3000 USER MANUAL

11

3、报警功能说明

(1)冷却机在长期使用后建议开盖清理灰垢,以保证散热性能良好。

(2)北方寒冷地区应该使用无腐蚀性的防冻液。

四、技术参数

型号 CW-3000AG CW-3000DG CW-3000AF CW-3000DF CW-3000AK CW-3000DK

工作电压 AC220~240V AC100~120V AC220~240V AC100~120V AC220~240V AC100~120V

工作频率 50/60Hz

工作电流 0.45A 0.9A 0.45A 0.9A 0.5A 1.0A

散热量 50W/ °C 60W/ °C

水箱容量 9 L

出入口 外径 10mm 铜咀 直径 8mm 快速接头 直径 6mm 快速接头

最大扬程 10 M 70 M

净重 9.5Kg 12Kg

毛重 12Kg 14.5Kg

机器尺寸 47X27X37cm (L x W x H)

包装尺寸 59X39X48cm (L x W x H)

Page 12

CW-3000 USER MANUAL

12

五、简单故障处理

故障现象 故障原因 处理方法

开机不通电

电源线没有插到位 把电源线插到位

保险管熔断

更换机器后面电源

接口内保险管

流量报警(面板红灯亮)

用水管直接连接出水口、

入水口,没有水流

储水箱水位太低 加水并检查管路渗漏情况

与设备连接使用时流量报

警(面板红灯亮),但用水

管直接连接出水口、

入水口,有水流不报警

循环水管路堵塞 检查循环水管路

水温超高

冷水机通风不好 改善通风条件

热负荷超标 降低热负荷或选用其它机型

开机后风扇不转 水温低于 20 度 正常现象,无需处理

加水或换水后开机报警

电路进水 自然晾干或开盖吹干

水泵干转损坏

更换或维修水泵,

严禁无水开机

排水口排水缓慢 注水口没有打开 打开注水口

六、装箱清单

(1)工业循环冷却机一台,使用说明书一份。

(2)电源线一条,连接软管一条,密封箍两个。

(3)250V/2A 备用保险管一个。(装在电源接口备用保险管座内)

(4)报警信号输出端插头一个。

注意:本产品为工业设备,请勿让儿童玩耍!

Loading...

Loading...