Page 1

XIW-3100

09-16

Page 2

1

* Battery pack (6) not included

6

4

2

3

5

1

Page 3

2

1 2

3

2

4

3

1

5

Page 4

THANK YOU FOR BUYING A RYOBI PRODUCT.

To ensure your safety and satisfaction, carefully read

through this OWNER’S MANUAL before using the

product.

3

General Safety Rules

SAVE THESE INSTRUCTIONS

WARNING! Read all instructions Failure to follow all instructions

listed below may result in electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below refers

to your mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1) Work area

a) Keep work area clean and well lit. Cluttered and dark

areas invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use safety equipment. Always wear eye rotection.

Safety equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the

off-position before plugging in. Carrying power tools

with your finger on the switch or plugging in power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning

the power

tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f ) Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices can

reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f ) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc.,

in

accordance with these instructions and in the manner

intended for the particular type of power tool, taking

into account the working conditions and the work to be

performed. Use of the power tool for operations different

from intended could result in a hazardous situation.

5) Battery tool use and care

a) Ensure the switch is in the off position before inserting

battery pack. Inserting the battery pack into power tools

that have the switch on invites accidents.

b) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of fire when used with

another battery pack.

c) Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

d) When battery pack is not in use, keep it away from

other metal objects like paper clips, keys, nails, screws,

or other metal objects that can make a connection from

one terminal to another. Shorting the battery terminals

together may cause burns or a fire.

e) Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally

occurs, flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from the

battery may cause irritation or burns.

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

(PJ27)

Page 5

4

This tool is started and stopped by depressing and releasing

the trigger (3).

The tool speed is variable from 0 through 2,200min

-1

by

controlling the trigger-squeezing force.

Insert the hex portion of the socket into the drive shank (1).

This tool is equipped with a LED work light (2) to illuminate the

tip of a bit. The light turns on by depressing the trigger.

1. Drive shank

2. LED work light

3. Trigger

4. Forward/Reverse switch

5. Battery clip

6. Battery pack (Not included)

1. Make sure that the tool is only connected to the voltage

marked on the name plate.

2. Never use the tool if its cover or any bolts are missing. If

the cover or bolts have been removed, replace them

prior to use.

Maintain all parts in good working order.

3. Always secure the tool when working in elevated

positions.

4. Never touch the blade, drill bit, grinding wheel or other

moving parts during use.

5. Never start the tool when its rotating component is in

contact with the work piece.

6. Never lay the tool down before its moving parts have

come to a complete stop.

7. ACCESSORIES: The use of accessories or attachments

other than those recommended in this manual might

present a hazard.

8. REPLACEMENT PARTS: When servicing use only

identical replacement parts.

1. Be aware that since this tool does not have to be plugged

into an electrical outlet, it is always in operating condition.

2. First, charge the battery.

3. Be sure the battery holder is securely snapped in place.

4. When not in use, lock the trigger.

5. When operating at high places, be aware of things below

you.

6. Make sure that the bit is securely mounted. An incorrectly

mounted bit is extremely dangerous since it can fly off or

break during operating.

7. Do not wear cloth gloves or a necktie since they could

become caught in a rotating bit.

8. Hold the tool securely.

9. Never touch the metal body parts when fastening walls,

floors, or other surfaces covering electrical wiring.

Hold the tool only by the plastic handle to prevent electric

shocks.

INSTRUCTIONS FOR SAFE HANDLING

CORDLESS IMPACT WRENCH SAFETY

PRECAUTIONS

Li-ion batteries must be recycled.

Take the battery to the shop from which it was purchased as

soon as the post-charging battery life becomes too short for

practical use.

Do not discard the exhausted battery.

DISPOSAL OF THE EXHAUSTED BATTERY

DESCRIPTION

Drive shank size .................................................. 1/2” Hex.

Fastening capacity...................................... M14 - M32 bolt

Max.fastening torque ............................................ 310N.m

Motor ..................................................................... DC18V

No load speed .............................................. 0-2,200 min

-1

Impact per minute ......................................... 0-3,000 min

-1

Net weight (not incl. battery pack) ......................... 1.7 Kg

SPECIFICATIONS

COMPATIBLE BATTERY PACK AND CHARGER

TRIGGER (Fig. 1)

To change the direction of rotation, stop the tool by releasing

the trigger and push the forward/reverse switch (4) to the

opposite side. When the reversing switch is set to the “R”

mark, the direction of rotation will be clockwise when viewed

from the handle end of the drill. When the reversing switch is

set to the “L” mark, the direction of rotation will be

counter-clockwise.

The trigger can be locked by positioning the reversing switch

at the center. Lock the trigger whenever the tool is not in use.

Since the suitable tightening torque varies with the material,

size, and condition of the material into which objects are

tightened, use a tightening time which is appropriate for the

work conditions. Since bolts may be stretched or broken if the

tightening time is long, confirm the tightening time and

tightening torque before starting the work.

The tightening torque varies with the condition of the battery

pack. Since the striking force will become weaker, the striking

times will become fewer, and the tightening torque will

suddenly drop if the battery pack is on the verge of complete

discharge, recharge the battery pack at regular intervals.

FORWARD/REVERSE SWITCH (Fig.1)

LED WORK LIGHT (Fig.1)

Hex socket (Type : Quick change)

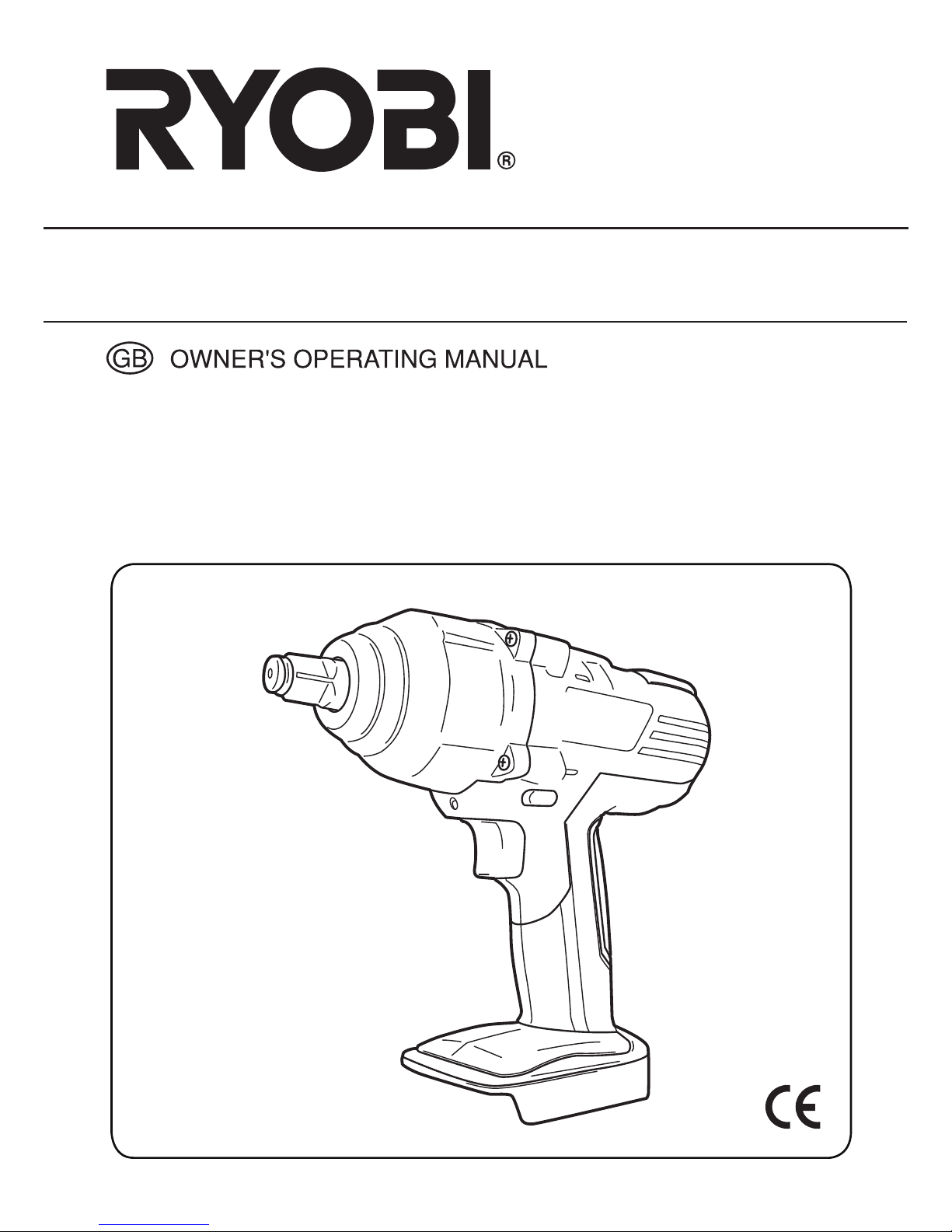

(Mounting)

To remove the socket, simply pull it off.

((Removing))

MOUNTING AND REMOVING THE SOCKET

(Fig. 2)

TIGHTENING TORQUE

BATTERY PACK (not included) ...... XB-1500, XB-3000

CHARGER (not included) ............... XPP-2700

Page 6

5

FACTORS AFFECTING THE TIGHTENING

TORQUE

CHARGING BATTERY PACK

MAINTENANCE

To ensure safety and reliability, all repairs should be

performed by an AUTHORIZED SERVICE CENTER or

other QUALIFIED SERVICE ORGANIZATION.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

WARNING!

After use, check the tool to make sure that it is in top

condition. It is recommended that you take this tool to a

RYOBI Authorized Service Center for a thorough cleaning

and lubrication at least once a year.

DO NOT MAKE ANY ADJUSTMENTS WHILE THE

MOTOR IS IN MOTION.

ALWAYS DISCONNECT THE POWER CORD FROM THE

RECEPTACLE BEFORE CHANGING REMOVABLE OR

EXPENDABLE PARTS (BLADE, BIT, SANDING PAPER

ETC.), LUBRICATING OR WORKING ON THE UNIT.

1. Voltage

When the battery pack is on the verge of discharging, the

voltage and tightening torque drop.

2. Tightening time

The tightening torque increases with the tightening time,

but does not increase after a certain amount of time.

The suitable tightening torque for the bolts varies with

their material, size, and grade. If bolts are tightened with

a high tightening torque, they may be stretched or broken.

Tighten with a tightening time and tightening torque

suitable for the bolts.

3. When the material into which objects are tightened is

different

When tightening a bolt into a soft material such as wood,

the tightening torque is much lower than when doing so

into a hard material such as steel.

4. When the bolt diameter is different

When the diameter of the bolt is different, so is the

tightening torque. Generally, when the diameter is large,

so is the tightening torque. The tightening torque also

varies with the torque coefficient, grade, and length of the

bolt.

5. Trigger position

When the trigger is not pulled fully back (when not at full

power), the tightening torque is lower.

6. Socket

The tightening torque is lower if a socket which is not

suitable for the bolt is used.

Read and follow all warnings and instructions in owner’s

manual of the XPP-2700.

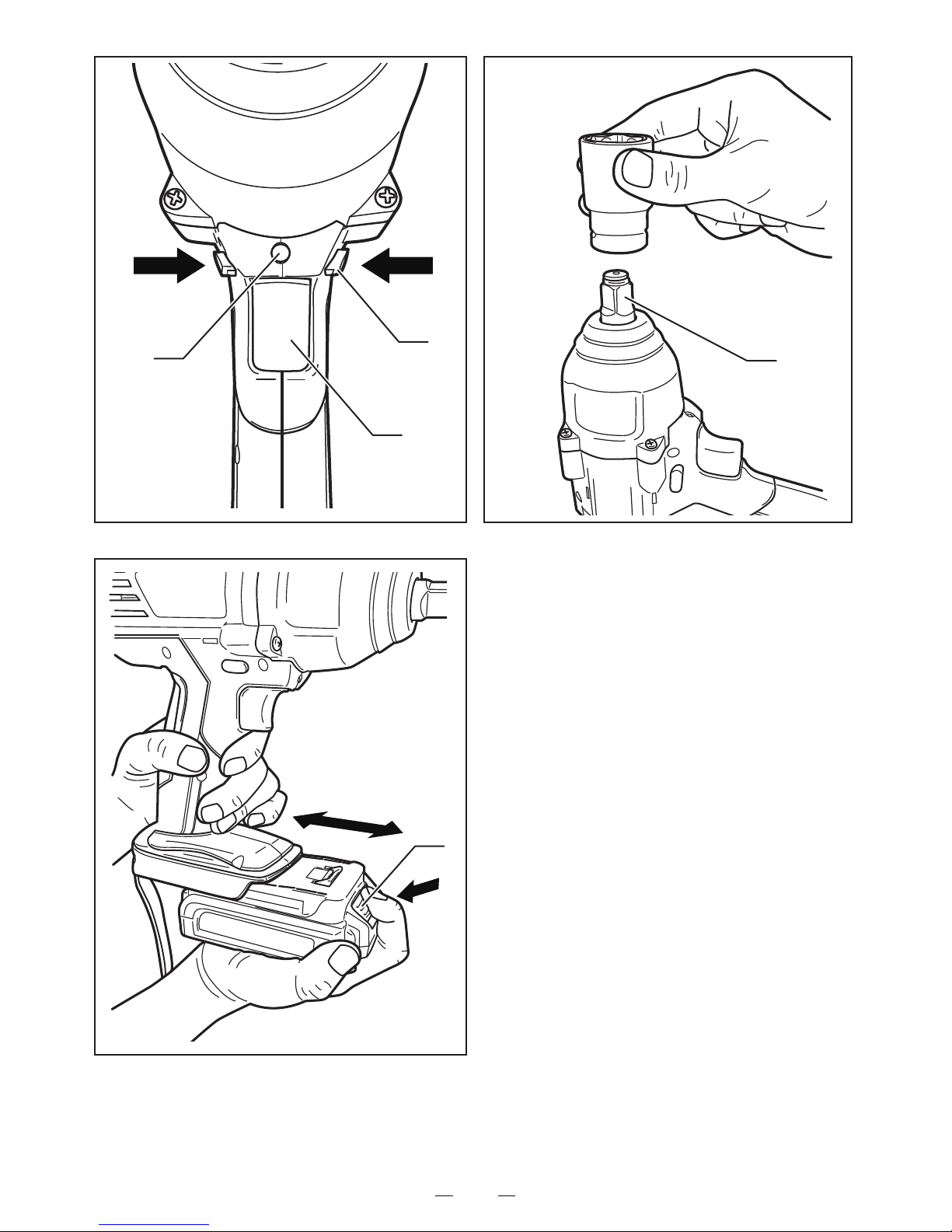

INSTALLING AND REMOVING BATTERY PACK

(Fig. 3)

To install battery pack, lock the trigger switch by placing the

forward/reverse switch in the center position. Align the body

with the groove in the battery pack and push in the direction

of the arrow until the battery pack is secured on the tool.

To remove the battery pack from the tool, push the push

button (5) on and remove the battery pack in the direction of

the arrow.

Always remove battery pack from your tool when you are

assembling parts, making adjustments, cleaning, or when

not in use. Removing battery pack will prevent accidental

starting that could cause serious personal injury.

Page 7

6

NOTE

Page 8

RYOBI POWER EQUIPMENT

WARRANTY

Subject to the warranty conditions below, this

RYOBI tool (hereinafter called “the Product”),

is warranted by Ryobi (herein called “the

Company”) to be free from defects in material

or workmanship for a period of 24 months

from the date of original purchase covering

both parts and labour. Under the terms of

this warranty, the repair or replacement of

any part shall be the opinion of the Company

or its authorised agent. Should service

become necessary during the warranty

period, the owner should contact the

authorised Ryobi retailer from whom the

product was purchased, or the nearest

Company branch of

fice. In order to obtain

warranty service, the owner must include the

Sales Docket and Warranty Certificate to

confirm date of purchase. This Product is

sold by the dealer or agent as principal and

the dealer has no authority from the Company

to give any additional warranty or guarantee

on the Company’s behalf except as herein

contained or herein referred to.

Warranty Conditions

This warranty only applies provided that the

Product has been used in accordance with

the manufacturer's recommendations under

normal use and reasonable care (in the

opinion of the Company) and such warranty

does not cover consumable components,

damage, malfunction or failure resulting from

misuse, neglect, abuse

, or used for a purpose

for which it was not designed, or is not suited

and no repairs, alterations or modifications

have been attempted by other than an

Authorised Service Agent. This guarantee

will not apply if the tool is damaged by

accident or if repairs arise from normal wear

and tear.

Accessories such as bits,blades, sanding

discs, cutting lines, etc., are excluded from

this guarantee. Normal consumable parts,

such as carbon brushes, bearings, chucks,

cord assembly’s, spark plugs, recoil pulleys

and bump head assembly’s are specifically

excluded from this guarantee.

The Company accepts no additional liability

pursuant to this warranty for the costs of

traveling or transportation of the Prod

uct or

parts to and from the sevice dealer or agent

- which costs are not included in the warranty.

Nothing herein shall have the effect of

excluding,

restricting or modifying any

conditions, warranty, right or liability imposed,

to the extent only that such exclusion,

restriction or modification would render any

term herein void.

THIS WARRANTY FORM

SHOULD BE RETAINED BY THE CUSTOMER AT ALL TIMES.

For your record and to assist in establishing date of purchase (necessary for in-warranty service), please

keep your purchase docket and this form, completed with the following particulars.

PURCHASED FROM:.........................................................................................................

ADDRESS OF DEALER:....................................................................................................

DATE:......................... MODEL NO................................ SERIAL NO.................................

Present this form with your Purchase Docket when Warranty Service is required.

STEVENS & CO (Pty) Ltd

604, 16th Street, Randjespark

Midrand, South Africa

Tel: +27 (11) 357-9600

Fax: +27 (11) 805-5541

email: stevens@ryobi.co.za

P O Box 4059

HALFWAY HOUSE

1685, South Africa

Loading...

Loading...