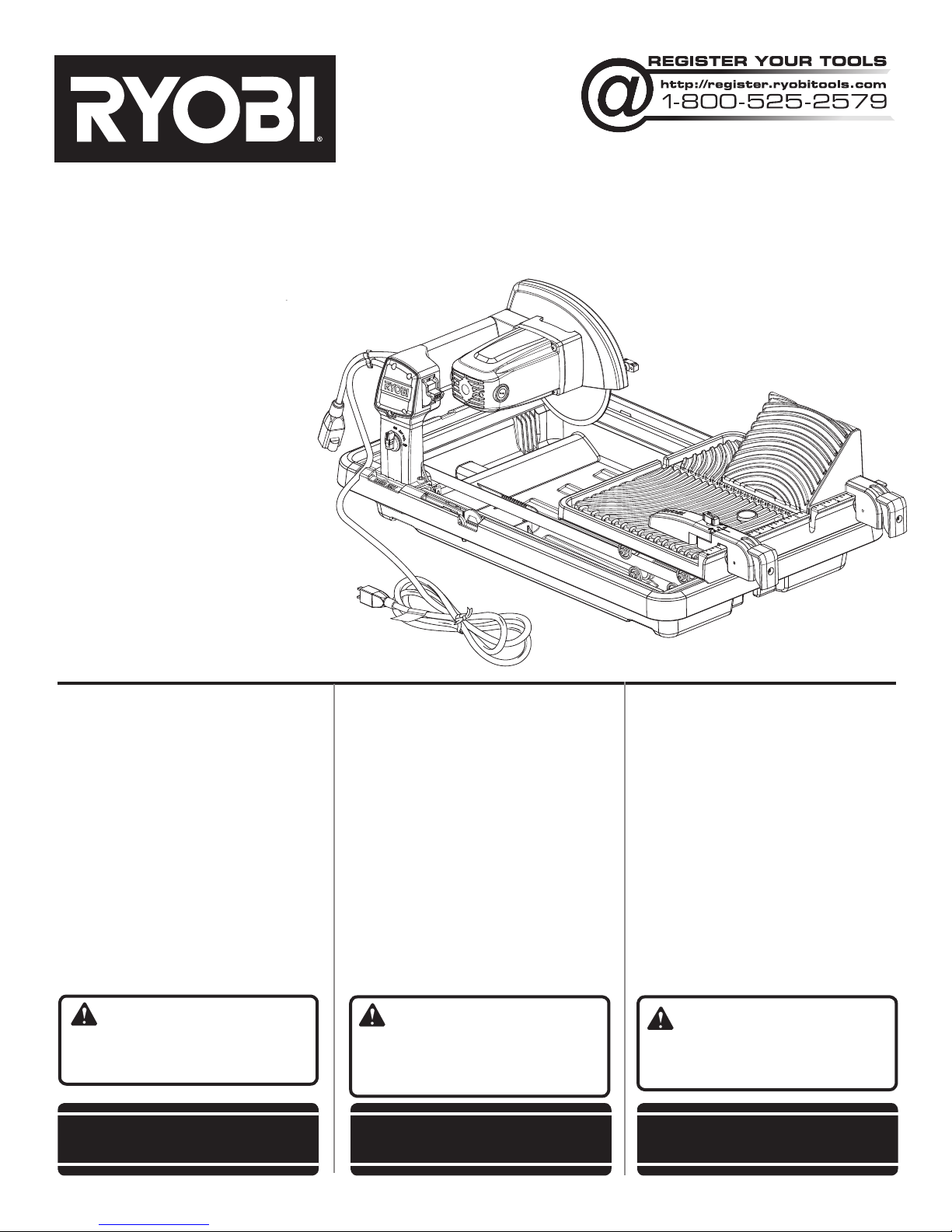

Ryobi WS731 Operator's Manual

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

7 in. TILE SAW

SCIE À CARREAUX

DE 178 mm (7 po)

SIERRA DE LOSAS

DE 178 mm (7 pulg.)

WS731

TABLE OF CONTENTS

General Safety Rules .......................2-3

Specific Safety Rules .........................4

Symbols ..............................................5

Electrical ..........................................6-7

Features .............................................. 7

Assembly .......................................8-10

Operation .....................................10-12

Adjustments .....................................13

Maintenance ..................................... 14

Accessories ...................................... 15

Illustrations ..................................16-23

Parts Ordering

and Service .........................Back page

WARNING: To reduce the

risk of injury, the user must read and

understand the operator’s manual

before using this product.

SAVE THIS MANUAL FOR

FUTURE REFERENCE

TABLE DES MATIÈRES

Règles de sécurité générales ............2-3

Règles de sécurité particulières ...........4

Symboles ..............................................5

Caractéristiques électriques ..............6-7

Caractéristiques ................................7-8

Assemblage .....................................8-10

Utilisation .......................................10-13

Réglages ............................................. 14

Entretien ........................................14-15

Accessoires ........................................ 15

Illustrations ....................................16-23

Commande de pièces

et dépannage ......................Page arrière

AVERTISSEMENT :

Pour réduire les risques de blessures,

l’utilisateur doit lire et veiller à bien

comprendre le manuel d’utilisation avant

d’employer ce produit.

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

ÍNDICE DE CONTENIDO

Reglas de seguridad generales .......2-3

Reglas de seguridad específicas .......4

Símbolos ............................................5

Aspectos eléctricos .........................6-7

Características ................................7-8

Armado ..........................................8-10

Funcionamiento ...........................10-13

Ajustes .............................................. 14

Mantenimiento .............................14-15

Accesorios ........................................ 15

Illustraciones ...............................16-23

Pedidos de piezas

y servicio ....................... Pág. posterior

ADVERTENCIA: Para reducir

el riesgo de lesiones, el usuario debe

leer y comprender el manual del

operador antes de usar este producto.

GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

READ ALL INSTRUCTIONS

KNOW YOUR POWER TOOL. Read the operator’s

manual carefully. Learn the saw’s applications and

limitations as well as the specific potential hazards related

to this tool.

GUARD AGAINST ELECTRICAL SHOCK BY PREVENT-

ING BODY CONTACT WITH GROUNDED SURFACES.

For example, pipes, radiators, ranges, refrigerator enclosures.

KEEP GUARDS IN PLACE and in good working order.

REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents. DO NOT leave tools or pieces of tile on

the saw while it is in operation.

DO NOT USE IN DANGEROUS ENVIRONMENTS. Do

not use power tools in damp or wet locations or expose

to rain. Keep the work area well lit.

KEEP CHILDREN AND VISITORS AWAY. All visi-

tors should wear safety glasses and be kept a safe

distance from work area. Do not let visitors contact

tool or extension cord while operating.

MAKE WORKSHOP CHILDPROOF with padlocks and

master switches, or by removing starter keys.

DON’T FORCE TOOL. It will do the job better and safer

at the feed rate for which it was designed.

USE RIGHT TOOL. Don’t force the tool or attachment to

do a job it was not designed for. Don’t use it for a purpose

not intended.

USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. Use only a cord heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. A wire gauge size

(A.W.G.) of at least 14 is recommended for an extension

cord 25 feet or less in length. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier

the cord.

DRESS PROPERLY. Do not wear loose clothing, gloves,

neckties, or jewelry. They can get caught and draw you

into moving parts. Rubber gloves and nonskid footwear

(rubber soled boots) are recommended when working

outdoors. Also wear protective hair covering to contain

long hair.

ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses, they are NOT safety glasses.

SECURE WORK. Use clamps or a vise to hold work

when practical, it is safer than using your hand and frees

both hands to operate the tool.

DON’T OVERREACH. Keep proper footing and

balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance. Follow instructions for lubricating and changing accessories.

DISCONNECT TOOLS. When not in use, before

servicing, or when changing attachments, wheels, bits,

cutters, etc., all tools should be disconnected.

AVOID ACCIDENTAL STARTING. Be sure switch is off

when plugging in any tool.

USE RECOMMENDED ACCESSORIES. Consult the

operator’s manual for recommended accessories. The

use of improper accessories may risk injury.

NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the cutting tool is unintentionally

contacted.

CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect

its operation. A guard or other part that is damaged must

be properly repaired or replaced by an authorized service

center to avoid risk of personal injury.

USE THE RIGHT DIRECTION OF FEED. Feed work into

a wheel or cutter against the direction of rotation of wheel

or cutter only.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

THE POWER OFF. Don’t leave tool until it comes to a

complete stop.

PROTECT YOUR LUNGS. Wear a face or dust mask if

the cutting operation is dusty.

PROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

DO NOT ABUSE CORD. Never yank cord to disconnect

from receptacle. Keep cord away from heat, oil, and sharp

edges.

ALWAYS USE AN OUTDOOR EXTENSION CORD

MARKED “W-A” OR “W”. These cords are rated for

outdoor use and reduce the risk of electric shock.

ALWAYS KEEP THE WHEEL GUARD IN PLACE and in

working order.

2 — English

GENERAL SAFETY RULES

KEEP HANDS AWAY FROM CUTTING AREA. Keep

hands away from wheels. Do not reach underneathwork

or around or over the wheel while wheel is rotating. Do not

attempt to remove cut material when wheel is moving.

WHEEL COASTS AFTER BEING TURNED OFF.

NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor could ignite fumes.

INSPECT TOOL CORDS PERIODICALLY. If dam-

aged, have repaired by a qualified service technician at

an authorized service facility. The conductor with insulation

having an outer surface that is green with or without yellow

stripes is the equipment-grounding conductor. If repair

or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to a

live terminal. Repair or replace a damaged or worn cord

immediately. Stay constantly aware of cord location and

keep it well away from the rotating wheel.

INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

GROUND ALL TOOLS. If tool is equipped with three-

prong plug, it should be plugged into a three-hole electrical receptacle.

CHECK WITH A QUALIFIED ELECTRICIAN or service

personnel if the grounding instructions are not completely

understood or if in doubt as to whether the tool is properly

grounded.

USE ONLY CORRECT ELECTRICAL DEVICES: 3-wire

extension cords that have 3-prong grounding plugs and

3-pole receptacles that accept the tool’s plug.

DO NOT MODIFY the plug provided. If it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum-based products, or

any solvents to clean tool.

STAY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate

tool when you are tired. Do not rush.

DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defective switches replaced by an

authorized service center.

USE ONLY CORRECT WHEELS. Do not use wheels with

incorrect size holes. Never use washers or arbor nuts that

are defective or incorrect. The maximum wheel capacity

of your saw is 7 in. (178 mm).

BEFORE MAKING A CUT, BE SURE ALL ADJUST-

MENTS ARE SECURE.

NEVER TOUCH WHEEL or other moving parts during

use.

NEVER START A TOOL WHEN ANY ROTATING COM-

PONENT IS IN CONTACT WITH THE WORKPIECE.

DO NOT OPERATE A TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY

MEDICATION.

WHEN SERVICING use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

USE ONLY RECOMMENDED ACCESSORIES listed in

this manual or addendums. Use of accessories that are

not listed may cause the risk of personal injury. Instructions for safe use of accessories are included with the

accessory.

DOUBLE CHECK ALL SETUPS. Make sure wheel is tight

and not making contact with saw or workpiece before

connecting to power supply.

3 — English

SPECIFIC SAFETY RULES

ALWAYS SECURE WORK firmly against the rip guide or

bevel block.

NEVER stand or have any part of your body in line with

the path of the wheel.

NEVER attempt to free a stalled wheel without first turning

the saw OFF and disconnecting the saw from the power

source.

IF THE POWER SUPPLY CORD IS DAMAGED, it must

be replaced only by the manufacturer or by an authorized

service center to avoid risk.

AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause your hand

to move into the cutting tool.

MAKE SURE THE WORK AREA HAS AMPLE LIGHTING

to see the work and that no obstructions will interfere with

safe operation BEFORE performing any work using the

saw.

ALWAYS TURN OFF SAW before disconnecting it, to

avoid accidental starting when reconnecting to power

supply.

THIS TOOL should have the following markings:

a) To reduce the risk of injury, the user must read and

understand operator’s manual.

b) Wear eye, hearing, and respiratory protection when

operating the tool.

c) Do not remove the wheel guard.

d) Never operate the tool without the wheel guard se-

curely closed.

e) Turn off tool, wait for the wheel to stop moving and

disconnect the power to the tool before servicing,

when changing cutting wheels, or cleaning.

f) Never use wheels that have openings, grooves, or

teeth on this tool.

g) Always inspect and replace damaged cutting wheels

before operating the tool.

h) Do not expose to rain or other damp locations.

i) Do not fill water bath above maximum water fill line.

SAVE THESE INSTRUCTIONS. Refer to them

frequently and use to instruct other users. If you loan

someone this tool, loan them these instructions too.

CALIFORNIA PROPOSITION 65

WARNING:

This product and some dust created by power sanding, sawing, grinding, drilling, and other construction activities may

contain chemicals, including lead, known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products and,

• arsenic and chromium from chemically treated lumber.

Your risk from exposure to these chemicals varies, depending on how often you do this type of work. To reduce your

exposure, work in a well-ventilated area and with approved safety equipment, such as dust masks that are specially

designed to filter out microscopic particles.

4 — English

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Eye, Ear, & Breathing

Protection

To reduce the risk of injury, user must read and understand operator’s manual before using this product.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1 along with hearing and breathing protection.

Wet Conditions Alert Do not expose to rain or use in damp locations.

No Hands Symbol

Electrocution Failure to properly ground can result in electrocution.

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

min Minutes Time

Alternating Current Type of current

n

o

No Load Speed Rotational speed, at no load

Failure to keep your hands away from the wheel will result in

serious personal injury.

.../min Per Minute Revolutions, strokes, surface speed, orbits etc., per minute

5 — English

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the tool’s plug.

When using a power tool at a considerable distance from

the power source, use an extension cord heavy enough

to carry the current that the tool will draw. An undersized

extension cord will cause a drop in line voltage, resulting in

a loss of power and causing the motor to overheat. Use the

chart provided below to determine the minimum wire size

required in an extension cord. Only round jacketed cords

listed by Underwriter’s Laboratories (UL) should be used.

**Ampere rating (on tool data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

Always use an extension cord that is designed for outside

use. This is indicated by the letters “W-A” or “W” on the

cord’s jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

Use only extension cords that are intended for outdoor use.

These extension cords are identified by a marking “Acceptable for use with outdoor appliances; store indoors while not

in use”. Use only extension cords having an electrical rating

not less than the rating of the product. Do not use damaged

extension cords. Examine extension cord before using and

replace if damaged. Do not abuse extension cords and do

not yank on any cord to disconnect. Keep cord away from

heat and sharp edges. Always disconnect the extension

cord from the receptacle before disconnecting the product

from the extension cord.

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on lumber,

tools or other obstructions while you are working with a

power tool. Failure to do so can result in serious personal

injury.

WARNING:

Check extension cords before each use. If damaged

replace immediately. Never use tool with a damaged cord

since touching the damaged area could cause electrical

shock resulting in serious injury.

ELECTRICAL CONNECTION

This tool is powered by a precision built electric motor. It

should be connected to a power supply that is 120 V, AC

only (normal household current), 60 Hz. Do not operate

this tool on direct current (DC). A substantial voltage drop

will cause a loss of power and the motor will overheat. If the

saw does not operate when plugged into an outlet, double

check the power supply.

SPEED AND WIRING

The no-load speed of this tool is approximately 4,500 rpm.

This speed is not constant and decreases under a load or

with lower voltage. For voltage, the wiring in a shop is as

important as the motor’s horsepower rating. A line intended

only for lights cannot properly carry a power tool motor. Wire

that is heavy enough for a short distance will be too light for

a greater distance. A line that can support one power tool

may not be able to support two or three tools.

GROUNDING INSTRUCTIONS

See Figure 1, page 16.

This product must be grounded. In the event of a malfunction

or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This

tool is equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified electrician.

WARNING:

Improper installation of the grounding plug is able to

result in a risk of electric shock. When repair or

replacement of the cord is required, do not connect the

grounding wire to either flat blade terminal. The wire with

insulation having an outer surface that is green with or

without yellow stripes is the grounding wire.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded.

Repair or replace a damaged or worn cord immediately.

This product is for use on a nominal 120 volt circuit and

has a grounding plug similar to the plug illustrated in

figure 1, page 16. Only connect the product to an outlet

having the same configuration as the plug. Do not use an

adapter with this product.

Ground Fault Circuit Interrupter (GFCI) protection should be

provided on the circuit(s) or outlet(s) to be used for the tile

saw. Outlets are available having built-in GFCI protection

and may be used for this measure of safety.

6 — English

ELECTRICAL

If the saw is used with an extension cord, ensure the connection of the tool’s power cord and the extension cord are

not on the ground.

If a protected outlet is not available, do not use the saw

until an outlet can be changed or auxiliary protection can

be obtained. These auxiliary protection devices are available

at your local retailer.

POSITION OF THE TILE SAW

See Figures 2 - 3, page 16.

To avoid the possibility of the tool plug or outlet getting

wet, position tile saw to one side of a wall-mounted outlet

to prevent water from dripping onto the outlet or plug. The

operator should arrange a “drip loop” in the cord connecting

the saw to the outlet. The “drip loop” is that part of the cord

FEATURES

PRODUCT SPECIFICATIONS

Wheel Diameter ............................................................7 in.

Wheel Arbor .............................................................. 5/8 in.

Throat Capacity ..................................................... 8-1/2 in.

Rip Capacity (tile size) ................................................16 in.

below the level of the outlet, or the connector if an extension

cord is used, to prevent water traveling along the cord and

coming in contact with the outlet.

If the plug or outlet does get wet, DO NOT unplug the cord.

Disconnect the fuse or circuit breaker that supplies power

to the tool then unplug and examine for the presence of

water in the outlet.

WARNING:

To reduce the risk of electrocution, keep all connections

dry and off the ground. Do not touch the plug with wet

hands.

Diagonal Capacity (tile size) .......................................12 in.

Maximum Depth of Cut ......................................... 2-1/8 in.

Rating .............................................120 V~, 60 Hz, 9 Amps

No Load Speed .....................................4,500 r/min. (RPM)

KNOW YOUR TILE SAW

See Figure 4, page 17.

The safe use of this product requires an understanding of

the information on the tool and in this operator’s manual as

well as a knowledge of the project you are attempting. Before

use of this product, familiarize yourself with all operating

features and safety rules.

7 in. TILE CUTTING WHEEL — A 7 in. tile cutting wheel is

included with your saw.

WARNING:

Do not use wheels rated less than the speed of this tool.

Failure to heed this warning could result in personal injury.

ARM FLOW CONTROL VALVE — When using the PUMPLESS FLOW SYSTEM™ to supply water to the tile saw

wheel, the arm flow control valve turns the water flow to the

wheel on and off. If using an optional pump, this valve also

controls the amount of water being supplied to the wheel.

BEVEL BLOCK — Bevel block supports tile for fast, clean,

and consistent 45º edges.

NOTE: Only use bevel block on the right-hand side of the

table.

CLEAN WAVE WALL™ — If you purchased the optional

pump, the CLEAN WAVE WALL™ system helps prevent

sediment from entering the pump to extend pump life.

NOTE: Optional pump sold separately.

EASY GLIDE™ TABLE — For precise and accurate cuts.

MOTOR — This machine has a strong motor with sufficient

power to handle tough cutting jobs. It also has externally

accessible brushes for ease of servicing.

ON/OFF SWITCH — This saw has an easy access power

switch located below the front rail. To lock the switch in the

OFF position, remove the switch key from the switch. Place

the key in a location that is inaccessible to children and others not qualified to use the tool.

PAN FLOW CONTROL VALVE — When using the PUMPLESS FLOW SYSTEM™, the pan flow control valve controls

the amount of water being supplied to the wheel.

RIP GUIDE — Rip guide is fully adjustable for straight and

miter cuts.

SPLASH GUARD — The splash guard provides protection

from overspray and mist.

UPPER WHEEL GUARD — Protects user from wheel contact on upper portion of wheel.

7 — English

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully lift the saw from the carton and place on a level

work surface.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

The saw is factory set for accurate cutting. After

assembling it, check for accuracy. If shipping has influenced the settings, refer to specific procedures explained

in this manual.

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

TOOLS NEEDED

See Figure 5, page 16.

The following tools (not included or drawn to scale) are

needed for alignment:

Adjustable wrench

13 mm wrench

3 mm hex key

Framing square

LOOSE PARTS LIST

See Figure 6, page 18.

Tile Cutting Wheel

Bevel Block

Rip Guide

Water Tray

Wheel Wrench

6 mm Hex Key

Large and Small Socket Head Screws

Motor Head Assembly

Water Tray Frame

Pan Flow Control Valve

Operator’s Manual (Not Shown)

WARNING:

If any parts are damaged or missing do not operate this

tool until the parts are replaced. Failure to heed this warning could result in serious personal injury.

WARNING:

Do not attempt to modify this tool or create accessories not

recommended for use with this tool. Any such alteration

or modification is misuse and could result in a hazardous

condition leading to possible serious personal injury.

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental starting and possible serious personal injury.

INSTALLING MOTOR HEAD ASSEMBLY TO

FRAME

See Figure 7, page 18.

Align the holes in the motor head assembly with the holes

on the side of the water tray frame.

Insert large and small socket head screws and finger

tighten.

Using the 6 mm hex key, securely tighten the large socket

head screws on the side of the water tray frame.

Tighten the small socket head screws last.

INSTALLING PAN FLOW CONTROL VALVE TO

THE WATER TRAY

See Figure 8, page 18.

Unscrew the pan flow control valve cap.

Place the pan flow control valve into the hole in the water

tray as shown. Set the valve lip on the tray ledge so that

the rib of the valve fits into the notch on the tray.

Reinstall the cap onto the threaded end of the valve and

tighten securely.

INSTALLING TILE SAW TO THE WATER TRAY

See Figure 8, page 18.

Carefully place the water tray frame inside the water tray.

Saw head assembly goes to the back of the frame where

the hose connections are located.

INSTALLING CLEAR HOSE TO WATER

CONNECTION

See Figure 9, page 19.

Attach the clear hose into the pan flow control valve con-

nection on the inside of the water tray. Make sure there

are no kinks in the hose.

8 — English

Loading...

Loading...