Page 1

OPERATOR'S MANUAL

CORDLESS DRILL-DRIVER

MODEL NOS. SA1202 / SA14402 / SA1802

24

20

5

This new drill has been engineered and manufactured to our Ryobi’s high standard for dependability, ease of operation,

and operator safety. When properly cared for, the drill will give you years of rugged, trouble-free performance.

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s manual before using this product.

Thank you for buying a Ryobi product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

■■

■ Introduction .................................................................................................................................................................... 2

■■

■■

■ General Safety Rules..................................................................................................................................................3-4

■■

■■

■ Specific Safety Rules..................................................................................................................................................... 4

■■

■■

■ Important Safety Instructions for Charger...................................................................................................................... 5

■■

■■

■ Symbols ......................................................................................................................................................................... 6

■■

■■

■ Specifications................................................................................................................................................................. 7

■■

■■

■ Unpacking ...................................................................................................................................................................... 7

■■

■■

■ Applications....................................................................................................................................................................7

■■

■■

■ Features......................................................................................................................................................................8-9

■■

■■

■ Adjustments ............................................................................................................................................................ 10-12

■■

■■

■ Operation ................................................................................................................................................................ 13-16

■■

■■

■ Maintenance ........................................................................................................................................................... 17-18

■■

■■

■ Parts Ordering / Service .............................................................................................................................................. 20

■■

INTRODUCTION

The Cordless Drill-Driver has many features for making the use of this product more pleasant and enjoyable. Safety,

performance, and dependability have been given top priority in the design of this product making it easy to maintain

and operate.

WARNING:

Do not attempt to use this product until you thoroughly read and completely understand the operator’ s manual. Pa y

close attention to the safety rules, including Dangers, W arnings, and Cautions. If you use y our product properly and

only as intended, you will enjoy years of safe, reliable service.

Look for this symbol to point out important safety precautions. It

means attention!!! Your safety is involved.

WARNING:

The operation of any tool can result in foreign objects being thrown into your eyes, which can result in

severe eye damage. Before beginning operation, always wear safety goggles or safety glasses with side

shields and a full face shield when needed. We recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields. Always wear eye protection which is marked to

comply with ANSI Z87.1.

Page 2

Page 3

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to

follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SA VE THESE INSTR UCTIONS

WORK AREA

■ Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

■ Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases,

or dust. Power tools create sparks which may ignite the

dust or fumes.

■ Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to

lose control.

ELECTRICAL SAFETY

■ A battery operated tool with integral batteries or a

separate battery pack must be recharged only with

the specified charger for the battery. A charger that

may be suitable f or one type of battery may create a risk

of fire when used with another battery .

■ Use battery operated tool only with specifically

designated battery pack. Use of any other batteries may

create a risk of fire.

■ Use battery only with charger listed.

MODEL BATTERY PACK CHARGER

SA1202 130147008 140120005

SA14402 130224010/1314702 1412001

SA1802 130224007/1323303 1423701

1322401/130256001

■ Do not abuse the cord. Never use the cord to carry

the charger. Keep cord away from heat, oil, sharp

edges, or moving parts. Replace damaged cords immediately. Damaged cords may create a fire.

PERSONAL SAFETY

■ Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use

tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while oper-

ating power tools may result in serious personal injury.

■ Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing, and

gloves away from moving parts. Loose clothes, jew-

elry, or long hair can be caught in moving parts.

■ Avoid accidental starting. Be sure switch is in the

locked or off position before inserting battery pack.

Carrying tools with your finger on the switch or inserting

the battery pack into a tool with the switch on invites accidents.

■ Remove adjusting keys or wrenches before turning

the tool on. A wrench or a key that is left attached to a

rotating part of the tool may result in personal injury.

■ Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enable better

control of the tool in unexpected situations.

■ Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

TOOL USE AND CARE

■■

■ Use clamps or other practical way to secure and sup-

■■

port the workpiece to a stable platform. Holding the

work by hand or against your body is unstable and may

lead to loss of control.

■ Do not force tool. Use the correct tool for your application. The correct tool will do the job better and saf er at

the rate for which it is designed.

■ Do not use tool if switch does not turn it on or off. A

tool that cannot be controlled with the switch is dangerous and must be repaired.

■ Disconnect battery pack from tool or place the switch

in the locked or off position before making any adjustments, changing accessories, or storing the tool.

Such preventiv e safety measures reduce the risk of starting the tool accidentally.

■ Store idle tools out of reach of children and other

untrained persons. Tools are dangerous in the hands of

untrained users.

■ When battery pack is not in use, keep it away from

other metal objects like: paper clips, coins, ke ys, nails,

screws, or other small metal objects that can make a

connection from one terminal to another . Shorting the

battery terminals together may cause sparks, burns, or a

fire.

■ Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cutting

edges are less likely to bind and are easier to control.

■ Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may

affect the tool's operation. If damaged, have the tool

serviced before using. Many accidents are caused by

poorly maintained tools.

■ Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool ma y create a risk of injury when used

on another tool.

■ Keep the tool and its handle dry, clean and free from

oil and grease. Always use a clean cloth when cleaning.

Never use brake fluids, gasoline, petroleum-based products, or any strong solvents to clean your tool. Following

this rule will reduce the risk of loss of control and deterioration of the enclosure plastic.

Page 3

Page 4

GENERAL SAFETY RULES

SERVICE

■ Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified personnel may result in a risk of injury.

■ When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

section of this manual. Use of unauthorized parts or

failure to follow Maintenance Instructions may create a

risk of shock or injury.

SPECIFIC SAFETY RULES

■■

■ Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact

■■

hidden wiring. Contact with a "live" wire will also make exposed metal parts of the tool "live" and shock the operator.

ADDITIONAL RULES FOR SAFE OPERATION

■ Know your power tool. Read operator's manual care-

fully. Learn its applications and limitations, as well as

the specific potential hazards related to this tool.

Following this rule will reduce the risk of electric shock,

fire, or serious injury.

■ Always wear safety glasses with side shields. Everyday glasses have only impact resistant lenses. They are

NOT safety glasses. Following this rule will reduce the risk

of eye injury.

IMPORTANT RULES FOR BATTERY TOOLS

■ Battery tools do not have to be plugged into an

electrical outlet; therefore, they are always in operating condition. Be aware of possible hazards when not

using your battery tool or when changing accessories. Following this rule will reduce the risk of electric

shock, fire, or serious personal injury.

■ Do not place battery tools or their batteries near fire

or heat. This will reduce the risk of explosion and possibly

injury.

■ WARNING: Batteries vent hydrogen gas and can ex-

plode in the presence of a source of ignition, such as a

pilot light. To reduce the risk of serious personal injury,

never use any cordless product in the presence of open

flame. An exploded battery can propel debris and chemicals. If exposed, flush with water immediately.

■ Do not charge battery tool in a damp or wet location.

Following this rule will reduce the risk of electric shock.

■ For best results, your battery tool should be charged in

a location where the temperature is more than 50°F but

less than 100°F. Do not store outside or in vehicles.

■ Under extreme usage or temperature conditions, battery leakage may occur. If liquid comes in contact

with your skin, wash immediately with soap and

water, then neutralize with lemon juice or vinegar. If

liquid gets into your eyes, flush them with clean water

for at least 10 minutes, then seek immediate medical

attention. Following this rule will reduce the risk of serious

personal injury.

Page 4

Page 5

IMPORTANT SAFETY INSTRUCTIONS FOR CHARGER

WARNING:

Read and understand all instructions. Failure to

follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

■ Never use a battery that has been dropped or

received a sharp blow. A damaged battery is subject

to explosion. Properly dispose of a dropped battery

immediately. Failure to heed this warning can result in

serious personal injury.

■ Save these instructions. This manual contains important safety and operating instructions for charger.

■ Before using battery charger, read all instructions

and cautionary markings in this manual, on battery

charger, and product using battery charger. Following

this rule will reduce the risk of electric shock, fire, or

serious personal injury.

■ CAUTION: To reduce risk of injury, charge only nickel-

cadmium type rechargeable batteries. Other types of

batteries may burst causing personal injury and damage. Following this rule will reduce the risk of electric

shock, fire, or serious personal injury.

■ Do not expose charger to wet or damp conditions.

Following this rule will reduce the risk of electric shock, fire,

or serious personal injury.

■ Use of an attachment not recommended or sold by

the battery charger manufacturer may result in a risk

of fire, electric shock, or injury to persons. Following

this rule will reduce the risk of electric shock, fire, or

serious personal injury.

■ To reduce risk of damage to charger body and cord,

pull by charger plug rather than cord when disconnecting charger. Following this rule will reduce the risk

of electric shock, fire, or serious personal injury.

■ Make sure cord is located so that it will not be stepped

on, tripped over, or otherwise subjected to damage or

stress. Following this rule will reduce the risk of serious

personal injury.

■■

■ Do not abuse cord. Never carry tool by cord or yank

■■

it to disconnect from receptacle. Keep cord from

heat, oil and sharp edges. Following this rule will reduce

the risk of electric shock or fire.

■ An extension cord should not be used unless absolutely necessary. Use of improper extension cord could

result in a risk of fire and electric shock. If extension cord

must be used, make sure:

a. That pins on plug of extension cord are the

same number, size and shape as those of

plug on charger.

b. That extension cord is properly wired and in

good electrical condition; and

c. That wire size is large enough for AC ampere

rating of charger as specified below:

Cord Length (Feet) 25' 50' 100'

Cord Size (AWG) 16 16 16

Note: AWG = American Wire Gage

■ Do not operate charger with a damaged cord or plug.

If damaged, have replaced immediately by a qualified

serviceman. Following this rule will reduce the risk of

electric shock, fire, or serious personal injury.

■ Do not operate charger if it has received a sharp blow,

been dropped, or otherwise damaged in any way;

take it to a qualified serviceman. Following this rule will

reduce the risk of electric shock, fire, or serious personal

injury.

■ Do not disassemble charger; take it to a qualified

serviceman when service or repair is required. Incorrect reassembly may result in a risk of electric shock

or fire. Following this rule will reduce the risk of electric

shock, fire, or serious personal injury.

■ To reduce the risk of electric shock, unplug charger

from outlet before attempting any maintenance or

cleaning. Turning off controls will not reduce this

risk. Following this rule will reduce the risk of electric

shock, fire, or serious personal injury.

■ Disconnect charger from power supply when not in

use. Following this rule will reduce the risk of electric

shock, fire, or serious personal injury.

■ Save these instructions. Refer to them frequently and

use them to instruct others who may use this tool. If

you loan someone this tool, loan them these instructions also. Following this rule will reduce the risk of

electric shock, fire, or serious personal injury.

WARNING:

Some dust created by power sanding, sa wing, grinding, drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and

other masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures v aries, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially designed

to filter out microscopic particles.

SA VE THESE INSTRUCTIONS

Page 5

Page 6

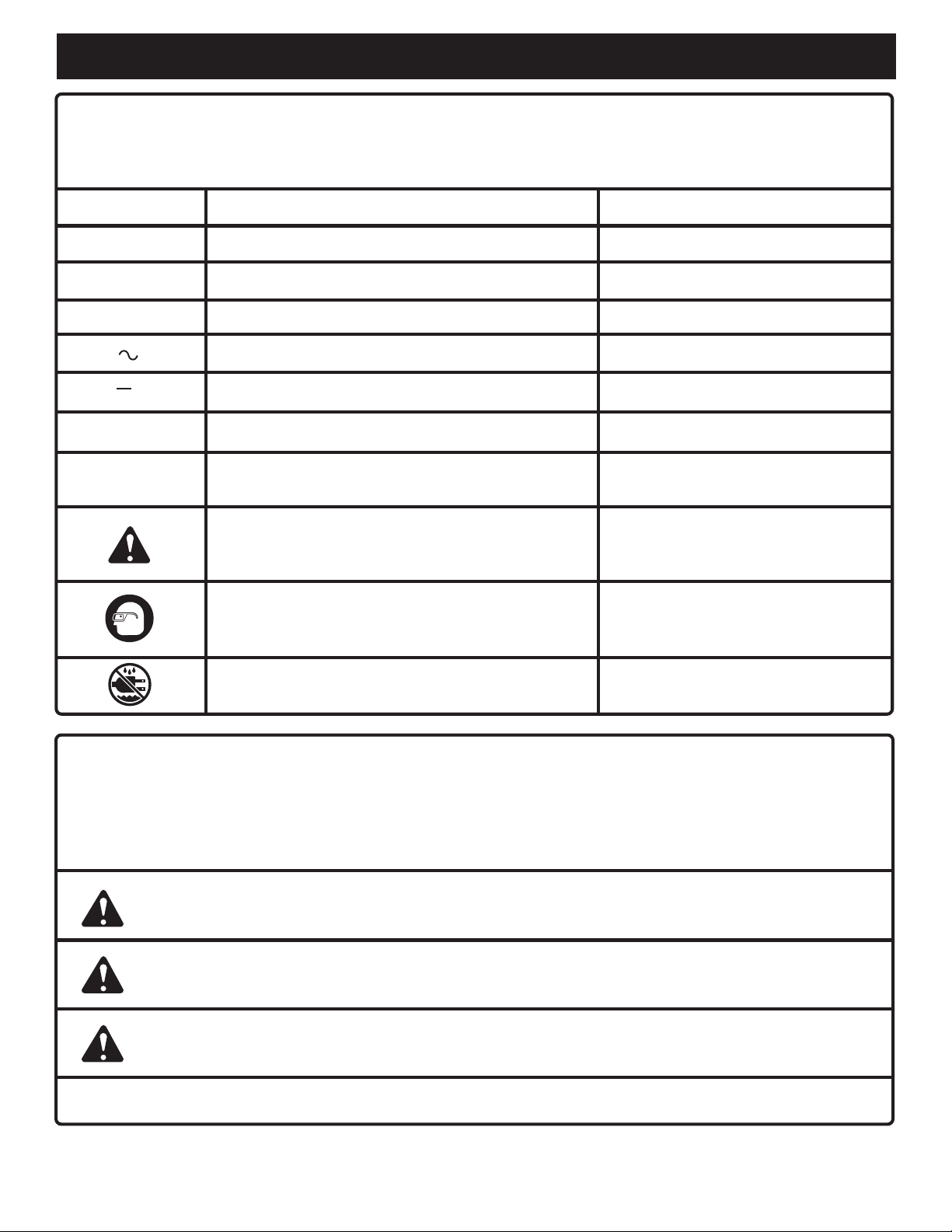

SYMBOLS

Important: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL NAME DESIGNATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

min Minutes Time

Alternating Current Type or a characteristic of current

--- Direct Current Type or a characteristic of current

n

0

.../min Revolutions or Reciprocation Per Minute

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety warnings do not by themselves

eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention

measures.

Symbol Meaning

No Load Speed Rotational speed, at no load

Revolutions, strokes,

surface speed, orbits etc. per minute

Indicates danger, warning or caution.

Safety Alert Symbol It means attention!!! Your safety is

involved.

Always wear safety goggles or

Wear Eye Protection safety glasses with side shields when

operating this product.

Wet Conditions Alert

Do not expose to rain or use in damp

locations.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices that may cause property damage.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

SA VE THESE INSTRUCTIONS

Page 6

Page 7

SPECIFICATIONS

DRILL-DRIVER SA1202 SA14402 SA1802

Chuck 3/8 in. (10 mm) Keylessw 3/8 in. (10 mm) Keyless 1/2 in. (13 mm) Keyless

Motor DC Motor 12 Volt DC Motor 14.4 Volt DC Motor 18 Volt

Gear Train Two Speed Two Speed Two Speed

Switch Variable Speed Variable Speed Variable Speed

No Load Speed 0-300 RPM (Low) 0-400 RPM (Low) 0-350 RPM (Low)

0-1000 RPM (High) 0-1400 RPM (High) 0-1300 RPM (High)

Clutch 24 Positions 24 Positions 24 Positions

Charger Input 120 V, 60 Hz, AC only 120 V, 60 Hz, AC only 120 V, 60 Hz, AC only

Charge Rate 1 Hour 1 Hour 1 Hour

Torque Maximum 220 in.lbs. Maximum 270 in.lbs. Maximum 400 in.lbs.

UNPACKING

INSTRUCTIONS

When unpacking the tool:

■ Carefully remove the tool and accessories from the box.

■ Make sure that all items listed in the packing list are in-

cluded.

■ Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

■ Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

■ If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

Cordless Drill

Charger

Battery Pack (2)

Operator’s Manual

Case

WARNING:

If any parts are missing do not operate the tool until

the missing parts are replaced. Failure to do so could

result in possible serious personal injury.

APPLICATIONS

You may use the two speed drill for the purposes listed below:

■ Drilling in wood

■ Drilling in ceramics, plastics, fiberglass, and laminates

■ Drilling in both hard and soft metals

■ Using driving accessories, such as driving screws with screwdriver bits

■ Mixing paints

Page 7

Page 8

FEATURES

KNOW YOUR DRILL-DRIVER

See Figure 1.

Before using this tool, familiarize yourself with all

operating features and safety requirements. However, do

not let familiarity with the tool make you careless.

This new drill-driver is equipped with the following

features.

KEYLESS CHUCK

The drill-driver has a keyless chuck that allo ws y ou to hand

tighten or release drill bit in the chuck jaws.

SWITCH

The drill-driver has a conveniently located variable speed

switch.

SWITCH LOCK

The switch trigger can be locked in the OFF position. This

feature helps reduce the possibility of accidental starting

when not in use.

VARIABLE SPEED

This tool has a variable speed switch that delivers higher

speed with increased trigger pressure. Speed is controlled

by the amount of switch trigger depression.

TWO SPEED GEAR TRAIN

Your drill has a two-speed gear train designed for drilling or

driving at LO (1) or HI (2) speeds. A slide switch is located

on top of your drill to select either LO (1) or HI (2) speed.

FORWARD/REVERSE SELECTOR

(DIRECTION OF ROTATION SELECTOR)

The drill-driver has a forward/rev erse selector located abov e

the switch trigger.

BIT STORAGE

When not in use, bits provided with your drill-driver can be

placed in the storage area located on the top of the motor

housing.

LEVEL

To keep drill bit level during drilling operations, a level is

located on the top and end of the motor housing.

Page 8

Page 9

FEATURES

TORQUE

ADJUSTMENT

RING

KEYLESS

CHUCK

TOP VIEW OF LEVEL FOR

HORIZONTAL DRILLING

TWO SPEED

GEAR TRAIN (HI-LO)

SWITCH

TRIGGER

MAG TRAY™

(SCREW HOLDER)

24

LEVEL

BIT

STORAGE

AREA

20

5

DIRECTION OF

ROTATION

SELECTOR

BATTERY

PACK

END VIEW OF LEVEL FOR

VERTICAL DRILLING

Fig. 1

Page 9

Page 10

ADJUSTMENTS

24

20

5

REVERSIBLE

See Figure 2.

This tool is reversible. The direction of rotation is controlled

by a selector located above the switch trigger. With the drill

held in normal operating position, the direction of rotation

selector should be positioned to the left of the switch for

drilling. The drilling direction is reversed when the selector is

to the right of the switch. When the selector is in center

position, the switch trigger is locked.

CAUTION:

T o pre vent gear damage, alw ays allow chuck to come

to a complete stop before changing the direction of

rotation.

To stop, release switch trigger and allow the chuck to

come to a complete stop.

WARNING:

Battery tools are always in operating condition. There-

fore, s witch should alwa ys be lock ed when not in use

or when carrying at your side.

HI (2) SPEED

RELEASE

(UNLOCK)

TWO SPEED

GEAR TRAIN

(HI-LO)

LO (1) SPEED

Fig. 2

CHUCK COLLAR

TWO SPEED GEAR TRAIN

See Figure 3.

Your drill has a two-speed gear train designed for drilling or

driving at LO (1) or HI (2) speeds. A slide switch is located

on top of your drill to select either LO (1) or HI (2) speed.

When using drill in the LO (1) speed range, speed will

decrease and unit will have more power and torque. When

using drill in the HI (2) speed range, speed will increase and

unit will have less power and torque. Use LO (1) speed for

high power and torque applications and HI (2) speed for f ast

drilling or driving applications.

KEYLESS CHUCK

See Figure 3.

A keyless chuck has been provided with your drill to allow for

easy installation and removal of bits. As the name implies,

you can hand tighten or release drill bits in the chuck jaws.

Grasp and hold the collar of the chuck with one hand. Rotate

the chuck body with your other hand. The arrows on the

chuck indicate which direction to rotate the chuck body in

order to GRIP (tighten) or RELEASE (unlock) the drill bit.

24

20

GRIP

(TIGHTEN)

CHUCK

BODY

5

WARNING:

Do not hold the chuck body with one hand and use

the power of the drill to tighten chuck jaws on drill

bits. Chuck body could slip in your hand or y our hand

could slip and come in contact with rotating drill bit.

This could cause an accident resulting in serious personal injury.

Fig. 3

Page 10

Page 11

ADJUSTMENTS

24

20

5

24

20

5

INSTALLING BITS

See Figures 4 and 5.

■ Place the direction of rotation selector in center position.

This will lock the switch trigger in the off position.

See

Figure 10.

■ Open or close the chuck jaws to a point where the opening

is slightly larger than the bit size you intend to use. Also,

raise the front of your drill slightly to keep the bit from

falling out of the chuck jaws.

■ Insert your drill bit into the chuck the full length of the jaws.

See Figure 4.

■ Tighten the chuck jaws on the drill bit. To tighten, grasp

and hold the collar of the chuck with one hand, while

rotating the chuck body with your other hand.

Note: Rotate the chuck body in the direction of the arrow

marked GRIP to tighten the chuck jaws.

■ DO NOT use a wrench to tighten or loosen the chuck

jaws.

WARNING:

Do not insert drill bit into chuck jaws and tighten as

shown in figure 5. This could cause drill bit to be thrown

from drill resulting in possible serious personal injury

or damage to the chuck.

DRILL BIT

CHUCK JAWS

CHUCK BODY

CHUCK COLLAR

RIGHT

Fig. 4

REMOVING BITS

See Figure 4.

■ Lock the switch trigger by placing the direction of

rotation selector in center position.

■ Loosen the chuck jaws from the drill bit

■ To loosen: grasp and hold the collar of the chuck with

one hand, while rotating chuck body with your other

hand.

NOTE: Rotate chuck body in the direction of the arrow

marked UNLOCK to loosen chuck jaws.

■ Do not use a wrench to tighten or loosen the chuck

jaws.

■ Remove the drill bit from the chuck jaws.

NOTE: Rotate the chuck body in the direction of the arrow

marked GRIP to tighten the chuck jaws. DO NOT use a

wrench to tighten or loosen the chuck jaws.

See Figure 10.

.

WRONG

Fig. 5

Page 11

Page 12

ADJUSTMENTS

ADJUSTABLE TORQUE CLUTCH

See Figure 6.

When using your drill-driver for various driving applications,

it becomes necessary to increase or decrease the torque in

order to help prevent the possibility of damaging scre w heads,

threads, workpiece, etc. In general, torque should correspond

to the intensity of the screw diameter. If the torque is too

high or the screws too small, the screws may be damaged or

broken.

The torque is adjusted by rotating the torque adjustment ring.

The torque is greater when the torque adjustment ring is set

on a higher setting. The torque is less when the torque adjustment ring is set on a lower setting.

The proper setting depends on the type of material and the

size of screw you are using.

TO ADJUST TORQUE

■ Identify the twenty four torque indicator settings located

on the front of the drill.

■ Rotate adjusting ring to the desired setting.

• 1 - 4 ..................For driving small screws.

• 5 - 8 ..................For driving screws into soft material.

• 9 - 12 ................For driving screws into soft and hard

materials.

• 13 - 16 ..............For driving screws in hard wood.

• 17 - 20 ..............For driving large screws.

• 21 - 24 ( ) ....For heavy drilling.

BIT STORAGE

See Figure 7.

When not in use, bits provided with your drill can be placed

in the storage area located on the top of your drill.

TO DECREASE

TORQUE

TO INCREASE

TORQUE

SCREWDRIVER BIT

24

24

20

5

TORQUE

ADJUSTMENT

RING

Fig. 6

BIT

STORAGE

AREA

20

5

SCREWDRIVER BIT

Fig. 7

Page 12

Page 13

OPERATION

WARNING:

Do not allow familiarity with the drill-driver to make

you careless. Remember that a careless fraction of a

second can result in a serious personal injury.

LED FUNCTION OF CHARGER

See Figure 8.

LED WILL BE LIGHTED TO INDICATE STATUS OF

CHARGER AND BATTERY PACK:

■ Red LED lighted = Fast Charging Mode

■ Green LED lighted = Fully Charged Battery Pack

■ Yellow and Green LED Lighted = Control Charge or

Defective Battery Pack.

CHARGING YOUR DRILL-DRIVER

The battery pack for this tool has been shipped in a low

charge condition to prevent possible problems. Therefore,

you should charge it prior to use.

Note: Batteries will not reach full charge the first time they

are charged. Allow several cycles (drilling followed by recharging) for them to fully charge.

TO CHARGE

■ Charge battery pack only with the charger provided.

■ Make sure power supply is normal house voltage,

120 Volts, 60 Hz, AC only.

■ Connect charger to power supply.

■ Place battery pack in charger.

rib on battery pack with groove in charger.

■ Press down on battery pack to be sure contacts on

battery pack engage properly with contacts in charger.

When properly connected, red light will turn on.

■ Normally, the yellow and green lights on the charger will

come on. This indicates charger is in control charge

mode and should switch to fast charge mode within 5

minutes. When charger is in fast charge mode the red

light will come on. If after a period of 15 minutes the

yellow and green lights remain on, remove the battery

pack, wait 1 minute and reinsert battery pack in charger.

If the yellow and green lights continue to remain on an

additional 15 minutes, the battery pack is damaged and

will not accept charge.

■ When your battery pack becomes fully charged, the red

light will turn off and the green light will turn on.

■ After normal usage, 1 hour of charge time is required to

be fully charged. A minimum charge time of 1 to 1-1/2

hours is required to recharge a completely discharged

tool.

■ The battery pack will become slightly warm to the touch

while charging. This is normal and does not indicate a

problem.

■ DO NOT place charger in an area of extreme heat or

cold. It will work best at normal room temperature.

See Figure 9.

Align raised

GREEN LIGHT "ON"

INDICATES FULLY

CHARGED

YELLOW AND GREEN LIGHTS "ON"

INDICATES CONTROL CHARGE OR

POSSIBLE FAULTY BATTERY

BATTERY

PACK

BATTERY

CHARGER

RED LIGHT "ON"

INDICATES FAST

CHARGING MODE

Fig. 8

BATTERY

CHARGER

Fig. 9

Page 13

Page 14

OPERATION

IMPORTANT INFORMATION FOR RECHARGING

HOT BATTERIES

When using your drill-driver continuously, the batteries in

your battery pack become hot. You should let a hot battery

pack cool down for approximately 30 minutes before attempting to recharge.

Note: This situation occurs when continuous use of your

drill-driver causes the batteries to become hot. It does not

occur under normal circumstances. Refer to “Charging Your

Drill-Driver” earlier in this manual, for normal recharging of

batteries. If the charger/charging assembly does not charge

your battery pack under normal circumstances, return both

the battery pack and charger/charging assembly to your

nearest Ryobi Authorized Service Center for electrical

check.

For more information on the battery recycling call

1-800-8 BATTERY.

TO INSTALL BATTERY PACK

■■

■ Place the direction of rotation selector in center posi-

■■

tion.

See Figure 10.

■■

■ Place the battery pack in your drill. Align raised rib on

■■

battery pack with groove in drill's battery port.

ure 11.

■■

■ Make sure the latches on each side of your battery pack

■■

snap in place and that battery pack is secured in drill

before beginning operation.

TO REMOVE BATTERY PACK

■■

■ Place the direction of rotation selector in center posi-

■■

tion.

See Figure 10.

■■

■ Locate latches on side of battery pack and depress both

■■

sides to release battery pack from your drill.

11.

■■

■ Remove battery pack from your drill.

■■

See Fig-

See Figure

DIRECTION OF

ROTATION

SELECTOR

CENTER POSITION

(LOCK)

BATTERY

PACK

24

20

5

FORWARD

REVERSE

SWITCH

TRIGGER

Fig. 10

BATTERY

PORT

LATCHES

CAUTION:

When placing battery pack in your drill, be sure raised

rib on battery pack aligns with groove in drill's battery

port and latches snap in place properly. Improper

assembly of battery pack can cause damage to internal components.

SWITCH

See Figure 10.

To turn your drill ON, depress the switch trigger. To turn it

OFF, release the switch trigger.

SWITCH LOCK

See Figure 10.

The switch trigger can be locked in the OFF position. This

feature helps reduce the possibility of accidental starting

when not in use. To lock the switch trigger, place the direction

of rotation selector in the center position.

Page 14

DEPRESS LATCHES TO

RELEASE BATTERY PACK

Fig. 11

VARIABLE SPEED

See Figure 10.

Your drill has a variable speed feature in the switch. The

switch delivers higher speed and torque with increased

trigger pressure. Speed is controlled by the amount of

switch trigger depression.

Page 15

OPERATION

WARNING:

Always wear safety goggles or safety glasses with

side shields when operating tool. Failure to do so

could result in objects being thrown into your eyes,

resulting in possible serious injury.

LEVEL

DRILLING

See Figure 12.

When drilling hard, smooth surfaces, use a center punch to

mark the desired hole location. This will prevent the drill bit

from slipping off center as the hole is started. However, the

lower speed feature allows starting holes without center

punching if desired. To accomplish this, simply operate your

drill at lower speed until the hole is started.

The material to be drilled should be secured in a vise or with

clamps to keep it from turning as the drill bit rotates.

Hold tool firmly and place the bit at the point to be drilled.

Depress the switch trigger to start tool.

Move the drill bit into the workpiece, applying only enough

pressure to keep the bit cutting. Do not force or apply side

pressure to elongate a hole.

WARNING:

Be prepared for binding or bit breakthrough. When

these situations occur, the drill has a tendency to grab

and kick opposite to the direction of rotation, and could

cause loss of control when breaking through material. If you are not prepared, this loss of control can

result in possible serious injury.

END VIEW

2

0

15

Fig. 12

When drilling metals, use a light oil on the drill bit to keep it

from overheating. The oil will prolong the life of the bit and

increase the drilling action.

If the bit jams in workpiece or if the drill stalls, release switch

trigger immediately . Remov e the bit from the workpiece and

determine the reason for jamming.

Page 15

Page 16

OPERATION

20

5

LEVEL DRILLING

See Figures 12 and 13.

A convenient new feature provided with your drill is a level.

It is recessed in the motor housing on top of your drill. It

can be used to keep drill bit level during drilling operations.

TOP VIEW

WARNING:

Do not force tool. Forcing tool can result in jamming

and loss of balance or footing, which could result in

personal injury .

MAG TRAY™

See Figure 14.

For convenience, your drill has a Mag Tray™ to place small

parts when doing a variety of tasks.

24

20

LEVEL

Fig. 13

MAG TRAY™

(SCREW HOLDER)

Page 16

Fig. 14

Page 17

MAINTENANCE

20

5

WARNING:

When servicing use only identical Ryobi replacement

parts. Use of any other parts may create a hazard or

cause product damage.

Do not abuse power tools. Abusive practices can damage

tool as well as workpiece.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc. come in

contact with plastic parts. They contain chemicals that

can damage, weaken or destroy plastic.

WARNING:

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such

alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury .

MALLET

CHUCK

JAWS

HEX KEY WRENCH

KEYLESS

CHUCK

24

20

5

Fig. 15

24

GENERAL

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carbon dust, etc. that can

damage, weaken, or destroy plastic.

WARNING:

Always wear eye protection marked to comply with

ANSI Z87.1. Failure to do so could result in dust, shavings, or loose particles being thrown into your eyes,

resulting in possible serious injury.

CHUCK REMOVAL

See Figures 15, 16, and 17.

■ The chuck must be removed in order to use some

accessories. To remove:

■ Lock the switch trigger by placing the direction of

rotation selector in center position. See

■ Insert a 5/16 in. or larger hex key into the chuck of the

drill and tighten the chuck jaws securely.

■ Tap the hex key sharply with a mallet in a clockwise

direction.

the chuck for easy removal.

See Figure 15.

This will loosen the screw in

Figure 4.

Fig. 16

24

20

5

Fig. 17

Page 17

Page 18

MAINTENANCE

■ Open the chuck jaws and remove the hex key. Remove

the chuck screw by turning it in a clockwise direction.

See Figure 16.

NOTE: The screw has left hand threads.

■ Insert the hex key in the chuck and tighten chuck jaws

securely. Tap sharply with a mallet in a counterclockwise direction. This will loosen the chuck on the

spindle. It can now be unscrewed by hand.

17.

See Figure

TO RETIGHTEN A LOOSE CHUCK

See Figure 17.

The chuck may become loose on spindle and develop a

wobble. Periodically check chuck screw for tightness.

To tighten, follow these steps:

■ Lock the switch trigger by placing the direction of

rotation selector in center position. See

■ Open the chuck jaws.

■ Insert the hex key into the chuck and tighten chuck

jaws securely. Tap the hex key sharply with a mallet in

a clockwise direction. This will tighten the chuck on the

spindle.

■ Open the chuck jaws and remove the hex key.

■ Tighten the chuck screw.

NOTE: The chuck screw has left hand threads.

See Figure 17.

Figure 4.

BATTERIES

The battery pack for your tool is equipped with nickelcadmium rechargeable batteries. Length of service from

each charging will depend on the type of work you are doing.

The batteries in this tool have been designed to provide

maximum trouble free life. However, like all batteries, they

will eventually wear out. Do not disassemble battery pack

and attempt to replace the batteries. Handling of these

batteries, especially when wearing rings and jewelry, could

result in a serious burn.

To obtain the longest possible battery life, we suggest the

following:

■ Store and charge your batteries in a cool area.

Temperatures below 50°F or above 100°F will shorten

battery life.

■ Never store batteries in a discharged condition. Recharge

them immediately after they are discharged.

■ All batteries gradually lose their charge. The higher the

temperature the quicker they lose their charge. If you

store your tool for long periods of time without using it,

recharge the batteries every month or two. This practice

will prolong battery life.

BATTERY PACK REMOVAL AND PREPARATION FOR RECYCLING

WARNING:

Upon removal, cov er the battery pack's terminals with

heavy duty adhesive tape. Do not attempt to destroy

or disassemble battery pack or remove any of its components. Nic k el-cadmium batteries must be recycled

or disposed of properly . Also , nev er touch both terminals with metal objects and/or body parts as shor t

circuit may result. Keep away from children. Failure

to comply with these warnings could result in fire and/

or serious injury.

Y

C

C

L

E

R

RBRC

1

.

8

0

0

Consult your local waste authority for information regarding

available recycling and/or disposal options

Ni

.

8

2

Cd

2

™

.

To preserve natural resources, please

E

recycle or dispose of batteries properly.

This product contains nickel-cadmium

batteries. Local, state or federal laws may

7

3

prohibit disposal of nickel-cadmium

8

8

batteries in ordinary trash.

Page 18

Page 19

NOTES

Page 19

Page 20

OPERATOR'S MANUAL

CORDLESS DRILL-DRIVER

MODEL NOS. SA1202 / SA14402 / SA1802

• SERVICE

Now that you have purchased your tool, should a need ever exist for repair parts or service,

simply contact your nearest Ryobi Authorized Service Center. Be sure to provide all

pertinent facts when you call or visit. Please call 1-800-525-2579 for your nearest Ryobi

Authorized Service Center. You can also check our web site at www.ryobitools.com for a

complete list of Authorized Service Centers.

• MODEL NO. AND SERIAL NO.

The model number of this tool will be found on a plate attached to the motor housing.

Please record the model number and serial number in the space provided below.

• HOW TO ORDER REPAIR PARTS

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING INFORMATION:

• MODEL NUMBERS

• SERIAL NUMBER

RYOBI TECHNOLOGIES, INC.

1428 Pearman Dairy Road Anderson SC 29625

Post Office Box 1207 Anderson SC 29622

SA1202 / SA14402 / SA1802

Phone 1-800-525-2579

www.ryobitools.com

983000-334

6-03

Loading...

Loading...