Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

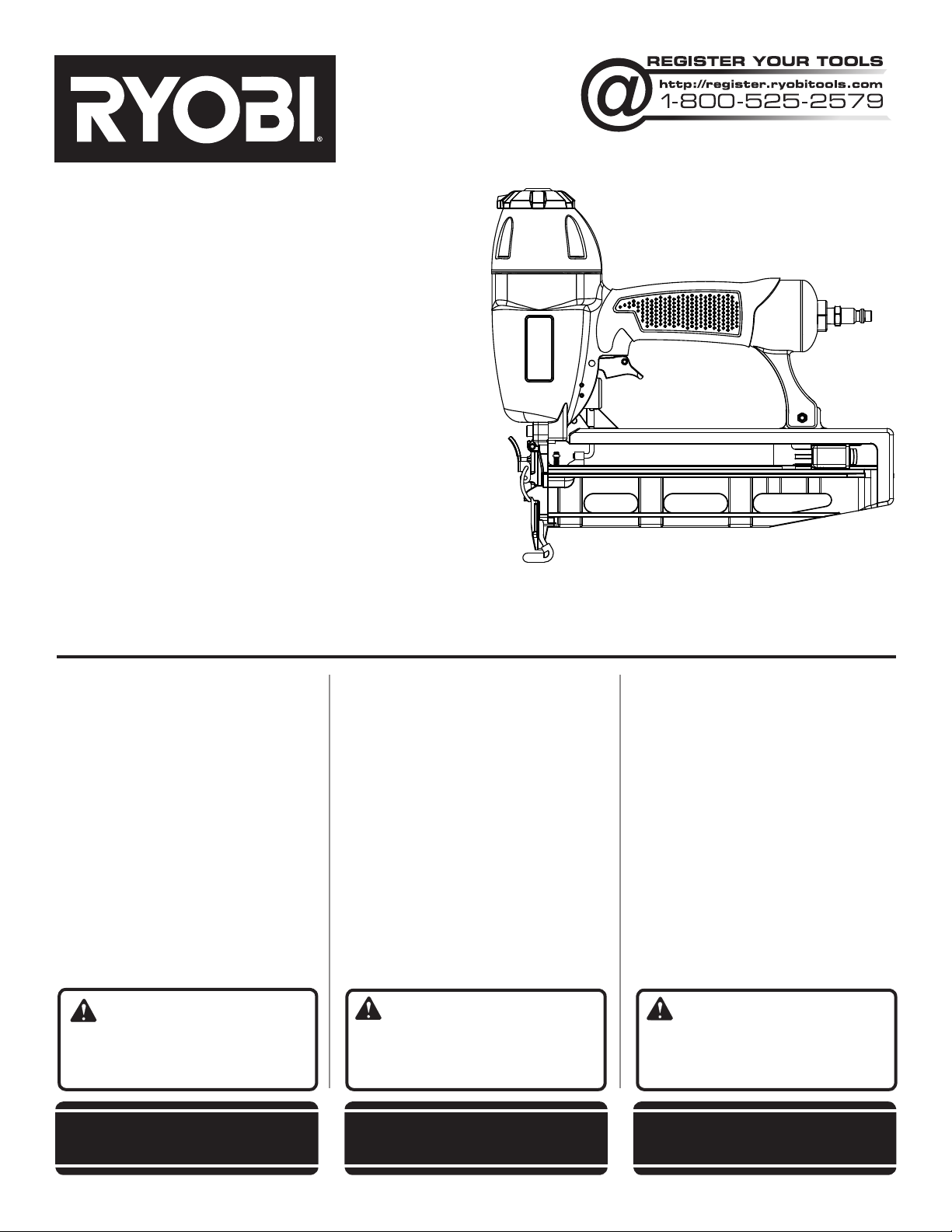

16 GAUGE STRAIGHT

FINISH NAILER

CALIBRE 16, CLOUSEUSE DE

FINITION DROITE

CALIBRE 16, CLAVADORA DE

ACABADO RECTA

YG250FS

TABLE OF CONTENTS

****************

General Safety Rules .......................... 2

Specific Safety Rules ......................3-4

Symbols ..............................................5

Glossary of Terms ...............................6

Features .............................................. 6

Assembly ............................................ 6

Operation .........................................7-9

Maintenance ................................10-11

Accessories ...................................... 11

Troubleshooting ................................12

Figures (Illustrations) ...................14-15

Parts Ordering

and Service .........................Back page

WARNING: To reduce the

risk of injury, the user must read and

understand the operator’s manual

before using this product.

SAVE THIS MANUAL FOR

FUTURE REFERENCE

TABLE DES MATIÈRES

****************

Règles de sécurité générales ............. 2

Règles de sécurité particulières ......3-4

Symboles ............................................5

Glossaire .............................................6

Caractéristiques .................................6

Assemblage ........................................ 6

Utilisation ........................................7-9

Entretien ......................................10-11

Accessoires ...................................... 11

Dépannage ....................................... 12

Figures (illustrations) ....................14-15

Commande de pièces

et dépannage ....................Page arrière

AVERTISSEMENT :

Pour réduire les risques de blessures,

l’utilisateur doit lire et veiller à bien

comprendre le manuel d’utilisation avant

d’employer ce produit.

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

ÍNDICE DE CONTENIDO

****************

Reglas de seguridad generales .........2

Reglas de seguridad específicas ... 3-4

Símbolos ............................................5

Glosario de términos .........................6

Características ...................................7

Armado ..............................................7

Funcionamiento ........................... 8-10

Mantenimiento ........................... 11-12

Accesorios .......................................12

Solución de problemas ....................13

Figuras (illustraciones) ............... 14-15

Pedidos de piezas

y servicio ....................... Pág. posterior

ADVERTENCIA: Para

reducir el riesgo de lesiones, el usuario

debe leer y comprender el manual del

operador antes de usar este producto.

GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

Page 2

GENERAL SAFETY RULES

DANGER:

READ AND UNDERSTAND TOOL LABELS AND

MANUAL. Failure to follow warnings could result in

DEATH or SERIOUS INJURY.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases,

or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to

lose control.

PERSONAL SAFETY

Eye protection which conforms to ANSI specifications

and provides protection against flying particles both

from the FRONT and SIDE should ALWAYS be worn

by the operator and others in the work area when

loading, operating or servicing this tool. Eye protection

is required to guard against flying fasteners and debris,

which could cause severe eye injury.

The employer and/or user must ensure that proper

eye protection is worn. We recommend Wide Vision

Safety Mask for use over eyeglasses or standard safety

glasses that provide protection against flying particles

both from the front and side. Always use eye protection

which is marked to comply with ANSI Z87.1.

Additional safety protection will be required in some

environments. For example, the working area may

include exposure to noise level which can lead to hearing

damage. The employer and user must ensure that any

necessary hearing protection is provided and used by the

operator and others in the work area. Some environments

will require the use of head protection equipment. When

required, the employer and user must ensure that head

protection conforming to ANSI Z89.1-1997 is used.

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool

while tired or under the influence of drugs, alcohol,

or medication. A moment of inattention while operating

power tools may result in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

Keep fingers away from trigger when not driving

fasteners to avoid accidental firing.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables better

control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, nonskid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Do not use on a ladder or unstable support. Stable

footing on a solid surface enables better control of the

tool in unexpected situations.

TOOL USE AND CARE

Do not force tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

Do not use tool if trigger does not actuate properly.

Any tool that cannot be controlled with the trigger is

dangerous and must be repaired.

Check operation of the workpiece contact mechanism

frequently. Do not use the tool if the workpiece contact

mechanism is not working correctly as accidental driving

of a fastener may result. Do not interfere with the proper

operation of the workpiece contact mechanism.

Store idle tools out of the reach of children and other

untrained persons. Tools are dangerous in the hands of

untrained users.

Maintain tools with care. Follow maintenance

instructions. Properly maintained tools are easier to

control.

Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may

affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by

poorly maintained tools.

Use only fasteners that are recommended for your

model.

Keep the tool and its handle dry, clean and free from oil

and grease. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum-based products, or

any strong solvents to clean your tool. Following this rule

will reduce the risk of loss of control and deterioration of

the enclosure plastic.

SERVICE

Tool service must be performed only by qualified

repair personnel. Service or maintenance performed by

unqualified personnel may result in a risk of injury.

When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section

of this manual. Use of unauthorized parts or failure to

follow Maintenance instructions may create a risk of injury.

2 — English

Page 3

SPECIFIC SAFETY RULES

Know your pneumatic tool. Read operator’s manual

carefully. Learn its applications and limitations, as well

as the specific potential hazards related to this tool.

Following this rule will reduce the risk of electric shock,

fire, or serious injury.

Always wear eye protection with side shields marked

to comply with ANSI Z87.1 when assembling parts,

operating the tool, or performing maintenance.

Following this rule will reduce the risk of serious personal

injury.

Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the risk

of serious personal injury.

Protect your hearing. Wear hearing protection during

extended periods of operation. Following this rule will

reduce the risk of serious personal injury.

Make sure the hose is free of obstructions or snags.

Entangled or snarled hoses can cause loss of balance or

footing and may become damaged.

Use the tool only for its intended use. Do not discharge

fasteners into open air.

Use the pneumatic tool only for the purpose for which

it was designed.

Use only the fasteners recommended for this tool.

Use of the wrong fasteners could result in poor fastener

feeding, jammed fasteners, and nails leaving the tool at

erratic angles. If fasteners are not feeding smoothly and

properly, discontinue their use immediately. Jammed

and improperly feeding fasteners could result in serious

personal injury.

Never use this tool in a manner that could cause a

fastener to be directed toward anything other than

the workpiece.

Do not use the tool as a hammer.

Always carry the tool by the handle. Never carry the

tool by the air hose.

Do not alter or modify this tool from the original design

or function without approval from the manufacturer.

Always be aware that misuse and improper handling

of this tool can cause injury to yourself and others.

Never clamp or tape the trigger or workpiece contact

in an actuated position.

Never leave a tool unattended with the air hose

attached.

Do not operate this tool if it does not contain a legible

warning label.

Do not continue to use a tool that leaks air or does

not function properly.

OPERATION

Always assume that the tool contains fasteners.

Do not carry the tool from place to place holding the

trigger. Accidental discharge could result.

Always handle the tool with care:

• Respect the tool as a working implement.

• Never engage in horseplay.

• Never pull the trigger unless nose is directed toward

the work.

• Keep others a safe distance from the tool while tool is in

operation as accidental actuation may occur, possibly

causing injury.

Choice of triggering method is important. Check

manual for triggering options.

Pneumatic tools are designed for single-hand use. Do

not hold the tool by the front of the magazine. Do not put

hands, head, or other parts of your body near the bottom

of the magazine where the nail exits the tool, as serious

personal injury could result.

Do not point the tool toward yourself or anyone whether

it contains fasteners or not.

Do not actuate the tool unless you intend to drive a

fastener into the workpiece.

Always ensure that the workpiece contact is fully

positioned on the workpiece. Positioning the work

contact element only partially on the workpiece could

cause the fastener to miss the workpiece completely and

result in serious personal injury.

Do not drive fasteners near edge of material. The

workpiece may split causing the fastener to ricochet,

injuring you or a co-worker. Be aware that the nail may

follow the grain of the wood, causing it to protrude

unexpectedly from the side of the work material.

Keep hands and body parts clear of immediate work

area. Hold workpiece with clamps when necessary to

keep hands and body out of potential harm. Be sure the

workpiece is properly secured before pressing the nailer

against the material. The workpiece contact may cause

the work material to shift unexpectedly.

Keep face and body parts away from back of the tool

cap when working in restricted areas. Sudden recoil

can result in impact to the body, especially when nailing

into hard or dense material.

3 — English

Page 4

SPECIFIC SAFETY RULES

During normal use the tool will recoil immediately

after driving a fastener. This is a normal function of

the tool. Do not attempt to prevent the recoil by holding

the nailer against the work. Restriction to the recoil can

result in a second fastener being driven from the nailer.

Grip the handle firmly and let the tool do the work. Failure

to heed this warning can result in serious personal injury.

Do not drive fasteners on top of other fasteners or with

the tool at an overly steep angle as this may cause

deflection of fasteners which could cause injury.

Do not drive fasteners close to the edge of the

workpiece as the wood may split, allowing the fastener

to be deflected possibly causing injury.

AIR SUPPLY AND CONNECTIONS

Do not use oxygen, combustible gases or bottled gases

as a power source for this tool as tool will explode,

possibly causing injury or death.

Do not use with an air compressor which can potentially

exceed 200 psi, as tool may burst, possibly causing

injury.

The connector on the tool must not hold pressure when

air supply is disconnected. If an incorrect fitting is used,

the tool can remain charged with air after disconnecting

and thus will be able to drive a fastener even after the air

line is disconnected, possibly causing injury.

Always disconnect air supply:

• Before making adjustments

• When servicing the tool

• When clearing a jam

• When tool is not in use

• When moving to a different work area, as accidental

actuation may occur, possibly causing injury.

LOADING TOOL

Do not load the tool with fasteners when any one of

the operating controls is activated.

When loading tool:

Never place a hand or any part of body in fastener

discharge area of tool.

Never point tool at anyone.

Do not pull the trigger or depress the workpiece

contact as accidental actuation may occur, possibly

causing injury.

SAVE THESE INSTRUCTIONS

Refer to them frequently and use them to instruct others

who may use this tool. If you loan someone this tool, loan

them these instructions also.

4 — English

Page 5

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper interpretation

of these symbols will allow you to operate the tool better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result

in minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related

to an injury hazard, such as a situation that may result in property damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Eye, Ear and Head Protection

Read The Operator’s Manual

Always wear eye protection with side shields marked to comply

with ANSI Z87.1 along with hearing and head protection.

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Keep Hands Away Keep hands and body away from the discharge area of the tool.

Hot Surface

To reduce the risk of injury or damage, avoid contact with any hot

surface.

5 — English

Page 6

GLOSSARY OF TERMS

Activate (operating controls)

To move an operating control so that it is in a position

that allows the tool to be actuated or that satisifes one

requirement for the tool to be actuated.

Actuate (tool)

To cause movement of the tool component(s) intended to

drive a fastener.

Air inlet port

In an air tool, the opening to which the compressed air supply

is connected, usually by means of a threaded fitting.

Fastener

A staple, pin, brad, nail, or other fastening device which is

designed and manufactured for use in the tools within the

scope of this standard.

Jam

An obstruction in the feed or drive areas of the tool.

Maximum air pressure

The maximum allowable pressure of the compressed air, as

specified by the manufacturer, for operating a tool.

FEATURES

Operating control

A control that separately, or as part of an actuation system,

can cause the actuation of a tool.

Single sequential actuation

An actuation system in which there is more than one operating

control and the operating controls must be activated in a

specific sequence to actuate the tool. Additional actuation

can occur when a specific operating control, other than a

workpiece contact, is released and re-activated.

Trigger

A tool operating control activated by a tool operator’s fingers.

Workpiece

The intended object into which a fastener is to be driven

by a tool.

Workpiece contact

An operating control element or assembly on the tool

intended to be activated by the material to be fastened.

PRODUCT SPECIFICATIONS

Operating Pressure.............................................70-120 psi

Fastener Type ..................................... 16 gauge finish nails

Fastener Range ..........................................1 in. to 2-1/2 in.

Magazine Capacity ................................................110 nails

Air Consumption.............................0.09 ft3/cycle at 100psi

Air Inlet .............................................................. 1/4 in. NPT

Weight ..................................................................... 4.2 lbs.

ASSEMBLY

WARNING:

Do not use this product if it is not completely assembled

or if any parts appear to be missing or damaged. Use of

a product that is not properly and completely assembled

or with damaged or missing parts could result in serious

personal injury.

If any parts are damaged or missing, please call 1-800-525-2579 for assistance.

WARNING:

Do not attempt to modify this product or create

accessories or attachments not recommended for use

with this product. Any such alteration or modification is

misuse and could result in a hazardous condition leading

to possible serious personal injury.

6 — English

Page 7

OPERATION

DANGER:

Do not use oxygen, combustible gases, or bottled gases

as a power source for this tool. The tool will explode and

cause death or serious injury.

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields or goggles

marked to comply with ANSI Z87.1. Failure to do so could

result in fluids entering your eyes resulting in possible

serious injury.

WARNING:

Disconnect the tool from the air supply before leaving the

work area, moving the tool to another location, or handing

the tool to another person. Failure to do so could result

in serious personal injury.

APPLICATIONS

You may use this product for the purpose listed below:

Finish and Trim (Interior and exterior)

Door & Window Casing

Door Jambs

Baseboard

Crown Molding

Cabinetry

Cap and Shoe Molding

Molding

Staircases

Door and Window Trim

Chair Rail

Brickmold

Hardwood Flooring

Paneling

Furniture

WARNING:

Always wear eye protection. Eye protection does not fit all

operators in the same way. Make sure the eye protection

chosen has side shields or provides protection from flying

debris both from the front and sides.

PREPARING THE TOOL FOR USE

See Figure 1, page 14.

Under normal use conditions, the tool should be lubricated

before connecting the tool to an air supply. Add air tool oil

into the air fitting on the tool once daily with minimal use,

or twice a day with heavy use. Only a few drops of oil at a

time is necessary. Too much oil will only collect inside the

tool and will be noticeable in the exhaust cycle.

Before connecting the tool, check the air compressor

gauge to be sure it is functioning within the proper range of

70-120 psi.

NO-MAR NOSEPIECE

See Figure 2, page 14.

The no-mar nosepiece prevents marring and denting when

using the tool on softer woods.

WARNING:

Disconnect the tool from the air supply before removing

or replacing the no-mar nosepiece. Failure to do so could

result in serious personal injury.

The no-mar nosepiece can be removed by pulling it down

and away from the nose. To replace the no-mar nosepiece

fit it into place over the workpiece contact and push up at

the back to reseat.

ADJUSTING THE EXHAUST

See Figure 3, page 14.

The adjustable exhaust on the end cap of the tool allows

the operator to direct the exhaust according to operator

preference. To adjust, turn the exhaust cap until the exhaust

blows in the desired direction.

WARNING:

Disconnect the tool from the air supply before leaving the

work area, moving the tool to another location, or handing

the tool to another person. Failure to do so could result

in serious personal injury.

CONNECTING THE TOOL TO AN AIR SUPPLY

See Figure 4, page 14.

DANGER:

Do not use oxygen, combustible gases or bottled gases

as a power source for this tool. The tool will explode and

cause death or serious injury.

This tool is designed to operate on clean, dry compressed air

at regulated pressures between 70 and 120 psi. The correct

air pressure is the lowest pressure that will do the job.

7 — English

Page 8

OPERATION

NOTE: Air pressure that is higher than 120 psi may damage

the tool.

The tool must have an air fitting that allows all pressure

to discharge from the tool when the air hose connector is

disconnected.

WARNING:

Never load nails with the workpiece contact or trigger

activated. Doing so could result in possible serious

personal injury.

WARNING:

Always use an air fitting that discharges all the

compressed air in the tool at the time the air fitting and

air hose connector is disconnected. Using an air fitting

that does not discharge the compressed air could cause

unintended operation and serious personal injury.

WARNING:

Do not climb rigging or scaffolding while carrying a tool

that is connected to an air hose. Doing so could result in

serious personal injury.

Connect the tool to the air supply with a 1/4 in. female quick

connector.

LOADING THE TOOL WITH NAILS

See Figures 5 - 6, page 15.

Connect the tool to the air supply.

WARNING:

The tool’s driving mechanism may cycle when the tool

is first connected to the air supply. Always connect the

tool to the air supply before loading nails to prevent

injury from unintended cycling. Always make sure the

tool’s magazine is empty at the beginning of each work

session, before connecting to an air supply.

Slide the pusher all the way to the rear of the magazine

until it locks into place.

With the nose of the tool pointed away from you, feed

a strip of nails into the magazine. Be sure the nails are

pointed downward as shown.

Depress the pusher release to allow the pusher to move

the nails up to the driving mechanism. The pusher will

stop when it rests against the end of the nail strip.

DRIVING A FASTENER

See Figure 7, page 15.

WARNING:

Never wedge or hold back the workpiece contact

mechanism during operation of the tool. Doing so could

result in possible serious injury.

SINGLE SEQUENTIAL ACTUATION

Single sequential actuation provides accurate fastener

placement.

Connect the tool to the air supply.

Grip the tool firmly to maintain control. Position the nose

of the tool onto the work surface.

Push the tool against the work surface to depress the

workpiece contact.

Pull the trigger to drive a fastener.

Allow the tool to recoil away from the work surface as the

fastener is driven.

WARNING:

Keep the tool pointed away from yourself and others

when loading nails. Failure to do so could result in

possible serious personal injury.

WARNING:

Use only the nails recommended for use with this tool.

The use of any other nails can result in tool malfunction,

leading to serious injuries.

8 — English

WARNING:

During normal use the tool will recoil immediately

after driving a fastener. This is a normal function of

the tool. Do not attempt to prevent the recoil by holding

the nailer against the work. Restriction to the recoil can

result in a second fastener being driven from the nailer.

Grip the handle firmly, let the tool do the work, and do

not place second hand on top of tool or near exhaust at

any time. Failure to heed this warning can result in serious

personal injury.

Page 9

OPERATION

SETTING THE AIR PRESSURE

The amount of air pressure required will depend on the size

of the nail and the workpiece material.

Begin testing the depth of drive by driving a test nail into

the same type of workpiece material used for the actual job.

Drive a test nail with the air pressure set at 90-95 psi. Raise

or lower the air pressure to find the lowest setting that will

perform the job with consistent results.

It may be possible to achieve the desired depth with air

pressure adjustments alone. If finer adjustments are needed,

use the drive depth adjustment on the tool.

DEPTH OF DRIVE ADJUSTMENT

See Figure 8, page 15.

The driving depth of the nail may be adjusted. It is advisable

to test the depth on a scrap workpiece to determine the

required depth for the application.

To determine depth of drive, first adjust the air pressure and

drive a test nail. To achieve the desired depth, use the drive

depth adjustment on the tool.

Disconnect the tool from the air supply.

Turn the depth selector left or right to change the driving

depth.

Reconnect the tool to the air supply.

Drive a test nail after each adjustment until the desired

depth is set.

WARNING:

Disconnect the tool from the air supply before removing

nails. Failure to do so could result in serious personal

injury.

REMOVING NAILS FROM THE TOOL

See Figure 9, page 15.

Disconnect the tool from the air supply.

Slide the pusher all the way to the rear of the magazine

until it locks into place.

NOTE: Always keep fingers clear of nail track of magazine

to prevent injury from unintended release of the pusher.

Tilt the tool as shown so that the nails slide out of the

magazine.

WARNING:

Disconnect the tool from the air supply before clearing a

jammed fastener. Failure to do so could result in serious

personal injury.

CLEARING A JAMMED FASTENER

See Figure 10, page 15.

If a nail or fastener becomes jammed in the tool, disconnect

the air hose and keep the tool pointed away from you while

clearing the jam.

Disconnect the tool from the air supply.

Remove fasteners from the tool.

Pull up on the latch and open the jam release.

Insert a flat blade screwdriver into the driving mechanism

and push the driver mechanism back, freeing the fastener

jam.

Remove the bent fastener.

Close the jam release and latch.

Reconnect the tool to the air supply.

Reinstall fasteners.

9 — English

Page 10

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

WARNING:

Always wear eye protection with side shields or goggles

marked to comply with ANSI Z87.1. Failure to do so could

result in fluids entering your eyes resulting in possible

serious injury.

WARNING:

Disconnect the tool from the air supply before performing

maintenance. Failure to do so could result in serious

personal injury.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which could result in serious personal

injury.

LUBRICATION

Frequent, but not excessive, lubrication is required for

best performance. Oil for pneumatic fastening tools added

through the air line connection will lubricate the internal parts.

Do not use detergent oil or additives as these lubricants will

cause accelerated wear to the seals and bumpers in the

tool, resulting in poor tool performance and frequent tool

maintenance.

COLD WEATHER OPERATION

For cold weather operation, near and below freezing, the

moisture in the air line may freeze and prevent tool operation.

We recommend the use of air tool lubricant or permanent

antifreeze (ethylene glycol) as a cold weather lubricant.

CAUTION:

Do not store tools in a cold weather environment to

prevent frost or ice formation on the tools’ operating

valves and mechanisms that could cause tool failure and

possible injury.

NOTE: Some commercial air line drying liquids are harmful

to “O” rings and seals. Do not use these low temperature

air dryers without checking compatibility.

AIR SUPPLY PRESSURE AND VOLUME

Air volume is as important as air pressure. The air volume

supplied to the tool may be inadequate because of undersize

fittings and hoses, or from the effects of dirt and water in the

system. Restricted air flow will prevent the tool from receiving

an adequate volume of air, even though the pressure reading

is high. The results will be a slow operation or reduced

driving power. Before evaluating tool problems for these

symptoms, trace the air supply from the tool to the supply

source for restrictive connectors, low points containing

water and anything else that would prevent full volume flow

of air to the tool.

10 — English

Page 11

MAINTENANCE

REQUIRED DAILY CHECKLIST

Disconnect the air supply from the tool and remove all

fasteners.

Check all screws, nuts, bolts, and pins on the tool. If

any of these are loose, they must be tightened with the

appropriate size wrench.

Press the workpiece contact against a workpiece to

ensure that it moves smoothly.

With the workpiece contact depressed, pull the trigger.

The trigger should move smoothly, without binding.

While the tool is not loaded, connect the appropriate air

supply (at 70 psi) to the tool.

Without pulling the trigger, press the workpiece contact

against a workpiece several times. The tool must not

operate. No air should leak from the tool.

With the workpiece contact not engaged on the

workpiece, point the tool down and away and pull the

trigger several times. Hold the trigger in this position for

a minimum of 5 seconds. The tool must not operate.

Press the workpiece contact firmly against the workpiece.

Pull the trigger. The tool must operate.

With the workpiece contact still depressed, release the

trigger. The driver must return to its up position.

If the tool successfully meets all the requirements in this

checklist, it is ready for use. Load the proper fasteners

for the desired application.

Set the depth of drive according to the Drive of Depth

Adjustment section in this manual. Repeat this checklist

before using the tool each day, or if the tool is dropped

or damaged in any way.

ACCESSORIES

To order parts and maintenance kits, call 1-800-525-2579.

Overhaul Maintenance Kit ................................................................................................................................079077005701

Driver Maintenance Kit .....................................................................................................................................079077005702

Driver Assembly Kit ..........................................................................................................................................079077005703

Trigger Valve Assembly Kit ...............................................................................................................................079077005704

Oil and Wrench Kit............................................................................................................................................079077005705

WARNING:

Current attachments and accessories available for use with this tool are listed above. Do not use any attachments or

accessories not recommended by the manufacturer of this tool. The use of attachments or accessories not recommended

can result in serious personal injury.

11 — English

Page 12

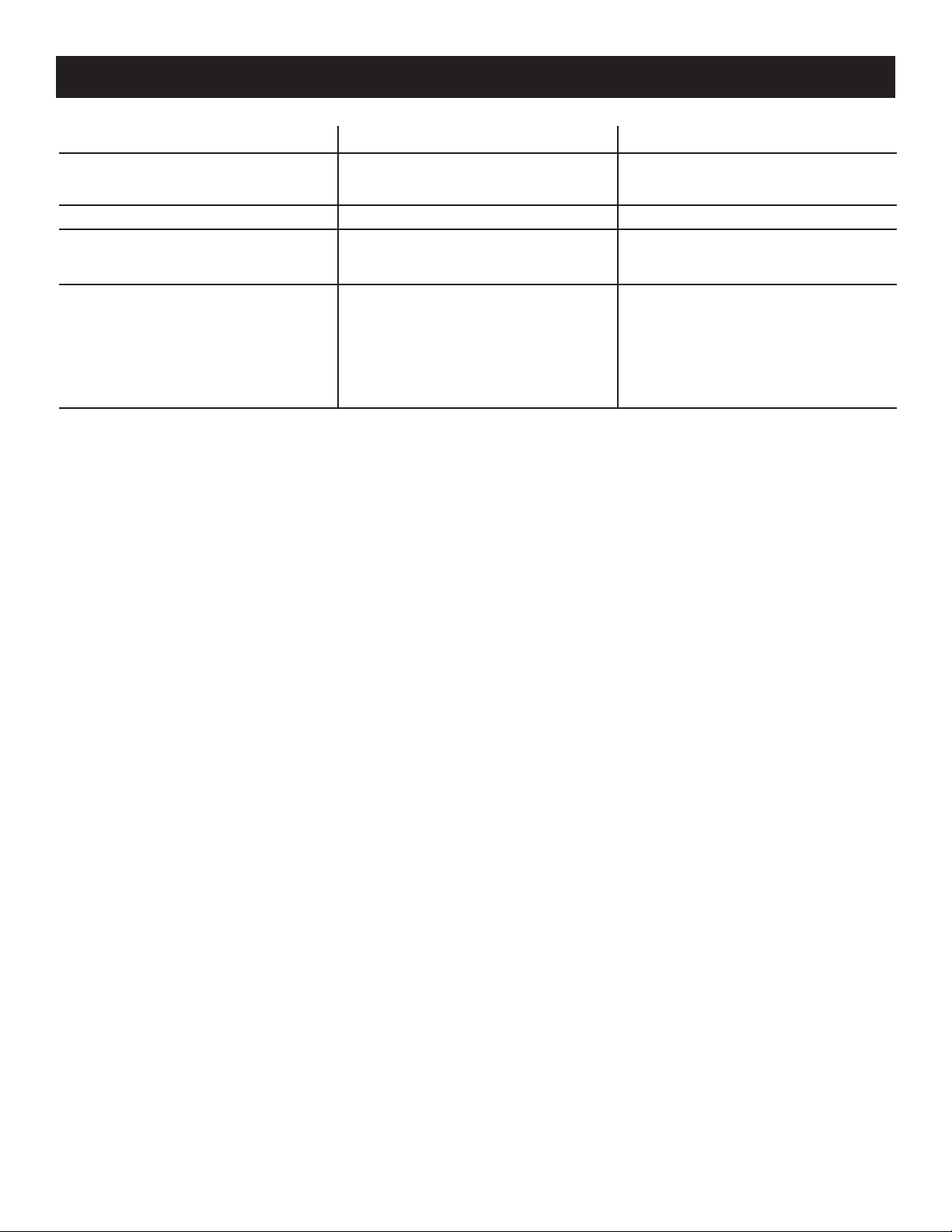

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Air leak near the top of the tool or in the

trigger area

Air leak near the bottom of the tool Worn or damaged O-rings or bumper Install Overhaul Kit

Tool does nothing or operates sluggishly Inadequate air supply

Loose screws

Worn or damaged O-rings or seals

Worn or damaged O-rings or bumper

Tighten screws

Install Overhaul Kit

Verify adequate air supply

Install Overhaul Kit

Tool jams frequently Incorrect fasteners

Damaged fasteners

Loose magazine

Dirty magazine

Worn or damaged driver

Verify that fasteners are the correct size

Replace fasteners

Tighten screws

Clean magazine

Install Driver Maintenance Kit

NOTE: FIGURES (ILLUSTRATIONS) START ON PAGE 14 AFTER

FRENCH AND SPANISH LANGUAGE SECTIONS.

12 — English

Page 13

RÈGLES DE SÉCURITÉ GÉNÉRALES

DANGER :

LIRE ET VEILLER À BIEN COMPRENDRE LES

AUTOCOLLANTS APPOSÉS SUR L’OUTIL ET LE MANUEL.

Le non respect de cet avertissement pourrait entraîner des

BLESSURES GRAVES ou MORTELLES.

CONSERVER CES INSTRUCTIONS

LIEU DE TRAVAIL

Garder le lieu de travail propre et bien éclairé. Les établis

encombrés et les endroits sombres sont propices aux

accidents.

Ne pas utiliser d’outils électriques dans des atmosphères

explosives, par exemple en présence de liquides, gaz

ou poussières inflammables. Les outils électriques

produisent des étincelles risquant d’enflammer les poussières

ou vapeurs.

Garder les badauds, enfants et visiteurs à l’écart pendant

l’utilisation d’un outil électrique. Les distractions peuvent

causer une perte de contrôle.

SÉCURITÉ PERSONNELLE

Lors du chargement, de l’utilisation ou de l’entretien de

cet outil, l’opérateur et les personnes se trouvant sur le

lieu de travail doivent TOUJOURS porter un dispositif

oculaire à protection FRONTALE et LATÉRALE, conforme

aux normes ANSI. Une telle protection est requise, car les

clous / agrafes et débris projetés peuvent causer des lésions

oculaires graves.

Il incombe à l’employeur et / ou l’utilisateur de veiller à

ce qu’une protection oculaire adéquate soit utilisée. Nous

recommandons d’utiliser un masque facial à champ de vision

se portant par-dessus des lunettes de vue ou de sécurité

et potégeant des débris projetés sur le devant et les côtés.

Toujours porter une protection oculaire certifiée conforme à

la norme ANSI Z87.1.

Des équipements de protection supplémentaires sont

requis dans certains environnements. Par exemple, le

lieu de travail peut présenter un niveau de bruit susceptible

d’entraîner des lésions auditives. Il incombe à l’opérateur et à

l’utilisateur qu’une protection audidive soit fournie et utilisée

par l’opérateur et les autres personnes se trouvant sur le lieu

de travail. Certains environnements requièrent le port d’un

casque. Il incombe à l’employeur et / ou l’utilisateur de veiller

à ce qu’un casque conforme à la norme ANSI Z89.1-1997 soit

utilisé.

Rester attentif, prêter attention au travail et faire preuve

de bon sens lors de l’utilisation de tout outil électrique. Ne

pas utiliser cet outil en état de fatigue ou sous l’influence

d’alcool, de drogues ou de médicaments. Un moment

d’inattention pendant l’utilisation d’un outil électrique peut

entraîner des blessures graves.

Porter une tenue appropriée. Ne porter ni vêtements

amples, ni bijoux. Attacher ou couvrir les cheveux longs.

Garder les cheveux, les vêtements et les gants à l’écart

des pièces en mouvement. Les vêtements amples, bijoux

et cheveux longs peuvent se prendre dans les pièces

en mouvement.

2 — Français

Excepté pour agrafer, garder les doigts à l’écart de la

gâchette, pour éviter un déclenchement accidentel.

Ne pas travailler hors de portée. Toujours se tenir

bien campé et en équilibre. Une bonne tenue et un bon

équilibre permettent de mieux contrôler l’outil en cas de

situation imprévue.

Utiliser l’équipement de sécurité. Toujours porter une

protection oculaire. Suivant les conditions, le port d’un

masque antipoussière, de chaussures de sécurité, d’un

casque ou d’une protection auditive est recommandé.

Ne pas utiliser l’outil sur une échelle ou un support

instable. Une bonne tenue et un bon équilibre permettent de

mieux contrôler l’outil en cas de situation imprévue.

UTILISATION ET ENTRETIEN DE L’OUTIL

Ne pas forcer l’outil. Utiliser un outil approprié pour le

travail. Un outil approprié exécutera le travail mieux et de

façon moins dangereuse s’il est utilisé dans les limites prévues.

Ne pas utiliser l’outil si la gâchette ne fonctionne pas

correctement. Tout outil qui ne peut pas être contrôlé par la

gâchette est dangereux et doit être réparé.

Vérifier le mécanisme de contact de la tête de l’outil

fréquemment. Ne pas utiliser l’outil si le mécanisme de

déclenchement par contact ne fonctionne pas correctement,

car l’éjection accidentelle d’une agrafe pourrait se produire.

Ne pas empêcher le fonctionnement correct du mécanisme

de contact de la tête de la cloueuse.

Ranger les outils non utilisés hors de portée des enfants

et des personnes n’ayant pas reçu des instructions

adéquates. Dans les mains de personnes n’ayant pas reçu

des instructions adéquates, les outils sont dangereux.

Entretenir soigneusement les outils. Respecter toutes les

instructions d’entretien. Les outils correctement entretenus

sont plus faciles à contrôler.

Vérifier qu’aucune pièce mobile n’est mal alignée, grippée

ou brisée et s’assurer qu’aucun autre problème risque

d’affecter le bon fonctionnement de l’outil. En cas de

dommages, faire réparer l’outil avant de l’utiliser de

nouveau. Beaucoup d’accidents sont causés par des outils

mal entretenus.

Utiliser exclusivement les clous / agrafes recommandés

pour le modèle d’outil.

Garder l’outil et sa poignée secs, propres et exempts

d’huile ou de graisse. Toujours utiliser un chiffon propre

pour le nettoyage. Ne jamais utiliser de liquide de freins,

d’essence, de produits à base de pétrole ou de solvants forts

pour nettoyer l’outil. Le respect de cette règle réduira les

risques de perte du contrôle et d’endommagement du boîtier

en plastique.

DÉPANNAGE

Le dépannage des outils doit être confié exclusivement à

un personnel qualifié. Les réparations ou entretiens effectués

par des personnes non qualifiées présentent des risques de

blessures.

Utiliser exclusivement des pièces identiques à celles

d’origine pour les réparations. Se conformer aux

instructions de la section Entretien de ce manuel. L’usage

de pièces non autorisées ou le non respect des instructions

d’entretien peut présenter des risques de blessures.

Page 14

RÈGLES DE SÉCURITÉ PARTICULIÈRES

Apprendre à pneumatique l’outil. Lire attentivement

le manuel d’utilisation. Apprendre les applications et les

limites de l’outil, ainsi que les risques spécifiques relatifs

à son utilisation. Le respect de cette règle réduira les

risques d’incendie, de choc électrique et de blessures.

Toujours porter une protection oculaire munie

d’écrans latéraux certifiée conforme à la norme ANSI

Z87.1 lors du montage des pièces, du fonctionnement

de l’outil ou au moment de l’entretien. Le respect de

cette règle réduira les risques de blessures graves.

Protection respiratoire. Porter un masque facial ou

respiratoire si le travail produit de la poussière. Le respect

de cette règle réduira les risques de blessures graves.

Protection auditive. Porter une protection auditive durant

les périodes d’utilisation prolongée. Le respect de cette

règle réduira les risques de blessures graves.

S’assurer que le flexible n’est ni bloqué, ni accroché.

Un flexible emmêlé ou entortillé peut causer une perte

d’équilibre et être endommagé.

L’outil ne doit être utilisé que pour les applications

pour lesquelles il est conçu. Ne pas décharger des

clous dans le vide.

Cet outil pneumatique ne doit être utilisé que pour les

applicactions pour lesquelles il est conçu.

Utiliser seulement les agrafes recommandées pour

cet outil. L’utilisation du mauvais type d’agrafes pourrait

nuire au débit des agrafes et entraîner des bourrages

d’agrafes ainsi que l’éjection des clous de l’outil à des

angles irréguliers. Si le débit des agrafes n’est pas

constant et fluide, cesser de les utiliser sur le champ.

Les bourrages et un débit d’agrafes irrégulier peuvent

occasionner des blessures graves.

Ne jamais utiliser cet outil de façon à ce qu’un clou

puisse être dirigé vers quoi que ce soit d’autre que la

pièce à clouer.

Ne pas utiliser cet outil comme un marteau.

Toujours transporter l’outil par la poignée. Ne jamais

transporter l’outil par le flexible d’air.

Ne pas altérer ou modifier cet outil, ni l’utiliser

pour des fonctions autres que celles prévues, sans

autorisation préalable de son fabricant.

Ne jamais oublier qu’un usage incorrect ou abusif

de cet outil peut mettre l’opérateur et les autres

personnes présentes en danger.

Ne jamais bloquer la gâchette ou le contact de la

cloususe en position de déclenchement avec du ruban

adhésif ou un quelconque autre système.

Ne jamais laisser l’outil sans surveillance avec le

flexible d’air branché.

Ne pas utiliser cet outil s’il ne comporte pas

d’autocollant d’avertissement.

Ne pas utiliser un outil qui présente des fuites d’air

ou ne fonctionne pas correctement.

UTILISATION

Toujours présumer que l’outil contient des clous.

Ne pas transporter l’outil avec le doigt sur la gâchette.

Un clou pourrait être éjecté accidentellement.

Toujours manipuler l’outil avec précaution :

• Respecter cet outil comme tout équipement

de travail.

• Ne pas l’utiliser l’utiliser comme un jouet,

• Ne jamais appuyer sur la gâchette si la tête de l’outil

n’est pas dirigée vers la pièce à clouer.

• Garder toutes les personnes présentes à distance sûre

de l’outil, car un éventuel déclenchement accidentel

pourraît entraîner des blessures.

Le choix de la méthode de déclenchement est

important. Voir les options de déclenchement dans

le manuel.

Les outils pneumatiques sont conçus pour une

utilisation à une main. Ne pas tenir l’outil par la face

avant du chargeur. Tenir les mains, la tête et toute autre

partie du corps à distance du point d’éjection des clous,

près du chargeur, afin d’éviter des blessures graves.

Ne pointer l’outil ni vers soi, ni vers quiconque, qu’il

contienne des clous ou non.

Ne pas actionner l’outil s’il n’est pas fermement

appuyé sur la pièce à clouer.

Toujours s’assurer que la surface de contact est

exactement positionnée sur la pièce à clouer. Un

positionnement seulement partiel de la surface de contact

sur la pièce à clouer peut occasionner des blessures

graves car l’agrafe risque d’être éjectée complètement

à côté de la pièce.

Ne pas planter de clous près du bord du matériau.

La pièce à clouer peut se fendre, causant un ricochet

du clou, qui risque alors de blesser l’opérateur ou une

autre personne présente. Ne pas oublier que le clou peut

suivre le grain du bois et que sa pointe peut ressortir

inopinément par le bord de la planche.

Garder les mains et toutes les parties du corps à

l’écart du point à clouer. Au besoin, assujettir la pièce à

clouer avec des serre-joint pour garder les mains à l’écart

de la zone dangereuse. S’assurer que la pièce à clouer

est correctement assujettie avant d’appuyer la cloueuse

à sa surface. Le contact de la cloueuse peut causer un

déplacement inopiné de la pièce.

Lors du travail dans des endroits confinés, garder le

visage et le corps à l’écart de l’arrière de l’outil. Un

recul brusque peut projeter la cloueuse contre le corps,

en particulier lors du clouage de matériaux denses.

3 — Français

Page 15

RÈGLES DE SÉCURITÉ PARTICULIÈRES

Durant l’utilisation normale de l’outil, un recul se

produit lorsqu’un clou est planté. Ce recul est normal.

Ne pas essayer de l’empêcher en maintenant l’outil contre

la pièce à clouer. Empêcher le recul pourrait causer

l’éjection d’un second clou. Tenir la poignée fermement,

laisser l’outil exécuter le travail et ne jamais placer l’autre

main sur le dessus de l’outil ou près de l’échappement.

Le non respect de cette mise en garde peut entraîner des

blessures graves.

Ne pas planter un clou sur un autre ou avec l’outil à

un angle trop prononcé, car le clou pourrait dévier et

blesser quelqu’un.

Ne pas planter de clous près du bord de la pièce, car

le bois pourrait se fendre et le clou risquerait alors

d’être projeté et de blesser quelqu’un.

ALIMENTATION ET CONNEXIONS

PNEUMATIQUES

Ne pas utiliser de l’oxygène ou des gaz combustibles

ou en bouteille pour alimenter l’outil, car celui-ci

pourrait exploser et infliger des blessures graves ou

mortelles.

Ne pas utiliser un compresseur d’air pouvant produire

une pression de plus de 200 psi, car l’outil pourrait

exploser et infliger des blessures.

Le connecteur utilisé sur l’outil ne doit pas maintenir

la pression une fois que l’alimentation pneumatique

a été débranchée. Si un fusible de type incorrect est

utilisé, l’outil peut resté chargé d’air une fois débranché

et éjecter un clou, risquant de blesser quelqu’un.

Toujours débrancher l’alimentation pneumatique :

• Avant d’effectuer des réglages

• Lors de l’entretien de l’outil

• Lors du déblocage de l’outil

• Lorsque l’outil n’est pas en usage

• Avant de se déplacer avec l’outil, car un déclenchement

accidentel pourrait entraîner des blessures.

CHARGEMENT DE L’OUTIL

Ne pas charger l’outil lorsque l’une des commandes

de déclenchement est activée.

Lors du chargement de l’outil :

Ne jamais placer une main ou une partie quelconque

du corps devant la tête de l’outil.

Ne jamais pointer l’outil sur qui que ce soit.

Ne pas appuyer sur la gâchette ou sur le mécanisme

de contact, car l’outil pourrait éjecter un clou, risquant

blesser quelqu’un.

CONSERVER CES INSTRUCTIONS

Les consulter fréquemment et les utiliser pour instruire

les autres utilisateurs éventuels. Si cet outil est prêté, il

doit être accompagné de ces instructions.

4 — Français

Page 16

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risque associé à l’utilisation

de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER :

AVERTISSEMENT :

ATTENTION :

AVIS :

Certains des symboles ci-dessous peuvent être utilisés sur l’outil. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser l’outil plus efficacement et de réduire les risques.

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée,

aura pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait avoir pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait avoir pour conséquences des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité) Indique une information importante

ne concernant pas un risque de blessure comme une situation pouvant

occasionner des dommages matériels.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

Alerte de sécurité Indique un risque de blessure potentiel.

Protection oculaire, protection

de l’ouïe et casque

Lire le manuel d’utilisation

Toujours porter une protection oculaire certifiée conforme à la

norme ANSI Z87.1, ainsi qu’une protection auditive et un casque

lors de l’utilisation de cet outil.

Pour réduire les risques de blessures, l’utilisateur doit lire et veiller à

bien comprendre le manuel d’utilisation avant d’utiliser ce produit.

Garder les mains à l’écart Garder les mains et le corps à l’écart de de la décharge de l’outil.

Surface brûlante

Pour éviter les risques de blessures ou de dommages, éviter tout

contact avec les surfaces bûlantes.

5 — Français

Page 17

GLOSSAIRE

Activer (commandes de l’outil)

Mettre une commande sur une position déclenchant ou

permettant de déclencher l’outil.

Actionner (outil)

Causer le mouvement des pièces conçues pour chasser

le clou.

Orifice d’entrée d’air

Sur un outil pneumatique, l’ouvreture sur laquelle la

source d’air est connectée, généralement au moyen d’un

raccord fileté.

Pièce de fixation

Agrafe, cheville, clou ou autre pièce de fixation conçue

et fabriquée pour être utilisée pour les outils répondant à

cette norme.

Blocage

Obstruction dans le système d’alimentation ou de décharge

de l’outil.

Pression d’air maximum

Pression maximale admissible de l’air comprimé, telle que

spécifiée par le fabricant, pour alimenter un outil

CARACTÉRISTIQUES

Commande

Dispositif qui, séparément ou en conjonction avec un

système, peut causer le déclenchement de l’outil.

Déclenchement par séquence unique

Système de déclenchement comprenant plus d’une

commande et dont les commandes doivent être

actionnées dans un ordre donné pour déclencher l’outil.

Le déclenchement peut être répété lorsqu’une commande,

autre que le déclencheur par contact, est relâchée, puis

actionnée de nouveau.

Gâchette

Commande de l’outil actionnée par le doigt de l’opérateur.

Pièce

Objet dans lequel un clou, une agrafe ou autre pièce de

fixation est enfoncé par l’outil.

Contact de déclenchement

Pièce ou partie de l’outil conçue pour le déclencher par

contact avec la pièce à assujettir.

FICHE TECHNIQUE

Pression de service ..........................................70 à 120 psi

Type de pièces de fixation ....Clous de finition de calibre 16

Tailles ...........................................................1 po à 2-1/2 po

Capacité du magasin ...........................................110 clous

Consommation d’air ....................... 0,09 ft3/cycle at 100psi

Entrée d’air ........................................................ 1/4 po NPT

Poids .............................................................1,9 kg (4,2 lb)

ASSEMBLAGE

AVERTISSEMENT :

Ne pas utiliser le produit s’il n’est pas complètement

assemblé ou si des pièces semblent manquantes

ou endommagées. L’utilisation d’un produit dont

l’assemblage est incorrect ou incomplet ou comportant

des pièces endommagées ou absentes représente un

risque de blessures graves.

Si des pièces manquent ou sont endommagées, veuillez appeler au 1-800-525-2579 pour obtenir de l’aide.

AVERTISSEMENT :

Ne pas essayer de modifier cet outil ou de créer des

pièces et accessoires non recommandés. De telles

altérations ou modifications sont considérées comme

un usage abusif et peuvent créer des conditions

dangereuses, risquant d’entraîner des blessures graves.

6 — Français

Page 18

UTILISATION

DANGER :

Ne pas utiliser de l’oxygène ou des gaz combustibles

ou en bouteille pour alimenter l’outil. L’outil exploserait,

causant des blessures graves ou mortelles.

AVERTISSEMENT :

Ne pas laisser la familiarité avec le produit faire oublier

la prudence. Ne pas oublier qu’une fraction de seconde

d’inattention peut entraîner des blessures graves.

AVERTISSEMENT :

Toujours porter une protection oculaire avec écrans

latéraux certifiée conforme à la norme ANSI Z87.1. Si

cette précaution n’est pas prise, des objets peuvent être

projetés dans les yeux et causer des lésions graves.

AVERTISSEMENT :

Débrancher l’outil de la source d’air avant de quitter le

lieu de travail, de transporter l’outil à un autre endroit ou

de le passer à une autre personne. Ne pas prendre cette

précaution peut entraîner des blessures graves.

APPLICATIONS

Cet outil peut être utilisé pour les applications ci-dessous :

Finition et décoration (intérieur et extérieur)

Encadrement de portes et fenêtres

Montants de porte

Plinthes

Moulure couronnée

Ébénisterie

Moulures de plinthes et cimaises

Moulures

Escaliers

Cadres de portes et fenêtres

Protections murales

Coffrages

Planchers en bois

Panneautage

Fabrication de meubles

PRÉPARATION DE L’OUTIL POUR

LE TRAVAIL

Voir la figure 1, page 14.

Dans des conditions d’utilisation normales, l’outil doit être

lubrifié avant d’être raccordé à l’alimentation pneumatique.

Lubrifier le raccord d’air de l’outil une fois par jour si

l’utilisation est minimale ou deux fois, si l’utilisation est

intensive. Quelques gouttes suffisent à chaque lubrification.

Une quantité excessive d’huile s’accumulerait à l’intérieur de

l’outil et serait visible lors du cycle d’échappement.

Avant de brancher l’outil, s’assurer que le manomètre du

compresseur d’air indique une pression correcte de 70 à

120 psi.

COUSSINET DE PROTECTION

Voir la figure 2, page 14.

Le coussinet de protection empêche de marquer ou d’érafler

les bois tendres.

AVERTISSEMENT :

Débrancher l’outil de la source d’air avant de retirer le

coussinet de protection ou de le remettre en place. Ne

pas prendre cette précaution peut entraîner des blessures

graves.

Le coussinet de protection peut être retiré en le tirant vers le

bas et vers l’avant. Pour remettre le coussinet de protection

en place, le placer sur la contact de déclenchement et le

pousser vers le haut pour l’engager.

RÉGLAGE DE L’ÉCHAPPEMENT

Voir la figure 3, page 14.

L’échappement réglable du capuchon de l’outil permet à

l’opérateur d’orienter l’échappement selon sa préférence.

Pour orienter l’échappement, tourner le capuchon dans la

direction désirée.

AVERTISSEMENT :

Débrancher l’outil de la source d’air avant de quitter le

lieu de travail, de transporter l’outil à un autre endroit ou

de le passer à une autre personne. Ne pas prendre cette

précaution peut entraîner des blessures graves.

RACCORDEMENT DE L’OUTIL À UNE

SOURCE D’AIR

Voir la figure 4, page 14.

AVERTISSEMENT :

Toujours porter une protection oculaire. Les protections

oculaires ne s’ajustent pas de la même façon sur toutes

les personnes. Veiller à ce que le dispositif oculaire soit

doté d’écrans latéraux protégeant des débris projetés

sur le devant et les côtés.

7 — Français

DANGER :

Ne pas utiliser de l’oxygène ou des gaz combustibles

ou en bouteille pour alimenter l’outil. L’outil exploserait,

causant des blessures graves ou mortelles.

Page 19

UTILISATION

Cet outil est conçu pour fonctionner avec de l’air comprimé

propre, sous pression régulée de 70 à 120 psi. La pression

d’air correcte est la plus basse permettant d’exécuter

le travail.

NOTE : Une pression d’air de plus de 120 psi peut

endommager l’outil.

L’outil doit être muni d’un raccord d’air qui permet l’évacuation

la pression de l’outil au moment de la déconnexion du

connecteur du tuyau à air.

AVERTISSEMENT :

Toujours utiliser un raccord d’air qui permet d’évacuer

l’air comprimé emmagasiné dans l’outil au moment de

la déconnexion du raccord d’air et du connecteur du

tuyau à air. L’utilisation d’un raccord d’air qui ne permet

pas l’évacuation de l’air comprimé pourrait causer un

fonctionnement imprévisible et des blessures graves.

AVERTISSEMENT :

Ne pas monter sur une échelle ou un échaffaudage et

transportant un outil connecté au flexible d’air. Cela

pourrait entraîner des blessures graves.

Raccorder l’outil à la source d’air au moyen d’un raccord

rapide femelle de 6,35 mm (1/4 po).

AVERTISSEMENT :

Ne jamais charger les clous avec la gâchette ou le

mécanisme de déclenchement par contact activé. Cela

pourrait entraîner des blessures graves.

Glisser le poussoir à fond vers l’arrière du magasin jusqu’à

ce qu’il se verrouille.

Insérez la bande de clous dans le magasin en pointant

la partie avant de l’outil loin de vous. Assurez-vous que

les clous sont orientés vers le bas comme il est indiqué.

Dégager le bouton de libération du poussoir pour

permettre au poussoir de déplacer les clous vers le

mécanisme d’entraînement. Le poussoir s’arrête lorsqu’il

est appuyé contre l’extrémité de la banmde de clous.

UTILISATION DE LA GÂCHETTE À

SÉLECTEUR

Voir la figure 7, page 15.

AVERTISSEMENT :

Ne jamais caler ou bloquer le mécanisme de sûreté de

déclenchement par contact pendant que l’outil est en

fonctionnement. Cela pourrait entraîner des blessures

graves.

CHARGEMENT DES CLOUS

Voir les figures 5 et 6, page 15.

Brancher l’outil sur la source d’air.

AVERTISSEMENT :

Le mécanisme d’entraînement de l’outil peut être actionné

lors du raccordement à la source d’air. Toujours raccorder

l’outil à la source d’air avant de charger les clous afin

d’éviter des blessures causées par un déclenchement

involontaire. Toujours s’assurer que le magasin est vide,

au début de chaque séance de travail, avant de raccorder

l’outil à la source d’air.

AVERTISSEMENT :

Veiller à ne pointer l’outil ni vers soi, ni vers d’autres

personnes lors du chargement de clous. Ne pas prendre

cette précaution pourrait entraîner des blessures graves.

AVERTISSEMENT :

Utiliser exclusivement les clous recommandés pour cet

outil. L’usage d’autres clous peut causer un mauvais

fonctionnement de l’outil, susceptible d’entraîner des

blessures graves.

DÉCLENCHEMENT PAR SÉQUENCE UNIQUE

Le mode de déclenchement par séquence unique permet

le placement le plus précis des agrafes.

Brancher l’outil sur la source d’air.

Saisir l’outil fermement pour maintenir le contrôle. Placer

la tête de l’outil contre la pièce à clouer.

Appuyer l’outil contre la pièce à clouer pour actionner le

dispositif de déclenchement par contact.

Appuyer à fond sur la gâchette pour planter une agrafe.

Ne pas empêcher le recul de l’outil lorsque l’agrafe

est plantée.

AVERTISSEMENT :

Durant l’utilisation normale de l’outil, un recul se

produit lorsqu’un clou est planté. Ce recul est normal.

Ne pas essayer de l’empêcher en maintenant l’outil

contre la pièce à clouer. Cela pourrait causer l’éjection

d’un second clou. Tenir la poignée fermement, laisser

l’outil exécuter le travail et ne jamais placer l’autre main

sur le dessus de l’outil ou près de l’échappement. Le

non respect de cette mise en garde peut entraîner des

blessures graves.

8 — Français

Page 20

UTILISATION

RÉGLAGE DE LA PRESSION D’AIR

Le réglage de pression d’air dépend de la taille des clous et

de la dureté du matériau à clouer.

Commencer par tester la profondeur d’enfoncement en

plantant l’un des clous à utiliser dans un morceau du même

bois que la pièce à clouer.

Pour le test, utiliser une pression de 90 à 95 psi. Augmenter

ou réduire la pression d’air de manière à obtenir le réglage

minimum permettant d’exécuter le travail uniformément.

Il est possible d’obtenir la profondeur désirée simplement en

réglant la pression d’air. Si un réglage plus fin est nécessaire,

utiliser le réglage de profondeur d’enfoncement de l’outil.

RÉGLAGE DE PROFONDEUR

D’ENFONCEMENT

Voir la figure 8, page 15.

La profondeur d’enfoncement des clous peut être ajustée.

Il est recommandé de faire un essai sur une chute afin de

déterminer la profondeur requise pour l’application.

Pour déterminer la profondeur, régler d’abord la pression

d’air, puis planter un clou. Pour obtenir la profondeur

nécessaire, utiliser le réglage de profondeur d’enfoncement

de l’outil.

Débrancher l’outil de la source d’air.

Tourner le sélecteur de profondeur vers la droite ou la

gauche pour accroître ou réduire la profondeur.

Rebrancher l’outil à la source d’air.

Planter un clou d’essai aprèchaque réglage, jusqu’à ce

que la profondeur voulue soit obtenue.

AVERTISSEMENT :

Débrancher l’outil de la source d’air avant de retirer les

clous. Ne pas prendre cette précaution peut entraîner

des blessures graves.

RETRAIT DE CLOUS DE L’OUTIL

Voir la figure 9, page 15.

Débrancher l’outil de la source d’air.

Glisser le poussoir à fond vers l’arrière du magasin jusqu’à

ce qu’il se verrouille.

NOTE : Toujours garder les doigts à l’écart du guide de

clous du magasin, pour éviter des blessures en cas de

désengagement imprévu du poussoir.

Inclinez l’outil comme indiqué pour sortir les clous hors

du magasin.

AVERTISSEMENT :

Débrancher l’outil de la source d’air avant de retirer ou

débloquer une agrafe. Ne pas prendre cette précaution

peut entraîner des blessures graves.

DÉBLOCAGE D’UNE AGRAFE

Voir la figure 10, page 15.

Si un clou ou une agrafe se bloque dans l’outil, débrancher

le flexible d’air et garder l’outil pointé à l’ecart de soi pour

le débloquer.

Débrancher l’outil de la source d’air.

Retirer les clous de l’outil.

Soulever le loquet et ouvrir le mécanisme.

Insérer un tournevis à lame plate dans le mécanisme

d’entraînement et pousser ce dernier vers l’arrière, pour

libérer le clou bloqué.

Retirer le clou tordu.

Refermer le couvercle de déblocage et le verrouiller.

Brancher l’outil sur la source d’air.

Réinsérer les clous.

9 — Français

Page 21

ENTRETIEN

AVERTISSEMENT :

Utiliser exclusivement des pièces d’origine pour les

réparations. L’usage de toute autre pièce peut créer une

situation dangereuse ou endommager le produit.

AVERTISSEMENT :

Toujours porter une protection oculaire avec écrans latéraux

ou lunettes de sécurité certifiée conforme à la norme ANSI

Z87.1. Si cette précaution n’est pas prise, des objets

peuvent être projetés dans les yeux et causer des lésions

graves.

AVERTISSEMENT :

Débrancher l’outil de la source d’air avant tout entretien.

Ne pas prendre cette précaution peut entraîner des

blessures graves.

ENTRETIEN GÉNÉRAL

Éviter d’utiliser des solvants pour le nettoyage des pièces en

plastique. La plupart des matières plastiques peuvent être

endommagées par divers types de solvants du commerce.

Utiliser un chiffon propre pour éliminer la saleté, la poussière,

l’huile, la graisse, etc.

AVERTISSEMENT :

Ne jamais laisser de liquides tels que le fluide de freins,

l’essence, les huiles pénétrantes, etc., entrer en contact avec

les pièces en plastique. Les produits chimiques peuvent

endommager, affaiblir ou détruire le plastique et représenter

un risque de blessures graves.

LUBRIFICATION

Une lubrification fréquente, mais pas excessive, est

nécessaire pour obtenir un fonctionnement optimal. De

l’huile pour outils pneumatiques, placée dans le connecteur

de flexible d’air, lubrifiera les pièces internes. Ne pas

utiliser une huile détergente ou un additif, car ces produits

accélèreraient l’usure des joints et butoirs de l’outil, nuisant

à son fonctionnement et exigeant des entretien fréquents.

UTILISATION PAR TEMPS FROID

Lorsque l’outil est utilisé par temps froid, l’humidité contenue

dans le flexible d’aire peut geler, empêchant le fonctionnement

de l’outil. Par temps froid, nous recommandons d’utiliser un

lubrifiant pour outils pneumatiques ou un antigel permanent

(glycoléthlène).

ATTENTION :

Ne pas entreposer les outils dans des endroits froids pour

éviter la formation de givre ou de glace sur les soupapes

et mécanismes, afin de ne pas risquer une défaillance de

l’outil et risque de blessures.

NOTE : Certains produits d’assèchement de flexibles d’air

sont nuisibles aux joints et joints toriques. Ne pas utiliser de

tels produits sans s’être assuré de leur compatibilité.

PRESSION ET VOLUME D’AIR

Le volume d’air est aussi important que la pression. Le

volume d’air parvenant à l’outil peut être insuffisant, du

fait de flexibles et raccords de trop petit diamètre ou de la

présence de saleté et d’eau dans le système. L’obstruction

du circuit d’air empêche l’outil de recevoir un volume

suffisant, même si l’indication de pression du manomètre

est élevée. Il en résulte un ralentissement du fonctionnement

ou une réduction de puissance. Avant d’examiner un outil

présentant ces symptômes, examiner l’alimentation d’air,

jusqu’à la source en vue de connecteurs obstrués, d’eau

dans les points bas et de tout ce qui pourrait empêcher

qu’un volume d’air suffisant parvienne à l’outil.

10 — Français

Page 22

ENTRETIEN

LISTE DE CONTRÔLE QUOTIDIEN

Débrancher l’alimentation d’air de l’outil et retirer toutes

les agrafes.

Vérifier toutes les vis et tiges, et tous les écrous et boulons

de l’outil. Resserrer au besoin toute pièce à l’aide d’une

clé de dimension appropriée.

Appuyer la surface de contact sur la pièce à clouer afin

d’en vérifier le mouvement.

Lorsque la surface de contact est enfoncée, appuyer

sur la gâchette. La gâchette devrait avoir un mouvement

fluide.

Brancher l’outil non chargé à une alimentation d’air

appropriée (70 psi).

Désengager le dispositif de verrouillage de tir à vide (s’il

y a lieu) et appuyer répétitivement la surface de contact

sur une pièce sans appuyer sur la gâchette. L’outil ne

doit pas fonctionner. L’outil ne devrait pas perdre d’air.

ACCESSOIRES

Pointer l’outil vers le sol et loin de soi, sans que la surface

de contact ne touche la pièce, et appuyer répétitivement

sur la gâchette. Tenir la gâchette dans cette position

pendant au moins 5 secondes. L’outil ne doit pas

fonctionner.

Appuyer la surface de contact fermement sur la pièce.

Appuyer sur la gâchette. L’outil doit fonctionner.

En tenant la surface de contact enfoncée, relâcher la

gâchette. Le poinçon devrait retourner à sa position

initiale.

Si l’outil satisfait à toutes les exigences de cette liste de

vérification, il peut être utilisé. Charger les agrafes qui

conviennent le mieux au travail à effectuer.

Régler la profondeur de clouage selon les

instructions de la section Réglage de Profondeur

D’enfoncement du manuel. Suivre cette liste de contrôle

avant chaque utilisation quotidienne ou si l’outil est

échappé ou endommagé de quelque manière que ce soit.

Pour la commande de pièces et kits d’entretien, appeler le 1-800-525-2579.

Kit d’entretien de remise à neuf .......................................................................................................................079077005701

Kit d’entretien du mécanisme d’entraînement .................................................................................................079077005702

Mécanisme d’entraînement .............................................................................................................................079077005703

Kit de soupape de gâchette ............................................................................................................................079077005704

Ensemble Clé et Huile ......................................................................................................................................079077005705

AVERTISSEMENT :

Les outils et accessoires disponibles actuellement pour cet outil sont listés ci-dessus. Ne pas utiliser d’outils ou

accessoires non recommandés pour cet outil. L’utilisation de pièces et accessoires non recommandés peut entraîner

des blessures graves.

11 — Français

Page 23

DÉPANNAGE

PROBLEM POSSIBLE CAUSE SOLUTION

Fuite d’air dans le haut de l’outil ou près

de la gâchette

Fuite au bas de l’outil Joints, joints toriques ou butoir usés Installer le kit de remise à neuf

L’outil est inopérant ou faible Alimentation pneumatique insuffisante

L’outil se bloque fréquemment Clous de type incorrects

NOTE : FIGURES (ILLUSTRATIONS) COMMENÇANT

SUR 14 DE PAGE APRÈS LA SECTION ESPAGNOL.

Vis desserrées

Joints ou joints toriques usés

Joints, joints toriques ou butoir usés

Clous endommagés

Magasin desserré

Magasin encrassé

Mécanisme d’entraînement usé ou

endommagé

Serrer les vis

Installer le kit de remise à neuf

Vérifier que l’alimentation en air est

suffisante

Installer le kit de remise à neuf

S’assurer que les clous sont de taille

correcte

Remplacer les clous

Serrer les vis

Nettoyer le magasin

Installer le kit d’entretien du mécanisme

d’entraînement

12 — Français

Page 24

REGLAS DE SEGURIDAD GENERALES

PELIGRO:

LEA Y COMPRENDA LAS ETIQUETAS DE LAS

HERRAMIENTAS Y EL MANUAL. La inobservancia de

los avisos de advertencia podría causar la MUERTE o

LESIONES SERIAS.

GUARDE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

Mantenga limpia y bien iluminada el área de trabajo. Una

mesa de trabajo mal despejada y una mala iluminación son

causas comunes de accidentes.

No utilice herramientas motorizadas en atmósferas

explosivas, como las existentes alrededor de líquidos,

gases y polvos inflamables. Las herramientas eléctricas

generan chispas que pueden encender el polvo y los vapores

inflamables.

Mantenga alejados a los circunstantes, niños y demás

presentes al utilizar una herramienta eléctrica. Toda

distracción puede causar la pérdida del control de la

herramienta.

SEGURIDAD PERSONAL

Al cargar, utilizar y dar servicio a esta herramienta, el

operador y demás personas SIEMPRE deben llevar puesta

protección ocular que cumpla con las especificaciones

ANSI y ofrezca protección contra partículas que salgan

disparadas del FRENTE y de los LADOS. Se requiere

protección ocular como protección contra sujetadores y

desechos que salgan disparados, los cuales pueden causar

lesiones oculares serias.

Tanto el patrón como el operador deben asegurarse de que

se use protección ocular adecuada. Recomendamos la careta

protectora de visión amplia encima de los anteojos normales o

de los anteojos de seguridad que ofrecen protección frontal y

lateral contra partículas que salen disparadas. Siempre póngase

protección ocular con la marca de cumplimiento de la norma

ANSI Z87.1.

En algunos entornos se requiere protección adicional. Por

ejemplo, en el área de trabajo puede haber exposición a un

nivel de ruido que puede dañar el oído. El patrón y el operador

deben asegurarse de contar con toda la protección auditiva

necesaria y de que sea usada por el operador mismo y demás

personas presentes en el área de trabajo. En algunos entornos

se requiere el uso de equipo de protección para la cabeza.

Cuando se requiera, el patrón y el operador deben asegurarse

de que la protección usada para la cabeza cumpla con la norma

ANSI Z89.1-1997.

Permanezca alerta, preste atención a lo que esté haciendo y

aplique el sentido común al utilizar herramientas eléctricas.

No utilice la herramienta si está cansado o se encuentra

bajo los efectos de alguna droga, alcohol o medicamento.

Un momento de inatención al utilizar una herramienta eléctrica

puede causar lesiones corporales serias.

Vístase adecuadamente. No vista ropas holgadas ni joyas.

Recójase el cabello si está largo. Mantenga el cabello, la

ropa y los guantes alejados de las piezas móviles. Las ropas

holgadas, las joyas y el cabello largo pueden engancharse en

las piezas móviles.

Para evitar disparar accidentalmente la herramienta, mantenga

los dedos lejos del gatillo cuando no esté clavando.

No estire el cuerpo para alcanzar mayor distancia. Mantenga

una postura firme y buen equilibrio en todo momento. La

postura firme y el buen equilibrio permiten un mejor control de

la herramienta en situaciones inesperadas.

Use equipo de seguridad. Siempre póngase protección

ocular. Cuando lo exijan las circunstancias debe ponerse careta

contra el polvo, zapatos de seguridad antiderrapantes, casco

o protección auditiva.

No utilice la unidad al estar en una escalera o en un soporte

inestable. Una postura estable sobre una superficie sólida

permite un mejor control de la herramienta en situaciones

inesperadas.

EMPLEO Y CUIDADO DE LA HERRAMIENTA

No fuerce la herramienta. Utilice la herramienta adecuada

al trabajo. La herramienta adecuada efectúa mejor y de manera

más segura el trabajo, si además se maneja a la velocidad para

la que está diseñada.

No utilice la herramienta si no funciona correctamente el

gatillo. Una herramienta que no pueda controlarse con el gatillo