Page 1

CSD-4107BG

4V LITHIUM-ION SCREWDRIVER

OWNER’S OPERATING MANUAL

Your screwdriver has been engineered and manufactured to our high standard for dependability, ease of operation,

and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual

before using this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

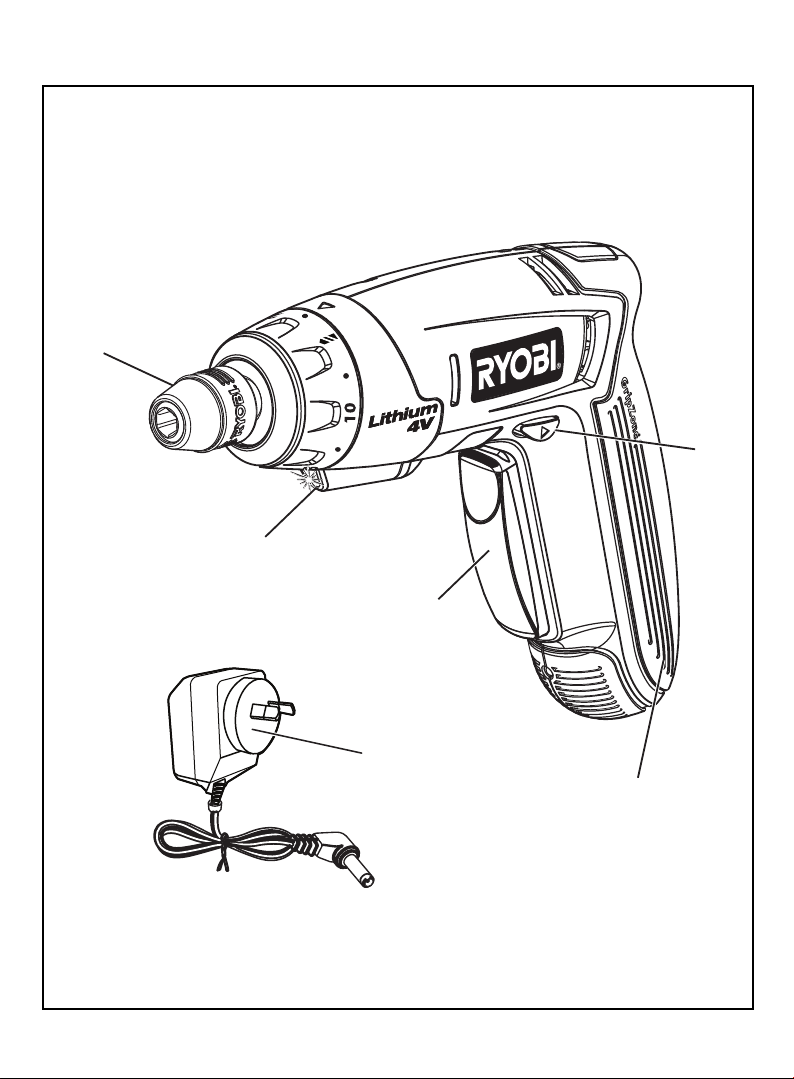

1

3

2

4

6

5

Fig.1

Page 3

8

15

16

7

9

6

Fig.2

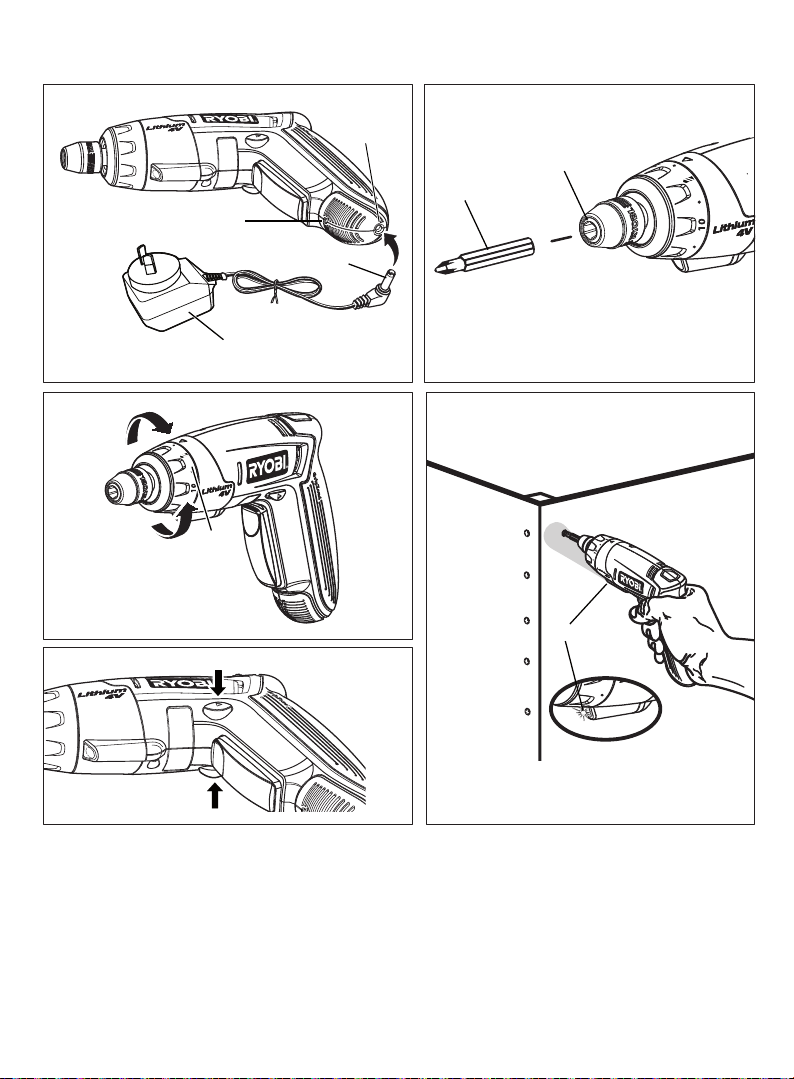

11

12

10

Fig.5

Fig.3

13

14

Fig.4

2

Fig.6

Page 4

GENERAL SAFETY RULES

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference. The term “power tool’’ in the warnings

refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

CLASS 1 LED PRODUCT

SAVE THESE INSTRUCTIONS.

WORK AREA

n Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

n Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

n Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

ELECTRICAL SAFETY

n Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed(grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

n Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

n Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

n Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

n When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

n If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk

of electric shock.

PERSONAL SAFETY

n Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

n Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

n Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch

on invites accidents.

n Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

n Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

n Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

n If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

POWER TOOL USE AND CARE

n Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

1

Page 5

GENERAL SAFETY RULES

n Do not use the power tool if the switch does not turn

it on and off. Any power tool that can not be controlled

with the switch is dangerous and must be repaired.

n Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

n Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

n Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

n Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

n Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking

into account the working conditions and the

work to be performed. Use of the power tool for

operations different from those intended could result

in a hazardous situation.

BATTERY TOOL USE AND CARE

n Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used

with another battery pack.

n Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

n When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal to

another. Shorting the battery terminals together may

cause burns or a fire.

n Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or

burns.

SERVICE

n Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool

is maintained.

CHARGER SAFETY

n Do not expose charger to wet or damp conditions.

n Use of an attachment not recommended or sold by

the battery charger manufacturer may result in a risk

of fire, electric shock, or injuries to person.

n To reduce risk of damage to charger body and

cord, pull by charger plug rather than cord when

disconnecting charger.

n Make sure cord is located so that it will not be stepped

on, tripped over, or otherwise subjected to damage

and stress.

n An extension cord should not be used unless

absolutely necessary. Use of improper extension

cord could result in a risk of fire and electric shock. If

extension cord must be used, make sure:

a. That pins on plug of extension cord are the same

number, size and shape as those of plug on charger.

b. That extension cord is properly wired and in good

electrical condition.

n Do not operate charger with a damaged cord or

plug. If damaged, have it replaced immediately by a

qualified serviceman.

n Do not operate charger if it has received a sharp

blow, been dropped, or otherwise damaged in any

way; take it to a qualified serviceman.

n Do not disassemble charger; take it to a qualified

serviceman when service or repair is required.

Incorrect reassembly may result in a risk of electric

shock or fire.

n To reduce risk of electric shock, unplug the charger

from outlet before attempting any maintenance or

cleaning. Turning off controls will not reduce this risk.

n Disconnect charger from power supply when not in

use.

n Risk of electric shock. Do not touch uninsulated

portion of output connector or uninsulated battery

terminal.

n Save these instructions. Refer to them frequently

and use them to instruct others who may use this

unit. If you loan someone this unit, loan them these

instructions also.

2

Page 6

SPECIFICATIONS

Motor 4 V DC

Switch Single Speed/Reversible

No load Speed 180 r/min.(RPM)

Clutch 12 Positions

Torque 5 Nm max

Collet 6.35 mm

Weight (included battery) 0.47 kg

Charger Rating Input: 240V, 50Hz, AC only

Output: 5.6V-DC 140mA

Charge Time 10-12 hours

DESCRIPTION

1. Quick change chuck

2. LED worklight

3. Direction of rotation selector ( forward/reverse/

center lock)

4. Switch Trigger

5. Grip zone

6. Charger

7. Red charge light

8. Input jack

9. Charger plug

10. To decrease torque

11. To increase torque

12. Torque adjustment ring

13. Reverse

14. Forward

15. Collet

16. Bit

OPERATION

WARNING:

Do not allow familiarity with products to make you

careless. Remember that a careless fraction of a

second is sufficient to inflict serious injury.

WARNING:

Always wear safety goggles or safety glasses with

side shields when operating products. Failure to

do so could result in objects being thrown into

your eyes, resulting in possible serious injury.

WARNING:

Do not use any attachments or accessories

not recommended by the manufacturer of this

product. The use of attachments or accessories

not recommended can result in serious personal

injury.

APPLICATIONS

You may use this product for the purposes listed below:

n Driving screws with screwdriver bits

n Light-duty drilling

TO CHARGE

See Figure 2.

When charging the screwdriver, a red charge light will

illuminate on the handle of the screwdriver. This red charge

light will go off when the screwdriver is fully charged.

n Insert charger plug into input jack making sure it is

properly connect ed.

n Charger can be used with normal household voltage

of 240 V, 50Hz, AC only.

n Connect charger to power supply.

n After normal usage, a minimum of hours charging

time is required to fully recharge the screwdriver.

n Do not place charger in an area of extreme heat or

cold. It will work best at normal room temperature.

n Remove the product from the charger once it is fully

charged and ready for use.

WARNING:

Battery products are always in operating condition.

Therefore, the switch should always be locked

when not in use or carrying at your side.

ADJUSTABLE TORQUE CLUTCH

This screwdriver is equipped with an adjustable torque

clutch for driving different types of screws into different ma te ri als. The proper setting depends on the type of ma te ri al

and the size of screw you are using.

ADJUSTING TORQUE

See Figure 3.

There are twelve torque indicator settings located on the

front of the screwdriver.

n Rotate adjustment ring to desired setting, aligning

num ber on adjustment ring with arrow on housing.

• 1 - 2 For driving small screws

• 3 - 4 For driving screws into soft material

• 5 - 7 For driving screws into soft and hard

materials

• 8 - 9 For driving screws into hard wood

• 10 - 11 For driving large screws

•

For full power applications

3

Page 7

OPERATION

DIRECTION OF ROTATION SELECTOR

(FORWARD/REVERSE/CENTER LOCK)

See Figure 4.

The direction of bit rotation is reversible and is controlled

by a selector located abo

screwdriver held in normal operating position, the direction

of rotation selector should be positioned to the left of the

switch trigger for forward motion. The direction is reversed

when the selector is to the right of the switch trigger.

Setting the switch trigger in the OFF (center lock) position

helps reduce the possibility of accidental starting when

not in use.

To stop the screwdriver, release the switch trigger and allow

the collet to come to a complete stop.

ve the switch trigger. With the

QUICK CHANGE CHUCK

See Figure 5.

A quick change chuck mounted on the screwdriver, is easy

ting or removing the bits. To insert a bit, insert the

for inser

bit into collet till lock. To remove a bit, simply pull the sleeve

of collet forward.

SPINDLE LOCK

The screwdriver spindle is locked when the On/Off switch

is not pressed.

This enables screws to be screwed in, even when the

battery is empty.

GRIP ZONE

Soft grip reduces the danger of slipping and thereby improves

the grip on the tool and handing.

At the same time, The rubber coating acheives a vibrationreducing effect.

LED WORKLIGHT

See Figure 6.

The screwdriver has a built-in LED worklight. This feature is

convenient when working in close or tight areas where

additional light is needed. Whenever the switch trigger is

depressed, the LED worklight will illuminate.

NOTE: Dur

illuminate, charge the screwdriver.

ing normal operation, if the LED w

orklight will not

MAINTENANCE

WARNING:

When servicing, use only identical replacement

parts. Use of any other parts may create a hazard

or cause product damage.

WARNING:

Always wear safety goggles or safety glasses with

side shields during product operation or when

blowing dust. If operation is dusty, also wear a

dust mask.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastic which may

result in serious personal injury.

Do not open the battery yourself. There is a danger of

short circuit.

Only the parts shown on the parts list are intended to be

repaired or replaced by the customer. All other par ts should

be replaced at an Authorized Service Center.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing

as waste. The machine, accessories and

packaging should be sorted for

environmental-friendly recycling.

4

Loading...

Loading...