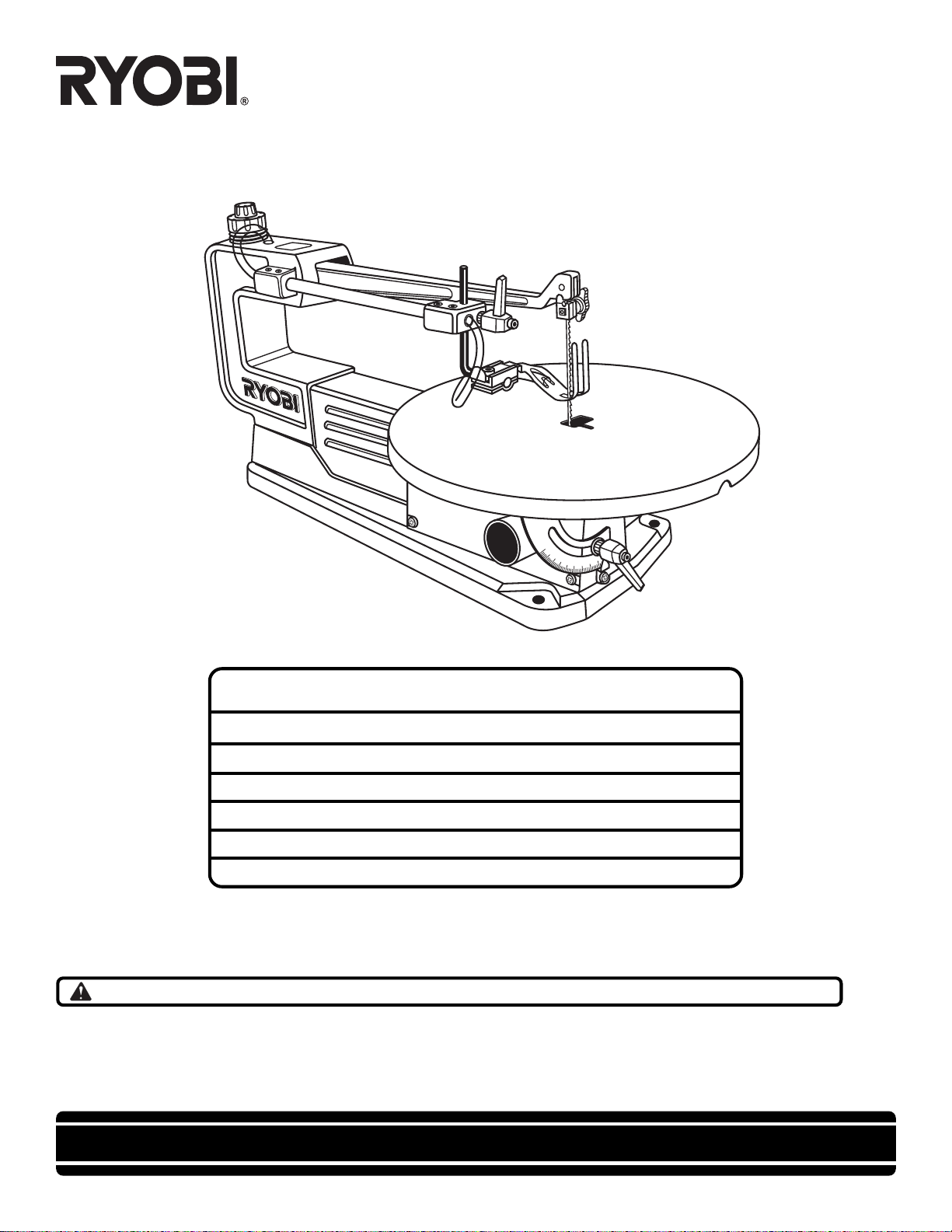

Page 1

OPERATOR'S MANUAL

16 in. (406 mm) Scroll Saw

Model SC155VS

45˚

30˚

15˚

SPECIFICATIONS:

Throat 16 in. (406 mm)

Blade Length 5 in. (127 mm) plain or pin

Motor Rating 120 volts, 60 Hz, AC

No Load Speed 400 – 1550 Strokes Per Minute

Amperes 1.2 Amperes

Net Weight 32 lbs. (14 kg.)

THANK YOU FOR BUYING A RYOBI SCROLL SAW.

Your new scroll saw has been engineered and manufactured to Ryobi's high standard for dependability, ease of operation,

and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

CAUTION: Carefully read through this entire operator's manual before using your new scroll saw.

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions. If you use your scroll saw properly and only

for what it is intended, you will enjoy years of safe, reliable service.

Please fill out and return the Warranty Registration Card so that we can be of future service to you.

Thank you again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

■ Table of Contents ........................................................................................................................................................ 2

■ Introduction.................................................................................................................................................................. 2

■ Rules For Safe Operation ......................................................................................................................................3 - 5

■ Electrical...................................................................................................................................................................... 6

■ Glossary and Product Specifications .......................................................................................................................... 7

■ Unpacking and Tools Needed..................................................................................................................................... 8

■ Features ................................................................................................................................................................. 9-10

■ Assembly .............................................................................................................................................................. 10-11

■ Adjustments.......................................................................................................................................................... 11-14

■ Operation.............................................................................................................................................................. 15-18

■ Maintenance.........................................................................................................................................................18-19

■ Troubleshooting......................................................................................................................................................... 19

■ Exploded View and Repair Parts List................................................................................................................... 20-23

■ Parts Ordering / Service............................................................................................................................................ 24

INTRODUCTION

Your saw has many features for making cutting operations

more pleasant and enjoyable. Safety, performance and

dependability have been given top priority in the design of

this saw making it easy to maintain and operate.

Look for this symbol to point out important safety precautions. It means attention!!! Your safety

is involved.

WARNING:

WEAR

YOUR

SAFETY

FORESIGHT IS BETTER

GLASSES

THAN NO SIGHT

The operation of any power tool can result in foreign objects being thrown into your eyes, which

can result in severe eye damage. Before beginning power tool operation, always wear safety

goggles or safety glasses with side shields and a full face shield when needed. We recommend

Wide Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields,

available at your local Ryobi dealer.

CAUTION:

Carefully read through this entire operator's manual

before using your new saw. Pay close attention to the

Rules For Safe Operation, and all Safety Alert Symbols

including Danger, Warning and Caution. If you use your

saw properly and only for what it is intended, you will

enjoy years of safe, reliable service.

Page 2

Page 3

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

SYMBOL MEANING

SAFETY ALERT SYMBOL:

Indicates danger, warning or caution. May be used in conjunction with other symbols or pictographs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others. Always follow

the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others. Always follow

the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to yourself or

to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

Note: Advises you of information or instructions vital to the operation or maintenance of the equipment.

IMPORTANT

Servicing requires extreme care and knowledge of the system and should be performed only by a qualified service technician.

For service we suggest you return the tool to your nearest Ryobi Authorized Service Center. When servicing always use

identical Ryobi replacement parts.

■ KEEP GUARDS IN PLACE and in good working order.

WARNING:

Do not attempt to operate this tool until you have read

thoroughly and understand completely all instructions,

safety rules, etc. contained in this manual. Failure to

comply can result in accidents involving fire, electric

shock, or serious personal injury. Save operator's manual

and review frequently for continuing safe operation, and

instructing others who may use this tool.

WARNING:

Do not connect your scroll saw to a power source until you

have assembled and adjusted the saw as described in

this manual and have read and understood all precautions

and operating instructions in the manual and printed on

the tool.

READ ALL INSTRUCTIONS

■ KNOW YOUR POWER TOOL. Read the operator's

manual carefully. Learn the saw's applications and limitations as well as the specific potential hazards related to

this tool.

■ GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING BODY CONTACT WITH GROUNDED SURFACES. For example; pipes, radiators, ranges, refrigera-

tor enclosures.

■ REMOVE ADJUSTING KEYS AND WRENCHES. Get in

the habit of checking to see that hex keys and adjusting

wrenches are removed from tool before turning on the

saw.

■ KEEP THE WORK AREA CLEAN. Cluttered work areas

and work benches invite accidents. DO NOT leave tools

or pieces of wood on the saw while it is in operation.

■ DO NOT USE IN DANGEROUS ENVIRONMENTS. Do

not use power tools near gasoline or other flammable

liquids, in damp or wet locations, or expose them to rain.

Keep the work area well lit.

■ KEEP CHILDREN AND VISITORS AWAY. All visitors

should wear safety glasses and be kept a safe distance

from work area. Do not let visitors contact tool or extension cord while operating.

■ MAKE WORKSHOP CHILD-PROOF with padlocks and

master switches or by removing starter keys.

■ DO NOT FORCE THE TOOL. It will do the job better and

safer at the rate for which it was designed.

■ USE THE RIGHT TOOL. Do not force the tool or attach-

ment to do a job it was not designed for. Don't use it for a

purpose not intended.

Page 3

Page 4

RULES FOR SAFE OPERATION

■ USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and

overheating. A wire gage size (A.W.G.) of at least 16 is

recommended for an extension cord 100 feet or less in

length. If in doubt, use the next heavier gage. The smaller

the gage number, the heavier the cord.

■ INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

■ DRESS PROPERLY. Do not wear loose clothing, gloves,

neckties, rings, bracelets, or other jewelry. They can get

caught and draw you into moving parts. Rubber gloves

and nonslip footwear are recommended. Also wear protective hair covering to contain long hair.

■ ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-resis-

tant lenses; they are NOT safety glasses.

■ PROTECT YOUR LUNGS. Wear a face or dust mask if

the cutting operation is dusty.

■ PROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

service technician at an authorized service center to

avoid risk of personal injury.

■ DIRECTION OF FEED. Feed work into blade against the

cutting portion of the blade only.

■ NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

THE POWER OFF. Do not leave tool until it comes to a

complete stop.

■ USE ONLY CORRECT BLADES. Use the right blade

size, style and cutting speed for the material and the type

of cut. Blade teeth should point down toward the table.

Sharp blades minimize stalling and kickback. Correctly

adjust blade tension.

■ TO PROTECT THE OPERATOR and minimize blade

breakage, ALWAYS adjust the hold down foot to apply

light pressure to the workpiece. Never operate the saw

with any guard or cover removed. Make sure all guards

are operating properly before each use.

■ KEEP HANDS AWAY FROM CUTTING AREA. Do not

hand hold pieces so small that your fingers go under the

blade guard. Never reach underneath work or behind,

under, or within three inches of the blade and its cutting

path with your hands and fingers for any reason. Do not

attempt to remove cut material when blade is moving.

■ SECURE WORK. Use clamps or a vise to hold work when

practical. It's safer than using your hand and it frees both

hands to operate tool.

■ DO NOT OVERREACH. Keep proper footing and bal-

ance at all times.

■ MAINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for better and safer performance. Follow instructions for lubricating and changing accessories.

■ DISCONNECT ALL TOOLS. When not in use, before

servicing, or when changing attachments, blades, bits,

cutters, etc., all tools should be disconnected from power

supply.

■ AVOID ACCIDENTAL STARTING. Be sure switch is off

when plugging in.

■ USE RECOMMENDED ACCESSORIES. The use of

improper accessories may cause risk of injury.

■ NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the blade is unintentionally contacted.

■ CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

saw stability, mounting and any other conditions that may

affect its operation. A guard or other part that is damaged

must be properly repaired or replaced by a qualified

WARNING: Blades coast after turn off.

■ AVOID PINCHING THE BLADE. Be cautious when cut-

ting off material which is irregular in cross section. For

example, molding must lay flat on the table and not be

permitted to rock.

■ DO NOT ABUSE CORD. Never yank cord to disconnect

it from receptacle. Keep cord from heat, oil, and sharp

edges.

■ INSPECT TOOL CORDS PERIODICALLY and if dam-

aged, have repaired by a qualified service technician at

an authorized service center. Stay constantly aware of

cord location and keep it well away from the blade.

■ DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defective switches replaced by a

qualified service technician at an authorized service

center.

■ KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning.

Never use brake fluids, gasoline, petroleum-based products, or any solvents to clean tool.

■ A LARGE PIECE OF MATERIAL SHOULD BE SUPPORTED while cutting. To minimize risk of blade pinching

and kickback, always support long workpieces. Saw may

slip, walk or slide while cutting long or heavy boards.

Page 4

Page 5

RULES FOR SAFE OPERATION

■ BEFORE MAKING A CUT, BE SURE ALL ADJUST-

MENTS ARE SECURE.

■ BEFORE CHANGING THE SETUP, REMOVING COV-

ERS, GUARDS OR BLADE, UNPLUG THE SAW.

■ DO NOT FEED THE MATERIAL TOO QUICKLY while

cutting. Do not force the workpiece against the blade.

■ NEVER CUT MORE THAN ONE WORKPIECE AT A

TIME. If making a stacked cut, all of the pieces must be

secured to each other with masking tape or double stick

tape to make one workpiece. Do not put more than one

workpiece on the saw table at a time. Always hold the

work firmly against the table. See page 17.

■ AVOID CUTTING NAILS. Inspect for and remove all nails

from lumber before cutting.

■ NEVER PERFORM LAYOUT, ASSEMBLY, OR SETUP

WORK ON THE TABLE while the cutting tool is operat-

ing.

■ NEVER TOUCH BLADE or other moving parts during

use.

■ NEVER START A TOOL WHEN THE BLADE IS IN

CONTACT WITH THE WORKPIECE. Clear the table of

debris before turning your scroll saw on.

■ ALLOW THE MOTOR TO COME UP TO FULL SPEED

before starting a cut.

■ FIRMLY CLAMP OR BOLT your scroll saw to a stable,

level workbench or table. The most comfortable table

height is at approximately waist height.

■ AVOID AWKWARD OPERATIONS AND HAND POSITIONS where a sudden slip could cause your hand to

move into the blade. ALWAYS make sure you have good

balance. Do not cut pieces of material that are too small

to hold comfortably in your hand.

■ REPLACEMENT PARTS. All repairs, whether electrical

or mechanical, should be made by qualified service

technician at a authorized service center.

WARNING:

When servicing use only identical Ryobi replacement

parts. Use of any other parts may create a hazard or

cause product damage.

■ NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Nor-

mal sparking of the motor could ignite fumes.

■ DO NOT OPERATE THIS TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY MEDICATION.

■ STAY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate

tool when you are tired. Do not rush.

■ MAKE SURE THE WORK AREA HAS AMPLE LIGHTING to see the work and that no obstructions will interfere

with safe operation BEFORE performing any work using

your saw.

■ ALWAYS TURN OFF SAW before disconnecting it to

avoid accidental starting when reconnecting to power

supply. NEVER leave the scroll saw unattended while

connected to a power source.

WARNING:

Do not allow familiarity with your saw to make you

careless. Remember that a careless fraction of a

second is sufficient to inflict severe injury.

■ SAVE THESE INSTRUCTIONS. Refer to them frequently

and use to instruct other users. If you loan someone this

tool, loan them these instructions also.

SAVE THESE INSTRUCTIONS

Page 5

Page 6

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the tool's plug.

When using a power tool at a considerable distance from the

power source, use an extension cord heavy enough to carry

the current that the tool will draw. An undersized extension

cord will cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the chart

provided below to determine the minimum wire size required

in an extension cord. Only round jacketed cords listed by

Underwriter's Laboratories (UL) should be used.

Length of Extension Cord Wire Size (A.W.G.)

Up to 100 feet 16

When working with the tool outdoors, use an extension cord

that is designed for outside use. This is indicated by the

letters WA on the cord's jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

CAUTION:

Keep the cord away from the cutting area and position the

cord so that it will not be caught on lumber, tools, or other

objects during cutting.

ELECTRICAL CONNECTION

Your Scroll Saw is powered by a precision built electric

motor. It should be connected to a power supply that is 120

volts, 60 Hz, AC only (normal household current). Do not

operate this tool on direct current (DC). A substantial voltage

drop will cause a loss of power and the motor will overheat.

If the saw does not operate when plugged into an outlet,

double check the power supply.

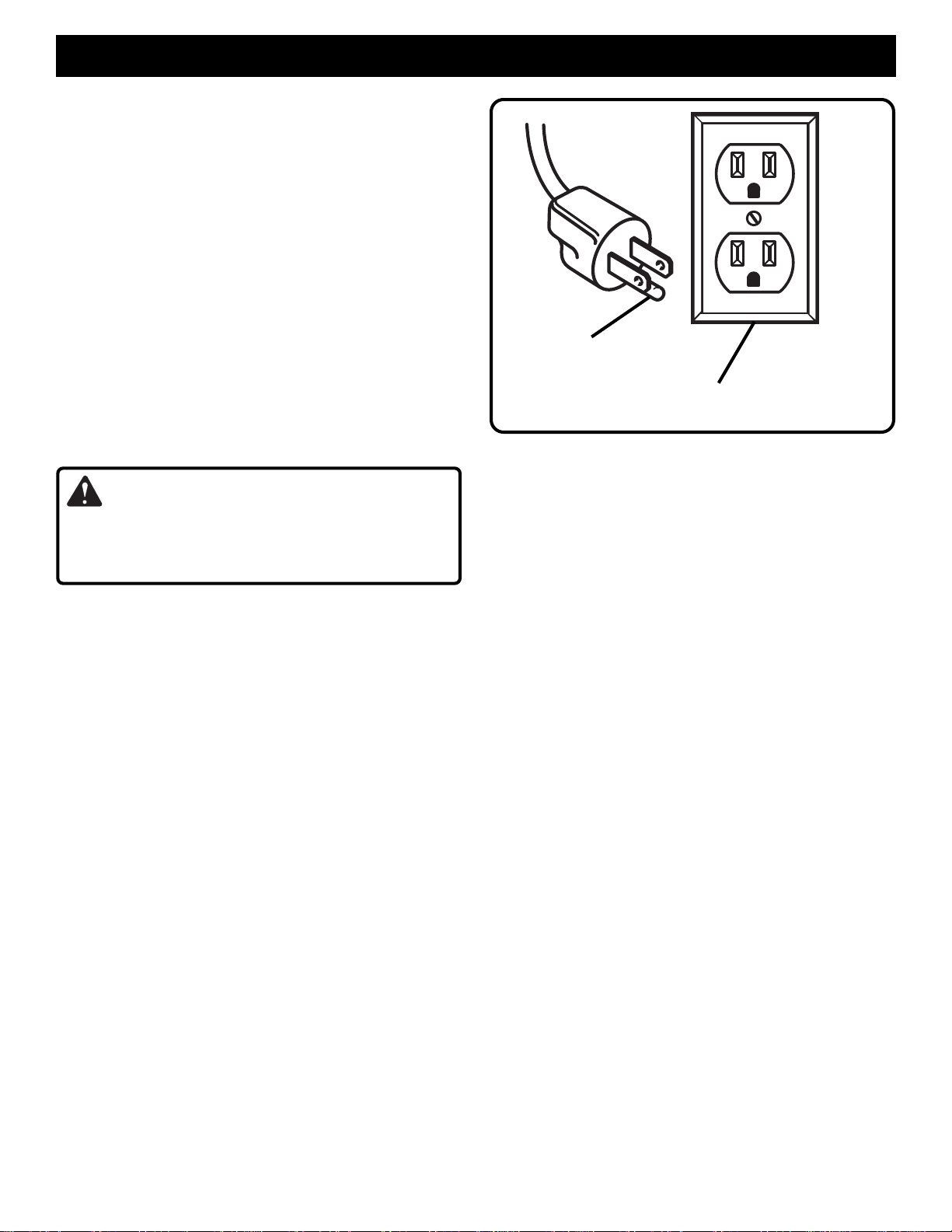

GROUNDING

PIN

COVER OF GROUNDED

OUTLET BOX

Fig. 1

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with an

electric cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have

the proper outlet installed by a qualified electrician. Improper

connection of the equipment-grounding conductor can result

in a risk of electric shock. The conductor with insulation

having an outer surface that is green with or without yellow

stripes is the equipment-grounding conductor. If repair or

replacement of the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

Repair or replace a damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet like

the one shown in

one shown.

Figure 1.

It also has a grounding pin like the

Page 6

Page 7

GLOSSARY OF TERMS FOR WOODWORKING

Bevel Cut

A cutting operation made with the table at any angle other

than 90˚ to the blade.

Crosscut

A cutting or shaping operation made across the grain of the

workpiece.

Compound Cut

A compound cut is a cut made using a miter angle and a

bevel angle at the same time.

Freehand (for scroll saw)

Performing a cut without the workpiece being guided by a

fence or miter gage. Work must be supported by the table.

Gum

A sticky, sap based residue from wood products.

Kerf

The material removed by the blade in a through cut or the slot

produced by the blade in a nonthrough or partial cut.

Leading End

The end of the workpiece pushed into the cutting tool first.

Miter Cut

A cutting operation made with the workpiece at any angle

other than 90˚ or parallel to the blade.

Nonferrous Metal

Metal that does not contain iron; such as aluminum, brass,

and copper.

Push Stick

A device used to feed the workpiece through the saw blade

during narrow wood cutting operations and helps keep the

operator's hands well away from the blade.

Resaw

A cutting operation to reduce the thickness of the workpiece

to make thinner pieces.

Resin

A sticky, sap base substance that has hardened.

Ripping

A cutting operation along the length of the workpiece.

Saw Blade Path

The area directly in line — over, under, behind, or in front of

the blade. As it applies to the workpiece, that area which will

be, or has been, cut by the blade.

Set

The distance that the tip of the saw blade tooth is bent (or set)

outward from the face of the blade.

SPM

Strokes per minute. Used in reference to blade movement.

Throw-Back

Throwing of a workpiece in a manner similar to a kickback.

Usually associated with a cause other than the kerf closing,

such as a workpiece not being against the fence, being

dropped into the blade, or being placed inadvertently in

contact with the blade.

Through Sawing

Any cutting operation where the blade extends completely

through the thickness of the workpiece.

Workpiece

The item on which the cutting operation is being done. The

surfaces of a workpiece are commonly referred to as faces,

ends, and edges.

Worktable

The surface on which the workpiece rests while performing

a cutting operation.

PRODUCT SPECIFICATIONS

Throat 16 in.

Motor 120 V, 1.2 amp, 60 HZ-AC only

Drive Variable Speed

400 – 1550 Strokes per minute

Blade Length 5 in. plain or pin

Table Tilt 45˚

Net Weight 32 lb. (14 kg.)

Page 7

Page 8

UNPACKING

CAUTION:

To prevent accidental starting or electrical shock that

could cause possible serious personal injury, assemble

all parts to your saw before connecting it to power supply.

Saw should never be connected to power supply when

you are assembling parts, making adjustments, lubricating,

installing or removing blades, cleaning, or when not in

use.

■ Carefully lift saw from the carton and place it on a level

work surface.

■ Remove pack of 4 extra blades and operator's manual

from the carton.

TOOLS NEEDED

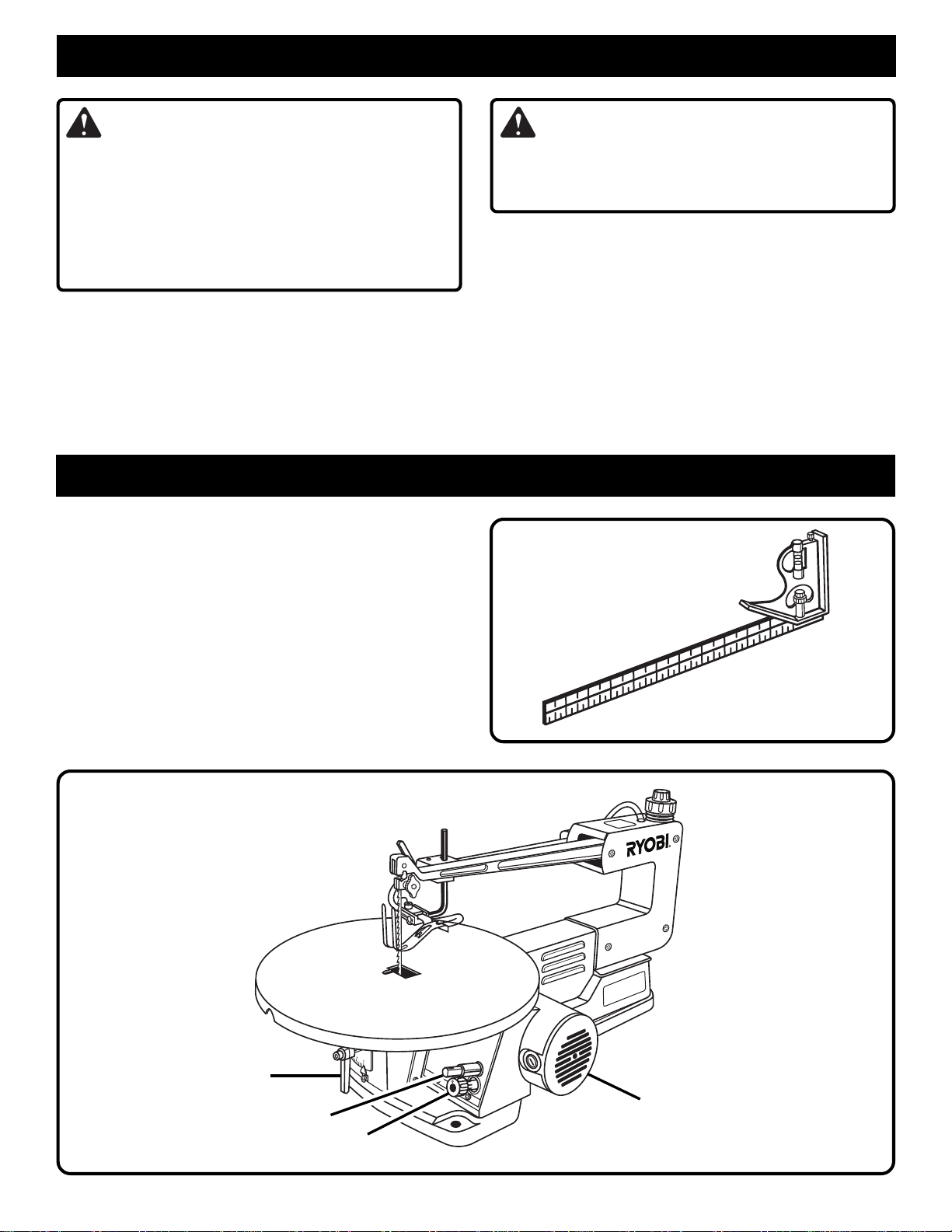

The small combination square shown in figure 2 is the only

tool (not provided) you will need for making adjustments and

alignment:

WARNING:

If any parts are missing, do not operate this tool until the

missing parts are replaced. Failure to do so could result

in possible serious personal injury.

■ Do not discard the packing materials until you have

carefully inspected the saw, identified all parts, and

satisfactorily operated your new saw.

Note: If any parts are damaged or missing, do not attempt to

plug in the power cord and turn the switch on until the

damaged or missing parts are obtained and are installed

correctly.

Your scroll saw comes completely assembled. A package of

4 extra blades, blade changing rod, "T" handle wrench, and

an operator's manual are included with your saw.

SMALL

COMBINATION

SQUARE

TABLE LOCK LEVER

LOCK OFF POST

Fig. 2

0˚

MOTOR

ON/OFF KNOB

Fig. 3

Page 8

Page 9

FEATURES

This versatile variable speed scroll saw is great for making

toys, puzzles, games, artwork, and jewelry. It is a handy doit-yourself tool. It cuts wood, wood composition products,

plastic, and other fibrous material up to 2 inches thick. It also

cuts nonferrous metals (aluminum, brass, copper).

KNOW YOUR SCROLL SAW

Before attempting to use your saw, familiarize yourself with

all operating features and safety requirements of your scroll

saw.

See Figures 3 and 4.

ON/OFF KNOB WITH VARIABLE SPEED

Your scroll saw has an easy access ON/OFF knob with

variable speed. Pull the knob out to turn ON the saw, and

push the knob in to turn OFF the saw. Turn the knob to adjust

the speed from the high speed of approximately 1550 SPM

(Strokes Per Minute) to the low speed of approximately 400

SPM.

LOCK OFF POST

Place a pad lock in the lock off post next to the ON/OFF knob

to lock the saw in the OFF position to prevent unauthorized

use of the saw by children or others.

BLADE HOLDERS

Blade holders retain and position the blades. Notches in

blade clamp have been designed to retain and position pin

type blades.

Convenient knobs, "T" handle wrench, and blade changing

rod are used for plain end blades.

BLADE TENSION KNOBS

Blade tension is controlled by a dual knob tension control

system. The inner (smaller) knob, tension adjusting knob, is

for making adjustments of the blade tension. The outer

(larger) knob, quick release knob, is used to quickly set and

release blade tension to facilitate blade changes.

HOLD DOWN FOOT/BLADE GUARD

The hold down foot should be adjusted to apply light pressure to the top of the workpiece to prevent the workpiece

from lifting while cutting, but not so much that the workpiece

drags. The vertical portion provides a blade guard to prevent

accidental blade contact.

HOLD DOWN FOOT LOCK LEVER

Allows you to raise or lower the hold down foot/blade guard

and secure it at desired heights.

SAWDUST BLOWER

Keeps the line of cut on workpiece clean for more accurate

scroll cuts.

SAWDUST EXHAUST

Your saw has a sawdust exhaust that fits a small shop

vacuum hose.

TENSION

ADJUSTING

KNOB

AIR HOSE

BLADE HOLDER

QUICK

RELEASE KNOB

SAWDUST

BLOWER

HOLD DOWN

FOOT LOCK LEVER

45˚

30˚

15˚

PLAIN END

BLADE KNOB

SAW BLADE

HOLD DOWN FOOT/

BLADE GUARD

SAW TABLE

TABLE LOCK / BEVEL

ADJUSTMENT LEVER

SAWDUST EXHAUST

Page 9

BEVEL SCALE

Fig. 4

Page 10

FEATURES

SAW TABLE

Your scroll saw has an aluminum saw table that provides a

working surface to support your workpiece.

TABLE LOCK LEVER

Allows you to tilt the table and lock it at the desired angle up

to 45 degrees.

ASSEMBLY

Your 16 in. scroll saw was fully assembled at the factory.

Before operating this tool, it is important to check all alignments and settings. Normal handling during shipment may

have changed settings.

WARNING:

To avoid serious personal injury from unexpected tool

movement, always securely mount scroll saw to a

workbench.

MOUNTING SCROLL SAW TO WORKBENCH

See Figure 5.

If the scroll saw is to be used in a permanent application, we

recommend that you secure it in a permanent location such

as a workbench. When mounting the saw to a workbench,

holes should be drilled through the supporting surface of the

workbench using dimensions illustrated.

BEVEL SCALE

The bevel scale and indicator are located on the front of the

saw for easy viewing. They show the angle of the table.

■ Each hole in the base of the saw should be bolted

securely using 5/16 in. diameter machine bolts, lock

washers, and hex nuts (not included). Bolts should be of

sufficient length to accommodate the saw base, lock

washers, hex nuts, and the thickness of the workbench.

■ Locate and mark the holes where scroll saw is to be

mounted.

■ Drill (3) 3/8 in. diameter holes through workbench.

■ Place scroll saw on workbench aligning holes in the

base with holes drilled in the workbench.

■ Insert all three 5/16 in. bolts and tighten securely with lock

washers and hex nuts.

Note: All bolts should be inserted from the top. Install the

lock washers and hex nuts from the underside of the bench.

Supporting surface where scroll saw is mounted should be

examined carefully after mounting to insure that no movement during use can result. If any tipping or walking is noted,

secure workbench or supporting surface before beginning

cutting operations.

12 in.

5 in.

dia. hole

2-5/32 in.

3/8 in.

24 in.

Page 10

17 in.

6-13/16 in.

2 in.

Fig. 5

Page 11

ASSEMBLY

CLAMPING SCROLL SAW TO WORKBENCH

See Figure 6.

If the scroll saw is to be used in a portable application, we

recommend that you fasten it permanently to a mounting

board that can easily be clamped to a workbench or other

supporting surface. The mounting board should be of sufficient size to avoid tipping of saw while in use.

■ Mount saw to board using holes in frame as a template for

hole pattern or the diagram in

the holes where scroll saw is to be mounted.

■ Follow last three steps in previous section called Mount-

ing Scroll Saw to Workbench.

Make sure mounting bolts are long enough to go through

holes in the saw frame, material being mounted to, lock

washers, and hex nuts.

Note: It may be necessary to countersink hex nuts and

washers on bottom side of mounting board.

Figure 5

. Locate and mark

C-CLAMP

MOUNTING

BOARD

C-CLAMP

45˚

30˚

15˚

WORKBENCH

Fig. 6

ADJUSTMENTS

WARNING:

To prevent accidental starting that could cause possible

serious personal injury, turn off the saw and unplug

before making any adjustments.

HOLD DOWN FOOT/BLADE GUARD

See Figure 7.

The hold down foot should be adjusted so it applies light

pressure to the top surface of the work being cut. Tighten

securely after adjustment has been made.

■ Loosen the hold down foot lock lever.

■ Move the hold down foot to the desired position.

■ Tighten the hold down foot lock lever.

The tall, front part of the hold down foot acts as a blade guard

to prevent accidental contact with the blade.

SAWDUST BLOWER

See Figure 7.

The dust blower is designed and preset to direct air to the

most effective point on the cutting line. Be sure hold down

foot is properly adjusted to secure workpiece and to direct air

to the cutting surface.

SAWDUST

BLOWER

HOLD DOWN FOOT/

BLADE GUARD

AIR

HOSE

HOLD DOWN FOOT

LOCK LEVER

45˚

30˚

15˚

Fig. 7

Page 11

Page 12

ADJUSTMENTS

SQUARING TABLE TO THE BLADE

See Figures 8 and 9.

■ Loosen the hold down foot lock lever and move hold down

rod all the way up. Tighten lever.

■ Loosen the table lock lever and move the table until it is

approximately perpendicular, or at right angle to the

blade.

■ Place a small square on the table next to the blade to

check if the table is 90 degrees to the blade. If adjustment

is needed, raise or lower the table until table is 90 degrees

to the blade and securely tighten the table lock lever.

■ Loosen the screw holding the scale indicator, move

indicator to the 0 degree mark and securely tighten screw.

Remember, the bevel scale is a convenient guide but

should not be relied upon for precision. Make practice

cuts on scrap material to determine if your angle settings

are correct.

■ Adjust the hold down foot to desired position and securely

tighten the hold down foot lock lever.

HOLD

DOWN ROD

SMALL

COMBINATION

SQUARE

HOLD DOWN FOOT

LOCK LEVER

HOLD DOWN FOOT/

BLADE GUARD

45˚

30˚

15˚

SAW

BLADE

SETTING THE TABLE FOR HORIZONTAL OR

BEVEL CUTTING

See Figure 9.

A bevel scale is provided under the work table as a convenient guide for setting the approximate table angle for bevel

cutting. When greater precision is required, make practice

cuts on scrap material and adjust the table as necessary for

your requirements.

INSTALLING BLADES

Scroll saw blades wear out quickly and must be replaced

frequently for best cutting results. Expect to break some

blades while you learn to use and adjust your saw. Blades

generally stay sharp for 1/2 hour to 2 hours of cutting,

depending on type of material and speed of operation.

Pin End Blades

See Figures 10 and 11.

■ Turn off and unplug the saw from outlet.

WARNING:

To avoid injury from accidental starting, always turn off

and unplug the saw before installing, removing or replacing

the blade.

TABLE LOCK

LEVER

BEVEL

SCALE

45˚

30˚

15˚

SCREW

TABLE LOCK

LEVER

0˚

Fig. 8

SCALE

INDICATOR

Fig. 9

■ On the top back of the saw, rotate the quick release knob

to the left or counterclockwise to loosen blade tension.

See Figure 4.

■ Place blade through the opening with the teeth of the

blade to the front of the saw and pointing down toward the

table. Engage the pin into the "V" notch of the lower blade

holder.

See Figure 10.

■ Pull up on the blade and push down on the saw arm to

engage the upper pin in the "V" notch of the upper blade

holder.

See Figure 11.

Page 12

Note: If the blade touches the hold down foot on either side

then the hold down foot must be adjusted.

■ Loosen the hold down foot lock lever.

See Figure 8.

■ To center the hold down foot around the saw blade, slide

the hold down foot to the side.

■ Tighten the hold down foot lock lever.

■ To tension the blade, rotate the quick release knob (outer,

larger knob) 1/4 turn to the right or clockwise to apply

tension to the blade. Fine adjustments of the blade

Page 13

ADJUSTMENTS

tension may be performed using the tension adjusting

knob (inner, smaller knob) at any time, while the blade is

under tension or not.

Plain End Blades

See Figures 12 – 15.

■ Turn off and unplug the saw from outlet.

WARNING:

To avoid injury from accidental starting, always turn off

and unplug the saw before installing, removing, or

replacing the blade.

■ On the top back of the saw, rotate the quick release knob

to the left or counterclockwise to loosen the blade tension.

See Figure 4.

■ Insert blade changing rod into blade clamp slot in lower

blade holder.

■ Using the "T" handle wrench provided, loosen the blade

knob.

See Figure 12.

repeat procedure with upper blade holder.

■ Remove the blade.

■ Take notice of the orientation of the blade holder blocks

on both the upper and lower blade holders. Note the

location of both the "V" notch and chamfer on each.

■ Carefully loosen lower blade knob until blade holder block

can be removed.

■ Flip blade holder block 180°, then rotate "V" notch up 90°

as shown in figure 13. Blade holder block will fit flush

against blade holder.

■ Secure in place with lower blade knob.

■ Carefully loosen upper blade knob until blade holder

block can be removed.

■ Flip blade holder block 180°, then rotate "V" notch down

90° as shown in figure 14. Blade holder block will fit flush

against blade holder.

■ Secure in place with upper blade knob.

■ Place new blade through the opening in the table with the

teeth of the blade to the front of the saw and pointing down

toward the table. Next, place blade in the lower blade

holder into the slot that enlarges as you loosen the blade

knob.

■ Position blade and securely tighten lower blade knob.

■ Remove blade changing rod and reposition it in blade

clamp slot in upper blade holder.

■ Pull up on the blade and down on the saw's upper arm to

install blade into upper blade holder.

Note: If the blade touches the hold down foot on either side

then the hold down foot must be adjusted.

■ Loosen the hold down foot lock lever.

■ To center the hold down foot around the saw blade, slide

the hold down foot to the side.

See Figure 12.

Remove the blade changing rod and

See Figure 8.

LOWER BLADE HOLDER FOR PIN END BLADES

PIN END BLADE

CHAMFER

BLADE

HOLDER BLOCK

CORRECT ORIENTATION

FOR BLADE HOLDER BLOCK

UPPER BLADE HOLDER FOR PIN END BLADES

BLADE HOLDER BLOCK

CHAMFER

CORRECT ORIENTATION

FOR BLADE HOLDER BLOCK

LOWER BLADE HOLDER FOR PLAIN END BLADES

BLADE KNOB WITH

SOCKET HEAD INSERT

"T" HANDLE WRENCH

BLADE CHANGING ROD

LOWER BLADE HOLDER FOR PLAIN END BLADES

BLADE

HOLDER BLOCK

CORRECT ORIENTATION

FOR BLADE HOLDER BLOCK

BLADE KNOB

(FOR USE WITH PLAIN

END BLADES ONLY)

BLADE CLAMP

BLADE KNOB

CHAMFER

BLADE

CLAMP

Fig. 10

BLADE KNOB

PIN

END BLADE

Fig. 11

Fig. 12

BLADE

CLAMP

Fig. 13

Page 13

Page 14

ADJUSTMENTS

■ Tighten the hold down foot lock lever.

■ Position blade and securely tighten upper blade knob.

■ Remove blade changing rod.

■ Turn the quick release knob to the right or clockwise to

tension the blade.

■ Turn the tension adjusting knob to the right, clockwise or

to the left, counterclockwise until the blade is in desired

tension.

ADJUSTING BLADE TENSION

See Figures 16 and 17.

■ Turn off and unplug the saw.

WARNING:

Failure to unplug your saw could result in accidental

starting causing possible serious personal injury.

■ Tension adjusting knob is on the top of the saw.

Figure 17.

knob) 1/4 turn to the left or counterclockwise to release

blade tension.

■ Turn tension adjusting knob (upper, smaller knob) to the

right or clockwise to increase tension. Turn it to the left or

counterclockwise to decrease blade tension.

Note: Adjustments of blade tension can be made at any-

time. The quick release knob can be either released

or engaged while making adjustments with the tension adjusting knob.

■ Rotate quick release knob to the right or clockwise 1/4

turn to engage tension before using the scroll saw.

Check tension by the sound the blade makes when plucked

like a guitar string. This method of adding tension to the blade

can be developed with practice and requires knowing your

scroll saw.

■ Pluck the back straight edge of blade while turning

tension adjusting knob. Sound should be a musical note.

Sound becomes less flat as tension increases. Sound

decreases with too much tension.

Note: Be careful not to over tension the blade. Too much

tension may cause blade to break as soon as you start

cutting. Too little tension may cause blade to bend or

break before teeth wear out.

Rotate the quick release knob (outer, larger

See

UPPER BLADE HOLDER FOR PLAIN END BLADES

CHAMFER

BLADE KNOB

PLAIN

END BLADE

BLADE

HOLDER BLOCK

CORRECT ORIENTATION

FOR BLADE HOLDER BLOCK

UPPER BLADE HOLDER FOR PLAIN END BLADES

BLADE KNOB WITH

"T" HANDLE

WRENCH

BLADE

CHANGING ROD

TO

RELEASE

QUICK RELEASE KNOB

TENSION ADJUSTING KNOB

SOCKET HEAD INSERT

ENGAGE

BLADE

CLAMP

Fig. 14

Fig. 15

TO

Fig. 16

Page 14

TO DECREASE

TENSION

TO INCREASE

TENSION

Fig. 17

Page 15

0˚

OPERATION

This scroll saw is designed to cut wood, wood composition

products, plastic, and nonferrous metals (aluminum, brass,

copper).

GENERAL OPERATION

Please read and understand the following items concerning

your scroll saw before attempting to use the saw.

■ There is a learning curve for each person who wants to

use this saw. During that period of time it is expected that

some blades will break until you learn how to use and

adjust the saw.

■ Allow the saw to cut material by guiding the workpiece into

the blade as it moves. Do not force the work.

■ The blade teeth cut material only on the down stroke.

■ You must guide the workpiece into the blade slowly

because the teeth of the blade are very small and can only

remove material on the down stroke.

■ Scroll saw blades wear out and must be replaced frequently for best cutting results. Scroll saw blades generally stay sharp for 1/2 hour to 2 hours of cutting, depending on type of material and speed of operation.

■ To get accurate cuts, be prepared to compensate for the

blade's tendency to follow the wood grain as you are

cutting wood.

■ In cutting wood, best results are achieved when cutting

wood less than one inch thick.

■ When cutting wood thicker than one inch, the user must

guide the workpiece very slowly into the blade and take

extra care not to bend or twist the blade while cutting.

■ When choosing a blade to use with your scroll saw,

consider the following carefully:

• Very fine, narrow blades should be used to scroll cut in

thin material 1/4 in. thick or less.

• Most blade packages state the size or thickness and

type of material which that blade is intended to cut.

Package should also state the radius, or size of curve,

which can be cut with that blade.

• Wider blades cannot cut curves as tight or small as

thinner blades.

■ Blades wear faster:

• When cutting plywood and other laminates.

• When cutting material thicker than 3/4 in.

• When cutting hardwood.

• When side pressure is applied to the blade.

ON/OFF KNOB WITH VARIABLE SPEED

See Figure 18.

Your scroll saw has an easy access On/Off knob with

variable speed.

■ Pull the knob out to turn ON the saw, and push the knob

in to turn OFF the saw.

Note: After saw is turned on, a hesitation before blade

movement is normal.

WARNING:

Never leave the saw unattended until the blade has come

to a complete stop to prevent serious personal injury.

LOCK

OFF POST

ON/OFF KNOB

■ By turning the knob, the variable speed control may be

adjusted from the high speed of approximately 1550 SPM

(Strokes Per Minute) to the low speed of approximately

400 SPM. Suggested speeds are identified under Choice

of Blade and Speed, page 17. Turn the On/Off knob to the

right or clockwise to increase strokes per minute and to

the left or counterclockwise to reduce the strokes per

minute.

Fig. 18

Page 15

Page 16

0˚

OPERATION

LOCK OFF POST

See Figure 19.

To prevent unauthorized use of your scroll saw, we suggest

that you disconnect it from the power supply and lock the

knob in the OFF position. A padlock with a 3/16 in. shackle

should be used. When the lock is installed and locked, as

illustrated, the switch is inoperable. Store the padlock key in

another location.

■ To lock saw in the OFF position, install a padlock through

the lock off post beside the knob as illustrated and lock the

padlock. (Padlock is not supplied with the saw.)

WARNING:

For your own safety, always push the knob OFF when

machine is not in use. Also, in the event of a power failure,

push knob OFF. Lock the scroll saw switch OFF with a

padlock. This will prevent the machine from starting up

again when the power comes back on. Failure to heed this

warning can result in serious personal injury.

INTERIOR SCROLL CUTTING

See Figure 20.

■ One of the features of a scroll saw is that it can be used

to make scroll cuts on the interior of a board without

breaking or cutting through the edge or perimeter of the

board.

PADLOCK

ON/OFF KNOB

Fig. 19

INTERIOR

CUT

WARNING:

To avoid possible serious injury from accidental starting,

always turn the switch OFF and remove plug from power

source outlet before removing or replacing the blade.

■ To make interior cuts in a board, remove the scroll saw

blade as explained in the Installing Blades section on

pages 12 – 14.

■ Drill a 1/4 in. hole in the board to be used to make interior

cuts.

■ Place the board on the saw table with the hole in the board

over the access hole in the table.

■ Install blade through hole in board then adjust the hold

down foot and the blade tension. See pages 16 and 17.

■ When finished making the interior scroll cuts, simply

remove the blade from the blade holders as described in

the Installing Blades section, and remove the board

from the table.

DRILL HOLE

WORKPIECE

45˚

30˚

15˚

Fig. 20

Page 16

Page 17

OPERATION

STACK CUTTING

See Figure 21.

After becoming well acquainted with your saw through

practice and experience, you may wish to try stack cutting.

Stack cutting may be used when several identical shapes

need to be cut. Several pieces of wood may be stacked on

top and secured to each other before cutting. The wood

pieces may be joined together by placing double sided tape

between each piece or by wrapping masking tape around the

corners or ends of the stacked wood. You must attach the

stacked pieces of wood to each other so they will move on the

table as a single piece of material.

TAPE

WARNING:

To avoid possible serious personal injury, do not cut more

than one loose piece of material at a time.

45˚

30˚

15˚

WOOD

PIECES

Fig. 21

CHOICE OF BLADE AND SPEED

The scroll saw accepts a wide variety of blade widths and thicknesses for cutting wood and other fibrous materials. Your saw

uses 5 inch long blades of either the pin end or the plain end style. The blade width and thickness and the number of teeth

per inch to use are determined by the type of material and the size of the radius being cut. A full selection of scroll saw blades

are available at your local Ryobi dealer.

Note: As a general rule, always select narrow blades for intricate curve cutting, and wide blades for straight and large curve

cutting.

Speed or

Teeth/Inch Width Thickness Strokes Per Material Cut

Minute

10 .110 in. .020 in. 1200-1550 Popular size for cutting hard and soft

woods 3/16 in. up to 2 in. Plastics, paper,

felt, bone, etc.

15 .110 in. .020 in. 600-1200 Wood, plastics, extremely thin cuts on

materials 3/32 in. to 1/2 in. thick.

18 .095 in. .010 in. 400-600 For tight radius work in thin materials

3/32 in. to 1/8 in. wood, veneer, bone,

fiber, ivory, plastic, etc.

BEFORE EACH USE:

■ INSPECT YOUR SAW. Disconnect the saw. To avoid

injury from accidental starting, turn the switch OFF and

unplug the saw before changing the setup or removing

covers, guards, or blade.

■ INSPECT YOUR WORKPIECE. Make sure there are no

nails or foreign objects in the workpiece to be cut.

■ USE EXTRA CAUTION WITH LARGE, VERY SMALL,

OR AWKWARD WORKPIECES.

• Never use this tool to cut pieces too small to hold by

hand.

Page 17

• Always use extra supports (tables, saw horses, blocks,

etc.) for any workpiece large enough to tip when not

held down to the table top.

• Never use another person as a substitute for a table

extension, or as additional support for a workpiece or to

help feed, support, or pull the workpiece.

• When cutting an irregularly shaped workpiece, plan

your work so it will not pinch the blade. A piece of

molding, for example, must lay flat or be held by a fixture

or jig that will not let it twist, rock, or slip while being cut.

Page 18

OPERATION

• Properly support round material such as dowel rods.

They have a tendency to roll during a cut, causing the

blade to "bite." To avoid this, always use a "v" block.

• Clear everything except the workpiece and related

support devices off the table before plugging into power

and turning the saw on.

■ PLAN THE WAY YOU WILL HOLD THE WORKPIECE

FROM START TO FINISH. Do not hand hold pieces so

small that your fingers will go under the work hold-down.

■ BEFORE FREEING ANY JAMMED MATERIAL:

• Turn switch OFF.

• Wait for all moving parts to stop.

• Unplug the saw.

■ WHEN BACKING OUT OF THE WORKPIECE, THE

BLADE MAY BIND IN THE KERF (CUT). THIS IS

MAINTENANCE

WARNING:

When servicing, use only identical Ryobi replacement

parts. Use of any other part may create a hazard or cause

product damage.

USUALLY CAUSED BY SAWDUST CLOGGING UP

THE KERF. IF THIS HAPPENS:

• Turn switch OFF.

• Wait for all moving parts to stop.

• Unplug the saw.

• Remove the blade from the blade holders.

• Remove the workpiece with blade from the table.

• Remove blade from workpiece.

WARNING:

Before removing loose pieces from the table, turn saw off

and wait for all moving parts to stop to avoid serious

personal injury.

BRUSH CAP

WARNING:

To prevent accidental starting that could cause possible

serious personal injury, turn off and unplug the saw

before maintaining or lubricating your scroll saw.

GENERAL MAINTENANCE

■ Keep your Scroll Saw clean.

■ After cleaning the table top initially, apply a thin coat of

automobile type (paste) wax to the table top so the wood

slides easily while cutting.

WARNING:

If the power cord is worn, cut, or damaged in any way,

have it replaced immediately by a qualified service

technician at an authorized service center to avoid risk of

personal injury.

MOTOR BRUSHES

See Figure 22.

Your saw has externally accessible brush assemblies that

should be checked periodically for wear. When one of the

two brushes becomes worn, replace both brushes.

■ Unplug your saw.

0˚

MOTOR BRUSH

BRUSH CAP

MOTOR BRUSH

Fig. 22

WARNING:

Failure to unplug your saw could result in accidental

starting causing serious injury.

■ Remove brush cap with a flat blade screwdriver.

■ Remove brush assembly. Gently pry the brush assembly

out using a small screwdriver, point of a nail or paperclip,

etc.

■ Check for wear. If one brush is worn down shorter than

1/4 in., replace both brushes. Do not replace one side

without replacing the other.

Page 18

Page 19

MAINTENANCE

■ Reassemble using new brush assembly. Make sure

curvature of brush matches curvature of motor and that

brush moves freely in brush tube. Use the blunt end of

something thin (eraser end of pencil, etc.) to push the

brush into the tube until it stays.

■ Make sure brush cap is oriented correctly (straight) and

replace.

■ Tighten brush cap using a hand powered screwdriver

only. Do not overtighten.

■ Repeat for other brush.

TROUBLESHOOTING

WARNING:

For your own safety, turn switch OFF and remove plug from power outlet before adjusting or aligning your scroll saw.

PROBLEM CAUSE SOLUTION

Motor will not run.

1. Problem with ON-OFF switch,

power cord, or outlet.

2. Motor defective.

1. Have worn parts replaced before using

Scroll Saw again. Have the proper

outlet installed by a qualified electrician.

2. Do not attempt any repair. Have

repaired by a qualified service technician at an authorized service center.

Blades breaking.

Vibration (there is always

some vibration when the saw

is running).

Excessive Noise.

1. Too much tension.

2. Feeding too quickly.

3. Wrong blade.

4. Blade twisting in wood.

1. Improper mounting of saw.

2. Mounting surface.

3. Loose table or table resting

against motor.

4. Loose motor mounting.

1. Blade tension rod has been

overtightened.

1. Adjust tension.

2. Reduce feed rate.

3. Narrow blades for cutting thin wood or

tight corners and turns, wide blades for

thicker wood or wide turns.

4. Reduce side pressure on blade, check

blade tension.

1. Check mounting.

2. Check mounting in manual.

3. Tighten table lock lever.

4. Tighten mounting screws.

1. Loosen tension adjusting knob.

2. Check blade length. Blade should be 5

inches long.

3. Make sure plain end blades have been

installed fully in blade clamp for correct

blade clamp engagement.

Page 19

Page 20

RYOBI 16 in. SCROLL SAW – MODEL NUMBER SC155VS

15

14

16

17

13

Page 20

8

12

23

20

5

7

18

21

6

4

11

19

10

3

54

2

9

1

50

53

46

52

37

38

35

34

22

26

27

28

29

25

30

24

19

49

45

43

31

33

51

47

48

46

45

44

41

42

36

32

35

34

37

40

FIGURE A

39

38

Page 21

RYOBI 16 in. SCROLL SAW – MODEL NUMBER SC155VS

The model number will be found on a plate attached to the base. Always mention the model number in all correspondence regarding your SCROLL

SAW or when ordering repair parts.

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

PARTS LIST FOR FIGURE A

Key Part

No. Number Description Quan.

Key Part

No. Number Description Quan.

1 350305122 Flat Washer (M5).....................................................1

2 105022006 Clamp ......................................................................1

3 105023002 Hold Down Foot.......................................................1

4 102031006 Support Plate...........................................................1

5 700305016 * Bolt (M5 x 16 Hex Socket) ...................................... 1

6 104056002 Lock Lever ...............................................................1

7 104055006 Connector ................................................................1

Page 21

8 700305018 * Bolt (M5 x 18 Hex Soc.) ..........................................2

9 105021000 Hold Down Rod .......................................................1

10 300030050 * Hex Nut (M5)........................................................... 2

11 981368001 Hex Nut (M6 x 3.6) ..................................................1

12 105020004 Support Bar .............................................................1

13 180030801 Screw (M8 x 10) ......................................................2

14 168043003 Warning Label .........................................................1

15 168042007 Warning Label .........................................................1

16 105013007 Hose ........................................................................1

17 102020005 Bellows ....................................................................1

18 105002006 Housing ...................................................................1

19 105016002 Bushing....................................................................2

20 979827001 Tension Adjusting Knob ..........................................1

21 979736001 Quick Release Knob................................................1

22 979742001 Rubber Boot ............................................................1

23 420010031 Roll Pin (M3 x 16).................................................... 1

24 160030601 * Screw (M6 x 15 Pan Hd.)........................................ 4

25 105025004 Arm Cover (Right) ...................................................1

26 105027006 Cam ......................................................................... 1

27 105024008 Arm Spring .............................................................. 1

28 102019004 Tension Nut ............................................................. 1

29 979828001 Spacer .....................................................................1

30 105028002 Tension Bolt .............................................................1

31 981366001 "E" Ring (E-3) .......................................................... 1

32 105012001 Wedge .....................................................................1

33 105019003 Arm Cover ...............................................................1

34 104030006 Shoulder Bolt........................................................... 2

35 380314300 Spring Washer.........................................................2

36 105016005 Lower Arm ............................................................... 1

37 420010501 Roll Pin (M5 x 14).................................................... 2

38 981395001 * Wing Knob...............................................................2

39 101004200 Lower Blade Holder................................................. 1

40 101031100 Lower Blade Clamp .................................................1

41 105014003 Eccentric Coupling ..................................................1

42 180030600 * Set Screw (M6 x 6 Hex Soc. Hd.) ........................... 1

43 101074001 * Blade ....................................................................... 1

44 100025009 Bearing ....................................................................1

45 979758001 Bearing (625ZZ) ......................................................2

46 360305000 * Lock Washer (M5)...................................................2

47 700305018 * Bolt (M5 x 18 Hex Soc. Hd.).................................... 1

48 104062002 Bearing Holder ........................................................1

49 230030400 * Screw (M4 x 8 Pan Hd.).......................................... 1

50 800305018 * Cap Screw (M5 x 20 Hex Soc. Hd.)........................ 1

51 104038004 Arm Link ..................................................................1

52 101003204 Upper Blade Holder................................................. 1

53 101030104 Upper Blade Clamp .................................................1

54 105011005 Upper Arm ............................................................... 1

* Standard Hardware Item – May Be Purchased Locally

Page 22

RYOBI 16 in. SCROLL SAW – MODEL NUMBER SC155VS

Page 22

5

6

4

3

7

8

10

9

11

2

27

28

29

1

31

30

12

26

13

38

41

34

37

40

39

35

34

32

33

36

34

37

25

15

23

14

24

FIGURE B

39

42

43

21

22

15

16

17

18

19

20

Page 23

RYOBI 16 in. SCROLL SAW – MODEL NUMBER SC155VS

The model number will be found on a plate attached to the base. Always mention the model number in all correspondence regarding your SCROLL

SAW or when ordering repair parts.

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

PARTS LIST FOR FIGURE B

Key Part

No. Number Description Quan.

Key Part

No. Number Description Quan.

1 102039004 Table Screw ............................................................ 1

2 105015009 Table........................................................................1

3 190030500 * Screw (M5 x 8 Pan Hd.).......................................... 3

4 979766001 Screw (M4 x 16 Pan Hd.) ........................................ 2

5 168041001 Warning Label .........................................................1

6 981365001 Cover Plate..............................................................1

7 981369001 Nozzle......................................................................1

Page 23

8 300305015 * Hex Bolt (M5 x 16)................................................... 3

9 Incl w/#8 Washer (M5)............................................................3

10 981362001 Base ........................................................................1

11 981363001 Data Plate................................................................1

12 979791001 Strain Relief .............................................................1

13 979790001 Cord Assembly ........................................................1

14 981377001 Motor Cover.............................................................1

15 981378001 Screw (M5 x 12 Pan Hd.) ........................................ 5

16 981375001 Control Box Cover ...................................................1

17 981372001 PC Board Assembly ................................................ 1

18 979798001 Gasket .....................................................................1

19 981376001 Control Box..............................................................1

20 981373001 Switch Knob ............................................................ 1

21 981370001 Switch Label ............................................................ 1

22 981371001 Screw (M5 x 9 Pan Hd.) .......................................... 3

23 981396001 Brush Assembly.......................................................2

24 981374001 Screw (M4 x 15 Pan Hd.) ........................................ 2

25 981397001 Brush Cap ............................................................... 2

26 980123001 Motor Assembly....................................................... 1

27 350308161 * Spring Washer (M8) ................................................2

28 360308000 * Lock Washer (M8) ................................................... 2

29 100308020 Screw (M8 x 25 Hex Hd.) ........................................ 2

30 981364001 Table Support ..........................................................1

31 160030400 * Screw (M4 x 8 Pan Hd.).......................................... 3

32 981379001 Star Washer (M5) .................................................... 1

33 100030501 * Screw (M5 x 15 Pan Hd.)........................................ 4

34 360305000 * Lock Washer (M5) ................................................... 7

35 981367001 Spacer .....................................................................3

36 104022003 Pointer .....................................................................1

37 190030500 * Screw (M5 x 8 Pan Hd.).......................................... 3

38 981361001 Support Screw .........................................................1

39 350306162 * Washer (M6)............................................................2

40 105018007 Bevel Scale ............................................................. 1

41 104056002 Lock Lever ...............................................................1

42 101060002 "T" Handle Wrench.................................................. 1

43 101058102 Blade Changing Rod ...............................................1

972000-704 Operator's Manual

* Standard Hardware Item – May Be Purchased Locally

Page 24

OPERATOR'S MANUAL

16 in. (406 mm) Scroll Saw

Model SC155VS

EXTENSION CORD CAUTION

When using a power tool at a considerable distance from a power

source, be sure to use an extension cord that has the capacity to

handle the current the tool will draw. An undersized cord will cause

a drop in line voltage, resulting in overheating and loss of power.

Use the chart to determine the minimum wire size required in an

extension cord. Only round jacketed cords should be used.

When working with a tool outdoors, use an extension cord that is

designed for outside use. This is indicated by the letters "WA" on

the cord's jacket.

Before using any extension cord, inspect it for loose or exposed

wires and cut or worn insulation.

• SERVICE

Now that you have purchased your tool, should a need ever exist for repair parts or service,

simply contact your nearest Ryobi Authorized Service Center. Be sure to provide all

pertinent facts when you call or visit. Please refer to the Service Center insert or call 1-800525-2579 in the United States or 1-800-265-6778 in Canada for your nearest Authorized

Service Center.

**Ampere rating

(on tool data plate) 0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

CAUTION: Keep the extension cord clear of the working

area. Position the cord so that it will not get caught on workpiece,

tools, or other obstructions while you are working with a power

tool.

**Used on 12 gauge - 20 amp circuit.

• MODEL NO.

The model number of your tool will be found on a plate attached to the motor housing.

Please record the model number and serial number in the space provided below.

• MODEL NUMBER SC155VS

• SERIAL NUMBER

RYOBI AMERICA CORPORATION

1424 Pearman Dairy Road Anderson SC 29625

Post Office Box 1207 Anderson SC 29622

Phone 1-800-525-2579

www.ryobi.com

972000-704

RYOBI CANADA INC.

P.O. Box 910

Cambridge, Ontario N1R 6K2

Phone 1-800-265-6778

Loading...

Loading...