Page 1

OPERATOR’S MANUAL

VARIABLE TEMPERATURE HEAT GUN

DOUBLE INSULATED

MANUEL D’UTILISATION

PISTOLET THERMIQUE VARIABLE

DOUBLE ISOLATION

MANUAL DEL OPERADOR

PISTOLA DE AIRE CALIENTE VARIABLE

DOBLE AISLAMIENTO

HG600

Your heat gun has been engineered and manufactured to our high standard for dependability, ease of operation, and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette pistolet thermique a été conçue et fabriquée conformément

à nos strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation. Correctement entretenue, elle vous donnera des

années de fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Merci de votre achat.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su pistola de aire calienteha sido diseñado y fabricado de

conformidad con las estrictas normas para brindar fiabilidad,

facilidad de uso y seguridad para el operador. Con el debido cuidado,

le brindará muchos años de sólido y eficiente funcionamiento.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

Le agradecemos su compra.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

TABLE OF CONTENTS

Introduction ..................................................................................................................................................................... 2

Warranty .......................................................................................................................................................................... 2

General Power Tool Safety Warnings ........................................................................................................................... 3-4

Heat Gun Safety Warnings .............................................................................................................................................. 4

Symbols ........................................................................................................................................................................... 5

Electrical .......................................................................................................................................................................... 6

Features ........................................................................................................................................................................... 7

Assembly ......................................................................................................................................................................... 7

Operation ...................................................................................................................................................................... 8-9

Maintenance .................................................................................................................................................................. 10

Figure numbers (illustrations) ........................................................................................................................................ 11

Parts Ordering / Service ................................................................................................................................... Back page

INTRODUCTION

This tool has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability have

been given top priority in the design of this product making it easy to maintain and operate.

WARRANTY

RYOBI® POWER TOOL - LIMITED TWO YEAR WARRANTY AND 90 DAY EXCHANGE POLICY

One World Technologies, Inc., warrants its RYOBI® power tools with the following conditions:

90-DAY EXCHANGE POLICY: During the first 90 days after date of purchase, you may either request service under this

warranty or you may exchange any RYOBI® power tool which does not work properly due to defective workmanship or

materials by returning the power tool to the dealer from which it was purchased. To receive a replacement power tool or

requested warranty service, you must present proof of purchase and return all original equipment packaged with the original

product. The replacement power tool will be covered by the limited warranty for the balance of the two year period from

the date of the original purchase.

WHAT THIS WARRANTY COVERS: This warranty covers all defects in workmanship or materials in your RYOBI® power

tool for a period of two years from the date of purchase. With the exception of batteries, power tool accessories are warranted for ninety (90) days. Batteries are warranted for two years.

HOW TO GET SERVICE: Just return the power tool, properly packaged and postage prepaid, to an Authorized Service

Center. You can obtain the location of the Service Center nearest you by contacting a service representative at One

World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207, by calling 1-800-525-2579 or by logging on to

www.ryobitools.com. When you request warranty service, you must also present proof of purchase documentation, which

includes the date of purchase (for example, a bill of sale). We will repair any faulty workmanship, and either repair or replace

any defective part, at our option. We will do so without any charge to you. We will complete the work in a reasonable time,

but, in any case, within ninety (90) days or less.

WHAT’S NOT COVERED: This warranty applies only to the original purchaser at retail and may not be transferred. This

warranty only covers defects arising under normal usage and does not cover any malfunction, failure or defects resulting

from misuse, abuse, neglect, alteration, modification or repairs by other than Authorized Service Centers. One World Technologies, Inc. makes no warranties, representations or promises as to the quality or performance of its power tools other

than those specifically stated in this warranty.

ADDITIONAL LIMITATIONS: Any implied warranties granted under state law, including warranties of merchantability or

fitness for a particular purpose, are limited to two years from the date of purchase. One World Technologies, Inc. is not

responsible for direct, indirect, or incidental damages, so the above limitations and exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

2 - English

Page 3

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases

or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body

is earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suit-

able for outdoor use reduces the risk of electric shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while op-

erating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites

accidents.

Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a ro-

tating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

Do not wear loose clothing or jewelry. Contain long

hair. Loose clothes, jewelry, or long hair can be drawn

into air vents.

Do not use on a ladder or unstable support. Stable

footing on a solid surface enables better control of the

power tool in unexpected situations.

POWER TOOL USE AND CARE

Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation.

If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

3 - English

Page 4

GENERAL POWER TOOL SAFETY WARNINGS

Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

HEAT GUN SAFETY WARNINGS

Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make exposed

metal parts of the power tool “live” and could give the

operator an electric shock.

The nozzle of the heat gun becomes very hot during

operation and should not be touched until the tool has

cooled. Always hold the tool by the insulated gripping

surface to reduce the risk of serious personal injury.

Heat guns produce very high temperatures and must

be used with caution to prevent combustible material

from igniting. Keep tool in constant motion; do not

stop or dwell in one spot. Following this rule will reduce

the risk of fire or serious personal injury.

Excessive heat can generate fumes which may be

dangerous when inhaled. Wear a dust respirator mask

or dual filter respirator mask when using the heat gun.

Following this rule will reduce the risk of serious personal

injury.

Keep a fully charged fire extinguisher close at hand

for emergency use. Following this rule will reduce the

risk of fire or serious injury.

Do not leave the heat gun unattended while running or

cooling down. Always set tool on a flat, level surface

so nozzle tip is directed upwards, away from supporting surface, while running or cooling down. Following

this rule will reduce the risk of fire or serious injury.

Know your power tool. Read operator’s manual care-

fully. Learn its applications and limitations, as well

as the specific potential hazards related to this tool.

Following this rule will reduce the risk of electric shock,

fire, or serious injury.

SERVICE

Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

When servicing a power tool, use only identical

replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized

parts or failure to follow Maintenance instructions may

create a risk of shock or injury.

Always wear eye protection marked to comply with

ANSI Z87.1. Following this rule will reduce the risk of

serious personal injury.

Protect your hearing. Wear hearing protectors during

extended periods of operation. Following this rule will

reduce the risk of serious personal injury.

Inspect tool cords periodically and, if damaged, have

repaired at your nearest Authorized Service Center.

Constantly stay aware of cord location. Following this

rule will reduce the risk of electric shock or fire.

Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate

properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions

that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced

by an authorized service center. Following this rule will

reduce the risk of shock, fire, or serious injury.

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one

heavy enough to carry the current your product will

draw. A wire gauge size (A.W.G.) of at least 14 is

recommended for an extension cord 50 feet or less

in length. A cord exceeding 100 feet is not recommended. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord. An

undersized cord will cause a drop in line voltage resulting

in loss of power and overheating.

Save these instructions. Refer to them frequently and

use them to instruct others who may use this product.

If you loan someone this product, loan them these

instructions also to prevent misuse of the product and

possible injury.

4 - English

Page 5

SYMBOLS

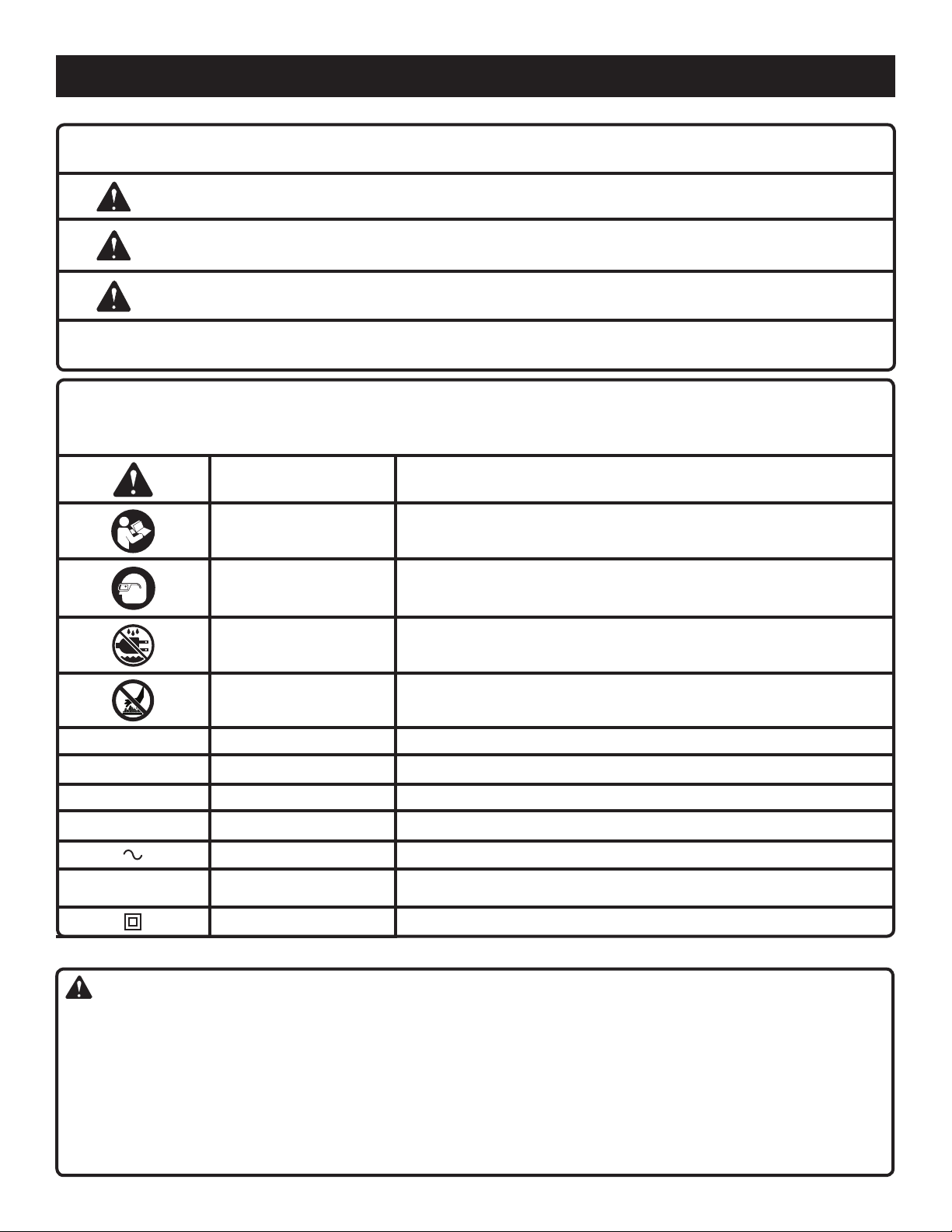

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the product better and safer.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s

Manual

Eye Protection

Wet Conditions Alert Do not expose to rain or use in damp locations.

To reduce the risk of injury, user must read and understand operator’s

manual before using this product.

Always wear eye protection with side shields marked to comply with

ANSI Z87.1.

To reduce the risk of injury or damage, avoid contact with any hot

surface.

V

A

Hz

min

n

o

Hot Surface

Volts Voltage

Amperes Current

Hertz Frequency (cycles per second)

Minutes Time

Alternating Current Type of current

No Load Speed Rotational speed, at no load

Class II Construction Double-insulated construction

CALIFORNIA PROPOSITION 65

WARNING:

This product and some dust created by power sanding, sawing, grinding, drilling, and other construction activities may contain

chemicals, including lead, known to the State of California to cause cancer, birth defects, or other reproductive harm. Wash

hands after handling. Some examples of these chemicals are:

• leadfromlead-basedpaints,

• crystallinesilicafrombricksandcementandothermasonryproductsand,

• arsenicandchromiumfromchemicallytreatedlumber.

Your risk from exposure to these chemicals varies, depending on how often you do this type of work. To reduce your exposure, work in a well-ventilated area and with approved safety equipment, such as dust masks that are specially designed to

filter out microscopic particles.

5 - English

Page 6

ELECTRICAL

DOUBLE INSULATION

Double insulation is a concept in safety in electric power

tools, which eliminates the need for the usual threewire grounded power cord. All exposed metal parts are

isolated from the internal metal motor components with

protecting insulation. Double insulated tools do not need

to be grounded.

WARNING:

The double insulated system is intended to protect the

user from shock resulting from a break in the tool’s internal insulation. Observe all normal safety precautions

to avoid electrical shock.

NOTE: Servicing of a tool with double insulation requires

extreme care and knowledge of the system and should be

performed only by a qualified service technician. For service,

we suggest you return the tool to your nearest authorized

service center for repair. Always use original factory replacement parts when servicing.

ELECTRICAL CONNECTION

This tool has a precision-built electric motor. It should be

connected to a power supply that is 120 volts, AC only

(normal household current), 60 Hz. Do not operate this

tool on direct current (DC). A substantial voltage drop will

cause a loss of power and the motor will overheat. If your

tool does not operate when plugged into an outlet, doublecheck the power supply.

EXTENSION CORDS

When using a power tool at a considerable distance from

a power source, be sure to use an extension cord that has

the capacity to handle the current the tool will draw. An undersized cord will cause a drop in line voltage, resulting in

overheating and loss of power. Use the chart to determine

the minimum wire size required in an extension cord. Only

round jacketed cords listed by Underwriter’s Laboratories

(UL) should be used.

When working outdoors with a tool, use an extension cord

that is designed for outside use. This type of cord is designated with “WA” or “W” on the cord’s jacket.

Before using any extension cord, inspect it for loose or exposed wires and cut or worn insulation.

**Ampere rating (on tool faceplate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

WARNING:

Keep the extension cord clear of the working area. Position the cord so that it will not get caught on lumber,

tools or other obstructions while you are working with a

power tool. Failure to do so can result in serious personal

injury.

Check extension cords before each use. If damaged replace immediately. Never use tool with a damaged cord

since touching the damaged area could cause electrical

shock resulting in serious injury.

6 - English

WARNING:

Page 7

FEATURES

PRODUCT SPECIFICATIONS

Heat Output ........................................................................................................................................................ 200˚F-1050˚F

Input .....................................................................................................................................120 V, AC only, 60 Hz, 11 Amps

Net Weight ....................................................................................................................................................................1.7 lbs.

KNOW YOUR HEAT GUN

See Figure 1, page 11.

Before attempting to use this product, familiarize yourself

with all operating features and safety rules.

HI/LO/OFF SWITCH

Your heat gun has a conveniently located on/off slide switch.

NOSE CONE

The nose cone on your heat gun can be removed for work

in confined spaces.

SUPPORT STAND

Your heat gun has a built-in support stand for ease of use

and convenient cool down.

ASSEMBLY

UNPACKING

This product has been shipped completely assembled.

Carefully remove the tool and any accessories from the

box. Make sure that all items listed in the packing list are

included.

TEMPERATURE ADJUSTMENT DIAL

The temperature of your heat gun can be adjusted from

200ºF to 1050ºF by rotating the temperature adjustment dial.

TEMPERATURE DISPLAY

The desired temperature is indicated by the position of the

temperature adjustment dial.

THERMAL PROTECTION

The heat gun is equipped with thermal protection that

deactivates the heating coil when the nozzle is too close

to a surface being heated. The fan will continue to operate

and the heating coil will automatically activate after the coil

has cooled down.

WARNING:

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING:

Do not use this product if it is not completely assembled

or if any parts appear to be missing or damaged. Use of

a product that is not properly and completely assembled

could result in serious personal injury.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

PACKING LIST

Heat Gun

Tube Bender Nozzle

Concentrator Nozzle

Operator’s Manual

7 - English

WARNING:

Do not attempt to modify this tool or create accessories

not recommended for use with this tool. Any such alteration or modification is misuse and could result in a hazardous condition leading to possible serious personal injury.

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

Page 8

OPERATION

WARNING:

Do not allow familiarity with tools to make you careless.

Remember that a careless fraction of a second is sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes resulting in possible

serious injury.

WARNING:

Do not use any attachments or accessories not recommended by the manufacturer of this tool. The use of

attachments or accessories not recommended can result

in serious personal injury.

APPLICATIONS

You may use this tool for the purposes listed below:

Soften paint, caulking and putty for easier removal

Soften adhesives to help remove stickers, floor tiles,

wallpaper, etc.

Heating plastic and metal for bending

Soldering pipe joints

Shrink tubing for electrical work

Shrink plastic film for wrapping or weatherproofing

Loosen rusted nuts, bolts, and fittings

READ THIS INSTRUCTION

WARNING:

Use extreme care when stripping paint. The peelings,

residue, and vapors of paint may contain lead, which

is poisonous. Any pre-1977 paint may contain lead and

paint applied to homes prior to 1950 is likely to contain

lead. Once deposited on surfaces, hand to mouth contact

can result in the ingestion of lead. Exposure to even low

levels of lead can cause irreversible brain and nervous

system damage; young and unborn children are particularly vulnerable. Before beginning any paint removal

process, you should determine whether the paint you are

removing contains lead. This can be done by your local

health department or by a professional who uses a paint

analyzer to check lead content of the paint to be removed.

LEAD-BASED PAINT SHOULD ONLY BE REMOVED BY

A PROFESSIONAL AND SHOULD NOT BE REMOVED

USING A HEAT GUN.

Persons removing paint should follow these guidelines:

Move the workpiece outdoors. If this is not possible, keep

the work area well ventilated. Open the windows and put

an exhaust fan in one of them. Be sure the fan is moving

the air from inside to outside.

Remove or cover any carpets, rugs, furniture, clothing,

cooking utensils, and air ducts.

Place drop cloths in the work area to catch any paint chips

or peelings. Wear protective clothing such as extra work

shirts, overalls, and hats.

Work in one room at a time. Furnishings should be re-

moved or placed in the center of the room and covered.

Work areas should be sealed off from the rest of the

dwelling by sealing doorways with drop cloths.

Children, pregnant or potentially pregnant women, and

nursing mothers should not be present in the work area

until the work is done and all clean up is complete.

Wear a dust respirator mask or a dual filter (dust and

fume) respirator mask which has been approved by the

Occupational Safety and Health Administration (OSHA),

the National Institute of Safety and Health (NIOSH), or

the United States Bureau of Mines. These masks and

replaceable filters are readily available at major hardware

stores. Be sure the mask fits. Beards and facial hair may

keep masks from sealing properly. Change filters often.

DISPOSABLE PAPER MASKS ARE NOT ADEQUATE.

Use caution when operating the heat gun. Keep the heat

gun moving as excessive heat will generate fumes

Keep food and drink out of the work area. Wash hands,

arms and face and rinse mouth before eating or drinking. Do not smoke or chew gum or tobacco in the work

area.

Clean up all removed paint and dust by wet mopping the

floors. Use a wet cloth to clean all walls, sills, and any

other surface where paint or dust is clinging. DO NOT

SWEEP, DRY DUST, OR VACUUM. Use a high phosphate

detergent or trisodium phosphate (TSP) to wash and mop

areas.

At the end of work session, put the paint chips and debris

in a double plastic bag, close it with tape or twist ties,

and dispose of properly.

Remove protective clothing and work shoes in the work

area to avoid carrying dust into the rest of the dwelling.

Wash work clothes separately. Wipe shoes off with a wet

rag that is then washed with the work clothes. Wash hair

and body thoroughly with soap and water.

8 - English

Page 9

OPERATION

WARNING:

This heat gun generates extremely high temperatures.

Hidden areas such as behind walls, ceilings, floors, soffit

boards, and other panels may contain flammable materials that could be ignited by the heat gun when working

in these locations. Keep tool in constant motion; do not

stop or dwell in one spot as the panel or material behind

it may ignite. The ignition of these materials may not be

readily apparent and could result in property damage and

injury to persons.

SAVE THIS INSTRUCTION

WARNING:

Do not direct hot tip or nozzle toward clothing, hands,

or other body parts. Intense heat from tip or nozzle can

cause serious burns or cause clothing to ignite.

SAVE THIS INSTRUCTION

STARTING/STOPPING THE HEAT GUN

See Figure 2, page 11.

The heat gun is started by sliding the hi/lo/off switch up to

the on ( l) position. To stop, slide the switch down to the off

(O ) position.

ADJUSTING THE TEMPERATURE

See Figure 2-3, page 11.

The temperature setting of the heat gun is shown on the

temperature display and is controlled by the temperature

adjustment dial located at the top of the tool. Turn the dial

to the right to raise the temperature and to the left to lower

the temperature.

To set the heat gun on the low fan setting, slide the hi/lo/off

switch to the I (middle position). To use the high fan setting,

slide the hi/lo/off switch to the II (top position).

WARNING:

The proper amount of heat necessary for a specific application depends on the distance between the nozzle

and workpiece and the length of time heat is applied.

Experiment with scrap materials and start with the lowest temperature range. Be cautious when working until

the proper combination of heat, distance and time has

been determined. Leaving the heat gun unattended could

increase the risk of fire or personal injury.

HANDS-FREE OPERATION

See Figure 4, page 11.

The heat gun has a flat bottom surface that acts as a support stand to allow hands-free operation and cooling. Rest

the tool on a flat surface and make sure the cord placement

does not cause the heat gun to tip over.

NOTE: Do not leave heat gun unattended while it is running

or cooling down. Always set on a flat, level surface with

nozzle tip directed upwards, away from supporting surface.

INSTALLING ATTACHMENTS

See Figures 5 - 6, page 11.

Several attachments are included with the heat gun to expand

its capabilities. Attachments are installed simply by placing

them on the end of the heat gun’s nozzle.

NOTE: Install or remove attachments only when both the

heat gun nozzle and the attachment nozzle are cool.

Tube bender nozzle: The tube bender nozzle is useful

for surround bending, soldering pipe, and applying heat to

shrinkable tubing.

Concentrator nozzle: The concentrator nozzle intensifies

the application of heat in a specific area. Uses for this nozzle

include bending acrylic plastic sheets, soldering pipe joints,

and directing heat into corners.

REMOVING THE NOSE CONE

See Figure 7, page 11.

The nose cone helps to limit exposure to the extremely hot

nozzle when the heat gun is in use. However, the nose cone

can be removed to allow use of the heat gun in tight spaces.

NOTE: Always reinstall the nose cone when finished.

To remove:

Unplug the heat gun.

With nozzle pointed away from you, rotate the nose cone

slightly counterclockwise and remove.

WARNING:

The nozzle of the heat gun is extremely hot during use.

It will stay hot for several minutes, depending on room

temperature. Allow heat gun to cool before attempting to

install or remove the nose cone to avoid possible serious

personal injury.

To reinstall:

Unplug the heat gun.

Slide nose cone over the heat gun nozzle.

Seat the nose cone against the body of the heat gun by

aligning tabs on heat gun body to notches on base of

nose cone.

Rotate the nose cone clockwise to secure.

9 - English

Page 10

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts can create a hazard or cause

product damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes resulting in possible

serious injury.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating lubricants, etc., come in

contact with plastic parts. Chemicals can damage,

weaken or destroy plastic which can result in serious

personal injury.

Electric tools used on fiberglass material, wallboard, spackling

compounds, or plaster are subject to accelerated wear and

possible premature failure because the fiberglass chips and

grindings are highly abrasive to bearings, brushes, commutators, etc. Consequently, we do not recommended using this

tool for extended work on these types of materials. However,

if you do work with any of these materials, it is extremely

important to clean the tool using compressed air.

WARNING:

Always unplug the heat gun before performing any type

of maintenance. Following this rule can reduce the risk

of serious personal injury.

CLEANING THE HEAT GUN

The heat gun and attachments should be kept clean, dry,

and free of oil or grease. Only a mild soap and damp cloth

should be used to clean the heat gun. Do not allow liquid

to enter the tool.

The high temperatures of the heat gun will cause the nozzle

to turn dark over time. This is normal and will not affect its

performance or life.

Ventilation openings must be kept clean and free of foreign

matter. The most effective method of cleaning the vents is

with compressed air. Do not attempt to clean by inserting

pointed objects through the openings.

POWER SUPPLY CORD REPLACEMENT

If replacement of the power supply cord is necessary, this

has to be done by an authorized service center in order to

avoid a safety hazard.

STORAGE

Always allow the heat gun and nozzle attachments to cool

to room temperature before storing. Store the heat gun out

of reach of children and untrained individuals.

WARNING:

The nozzle of the heat gun will stay hot for several minutes

after use. Always allow heat gun to cool before storage.

Following this rule will reduce the risk of serious personal

injury or property damage.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrication is required.

NOTE: FIGURES (ILLUSTRATIONS) START ON PAGE 11

AFTER FRENCH AND SPANISH LANGUAGE SECTIONS.

10 - English

Page 11

TABLE DES MATIÈRES

Introduction ..................................................................................................................................................................... 2

Garantie ........................................................................................................................................................................... 2

Avertissements généraux de sécurité en ce qui a trait aux outils électriques ............................................................. 3-4

Avertissements de sécurité relatifs pistolet thermique .................................................................................................... 4

Symboles ......................................................................................................................................................................... 5

Caractéristiques électriques ............................................................................................................................................ 6

Caractéristiques .............................................................................................................................................................. 7

Assemblage ..................................................................................................................................................................... 7

Utilisation ...................................................................................................................................................................... 8-9

Entretien ........................................................................................................................................................................ 10

Figure numéros (illustrations) ........................................................................................................................................ 11

Commande de pièces/réparation ................................................................................................................... Page arrière

INTRODUCTION

Cet outil offre de nombreuses fonctions destinées à rendre son utilisation plaisante et plus satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile

à utiliser et à entretenir.

GARANTIE

OUTILS ÉLECTRIQUES RYOBI® – GARANTIE LIMITÉE DE DEUX ANS ET POLITIQUE D’ÉCHANGE DE 90 JOURS

One World Technologies, Inc., garantit ses outils électriques dans les conditions suivantes :

POLITIQUE D’ÉCHANGE DE 90 JOURS : En cas de défaillance due à des vices de matériaux ou de fabrication au cours

des 90 jours suivant la date d’achat, l’acheteur pourra faire réparer tout outil électrique RYOBI® au titre de cette garantie

ou le retourner l’établissement où il a été acheté. Pour obtenir un outil en échange ou demander la réparation en garantie,

l’équipement complet devra être retourné, dans son emballage d’origine, accompagné d’une preuve d’achat. L’outil fourni

en échange sera couvert par la garantie limitée pour le restant de la période de validité de deux ans à compter de la date

d’achat.

CE QUI EST COUVERT PAR LA GARANTIE : Cette garantie couvre tous les vices de matériaux et de fabrication de

cet outil électrique RYOBI®, pour une période de deux ans, à compter de la date d’achat. À l’exception des piles, les

accessoires sont garantis pour une période de quatre-vingt-dix (90) jours. Les piles sont garanties deux ans.

RÉPARATIONS SOUS GARANTIE : Il suffit de retourner l’outil, correctement emballé, en port payé, à un centre de

réparations agréé. L’adresse du centre de réparations agréé le plus proche peut être obtenue en contactant un représentant

du service après-vente par courrier, à l’adresse One World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207,

par téléphone au 1-800-525-2579 ou par courriel, à l’adresse Internet www.ryobitools.com. Lors de toute demande de

réparation sous garantie, une preuve d’achat datée (par exemple un reçu de vente) doit être fournie. Nous nous engageons

à réparer tous les défauts de fabrication et à réparer ou remplacer, à notre choix, toutes les pièces défectueuses. Les

réparations et remplacements seront gratuits. Les réparations sous garantie seront effectuées dans un délai raisonnable,

ne dépassant en aucun cas quatre-vingt-dix (90) jours.

CE QUI N’EST PAS COUVERT : La garantie ne couvre que l’acheteur au détail original et n’est pas transférable. Cette

garantie ne couvre que les défauts résultant d’une utilisation normale. Elle ne couvre pas les problèmes de fonctionnement,

défaillances ou autres défauts résultant d’un usage incorrect ou abusif, de la négligence, de la modification, de l’altération

ou de réparations effectuées par quiconque autre qu’un centre de réparations agréé. One World Technologies, Inc. ne fait

aucune autre garantie, représentation ou promesse concernant la qualité et les performances de cet outil électrique, autres

que celles expressément indiquées dans le présent document.

AUTRES LIMITATIONS : Toutes les garanties implicites accordées par les lois en vigueur, y compris les garanties de valeur

marchande ou d’adéquation à un usage particulier, sont limitées à une durée de deux ans, à compter de la date d’achat.

One World Technologies, Inc. déclinant toute responsabilité pour les dommages directs ou indirects, les limitations et

exclusions peuvent ne pas s’appliquer à chaque acheteur. Cette garantie donne au consommateur des droits spécifiques,

et celui-ci peut bénéficier d’autres droits, qui varient selon les états ou provinces.

2 - Français

Page 12

RÈGLES DE SÉCURITÉ RELATIVES AUX OUTILS ÉLECTRIQUES

ou d’une protection auditive, utilisé dans des conditions

AVERTISSEMENT

Lire tous les avertissements et toutes les instructions.

Ne pas suivre l’ensemble des avertissements et des

instructions peut entraîner une électrocution, un incendie

ou des blessures graves.

Conserver les avertissements et les instructions à des fins

de référence ultérieure.

tous les avertissements ci-dessous désigne tout outil fonctionnant sur secteur (câblé) ou sur piles (sans fil).

Le terme « outil motorisé », utilisé dans

SÉCURITÉ DU LIEU DE TRAVAIL

Garder le lieu de travail propre et bien éclairé. Les endroits

encombrés ou sombre s sont propices aux accidents.

Ne pas utiliser d’outils électriques dans des atmosphères

explosives, par exemple en présence de liquides, gaz ou

poussières inflammables. Les outils électriques produisent

des étincelles risquant d’enflammer les poussières ou vapeurs.

Garder les enfants et badauds à l’écart pendant

l’utilisation d’un outil électrique. Les distractions peuvent

causer une perte de contrôle.

SÉCURITÉ ÉLECTRIQUE

Les fiches des outils électriques doivent correspondre à

la prise secteur utilisée. Ne jamais modifier la fiche, de

quelque façon que ce soit. Ne jamais utiliser d’adaptateurs

de fiche avec des outils mis à la terre. Les fiches et

prises non modifiées réduisent le risque de choc électrique.

Éviter tout contact du corps avec des surfaces mises à

la terre, telles que tuyaux, radiateurs, cuisinières et réfrigérateurs. Le risque de choc électrique est accru lorsque

le corps est mis à la terre.

Ne pas exposer les outils électriques à l’eau ou

l’humidité. La pénétration d’eau dans ces outils accroît le

risque de choc électrique.

Ne pas maltraiter le cordon d’alimentation. Ne jamais

utiliser le cordon d’alimentation pour transporter l’outil et

ne jamais débrancher ce dernier en tirant sur le cordon.

Garder le cordon à l’écart de la chaleur, de l’huile, des objets tranchants et des pièces en mouvement. Un cordon

endommagé ou emmêlé accroît le risque de choc électrique.

Pour les travaux à l’extérieur, utiliser un cordon spéci-

alement conçu à cet effet. Utiliser un cordon conçu pour

l’usage extrérieur pour réduire les risques de choc électrique.

SÉCURITÉ PERSONNELLE

Rester attentif, prêter attention au travail et faire preuve

de bon sens lors de l’utilisation de tout outil électrique.

Ne pas utiliser cet outil en état de fatigue ou sous

l’influence de l’alcool, de drogues ou de médicaments.

Un moment d’inattention pendant l’utilisation d’un outil

électrique peut entraîner des blessures graves.

Utiliser l’équipement de sécurité. Toujours porter une

protection oculaire. L’équipement de sécurité, tel qu’un

masque filtrant, de chaussures de sécurité, d’un casque

appropriées réduira le risque de blessures.

Éviter les démarrages accidentels. S’assurer que le

commutateur est en position d’arrêt avant de brancher

l’outil. Porter un outil avec le doigt sur son commutateur ou

brancher un outil dont le commutateur est en position de

marche peut causer un accident.

Retirer les clés de réglage avant de mettre l’outil en

marche. Une clé laissée sur une pièce rotative de l’outil

peut causer des blessures.

Ne pas travailler hors de portée. Toujours se tenir bien

campé et en équilibre. Ceci permettra de mieux contrôler

l’outil en cas de situation imprévue.

Porter une tenue appropriée. Ne porter ni vêtements

amples, ni bijoux. Garder les cheveux, les vêtements et

les gants à l’écart des pièces en mouvement. Les vête-

ments amples, bijoux et cheveux longs peuvent se prendre

dans les pièces en mouvement.

Si les outils sont équipés de dispositifs de dépous-

siérage, s’assurer qu’ils sont connectés et correctement

utilisés. L’usage de ces dispositifs de dépoussiérage peut

réduire les dangers présentés par la poussière.

Ne porter ni vêtements amples, ni bijoux. Attacher ou

couvrir les cheveux longs. Les vêtements amples, bijoux et

cheveux longs peuvent se prendre dans les ouïes d’aération.

Ne pas utiliser l’outil sur une échelle ou un support in-

stable. Une bonne tenue et un bon équilibre permettent de

mieux contrôler l’outil en cas de situation imprévue.

UTILISATION ET ENTRETIEN DES OUTILS

ÉLECTRIQUES

Ne pas forcer l’outil. Utiliser l’outil approprié pour

l’application. Un outil approprié exécutera le travail mieux et de

façon moins dangereuse s’il est utilisé dans les limites prévues.

Ne pas utiliser l’outil si le commutateur ne permet pas

de le mettre en marche ou de l’arrêter. Tout outil qui ne

peut pas être contrôlé par son commutateur est dangereux

et doit être réparé.

Débrancher l’outil et/ou retirer le bloc-piles avant

d’effectuer des réglages, de changer d’accessoire ou

de remiser l’outil. Ces mesures de sécurité préventives

réduisent les risques de démarrage accidentel de l’outil.

Ranger les outils motorisés hors de la portée des en-

fants et ne laisser personne n’étant pas familiarisé avec

l’outil ou ces instructions utiliser l’outil. Dans les mains

de personnes n’ayant pas reçu des instructions adéquates,

les outils sont dangereux.

Entretenir les outils motorisés. Vérifier qu’aucune pièce

mobile n’est mal alignée ou bloquée, qu’aucune pièce

n’est brisée et s’assurer qu’aucun autre problème ne

risque d’affecter le bon fonctionnement de l’outil. En

cas de dommages faire réparer l’outil avant de l’utiliser de

nouveau. Beaucoup d’accidents sont causés par des outils

mal entretenus.

Garder les outils bien affûtés et propres. Des outils cor-

rectement entretenus et dont les tranchants sont bien affûtés

risquent moins de se bloquer et sont plus faciles à contrôler.

3 - Français

Page 13

RÈGLES DE SÉCURITÉ RELATIVES AUX OUTILS ÉLECTRIQUES

Utiliser l’outil, les accessoires et embouts, etc. confor-

mément à ces instrutions pour les applications pour

lesquelles ils sont conçus, en tenant compte des conditions et du type de travail à exécuter. L’usage d’un outil

motorisé pour des applications pour lesquelles il n’est pas

conçu peut être dangereux.

DÉPANNAGE

Les réparations doivent être confiées à un technicien

qualifié, utilisant exclusivement des pièces identiques

à celles d’origine. Ceci assurera le maintien de la sécurité

de l’outil.

Utiliser exclusivement des pièces identiques à celles

d’origine pour les réparations. Se conformer aux instructions de la section Entretien de ce manuel. L’usage de

pièces non autorisées ou le non-respect des instructions peut

présenter des risques de choc électrique ou de blessures.

AVERTISSEMENTS DE SÉCURITÉ RELATIFS PISTOLET THERMIQUE

Lorsque l’outil est utilisé pour un travail risquant de le

mettre en contact avec des fils électriques cachés, le

tenir par les surfaces de prise isolées. Le contact d’un

accessoire de coupe avec un fil sous tension « électrifie » les

pièces métalliques exposées de l’outil et peut électrocuter

l’utilisateur.

La buse du pistolet thermique devient brûlante pendant

l’utilisation et ne doit pas être touchée avant que l’outil

ait refroidi. Toujours tenir l’outil par la surface de prise isolée

pour réduire les risques de blessures graves.

Les pistolets thermiques produisent des températures

extrêmement élevées et doivent être utilisés avec prudence

pour éviter d’enflammer les matériaux combustibles.

Garder constamment l’outil en mouvement, ne pas le

tenir immobile à un endroit. Le respect de cette consigne

réduira les risques d’incendie ou de blessures graves.

Une chaleur excessive peut produire des vapeurs

dangereuses si elles sont inhalées. Lors de l’utilisation

du pistolet thermique, porter un masque filtrant ou un

respirateur à double filtre. Le respect de cette consigne

réduira les risques de blessures graves.

Garder un extincteur complètement chargé à portée de

main, pour les cas d’urgence. Le respect de cette règle

réduira les risques d’incendie ou de blessures graves.

Ne pas laisser le pistolet thermique sans surveillance

lorsqu’il est en fonctionnement ou pendant qu’il refroidit.

Lorsqu’il est en fonctionnement ou en train de refroidir,

toujours poser l’outil sur une surface plane et horizontale,

la buse orientée vers le haut. Le respect de cette règle

réduira les risques d’incendie ou de blessures graves.

Apprendre à connaître l’outil. Lire attentivement le manuel

d’utilisation. Apprendre les applications et les limites de

l’outil, ainsi que les risques spécifiques relatifs à son

utilisation. Le respect de cette consigne réduira les risques

d’incendie, de choc électrique et de blessures graves.

Toujours porter une protection oculaire certifiée

conforme à la norme ANSI Z87.1. Le respect de cette règle

réduira les risques de blessures graves.

Protection auditive. Porter une protection auditive lors

de l’utilisation prolongée. Le respect de cette règle réduira

les risques de blessures graves.

Inspecter régulièrement le cordon d’alimentation de

l’outil et le cordon prolongateur. S’ils sont endommagés,

les confier au centre de réparations agréé le plus proche.

Toujours être conscient de l’emplacement du cordon.

Le respect de cette consigne réduira les risques de choc

électrique et d’incendie.

Vérifier l’état des pièces. Avant d’utiliser l’outil de

nouveau examiner soigneusement les pièces et

dispositifs de protection qui semblent endommagés afin

de déterminer s’ils fonctionnent correctement et s’ils

remplissent les fonctions prévues. Vérifier l’alignement

des pièces mobiles, s’assurer qu’aucune pièce n’est

bloquée ou cassée, vérifier la fixation de chaque pièce et

s’assurer qu’aucun autre problème ne risque d’affecter

le bon fonctionnement de l’outil. Toute protection ou

pièce endommagée doit être correctement réparée

ou remplacée dans un centre de réparations agréé.

Le respect de cette consigne réduira les risques de choc

électrique, d’incendie et de blessures graves.

S’assurer que le cordon prolongateur est en bon état.

Si un cordon prolongateur est utilisé, s’assurer que

sa capacité est suffisante pour supporter le courant

de fonctionnement de l’outil. Un calibre de fil (A.W.G)

d’au minimum 14 est recommandé pour un cordon

prolongateur de 15 m (50 pi) maximum. L’usage d’un

cordon de plus de 30 m (100 pi) est déconseillé. En cas

de doute, utiliser un cordon du calibre immédiatement

supérieur. Moins le numéro de calibre est élevé, plus

la capacité du fil est grande. Un cordon de capacité

insuffisante causerait une baisse de la tension de ligne,

entraînant une perte de puissance et une surchauffe.

Conserver ces instructions. Les consulter fréquemment

et les utiliser pour instruire les autres utilisateurs éventuels.

Si ce produit est prêté, il doit être accompagné de ces

instructions, afin d’éviter un usage incorrect et d’éventuelles

blessures.

4 - Français

Page 14

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à l’utilisation

de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER :

AVERTISSEMENT :

ATTENTION :

AVIS :

Certains des symboles ci-dessous peuvent être utilisés sur produit. Veiller à les étudier et à apprendre leur signification. Une

interprétation correcte de ces symboles permettra d’utiliser produit plus efficacement et de réduire les risques.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée, aura

pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourraît entraîner des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité) Indique une information importante ne

concernant pas un risque de blessure comme une situation pouvant occasionner

des dommages matériels.

V

A

Hz

min

n

o

Symbole d’alerte de

sécurité

Lire manuel d’utilisation

Protection oculaire

Avertissement concernant

l’humidité

Surface brûlante

Volts Tension

Ampères Intensité

Hertz Fréquence (cycles par seconde)

Minutes Temps

Courant alternatif Type de courant

Vitesse à vide Vitesse de rotation à vide

Indique un risque de blessure potentiel.

Pour réduire les risques de blessures, l’utilisateur doit lire et veiller à

bien comprendre le manuel d’utilisation avant d’utiliser ce produit.

Toujours porter une protection oculaire avec écrans latéraux certifiée

conforme à la norme ANSI Z87.1.

Ne pas exposer à la pluie ou l’humidité.

Pour éviter les risques de blessures ou de dommages, éviter tout

contact avec les surfaces brûlantes.

Class II Construction Double-insulated construction

PROPOSITION 65 DE LA CALIFORNIE

AVERTISSEMENT :

Ce produit et la poussière dégagée lors du ponçage, sciage, meulage, perçage de certains matériaux et lors d’autres opérations de construction contient des produits chimiques, notamment du plomb, identifiés par l’état de Californie comme causes

de cancer, des malformations congénitales ou des lésions de l’appareil reproducteur. Bien se laver les mains après toute

manipulation. Voici certains exemples de ces produits chimiques :

• leplombcontenudanslapeintureauplomb,

• lasilicecristallinecontenuedanslesbriques,lebétonetd’autresproduitsdemaçonnerie,ainsique

• l’arsenicetlechromecontenusdansleboisdeconstructiontraitéparproduitschimiques.

Le risque présenté par l’exposition à ces produits varie en fonction de la fréquence de ce type de travail. Pour réduire l’exposition,:

travailler dans un endroit bien aéré et utiliser des équipements de sécurité approuvés tels que masques antipoussière spécialement conçus pour filtrer les particules microscopiques.

5 - Français

Page 15

CARACTÉRISTIQUES ÉLECTRIQUES

DOUBLE ISOLATION

La double isolation est un dispositif de sécurité utilisé sur les

outils à moteur électriques, éliminant le besoin de cordon

d’alimentation habituel à trois fils avec terre. Toutes les pièces

métalliques exposées sont isolées des composants internes

du moteur par l’isolation protectrice. Les outils à double

isolation ne nécessitent pas de mise à la terre.

AVERTISSEMENT :

Le système à double isolation est conçu pour protéger

l’utilisateur contre les chocs électriques causés par une

rupture de l’isolation interne de l’outil. Prendre toutes les

précautions de sécurité normales pour éviter les chocs

électriques.

NOTE : La réparation d’un outil à double isolation exigeant

des précautions extrêmes ainsi que la connaissance du

système, elle ne doit être confiée qu’à un réparateur qualifié.

En ce qui concerne les réparations, nous recommandons de

confier l’outil au centre de réparations le plus proche. Utiliser

exclusivement des pièces d’origine pour les réparations.

CONNEXIONS ÉLECTRIQUES

Cet outil est équipé d’un moteur électrique de précision. Elle

doit être branchée uniquement sur une alimentation 120 V,

c.a. (courant résidentiel standard), 60 Hz. Ne pas utiliser

cet outil sur une source de courant continu (c.c.). Une chute

de tension importante causerait une perte de puissance et

une surchauffe du moteur. Si l’outil ne fonctionne pas une

fois branché, vérifier l’alimentation électrique.

CORDONS PROLONGATEURS

Lors de l’utilisation d’un outil électrique à grande distance

d’une prise secteur, veiller à utiliser un cordon prolongateur

d’une capacité suffisante pour supporter l’appel de courant de

l’outil. Un cordon de capacité insuffisante causerait une baisse

de la tension de ligne, entraînant une perte de puissance

et une surchauffe. Se reporter au tableau ci-dessous pour

déterminer le calibre minimum de fil requis pour un cordon

donné. Utiliser exclusivement des cordons à gaine cylindrique

homologués par Underwriter’s Laboratories (UL).

Pour le travail à l’extérieur, utiliser un cordon prolongateur

spécialement conçu à cet effet. Ce type de cordon porte

l’inscription « WA » ou « W »sur sa gaine.

Avant d’utiliser un cordon prolongateur, vérifier que ses fils

ne sont ni détachés ni exposés et que son isolation n’est ni

coupée, ni usée.

**Intensité nominale (sur la plaquette signalétique de l’outil)

0-2,0 2,1-3,4 3,5-5,0 5,1-7,0 7,1-12,0 12,1-16,0

Longueur Calibre de fil

du cordon (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Utilisé sur circuit de calibre 12 - 20 A

NOTE : AWG = American Wire Gauge

AVERTISSEMENT :

Maintenir le cordon prolongateur à l’écart de la zone de

travail. Lors du travail avec un cordon électrique, placer le

cordon de manière à ce qu’il ne risque pas de se prendre

dans les pièces de bois, outils et autres obstacles. Ne

pas prendre cette précaution peut entraîner des blessures

graves.

Vérifier l’état des cordons prolongateurs avant chaque

utilisation. Remplacer immédiatement tout cordon

endommagé. Ne jamais utiliser un outil dont le cordon

d’alimentation est endommagé, car tout contact avec la

partie endommagée pourrait causer un choc électrique

et des blessures graves.

6 - Français

AVERTISSEMENT :

Page 16

CARACTÉRISTIQUES

FICHE TECHNIQUE

Température produite ...................................................................................................................200à1050˚F(93à565˚C)

Alimentation...................................................................................................................... 120 V, c.a. seulement, 60 Hz, 11 A

Poids net ..........................................................................................................................................................1,7 lb (0,77 kg)

APPRENDRE À CONNAÎTRE LE PISTOLET

THERMIQUE

Voir la figure 1, page 11.

Avant d’essayer d’utiliser ce produit, se familiariser avec

toutes ses fonctions et tous ses dispositifs de sécurité.

COMMUTATEUR DE ÉLEVÉE/BASSE/ARRÊT

L’emplacement du commutateur de élevée/basse/arrêt

assure la facilité d’utilisation.

CONE DE BUSE

Le cône de protection du pistolet thermique peut être retiré

pour travailler dans les endroits confinés.

STAND

Le pistolet thermique est doté d’un stand intégré commode

pour l’utilisation et le refroidissement.

ASSEMBLAGE

DÉBALLAGE

Ce produit a été expédié complètement assemblé.

Avec précaution, sortir l’outil et les accessoires de la

boîte. S’assurer que toutes les pièces figurant sur la liste

de contrôle sont incluses.

AVERTISSEMENT :

Ne pas utiliser le produit s’il n’est pas complètement

assemblé ou si des pièces semblent manquantes ou

endommagées. Le fait d’utiliser un produit assemblé

de façon inadéquate ou incomplète peut entraîner des

blessures graves.

Examiner soigneusement l’outil pour s’assurer que rien

n’a été brisé ou endommagé en cours de transport.

Ne pas jeter les matériaux d’emballage avant d’avoir

soigneusement examiné l’outil et avoir vérifié qu’il

fonctionne correctement.

Si des pièces sont manquantes ou endommagées,

appeler le 1-800-525-2579.

LISTE DE CONTRÔLE D’EXPÉDITION

Pistolet thermique

Embout pour cintrage de tubes

Embout concentrateur

Manuel d’utilisation

7 - Français

MOLETTE DE RÉGLAGE DE TEMPÉRATURE

La température produite par le pistolet thermique, peut

être ajustée de 200à1050˚F(93à565˚C), au moyen de la

molette de réglage.

AFFICHAGE DEL DE TEMPÉRATURE

La température désirée est indiquée par la position du molette

de réglage de température.

PROTECTION THERMIQUE

Le pistolet thermique est équipé avec la protection

thermique qui inactive la bobine de chauffage quand le

jet est aussi près d’une surface est chauffé. Le ventilateur

continuera à fonctionner et la bobine de chauffage activera

automatiquement après que la bobine s’est refroidi.

AVERTISSEMENT :

Si des pièces manquent ou sont endommagées, ne pas

utiliser cet outil avant qu’elles aient été remplacées. Le

fait d’utiliser ce produit même s’il contient des pièces

endommagées ou s’il lui manque des pièces peut

entraîner des blessures graves.

AVERTISSEMENT :

Ne pas essayer de modifier cet outil ou de créer des

accessoires non recommandés pour l’outil. De telles

altérations ou modifications sont considérées comme

un usage abusif et peuvent créer des conditions

dangereuses, risquant d’entraîner des blessures graves.

AVERTISSEMENT :

Ne pas brancher sur le secteur avant d’avoir terminé

l’assemblage. Le non respect de cet avertissement peut

causer un démarrage accidentel, entraînant des blessures

graves.

Page 17

UTILISATION

AVERTISSEMENT :

Ne pas laisser la familiarité avec l’outil faire oublier la

prudence. Ne pas oublier qu’une fraction de seconde

d’inattention peut entraîner des blessures graves.

AVERTISSEMENT :

Toujours porter une protection oculaire avec écrans

latéraux certifiée conforme à la norme ANSI Z87.1. Si cette

précaution n’est pas prise, des objets peuvent être projetés

dans les yeux et causer des lésions graves.

AVERTISSEMENT :

Ne pas utiliser d’outils ou accessoires non recommandés

pour cet outil. L’utilisation de pièces et accessoires non

recommandés peut entraîner des blessures graves.

APPLICATIONS

Cet outil peut être utilisé pour les applications ci-dessous :

Amolissement de la peinture, des mastics et produits de

calfatage pour faciliter leur élimination

Amolissement des adhésifs pour faciliter le décollement des

autocollants, carreaux de sol, papiers peints, etc.

Chauffage des matières plastique et métaux pour la mise

en forme

Soudage de raccords de tuyaux

Installation de tubes thermorétrécissables pour les travaux

électriques

Films thermorétrécissables pour l’emballage ou la protection

contre les intempéries

Desserrage des écrous, boulons et raccords rouillés

LISEZ CETTE INSTRUCTION

AVERTISSEMENT :

Faire preuve de la plus extrême prudence lors du décapage

de peinture. Les déchets, résidus et vapeurs de la peinture

peuvent contenir du plomb, qui est une substance toxique.

Toute peinture antérieure à 1977 peut contenir du plomb

et la peinture résidentélle antérieure à 1950 contient

probablement du plomb. Si l’on touche la peinture déposée

sur les surfaces, le contact des doigts avec la bouche peut

causer l’ingestion de plomb. L’exposition au plomb, même

à doses faibles, peut causer des lésions cérébrales et

nerveuses irréversibles, les nouveau nés et fœtus étant

particulièrement vulnérables. Avant d’entreprendre toute

opération de décapage, il est impératif de déterminer si

la peinture à éliminer contient du plomb. Pour ce faire,

contacter les services d’hygiène locaux ou un professionnel

qui utilise un analyseur de peinture pour vérifier le contenu en

plomb de la peinture à décaper. LA PEINTURE AU PLOMB

NEDOITÊTREDÉCAPÉEQUEPASUNPROFESSIONNEL

ET NE DOIT PAR ÊTRE ÉLIMINÉE AU MOYEN D’UN

PISTOLETTHERMIQUE.

Les personnes effectuant l’écapage doivent se conformer aux

directives suivantes :

Emmener la pièce à décaper à l’extérieur. Si cela n’est pas

possible, garder le lieu de travail bien ventilé. Ouvrir les

fenêtres et placer un ventilateur dans l’une d’elles. Veiller à

ce que le ventilateur évacue l’air vers l’extérieur.

Retirer ou couvrir les tapis, moquettes, meubles, vêtements,

ustensiles de cuisine et conduits d’air.

Placer des toiles de protection sur la zone de travail pour

recueillir tous les déchets de peinture. Porter des vêtements

protecteurs tels qu’une chemise de travail supplémentaire

ou une combinaison et un couvre-chef.

Ne travailler que dans une pièce à la fois. Les meubles

doivent être retirés ou placés au centre de la pièce et

couverts. Les zones de travail doivent être isolées du reste

de la résidence en calfeutrant les entrées avec des toiles de

protection.

Les enfants et femmes enceintes ou susceptibles de l’être,

ainsi que les mères allaitantes ne doivent pas se trouver sur

le lieu de travail avant que le nettoyage soit terminé.

Porter un masque respiratoire simple (poussières) ou double

(poussières et vapeurs) agréé par l’OSHA (Occupational

Safety and Health Administration), le NIOSH (National

Institute of Safety and Health) ou le bureau des mines

américain. Ces masques et filtres remplaçables sont en

ventre dans la plupart des quincailleries. S’assurer que le

masque est bien ajusté. La barbe et les cheveux peuvent

empêcher une bonne étanchéité à l’air. Changer les filtres

fréquemment.LES MASQUES EN PAPIER JETABLES

N’OFFRENT PAS UNE PROTECTION SUFFISANTE.

Utiliser le pistolet thermique avec prudence. Il doit toujours

être gardé en mouvement, car une chaleur excessive peut

dégager des vapeurs.

Garder les aliments et boissons loin de la zone de travail. Se

laver les mains, les bras et le visage, puis effectuer un rinçage

de bouche avant de boire ou manger. Ne pas fumer ou

mâcher du tabac ou du chewing-gum sur le lieu de travail.

Éliminerlesrésidusetlapoussièredusolenlenettoyant

avec une serpillère humide. Nettoyer les murs, seuils et toute

surface couverte de résidus ou de poussière de peinture

avec un chiffon humide. NE PAS BALAYER, ESSUYER À

SEC OU ASPIRER. Utiliser du phosphate trisodique (TSP)

pour laver et nettoyer les lieux de travail.

À la fin de la séance de travail, placer les résidus et débris

dans un sac en plastique double et fermer ce sac avec un

ruban ou une attache.

Retirer les vêtements et chaussures de protection sur le lieu

de travail et éviter de transporter des poussières dans le reste

de la résidence. Laver les vêtements de travail séparément.

Essuyer les chaussures avec un chiffon humide et laver ce

chiffon avec les vêtements de travail. Se laver les cheveux

et le corps avec de l’eau et du savon.

8 - Français

Page 18

UTILISATION

AVERTISSEMENT :

Ce pistolet thermique produit des températures extrêmement

élevées. Les endroits cachés par les murs, plafonds,

planchers, intrados et autres panneaux peuvent contenir

des matériaux inflammables susceptible de prendre feu

sous l’effet du pistolet thermique. Garder constament l’outil

en mouvement, ne pas le tenir immobile à un endroit, ce

qui resiquerait d’enflammer les matériaux cachés par les

panneaux. L’inflammation de ces matériaux peut ne pas être

immédiatement apparente, ce qui peut causer des sérieux

dommages et blessures.

CONSERVEZ CETTE INSTRUCTION

AVERTISSEMENT :

Ne pas diriger la buse vers les vêtements, les mains

ou une partie quelconque du corps. La chaleur intense

peut causer des brûlures graves ou l’inflammation des

vêtements.

CONSERVEZ CETTE INSTRUCTION

MISE EN MARCHE ET ARRÊT DU PISTOLET

THERMIQUE

Voir la figure 2, page 11.

Pour mettre le pistolet thermique en marche, glisser le sélecteur

en position de marche (I) . Pour l’arrêter, mettre le commutateur

en position arrêt (O).

RÉGLAGE DE TEMPÉRATURE

Voir la figure 2 et 3, page 11.

La réglages de température du pistolet thermique est présentée

sur l’affichage de température et est contrôlée par la molette

de réglage du dessus de l’outil. Tourner la molette vers la droite

pour augmenter la température et vers la gauche pour la réduire.

Pour régler le pistolet thermique sur le réglages de termique

basse, glisser l’commutateur de élevée/basse/arrêt au I

(position centre). Pour utiliser l’haut réglages de termique

élevée, glisser l’commutateur de élevée/basse/arrêt à II

(position élevée).

UTILISATION MAINS LIBRES

Voir la figure 4, page 11.

Le bas de la crosse du pistolet thermique présente une surface

plate qui fait office de stand pour les opérations mains libres

et le refroidissement. Poser l’outil sur une surface plate et

s’assurer que le placement du cordon d’alimentation ne risque

pas de la faire basculer.

NOTE : Ne pas laisser le pistolet thermique sans surveillance

lorsqu’il est en fonctionnement ou pendant qu’il refroidit.

Toujours poser l’outil sur une surface plane et horizontale, la

buse orientée vers le haut, à l’opposé de la surface.

INSTALLATION DES ACCESSOIRES

Voir les figures 5 et 6, page 11.

Plusieurs accessoires sont inclus avec le pistolet thermique,

pour diverses applications. Pour installer les accesssoires,

il suffit de les glisser sur la buse du pistolet.

NOTE : N’installer les accessoires que lorsque le pistolet

thermique et les accessoires sont froids.

Embout pour cintrage de tubes : Cet embout est utile

pour le cintrage, le soudage des tubes et le chauffage des

tubes thermorétrécissables.

Embout concentrateur : L’embout concentrateur

concentre la chaleur à l’endroit où il est utilisé. Cet embout

est utilisé pour mettre en forme les feuilles de plastique

acrylique, souder les raccords de tuyaux et diriger la chaleur

dans les coins.

RETRAIT DU CONE DE BUSE

Voir la figure 7, page 11.

Le cône de buse réduit le risque d’exposition aux surfaces

brûlantes du pistolet thermique pendant le fonctionnement.

Toutefois, il peut être retiré pour le travail dans les espaces

restreints.

NOTE : Toujours remettre le cône en place une fois l’opération

terminée.

Retrait :

Débrancher le pistolet thermique.

La buse étant dirigée vers l’ gauche, tourner le cône et

le retirer.

AVERTISSEMENT :

Le réglage de température approprié pour une application

donnée dépend de la distance entre la buse et lapièce à

décaper, ainsi que de la durée de chauffage. Expérimenter

sur des pièces à jeter et commencer avec le réglage de

température le plus bas. Procéder avec prudence jusqu’à

ce que la combinaison correcte de réglage de température,

de distance et de durée de chauffage ait été déterminée.

Partir le pistolet thermique sans surveillance augmenter

le risque de flammes ou des blessures graves.

9 - Français

AVERTISSEMENT :

La buse du pistolet thermique devient brûlante pendant le

fonctionnement. Elle le reste pendant plusieurs minutes,

en fonction de la température ambiante. Pour éviter des

brûlures graves, laisser le pistolet thermique refroidir

avant d’essayer d’installer ou de retirer le cône.

Installation :

Débrancher le pistolet thermique.

Glisser le cône sur la buse du pistolet.

Le pousser contre le corps du pistolet thermique en

alignant les encoches de sa base sur les saillies du corps

du pistolet.

Tourner le cône vers la avant pour l’assujettir.

Page 19

ENTRETIEN

AVERTISSEMENT :

Utiliser exclusivement des pièces d’origine pour les

réparations. L’usage de toute autre pièce pourrait créer une

situation dangereuse ou endommager l’outil.

AVERTISSEMENT :

Toujours porter une protection oculaire certifiée conforme

à la norme ANSI Z87.1. Si cette précaution n’est pas prise,

des objets peuvent être projetés dans les yeux et causer

des lésions graves.

ENTRETIEN GÉNÉRAL

Éviter d’utiliser des solvants pour le nettoyage des

pièces en plastique. La plupart des matières plastiques

peuvent être endommagées par divers types de solvants

du commerce. Utiliser un chiffon propre pour éliminer la

saleté, la poussière, l’huile, la graisse, etc.

AVERTISSEMENT :

Ne jamais laisser de liquides tels que le fluide de freins,

l’essence, les produits à base de pétrole, les lubrifiants

pénétrantes, etc., entrer en contact avec les pièces en

plastique. Les produits chimiques peuvent endommager,

affaiblir ou détruire le plastique, ce qui peut entraîner des

blessures graves.

Les outils électriques utilisés sur la fibre de verre, le

placoplâtre, les mastics de bouchage ou le plâtre s’usent

plus vite et sont susceptibles de défaillance prématurée, car

les particules et les éclats de fibre de verre sont fortement

abrasifs pour les roulements, balais, commutateurs, etc.

Toutefois, si l’outil a été utilisé sur l’un de ces matériaux, il est

extrêmement important de le nettoyer à l’air comprimé.

LUBRIFICATION

Tous les roulements de cet outil sont enduits d’une quantité

suffisante de lubrifiant de haute qualité pour la durée de vie

de l’outil, dans des conditions d’utilisation normales. Aucune

autre lubrification n’est donc nécessaire.

AVERTISSEMENT :

Toujours débrancher le pistolet thermique avant de

procéder à un entretien quel qu’il soit. Le respect de