Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

7 in. TILE SAW

SCIE À CARREAUX

DE 178 mm (7 po)

SIERRA DE LOSAS

DE 178 mm (7 pulg.)

WS7211

Your saw has been engineered and manufactured to our high standard for dependability, ease of operation, and operator

safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette scie a été conçue et fabriquée conformément aux

strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation. Correctement entretenu, cet outil vous donnera des

années de fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Merci de votre achat.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su sierra ha sido diseñado y fabricado de conformidad con

nuestras estrictas normas para brindar fiabilidad, facilidad de

uso y seguridad para el operador. Con el debido cuidado, le

brindará muchos años de sólido funcionamiento y sin problemas.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

Le agradecemos su compra.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

TABLE OF CONTENTS

Introduction ..................................................................................................................................................................... 2

Warranty .......................................................................................................................................................................... 2

General Safety Rules .................................................................................................................................................. 3 - 4

Specific Safety Rules ....................................................................................................................................................... 4

Symbols ........................................................................................................................................................................... 5

Electrical ..................................................................................................................................................................... 6 - 7

Features ........................................................................................................................................................................... 7

Assembly .................................................................................................................................................................... 8 - 9

Operation .................................................................................................................................................................. 9 - 11

Maintenance .................................................................................................................................................................. 12

Figure numbers (illustrations) ................................................................................................................................. 13 - 17

Parts Ordering / Service ................................................................................................................................... Back page

INTRODUCTION

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

WARRANTY

RYOBI® POWER TOOL - LIMITED THREE YEAR WARRANTY AND 90 DAY EXCHANGE POLICY

One World Technologies, Inc., warrants its RYOBI® power tools with the following conditions:

90-DAY EXCHANGE POLICY: During the first 90 days after date of purchase, you may either request service under this

warranty or you may exchange any RYOBI® power tool which does not work properly due to defective workmanship or

materials by returning the power tool to the dealer from which it was purchased. To receive a replacement power tool or

requested warranty service, you must present proof of purchase and return all original equipment packaged with the original

product. The replacement power tool will be covered by the limited warranty for the balance of the three year period from

the date of the original purchase.

WHAT THIS WARRANTY COVERS: This warranty covers all defects in workmanship or materials in your RYOBI® power

tool for a period of three years from the date of purchase. With the exception of batteries, power tool accessories are warranted for ninety (90) days. Batteries are warranted for three years.

HOW TO GET SERVICE: Just return the power tool, properly packaged and postage prepaid, to an Authorized Service

Center. You can obtain the location of the Service Center nearest you by contacting a service representative at One

World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207, by calling 1-800-525-2579 or by logging on to

www.ryobitools.com. When you request warranty service, you must also present proof of purchase documentation, which

includes the date of purchase (for example, a bill of sale). We will repair any faulty workmanship, and either repair or replace

any defective part, at our option. We will do so without any charge to you. We will complete the work in a reasonable time,

but, in any case, within ninety (90) days or less.

WHAT’S NOT COVERED: This warranty applies only to the original purchaser at retail and may not be transferred. This

warranty only covers defects arising under normal usage and does not cover any malfunction, failure or defects resulting

from misuse, abuse, neglect, alteration, modification or repairs by other than Authorized Service Centers. One World Technologies, Inc. makes no warranties, representations or promises as to the quality or performance of its power tools other

than those specifically stated in this warranty.

ADDITIONAL LIMITATIONS: Any implied warranties granted under state law, including warranties of merchantability or

fitness for a particular purpose, are limited to three years from the date of purchase. One World Technologies, Inc. is not

responsible for direct, indirect, or incidental damages, so the above limitations and exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

2

Page 3

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

READ ALL INSTRUCTIONS

KNOW YOUR POWER TOOL. Read the operator’s

manual carefully. Learn the saw’s applications and

limitations as well as the specific potential hazards related

to this tool.

GUARD AGAINST ELECTRICAL SHOCK BY PREVENT-

ING BODY CONTACT WITH GROUNDED SURFACES.

For example, pipes, radiators, ranges, refrigerator enclosures.

KEEP GUARDS IN PLACE and in good working order.

REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents. DO NOT leave tools or pieces of wood

on the saw while it is in operation.

DO NOT USE IN DANGEROUS ENVIRONMENTS. Do

not use power tools in damp or wet locations or expose

to rain. Keep the work area well lit.

KEEP CHILDREN AND VISITORS AWAY. All visi-

tors should wear safety glasses and be kept a safe

distance from work area. Do not let visitors contact

tool or extension cord while operating.

MAKE WORKSHOP CHILDPROOF with padlocks and

master switches, or by removing starter keys.

DON’T FORCE TOOL. It will do the job better and safer

at the feed rate for which it was designed.

USE RIGHT TOOL. Don’t force the tool or attachment to

do a job it was not designed for. Don’t use it for a purpose

not intended.

USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. Use only a cord heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. A wire gauge size

(A.W.G.) of at least 16 is recommended for an extension

cord 50 feet or less in length. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier

the cord.

DRESS PROPERLY. Do not wear loose clothing, gloves,

neckties, or jewelry. They can get caught and draw you

into moving parts. Rubber gloves and nonskid footwear

(rubber soled boots) are recommended when working

outdoors. Also wear protective hair covering to contain

long hair.

ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses, they are NOT safety glasses.

SECURE WORK. Use clamps or a vise to hold work

when practical, it is safer than using your hand and frees

both hands to operate the tool.

DON’T OVERREACH. Keep proper footing and

balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance. Follow instructions for lubricating and changing accessories.

DISCONNECT TOOLS. When not in use, before

servicing, or when changing attachments, wheels, bits,

cutters, etc., all tools should be disconnected.

AVOID ACCIDENTAL STARTING. Be sure switch is off

when plugging in any tool.

USE RECOMMENDED ACCESSORIES. Consult the

operator’s manual for recommended accessories. The

use of improper accessories may risk injury.

NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the cutting tool is unintentionally

contacted.

CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect

its operation. A guard or other part that is damaged must

be properly repaired or replaced by an authorized service

center to avoid risk of personal injury.

USE THE RIGHT DIRECTION OF FEED. Feed work into

a wheel or cutter against the direction of rotation of wheel

or cutter only.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

THE POWER OFF. Don’t leave tool until it comes to a

complete stop.

PROTECT YOUR LUNGS. Wear a face or dust mask if

the cutting operation is dusty.

PROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

DO NOT ABUSE CORD. Never yank cord to disconnect

from receptacle. Keep cord away from heat, oil, and sharp

edges.

ALWAYS USE AN OUTDOOR EXTENSION CORD

MARKED “W-A” OR “W”. These cords are rated for

outdoor use and reduce the risk of electric shock.

ALWAYS KEEP THE SPLASH HOOD IN PLACE and in

working order.

3 — English

Page 4

GENERAL SAFETY RULES

KEEP HANDS AWAY FROM CUTTING AREA. Keep

hands away from wheels. Do not reach underneathwork

or around or over the wheel while wheel is rotating. Do not

attempt to remove cut material when wheel is moving.

WHEEL COASTS AFTER BEING TURNED OFF.

NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor could ignite fumes.

INSPECT TOOL CORDS PERIODICALLY. If dam-

aged, have repaired by a qualified service technician at

an authorized service facility. The conductor with insulation

having an outer surface that is green with or without yellow

stripes is the equipment-grounding conductor. If repair

or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to a

live terminal. Repair or replace a damaged or worn cord

immediately. Stay constantly aware of cord location and

keep it well away from the rotating wheel.

INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

GROUND ALL TOOLS. If tool is equipped with three-

prong plug, it should be plugged into a three-hole electrical receptacle.

CHECK WITH A QUALIFIED ELECTRICIAN or service

personnel if the grounding instructions are not completely

understood or if in doubt as to whether the tool is properly

grounded.

USE ONLY CORRECT ELECTRICAL DEVICES: 3-wire

extension cords that have 3-prong grounding plugs and

3-pole receptacles that accept the tool's plug.

DO NOT MODIFY the plug provided. If it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum-based products, or

any solvents to clean tool.

STAY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate

tool when you are tired. Do not rush.

DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defective switches replaced by an

authorized service center.

USE ONLY CORRECT WHEELS. Do not use wheels with

incorrect size holes. Never use washers or arbor nuts that

are defective or incorrect. The maximum wheel capacity

of your saw is 7 in. (178 mm).

BEFORE MAKING A CUT, BE SURE ALL ADJUST-

MENTS ARE SECURE.

NEVER TOUCH WHEEL or other moving parts during

use.

NEVER START A TOOL WHEN ANY ROTATING COM-

PONENT IS IN CONTACT WITH THE WORKPIECE.

DO NOT OPERATE A TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY

MEDICATION.

WHEN SERVICING use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

USE ONLY RECOMMENDED ACCESSORIES listed in

this manual or addendums. Use of accessories that are

not listed may cause the risk of personal injury. Instructions for safe use of accessories are included with the

accessory.

DOUBLE CHECK ALL SET-UPS. Make sure wheel is tight

and not making contact with saw or workpiece before

connecting to power supply.

SPECIFIC SAFETY RULES

ALWAYS SECURE WORKPIECE firmly against the rip

guide, miter guide, or bevel table.

NEVER stand or have any part of your body in line with

the path of the wheel.

NEVER attempt to free a stalled wheel without first turning

the saw OFF and disconnecting the saw from the power

source.

IF THE POWER SUPPLY CORD IS DAMAGED, it must

be replaced only by the manufacturer or by an authorized

service center to avoid risk.

AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause your hand

to move into the cutting tool.

MAKE SURE THE WORK AREA HAS AMPLE LIGHTING

to see the work and that no obstructions will interfere with

safe operation BEFORE performing any work using the

saw.

4 — English

ALWAYS TURN OFF SAW before disconnecting it, to

avoid accidental starting when reconnecting to power

supply.

THIS TOOL should have the following markings:

a) Wear eye protection.

b) Use splash hood for every operation for which it can

be used.

c) Disconnect saw before servicing, when changing

cutting wheels, and cleaning.

d) Use tool only with smooth edge cutting wheels free

of openings, grooves, and teeth.

e) Replace damaged cutting wheel before operating.

f) Do not fill water bath above water fill line.

SAVE THESE INSTRUCTIONS. Refer to them

frequently and use to instruct other users. If you loan

someone this tool, loan them these instructions too.

Page 5

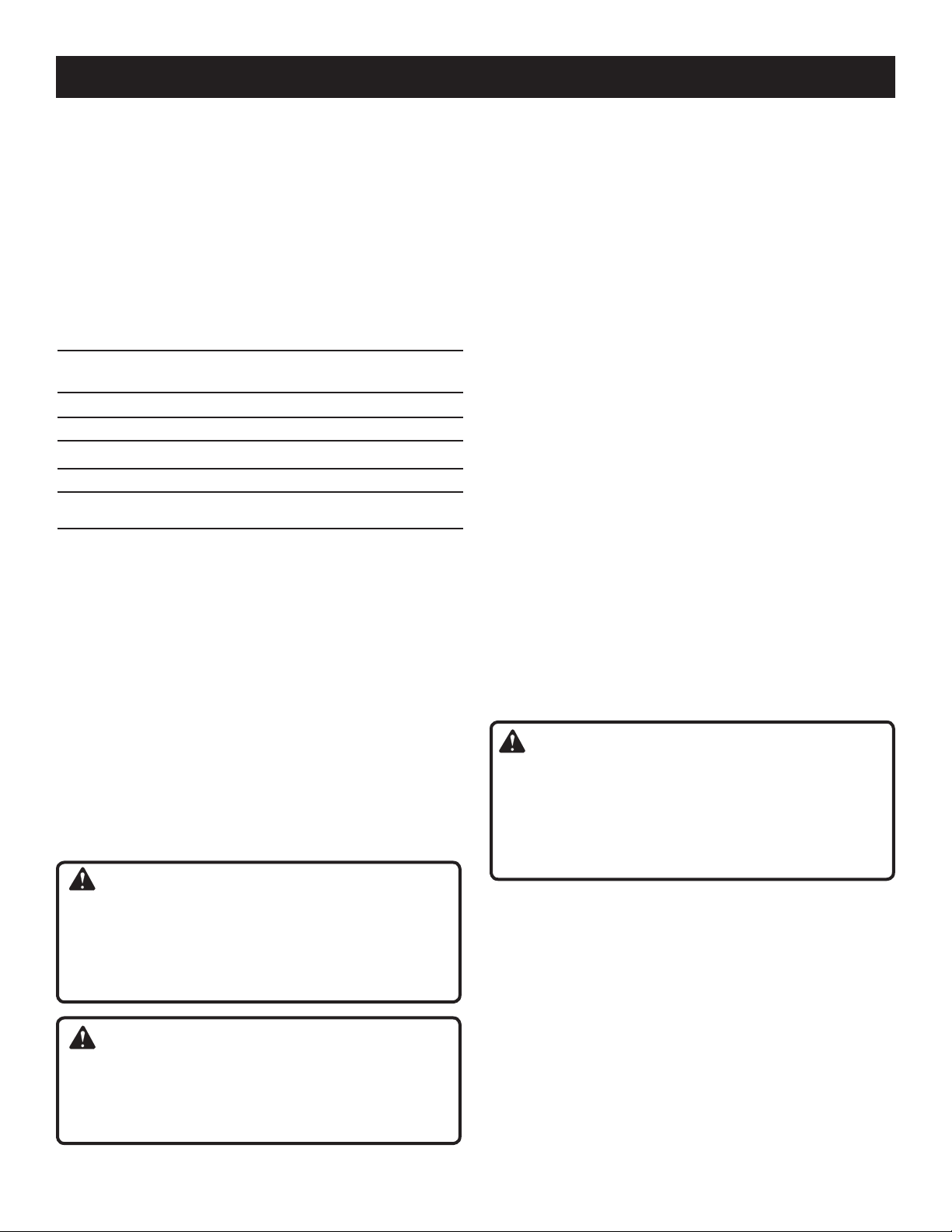

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert

Read The Operator’s Manual

Eye, Ear, & Breathing

Protection

Indicates a potential personal injury hazard.

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1 along with hearing and breathing protection.

Wet Conditions Alert

No Hands Symbol

Electrocution Failure to properly ground can result in electrocution.

V Volts

A Amperes

Hz Hertz

W Watt

min Minutes

Alternating Current

Direct Current

n

o

No Load Speed

Class II Construction

Do not expose to rain or use in damp locations.

Failure to keep your hands away from the wheel will result in

serious personal injury.

Voltage

Current

Frequency (cycles per second)

Power

Time

Type of current

Type or a characteristic of current

Rotational speed, at no load

Double-insulated construction

.../min

Per Minute

Revolutions, strokes, surface speed, orbits etc., per minute

5 — English

Page 6

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the tool’s plug.

When using a power tool at a considerable distance from the

power source, use an extension cord heavy enough to carry

the current that the tool will draw. An undersized extension

cord will cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the chart

provided below to determine the minimum wire size required

in an extension cord. Only round jacketed cords listed by

Underwriter’s Laboratories (UL) should be used.

**Ampere rating (on tool data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

Always use an extension cord that is designed for outside

use. This is indicated by the letters “W-A” or “W” on the

cord’s jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

Use only extension cords that are intended for outdoor use.

These extension cords are identified by a marking “Acceptable for use with outdoor appliances; store indoors while not

in use”. Use only extension cords having an electrical rating

not less than the rating of the product. Do not use damaged

extension cords. Examine extension cord before using and

replace if damaged. Do not abuse extension cords and do

not yank on any cord to disconnect. Keep cord away from

heat and sharp edges. Always disconnect the extension

cord from the receptacle before disconnecting the product

from the extension cord.

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on lumber,

tools or other obstructions while you are working with a

power tool. Failure to do so can result in serious personal

injury.

WARNING:

Check extension cords before each use. If damaged

replace immediately. Never use tool with a damaged cord

since touching the damaged area could cause electrical

shock resulting in serious injury.

ELECTRICAL CONNECTION

This tool is powered by a precision built electric motor. It

should be connected to a power supply that is 120 V, AC

only (normal household current), 60 Hz. Do not operate

this tool on direct current (DC). A substantial voltage drop

will cause a loss of power and the motor will overheat. If the

saw does not operate when plugged into an outlet, double

check the power supply.

SPEED AND WIRING

The no-load speed of this tool is approximately 3,450 rpm.

This speed is not constant and decreases under a load or

with lower voltage. For voltage, the wiring in a shop is as

important as the motor’s horsepower rating. A line intended

only for lights cannot properly carry a power tool motor. Wire

that is heavy enough for a short distance will be too light for

a greater distance. A line that can support one power tool

may not be able to support two or three tools.

GROUNDING INSTRUCTIONS

See Figure 1, page 13.

This product must be grounded. In the event of a malfunction

or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This

tool is equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

WARNING:

Improper installation of the grounding plug is able to

result in a risk of electric shock. When repair or

replacement of the cord is required, do not connect the

grounding wire to either flat blade terminal. The wire with

insulation having an outer surface that is green with or

without yellow stripes is the grounding wire.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded.

Repair or replace a damaged or worn cord immediately.

This product is for use on a nominal 120 volt circuit and

has a grounding plug similar to the plug illustrated in

figure 1, page 13. Only connect the product to an outlet

having the same configuration as the plug. Do not use an

adapter with this product.

Ground Fault Circuit Interrupter (GFCI) protection should be

provided on the circuit(s) or outlet(s) to be used for the tile

saw. Outlets are available having built-in GFCI protection

and may be used for this measure of safety.

6 — English

Page 7

ELECTRICAL

If the saw is used with an extension cord, ensure the connection of the tool’s power cord and the extension cord are not

on the ground. Auxiliary devices should always be plugged

into the wall outlet and not at the connection of an extension

cord and the power tools’ power cord.

If a protected outlet is not available, do not use the saw

until an outlet can be changed or auxiliary protection can

be obtained. These auxiliary protection devices are available

at your local retailer.

POSITION OF THE TILE SAW

See Figure 2, page 13.

To avoid the possibility of the tool plug or outlet getting

wet, position tile saw to one side of a wall-mounted outlet

to prevent water from dripping onto the outlet or plug. The

operator should arrange a “drip loop” in the cord connecting

FEATURES

PRODUCT SPECIFICATIONS

Wheel Diameter ............................................................7 in.

Wheel Arbor .............................................................. 5/8 in.

Rip Capacity (tile size) ................................................16 in.

Diagonal Capacity (tile size) .......................................12 in.

the saw to the outlet. The “drip loop” is that part of the cord

below the level of the outlet, or the connector if an extension

cord is used, to prevent water traveling along the cord and

coming in contact with the outlet.

If the plug or outlet does get wet, DO NOT unplug the cord.

Disconnect the fuse or circuit breaker that supplies power

to the tool then unplug and examine for the presence of

water in the outlet.

WARNING:

To reduce the risk of electrocution, keep all connections

dry and off the ground. Do not touch the plug with wet

hands.

Maximum Depth of Cut ......................................... 1-1/4 in.

Rating ..........................................120 V~, 60 Hz, 4.8 Amps

No Load Speed .....................................3,450 r/min. (RPM)

KNOW YOUR TILE SAW

See Figure 3, page 13.

The safe use of this product requires an understanding of

the information on the tool and in this operator’s manual as

well as a knowledge of the project you are attempting. Before

use of this product, familiarize yourself with all operating

features and safety rules.

7 in. TILE CUTTING WHEEL - A 7 in. tile cutting wheel is

included with your saw.

WARNING:

Do not use wheels rated less than the speed of this tool.

Failure to heed this warning could result in personal

injury.

BEVEL TABLE - Beveled 22.5° and 45° cuts can be made

using the bevel table.

HANDLES - Saw has convenient handles located on left

and right side for lifting and carrying.

MITER GUIDE - The miter guide is fully adjustable for diagonal cuts and miter cuts.

MOTOR - This machine has a strong motor with sufficient

power to handle tough cutting jobs.

ON/OFF SWITCH - This saw has an easy access power

switch located below the front rail. To lock the switch in the

OFF position, remove the switch key from the switch. Place

the key in a location that is inaccessible to children and others not qualified to use the tool.

RIP GUIDE - Rip guide is fully adjustable for making cross

cuts and using the miter guide.

SPLASH HOOD - The splash hood provides protection from

overspray and mist.

7 — English

Page 8

ASSEMBLY

UNPACKING

See Figure 4, page 14.

This product requires assembly.

Carefully lift the saw from the carton and place on a level

work surface.

WARNING:

WARNING:

Do not attempt to modify this tool or create accessories

not recommended for use with this tool. Any such alteration or modification is misuse and could result in a hazardous condition leading to possible serious personal injury.

Do not use this product if any parts on the Loose Parts List

are already assembled to your product when you unpack

it. Parts on this list are not assembled to the product by

the manufacturer and require customer installation. Use

of a product that may have been improperly assembled

could result in serious personal injury.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

The saw is factory set for accurate cutting. After

assembling it, check for accuracy. If shipping has influenced the settings, refer to specific procedures explained

in this manual.

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

PACKING LIST

Tile saw

Tile cutting wheel

Bevel table

Splash hood with knob and hex bolt

Splash hood bracket

Screws (2)

Overflow drain

Rip guide

Miter guide

Hex wrench

Arbor wrench

Washers (2)

Operator’s Manual

WARNING:

If any parts are damaged or missing do not operate this

tool until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

INSTALLING THE TILE CUTTING WHEEL

See Figure 5, page 14.

WARNING:

A 7 in. tile cutting wheel is the maximum wheel capacity

of the saw. Never use a wheel that is too thick to allow

wheel washer to engage with the flats on the spindle.

Larger wheels will come in contact with the splash hood,

while thicker wheels will prevent the wheel bolt from securing the wheel on the spindle. Either of these situations

could result in a serious accident and can cause serious

personal injury.

Remove bevel table.

Slide inner cutting wheel washer onto arbor.

WARNING:

Always install the inner wheel washer before placing

wheel on arbor. Failure to do so could cause an accident

since the wheel will not tighten properly. Never use wheels

that have openings, grooves, or teeth on this tool.

Place the cutting wheel onto arbor with arrrows on cutting

wheel going in the counterclockwise direction.

Place outer cutting wheel washer onto arbor. The double

“D” flats on the wheel washers align with the flats on the

spindle.

Install arbor nut onto arbor. Using wheel wrench and arbor

wrench, tighten arbor nut securely.

Replace bevel table.

To remove tile cutting wheel:

Remove bevel table.

Slide the hex wrench over the wheel arbor nut. Using

other hand, slide arbor wrench onto wheel arbor.

Hold arbor wrench firmly to prevent the wheel from mov-

ing. Turn arbor nut counterclockwise to loosen.

Remove arbor nut, outer wheel washer, and cutting-

wheel.

8 — English

Page 9

ASSEMBLY

INSTALLING THE SPLASH HOOD

See Figure 6 - 7, page 14.

Remove bevel table.

Install the L-shaped splash hood bracket into the lip

located under the table behind the wheel.

Install the washers and screws into table and through

splash hood bracket then tighten securely.

NOTE: Be sure that hood bracket is aligned with cutting

wheel so that it does not interfere with material being

cut.

Align splash hood with wheel and slide over bracket. Line

up through holes in splash hood with slot in splash hood

bracket.

NOTE: Always adjust splash hood horizontally to table

and slightly above tile thickness. Hood should not be

touching tile.

Install hex bolt through hood and bracket. Thread splash

hood knob onto bolt and tighten to desired height.

Replace bevel table.

INSTALLING THE RIP GUIDE

See Figure 8, page 15.

Turn knob on rip guide counterclockwise to loosen.

Slide rip guide onto side of table.

Use rip guide scale, located on front and rear of table, to

set rip guide to desired width of cut.

Turn rip guide knob clockwise to tighten securely.

INSTALLING THE MITER GUIDE

See Figure 8, page 15.

Slide miter guide onto rip guide from front.

Adjust rip guide to desired position and secure.

Adjust to desired angle using angle scale and tighten

securely with miter guide knob.

INSTALLING THE OVERFLOW DRAIN

See Figure 9, page 15.

Remove bevel table.

Locate hole on bottom of water fill reservoir.

Push overflow drain into hole firmly.

Replace bevel table.

FILLING THE WATER RESERVOIR

See Figure 10, page 15.

Remove bevel table.

Fill water reservoir with clean tap water to fill line.

NOTE: Overflow drain prevents overfilling.

Replace bevel table.

To change reservoir water:

Unplug tile saw.

Remove overflow drain and empty into a bucket, do not

allow water to splash onto ground or around machine.

Discard waste water in accordance with local regulations.

OPERATION

WARNING:

Do not allow familiarity with tools to make you careless.

Remember that a careless fraction of a second is sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes, resulting in possible

serious injury.

WARNING:

Do not use any attachments or accessories not recommended by the manufacturer of this tool. The use of attachments or accessories not recommended can result

in serious personal injury.

APPLICATIONS

You may use this tool for the purposes listed below:

Straight line cutting operations such as cross cutting,

mitering, ripping, and beveling

NOTE: This saw is designed to cut man-made tile, pavers,

natural stone products, and stone tile products only.

9 — English

Page 10

OPERATION

ON/OFF SWITCH

See Figure 11, page 15.

Your saw is equipped with an on/off switch that has a built-in

locking feature. This feature is intended to prevent unauthorized and possible hazardous use by children and others.

TO TURN YOUR SAW ON:

With the switch key inserted into the switch, lift the switch

button to turn ON.

TO TURN YOUR SAW OFF:

Press the switch button down to turn OFF.

TO LOCK YOUR SAW:

With the saw turned OFF, pull the switch key from the

switch and store in a safe, secure location.

WARNING:

In the event of a power failure or when the tool is not in

use, turn the switch OFF and remove the switch key.

This action will prevent the tool from accidentally starting

when power returns.

WARNING:

ALWAYS make sure your workpiece is not in contact

with the cutting wheel before operating the switch to

start the tool. Failure to heed this warning may cause the

workpiece to be kicked back toward the operator and

result in serious personal injury.

WARNING:

To reduce the risk of accidental starting, ALWAYS make

sure the switch is in the OFF position before plugging

tool into the power source.

USING THE RIP GUIDE AND MITER GUIDE

See Figure 12, page 15.

The rip guide can be used from both the left and right side

of the cutting wheel.

Turn knob on rip guide counterclockwise to loosen.

Adjust the rip guide in the desired position using the rip

guide scale, located on front and rear of table, to set rip

guide to desired width of cut.

Rotate the knob, clockwise, to tighten securely.

To adjust angles:

Slide miter guide onto rip guide from the front.

Adjust rip guide to desired position and secure tightly.

Adjust to desired angle using angle scale and tighten

securely with miter guide knob.

MAKING CUTS

Always draw the line to be cut on the tile using a marker or

grease pencil. If the tile is shiny and hard-to-mark, place

masking tape on the tile and mark the tape.

A common problem when cutting tile is straying from the

marked line. Once you’ve strayed from the mark, you can not

force the wheel back to the line by twisting the tile. Instead,

back up and recut the tile slicing off a small amount of tile

until the wheel is back on track.

To avoid this problem, use the rip guide when making cross

cuts, the miter guide for miter cuts and the adjustable right

side table for making bevel cuts, whenever possible.

TO MAKE A CROSS CUT

See Figure 13, page 16.

Cross cuts are straight 90° cuts. The material is fed into the

cut at a 90° angle to the wheel.

Using a marker or grease pencil, mark the area to be cut

on material.

Adjust rip guide to desired position and secure tightly.

Place the material on the table and firmly against the rip

guide.

Make sure the material is clear of the cutting wheel before

turning on the saw.

Turn the on/off switch to the ON position.

Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

Hold the material firmly against the rip guide and feed

the material into the cutting wheel.

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before removing any part of the material.

TO MAKE A 45° DIAGONAL CUT

See Figure 14, page 16.

45° Diagonal cuts are also referred to as “long point to long

point cuts”.

Using a marker or grease pencil, mark the area to be cut

on material.

Slide miter guide onto rip guide from front.

Set the rip guide to desired width, and tighten the knob

to secure in place.

Adjust miter guide to

securely with knob.

Make sure the material is clear of the cutting wheel before

turning on the saw.

Turn the on/off switch to the ON position.

Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

using angle scale and tighten

45°

10 — English

Page 11

OPERATION

Hold the material firmly against the miter guide and slide

miter guide along rip guide. Feed the material into the

cutting wheel.

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before removing any part of the material.

TO MAKE A MITER CUT

See Figure 15, page 16.

Miter cuts are used for cutting outside and inside corners

on material, decorative chair rail, and base molding with the

material at any angle to the wheel other than 90°. Miter cuts

tend to “creep” during cutting. This can be controlled by

holding the workpiece securely against the miter guide.

Using a marker or grease pencil, mark the area to be cut

on material.

Slide miter guide onto rip guide from front.

Set the rip guide to desired width, and tighten the knob

to secure in place.

Adjust miter guide to desired angle, using angle scale,

and tighten securely with knob.

Make sure the material is clear of the cutting wheel before

turning on the saw.

Turn the on/off switch to the ON position.

Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

Hold the material firmly against the miter guide and slide

miter guide along rip guide. Feed the material into the

cutting wheel.

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before removing any part of the material.

TO MAKE AN L-CUT

See Figure 16, page 16.

L-cuts are cuts that remove a piece of tile to fit in a corner,

around a cabinet, or a piece of molding and are made by

two separate cuts.

NOTE: Only overcut on the bottom or underneath side of

the material being cut.

Cut material to desired width using directions for cross

cut

Adjust rip guide to desired position and secure tightly.

Place the material on the table and firmly against the rip

guide.

Make sure the material is clear of the cutting wheel before

turning on the saw.

Turn the on/off switch to the ON position.

Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

Hold the material firmly against the rip guide and feed

the material into the cutting wheel.

Make the cut far enough into the material without over-

cutting.

Turn the on/off switch to the OFF position.

Turn the material over and make the cut along one of the

marks. This time overcut the other line and the cut piece

should separate from the rest of the material.

Turn the on/off switch to the ON position.

Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before removing any part of the material.

TO MAKE A BEVEL CUT

See Figures 17 - 18, page 17.

Beveled 22.5° and 45° cuts can be made using the bevel

table.

Using a marker or grease pencil, mark the area to be cut

on material.

Tip up the bevel table.

On underside of bevel table, pull down the two table legs

into right angles of the plate.

Use first notches in legs to rest plate into 22.5° angle.

Use second set of notches to angle bevel table into high-

est 45° angle.

NOTE: Make sure bevel table is locked firmly in place

before beginning cut

Fold legs up and lay bevel table flat for 0° angle.

Turn the on/off switch to the ON position.

Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

Hold the material firmly against the bevel table and feed

the material into the cutting wheel.

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before removing

any part of the material.

11 — English

Page 12

MAINTENANCE

WARNING:

When servicing, use only identical Ryobi replacement

parts. Use of any other parts may create a hazard or

cause product damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes, resulting in possible

serious injury.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions.

TILE CUTTING WHEEL

For maximum performance and safety, it is recommended

that you use the 7 in. cutting wheel provided with your

saw. Additional cutting wheels of the same high quality are

available at your local dealer.

WARNING:

Do not use cutting wheels rated less than the no load

speed of this tool. Failure to heed this warning could

result in personal injury. Do not use wheel with cracks,

gaps, or teeth.

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal

injury.

NOTE: FIGURES (ILLUSTRATIONS) START ON PAGE 13 AFTER

FRENCH AND SPANISH LANGUAGE SECTIONS.

12 — English

Page 13

TABLE DES MATIÈRES

Introduction ..................................................................................................................................................................... 2

Garantie ........................................................................................................................................................................... 2

Règles de sécurité générales ..................................................................................................................................... 3 - 4

Règles de sécurité particulières ...................................................................................................................................... 4

Symboles ......................................................................................................................................................................... 5

Caractéristiques électriques ....................................................................................................................................... 6 - 7

Caractéristiques .............................................................................................................................................................. 7

Assemblage ................................................................................................................................................................ 8 - 9

Utilisation .................................................................................................................................................................. 9 - 11

Entretien ........................................................................................................................................................................ 12

Figure numéros (illustrations ..................................................................................................................................13 - 17

Commande de pièces / réparation ................................................................................................................. Páge arrière

INTRODUCTION

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile à

utiliser et à entretenir.

GARANTIE

OUTILS ÉLECTRIQUES RYOBI® – GARANTIE LIMITÉE DE TROIS ANS ET POLITIQUE D’ÉCHANGE DE 90 JOURS

One World Technologies, Inc., garantit ses outils électriques dans les conditions suivantes :

POLITIQUE D’ÉCHANGE DE 90 JOURS : En cas de défaillance due à des vices de matériaux ou de fabrication au cours

des 90 jours suivant la date d’achat, l’acheteur pourra faire réparer tout outil électrique RYOBI® au titre de cette garantie

ou le retourner l’établissement où il a été acheté. Pour obtenir un outil en échange ou demander la réparation en garantie,

l’équipement complet devra être retourné, dans son emballage d’origine, accompagné d’une preuve d’achat. L’outil fourni

en échange sera couvert par la garantie limitée pour le restant de la période de validité de trois ans à compter de la date

d’achat.

CE QUI EST COUVERT PAR LA GARANTIE : Cette garantie couvre tous les vices de matériaux et de fabrication de

cet outil électrique RYOBI®, pour une période de trois ans, à compter de la date d’achat. À l’exception des piles, les

accessoires sont garantis pour une période de quatre-vingt-dix (90) jours. Les piles sont garanties trois ans.

RÉPARATIONS SOUS GARANTIE : Il suffit de retourner l’outil, correctement emballé, en port payé, à un centre de

réparations agréé. L’adresse du centre de réparations agréé le plus proche peut être obtenue en contactant un représentant

du service après-vente par courrier, à l’adresse One World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207,

par téléphone au 1-800-525-2579 ou par courriel, à l’adresse Internet www.ryobitools.com. Lors de toute demande de

réparation sous garantie, une preuve d’achat datée (par exemple un reçu de vente) doit être fournie. Nous nous engageons

à réparer tous les défauts de fabrication et à réparer ou remplacer, à notre choix, toutes les pièces défectueuses. Les

réparations et remplacements seront gratuits. Les réparations sous garantie seront effectuées dans un délai raisonnable,

ne dépassant en aucun cas quatre-vingt-dix (90) jours.

CE QUI N’EST PAS COUVERT : La garantie ne couvre que l’acheteur au détail original et n’est pas transférable. Cette

garantie ne couvre que les défauts résultant d’une utilisation normale. Elle ne couvre pas les problèmes de fonctionnement,

défaillances ou autres défauts résultant d’un usage incorrect ou abusif, de la négligence, de la modification, de l’altération

ou de réparations effectuées par quiconque autre qu’un centre de réparations agréé. One World Technologies, Inc. ne fait

aucune autre garantie, représentation ou promesse concernant la qualité et les performances de cet outil électrique, autres

que celles expressément indiquées dans le présent document.

AUTRES LIMITATIONS : Toutes les garanties implicites accordées par les lois en vigueur, y compris les garanties de valeur

marchande ou d’adéquation à un usage particulier, sont limitées à une durée de trois ans, à compter de la date d’achat.

One World Technologies, Inc. déclinant toute responsabilité pour les dommages directs ou indirects, les limitations et

exclusions peuvent ne pas s’appliquer à chaque acheteur. Cette garantie donne au consommateur des droits spécifiques,

et celui-ci peut bénéficier d’autres droits, qui varient selon les états ou provinces.

2 — Français

Page 14

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT :

Lire et veiller à bien comprendre toutes les instructions.

Le non respect de toutes les instructions ci-dessous

peut entraîner un choc électrique, un incendie et / ou des

blessures graves.

LIRE TOUTES LES INSTRUCTIONS

VEILLER À BIEN CONNAÎTRE L’OUTIL. Lire attentivement

le manuel d’utilisation. Apprendre les applications et les

limites de l’outil, ainsi que les risques spécifiques relatifs à

son utilisation.

SE PROTÉGER DES CHOCS ÉLECTRIQUES EN ÉVITANT

TOUT CONTACT DU CORPS AVEC DES SURFACES MISES

À LA TERRE. Par exemple : tuyaux, radiateurs, cuisinières,

réfrigérateurs.

MAINTENIR TOUS LES DISPOSITIFS DE PROTECTION

EN PLACE et en bon état de fonctionnement.

RETIRER LES CLÉS ET OUTILS DE RÉGLAGE. Prendre

l’habitude de vérifier que tous les outils et clés de réglage

en ont été retirés de l’outil avant de le mettre en marche.

GARDER LE LIEU DE TRAVAIL PROPRE. Les établis

encombrés et les endroits sombres sont propices aux

accidents. NE PAS laisser d’outils ou de pièces de bois sur

la machine en fonctionnement.

NE PAS UTILISER DANS UN ENVIRONNEMENT

DANGEREUX. Ne pas utiliser les outils électriques dans

des endroits mouillés ou humides, ne pas les exposer à la

pluie. Garder le lieu de travail bien éclairé.

GARDER LES ENFANTS ET VISITEURS À L’ÉCART. Tous

les visiteurs doivent porter des lunettes de sécurité et se

tenir à bonne distance de la zone de travail. Ne pas laisser

les visiteurs toucher l’outil ou son cordon d’alimentation

pendant le fonctionnement.

ASSURER LA SÉCURITÉ DES ENFANTS dans l’atelier en

installant des cadenas et des disjoncteurs ou en retirant les

clés de contact.

NE PAS FORCER L’OUTIL. Il exécutera le travail mieux et

de façon moins dangereuse s’il fonctionne dans les limites

prévues.

UTILISER L’OUTIL APPROPRIÉ. Ne pas utiliser l’outil ou

un accessoire pour effectuer un travail pour lequel il n’est

pas conçu.

UTILISER UN CORDON PROLONGATEUR ADÉQUAT.

S’assurer que le cordon prolongateur est en bon état.

Utiliser exclusivement un cordon d’une capacité suffisante

pour supporter le courant de fonctionnement de l’outil. Un

cordon de capacité insuffisante causerait une baisse de la

tension de ligne, entraînant une perte de puissance et une

surchauffe. Un calibre de fil (A.W.G) d’au minimum 16 est

recommandé pour un cordon prolongateur de 15,24 mètres

(50 pi) ou moins. En cas de doute, utiliser un cordon du calibre

immédiatement supérieur. Moins le numéro de calibre est

élevé, plus la capacité du fil est grande.

PORTER UNE TENUE APPROPRIÉE. Ne pas porter de

vêtements amples, cravates, ou bijoux susceptibles de se

prendre et vous entraîner dans les pièces mobiles. Des gants

en caoutchouc et des chaussures antidérapantes (carter en

caoutchouc) sont recommandées pour le travail à l’extérieur.

Les cheveux longs doivent être ramassés sous un couvre-chef.

TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ À

COQUES LATÉRALES. Les lunettes de vue ordinaires sont

munies seulement de verres résistants aux impacts ; ce ne

sont PAS des lunettes de sécurité.

ASSUJETTIR LES PIÈCES. Dans la mesure du possible,

utiliser des serre-joint ou un étau, ce qui réduit les risques

et laisse les deux mains libres pour contrôler l’outil.

NE PAS TRAVAILLER HORS DE PORTÉE. Toujours se tenir

bien campé et en équilibre.

ENTRETENIR SOIGNEUSEMENT LES OUTILS. Garder

les outils bien affûtés et propres pour accroître la sécurité

et les performances. Suivre les instructions de lubrification

et de changement d’accessoires.

DÉBRANCHER TOUS LES OUTILS. Tous les outils doivent

être débranchés lorsqu’ils ne sont pas en usage et avant

toute opération d’entretien ou de changement d’accessoire,

meule, forer, fers, etc.

ÉVITER LES DÉMARRAGES ACCIDENTELS. S’assurer que

le commutateur est en position d’arrêt avant de brancher

un outil.

UTILISER LES ACCESSOIRES RECOMMANDÉS. Voir

les accessoires recommandés dans le manuel d’utilisation.

L’usage de tout accessoire incorrect peut être dangereux.

NE JAMAIS MONTER SUR L’OUTIL. Un basculement de

l’outil ou le contact accidentel avec l’accessoire de coupe

peut causer des blessures graves.

VÉRIFIER L’ÉTAT DES PIÈCES. Avant d’utiliser l’outil de

nouveau examiner soigneusement les pièces et dispositifs de

protection qui semblent endommagés afin de déterminer s’ils

fonctionnent correctement et s’ils remplissent les fonctions

prévues. Vérifier l’alignement des pièces mobiles, s’assurer

qu’aucune pièce n’est bloquée ou cassée, vérifier la fixation

de chaque pièce et s’assurer qu’aucun autre problème ne

risque d’affecter le bon fonctionnement de l’outil. Pour

éviter les risques de blessures, toute protection ou pièce

endommagée doit être correctement réparée ou remplacée

dans un centre de réparations agréé.

ENGAGER LES PIÈCES DANS LE SENS CORRECT. La

pièce ne doit être engagée que contre le sens de rotation

de la meule, de l’accessoire ou de la toupie de ponçage.

NE JAMAIS LAISSER L’OUTIL EN FONCTIONNEMENT

SANS SURVEILLANCE. COUPER L’ALIMENTATION

ÉLECTRIQUE. Ne pas s’éloigner de l’outil avant qu’il soit

parvenu à un arrêt complet.

PORTER UNE PROTECTION RESPIRATOIRE. Porter

un masque facial ou respiratoire si le travail produit de la

poussière.

PORTER UNE PROTECTION AUDITIVE. Porter une

protection auditive durant les périodes d’utilisation

prolongée.

NE PAS MALTRAITER LE CORDON D’ALIMENTATION. Ne

jamais utiliser le cordon d’alimentation pour transporter l’outil et

ne jamais débrancher ce dernier en tirant sur le cordon. Garder

le cordon à l’écart de la chaleur, de l’huile et des objets tranchants.

TOUJOURS UTILISER UN CORDON SPÉCIALEMENT

CONÇU À CET EFFET, MARQUÉ « W-A » OU « W ». Ces

cordons réduisent les risques de choc électrique.

TOUJOURS PROTECTION ÉCLABOUSSER EN PLACE

et en bon état de fonctionnement.

3 — Français

Page 15

RÈGLES DE SÉCURITÉ GÉNÉRALES

GARDER LES MAINS À L’ÉCART DE LA ZONE DE COUPE.

Ne placer en aucun cas la main ou les doigts au-dessous de

la pièce à couper ou sur la trajectoire de la muele. Toujours

éteindre la scie.

LES MUELES CONTINUENT DE TOURNER EN ROUE

LIBRE UNE FOIS QUE LA SCIE EST ÉTEINTE.

NE JAMAIS UTILISER CET OUTIL DANS UNE

ATMOSPHÈRE EXPLOSIVE. Les étincelles normalement

produites par le moteur pourraient enflammer les vapeurs.

INSPECTER RÉGULIÈREMENT LES CORDONS DE

L’OUTIL. Faire remplacer tout commutateur défectueux par

un technicien qualifié ou un centre de réparations agréé. Le fil

à gaine verte, avec ou sans traceur jaune est le fil de terre. Si

le cordon doit être réparé ou remplacé, ne pas connecter le

fil de terre de l’outil sur une borne sous tension. Tout cordon

endommagé doit être réparé ou remplacé immédiatement.

Toujours rester conscient de l’emplacement du cordon et

veiller à le tenir à l’écart de la meule en rotation.

INSPECTER RÉGULIÈREMENT LES CORDONS

PROLONGATEURS et les remplacer s’ils sont

endommagés.

METTRE TOUS LES OUTILS À LA TERRE. Si un outil est

équipé d’une fiche à trois broches, il doit être branché sur

une prise secteur à trois trous.

CONSULTER UN ÉLECTRICIEN QUALIFIÉ ou le personnel

de service si les instructions de mise à la terre ne sont pas bien

comprises, ou en cas de doute au sujet de la mise à la terre.

N’UTILISER QUE DES ACCESSOIRES ÉLECTRIQUES

APPROPRIÉS : Utiliser exclusivement des cordons

prolongateurs à 3 fils doté d’une fiche à prise de terre

branchés sur une prise triphasée compatible avec la fiche

de l’outil.

NE PAS MODIFIER la fiche fournie. Si elle ne peut pas

être insérée dans la prise secteur, faire installer une prise

adéquate par un électricien qualifié.

GARDER L’OUTIL SEC, PROPRE ET EXEMPT D’HUILE

OU DE GRAISSE. Toujours utiliser un chiffon propre pour le

nettoyage. Ne jamais utiliser de liquide de freins, d’essence

ou de produits à base de pétrole pour nettoyer l’outil.

RESTER VIGILANT ET GARDER LE CONTRÔLE. Se

montrer attentif et faire preuve de bon sens. Ne pas utiliser

l’outil en état de fatigue. Ne pas se presser.

NE PAS UTILISER L’OUTIL SI LE COMMUTATEUR NE

PERMET PAS DE LE METTRE EN MARCHE OU DE

L’ARRÊTER. Faire remplacer les commutateurs défectueux

dans un centre de réparations agréé.

N’UTILISER QUE LES MUELES APPROPRIÉES. Ne pas

utiliser de mueles dont le trou n’est pas de la taille correcte. Ne

jamais utiliser de rondelles ou boulons de muele défectueux

ou de type incorrect. La taille maximum de muele pouvant

être utilisée sur cet outil est de 178 mm (7 po).

S’ASSURER QUE TOUS LES DISPOSITIFS DE

PROTECTION FONCTIONNENT CORRECTEMENT

AVANT D’EFFECTUER UNE COUPE.

NE JAMAIS TOUCHER LA MUELE ou les pièces en

mouvement pendant le fonctionnement.

NE JAMAIS METTRE UN OUTIL EN MARCHE

LORSQU’UNE PIÈCE EN ROTATION QUELCONQUE

EST EN CONTACT AVEC LA PIÈCE À COUPER.

NE PAS UTILISER CET OUTIL SOUS L’INFLUENCE DE

L’ALCOOL, DE DROGUES OU DE MÉDICAMENTS.

Utiliser exclusivement des pièces identiques à celles d’origine

POUR LES RÉPARATIONS. L’usage de toute autre pièce

pourrait créer une situation dangereuse ou endommager

l’outil.

UTILISER EXCLUSIVEMENT LES ACCESSOIRES

RECOMMANDÉS dans ce manuel ou ses addendas. L’emploi

de tout accessoire non recommandé peut présenter un risque

de blessure. Les instructions de sécurité d’utilisation sont

fournies avec les accessoires.

VÉRIFIER DEUX FOIS TOUS LES RÉGLAGES. S’assurer

que la meule est bien serrée et ne touche ni la scie, ni la

pièce à couper avant de brancher la scie sur le secteur.

RÈGLES DE SÉCURITÉ PARTICULIÈRES

TOUJOURS ASSUJETTIR LA PIÈCE À COUPER

fermement contre le guide de bord, guide d’onglet ou le

bois de biseau.

NE JAMAIS se tenir ou laisser une partie du corps se trouver

dans la trajectoire de la meule.

NE JAMAIS essayer de débloquer une muele coincées avant

d’avoir ÉTEINT et débranché la scie.

SI LE CORDON D’ALIMENTATION EST ENDOMMAGÉ,

il doit être remplacé uniquement pas le fabricant ou par un

centre de réparation agréé pour éviter tout risque.

ÉVITER LES OPÉRATIONS ET POSITIONS INCOMMODES

posant un risque de glissement soudain de la main vers la

meule. TOUJOURS se tenir bien en équilibre. NE JAMAIS

utiliser la scie à onglets sur le sol ou en se tenant accroupi.

S’ASSURER QUE LA ZONE DE TRAVAIL EST

SUFFISAMMENT ÉCLAIRÉE pour voir ce que l’on fait et

qu’aucun obstacle ne peut nuire à la sécurité d’utilisation

AVANT d’effectuer quelque coupe que ce soit.

TOUJOURS ÉTEINDRE LA SCIE avant de la débrancher

pour éviter un démarrage accidentel lors du branchement

4 — Français

pour l’utilisation suivante. NE JAMAIS laisser la scie

branchée sans surveillance.

Les avertissements ci-dessous doivent être apposés sur

CET OUTIL :

a) Porter une protection oculaire.

b) Utiliser protection éclatement pour chaque opération

pour laquelle il peut être utilisé.

c) Couper l’alimentation électrique avant d’effectuer

l’entretien, lors du remplacement de la meule ou du

nettoyage.

d) Utiliser l’outil avec le bord lisse muele de coupe des

ouvertures et des rainures.

e) Remplacer endommagé muele de coupe avant de

opération

f) Ne pas remplir le réservoir d’eau au-delà de la ligne de

remplissage maximal.

CONSERVER CES INSTRUCTIONS. Les consulter

fréquemment et les utiliser pour instruire les autres utilisateurs.

Si cet outil est prêté, il doit être accompagné de ces

instructions.

Page 16

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à

l’utilisation de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée, aura pour

DANGER :

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait

AVERTISSEMENT :

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait

ATTENTION :

(Sans symbole d’alerte de sécurité) Indique une information importante ne concernant pas

AVIS :

Certains des symboles ci-dessous peuvent être utilisés sur l’outil. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser l’outil plus efficacement et de réduire les risques.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

conséquences des blessures graves ou mortelles.

entraîner des blessures graves ou mortelles.

entraîner des blessures légères ou de gravité modérée.

un risque de blessure comme une situation pouvant occasionner des dommages matériels.

Symbole d’alerte de sécurité

Lire le manuel d’utilisation

Protection oculaire, auditive et

respiration

Avertissement concernant

l’humidité

Symbole Mains à l’écart

Électrocution

V Volts

A Ampères

Hz Hertz

W Watts

Indique un risque de blessure potentiel.

Pour réduire les risques de blessures, l’utilisateur doit lire et

veiller à bien comprendre le manuel d’utilisation avant d’utiliser

ce produit.

Toujours porter une protection oculaire certifiée conforme à la

norme ANSI Z87.1 ainsi qu’une protection auditive et respiration.

Ne pas exposer l’outil à la pluie ni à l’humidité.

Le non respect de cette mise en garde peut entraîner des blessures

graves.

Une mauvaise mise à la terre peut causer une électrocution.

Tension

Intensité

Fréquence (cycles par seconde)

Puissance

min Minutes

Courant alternatif

Courant continu

n

o

…/min

Vitesse à vide

Construction de classe II

Par minute

Temps

Type de courant

Type ou caractéristique du courant

Vitesse de rotation à vide

Construction à double isolation

Tours, coups, vitesse périphérique, orbites, etc., par minute

5 — Français

Page 17

CARACTÉRISTIQUES ÉLECTRIQUES

CORDONS PROLONGATEURS

Utiliser exclusivement des cordons prolongateurs à 3 fils doté

d’une fiche à prise de terre branchés sur une prise triphasée

compatible avec la fiche de l’outil. Lors de l’utilisation d’un

outil électrique à grande distance d’une prise secteur, veiller

à utiliser un cordon prolongateur d’une capacité suffisante

pour supporter l’appel de courant de l’outil. Un cordon de

capacité insuffisante causerait une baisse de la tension de

ligne, entraînant une perte de puissance et une surchauffe.

Se reporter au tableau ci-dessous pour déterminer le

calibre minimum de fil requis pour un cordon donné. Utiliser

exclusivement des cordons à gaine cylindrique homologués

par Underwriter’s Laboratories (UL).

**Intensité nominale (sur la plaquette signalétique de l’outil)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Longueur Calibre de fil

du cordon (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Utilisé sur circuit de calibre 12 – 20 A

NOTE : AWG = American Wire Gauge

Pour les travaux à l’extérieur, utiliser un cordon prolongateur

spécialement conçu à cet effet. La gaine des cordons de ce

type porte l’inscription « W-A » ou « W ».

Avant d’utiliser un cordon prolongateur, vérifier que ses fils

ne sont ni détachés ni exposés et que son isolation n’est ni

coupée, ni usée.

N’utiliser que des rallonges électriques conçues pour être

utilisées à l’extérier. Ces rallonges sont identifiées par une

étiquette “Peut être utilisée avec des appareils de plein air.

Ranger à l’intérieur lorqu’elle n’est pas utlisée.” Ne pas

utiliser de rallonges endommagées. Examiner la rallonge

avant de l’utiliser et la remplacer si elle est endommagée.

Ne pas maltraiter les rallonges électriques et ne pas les

tirer brusquement pour les débrancher. Garder les rallonges

loin de toute source de chaleur et d’arêtes vives. Toujours

débrancher la rallonge de la prise de courant avant de

débrancher l’appareil de la rallonge.

AVERTISSEMENT :

Maintenir le cordon prolongateur à l’écart de la zone de

travail. Lors du travail avec un cordon électrique, placer le

cordon de manière à ce qu’il ne risque pas de se prendre

dans les pièces de bois, outils et autres obstacles. Ne

pas prendre cette précaution peut entraîner des blessures graves.

AVERTISSEMENT :

Vérifier l’état des cordons prolongateurs avant chaque

utilisation. Remplacer immédiatement tout cordon endommagé. Ne jamais utiliser un outil dont le cordon

d’alimentation est endommagé, car tout contact avec la

partie endommagée pourrait causer un choc électrique

et des blessures graves.

CONNEXION ÉLECTRIQUE

Cet outil est équipé d’un moteur électrique de précision. Il

doit être branchée uniquement sur une alimentation 120 V,

c.a. (courant résidentiel standard), 60 Hz. Ne pas utiliser

cet outil sur une source de courant continu (c.c.). Une chute

de tension importante causerait une perte de puissance et

une surchauffe du moteur. Si l’outil ne fonctionne pas une

fois branché, vérifier l’alimentation électrique.

VITESSE ET CÂBLAGE

La vitesse à vide de cet outil est d’environ 3 450 tr/min. La

vitesse n’est pas constante et elle diminue sous une charge

ou en présence d’une baisse de tension. Le câblage de

l’atelier est aussi important que la puissance nominale du

moteur. Une ligne conçue seulement pour l’éclairage ne peut

pas alimenter correctement le moteur d’un outil électrique.

Un fil électrique d’une capacité suffisante pour une courte

distance ne le sera pas nécessairement pour une distance

plus longue. Une ligne dont la capacité est suffisante pour

un outil électrique ne l’est pas nécessairement pour deux

ou trois.

INSTRUCTIONS DE MISE À LA TERRE

Voir la figure 1, page 13.

Ce produit doit être fondé. En cas de problème de fonctionnement ou de panne, la mise à la terre fournit un chemin de

résistance au courant électrique, pour réduire le risque de

choc électrique. Cet produit est équipé d’un cordon électrique avec conducteur et fiche de mise à la terre. Le cordon

doit être branché sur une prise correctement installée et mise

à la terre conformément à tous les codes et réglementations

locaux en vigueur.

Ne pas modifier la fiche fournie. Si elle ne peut pas être insérée dans la prise secteur, faire installer une prise adéquate

par un électricien qualifié.

AVERTISSEMENT :

L’usage d’un cordon prolongateur incorrect peut présenter des risques de choc électrique. Si le cordon doit être

réparé ou remplacé, ne pas connecter le fil de terre de

l’outil sur une borne sous tension.Le fil à gaine verte, avec

ou sans traceur jaune est le fil de terre.

Consulter un électricien qualifié ou le personnel de service si

les instructions de mise à la terre ne sont pas bien comprises,

ou en cas de doute au sujet de la mise à la terre.

6 — Français

Page 18

CARACTÉRISTIQUES ÉLECTRIQUES

Tout cordon endommagé doit être réparé ou remplacé

immédiatement.

Ce produit est pour l’usage sur un nominal 120 circuit de

volt et a un fonder bouche similaire au bouchon illustré dans

la figure 1, page 13. Seulement connecter le produit à une

sortie ayant la même configuration comme le bouchon. Ne

pas utiliser un adaptateur avec ce produit.

Les circuits utilisés avec la tondeuse devraient être munis

d’un interrupteur de défaut à la terre. Des connecteurs

avec un interrupteur de défaut à la terre sont disponibles

et peuvent être utilisés pour satisfaire à cette mesure de

sécurité.

Si la scie est utilisée avec une cordon prolongatuer, garantir

la connexion du cordon d’alimentation de l’outil et la cordon

prolongatuer n’est pas par terre. Les appareils auxiliaires

toujours devraient être connectés à la prise murale et pas au

connectin d’une rallonge et les outils de pouvoir › le cordon

d’alimentation.

Si une sortie protégée n’est pas disponible, ne pas utiliser la

scie jusqu’à ce qu’une sortie peut être changée ou la protection auxiliaire peut être obtenue. Ces appareils auxiliaires de

protection sont disponibles à votre détaillant local.

PLACER DE LA SCIE À CARREAUX

Voir la figure 2, page 13.

Afin d’éviter de mouiller la fiche de l’appareil ou la prise de

courant, placer la scie à carreaux du côté d’une prise de

courant murale afin d’empêcher l’eau de s’égoutter dans

la prise ou la fiche. L’utilisateur doit arranger une boucle

d’égouttement dans le cordon reliant la scie à la prise de

courant. La boucle d’égouttement est la partie du cordon

qui se trouve sous le niveau de la prise, ou du connecteur

dans le cas d’utilisation d’une rallonge, pour empêcher l’eau

de s’égoutter le long du cordon et d’entrer en contact avec

la prise.

Si la fiche ou la prise entrent en contact avec de l’eau NE

PAS débrancher le cordon. Débrancher le fusible ou le disjoncteur qui alimentent l’outil. Ensuite, débrancher l’appareil

et vérifier s’il y a de l’eau dans la prise.

AVERTISSEMENT :

Pour réduire le risque d’électrocution, garder toutes les

connexions sèches et dégagées du sol. Ne pas toucher

à la fiche lorsque les mains sont mouillées.

CARACTÉRISTIQUES

FICHE TECHNIQUE

Diamètre de la meule.................................. 178 mm (7 po)

Arbre de la meule ...................................15,8 mm (5/8 po)

Capacité de refente (carreaux la taille) ...... 406 mm (16 po)

POUR SE FAMILIARISER AVEC LA SCIE À

CARREAUX

Voir la figure 3, page 13.

L’utilisation sûre de ce produit exige une compréhension

des renseignements figurant sur l’outil et contenus dans le

manuel d’utilisation, ainsi qu’une bonne connaissance du

projet entrepris. Avant d’utiliser ce produit, se familiariser

avec toutes ses fonctions et règles de sécurité.

178 mm (7 po) MEULE À CARREAUX - 178 mm (7 po)

meule à carreaux est inclus avec votre scie

AVERTISSEMENT :

Ne pas utiliser de muelas dont la vitesse de rotation nominale est inférieure à celle de l’outil. Ne pas prendre cette

précaution pourrait entraîner des blessures graves.

TABLE DE BISEAU – La table de biseau permet d’effectuer

des coupes en biseau de 22,5° et 45°.

POIGNÉES – La scie comprend des poignées pratiques

situées des côtés gauche et droit qui permettent de la soulever et de la transporter.

Capacité de diagonale (carreaux la taille) ... 305 mm (12 po)

Profondeur de coupe maximum ...........31,7 mm (1-1/4 po)

Alimentation nominale ........................120 V~, 60 Hz, 4,8 A

Vitesse à vide .........................................3 450 r/min (RPM)

GUIDE D’ONGLET – Le guide d’onglet est entièrement réglable pour effectuer des coupes diagonales et des coupes

d’onglet.

MOTEUR - Cette scie est équipée d’un moteur de 15

ampères assez puissant pour effectuer les coupes les plus

difficiles.

INTERRUPTEUR MARCHE/ARRÊT - La scie est dotée

d’un commutateur marche/arrêt facile d’accès se trouvant

au-dessous du rail avant. Pour verrouiller le commutateur

en position ARRÊT, retirer la clé du commutateur. Placer la

clé dans un lieu inaccessible aux enfants et personnes non

qualifiées pour utiliser l’outil.

GUIDE LONGITUDINAL – Le guide longitudinal est entièrement réglable pour effectuer des coupes transversales et

utiliser le guide d’onglet.

PROTECTION ÉCLABOUSSER - Protection éclabousser

fournit la protection d’overspray et de la brume.

7 — Français

Page 19

ASSEMBLAGE

DÉBALLAGE

Voir la figure 4, page 14.

Ce produit doit être assemblé.

Sortir soigneusement la scie du carton et la poser sur un

plan de travail horizontal.

AVERTISSEMENT :

Ne pas utiliser le produit si, en le déballant, vous constatez

que des éléments figurant dans la liste des pièces détachées

sont déjà assemblés. Certaines pièces figurant sur cette

liste n’ont pas été assemblées par le fabricant et exigent

une installation. Le fait d’utiliser un produit qui a été assemblé de façon inadéquate peut entraîner des blessures.

Examiner soigneusement l’outil pour s’assurer que rien

n’a été brisé ou endommagé en cours de transport.

Ne pas jeter les matériaux d’emballage avant d’avoir soi-

gneusement examiné l’outil et avoir vérifié qu’il fonctionne

correctement.

La scie est réglée en usine pour effectuer une coupe

précise. Après l’avoir assemblée, vérifier sa précision. Si

les réglages ont été modifiés en cours d’expédition, voir

les procédures spécifiques présentées dans ce manuel.

Si des pièces sont manquantes ou endommagées,

appeler le 1-800-525-2579.

LISTE DE CONTRÔLE D’EXPÉDITION

Scie à carreaux

Meule à carreaux

Table de biseau

Capot anti-éclaboussures avec bouton et boulon hexagonal

Support du capot anti-éclaboussures

Vis (2)

Tuyau de trop-plein

Guide de bord

Guide d’onglet

Clé hex.

Clé d’arbre

Rondelles (2)

Manuel d’utilisation

AVERTISSEMENT :

Si des pièces manquent ou sont endommagées, ne pas

utiliser ce outil avant qu’elles aient été remplacées. Le

fait d’utiliser ce produit même s’il contient des pièces endommagées ou s’il lui manque des pièces peut entraîner

des blessures graves.

AVERTISSEMENT :

Ne pas essayer de modifier cet outil ou de créer des accessoires non recommandés pour l’outil. De telles altérations ou modifications sont considérées comme un usage

abusif et peuvent créer des conditions dangereuses,

risquant d’entraîner des blessures graves.

AVERTISSEMENT :

Ne pas brancher sur le secteur avant d’avoir terminé

l’assemblage. Le non-respect de cet avertissement peut

causer un démarrage accidentel, entraînant des blessures graves.

INSTALLATION DE LA MEULE

Voir la figure 5 page 14.

AVERTISSEMENT :

Cette scie n’utilise que des mueles dont la largeur maximale de 7 po. Ne jamais utiliser une muele trop épaisse

car elle empêcherait la rondelle extérieure de le muele

de s’engager sur les méplats de la broche. Des mueles

de trop grand diamètre toucheraient les protections de

muele et des meules trop épaisses empêcheraient le

boulon le muele de maintenir le muele sur la broche.