Ryobi ZR51950A—250000001, ZR51970A—250000001, ZR51990A—250000001, ZR51950A, ZR51970A Operator's Manual

...Page 1

Trimmer/Brushcutter

Model No. ZR51950A—250000001 & Up

Model No. ZR51970A—250000001 & Up

Model No. ZR51990A—250000001 & Up

Operator’s Manual

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s manual. Save this manual.

1

Page 2

3

READ THIS INFORMATION

Before you use your new trimmer/brushcutter, read the following helpful hints to get you started.

Fueling

DANGER:

Gasoline is extremely ammable and explosive. A

re or explosion from gasoline will burn you and

others.

1. Obtain a clean container that is approved for use with gasoline.

2. Mix all of the 2-cycle oil provided with 1 US gallon of 87-octane, unleaded

gasoline.

3. Fill the trimmer’s gas tank carefully.

Cold Starting vs. Warm Starting

When you restart the trimmer/brushcutter and you are not sure whether the engine is still warm, set

the start lever to RUN (Choke Open) and pull the starter cord. If the engine does not start within 5

pulls, refer to “To Start a Cold Engine” later in this manual.

Flooded Engine

Will the engine start? If not, it may be ooded. Relax, this is easy to correct. Set the start lever to

RUN (Choke Open). Squeeze the trigger and pull the starter cord quickly for 10 to 12 pulls.

If the engine does not start, refer to “Troubleshooting” later in this manual.

WARNING: The engine exhaust from this product contains chemicals known to the State

of California to cause cancer, birth defects, or other reproductive harm.

2

Printed in USA

All rights reserved

Page 3

Table of Contents

Introduction...................................................................................................................................................................................4

Safety Rules .............................................................................................................................................................................. 5-6

Symbols .................................................................................................................................................................................... 6-7

Product Labels ..............................................................................................................................................................................8

Features................................................................................................................................................................................... 9-10

Product Specications ...........................................................................................................................................................9

Assembly................................................................................................................................................................................11-15

Unpacking............................................................................................................................................................................ 11

Connecting the Attachment to the Upper Shaft...................................................................................................................12

Removing the Attachment from the Upper Shaft ................................................................................................................12

Attaching the Front Handle..................................................................................................................................................12

Attaching the Shoulder Strap...............................................................................................................................................12

Attaching the Grass Deector..............................................................................................................................................12

Converting from Brushcutter to Trimmer............................................................................................................................14

Converting from Trimmer to Brushcutter............................................................................................................................15

Operation............................................................................................................................................................................... 16-19

Applications.........................................................................................................................................................................16

Mixing the Fuel....................................................................................................................................................................16

Filling the Tank ....................................................................................................................................................................16

Starting the Product .............................................................................................................................................................17

Stopping the Product............................................................................................................................................................17

Operating the Trimmer ........................................................................................................................................................18

Operating the Brushcutter....................................................................................................................................................19

Maintenance.......................................................................................................................................................................... 20-23

Emissions Maintenance Schedule........................................................................................................................................20

Cleaning the Product............................................................................................................................................................20

Servicing the Product...........................................................................................................................................................20

Replacing the Cutting Line............................................................................................................................................ 20-21

Replacing the Spool.............................................................................................................................................................21

Checking the Fuel Cap.........................................................................................................................................................22

Cleaning the Air Filter .........................................................................................................................................................22

Replacing the Spark Arrester............................................................................................................................................... 22

Replacing the Spark Plug.....................................................................................................................................................23

Storing the Product .............................................................................................................................................................. 23

Transporting the Product......................................................................................................................................................23

Troubleshooting ..........................................................................................................................................................................24

Warranty................................................................................................................................................................................ 25-26

Table of Contents

3

Page 4

5

Introduction

Thank you for purchasing a Ryobi product.

We would like for you to be completely satised with your new product, so feel free to contact an authorized service dealer

for help with service, genuine Ryobi parts, or other information you may require.

Whenever you contact an authorized service dealer, always know the model and serial numbers of the product. These numbers will help the service representative provide exact information about your specic product. You will nd the model and

serial number decal located on the motor housing.

For your convenience, write the product model and serial numbers in the space below.

Model No.

Serial No.

Model No./Serial No.

Label

Read this manual carefully to learn how to operate and maintain your product correctly. Reading this manual will help you

and others avoid personal injury and damage to the product. Although Ryobi designs, produces, and markets safe, state-ofthe-art products, you are responsible for using the product properly and safely. You are also responsible for training persons

you allow to use the product about safe operation.

The Ryobi warning system in this manual identies potential hazards and has special safety messages that help you and

others avoid personal injury, even death. DANGER, WARNING, and CAUTION are signal words that identify the level of

hazard. However, regardless of the hazard, be extremely careful. Two other words, “Important” and “Note,” highlight information.

Signal Word Explanation

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert against unsafe practices that may cause

property damage.

Important Advises you of important information or instructions vital to the operation or maintenance

of the equipment.

Note Advises you of additional information concerning the operation or maintenance of the

equipment.

4

Introduction

Page 5

Safety Rules

WARNING:

Read and understand all instructions. Failure to follow all instructions may result in serious personal

injury as well as damage to the product.

This product has been designed and manufactured to

meet or exceed the requirements of the current version of

ANSI B175.3, safety requirements for gasoline-powered

string trimmers and brushcutters.

■ Physical Condition of the Operator. Do not operate

this product when tired, ill, or under the inuence of

alcohol, drugs, or medication.

■ Clothing Requirements. Always wear long heavy

pants, boots, and gloves. Do not wear loose clothing, jewelry, short pants, sandals, or go barefoot.

Secure hair so that it is above shoulder level to avoid

entanglement in moving parts.

■ Protective Accessories Requirements. Wear eye

protection marked to comply with ANSI Z87.1

standards when operating this product. Wear hearing

protection during extended periods of operation.

■ Condition of Trimmer Before Use. Inspect the

product before each use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are

in place and secure. Replace cutting attachment

parts that are cracked, chipped, or damaged in any

way. Make sure the cutting attachment is properly

installed and securely fastened. Be sure the cutting

attachment shield is properly attached, and in the

position recommended by the manufacturer. Use

only exible, non-metallic line recommended by the

manufacturer. For example, never use wire or wirerope, which can break off and become a dangerous

projectile.

■ Proper Stance. Keep rm footing and balance. Do

not overreach. Keep the cutting attachment below

waist level. Keep all parts of your body away from

the rotating cutting attachment and hot surfaces.

■ Exhaust Gases. Never start or run the product inside

a closed room or building; breathing exhaust fumes

can cause illness or death.

■ Fueling. Mix and pour fuel outdoors where there are

no sparks and ames. Slowly remove the fuel cap

only after stopping the engine. Do not smoke while

fueling or mixing fuel. Wipe spilled fuel from the

product. Move at least 30 ft. (9 m) away from the

fueling source and site before starting the engine.

■ Work Area. Clear the area to be cut before each

use. Remove all objects, such as rocks, broken glass,

nails, wire, or string, that can be thrown or become

entangled in the cutting attachment. Clear the area

of children, bystanders, and pets. At a minimum,

keep all children, bystanders, and pets outside a 50

ft. (15 m) radius. Because there still may be a risk of

injury to bystanders from thrown objects, bystanders

should be encouraged to wear eye protection. If you

are approached while operating the product, stop the

engine and the cutting attachment.

■ Dangerous Environments. To avoid falling, do not

use the product in damp or wet locations.

■ Controlling the Product. During carburetor adjustments the cutting attachment may spin. Therefore,

you should wear protective equipment and observe

all safety instructions when adjusting the carburetor. For products equipped with a clutch, be sure the

cutting attachment stops turning when the engine

idles. When the product is turned off, make sure the

cutting attachment has stopped before setting down

the product.

■ Use the Right Product. Use the product for the

intended purpose only.

■ Condition of Brushcutter Before Use. The handles

shall be mounted according to the manufacturer’s

instructions. Do not attach any blade to a product

without proper installation of all required parts. Failure to use the proper parts can cause the blade to y

off and seriously injure the operator and/or bystanders. Discard blades that are bent, warped, cracked,

broken, or damaged in any way.

■ Use the Right Equipment. Always use the barrier

bar on the front handle and the shoulder strap with

the brushcutter.

■ Blade Thrust. Blade thrust may occur when the

spinning blade contacts an object that it does not immediately cut. A blade thrust can be violent enough

to cause the product and/or operator to be propelled

in any direction, and possibly lose control of the

product. Blade thrust can occur without warning if

the blade snags, stalls, or binds. This is more likely

to occur in areas where it is difcult to see the material being cut.

■ Stopping the Product. A coasting blade can cause

injury while it continues to spin after the engine is

stopped or throttle is released. Maintain proper control until the blade has completely stopped rotating.

Safety Rules

5

Page 6

7

Safety Rules

This engine is equipped with a spark arrester mufer. It is a violation of California Public Resource Code Section

4442 to use or operate this engine without a spark arrester mufer on any forest-covered, brush-covered, or grasscovered land. Other states or federal areas may have similar laws.

This spark ignition system complies with Canadian ICES-002.

Save these instructions. Refer to them frequently and use them to instruct others who may use this product. If you

loan someone this product, loan these instructions also.

Symbols

The following symbols are located on the product. Please study them and learn their meaning. Proper interpretation of these

symbols allows you to operate the product better and safer.

Symbol Name Explanation

Safety Alert Symbol Precautions that involve your safety.

Read the Operator’s Manual Read the operator’s manual before starting or operating this product.

Failure to follow operating instructions and safety precautions in the

operator’s manual can result in serious injury.

Wear Eye and Hearing Protection Wear eye protection which is marked to comply with ANSI Z87.1 as

well as hearing protection when operating this equipment.

Keep Bystanders Away Keep all bystanders at least 50 feet (15 m) away.

Ricochet Thrown objects can ricochet and result in personal injury or property

damage.

No Blade Do not install or use any type of blade on a product displaying this

symbol.

Blade Thrust Beware of blade thrust. Products authorized for blade use will

display this symbol to warn of blade thrust.

Gasoline and Oil Use unleaded gasoline intended for motor vehicle use with an octane

rating of 87 ([R + M] / 2) or higher. This product is powered by a

2-cycle engine and requires pre-mixing gasoline and 2-cycle oil.

6

Symbols

Page 7

Symbols

The following signal words and meanings are intended to explain the levels of risk associated with this

product.

SYMBOL SIGNAL MEANING

DANGER: Indicates an imminently hazardous situation, which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may result

in minor or moderate injury.

CAUTION: (Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

SERVICE

Servicing requires extreme care and knowledge and should

be performed only by a qualied service technician. For

service we suggest you return the product to your nearest

AUTHORIZED SERVICE CENTER for repair. When

servicing, use only identical replacement parts.

WARNING:

The operation of any power tool can result in foreign objects being thrown into your

eyes, which can result in severe eye damage. Before beginning power tool operation,

always wear safety goggles or safety glasses with side shields and, when needed, a full

face shield. We recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields. Always use eye protection which is marked to

comply with ANSI Z87.1.

SAVE THESE INSTRUCTIONS

WARNING:

To avoid serious personal injury, do not attempt

to use this product until you read thoroughly and

understand completely the operator’s manual. Save

this operator’s manual and review frequently for

continuing safe operation and instructing others who

may use this product.

Symbols

7

Page 8

9

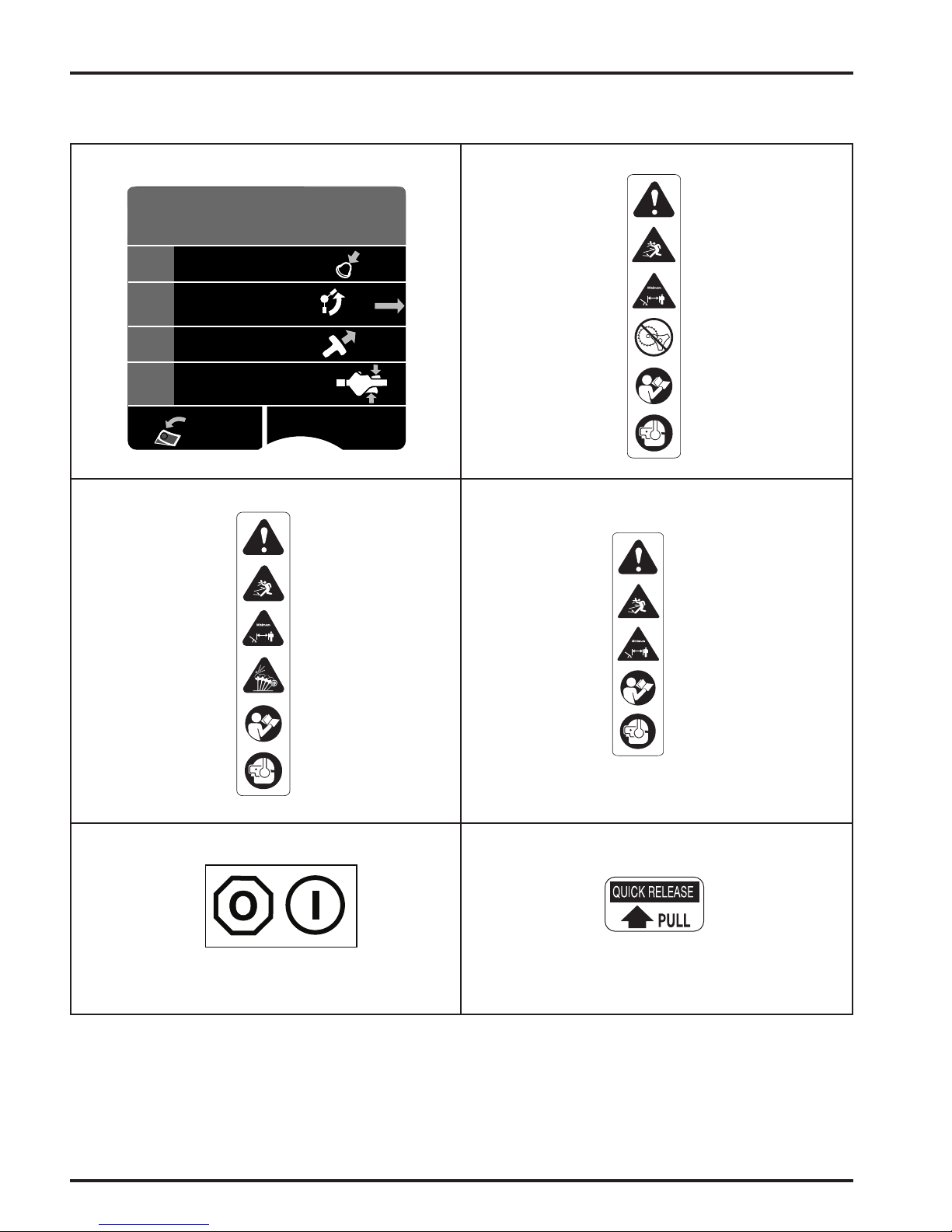

Product Labels

50' 15m

50' 15m

50' 15m

I

Product labels and instructions are easily visible to the operator and are located near any area of potential danger.

Replace damaged or lost labels.

Part No. 986178-001

Part No. 985102-001

Part No. 984032-001

Part No. 984105-001

OFF ON

8

Part No. 983961-001 (Shoulder Strap)Part No. 984240-001

Product Labels

Page 9

Features

Product Specifications

Engine 25.4 cc Full Crank

Cutting Width

Model No. ZR51950A 17 in.

Model No. ZR51970A 18 in.

Model No. ZR51990A 8 in. for brushcutter, 18 in. for trimmer

Line Size .095 in.

Weight

Model No. ZR51950A 12-1/2 lbs.

Model No. ZR51970A 13-1/2 lbs.

Model No. ZR51990A 13-1/2 lbs.

Know Your Trimmer/Brushcutter

See Figure 1.

Before attempting to use this product, familiarize yourself

with all operating features and safety rules.

Common Features

Engine

The engine is powerful and easy to start. It is effectively

counterbalanced, which allows for less vibration and more

durability.

Ergonomic Design

The design of the product provides for easy handling. It is

designed for comfort and ease of grasp when operating in

different positions and at different angles.

Curved/Straight Shaft Features

(Model No. ZR51950A/ZR51970A)

Dual Line

The dual line permits more efcient cutting than a single

line.

Grass Deflector

The grass deector helps protect you from ying debris.

Brushcutter Features

(Model No. ZR51990A)

Blade

The Tri-Arc® blade allows you to brushcut weeds, vines

and light brush.

Brushcutter Guard

The brushcutter guard helps protect you from the blade and

from ying debris.

Shoulder Strap

The brushcutter includes a shoulder strap that helps support

the product.

Barrier Bar

The handle on the brushcutter contains a barrier bar that

restrains the operator in position and maintains a proper

distance between the operator and the blade.

Features

9

Page 10

11

Curved Shaft Trimmer

(Model No. ZR51950A)

Dual

Line

Grass

Barrier

Front Handle

Curved Shaft

Grass Deflector

Engine

Trigger

Handle

Straight Shaft Trimmer

(Model No. ZR51970A)

Front Handle

Engine

Grass Deflector

Blade

Brushcutter

Guard

Straight Shaft

Trigger

Handle

Brushcutter

(Model No. ZR51990A)

Front Handle

Engine

Shoulder

Strap

Features

10

Barrier

Bar

Trigger

Handle

Figure 1

Page 11

Assembly

Unpacking

■ Carefully remove the product from the box.

■ Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

■ Do not discard the packing material until you have

carefully inspected and satisfactorily operated the product.

■ If any parts are damaged or missing, please call toll free

1-800-860-4050 for assistance.

Packing List

Upper shaft (Power head) (1)

Attachment shaft (Cutting head) (1)

Handle (1)

Curved shaft grass deector (1) (Model No. ZR51950A)

Straight shaft grass deector (1) (Model No. ZR51970A and

Model No. ZR51990A)

Grass barrier (Model No. ZR51950A)

Hex head cap screw - 1/4-20 x 2 in. (1)

(Model No. ZR51950A)

Lock washer (1) (Model No. ZR51950A)

Flat washer (1) (Model No. ZR51950A)

Wing nut (1) (Model No. ZR51950A)

Oil

Head locking tool (1) (Model No. ZR51990A)

Shoulder strap (1) (Model No. ZR51990A)

Storage cap

WARNING:

If any parts are missing, do not operate the

product until the missing parts are replaced.

Failure to do so could result in serious personal

injury.

WARNING:

Do not attempt to modify this tool or create

accessories not recommended for use with this

tool. Any such alteration or modication is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING:

Do not start trimmer until assembly is complete.

Failure to comply could result in accidental

starting and possible serious personal injury.

Assembly

11

Page 12

13

Connecting the Attachment to the

Upper Shaft

See Figure 2.

Follow these steps to connect the attachment to the upper

shaft.

1. Loosen the knob by turning it counterclockwise.

2. Remove the end cap from the attachment shaft.

3. Align the button on the attachment shaft with the guide

recess on the upper shaft.

4. Slide the attachment shaft into the upper shaft until the

attachment shaft clicks into place.

Note: You may need to turn the attachment shaft to

properly align the two shafts.

5. Tighten the knob securely by turning it clockwise.

Upper

Shaft

3. Place the handle along the upper shaft to a position that

allows for comfortable operation.

4. Place the handle support on the bottom of the tube on

the opposite side of the front handle.

5. Secure the handle with the slotted Torx™ screws.

Slotted

Torx

Screw

Front

Handle

Trigger

Handle

Barrier Bar

(Model No.

ZR51990A)

Guide

Recess

Button

Knob

Attachment

Shaft

Figure 2

Removing the Attachment from the

Upper Shaft

See Figure 2.

Follow these steps to remove the attachment from the upper

shaft.

1. Loosen the knob by turning it counterclockwise.

2. Push the button while pulling out the attachment.

Attaching the Front Handle

See Figure 3.

Follow these steps to attach the front handle.

1. Remove the slotted Torx™ screws to separate the

handle from the handle support.

2. Press the handle onto the top of the upper shaft, no

less than 10 in. (25.4 cm) from the center of the trigger

handle, angling the handle toward the trigger handle.

Handle

Support

Figure 3

Attaching the Shoulder Strap

Model No. ZR51990A

See Figure 4.

Follow these steps to attach the shoulder strap.

1. Connect the latch on the strap to the hanger bracket.

2. Adjust the strap to a comfortable position.

Note: To quickly release the product from the shoulder

strap, sharply pull the quick release tab.

Strap

Quick

Release

Tab

Hanger

Bracket

Latch

Figure 4

Assembly

12

Page 13

Attaching the Grass Deflector

Attaching the grass deector differs depending on the type

of trimmer: curved shaft or straight shaft.

WARNING:

The line cutting blade on the grass deector

is sharp. Avoid contact with the blade. Failure

to avoid contact can result in serious personal

injury.

Note: To protect the operator, always be sure to attach the

grass deector.

To Attach the Curved Shaft Grass Deflector

Model No. ZR51950A

See Figure 5.

Follow these steps to attach the curved shaft grass deector.

1. Press the grass deector onto the bottom of the curved

shaft as shown.

2. Lift the grass barrier up slightly.

3. Insert the hex head cap screw through the grass deec-

tor, bracket, and grass barrier.

4. Place the at washer and lock washer on the hex head

cap screw.

5. Place the wing nut or hex nut on the hex head cap screw

and turn clockwise to secure.

To Attach the Straight Shaft Grass Deflector

Model No. ZR51970A and Model No. ZR51990A

See Figure 6.

Follow these steps to attach the straight shaft grass deector.

1. Remove the slotted hex head screw from the grass

deector.

2. Insert the tab on the mounting bracket in the slot on the

grass deector.

3. Align the screw hole in the mounting bracket with the

screw hole in the grass deector.

4. Insert the slotted hex head screw through the mounting

bracket and into the grass deector.

5. Tighten the screw securely.

Tab

Straight Shaft

Grass Deflector

Slot

Curved Shaft

Grass Deflector

Line

Cutting

Blade

Bracket

Hex Head

Cap Screw

Lock

Washer

Flat

Washer

Grass

Barrier

Wing

Nut

Figure 5

Figure 6

Assembly

13

Page 14

15

Converting From Brushcutter To

Trimmer

Model No. ZR51990A

To convert from the brushcutter to the trimmer, remove the

blade, remove the brushcutter guard, attach the grass deector, and install the trimmer head assembly.

To Remove the Blade and Brushcutter Guard

See Figure 7 and Figure 8.

Follow these steps to remove the blade and brushcutter

guard.

1. Align the slot in the anged washer with the slot in the

gear head.

2. Place the head locking tool through the slot in the

anged washer and gear head.

3. Remove the blade nut by turning it clockwise (left-

handed threads).

4. Remove the cupped washer and the blade.

Head

Locking

Tool

Gear Head

Slot

Figure 7

Flanged

Washer

Blade

WARNING:

Be careful when handling the blade. It is sharp.

Failure to heed this warning can result in serious

personal injury.

5. Remove the anged washer from the gear shaft and

retain it for the trimmer head assembly installation.

6. Remove the three screws securing the brushcutter

guard.

7. Remove the brushcutter guard.

Note: Store the brushcutter parts together for future

use.

To Attach the Grass Deflector

Refer to “To Attach the Straight Shaft Grass Deector”

earlier in this manual.

To Install the Trimmer Head Assembly

See Figure 9.

Follow these steps to install the trimmer head assembly.

1. Align the slot in the anged washer with the slot in the

gear head.

2. Insert the head locking tool through the anged washer

and gear head.

3. Install the drive shaft and trimmer head assembly onto

the gear shaft by turning the drive shaft counterclockwise (left-handed threads).

4. Tighten the drive shaft securely.

Brushcutter

Guard

Gear

Head

Slot

Cupped

Washer

Flanged

Washer

Blade Nut

Drive

Shaft

Figure 8

Trimmer

Head

Assembly

Figure 9

Assembly

14

Page 15

Converting From Trimmer To Brushcutter

Model No. ZR51990A

To convert from the trimmer to the brushcutter, remove the

trimmer head assembly, remove the grass deector, attach

the brushcutter guard, and install the blade.

To Remove the Trimmer Head Assembly and Grass

Deflector

See Figures 10 and 11.

Follow these steps to remove the trimmer head assembly

and grass deector.

1. Align the slot in the anged washer with the slot in the

gear head.

2. Insert the head locking tool through the anged washer

and gear head.

3. Remove the drive shaft and trimmer head assembly by

turning the drive shaft clockwise (left-handed threads).

4. Remove the anged washer and retain it for the blade

installation.

5. Remove the screw securing the grass deector.

6. Remove the grass deector.

Note: Store the trimmer head assembly parts together

for future use.

To Attach the Brushcutter Guard

See Figure 12.

Note: To protect the operator, always be sure to attach the

brushcutter guard.

Follow these steps to attach the brushcutter guard.

1. Place the guard onto the gear head as shown.

2. Insert the three hex head screws from the bottom

through the guard into the gear head.

3. Tighten the screws securely and torque to 40-50 in.lb.

To Install the Blade

See Figure 13.

Follow these steps to install the blade.

1. Place anged washer over the gear shaft with the

hollow side toward the brushcutter guard.

2. Center the blade on the anged washer, making sure the

blade ts at and the raised hub goes through the hole

in the blade.

3. Install the cupped washer with the raised center away

from the blade.

4. Place the blade nut onto the gear shaft.

5. Insert the head locking tool through the anged washer

and gear head.

6. Install the blade nut by turning it counterclockwise

(left-handed threads).

7. Tighten the blade nut and torque to 120 in.lb. minimum

(nger tight plus 1/2 turn).

Gear

Head

Brushcutter

Guard

Brushcutter

Guard

Head

Locking

Tool

Slot

Grass Deflector

Flanged

Washer

Straight Shaft

Gear Shaft

Flanged

Washer

Cupped

Washer

Drive

Shaft

Gear Head

Hex Head

Screw

Figure 10

Trimmer

Head

Assembly

Figure 11

Figure 12

Blade

Blade Nut

Figure 13

Assembly

15

Page 16

17

Operation

WARNING:

Do not allow familiarity with tools to make you

careless. Remember that a careless fraction of a

second is sufcient to inict serious injury.

WARNING:

Always wear safety goggles or safety glasses

with side shields when operating power tools.

Failure to do so could result in objects being

thrown into your eyes resulting in possible serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this tool.

The use of attachments or accessories not rec-

ommended can result in serious personal injury.

50:1 Gasoline to Oil Mixing Chart

Gasoline Oil

1/2 US gallon 1.3 oz.

1 US gallon 2.6 oz.

2 US gallons 5.2 oz.

1 liter 20 ml

2 liters 40 ml

3 liters 60 ml

4 liters 80 ml

5 liters 100 ml

+ =

Filling the Tank

Applications

Use this product for the following applications:

■ Cutting grass, weeds, and light undergrowth

(all models)

■ Edging along sidewalks and driveways (all models)

■ Cutting pulpy weeds, vines, and light brush

(Model No. ZR51990A)

Mixing the Fuel

DANGER:

Gasoline is extremely ammable and explosive.

A re or explosion from gasoline will burn you

and others.

This product is powered by a 2-cycle engine and requires premixing gasoline and 2-cycle oil. The oil mix should be 50:1,

using oil that meets or exceeds JASO-FC specications.

Follow these steps to mix the fuel.

1. Obtain a clean container that is approved for use with

gasoline.

2. Mix the 2-cycle engine oil provided with unleaded

gasoline in the container, according to the instructions

on the oil carton.

Important: This engine is certied to operate on unleaded

gasoline intended for automotive use with an octane rating

of 87 ([R + M] / 2) or higher. Do not use automotive oil or

2-cycle outboard oil. Store the container out of the reach of

children.

WARNING:

Always stop the engine before lling the tank.

Never add fuel to a machine with a running or

hot engine. Move at least 30 ft. (9 m) away from

the refueling site before starting the engine. Do

not smoke while lling the tank.

Follow these steps to ll the tank.

1. Clean the surface around the fuel cap to prevent con-

tamination.

2. Loosen the fuel cap by turning it counterclockwise.

3. Pour the fuel mixture carefully into the tank.

4. Clean and inspect the gasket.

Note: Replace the fuel cap if the gasket is damaged.

5. Install the fuel cap and tighten it by turning it clock-

wise.

WARNING:

Check for fuel leaks. If you nd any leaks, correct

the problem before using the product.

6. Wipe spilled fuel from the product.

7. Move at least 30 ft. (9 m) away before starting the

product.

Note: It is normal for the engine to emit smoke during

use.

Operation

16

Page 17

WARNING:

The product may throw objects during operation, causing injury to the operator or to bystanders. Always wear suitable eye protection,

long heavy pants, and boots while operating the

product.

Starting/Stopping the Product

See Figure 14a, Figure 14b, Figure 14c and Figure 15.

To start an engine that is cold or has run dry:

1. Fill the fuel tank, if necessary. Always use the proper

oil/gasoline mixture. See “Mixing the Fuel” on page 17.

2. Place the engine switch in the RUN ( | ) position.

Note: Do not engage the throttle lever during the start-

ing process.

3. Slowly push the primer bulb seven times.

Note: If restarting a warm engine, do not push the

primer bulb.

4. Set the start lever to the START position.

Note: If restarting a warm engine, leave the choke in

the RUN position.

5. Pull the starter cord until the engine runs.

6. Return the starter cord gently to the starter housing. Do

not allow the rope to snap back.

7. Allow the engine to run for 15 seconds to warm up

before using.

8. Engage the throttle lever to operate.

Primer

Bulb

Start

Lever

Start

Position

Figure 14b

Start

Lever

Run

Positon

Figure 14c

Switch

Trigger

Lock-off

Button

Primer

Bulb

Starter

Cord

Figure 14a

Stopping the Product

See Figure 15.

1. Release the throttle lever.

2. Move the engine switch to the OFF ( O ) position.

Switch

Trigger

Figure 15

Operation

17

Page 18

19

Operating the Trimmer

Operating the trimmer differs, depending on whether you are

using the curved shaft trimmer or the straight shaft trimmer.

WARNING:

Always hold the string trimmer away from the

body, keeping clearance between the body and

the product. Any contact with the housing or

string trimmer cutting head can result in burns

and/or other serious personal injury.

To Operate the Curved Shaft Trimmer

(Model No. ZR51950A)

See Figure 16a.

Follow these steps to operate the curved shaft trimmer.

1. Start the trimmer.

2. Hold the trimmer at waist level with your right hand

on the trigger handle and your left hand on the front

handle.

3. Place the product on the right side of your body with

the engine behind and away from your body.

4. Trim grass and weeds in a right-to-left motion with the

line parallel to the ground.

PROPER OPERATING

POSITION

PROPER OPERATING

POSITION

Figure 16b

To Advance the Cutting Line

See Figure 16c.

Follow these steps to advance the cutting line.

1. Start the trimmer.

2. Tap the retaining cap lightly on the ground while the

motor is running. The line will only advance with the

engine at full throttle. Do not hold the retaining cap

on the ground.

Note: The line cutting blade on the grass deector will

cut the line to the proper length.

Note: To help prevent line tangle, tap only once to

lengthen the line. If additional line is required, wait a

few seconds before retapping the retaining cap. Do not

allow the line to wear too short. Keep the cutting line at

full length.

To Operate the Straight Shaft Trimmer

(Model No. ZR51970A)

See Figure 16b.

Follow these steps to operate the straight shaft trimmer.

1. Start the trimmer.

2. Hold the trimmer at waist level with your right hand

on the trigger handle and your left hand on the front

handle.

3. Place the product on the right side of your body with

the engine behind and away from your body.

4. Trim grass and weeds in a left-to-right motion with the

line parallel to the ground.

Operation

18

Figure 16a

Retaining

Cap

Figure 16c

Page 19

Operating the Brushcutter

(Model No. ZR51990A)

See Figure 17.

Follow these steps to operate the brushcutter.

1. Start the brushcutter.

2. Hold the brushcutter at waist level with your right hand

(arm extended) on the trigger handle and your left hand

on the front handle.

3. Place the product on the right side of your body with

the engine behind and away from your body.

4. Brushcut weeds and vines in a right-to-left motion with

the blade parallel to the ground.

Dangerous

Cutting Area

Curved Shaft Trimmer

Direction of

Rotation

PROPER OPERATING

POSITION

Figure 17

Cutting Tips

See Figures 18 and 19.

1. Avoid hot surfaces by always keeping the tool away

from your body. (Proper operating position is shown in

Figures 16a, 16b and 17.)

2. Keep the trimmer tilted toward the area being cut; this

is the best cutting area.

3. The curved shaft trimmer cuts when passing the unit

from right to left. the straight shaft trimmer cuts when

passing the unit from left to right. This will avoid

throwing debris at the operator. Avoid cutting in the

dangerous area shown in gures 18 and 19.

4. Use the tip of string to do the cutting; do not force

string head into uncut grass.

5. Wire and picket fences cause extra string wear, even

breakage. Stone and brick walls, curbs and wood may

wear string rapidly.

6. Avoid trees and shrubs. Tree bark, wood moldings, siding and fence posts can easily be damaged by the string.

Direction of

Rotation

Best Cutting

Area

Figure 18

Straight Shaft Trimmer

Dangerous

Cutting Area

Best Cutting

Area

Figure 19

Operation

19

Page 20

21

Maintenance

Emissions Maintenance Schedule

Maintenance, replacement, or repair of the emission control device and systems may be performed by any nonroad engine repair establishment or individual.

Emission Part

Fuel Tank Assembly (Includes Fuel

Lines, Fuel Cap, and Fuel Filter)

Air Filter

Spark Arrester

Spark Plug

Inspect before

each use

X

X X

X

X

WARNING:

When servicing, use only Ryobi replacement

parts. Use of any other parts may create a hazard or cause product damage.

Cleaning the Product

■ Stop the product before cleaning.

■ Clean the exterior of the product with a damp cloth.

■ Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

■ Wipe or scrape the trimmer head and spool area when

they accumulate dirt or clippings.

■ Scrape debris away from air intake vents on both sides

of the motor housing.

CAUTION:

Keeping air intake vents free of grass and debris

prevents motor overheating and possible failure.

Note: Depending on the type of fuel used, the type and

amount of oil used, and/or your operating conditions,

the exhaust port and mufer may become blocked with

carbon deposits. If you notice a power loss with your

gas powered tool, you may need to remove these deposits to restore performance. We highly recommended that

only qualied service technicians perform this service.

Servicing the Product

■ Check and tighten all fasteners. If any part is damaged

or lost, repair it or replace it.

Clean every

5 hours

Replace every 25

hours or yearly

Clean every 25

hours or yearly

Replacing the Cutting Line

See Figures 20 and 21.

WARNING:

Use of line other than the proper monolament

cutting line could cause personal injury.

Follow these steps to replace the cutting line.

1. Stop the trimmer.

WARNING:

Make sure the trimmer head stops rotating.

Contact with a rotating trimmer head could

cause personal injury.

2. Remove the spark plug boot. See Figure 24.

3. Remove the retaining cap.

4. Remove the empty spool.

5. Clean the trimmer head thoroughly. Inspect the trimmer

head for any damaged or worn parts.

6. Hold the spool with the spring positioned upward.

7. Insert the end of the new line into the hole in the upper

threaded area of the spool.

8. Wind the line around the spool as indicated by the ar-

rows on the top of the spool until the line reaches the

edge of the spool. Do not wind the line beyond the

edge of the inner ring.

9. Secure the line temporarily by pushing it into one of the

slotted tabs on the spool.

10. Measure six inches of line from the slotted tab and cut

the line at that point.

Maintenance

20

Page 21

11. Repeat the process for the lower threaded area of the

spool, winding the line and securing it in the slotted tab

opposite the rst secured line.

12. Insert the lines into the eyelets on the trimmer head.

13. Place the spool on the drive shaft.

Note: To install the spool, you may need to rotate it

slightly. If the line should tangle or break at the eyelet,

remove the spool, refeed the line through the eyelets,

and reassemble the spool on the trimmer.

14. Release the lines from the tabs by sharply pulling each

line.

15. Push down on the spool to reveal the threads inside the

drive shaft.

16. Thread the retaining cap on the drive shaft.

17. Secure the retaining cap.

WARNING:

An improperly installed retaining cap or spool

could y off the trimmer. Contact with a thrown

retaining cap or spool could cause personal

injury.

18. Replace the spark plug boot. See Figure 24.

Inner Ring

Upper

Threaded Area

Follow these steps to replace the spool.

1. Stop the trimmer.

WARNING:

Make sure the trimmer head stops rotating when

you release the trigger. Contact with a rotating

trimmer head could cause personal injury.

2. Remove the spark plug boot. See Figure 24.

3. Remove the retaining cap by turning as indicated by the

arrow on the cap.

4. Remove the empty spool.

5. Clean the trimmer head thoroughly. Inspect the trimmer

head for any damaged or worn parts.

6. Remove the lines from the slotted tabs on the spool and

unwind approximately six inches.

7. Secure the lines temporarily by pushing them into the

slotted tabs on the spool.

8. Insert the lines of the new spool into the eyelets on the

trimmer head.

9. Place the spool on the drive shaft.

Note: To install the spool, you may need to rotate it

slightly.

Note: If the line should tangle or break at the eyelet,

remove the spool, refeed the line through the eyelets,

and reassemble the spool on the trimmer.

10. Release the lines from the tabs by sharply pulling each

line.

11. Push down on the spool to reveal the drive shaft.

12. Thread the retaining cap on the drive shaft.

13. Secure the retaining cap.

14. Replace the spark plug boot. See Figure 24.

Lower

Threaded Area

Replacing the Spool

See Figure 21.

Note: For best performance, use only Ryobi spools (Part

No. AR04118). The spool may wear during normal use of

the line advance feature and may require occasional replacement. Replacement spools are available through your Ryobi

retailer.

Slotted

Tab

Figure 20

Drive

Shaft

Eyelet

Trimmer

Head

Slotted

Tab

Retaining

Cap

Spool

Figure 21

Maintenance

21

Page 22

23

Checking the Fuel Cap

WARNING:

A leaking fuel cap is a re hazard and must be

replaced immediately.

The fuel cap contains a non-serviceable lter and check

valve. A clogged fuel lter causes poor engine performance.

If performance improves when the fuel cap is loosened,

the check valve may be faulty or the lter may be clogged.

Replace the fuel cap if necessary.

Cleaning the Air Filter

See Figure 22.

Clean the air lter as indicated by the maintenance schedule.

Follow these steps to clean the air lter.

1. Stop the trimmer.

WARNING:

Make sure the trimmer head stops rotating when

you release the trigger. Contact with a rotating

trimmer head could cause personal injury.

2. Remove the spark plug boot.

3. Loosen the air lter cover by turning the knob counter-

clockwise.

4. Remove the air lter cover.

5. Remove the air lter.

6. Clean the air lter with warm soapy water.

7. Rinse the air lter and let it dry completely.

8. Work two drops of oil into the air lter.

9. Replace the air lter (ts only one way).

10. Replace the air lter cover.

11. Tighten the air lter cover by turning the knob clock-

wise.

12. Replace the spark plug boot.

Note: Replace the air lter (Part No. 88048) as indi-

cated by the maintenance schedule.

Replacing the Spark Arrester

See Figure 23.

The spark arrester may need to be replaced after repeated

use. If replacement is necessary, use Ryobi part number

986179001.

To replace the spark arrester:

1. Remove the ve screws that hold the cover.

Note: Removing these screws requires the use of a T20

and T25 torx screwdriver.

2. Remove the cover.

3. Remove the mufer assembly and mufer gasket. It

may be necessary to work the mufer assembly free

from the mufer gasket.

4. Remove the three screws that hold the plates on the

mufer.

5. Remove the spark arrester.

6. Replace the old spark arrester with the new one.

7. Reassemble the mufer by reinstalling the plates and

tightening the three screws.

8. Reassemble the mufer and mufer cover and attach to

the mufer gasket with the two screws.

9. Reinsert the mufer assembly.

10. Reinstall the cover on the tool and fasten with the ve

screws.

Note: Do not overtighten screws.

Cover

Screw(s)

Muffler

Cover

Air Filter

Air

Filter

Cover

Maintenance

22

Knob

Figure 22

Muffler

Gasket

Muffler

Spark

Arrester

Screw(s)

Plates

Screw(s)

Figure 23

Page 23

Replacing the Spark Plug

See Figure 24.

All model numbers included in this manual use an

NGK BPMR7A or Champion RCJ-6Y spark plug. Use an

exact replacement and replace annually.

1. Remove the spark plug boot.

2. Loosen the spark plug by turning it counterclockwise

with a socket.

3. Remove the spark plug.

4. Hand thread the new spark plug, turning it clockwise.

5. Tighten with a socket and torque to 170 in.lb. mini-

mum, 190 in.lb. maximum. Do not over tighten.

CAUTION:

Be careful not to cross-thread the spark plug.

Cross-threading will seriously damage the

product.

Spark Plug Boot

Spark

Plug

Storing the Product

Storing the product differs depending on the amount of time

it will be in storage.

Note: If the product includes another attachment, place the

storage cap on the end of the attachment shaft and hang it up

to store.

To Store the Product Short Term

Follow these steps to store the product short term.

1. Clean all foreign material from the product.

2. Store the product in a well-ventilated place that is inac-

cessible to children.

To Store the Product Long Term

If you do not intend to use the product for more than one

month, follow the storage procedures below.

Follow these steps to store the product long term.

1. Drain all of the fuel from the tank into a container ap-

proved for gasoline.

2. Run the engine until it stops.

3. Clean all foreign material from the product.

4. Store the product in a well-ventilated place that is inac-

cessible to children.

Note: Keep the product away from corrosive agents

such as garden chemicals and de-icing salts.

Important: Abide by all federal and local regulations

for the safe storage and handling of gasoline.

Transporting the Product

Follow these steps to transport the product.

1. Drain the fuel mixture into a container that is approved

for use with gasoline.

2. Carry the product by the front handle.

3. Secure the product in your vehicle or on a trailer.

Figure 24

Maintenance

23

Page 24

25

Troubleshooting

Problem Possible Cause Solution

Engine will not start

1. Switch set to the O (OFF)

position.

2. No spark

3. No fuel

4. Flooded engine

5. Starter cord pulls harder now

then when new

1. Set switch to the I (ON) position.

2. Remove the spark plug. Reattach the spark

plug cap and lay the spark plug on the metal

cylinder. Pull the starter cord and watch for a

spark at the spark plug tip. If there is no spark,

repeat the test with a new spark plug.

3. Push primer bulb until the bulb is full of fuel.

If the bulb does not ll, the primary fuel delivery system is blocked. If the primer bulb lls,

the engine may be ooded. (See next item.)

4. Remove the spark plug. Turn the product so

that the spark plug hole is aimed at the ground.

Make sure the start lever is set to RUN

and pull the starter cord 10 to 14 times. This

clears excess fuel from the engine. Clean and

reinstall the spark plug. With the trigger fully

depressed, pull the starter cord 3 times. If the

engine does not start, set the start lever to

START and follow normal starting instruc-

tions. If the engine still fails to start, repeat the

procedure with a new spark plug.

5. Contact an authorized service dealer.

Engine does not reach full speed

and emits excessive smoke

Line will not advance when using automatic line lengthening

Retaining cap hard to turn when

using automatic line lengthening

Grass wraps around the trimmer head assembly and the

attachment shaft

Oil drips from mufer

1. Check oil fuel mixture

2. Air lter is dirty

3. Spark arrestor screen is dirty

1. Line welded to itself

2. Not enough line on the spool

3. Line worn too short

4. Line tangled on spool

5. Engine speed too slow

Screw threads are dirty or

damaged

1. Cutting tall grass at ground

level

2. Operating the product at part

throttle

1. Operating the product at part

throttle

2. Check oil/fuel mixture

3. Air lter is dirty

1. Use fresh fuel and the correct 2-cycle oil mix.

2. Clean the air lter.

3. Clean the spark arrester.

1. Lubricate with silicone spray.

2. Install more line.

3. Pull line while alternately pressing down on

and releasing the retaining cap.

4. Remove line from spool and rewind.

5. Advance line at full throttle.

Clean the threads and lubricate with grease. If this

does not solve the problem, replace the retaining cap.

1. Cut tall grass from the top down.

2. Operate the product at full throttle.

1. Operate the product at full throttle.

2. Use fresh fuel and the correct 2-cycle oil mix.

3. Clean the air lter.

Troubleshooting

24

Page 25

Warranty

LIMITED WARRANTY STATEMENT

Ryobi Technologies, Inc. warrants to the original retail

purchaser that this Ryobi Technologies, Inc. product

is free from defect in material and workmanship and

agrees to repair or replace, at Ryobi Technologies, Inc.’s

discretion, any defective product free of charge within

these time periods from the date of purchase.

�n One year if the product is used for personal, family

or household use;

�n 90 days, if used for any other purpose, such as

commercial or rental.

This warranty extends to the original retail purchaser

only and commences on the date of the original retail

purchase.

Any part of the Ryobi Technologies, Inc. product

manufactured or supplied by Ryobi Technologies, Inc. and

found in the reasonable judgment of Ryobi Technologies,

Inc. to be defective in material or workmanship will be

repaired or replaced by an authorized Ryobi Technologies,

Inc. service dealer without charge for parts and labor.

The product, including any defective part, must be

returned to an authorized service dealer within the

warranty period. The expense of delivering the Ryobi

Technologies, Inc. product to the dealer for warranty work

and the expense of returning it back to the owner after

repair or replacement will be paid by the owner. Ryobi

Technologies, Inc.’s responsibility in respect to claims is

limited to making the required repairs or replacements

and no claim of breach of warranty shall be cause for

cancellation or rescission of the contract of sale of any

Ryobi Technologies, Inc. product. Proof of purchase will

be required by the dealer to substantiate any warranty

claim. All warranty work must be performed by an

authorized Ryobi Technologies, Inc. service dealer.

This warranty is limited to ninety (90) days from the date

of original retail purchase for any Ryobi Technologies, Inc.

product that is used for rental or commercial purposes,

or any other income-producing purpose.

This warranty does not cover any Ryobi Technologies,

Inc. product that has been subject to misuse, neglect,

negligence, or accident, or that has been operated in any

way contrary to the operating instructions as specified

in this operator’s manual. This warranty does not apply

to any damage to the Ryobi Technologies, Inc. product

that is the result of improper maintenance or to any

Ryobi Technologies, Inc. product that has been altered

or modified. The warranty does not extend to repairs

made necessary by normal wear or by the use of parts

or accessories which are either INCOMPATIBLE WITH

THE RYOBI TECHNOLOGIES, INC. product or adversely

affect its operation, performance, or durability.

In addition, this warranty does not cover:

A. Tune-ups – Spark Plugs, Carburetor, Carburetor

Adjustments, Ignition, Filters

B. Wear items – Bump Knobs, Outer Spools, Cutting

Lines, Inner Reels, Starter Pulleys, Starter Ropes,

Drive Belts, Tines, Felt Washers, Hitch Pins, Mulching

Blades, Blower Fans, Blower and Vacuum Tubes,

Vacuum Bag and Straps, Guide Bars, Saw Chains

Ryobi Technologies, Inc. reserves the right to change

or improve the design of any Ryobi Technologies, Inc.

product without assuming any obligation to modify any

product previously manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED IN

DURATION TO THE STATED WARRANTY PERIOD.

ACCORDINGLY, ANY SUCH IMPLIED WARRANTIES

INCLUDING MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, OR OTHERWISE, ARE

DISCLAIMED IN THEIR ENTIRETY AFTER THE

EXPIRATION OF THE APPROPRIATE TWO-YEAR,

ONE-YEAR, OR NINETY DAY WARRANTY PERIOD.

RYOBI TECHNOLOGIES, INC.’S OBLIGATION UNDER

THIS WARRANTY IS STRICTLY AND EXCLUSIVELY

LIMITED TO THE REPAIR OR REPLACEMENT OF

DEFECTIVE PARTS AND RYOBI TECHNOLOGIES,

INC.DOES NOT ASSUME OR AUTHORIZE ANYONE

TO ASSUME FOR THEM ANY OTHER OBLIGATION.

SOME STATES DO NOT ALLOW LIMITATIONS

ON HOW LONG AN IM PLI ED WARRA NTY

LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU. RYOBI TECHNOLOGIES, INC.

ASSUMES NO RESPONSIBILITY FOR INCIDENTAL,

CONSE QUE NTI AL, OR O THE R DA MAGES

INCLUDING, BUT NOT LIMITED TO, EXPENSE

OF RETURNING THE RYOBI TECHNOLOGIES,

INC. PRODUCT TO AN AUTHORIZED SERVICE

DEALER AND EXPENSE OF DELIVERING IT BACK

TO THE OWNER, MECHANIC’S TRAVEL TIME,

TELEPHONE OR TELEGRAM CHARGES, RENTAL OF

A LIKE PRODUCT DURING THE TIME WARRANTY

SERVICE IS BEING PERFORMED, TRAVEL, LOSS

OR DAMAGE TO PERSONAL PROPERLY, LOSS OF

REVENUE, LOSS OF USE OF THE PRODUCT, LOSS

OF TIME, OR INCONVENIENCE. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT

APPLY TO YOU.

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to

state.

This warranty applies to all Ryobi Technologies, Inc.

products manufactured by Ryobi Technologies, Inc.

and sold in the United States and Canada.

To locate your nearest service dealer, dial 1-800-860-4050.

Warranty

25

Page 26

27

Warranty

THE FOLLOWING CALIFORNIA AIR RESOURCES BOARD (CARB) STATEMENT ONLY AP-

PLIES TO MODEL NUMBERS REQUIRED TO MEET THE CARB REQUIREMENTS.

RYOBI TECHNOLOGIES, INC. LIMITED WARRANTY FEDERAL AND CALIFORNIA

EMISSION CONTROL SYSTEMS NON-ROAD AND SMALL OFF-ROAD ENGINES

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board (CARB), and Ryobi Technologies, Inc. are

pleased to explain the Emission Control System Warranty on your non-road or small off-road engine. In California, new small

off-road engines must be designed, built and equipped to meet the state’s stringent anti-smog standards. In other states, new

2000 and later model year non-road engines must be designed, built, and equipped, at the time of sale, to meet the U.S. EPA

regulations for small non-road engines. The non-road engine must be free from defects in materials and workmanship which

cause it to fail to conform with U.S. EPA standards for the first two years of engine use from the date of sale to the ultimate

purchaser. Ryobi Technologies, Inc. must warrant the emission control system on your non-road or small off-road engine for

the period of time listed above provided there has been no abuse, neglect, or improper maintenance of your non-road or small

off-road engine.

Your emission control system may include parts such as the carburetor or fuel injection system, the ignition system, and the

catalytic converter. Also included may be hoses, belts and connectors, and other emission related assemblies.

Where a warrantable condition exists, Ryobi Technologies, Inc. will repair your non-road or small off-road engine at no cost to

you, including diagnosis (if the diagnostic work is performed at an authorized dealer), parts, and labor.

MANUFACTURER’S WARRANTY COVERAGE:

The 1995 and later small off-road engines are warranted for two years in California. In other states, 1997 and later model year

non-road engines are also warranted for two years. If any emission-related part on your engine is defective, the part will be

repaired or replaced by Ryobi Technologies, Inc. free of charge.

OWNER’S WARRANTY RESPONSIBILITIES

(a) As the non-road or small off-road engine owner, you are responsible for the performance of required maintenance listed in your

operator’s manual. Ryobi Technologies, Inc. recommends that you retain all receipts covering maintenance on your non-road or

small off-road engine, but Ryobi Technologies, Inc., cannot deny warranty solely for the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance. Any replacement part or service that is equivalent in performance and durability

may be used in non-warranty maintenance or repairs, and shall not reduce the warranty obligations of the engine manufacturer.

(b) As the non-road or small off-road engine owner, you should be aware, however, that Ryobi Technologies, Inc., may deny you

warranty coverage if your non-road or small off-road engine or a part has failed due to abuse, neglect, improper maintenance, or unapproved modifications.

(c) You are responsible for presenting your non-road or small off-road engine to a Ryobi Technologies, Inc., service dealer as

soon as a problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30

days.

If you have any questions regarding your warranty rights and responsibilities, you should contact a Ryobi Technologies, Inc.,

Customer Representative at 1-800-860-4050.

COVERAGE:

Ryobi Technologies, Inc. warrants to the ultimate purchaser and each subsequent purchaser that your non-road or small off-road

engine will be designed, built, and equipped, at the time of sale, to meet all applicable regulations. Ryobi Technologies, Inc. also

warrants to the initial purchaser and each subsequent purchaser that your non-road or small off-road engine is free from defects in

materials and workmanship which cause the engine to fail to conform with applicable regulations for a period of two years. The 1995

and later small off road engines are warranted for two years in California. In all other states for 1997 and later model years, EPA requires

manufacturers to warrant non-road engines for two years. These warranty periods will begin on the date the non-road or small

off-road engine is purchased by the initial purchaser. If any emission-related part on your engine is defective, the part will be

replaced by Ryobi Technologies, Inc. at no cost to the owner.

Ryobi Technologies, Inc. shall remedy warranty defects at any authorized Ryobi Technologies, Inc. engine dealer or warranty station. Any authorized work done at an authorized dealer or warranty station shall be free of charge to the owner if such work determines that a warranted part is defective. Any manufacturer-approved or equivalent replacement part may be used for any warranty

maintenance or repairs on emission-related parts, and must be provided free of charge to the owner if the part is still under warranty.

Ryobi Technologies, Inc. is liable for damages to other engine components caused by the failure of a warranted part still under warranty.

The California Air Resources Board’s Emission Warranty Parts List specifically defines the emission-related warranted parts.

(EPA’s regulations do not include a parts list, but EPA considers emission-related warranted parts to include all the parts listed

below.)

These warranted parts are: Carburetor, Spark Plug, Ignition, Air Filter, and Fuel Filter.

MAINTENANCE REQUIREMENTS

The owner is responsible for the performance of the required maintenance as defined by Ryobi Technologies, Inc. in the

operator’s manual.

LIMITATIONS

The Emission Control Systems Warranty shall not cover any of the following:

(a) repair or replacement required because of misuse or neglect, lack of required maintenance, repairs improperly performed

or replacements not conforming to Ryobi Technologies, Inc. specifications that adversely affect performance and/or durability, and alterations or modifications not recommended or approved in writing by Ryobi Technologies, Inc., and

(b) replacement of parts and other services and adjustments necessary for required maintenance at and after the first sched-

uled replacement point.

The Emissions Compliance Period referred to on the Emissions Compliance label indicates the number of operating hours for

which the engine has been shown to meet Federal emission requirements. Category C=50 hours, B=125 hours, and A=300

hours.

Warranty

26

Page 27

Warranty

THIS PRODUCT WAS MANUFACTURED WITH A CATALYST MUFFLER

Congratulations! You have made an investment toward protecting the environment. In order to maintain this

product’s original emission level, please refer to the maintenance section below.

EMISSIONS MAINTENANCE SCHEDULE AND WARRANTED PARTS LIST

Emissions Parts Inspect Before Clean Every Replace Clean Every Replace Every

Each Use 5 Hours Every 25 Hours 25 Hours 50 Hours

or Yearly or Yearly

CATALYTIC MUFFLER ASSEMBLY ................................................................................................................... X

AIR FILTER ASSY

includes:

Filter ................................................................. X............................. X

SPARK SCREEN ..................................................................................................................X

CARBURETOR ASSY

includes:

Heat Dam

Gaskets

FUEL TANK ASSY

includes:

Fuel Lines........................ X

Fuel Cap.......................... X

Fuel Filter

IGNITION ASSY

includes:

Spark Plug........................................................................................ X

ALL EMISSIONS RELATED PARTS ARE WARRANTED FOR ONE YEAR OR FOR THE PERIOD OF TIME PRIOR TO

THE PARTS FIRST SCHEDULED REPLACEMENT WHICHEVER COMES FIRST.

27

Page 28

Customer Service Information

If your product requires service or maintenance, contact your nearest authorized service

dealer. To locate your nearest authorized service dealer for this product, contact us toll

free at 1-800-860-4050.

RYOBI TECHNOLOGIES, INC.

1428 Pearman Dairy Road Anderson, SC 29625

Post Office Box 1207. Anderson, SC 29622-1207

Phone 1-800-860-4050

www.ryobitools.com

983000-899

10-19-05 (REV:00)

28

Warranty

Loading...

Loading...