Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

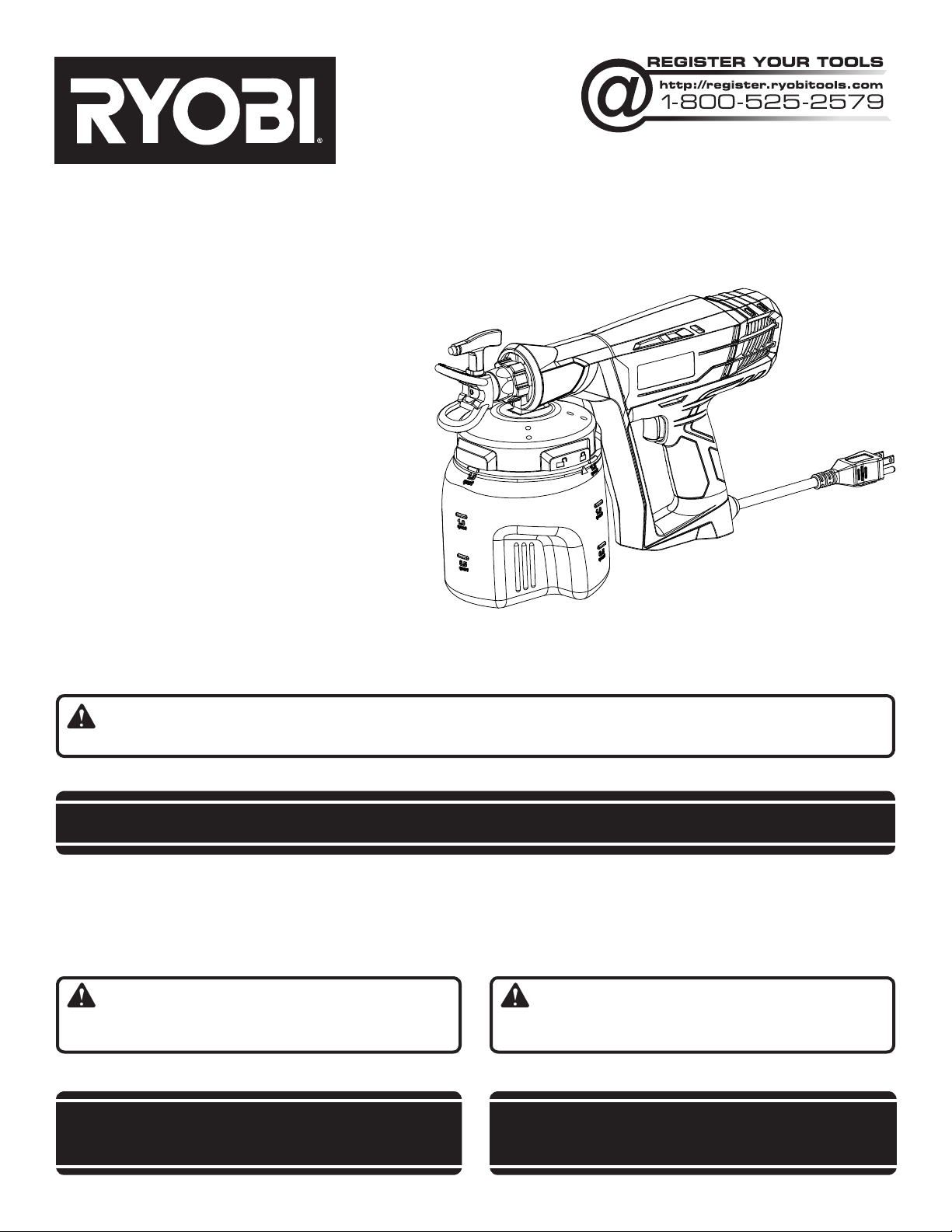

POWER PAINT SPRAYER

TOOL

PISTOLET À PEINDRE

ÉLECTRIQUE

ROCIADOR ELÉCTRICO

DE PINTURA

SSP300

Your power paint sprayer tool has been engineered and manufactured to our high standard for dependability, ease of

operation, and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette pistolet à peindre électrique a été conçue et fabriquée

conformément à nos strictes normes de fiabilité, simplicité

d’emploi et sécurité d’utilisation. Correctement entretenue, elle

vous donnera des années de fonctionnement robuste et sans

problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Merci de votre achat.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su herramienta para rociador eléctrico de pintura ha sido

diseñado y fabricado de conformidad con nuestras estrictas

normas para brindar fiabilidad, facilidad de uso y seguridad

para el operador. Con el debido cuidado, le brindará muchos

años de sólido y eficiente funcionamiento.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

Le agradecemos su compra.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

TABLE OF CONTENTS

Introduction .......................................................................................................................................................................2

Warranty ............................................................................................................................................................................2

Important Safety Instructions ............................................................................................................................................3

Specific Safety Rules .........................................................................................................................................................4

Symbols .............................................................................................................................................................................5

Electrical ............................................................................................................................................................................6

Features .............................................................................................................................................................................7

Assembly ...........................................................................................................................................................................7

Operation .......................................................................................................................................................................8-9

Maintenance ................................................................................................................................................................ 9-10

Troubleshooting ...............................................................................................................................................................11

Figure Numbers (Illustrations) ....................................................................................................................................12-13

Parts Ordering / Service .................................................................................................................................... Back page

INTRODUCTION

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

WARRANTY

RYOBI® POWER TOOL - LIMITED TWO YEAR WARRANTY AND 90 DAY EXCHANGE POLICY

One World Technologies, Inc., warrants its RYOBI® power tools with the following conditions:

90-DAY EXCHANGE POLICY: During the first 90 days after date of purchase, you may either request service under this

warranty or you may exchange any RYOBI® power tool which does not work properly due to defective workmanship or

materials by returning the power tool to the dealer from which it was purchased. To receive a replacement power tool or requested warranty service, you must present proof of purchase and return all original equipment packaged with the original

product. The replacement power tool will be covered by the limited warranty for the balance of the two year period from

the date of the original purchase.

WHAT THIS WARRANTY COVERS: This warranty covers all defects in workmanship or materials in your RYOBI® power

tool for a period of two years from the date of purchase. With the exception of batteries, power tool accessories are warranted for ninety (90) days. Batteries are warranted for two years.

HOW TO GET SERVICE: Just return the power tool, properly packaged and postage prepaid, to an Authorized Service Center. You can obtain the location of the Service Center nearest you by contacting a service representative at

One World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207, by calling 1-800-525-2579 or by logging on to

www.ryobitools.com. When you request warranty service, you must also present proof of purchase documentation, which

includes the date of purchase (for example, a bill of sale). We will repair any faulty workmanship, and either repair or replace

any defective part, at our option. We will do so without any charge to you. We will complete the work in a reasonable time,

but, in any case, within ninety (90) days or less.

WHAT’S NOT COVERED: This warranty applies only to the original purchaser at retail and may not be transferred. This

warranty only covers defects arising under normal usage and does not cover any malfunction, failure or defects resulting

from misuse, abuse, neglect, alteration, modification or repairs by other than Authorized Service Centers. One World Technologies, Inc. makes no warranties, representations or promises as to the quality or performance of its power tools other

than those specifically stated in this warranty.

ADDITIONAL LIMITATIONS: Any implied warranties granted under state law, including warranties of merchantability or

fitness for a particular purpose, are limited to two years from the date of purchase. One World Technologies, Inc. is not

responsible for direct, indirect, or incidental damages, so the above limitations and exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

2 — English

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

SAVE THESE INSTRUCTIONS. To reduce the risks of

fire or explosion, electric shock, and the injury to persons, read and understand all instructions included in

this manual. Be familiar with the controls and the proper

usage of the equipment.

READ ALL INSTRUCTIONS

KNOW YOUR POWER TOOL. Read the operator’s

manual carefully. Learn the machine’s applications and

limitations as well as the specific potential hazards related

to this tool.

WARNING: To reduce the risk of fire or explosion:

Do not spray flammable or combustible materials near

an open flame or sources of ignition such as cigarettes,

motors, and electrical equipment.

For units intended for use with only water-based or

mineral spirit-type materials with a minimum flash point

of 60°C (140°F), do not spray or clean with liquids having

a flash point less than 60°C (140°F).

Paint or solvent flowing through the equipment is able to

result in static electricity. Static electricity creates a risk

of fire or explosion in the presence of paint or solvent

fumes. All parts of the spray system, including the pump,

spray gun, and objects in and around the spray area shall

be properly grounded to protect against static discharge

and sparks.

Verify that all containers and collection systems are

grounded to prevent static discharge.

Connect to a grounded outlet and use grounded

extension cords. Do not use a 3-to-2 adapter.

Do not use a paint or a solvent containing halogenated

hydrocarbons.

Keep spray area well ventilated. Keep a good supply of

fresh air moving through the area. Keep pump assembly

in a well-ventilated area.

Do not smoke in the spray area.

Do not operate light switches, engines, or similar spark-

producing products in the spray area.

Keep area clean and free of paint or solvent containers,

rags, and other flammable materials.

Know the contents of the paints and solvents being

sprayed. Read all Material Safety Data Sheets (MSDS) and

container labels provided with the paints and solvents.

Follow the paint and solvent manufacturer’s safety

instructions.

Fire extinguisher equipment shall be present and working.

WARNING: To reduce the risk of skin injection:

Do not aim the nozzle at, or spray any person or animal.

Keep hands and other body parts away from the

discharge. For example, do not try to stop leaks with

any part of the body.

Always use the spray tip. Do not spray without spray

tip in place.

Only use a spray tip specified by the manufacturer.

Use caution when cleaning and changing spray tips.

In the case where the spray tip clogs while spraying,

follow the manufacturer’s instructions for turning off

the unit before removing the spray tip to clean.

Do not leave the unit energized while unattended. When

the unit is not in use, turn off the unit in accordance

with the manufacturer’s instructions.

High pressure spray is able to inject toxins into the

body and cause serious bodily injury. In the event that

injection occurs, seek medical attention immediately.

Check parts for signs of damage. Replace any

damaged parts.

This system is capable of producing 2500 psi. Only use

replacement parts or accessories that are specified

by the manufacturer and that are rated a minimum of

2500 psi.

Know how to stop the unit quickly. Be thoroughly

familiar with the controls.

Verify that all connections are secure before operating

this unit.

For household use only.

WARNING: To reduce the risk of injury:

Do not operate or spray near children. Keep children

away from equipment at all times.

Do not overreach or stand on an unstable support.

Keep effective footing and balance at all times.

Stay alert and watch what you are doing.

Do not operate the unit when fatigued or under the

influence of drugs or alcohol.

3 — English

Page 4

SPECIFIC SAFETY RULES

Keep guards in place and in working order. Never oper-

ate the tool with any guard or cover removed. Make sure

all guards are operating properly before each use.

To reduce the risk of injury, keep children and visitors

away. All visitors should wear safety glasses and be kept

a safe distance from work area.

Keep the area of operation clear of all persons,

particularly small children, and pets.

Use right tool. Don’t force tool or attachment to do a

job it was not designed for. Don’t use it for a purpose not

intended.

Do not operate the equipment while barefoot or when

wearing sandals or similar lightweight footwear. Wear

protective footwear that will protect your feet and improve

your footing on slippery surfaces.

Exercise caution to avoid slipping or falling.

Always wear eye protection with side shields marked

to comply with ANSI Z87.1. Following this rule will

reduce the risk of serious personal injury.

Use only recommended accessories. The use of im-

proper accessories may cause risk of injury.

Follow the maintenance instructions specified in this

manual.

Check damaged parts. Before further use of the tool,

a guard or other part that is damaged should be carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged must

be properly repaired or replaced by an authorized service

center to avoid risk of personal injury.

Never leave tool running unattended. Turn power off.

Don’t leave tool until it comes to a complete stop.

Be thoroughly familiar with controls. Know how to stop

the product quickly.

Keep tool dry, clean, and free from oil and grease.

Always use a clean cloth when cleaning. Never use brake

fluids, gasoline, petroleum-based products, or any solvents

to clean tool.

Do not use tool if switch does not turn it off. Have de-

fective switches replaced by an authorized service center.

Before cleaning, repairing, or inspecting, shut off the

motor and make certain all moving parts have stopped.

Avoid dangerous environment. Don’t use in damp or wet

locations or expose to rain. Keep work area well lit.

Never direct a paint stream toward people or pets, or

any electrical device.

Never start the machine if ice has formed in any part of

the equipment.

WARNING: High pressure spray can be dangerous if

subject to misuse. The spray must not be directed at

persons, animals, electrical devices, or the machine itself.

Keep away from hot parts.

Check bolts and nuts for looseness before each use. A

loose bolt or nut may cause serious motor problems.

Before storing, allow the product to cool.

Store in a cool, well-ventilated area, safely away from

spark and/or flame-producing equipment.

When servicing use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

Never use the sprayer without a spray tip installed.

An injection injury can lead to possible amputation.

See a physician immediately.

Never put your hand in front of the spray tip when in

use. Gloves will not always provide protection against an

injection injury.

Wear clothing to keep paint off skin and hair, along with

a mask or respirator during use. Paints, solvents, and

other materials can be harmful if inhaled or if they come

into contact with the body.

Always unplug the sprayer and shut the unit off before

servicing, cleaning the tip or guard, changing the tip,

or leaving unattended.

Plastic can cause sparks. Never hang plastic to enclose

a spray area. Do not use plastic drop cloths when spraying

flammable materials.

Do not spray outdoors on windy days.

Do not attempt to clean or unclog the spray tip with

your finger.

Save these instructions. Refer to them frequently and

use them to instruct other users. If you loan someone this

tool, loan them these instructions also.

4 — English

Page 5

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

CAUTION:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read The Operator’s Manual

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Eye Protection

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

Alternating Current Type of current

PSI Pressure Pressure is measured in pounds per square inch

GPH Flow Rate

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

Flow rate is measured in maximum gallons of paint sprayed per

hour

CALIFORNIA PROPOSITION 65

WARNING:

This product, and the paints designed to be applied with this product, may contain chemicals, including lead, known to

the State of California to cause cancer, birth defects, or other reproductive harm. Wash hands after handling.

5 — English

Page 6

ELECTRICAL

EXTENSION CORDS

Be sure to use an extension cord that has the capacity to

handle the current the product will draw. An undersized cord

will cause a drop in line voltage, resulting in overheating and

loss of power. Use the chart to determine the minimum wire

size required in an extension cord. Only round jacketed cords

listed by Underwriter’s Laboratories (UL) should be used.

When working outdoors with a product, use an extension

cord that is designed for outside use. This type of cord is

designated with “W-A” or “W” on the cord’s jacket.

Before using any extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

A proper extension cord is available at an authorized service

center.

If two extension cords are needed, knot them together to

prevent them from becoming disconnected during use. Make

the knot as shown in figure 1, then connect the plug end of

once extension cord into the receptacle end of the other.

**Ampere rating (on product data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on lumber, tools, or other obstructions while you are working

with a power tool. Failure to do so can result in serious

personal injury.

ELECTRICAL CONNECTION

This product is powered by a precision-built electric motor. It

should be connected to a power supply that is 120 V, AC only

(normal household current), 60 Hz. Do not operate this

product on direct current (DC). A substantial voltage drop

will cause a loss of power and the motor will overheat. If

the product does not operate when plugged into an outlet,

double check the power supply.

GROUNDING INSTRUCTIONS

See Figure 1, page 12.

This product must be grounded. In the event of a malfunction

or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock.

This product is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

WARNING:

Improper installation of a grounded plug increase the

risk of electric shock. When repair or replacement of the

cord or plug is required, take the tool to an authorized

service center.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely understood,

or if in doubt as to whether the product is properly grounded.

Repair or replace a damaged or worn cord immediately.

This product is for use on a nominal 120 V circuit and has a

grounding plug similar to the plug illustrated in figure 1. Only

connect the product to an outlet having the same configuration

as the plug. Do not use an adapter with this product.

WARNING:

Check extension cords before each use. If damaged

replace immediately. Never use the product with a damaged cord since touching the damaged area could cause

electrical shock resulting in serious injury.

6 — English

Page 7

FEATURES

PRODUCT SPECIFICATIONS

Flow Rate ...................................................................................................................................................................5.5 GPH

Container Size ............................................................................................................................................................... 1.5 qt.

Input ...................................................................................................................................... 120 V, 60 Hz, AC only, 1.4 Amp

KNOW YOUR POWER SPEED SPRAYER

See Figure 2, page 12.

The safe use of this product requires an understanding of

the information on the product and in this operator’s manual

as well as a knowledge of the project you are attempting.

Before use of this product, familiarize yourself with all

operating features and safety rules.

GRIPZONE™ TECHNOLOGY

The sprayer features Gripzone™ technology for improved

comfort with a positive grip.

ASSEMBLY

UNPACKING

This product has been shipped completely assembled.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

INNOVATIVE MOTOR DESIGN

The innovative motor design means less vibration and noise

when using your sprayer.

QUICK-LOCK PAINT CONTAINER

The quick-lock paint container is easy to install and remove.

PRO-TIP™ REVERSIBLE SPRAY TIP

Reversible spray tip rotates 180º to clear clogs quickly.

WARNING:

If any parts are damaged or missing do not operate

this product until the parts are replaced. Use of this

product with damaged or missing parts could result in

serious personal injury.

WARNING:

Do not use this product if it is not completely assembled

or if any parts appear to be missing or damaged. Use of

a product that is not properly and completely assembled

could result in serious personal injury.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

PACKING LIST

Power Paint Sprayer with Quick-Lock Container

Replacement Atomizer Valve Assembly

Cleaning Brush

Lubricant

Operator’s Manual

WARNING:

Do not attempt to modify this product or create accessories not recommended for use with this product. Any

such alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

7 — English

Page 8

OPERATION

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result

in fluids entering your eyes resulting in possible serious

injury.

WARNING:

Do not use any attachments or accessories not recommended by the manufacturer of this product. The use of

attachments or accessories not recommended can result

in serious personal injury.

APPLICATIONS

You may use this product for the purpose listed below:

Interior and exterior painting and staining of decks,

outdoor furniture, fences, and walls

WARNING:

Risk of fire or explosion. Spray area must be well-ventilated and away from sparks or flames.

FILLING SPRAYER WITH PAINT/STAIN

See Figures 3 - 4, page 12.

Remove and discard any skin that has formed on top of the

paint or stain, then thoroughly mix the material in its original

container before beginning.

NOTE: Older containers of stain and paint may need to be

strained before use.

Unplug the sprayer.

Remove the quick-lock container by twisting

counterclockwise so that the arrow on the container

lines up with the “unlock” symbol on the lid.

Fill the container with paint or stain as desired. Do not fill

above the max fill (1.5 qt.) mark on the container.

Reinstall the container on the sprayer and twist clockwise

so that the arrow on the container lines up with the “lock”

symbol on the lid.

WARNING:

To reduce the risk of injection, do not point sprayer at

any part of the body or person. In case of skin injection,

seek medical attention immediately. Do not use without

spray tip in place.

OPERATING THE SPRAYER

See Figures 5 - 7, pages 12 - 13.

Ensure the surface to be painted is free of dust, dirt, and

grease.

Mask or cover any areas not intended to be painted or

stained. Be aware of wind that may cause your paint or

stain to spray into areas not desired. Always use drop

cloths or other cover to protect areas that are not intended

to be painted or stained.

Place a line of lubricant on the piston. To gain access to

the piston, follow the instructions in Cleaning the Sprayer

for Storage in the Maintenance section of this manual.

Re-assemble the spray tip assembly.

The tip guard may be set to spray paint in either a

horizontal or vertical pattern. To change the direction

of the spray, loosen the metal collar of the spray tip

assembly by turning it clockwise. Adjust the spray tip

and tip guard as shown, and tighten the metal collar to

secure the spray tip assembly.

Fill the quick-lock paint container with no more than

1.5 quarts of desired paint or stain.

Plug in the sprayer.

Pull the switch trigger to spray paint. Release the switch

trigger to stop paint spray.

Practice spraying on a piece of scrap material to test your

spray pattern and to prime the pump before beginning. If

you cannot get a good spray pattern with an even amount

of paint or stain throughout, refer to the Troubleshooting

section later in this manual.

NOTE: The pump must be primed after every paint

change and at first use after storing. Spray paint at a

scrap surface for at least 20 seconds to prime.

To create an even coating over the entire surface:

• Move your arm at a steady rate of speed and make

sure to move your entire arm, not just your wrist.

• Keep the sprayer an even distance from the area

being sprayed, which should be between 8 to 10

inches from the tip of the sprayer to the surface

being sprayed.

8 — English

Page 9

OPERATION

• Depress the trigger to begin the spray off the

material you want to paint. Operate the sprayer in

straight horizontal or vertical strokes across the

surface being painted, then release the trigger off

the material to end the stroke.

NOTE: For spray quality consistency when using thinner

paints, it may be necessary to keep the trigger depressed

between strokes.

When finished, unplug the sprayer, return any unused

paint or stain to its original container, and thoroughly

clean the sprayer.

CLEARING A PAINT CLOG

See Figure 8, page 13.

If paint is not flowing freely through the spray tip or the surface

does not show an even coat of paint, the spray tip may be

clogged. Reversing the spray tip can help to free the clog.

Twist the spray tip so that the pointed end is turned

toward you.

Point the paint sprayer toward a piece of scrap material.

Press the trigger until paint flows through the spray tip.

This should clear the clog.

Turn the spray tip so that the pointed end is facing away

from you.

Test the sprayer on a piece of scrap material before you

resume painting.

CAUTION:

It is important to thoroughly clean the sprayer after each

use or when changing colors. Allowing paint or stain to

remain in an idle tool for an extended period can cause

its moving pieces to seize up.

WARNING:

Do not clean with any flammable liquids such as paint

stripper, paint remover, brush cleaner, mineral spirits, lacquer thinner, turpentine, acetone, gasoline, kerosene, etc.

CLEANING THE SPRAYER AFTER USE

The solution used to clean the sprayer is determined by

the type of material that has been sprayed. For anything

other than latex material, follow the material manufacturer’s

directions for appropriate clean-up.

To clean the sprayer for short term storage:

Unplug the sprayer.

If you haven’t already done so, remove the paint container

and return any unused paint or stain to its original

container.

Fill the paint container with lukewarm water (for water

based paints) or non-flammable solvent (for oil-based

paints or varnish, or any other non-flammable paint

thinner (following the use of oil-based products).

NOTE: For best results, clean the container first.

Reinstall the paint container.

Plug in the sprayer.

Spray the solution onto a piece of cardboard or other

scrap material. Continue spraying until all the solution is

used.

Unplug the sprayer.

Place a line of lubricant on the piston. To gain access to

the piston, follow the instructions in Cleaning the Sprayer

for Storage in the Maintenance section of this manual.

Use a damp cloth to wipe the exterior of the sprayer. The

unit is now ready to put away.

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result

in fluids entering your eyes resulting in possible serious

injury.

9 — English

GENERAL MAINTENANCE

NOTE: Always unplug the unit before attempting a service

operation.

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, penetrating

oils, etc., come in contact with plastic parts. Chemicals

can damage, weaken, or destroy plastic which could

result in serious personal injury.

Page 10

MAINTENANCE

CLEANING THE SPRAYER FOR STORAGE

See Figure 9, page 13.

When you’ve finished your project and are ready to store the

sprayer, a thorough cleaning and lubrication is recommended.

Unplug the sprayer.

Remove the paint container.

If you haven’t already done so, return any unused paint

or stain to its original container.

Fill the paint container with lukewarm water (for water

based paints) or non-flammable solvent (for oil-based

paints or varnish), or any other non-flammable paint

thinner (following the use of oil-based products).

NOTE: For best results, clean the container first.

Reinstall the paint container.

Plug in the sprayer.

Spray the solution onto a piece of cardboard or other

scrap material. Continue spraying until all the solution is

used.

Unplug the sprayer.

Remove the paint container.

Remove the suction tube and filter.

Remove the installed spray tip by loosening the metal

collar and turning the tip guard counterclockwise.

Remove the atomizer valve assembly and tip saddle. If

the tip saddle is difficult to remove, you may use the end

of the spray tip to push it out.

Remove the locking nut by turning it counterclockwise.

Slide the pump housing assembly/container lid forward

off the sprayer.

Pull the piston and spring off the pump housing.

Using the provided cleaning brush and a solution

determined by the last type of paint or stain sprayed,

clean all of the above parts thoroughly.

NOTE: Make sure to scrub thoroughly inside the pump

housing opening so that no paint or stain material is left

behind.

Clean the vent hole in the pump housing using a

straightened paper clip or toothpick.

To reassemble:

Place a line of lubricant on the piston.

NOTE: Once the provided lubricant has been used,

vegetable oil may be substituted.

Slide the spring back onto the piston.

Insert the piston and spring assembly inside the back of

the pump housing.

Replace the pump housing assembly/container lid into

the sprayer.

Replace the locking nut on the sprayer housing by

pushing in while rotating clockwise to secure.

Insert the atomizer valve assembly and tip saddle into

the pump housing front opening.

NOTE: The atomizer valve assembly can be used to guide

the tip saddle into the tip guard.

Replace the spray tip and rotate the tip guard clockwise

to secure.

Reinstall the suction tube and filter.

Reinstall the paint container.

The sprayer is now ready to be stored.

REPLACING THE ATOMIZER VALVE ASSEMBLY

See Figure 10, page 13.

The atomizer valve causes the paint or stain material to spin

as it comes out of the sprayer. After 7 to 10 gallons of paint

or stain, the atomizer valve may no longer produce a good

spray pattern and may need to be replaced.

To replace:

Unplug the sprayer.

Rotate the tip guard counterclockwise and remove.

Remove the atomizer valve assembly and discard.

NOTE: Do not discard the tip or tip saddle.

Install the new atomizer valve assembly.

NOTE: If the tip saddle is not installed, the paint sprayer

will not work.

Replace the spray tip and tip guard and rotate clockwise

to secure.

10 — English

Page 11

TROUBLESHOOTING

PROBLEM CAUSE POSSIBLE SOLUTION

Motor does not run. Sprayer is not plugged in.

Breaker is tripped.

Make sure unit is plugged in.

Reset breaker.

Motor overheats. Piston has seized up.

Extension cord is too long.

Continuous spray operation.

Motor has a low hum but does

not spray.

Motor seems to be running

properly but doesn’t spray.

Paint will not spray through

the tip

Sprayed material is spitting or

globbing up.

Paint/stain spray overspray is

excessive.

Paint/stain runs or sags on the

work surface.

Paint/stain is leaking behind the

spray tip.

Unit will not prime Atomizer valve is worn Replace the atomizer valve

Small bead in spray pattern Moving the sprayer too fast

Piston has seized up. Thoroughly clean the sprayer using long-term

Suction tube and filter are loose or

damaged.

Atomizer valve is clogged or worn out.

Material being sprayed is too thick.

Plugged spray tip or intake filter;

worn piston.

Spray tip is clogged Reverse the spray tip and press trigger

Paint container volume is getting low.

Material being sprayed is too thick.

Suction tube is loose.

Atomizer valve is clogged or worn out.

Worn spray tip or piston.

Material being sprayed has been

shaken and has air pockets

Spray tip is too far from the surface

being sprayed.

Proper paint methods not being ob-

served.

Spray tip is loose.

Atomizer valve is worn or not posi-

tioned properly.

Tip is clogged

Thoroughly clean the sprayer using long-term

storage cleaning instructions in the Maintenance

section of this manual.

Use only the size extension cord recommended

previously in this manual.

Release trigger at the end of each pass to allow

the motor to cool.

storage cleaning instructions in the Maintenance

section of this manual.

Reinstall or replace suction tube and filter as

needed.

Clean or replace atomizer valve assembly.

Follow material manufacturer’s directions and

thin material as needed.

Thoroughly clean the sprayer and, if necessary,

replace piston*, using storage cleaning instructions in the Maintenance section of this manual.

Refill paint container.

Follow material manufacturer’s directions to thin

material as needed.

Reinstall suction tube securely.

Clean or replace atomizer valve assembly.

Clean or replace spray tip or piston*.

Allow paint to sit for approximately 1 hour.

Hold sprayer closer to the surface being sprayed.

Refer to Operating the Sprayer earlier in this

manual.

Tighten spray tip.

Replace or reposition atomizer valve as needed.

Slow arm speed down

Reverse the spray tip to clear the clog

* Although unlikely, a worn piston is possible. A replacement piston can be purchased by calling customer service at

1-800-525-2579. Follow the instructions in Cleaning the Sprayer for Storage to access the piston for replacement.

NOTE: FIGURES (ILLUSTRATIONS) START ON PAGE 12

AFTER FRENCH AND SPANISH LANGUAGE SECTIONS.

11 — English

Page 12

TABLE DES MATIÈRES

Introduction .......................................................................................................................................................................2

Garantie .............................................................................................................................................................................2

Instructions importantes concernant la sécurité ...............................................................................................................3

Règles de sécurité particulières ........................................................................................................................................4

Symboles ...........................................................................................................................................................................5

Caractéristiques électriques ..............................................................................................................................................6

Caractéristiques ................................................................................................................................................................7

Assemblage .......................................................................................................................................................................7

Utilisation ....................................................................................................................................................................... 8-9

Entretien ......................................................................................................................................................................9-10

Dépannage ......................................................................................................................................................................11

Figure numéros (illustrations) .....................................................................................................................................12-13

Commande de pièces / réparation .................................................................................................................. Page arrière

INTRODUCTION

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile à

utiliser et à entretenir.

GARANTIE

OUTILS ÉLECTRIQUES RYOBI® – GARANTIE LIMITÉE DE DEUX ANS ET POLITIQUE D’ÉCHANGE DE 90 JOURS

One World Technologies, Inc., garantit ses outils électriques dans les conditions suivantes :

POLITIQUE D’ÉCHANGE DE 90 JOURS : En cas de défaillance due à des vices de matériaux ou de fabrication au cours

des 90 jours suivant la date d’achat, l’acheteur pourra faire réparer tout outil électrique RYOBI® au titre de cette garantie

ou le retourner l’établissement où il a été acheté. Pour obtenir un outil en échange ou demander la réparation en garantie,

l’équipement complet devra être retourné, dans son emballage d’origine, accompagné d’une preuve d’achat. L’outil fourni en

échange sera couvert par la garantie limitée pour le restant de la période de validité de deux ans à compter de la date d’achat.

CE QUI EST COUVERT PAR LA GARANTIE : Cette garantie couvre tous les vices de matériaux et de fabrication de cet

outil électrique RYOBI®, pour une période de deux ans, à compter de la date d’achat. À l’exception des batteries, les

accessoires sont garantis pour une période de quatre-vingt-dix (90) jours. Les piles sont garanties deux ans.

RÉPARATIONS SOUS GARANTIE : Il suffit de retourner l’outil, correctement emballé, en port payé, à un centre de

réparations agréé. L’adresse du centre de réparations agréé le plus proche peut être obtenue en contactant un représentant

du service après-vente par courrier, à l’adresse One World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207,

par téléphone au 1-800-525-2579 ou par courriel, à l’adresse Internet www.ryobitools.com. Lors de toute demande de

réparation sous garantie, une preuve d’achat datée (par exemple un reçu de vente) doit être fournie. Nous nous engageons

à réparer tous les défauts de fabrication et à réparer ou remplacer, à notre choix, toutes les pièces défectueuses. Les

réparations et remplacements seront gratuits. Les réparations sous garantie seront effectuées dans un délai raisonnable,

ne dépassant en aucun cas quatre-vingt-dix (90) jours.

CE QUI N’EST PAS COUVERT : La garantie ne couvre que l’acheteur au détail original et n’est pas transférable. Cette

garantie ne couvre que les défauts résultant d’une utilisation normale. Elle ne couvre pas les problèmes de fonctionnement,

défaillances ou autres défauts résultant d’un usage incorrect ou abusif, de la négligence, de la modification, de l’altération

ou de réparations effectuées par quiconque autre qu’un centre de réparations agréé. One World Technologies, Inc. ne fait

aucune autre garantie, représentation ou promesse concernant la qualité et les performances de cet outil électrique, autres

que celles expressément indiquées dans le présent document.

AUTRES LIMITATIONS : Toutes les garanties implicites accordées par les lois en vigueur, y compris les garanties de valeur

marchande ou d’adéquation à un usage particulier, sont limitées à une durée de deux ans, à compter de la date d’achat.

One World Technologies, Inc. déclinant toute responsabilité pour les dommages directs ou indirects, les limitations et

exclusions peuvent ne pas s’appliquer à chaque acheteur. Cette garantie donne au consommateur des droits spécifiques,

et celui-ci peut bénéficier d’autres droits, qui varient selon les états ou provinces.

2 — Français

Page 13

INSTRUCTIONS IMPORTANTES CONCERNANT LA SÉCURITÉ

Bien connaître le contenu des peintures et des solvants

AVERTISSEMENT :

CONSERVER CES INSTRUCTIONS. Pour réduire les

risques d’incendie ou d’explosion, choc électrique, et la

blessure aux personnes lire et veiller à bien comprendre

toutes instructions incluses le manuel. Familarisez-vous

avec toutes les commandes et l’utilisation correcte de

l’équipement.

LIRE TOUTES LES INSTRUCTIONS

APPRENDRE À CONNAÎTRE L’OUTIL. Lire attentivement

le manuel d’utilisation. Apprendre les applications et les

limites de l’outil, ainsi que les risques spécifiques relatifs à

son utilisation.

AVERTISSEMENT : Pour réduire les risques d’incendie

ou d’explosion :

Ne pas pulvériser de substances inflammables ou

combustibles à proximité des flammes vives ou des

sources d’inflammation comme les cigarettes, les

moteurs et l’équipement électrique.

Dans le cas des unités uniquement compatibles avec des

substances à base d’eau ou avec des essences minérale

ayant un point d’éclair de 60 °C (140 °F), ne pulvériser

aucun liquide ayant un point d’éclair inférieur à 60 °C (140

°F) et n’effectuer aucune opération de nettoyage avec ce

type de liquide.

La peinture ou le solvant qui circule dans l’équipement

peut créer de l’électricité statique. L’électricité statique

crée un risque d’incendie ou d’explosion en présence

de vapeurs de peinture ou de solvant. Toutes les pièces

du système de pulvérisation, y compris la pompe, le

pulvérisateur ainsi que les objets se trouvant dans la

zone de pulvérisation ou autour de celle-ci, doivent

être correctement mises à la terre afin d’assurer une

protection contre les décharges statiques et les étincelles.

S’assurer que tous les contenants et les systèmes de

dépoussiérage sont mis à la terre afin d’empêcher une

décharge statique.

Brancher l’outil dans une prise de courant mise à la terre

et utiliser des cordons prolongateurs avec mise à la terre.

Ne pas utiliser un adaptateur 3 voies vers 2 voies.

Ne pas utiliser une peinture ou un solvant qui contient

des hydrocarbures halogénés.

L’aire de pulvérisation doit être bien ventilée. S’assurer

que le lieu de travail comprend une bonne alimentation

en air frais. Garder l’ensemble de pompe dans un endroit

bien ventilé.

Ne pas fumer à proximité du l’aire de pulvérisation.

Ne pas faire fonctionner les interrupteurs d’éclairage, les

moteurs ou d’autres dispositifs produisant des étincelles

à proximité du l’aire de pulvérisation.

Garder le lieu de travail propre et exempt de contenants

de peinture ou de solvant, de chiffons et d’autres

matériaux inflammables.

qui sont pulvérisés. Lire toutes les fiches signalétiques

et les étiquettes du contenant fournies avec les peintures

et les solvants. Suivre les instructions de sécurité du

fabricant concernant les peintures et les solvants.

On doit retrouver un extincteur sur le lieu de travail et

celui-ci doit fonctionner.

AVERTISSEMENT : Pour réduire les risques d’injection:

Ne pas orienter la buse ou pulvériser en direction des

personnes ou des animaux.

Garder les mains et les autres parties du corps à l’écart

de la décharge. Par exemple, ne pas tenter de bloquer

une fuite avec une partie du corps.

Toujours utiliser l’embout de pulvérisation. Ne pas utiliser

l’outil si l’embout de pulvérisation n’est pas en place.

Utiliser seulement un embout de pulvérisation recommandé

par le fabricant.

Faire preuve de prudence au moment de nettoyer et de

changer les embouts de pulvérisation. Si l’embout de

pulvérisation s’encrasse pendant l’opération, suivre les

instructions du fabricant pour éteindre l’unité et relâcher

la pression avant de retirer l’embout pour le nettoyer.

Ne pas laisser l’unité sans surveillance lorsque celle-ci est

en marche. Éteindre l’unité lorsqu’elle n’est pas utilisée,

conformément aux instructions du fabricant.

Le pulvérisateur haute pression peut injecter des

substances toxiques dans le corps et entraîner des

blessures graves. Au cas où ce genre d’injection

surviendrait, consulter immédiatement un médecin.

Vérifier les tuyaux flexibles et les pièces afin de s’assurer

qu’ils ne sont pas endommagés. Remplacer tout tuyau

flexible endommagé ou toute pièce endommagée.

Ce système peut produire une pression de 2 500 psi.

Utiliser uniquement des pièces de remplacement ou des

accessoires recommandés par le fabricant et qui tolèrent

une pression nominale de 2 500 psi.

Savoir comment arrêter rapidement l’unité. Se familiariser

avec toutes les commandes.

S’assurer que tous les raccords sont solides avant

d’utiliser cette unité.

Pour l’usage de ménage seulement.

AVERTISSEMENT : Pour réduire les risques de blessure :

Ne pas utiliser ou pulvériser le produit à proximité des

enfants. Garder les enfants à l’écart de l’équipement en

tout temps.

Ne pas travailler hors de portée ou se tenir sur un support

instable. Se tenir bien campé et en équilibre en tout

temps.

Rester attentif et prêter attention au travail.

Ne pas utiliser cet appareil en cas de fatigue ou sous

l’influence de l’alcool ou de drogues.

3 — Français

Page 14

RÈGLES DE SÉCURITÉ PARTICULIÈRES

Maintenir tous les dispositifs de protection en place et en

bon état de fonctionnement. Ne jamais utiliser l’outil avec des

couvercles ou dispositifs de protection retirés. S’assurer que

tous les dispositifs de protection fonctionnent correctement

avant chaque utilisation.

Pour réduire les risques de blessures, garder les enfants

et visiteurs à l’écart. Tous les visiteurs doivent porter des

lunettes de sécurité et se tenir à bonne distance de la zone

de travail.

Ne laisser personne approcher la zone de travail,

particulièrement les petits enfants et les animaux

domestiques.

Utiliser l’outil approprié. Ne pas utiliser l’outil ou un

accessoire pour effectuer un travail pour lequel il n’est pas

conçu. Ne ne pas utiliser l’outil pour une application non

prévue.

Ne pas faire fonctionner l’équipement pied-nu ou

en portant des sandales ou des chaussures légères

similaires. Porter des chaussures de sécurité protégeant les

pieds et améliorant l’équilibre sur des surfaces glissantes.

Faire preuve de prudence pour éviter de glisser ou

tomber.

Toujours porter des lunettes de sécurité avec écrans

latéraux. Les lunettes de vue ordinaires sont munies

seulement de verres résistants aux impacts ; ce ne sont

PAS des lunettes de sécurité.

N’utiliser que les accessoires recommandés. L’emploi

de tout accessoire inadapté peut présenter un risque de

blessure.

Suivre les instructions d’entretien spécifiées dans ce

manuel.

Vérifier l’état des pièces. Avant d’utiliser l’outil de nouveau

examiner soigneusement les pièces et dispositifs de

protection qui semblent endommagés afin de déterminer s’ils

fonctionnent correctement et s’ils remplissent les fonctions

prévues. Vérifier l’alignement des pièces mobiles, s’assurer

qu’aucune pièce n’est bloquée ou cassée, vérifier la fixation

de chaque pièce et s’assurer qu’aucun autre problème ne

risque d’affecter le bon fonctionnement de l’outil. Pour

éviter les risques de blessures, toute protection ou pièce

endommagée doit être correctement réparée ou remplacée

dans un centre de réparations agréé.

Ne jamais laisser un outil en fonctionnement sans

surveillance. Ne pas s’éloigner de l’outil avant qu’il soit

parvenu à un arrêt complet.

Se familiariser complètement avec les commandes. Veiller

à savoir arrêter la machine rapidement.

Garder l’outil sec, propre et exempt d’huile ou de graisse.

Toujours utiliser un chiffon propre pour le nettoyage. Ne

jamais utiliser de liquide de freins, d’essence ou de produits

à base de pétrole pour nettoyer l’outil.

Ne pas utiliser l’outil si le commutateur ne permet pas

de l’arrêter. Faire remplacer les commutateurs défectueux

dans un centre de réparations agréé.

Avant de nettoyer, réparer ou inspecter, couper le moteur

et vérifier que toutes les pièces en mouvement sont arrêtées.

Éviter les environnements dangereux. Ne pas utiliser dans

des endroits mouillés ou humides, ne pas exposer à la pluie.

Garder le lieu de travail bien éclairé.

Ne jamais diriger un jet de peinture vers des personnes,

des animaux et des appareils électriques.

Ne jamais mettre la machine en marche si de la glace

s’est formée sur quelque partie que ce soit.

AVERTISSEMENT : Les pulvérisateur à haute pression

peuvent être dangereux s’ils sont utilisés incorrectement.

Le pulvérisateur ne doit pas être dirigé vers des personnes,

animaux, dispositifs électriques ou l’équipement lui-même.

Rester à l’écart des pièces brûlantes.

Vérifier le serrage de la boulonnerie avant chaque

utilisation. Un boulon ou écrou desserré peut causer de

sérieux problèmes de moteur.

Laisser le produit refroidir avant de remiser l’outil.

Remiser dans un endroit frais, bien aéré, à l’écart

d’étincelle et/ou d’appareils produisant des flammes.

Utiliser exclusivement des pièces identiques à celles

d’origine pour les réparations. L’usage de toute autre pièce

pourrait créer une situation dangereuse ou endommager

l’outil.

Ne pas utiliser l’outil si l’embout de pulvérisation n’est

pas en place.

Les conséquences d’une blessure par injection peuvent

aller jusqu’à l’amputation. Consulter immédiatement un

médecin.

Ne jamais mettre les mains devant l’embout de

pulvérisation pendant l’utilisation. Le fait de porter des

gants ne protège pas toujours l’utilisateur des blessures

par injection.

Porter des vêtements afin de protéger la peau et les

cheveux de la peinture, ainsi qu’un masque ou un

respirateur pendant l’utilisation. Les peintures, les

solvants et les autres substances peuvent être dangereux

s’ils sont inhalés ou s’ils entrent en contact avec le corps.

Toujours débrancher le pulvérisateur, éteindre l’unité

avant de procéder à l’entretien ou au nettoyage de

l’embout ou du dispositif de protection de l’embout,

de changer d’embout, ou de laisser l’unité sans

surveillance.

Le plastique peut provoquer des étincelles. Ne jamais

suspendre du plastique pour clôturer une aire de

pulvérisation. Ne pas utiliser de toiles de peintre en

plastique au moment de pulvériser des substances

inflammables.

Ne pas pulvériser à l’extérieur lors de journées

venteuses.

Ne pas tenter de nettoyer ou de décrasser l’embout

de pulvérisation avec son doigt.

Conserver ces instructions. Les consulter fréquemment

et les utiliser pour instruire d’autres utilisateurs. Si cet outil

est prêté, il doit être accompagné de ces instructions.

4 — Français

Page 15

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à l’utilisation

de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER :

AVERTISSEMENT :

ATTENTION :

ATTENTION :

Certains des symboles ci-dessous peuvent être présents sur le produit. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser le produit plus efficacement et de réduire les risques.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

Symbole d’alerte de sécurité Indique un risque de blessure potentiel.

Lire le manuel d’utilisation

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée,

aura pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourraît entraîner des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité) Indique une situation pouvant entraîner

des dommages matériels.

Pour réduire les risques de blessures, l’utilisateur doit lire et veiller à

bien comprendre le manuel d’utilisation avant d’utiliser ce produit.

Protection oculaire

V Volts Tension

A Ampères Intensité

Hz Hertz Fréquence (cycles par seconde)

Courant alternatif Type de courant

PSI Pression La pression est mesurée en livres par pouce carré

GPH Débit

Toujours porter une protection oculaire avec écrans latéraux

certifiée conforme à la norme ANSI Z87.1.

Le débit est mesuré selon le nombre de gallons de peinture

pulvérisés par heure

PROPOSITION 65 DE LA CALIFORNIE

AVERTISSEMENT :

Ce produit, et les peintures peut contenir des produits chimiques, notamment du plomb, identifiés par l’état de Californie

comme causes de cancer, de malformations congénitales et d’autres troubles de l’appareil reproducteur. Bien se laver

les mains après toute manipulation.

5 — Français

Page 16

CARACTÉRISTIQUES ÉLECTRIQUES

CORDONS PROLONGATEURS

Assurez-vous d’utiliser un cordon prolongateur de capacité

suffisante pour rapporter le courant que le produit soutirera Un

cordon prolongateur de calibre insuffisant causera une perte

de tension et provoquera ainsi une surchauffe et une perte

de puissance. Utilisez le tableau pour déterminer le calibre

minimum de fil requis pour un cordon prolongateur. Utilisez

exclusivement des cordons à gaine cylindrique homologués

par Underwriter’s Laboratories (UL).

Pour les travaux à l’extérieur, utilisez un cordon prolongateur

spécialement conçu à cet effet. La gaine des cordons de ce

type porte l’inscription « W-A » ou « W ».

Avant d’utiliser un cordon prolongateur, vérifier que ses fils

ne sont ni détachés ni exposés et que son isolation n’est ni

coupée, ni usée.

Il est possible de se procurer une rallonge électrique

appropriée dans un centre de service autorisé.

S’il est nécessaire d’utiliser deux cordons prolongateurs,

les nouer ensemble pour éviter qu’ils se détachent pendant

l’utilisation. Faire le nœud tel qu’illustré à la figure 1 et brancher

la fiche d’un des cordons dans la prise de l’autre.

**Intensité nominale (sur la plaquette signalétique de l’outil)

0-2,0 2,1-3,4 3,5-5,0 5,1-7,0 7,1-12,0 12,1-16,0

Longueur Calibre de fil

du cordon (A.W.G.)

25’ 16 16 16 16 14 14

50’ 16 16 16 14 14 12

100’ 16 16 14 12 10 —

**Utilisé sur circuit de calibre 12 – 20 A.

NOTE : AWG = American Wire Gauge

AVERTISSEMENT :

Maintenir le cordon prolongateur à l’écart de la zone de

travail. Lors du travail avec un cordon électrique, placer le

cordon de manière à ce qu’il ne risque pas de se prendre

dans les pièces de bois, outils et autres obstacles. Ne

pas prendre cette précaution peut entraîner des blessures

graves.

CONNEXION ÉLECTRIQUE

Cet outil est équipé d’un moteur électrique de précision. Elle

doit être branchée uniquement sur une alimentation 120 V,

60 Hz, c.a. (courant résidentiel standard). Ne pas utiliser

cet outil sur une source de courant continu (c.c.). Une chute

de tension importante causerait une perte de puissance et

une surchauffe du moteur. Si l’outil ne fonctionne pas une

fois branché, vérifier l’alimentation électrique.

INSTRUCTIONS DE MISE À LA TERRE

Voir figure 1, page 12.

En cas de problème de fonctionnement ou de panne, la

mise à la terre fournit un chemin de résistance au courant

électrique, pour réduire le risque de choc électrique. Cet

outil est équipé d’un cordon électrique avec conducteur et

fiche de mise à la terre. Le cordon doit être branché sur une

prise correctement installée et mise à la terre conformément

à tous les codes et réglementations locaux en vigueur.

Ne pas modifier la fiche fournie. Si elle ne peut pas être insérée

dans la prise secteur, faire installer une prise adéquate par

un électricien qualifié.

AVERTISSEMENT :

L’usage d’un cordon prolongateur incorrect peut

présenter des risques de choc électrique. Si le cordon

doit être réparé ou remplacé, ne pas connecter le fil de

terre de l’outil sur une borne sous tension.Le fil à gaine

verte, avec ou sans traceur jaune est le fil de terre.

Consulter un électricien qualifié ou le personnel de service si

les instructions de mise à la terre ne sont pas bien comprises,

ou en cas de doute au sujet de la mise à la terre.

Tout cordon endommagé doit être réparé ou remplacé

immédiatement.

Ce produit est pour l’usage sur un nominal 120 circuit de volt

et a un fonder bouche similaire au bouchon illustré dans la

figure 1. Seulement connecter le produit à une sortie ayant

la même configuration comme le bouchon. Ne pas utiliser

un adaptateur avec ce produit.

AVERTISSEMENT :

Vérifier l’état des cordons prolongateurs avant chaque

utilisation. Remplacer immédiatement tout cordon

endommagé. Ne jamais utilise un outil dont le cordon

d’alimentation est endommagé car tout contact avec la

partie endommagée pourrait causer un choc électrique

et des blessures graves.

6 — Français

Page 17

CARACTÉRISTIQUES

FICHE TECHNIQUE

Débit ....................................................................................................................................................................18,93 l/h (5,5 gal/h)

Dimensions du réservoir................................................................................................................................................. 1,4 l (1,5 qt)

Alimentation ............................................................................................................................... 120 V, 60 Hz, c.a. seulement, 1,4A

VEILLEZ À BIEN CONNAÎTRE LE PISTOLET À

PEINDRE ÉLECTRIQUE

Voir la figure 2, page 12.

L’utilisation sûre de ce produit exige une comprehension des

renseignements figurant sur l’outil et contenus dans le manuel

d’utilisation, ainsi qu’une bonne connaissance du projet

entrepris. Avant d’utiliser ce produit, se familiariser avec toutes

ses caractéristiques et règles de sécurité.

TECHNOLOGIE DE GRIPZONE

La pulvériser utilise la technologie de GripZone™ pour un confort

accru et une prise plus ferme.

™

ASSEMBLAGE

DÉBALLAGE

Ce produit a été expédié complètement assemblé.

Avec précaution, sorvtir le produit et les accessoires de la

boîte. S’assurer que toutes les pièces figurant sur la liste de

contrôle sont incluses.

AVERTISSEMENT :

MOTEUR DE CONCEPTION NOVATRICE

La conception novatrice du moteur permet de réduire les

vibrations et le bruit pendant l’utilisation.

RÉSERVOIR DE PEINTURE À VERROUILLAGE

RAPIDE

La fonction de verrouillage rapide permet d’installer et de retirer

facilement le réservoir de peinture.

EMBOUT DE PULVÉRISATION RÉVERSIBLE

PRO-TIP

L’embout de pulvérisation peut être à 180º inversé pour aider

à déloger les résidus.

™

AVERTISSEMENT :

Si des pièces manquent ou sont endommagées, ne pas

utiliser ce produit avant qu’elles aient été remplacées.

Le fait d’utiliser ce produit même s’il contient des pièces

endommagées ou s’il lui manque des pièces peut entraîner

des blessures graves.

Ne pas utiliser le produit s’il n’est pas complètement

assemblé ou si des pièces semblent manquantes ou

endommagées. Le fait d’utiliser un produit assemblé

de façon inadéquate ou incomplète peut entraîner des

blessures graves.

Examiner soigneusement le produit pour s’assurer que rien

n’a été brisé ou endommagé en cours de transport.

Ne pas jeter les matériaux d’emballage avant d’avoir

soigneusement examiné le produit et avoir vérifié qu’il

fonctionne correctement.

Si des pièces sont manquantes ou endommagées, appeler

le 1-800-525-2579.

LISTE DE CONTRÔLE D’EXPÉDITION

Pistolet à peindre électrique avec

réservoir de peinture à verrouillage rapide

Ensemble valve de pulvérisateur de remplacement

Lubrifiant

Brosse de nettoyage

Manuel d’utilisation

AVERTISSEMENT :

Ne pas essayer de modifier ce produit ou de créer des

accessoires non recommandés pour le produit. De telles

altérations ou modifications sont considérées comme un

usage abusif et peuvent créer des conditions dangereuses,

risquant d’entraîner des blessures graves.

AVERTISSEMENT :

Ne pas brancher sur le secteur avant d’avoir terminé

l’assemblage. Le non respect de cet avertissement peut

causer un démarrage accidentel, entraînant des blessures

graves.

7 — Français

Page 18

UTILISATION

AVERTISSEMENT :

Ne pas laisser la familiarité avec le produit faire oublier

la prudence. Ne pas oublier qu’une fraction de seconde

d’inattention peut entraîner des blessures graves.

AVERTISSEMENT :

Toujours porter une protection oculaire avec écrans

latéraux certifiée conforme à la norme ANSI Z87.1. Le non

respect de cette règle peut faire en sorte que des liquides

soient projetés dans vos yeux, ce qui peut entraîner des

blessures graves.

AVERTISSEMENT :

Ne pas utiliser d’outils ou accessoires non recommandés

par le fabricant pour cet outil. L’utilisation de pièces

et accessoires non recommandés peut entraîner des

blessures graves.

APPLICATIONS

Ce produit peut être utilisé pour l’application ci-dessous :

Pour peinture ou teinture d’intérieur ou d’extérieur sur

patios, meubles d’extérieur, clôtures et murs

AVERTISSEMENT :

Risque d’incendie ou d’explosion. L’aire de pulvérisation

doit être ventilée et située à l’écart des étincelles et des

flammes.

REMPLIR LE PISTOLET DE PEINTURE OU DE

TEINTURE

Voir les figures 3 et 4, page 12.

Retirer et jeter la pellicule qui s’est formée sur le dessus de

la peinture ou de la teinture, puis bien mélanger la substance

dans son contenant original avant de débuter l’opération.

NOTE : Il peut être nécessaire de filtrer le contenu des vieux

récipients de peinture et de teinture avant de l’utiliser.

Débrancher le pistolet.

Retirer le réservoir de peinture à verrouillage rapide en

le tournant dans le sens contraire de façon à ce que

la flèche du réservoir soit alignée avec le symbole de

« déverrouillage » situé sur le couvercle.

Remplir le réservoir de peinture ou de teinture, au choix.

Ne pas dépasser la ligne de remplissage maximal (1,4 l

[1,5 qt]) du réservoir.

Réinstaller le réservoir sur le pistolet et le tourner dans

le sens horaire de façon à ce que la flèche du réservoir

soit alignée avec le symbole de « verrouillage » situé sur

le couvercle.

AVERTISSEMENT :

Pour réduire le risque d’injection, ne pas diriger le

pulvérisateur vers soi ou vers quiconque. En cas

d’injection cutanée, consulter immédiatement un

médecin. Ne pas utiliser l’outil si l’embout de pulvérisation

n’est pas en place.

UTILISATION DU PISTOLET

Voir les figures 5 à 7, pages 12 - 13.

S’assurer que la surface à peindre est exempte de

poussière, de saleté et de graisse.

Masquer ou recouvrir les surfaces sur lesquelles on ne

prévoit pas appliquer de peinture ou de teinture. Attention

au vent; il pourrait entraîner la peinture ou la teinture vers

des endroits non désirés. Toujours utiliser une toile de

peintre ou un autre recouvrement pour protéger les zones

sur lesquelles on ne prévoit pas appliquer de peinture ou

de teinture.

Placer une pellicule de lubrifiant sur le piston. Pour

accéder au piston, suivre les instructions décrites sous

Nettoyage du pulvérisateur aux fins d’entreposage, à

la section Entretien du présent manuel.

Remonter l’ensemble de l’embout de pulvérisation.

Le protecteur d’embout de pulvérisation peut être ajusté

pour peindre à l’horizontale ou à la verticale. Pour modifier

la trajectoire de l’embout, dévisser le collier métallique

de l’ensemble d’embout de pulvérisation en tournant

dans le sens contraire aux aiguilles d’une montre. Ajuster

l’embout de pulvérisation et son protecteur puis serrer

fermement le collier métallique pour fixer l’ensemble

d’embout de pulvérisation.

Remplir le réservoir à verrouillage rapide avec au

maximum 1,4 l (1,5 qt) de la peinture ou de la teinture

désirée.

Brancher le pistolet.

Appuyer sur la gâchette pour pulvériser la peinture.

Relâcher la gâchette pour cesser l’opération.

S’exercer à pulvériser sur des matériaux de rebut afin

de tester le pistolet. S’il est impossible d’obtenir une

bonne forme de jet avec une quantité égale de peinture

ou de teinture, consulter la section Dépannage présentée

ultérieurement dans le présent manuel.

NOTE : Il est nécessaire d’amorcer la pompe chaque fois

que la peinture est changée, ainsi que lors de la première

utilisation suivant l’entreposage. Pulvériser la peinture sur

une surface de rebut pendant au moins 20 secondes pour

amorcer la pompe.

8 — Français

Page 19

UTILISATION

Pour créer un revêtement égal sur toute la surface :

• Déplacersonbrasàunevitesseconstanteets’assurer

de bouger tout le bras, pas seulement le poignet.

• Garderle pistolet à une distance égale dela

zone de pulvérisation, soit de 203,2 mm (8 po) à

254 mm (10 po) entre l’embout du pistolet et la surface

à pulvériser.

• Appuyersurlagâchettepourcommenceràpulvériser

l’enduit à appliquer. Utiliser le pistolet en lui faisant

effectuer des mouvements horizontaux ou verticaux

devant la surface à peindre, puis relâcher la gâchette

pour cesser la pulvérisation.

NOTE : Pour assurer une pulvérisation de qualité uniforme

avec des peintures plus fluides, il peut être nécessaire de

tenir la gâchette enfoncée entre les mouvements.

Une fois l’opération terminée, débrancher le pistolet, remettre

la peinture ou la teinture non utilisée dans son contenant

d’origine, et bien nettoyer le pistolet.

DÉGAGEMENT DES RÉSIDUS DE PEINTURE

Voir le figure 8, page13.

Un embout de pulvérisation obstrué dénote une peinture qui ne se

pulvérise pas librement de l’embout ou lorsque la surface peinte

démontre un enduit inégal. Inverser l’embout de pulvérisation

pour aider à libérer les résidus.

Tourner l’embout de pulvérisation de manière diriger

l’extrémité pointue vers vous.

Pointer le pistolet de pulvérisation vers un échantillon de

matériau à peindre.

Appuyer sur la gâchette jusqu’à ce que la peinture s’écoule par

l’embout de pulvérisation. Ceci devrait permettre de déloger

les résidus.

Tourner l’embout de pulvérisation de manière à pointer et

éloigner l’extrémité du corps.

Faire l’essai du pistolet de pulvérisation sur un échantillon du

matériau avant de reprendre le travail.

ATTENTION :

Il est important de bien nettoyer le pistolet après chaque

utilisation ou au moment de changer de couleur. Le fait de

laisser de la peinture ou de la teinture dans un outil au repos

pendant une longue période peut entraîner le grippage des

pièces mobiles de l’appareil.

AVERTISSEMENT :

Ne pas nettoyer l’appareil avec des liquides inflammables

comme du décapant pour peinture, du décapeur, du nettoyant

pour pinceaux, de l’essence minérale, du diluant à peinturelaque, de la térébenthine, de l’acétone, de l’essence, du

kérosène, etc.

NETTOYAGE DU PISTOLET APRÈS UTILISATION

La solution utilisée pour nettoyer le pistolet est déterminée en

fonction du type de substance pulvérisée. Pour toute autre

substance qu’un enduit au latex, suivre les directives du fabricant

pour effectuer un nettoyage approprié.

Pour nettoyer le pistolet en vue d’un entreposage à court

terme :

Débrancher le pistolet.

Si ce n’est déjà fait, retirer le réservoir de peinture et verser

toute peinture ou teinture non utilisée dans son contenant

d’origine.

Remplir le réservoir de peinture avec de l’eau tiède (pour les

peintures à base d’eau) ou un solvant ininflammable (pour

les peintures ou vernis à base d’huile, ou tout autre solvant

ininflammable [selon l’utilisation des produits à base d’huile]).

NOTE : Nettoyer d’abord le réservoir pour obtenir des

résultats optimaux.

Réinstaller le réservoir de peinture.

Brancher le pistolet.

Pulvériser la solution sur un morceau de carton ou sur un

autre matériau de rebut. Continuer de pulvériser jusqu’à ce

que toute la solution ait été utilisée.

Débrancher le pistolet.

Placer une pellicule de lubrifiant sur le piston. Pour accéder

au piston, suivre les instructions décrites sous Nettoyage du

pulvérisateur aux fins d’entreposage, à la section Entretien

du présent manuel.

Utiliser un linge humide pour essuyer l’extérieur du pistolet.

L’unité peut maintenant être entreposée.

ENTRETIEN

AVERTISSEMENT :

Utiliser exclusivement des pièces d’origine pour les

réparations. L’usage de toute autre pièce pourrait créer une

situation dangereuse ou endommager le produit.

AVERTISSEMENT :

Toujours porter une protection oculaire avec écrans

latéraux certifiée conforme à la norme ANSI Z87.1. Le non

respect de cette règle peut faire en sorte que des liquides

soient projetés dans vos yeux, ce qui peut entraîner des

blessures graves.

9 — Français

ENTRETIEN GÉNÉRAL

NOTE : Toujours débrancher l’unité avant de tenter d’effectuer

un entretien.

Éviter d’utiliser des solvants pour le nettoyage des pièces en

plastique. La plupart des matières plastiques peuvent être

endommagées par divers types de solvants du commerce.

Utiliser un chiffon propre pour éliminer la saleté, la poussière,

l’huile, la graisse, etc.

Page 20

ENTRETIEN

AVERTISSEMENT :

Ne jamais laisser de liquides tels que le fluide de freins,

l’essence, les huiles pénétrantes, etc., entrer en contact

avec les pièces en plastique. Les produits chimiques

peuvent endommager, affaiblir ou détruire le plastique, ce

qui peut entraîner des blessures graves.

NETTOYAGE DU PISTOLET AUX FINS

D’ENTREPOSAGE

Voir le figure 9, page 13.

Lorsque le projet est terminé et qu’il temps d’entreposer le

pistolet, il est recommandé de bien nettoyer et lubrifier l’outil.

Débrancher le pistolet.

Retirer le réservoir de peinture.

Si ce n’est déjà fait, verser toute peinture ou teinture non

utilisée dans son contenant d’origine.

Remplir le réservoir de peinture avec de l’eau tiède (pour

les peintures à base d’eau) ou un solvant ininflammable

(pour les peintures ou vernis à base d’huile, ou tout autre

solvant ininflammable [selon l’utilisation des produits à

base d’huile]).

NOTE : Nettoyer d’abord le réservoir pour obtenir des

résultats optimaux

Réinstaller le réservoir de peinture.

Brancher le pistolet.

Pulvériser la solution sur un morceau de carton ou sur un

autre matériau de rebut. Continuer de pulvériser jusqu’à

ce que toute la solution ait été utilisée.

Débrancher le pistolet.

Retirer le réservoir de peinture.

Retirer le tube et le filtre de succion et les mettre à l’écart.

Retirer l’embout de pulvérisation installée en desserrant

le collier métallique et en tournant le protecteur d’embout