Page 1

OPERATOR'S MANUAL

18 VOLT CORDLESS CHAIN SAW

MODEL NO. CS1800

Your new cordless chain saw has been engineered and manufactured to Ryobi's high standard for dependability, ease

of operation, and operator safety. When properly cared for, the saw will give you years of rugged, trouble-free

performance.

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s manual before using this product.

Thank you for buying a Ryobi product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

■ Table of Contents / Introduction ......................................................................................................................... 2

■ Important Safety Instructions ...................................................................................................................... 3 - 7

■ Symbols ....................................................................................................................................................... 8 - 9

■ Specifications .................................................................................................................................................. 10

■ Unpacking ........................................................................................................................................................ 10

■ Applications ..................................................................................................................................................... 10

■ Features....................................................................................................................................................10 - 11

■ Glossary of Terms ........................................................................................................................................... 12

■ Operation ..................................................................................................................................................13 - 22

■ Maintenance .............................................................................................................................................23 - 30

■ Bar and Chain Combinations ........................................................................................................................... 31

■ Troubleshooting ...............................................................................................................................................31

■ Warranty .......................................................................................................................................................... 32

■ Parts Ordering / Service .................................................................................................................................. 34

INTRODUCTION

Cutting wood is an easy task with the 18V chain saw. With the charger and removable battery pack, the chain saw

can be charged and conveniently ready to use. Safety, performance, and dependability have been given top

priority in the design of this chain saw making it easy to maintain and operate.

This saw was designed for occasional light duty use and has some limitations as to what can be cut with it. It was

not designed for felling large trees or sawing of large logs.

Look for this symbol to point out important safety

precautions. It means attention!!! Your safety is involved.

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

Do not attempt to operate this unit until you have

read thoroughly and understand completely all

instructions, safety information, etc. contained in

this manual. Failure to comply can result in

accidents involving fire, electric shock, or

serious personal injury.

READ ALL INSTRUCTIONS

BASIC SAFETY PRECAUTIONS

■ Do not operate a chain saw with one hand! Use a

firm grip with thumbs and fingers encircling the

chain saw handles. Serious injury to the operator,

helpers, bystanders, or any combination of these

persons may result from one-handed operation. A

chain saw is intended for two-handed use.

■ Always be aware of what you are doing when using

the chain saw. Use common sense. Do not operate

the chain saw when you are tired, ill, or under the

influence of alcohol, drugs, or medication.

■ Stay alert and pay attention to what you are doing.

Use common sense when using this unit.

■ Keep all parts of your body away from the saw

chain when the unit is running.

■ Always carry the chain saw by the front handle with

the unit stopped and the guide bar and saw chain

positioned to the rear. When transporting your

chain saw, use the appropriate guide bar scabbard.

■ Never let anyone use your chain saw who has not

received adequate instructions in its proper use.

This applies to rentals as well as privately owned

saws.

■ Before you start the unit, make sure the saw chain

is not contacting any object.

■ Stop the chain saw before setting it down. Do not

leave the unit running unattended.

■ To avoid accidental starting, never carry the unit

with your finger on the trigger.

■ Maintain the unit with care. Keep the cutting edge

sharp and clean for best performance and to

reduce the risk of injury. Follow instructions for

lubricating and changing accessories. Inspect the

battery charger cord periodically, and if damaged,

have it replaced or repaired by an authorized

service dealer.

■ Keep handles dry, clean, and free of oil and grease.

■ Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and securely

assembled. Chain should stop turning when the

trigger is released. If the chain turns after the

trigger has been released, have the unit serviced

by your nearest Ryobi service dealer.

■ Check for damaged parts. Any part or guard that

has been damaged should be carefully checked to

determine that it will operate properly and perform

its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or replaced

by an authorized service dealer unless otherwise

indicated elsewhere in this manual.

■ All chain saw service, other than the items listed in

the operation and maintenance sections, should be

performed by your nearest Ryobi service dealer.

■ Do not use in the rain, snow or wet conditions.

■ Always maintain a proper stance.

■ Do not adapt your powerhead to a bow guide or

use it to power any attachments or devices not

listed for your saw.

■ Do not cut vines and/or small underbrush.

SAFETY APPAREL

■ Wear snug fitting clothing. Always wear heavy, long

pants, overalls, jeans or chaps made of cut resistant material or ones that contain cut resistant

inserts. Wear non-slip safety footwear. Wear nonslip heavy duty gloves to improve your grip and to

protect your hands. Do not wear jewelry, short

pants, sandals, or go barefoot. Do not wear loose

fitting clothing, which could be drawn into the motor

or catch the chain or underbrush. Secure hair so it

is above shoulder level.

■ Wear eye protection which is marked to comply

with ANSI Z87.1 as well as hearing and head

protection when operating this equipment.

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

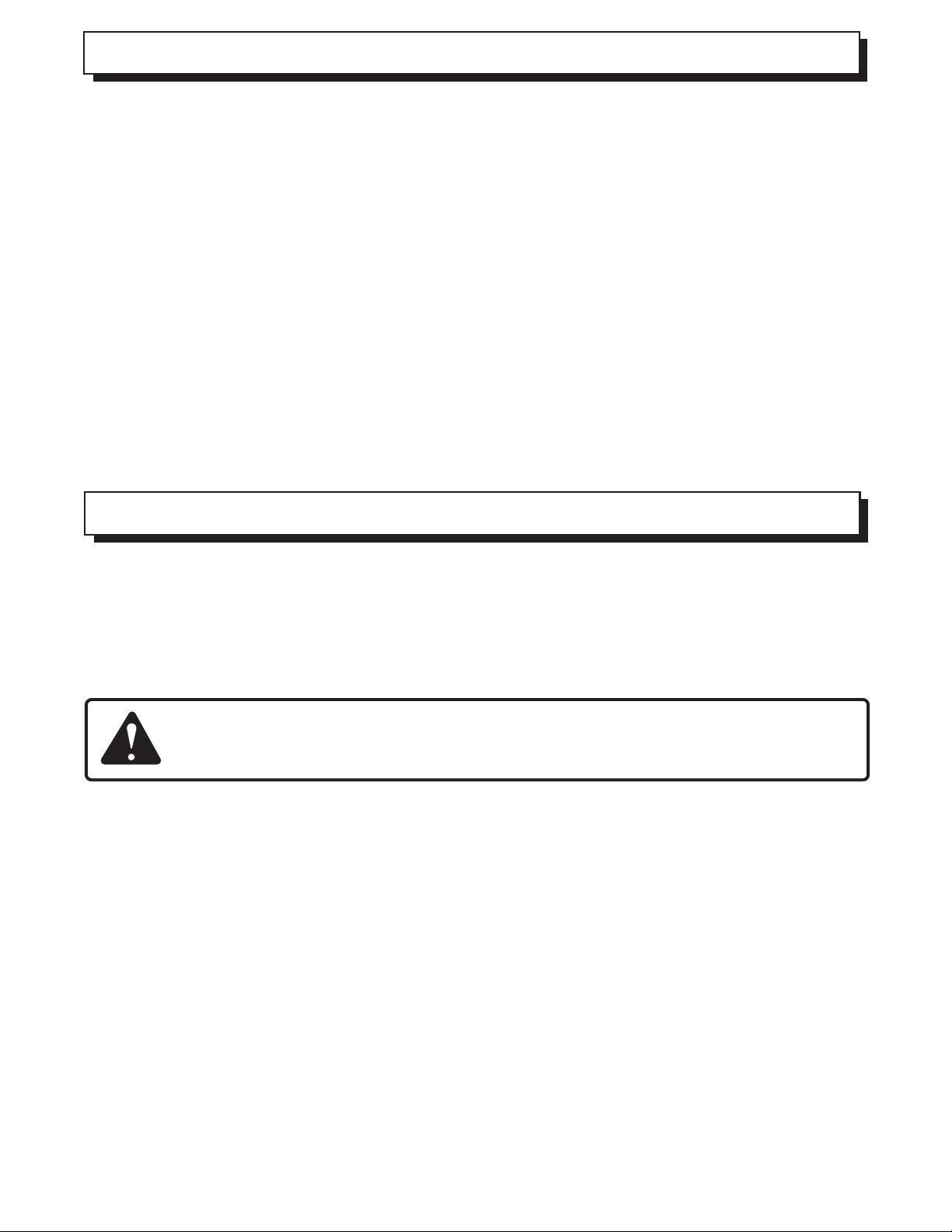

KICKBACK

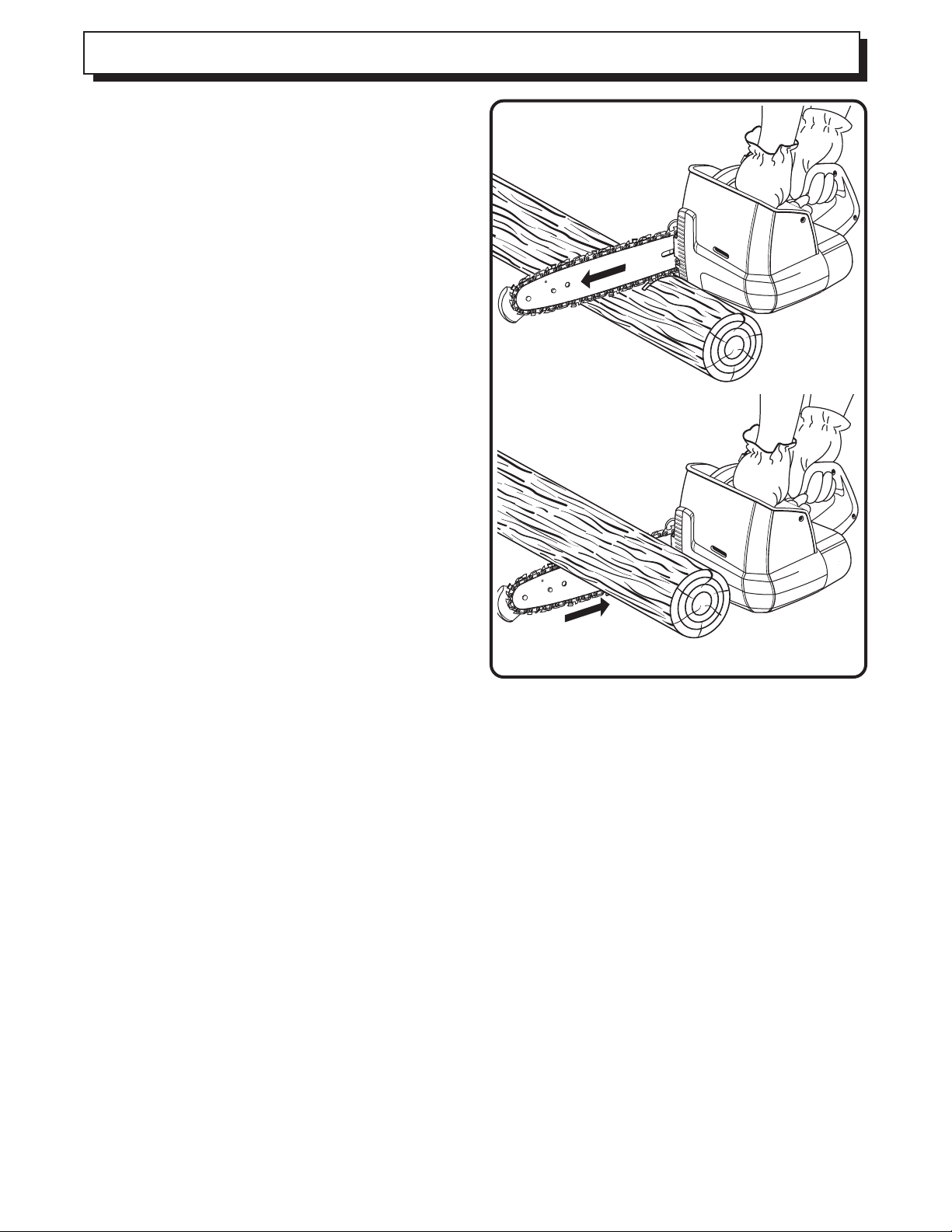

See Figures 1 and 2.

■ WARNING: Kickback may occur when the moving

chain contacts an object at the upper portion of the

tip of the guide bar or when the wood closes in and

pinches the saw chain in the cut. Contact at the

upper portion of the tip of the guide bar can cause

the chain to dig into the object and stop the chain

for an instant. The result is a lightning fast, reverse

reaction which kicks the guide bar up and back

toward the operator. If the saw chain is pinched

along the top of the guide bar, the guide bar can be

driven rapidly back toward the operator. Either of

these reactions can cause loss of saw control

which can result in serious injury. Do not rely

exclusively upon the safety devices built into your

saw. As a chain saw user, you should take several

steps to keep your cutting jobs free from accident

or injury.

■ The following precautions should be followed

to minimize kickback:

1. Always grip the saw firmly with both hands. Hold

the saw firmly with both hands when the unit is

running. Place your right hand on the rear

handle and the left hand on the front handle with

your thumbs and fingers encircling the chain

saw handles. A firm grip together with a stiff left

arm will help you maintain control of the saw if

kickback occurs.

2. Make sure that the area in which you are cutting

is free from obstructions. Do not let the nose of

the guide bar contact a log, branch, fence, or

any other obstruction that could be hit while you

are operating the saw.

3. Always cut with the unit running at full speed.

Fully squeeze the throttle trigger and maintain a

steady cutting speed.

4. Use replacement parts such as low kickback

chain, SAFE-T-TIP anti-kickback nose guards,

chain brakes and special guide bars that reduce

the risks associated with rotational kickback.

Use only the replacement guide bars and low

kickback chains specified by the manufacturer

for your saw.

■ With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sudden surprise contributes to accidents.

■ Keep proper footing and balance at all times.

■ Do not cut above shoulder height or overreach

when cutting.

■ Keep the SAFE-T-TIP anti-kickback nose guard

properly mounted on the guide bar to prevent

rotational kickback.

■ Follow the sharpening and maintenance instructions for the saw chain.

ROTATIONAL

KICKBACK

BAR SHOWN WITHOUT SAFE-T-TIP® NOSE GUARD

FOR ILLUSTRATION PURPOSES ONLY.

Fig. 1

KICKBACK

DANGER ZONE

Fig. 2

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

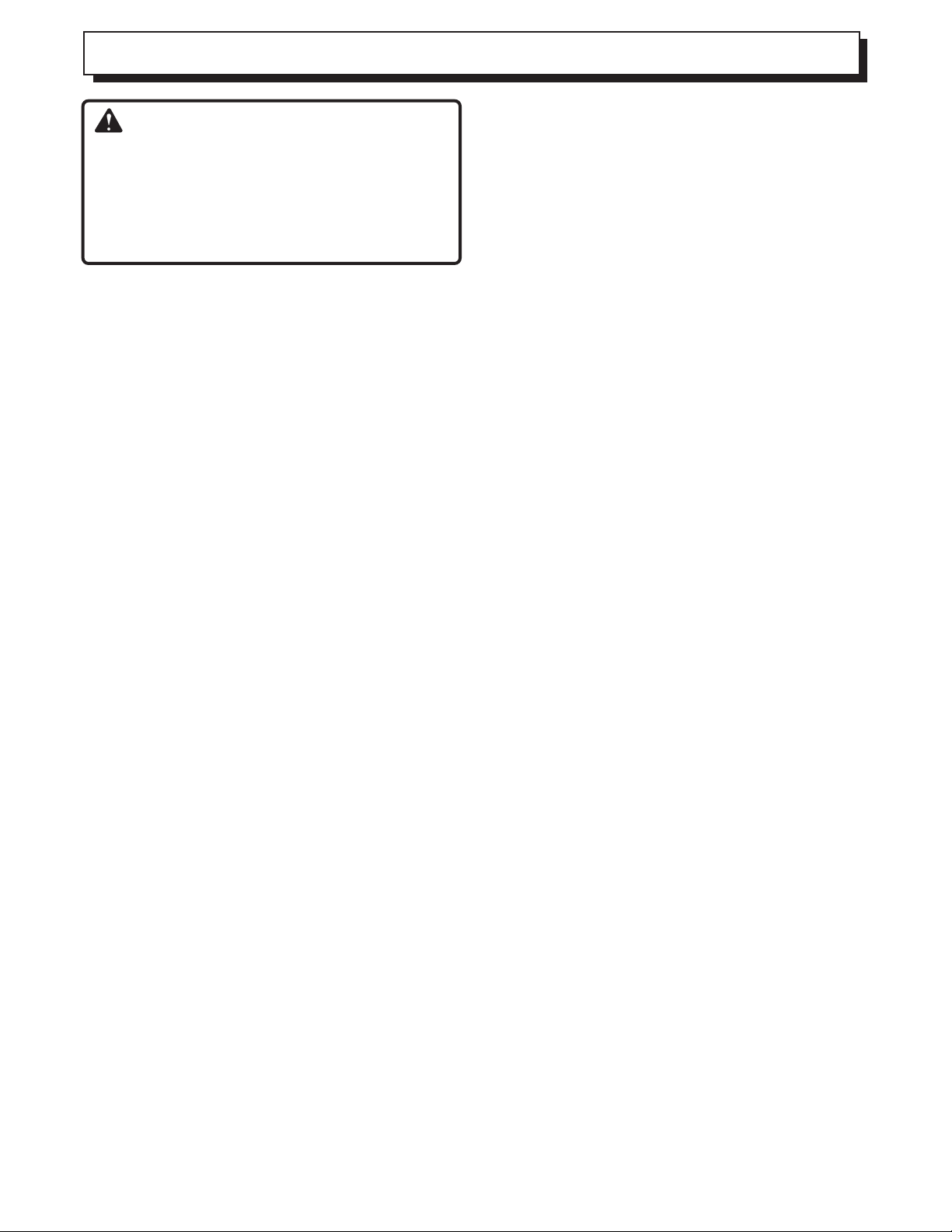

■ Push and Pull - This reaction force is always

opposite to the direction the chain is moving where

wood contact is made. Thus, the operator must be

ready to control the PULL when cutting on the

bottom edge of the bar, and PUSH when cutting

along the top edge.

IN THE CUTTING/WORK AREA

■ Do not operate a chain saw in a tree, on a ladder,

or scaffold; this is extremely dangerous.

■ Keep ALL children, bystanders, visitors, and

animals out of the work area while starting or

cutting with the chain saw.

NOTE: The size of the work area depends on the

job being performed as well as the size tree or

work piece involved. For example, felling a tree

requires a larger work area than making bucking

cuts.

■ Never start cutting until you have a clear work

area, secure footing, and a planned retreat path

from the falling tree. Cluttered area invite injuries.

■ Do not expose the chain saw to rain.

■ Do not use the chain saw in damp or wet locations.

■ Do not use the chain saw near flammable liquids,

gases, or in any type of explosive atmosphere.

■ Use extreme caution when cutting small size brush

and saplings, because slender material may catch

the saw chain and be whipped toward you or pull

you off balance.

■ When cutting a limb that is under tension, be alert

for spring back so that you will not be struck when

the tension in the wood fibers is released.

■ Do not force the chain saw. The job can be performed better and safer at the rate for which it was

intended.

■ Always use the right product for your application.

The chain saw should be used for cutting wood

only. Never use the chain saw to cut plastic,

masonry or non-wood building materials.

■ Do not use the chain saw for purposes not intended.

■ Store idle chain saw when not in use, chain saw

should be stored in a dry and high or locked area

out of the reach of children. When storing chain

saw, remove battery and place the scabbard on the

bar and chain or store the chain saw in a carry

case.

■ Remove the battery pack from the chain saw

before cleaning, servicing, storing, removing

material from the unit, changing accessories such

as the bar and chain, or when not in use.

See Figure 3.

PULL

PUSH

Fig. 3

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

UNDERSTANDING YOUR CHAIN SAW

SAFETY DEVICES

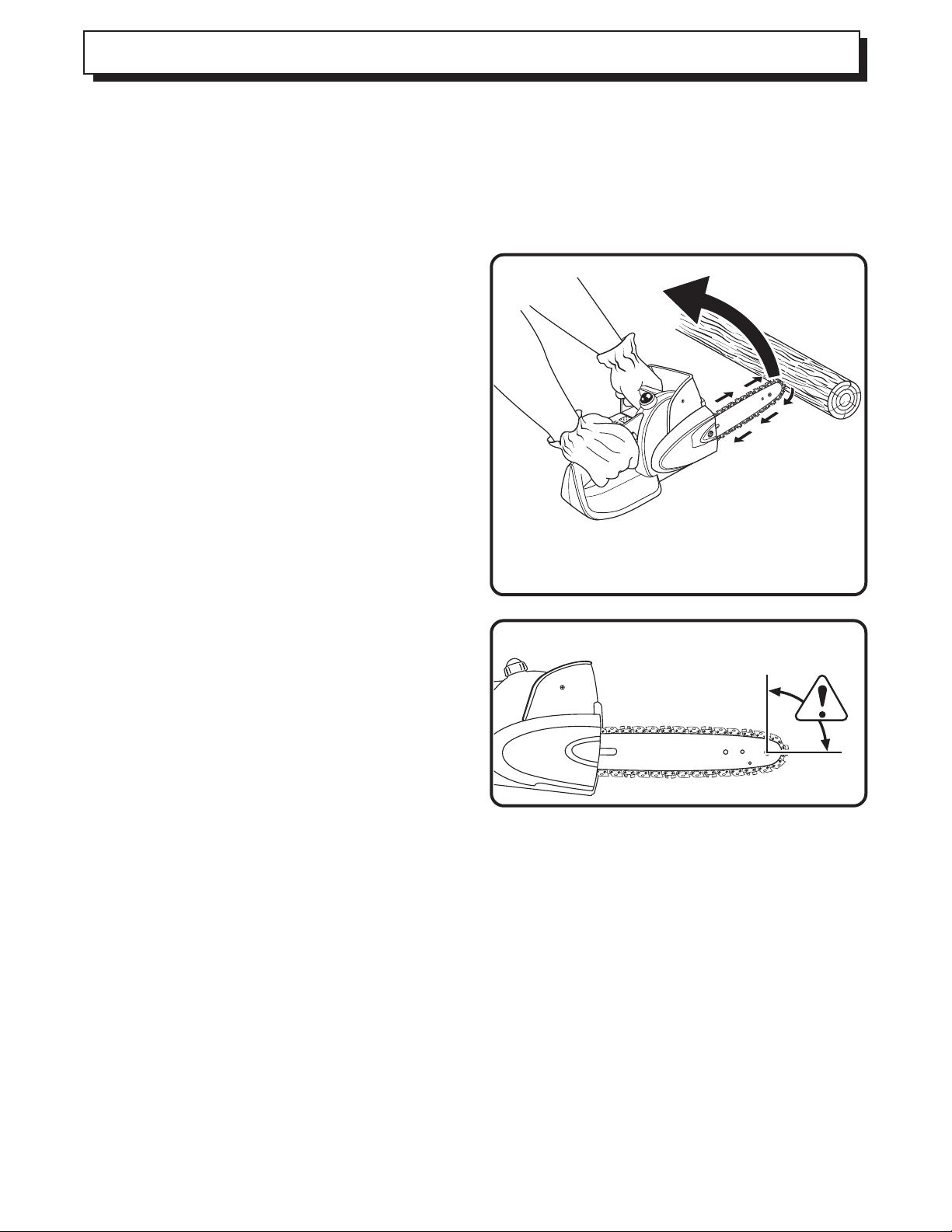

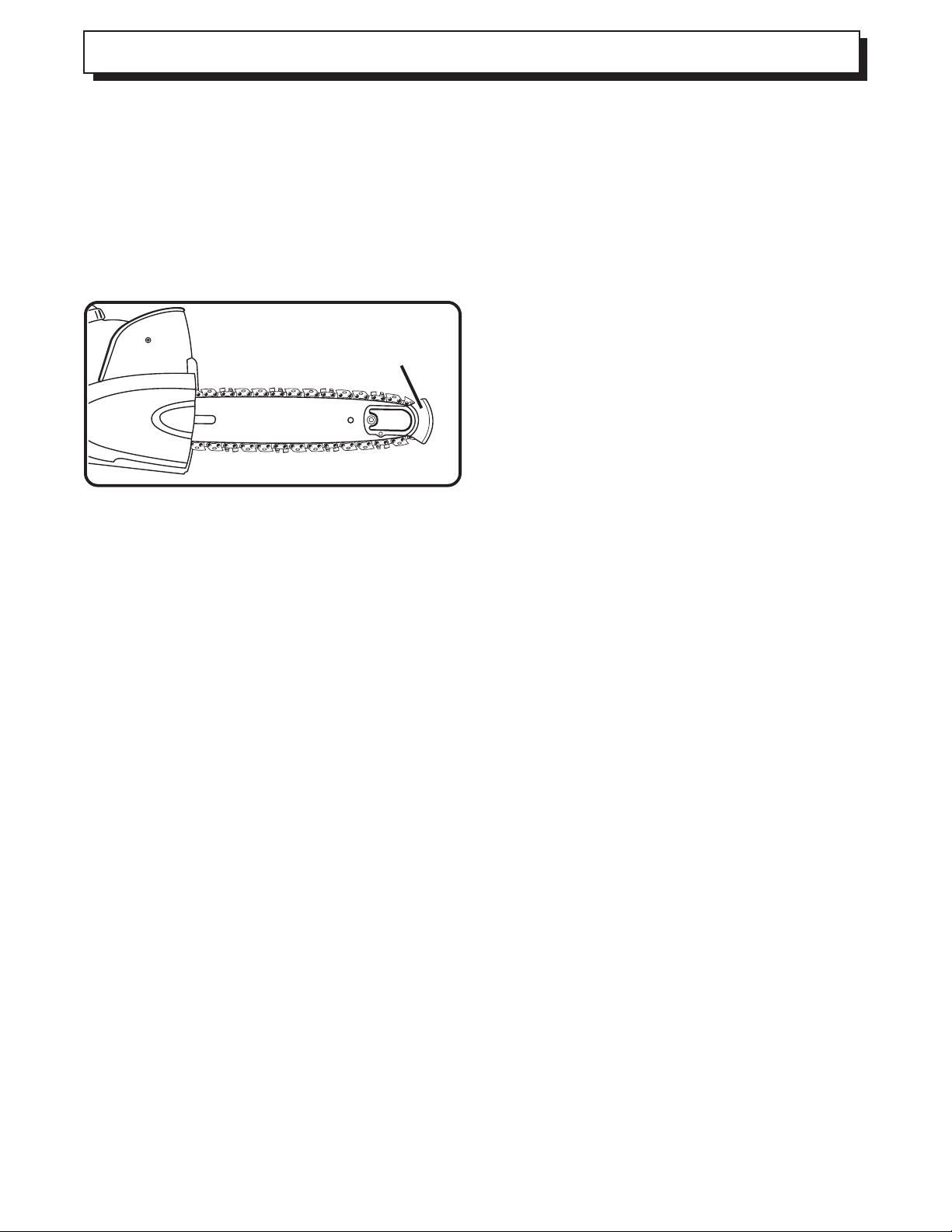

See Figure 4.

SAFE-T-TIP® Anti-Kickback Nose Guard

The SAFE-T-TIP® prevents kickback from happening,

because it covers the tip of the bar where kickback is

generated. Never attempt any kind of cutting where the

SAFE-T-TIP® would have to be removed from the bar

tip.

SAFE-T-TIP

Fig. 4

LOW KICKBACK SAW CHAIN

The rakers (depth gauges) ahead of each cutter can

minimize the force of a kickback reaction by preventing

the cutters from digging in too deeply at the kickback

zone. Only use replacement chain that is equivalent to

original chain or has been certified as low kickback

chain per ANSI B175.1.

Low kickback saw chain is chain that has met the

kickback performance requirements of ANSI B175.1 1991 (American National Standard for Power Tools Gasoline-Powered Chain Saws-Safety Requirements)

when tested on the representative sample of chain

saws below 3.8 c.i.d. specified in ANSI B175.1 - 1991.

As saw chains are sharpened during their useful life,

they lose some of the low kickback qualities and extra

caution should be used.

GUIDE BARS

Generally, guide bars with small radius tips have

somewhat lower kickback potentials.

When making a replacement, be sure to order one of

the Ryobi bars listed for your saw in this operator's

manual. The proper size SAFE-T-TIP® nose guard

comes installed on the bar. Use only guide bars that

have a provision for mounting the SAFE-T-TIP®.

BATTERY SAFETY

■ Battery operated units do not have to be plugged

into an electrical outlet; therefore, they are always

in operating condition. Be aware of possible hazards even when unit is not operating.

■ Remove the battery pack from the chain saw before

cleaning, servicing, storing, removing material from

the unit, changing accessories such as the bar and

chain, or when not in use.

■ A battery pack must be recharged only with the

specified charger for the battery pack. A charger

that may be suitable for one type of battery pack

may create a risk of fire when used with another

battery pack. Use battery pack only with charger

listed.

BATTERY PACK: Item # 1322401,

1323303, 130224007,

or 130256001

CHARGER: Item # 1423701

■ To reduce the risk of explosion and possible injury,

Do not place battery units or their batteries near fire

or heat.

■ Do not open or mutilate the battery pack. Released

electrolyte is corrosive and may cause damage to

the eyes or skin. It may be toxic if swallowed.

■ A damaged battery pack is subject to explosion. To

avoid serious personal injury, properly dispose of a

damaged battery pack.

■ Batteries vent hydrogen gas and can explode in the

presence of a source of ignition, such as a pilot

light. To reduce the risk of serious personal injury,

never use any cordless product in the presence of

open flame. An exploded battery pack can propel

debris and chemicals. If exposed, flush with water

immediately.

■ Do not charge unit in a damp or wet location.

Following this rule will reduce the risk of electric

shock.

■ For best results, your battery unit should be

charged in a location where the temperature is

more than 50°F (10°C) but less than 100°F (38°C).

Do not store outside or in vehicles.

■ Under extreme usage or temperature conditions,

battery pack leakage may occur. If liquid comes in

contact with your skin, wash immediately with soap

and water, then neutralize with lemon juice or

vinegar. If liquid gets into your eyes, flush them with

clean water for at least 10 minutes, then seek

immediate medical attention.

6

Page 7

IMPORTANT SAFETY INSTRUCTIONS

■ Do not dispose of batteries in a fire. The cell may

explode. Batteries should be recycled, consult your

local waste authority for information regarding

available recycling and/or disposal options.

■ When battery pack is not in use, keep it away from

other metal objects like: paper clips, coins, keys,

nails, screws, or other small metal objects that can

make a connection from one terminal to another.

Shorting the battery pack terminals together may

cause sparks, burns, or a fire.

CHARGER SAFETY

■ Save these instructions. This manual contains

important Rules for Safe Operation and operating

instructions for charger.

■ Before using battery charger, read all instructions

and cautionary markings in this manual, on battery

charger, and product using battery charger.

■ To reduce risk of injury, charge only nickel-cadmium type rechargeable batteries. Other types of

batteries may burst, causing personal injury and

damage.

■ Do not expose charger to wet or damp conditions.

■ Use of an attachment not recommended or sold by

the battery charger manufacturer may result in a

risk of fire, electric shock, or injury to persons.

■ To reduce risk of damage to charger body and

cord, pull by charger plug rather than cord when

disconnecting charger.

■ Make sure cord is located so that it will not be

stepped on, tripped over, or otherwise subjected to

damage or stress.

■ An extension cord should not be used unless

absolutely necessary. Use of improper extension

cord could result in a risk of fire and electric shock.

If extension cord must be used, make sure:

a. That pins on plug of extension cord are the

same number, size and shape as those of plug

on charger.

b. That extension cord is properly wired and in

good electrical condition; and

c. That wire size is large enough for AC ampere

rating of charger as specified below:

Cord Length (Feet) 25' 50' 100'

Cord Size (AWG) 16 16 16

NOTE: AWG = American Wire Gage

■ Do not operate charger with a damaged cord or

plug. If damaged, have replaced immediately by a

qualified serviceman.

■ Do not operate charger if it has received a sharp

blow, been dropped, or otherwise damaged in any

way; take it to a qualified serviceman.

■ Do not disassemble charger; take it to a qualified

serviceman when service or repair is required.

Incorrect reassembly may result in a risk of electric

shock or fire.

■ To reduce risk of electric shock, unplug the

charger from outlet before attempting any maintenance or cleaning. Turning off controls will not

reduce this risk.

■ Disconnect charger from power supply when not in

use.

■ Risk of electric shock. Do not touch uninsulated

portion of output connector or uninsulated battery

terminal.

■ Save these instructions. Refer to them frequently

and use them to instruct others who may use this

unit. If you loan someone this unit, loan them these

instructions also.

SAVE THESE INSTRUCTIONS

7

Page 8

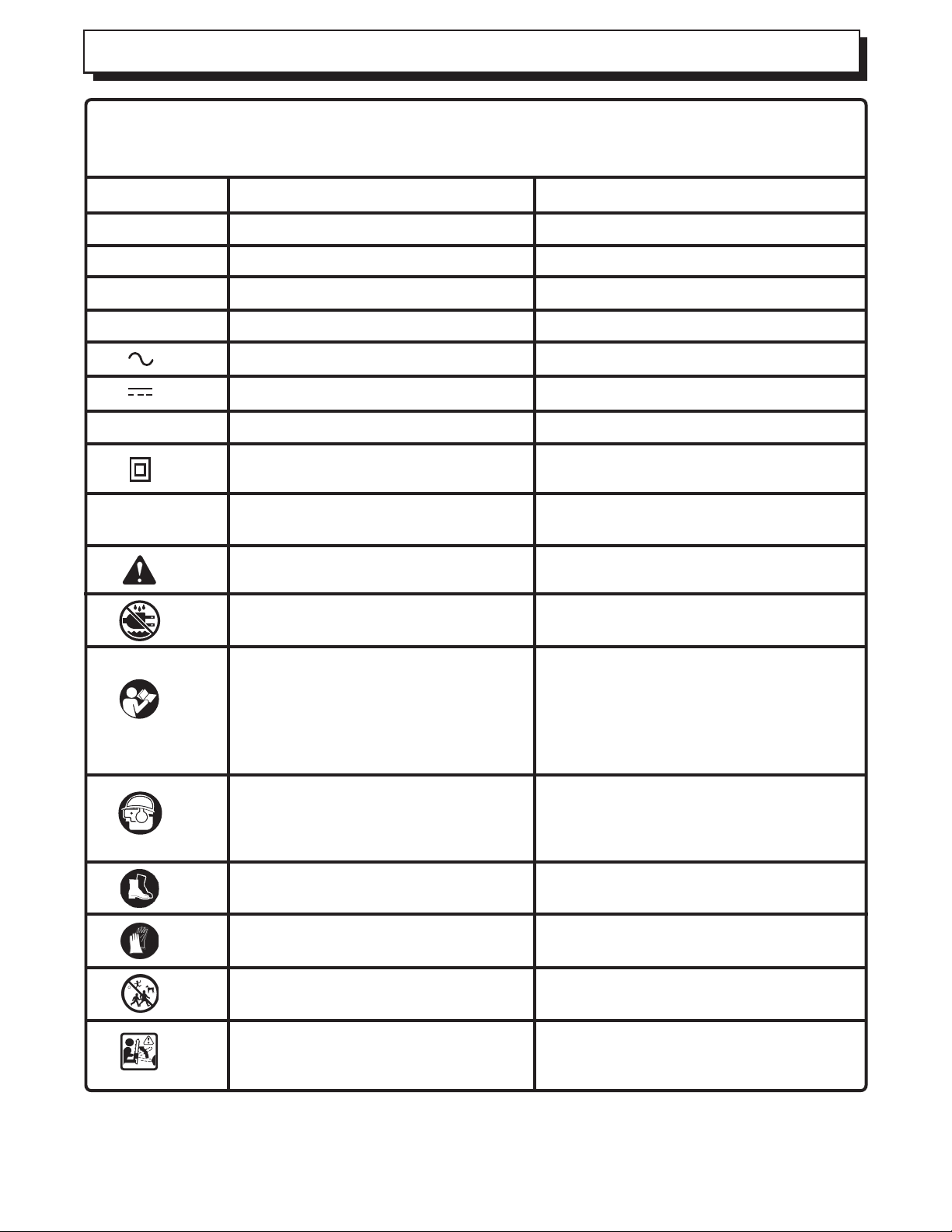

SYMBOLS

Important: Some of the following symbols may be used on your tool. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL NAME EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Alternating Current Type or a characteristic of current

Direct Current Type or a characteristic of current

n

0

.../min Revolutions or Reciprocation Per Minute Revolutions, strokes, surface speed, orbits

No Load Speed Rotational speed, at no load

Class II Construction Designates Double Insulated Construction

tools

etc. per minute

Safety Alert Symbol Indicates danger, warning or caution. It means

attention!!! Your safety is involved.

Wet Conditions Alert Do not expose to rain or use in damp

locations.

Read Your Operator’s Manual Your manual contains special messages to

bring attention to potential safety concerns,

machine damage as well as helpful operating

and servicing information. Please read all the

information carefully to avoid injury and machine damage.

Wear Eye, Hearing, and Head Protection Wear eye protection which is marked to com-

ply with ANSI Z87.1 as well as hearing and

head protection when operating this equipment.

Wear Safety Footwear Wear non-slip safety footwear when using this

equipment.

Wear Gloves Wear non-slip, heavy-duty protective gloves

when handling the pruner.

Keep Children and Pets Away Danger- Keep children and pets away.

Beware of Kickback DANGER! Beware of kickback.

8

Page 9

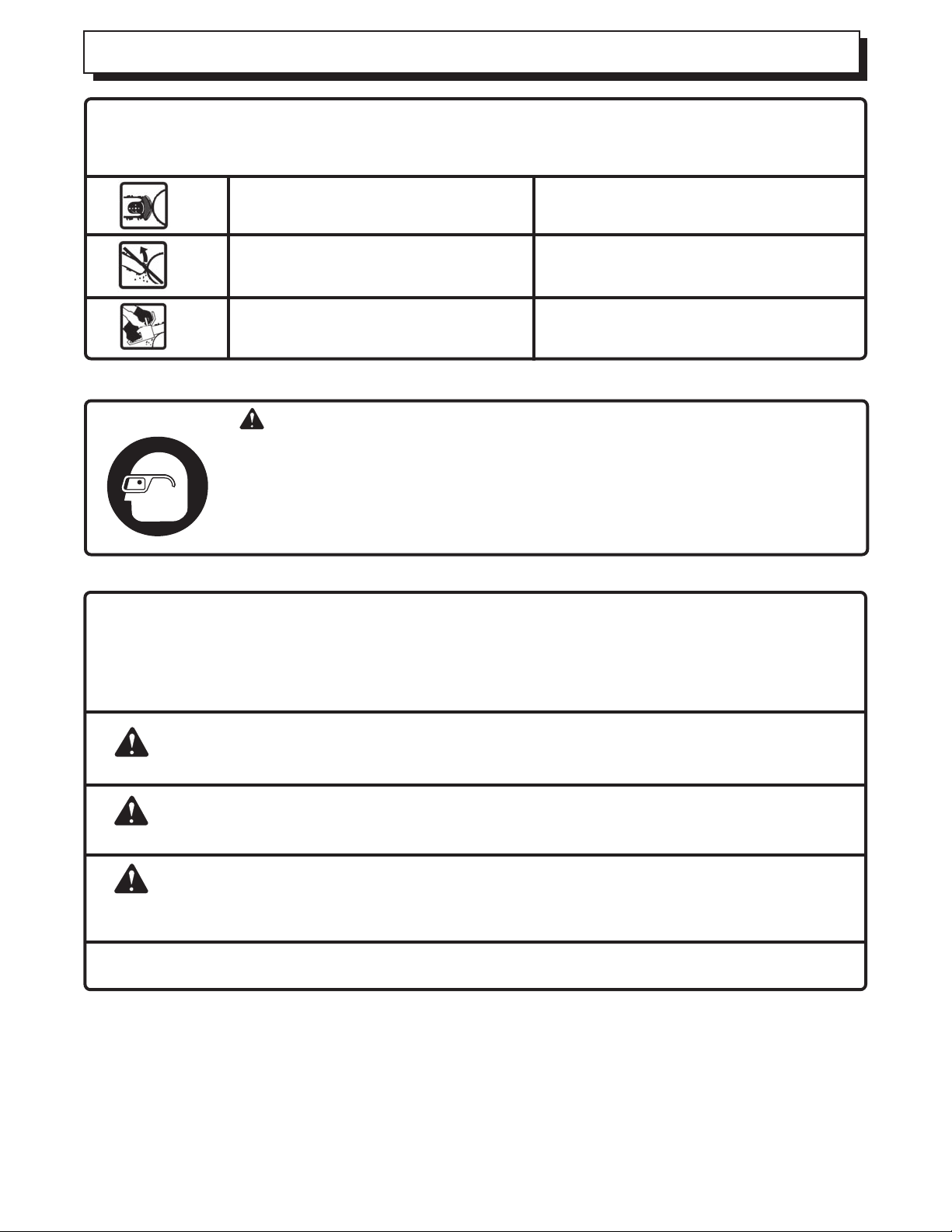

SYMBOLS

Important: Some of the following symbols may be used on your tool. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL NAME EXPLANATION

SAFE-T-TIP The SAFE-T-TIP® nose guard on your bar

nose prevents rotational kickback.

Bar nose contact Avoid bar nose contact.

Holding saw Hold saw properly with both hands.

WARNING:

The operation of any power tool can result in foreign objects being thrown into your

eyes, which can result in severe eye damage. Before beginning tool operation, always

wear safety goggles or safety glasses with side shields and a full face shield when

needed. We recommend Wide Vision Safety Mask for use over eyeglasses or standard

safety glasses with side shields. Always wear eye protection which is marked to comply

with ANSI Z87.1.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

SYMBOL MEANING

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert against unsafe practices that may cause property

damage.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

SAVE THESE INSTRUCTIONS

NOTE: Save these instructions. Refer to them frequently and use them to instruct others who may use this unit. If

you loan someone this unit, loan them these instructions also.

9

Page 10

SPECIFICATIONS

PRODUCT SPECIFICATIONS:

Motor 18 Volt, DC

Bar Length 10 in. (254 mm)

Replacement Bar Part No. 671256002 or 671667002

Replacement Chain Part No. 6958301 or 690583002

Net Weight 7.5 lbs. (3.4 kg.)

Charger Replacement Part Number 1423701

NOTE: This saw was designed for occasional light duty use and has some limitations as to what can

be cut with it.

Battery Pack Replacement 1322401, 1323303,

Part Number 130224007,

or 130256001

Charger Rating 120V, 60 Hz, AC Only

Charger Voltage 18 Volt

Charger Rate 1 Hour

UNPACKING

This chain saw has been shipped completely assembled and ready for use. After removing it from the box, inspect

it carefully to make sure no breakage or damage has occurred during shipping. If any parts are damaged or missing,

contact your nearest Ryobi Authorized Service dealer to obtain replacement parts before attempting to operate the

chain saw. The guide bar, chain, wrench, bar and chain oil, scabbard, battery pack, battery charger, and this operator’s

manual are also included.

APPLICATIONS

The chain saw can be used for the following applications only:

■ Limbing and pruning branches from trees.

■ Felling small trees up to 5 in. (127 mm) diameter.

■ Bucking the fallen tree into shorter lengths.

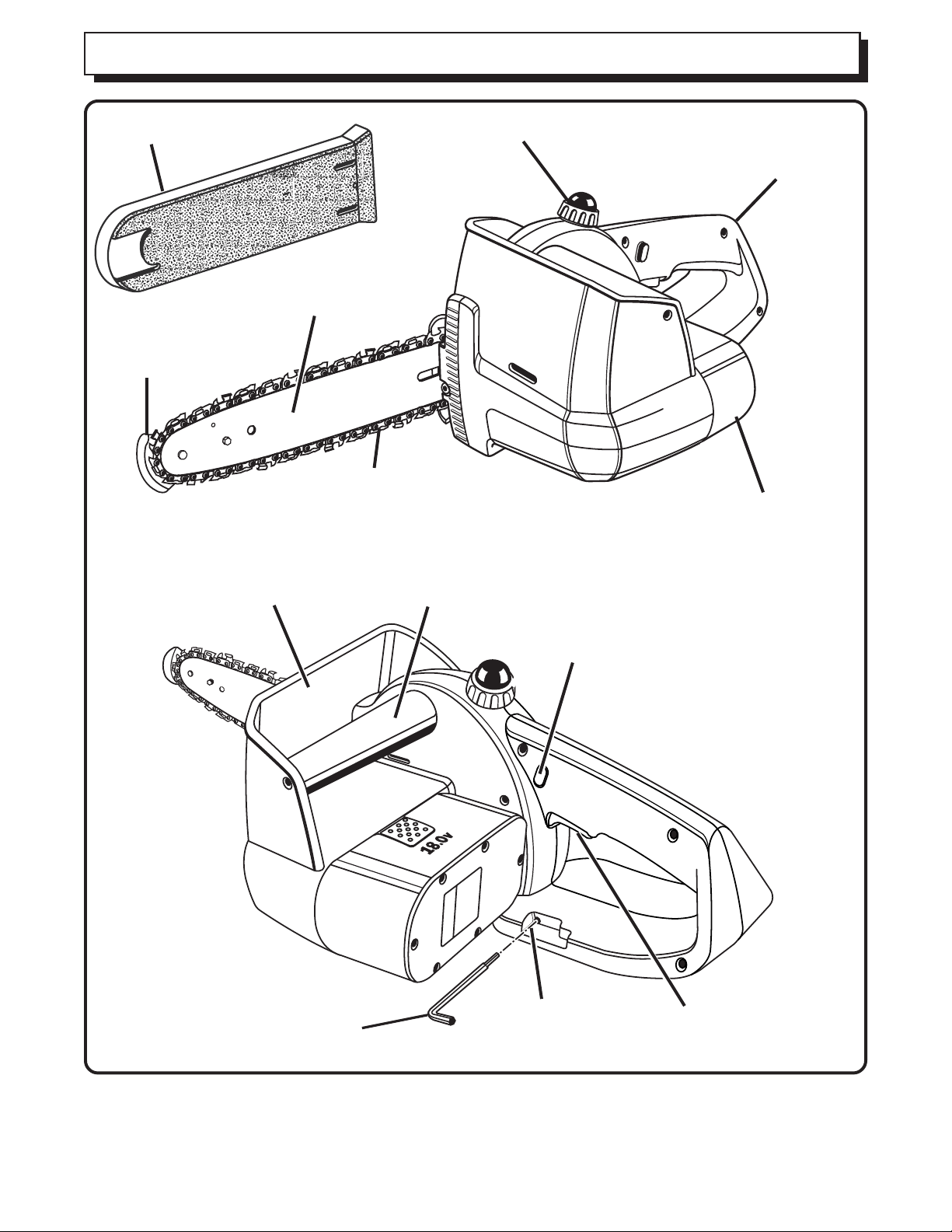

FEATURES

KNOW YOUR CHAIN SAW

See Figure 1.

Before attempting to use the chain saw, familiarize

yourself with all operating features and safety requirements.

WARNING:

Carefully read through this entire operator’s

manual before using your chain saw. Pay close

attention to the Important Safety Instructions,

Warnings and Cautions. If you use your chain

saw properly and only for what it is intended, you

will enjoy years of safe, reliable service.

WARNING:

If any parts are missing, do not operate your

chain saw until the missing parts are replaced.

Failure to do so could result in possible serious

personal injury.

WARNING:

Do not allow familiarity with your chain saw to

make you careless. Remember that a careless

fraction of a second is sufficient to inflict severe

injury.

10

Page 11

FEATURES

SCABBARD

SAFE-T-TIP®

CHAIN OIL TANK CAP

REAR HANDLE

BAR

CHAIN

BATTERY PACK

HAND GUARD

HEX KEY

FRONT HANDLE

TRIGGER LOCK

BUTTON

HEX KEY

STORAGE AREA

TRIGGER

Fig. 5

11

Page 12

GLOSSARY OF TERMS

Front Handle

The support handle located at or toward the front of

the chain saw.

Front Handle Guard

A structural barrier between the front handle of a chain

saw and the guide bar, typically located close to the

hand position on the front handle and sometimes

employed as an activating lever for a chain brake.

Guide Bar

A solid railed structure that supports and guides the

saw chain.

Saw Chain

A loop of chain that has cutting teeth for cutting wood.

It is driven by the motor and is supported by the guide

bar.

Kickback

The backward and/or upward motion of the guide bar

occurring when the moving chain contacts an object at

the upper portion of the tip of the guide bar, or when

the wood closes in and pinches the saw chain in the

cut.

Kickback, Pinch

The rapid push back of the saw which can occur when

the wood closed in and pinches the moving saw chain

in the cut along the top of the guide bar.

Kickback, Rotational

The rapid upward and backward motion of the saw

which can occur when the moving saw chain, near the

upper portion of the top of the guide bar, contacts an

object such as a log or branch.

Low-Kickback Chain

A chain that complies with the kickback performance

requirements of ANSI B175-1-1991 when tested on a

representative sample of chain saws.

Normal Cutting Position

Those positions assumed in performing the bucking

and felling cuts.

Notching Undercut

A notch cut in a tree that directs the tree’s fall.

Felling

The process of cutting down a tree.

Felling Back Cut

The final cut in a tree felling operation, made on the

opposite side of the tree from the notching undercut.

Oiler Control

A system for oiling the guide bar and saw chain.

Rear Handle

The support handle located at or toward the rear of the

saw.

Reduced Kickback Guide Bar

A guide bar which has been demonstrated to reduce

kickback significantly.

Replacement Saw Chain

A chain that complies with the kickback performance

requirements of ANSI B175.1-1991 when tested with

specific chain saws. It may not meet the ANSI performance requirements when used with other saws.

Switch

A device that when operated will complete or interrupt

an electrical power circuit to the motor of the chain

saw.

Switch Lockout

A movable stop that prevents the unintentional operation of the switch until manually actuated.

Safe-T-Tip

An attachment that may be provided on the end of the

guide bar to prevent the chain, on the end of the guide

bar, from contacting the wood.

Drive Sprocket or Sprocket

The toothed part that drives the saw chain.

12

Page 13

OPERATION

BATTERY PACK AND CHARGER

LED FUNCTION OF CHARGER

See Figure 6.

LED WILL BE ON TO INDICATE STATUS OF

CHARGER AND BATTERY PACK:

■ Red LED on = Fast charging mode.

■ Green LED on = Fully charged battery pack.

■ Yellow and Green LEDs on = Control charge or

defective battery pack.

■ No LED on = Defective charger or battery pack.

CHARGING YOUR CHAIN SAW

The battery pack for your chain saw has been shipped

in a low charge condition to prevent possible problems.

Therefore, you should charge it prior to use.

NOTE: Batteries will not reach full charge the first time

they are charged. Allow several cycles (pruning

followed by recharging) for them to fully charge.

TO CHARGE

■ Charge battery pack only with the charger provided.

■ Make sure power supply is normal household

voltage, 120 volts, 60 Hz, AC only.

■ Connect charger to power supply.

■ Place battery pack in charger.

raised rib on battery pack with groove in charger.

■ Press down on battery pack to be sure contacts on

battery pack engage properly with contacts in

charger. When properly connected, red light will

turn on.

■ Normally, the yellow and green lights on the

charger will come on. This indicates charger is in

control charge mode and should switch to fast

charge mode within 5 minutes. When charger is in

fast charge mode the red light will come on. If after

a period of 15 minutes the yellow and green lights

remain on, remove the battery pack, wait 1 minute

and reinsert battery pack in charger. If the yellow

and green lights continue to remain on an additional 15 minutes, the battery pack is damaged and

will not accept charge.

■ When your battery pack becomes fully charged,

the red light will turn off and the green light will turn

on.

■ After normal usage, 1 hour of charge time is

required to be fully charged. A minimum charge

time of 1 to 1-1/2 hours is required to recharge a

completely discharged tool.

See Figure 3.

Align

BATTERY

PACK

BATTERY

CHARGER

RED LIGHT

YELLOW

LIGHT

■ RED LIGHT “ON” INDICATES FAST CHARGING

MODE

■ YELLOW AND GREEN LIGHTS “ON” INDICATES

CONTROL CHARGE OR POSSIBLE FAULTY

BATTERY

■ GREEN LIGHT “ON” INDICATES FULLY CHARGED

■ The battery pack will become slightly warm to the

touch while charging. This is normal and does not

indicate a problem.

■ DO NOT place charger in an area of extreme heat

or cold. It will work best at temperatures above

50°F and below 100°F.

IMPORTANT INFORMATION FOR RECHARGING

HOT BATTERIES

When using your chain saw continuously, the batteries

in your battery pack will become hot. You should let a

hot battery pack cool down for approximately 30

minutes before attempting to recharge.

NOTE: This situation only occurs when continuous use

of your chain saw causes the batteries to become hot.

It does not occur under normal circumstances. Refer

to “Charging Your Chain saw” earlier in this manual, for

normal recharging of batteries. If the charger/charging

assembly does not charge your battery pack under

normal circumstances, return both the battery pack

and charger/charging assembly to your nearest Ryobi

Authorized Service dealer for electrical check.

GREEN

LIGHT

Fig. 6

13

Page 14

OPERATION

TO INSTALL BATTERY PACK

See Figure 7

1. Place the battery pack in your chain saw. Align

raised rib on battery pack with groove in chain

saw’s battery port.

2. Make sure the latches on each side of the battery

pack snap in place and that battery pack is secured

in chain saw before beginning operation.

TO REMOVE BATTERY PACK

See Figure 7

Locate latches on side of battery pack and depress

both sides to release the battery pack from the chain

saw.

When placing battery pack in your chain saw, be

sure raised rib on battery pack aligns with

groove in chain saw's battery port and latches

snap in place properly. Improper assembly of

battery pack can cause damage to internal

components.

.

.

CAUTION:

CAUTION:

Remove battery pack from unit. Fill oil tank with

Homelite Bar and Chain Oil before starting the

chain saw. Failure to lubricate the chain will

cause damage to the bar and chain.

CHAIN OIL SYSTEM

See Figure 8.

1. Use Homelite Bar and Chain Oil. It is formulated to

perform over a wide temperature range with no

dilution required.

NOTE: Do not use dirty, used or otherwise contaminated oils. Damage may occur to the bar or chain.

2. Carefully pour the bar and chain oil into the tank.

3. Check and fill the oil tank when battery is recharged, or as needed.

4. Depress the oil tank cap several times to pump the

oil to the chain before starting the saw.

5. Depress the oil tank cap every 20-30 seconds while

cutting to keep the chain lubricated.

NOTE: It is normal for oil to seep from the saw when

not in use. To prevent seepage, empty the oil tank after

each use. When storing the unit for a long period of

time (three months or longer) be sure the chain is

lightly lubricated; this will prevent rust on the chain and

bar sprocket.

BATTERY

PORT

LATCHES

BATTERY

PACK

Fig. 7

Fig. 8

14

Page 15

OPERATION

STARTING AND STOPPING THE CHAIN

SAW

See Figure 9.

WARNING:

Keep body to the left of the chain line. Never

straddle the saw or chain, or lean over past the

chain line.

STARTING THE CHAIN SAW

1. Place the chain saw on a flat bare surface and

make sure no objects or obstructions are in immediate vicinity which could come in contact with the

bar and chain.

2. Press and hold the trigger lock button. This makes

the trigger operational.

3. Press and hold the trigger, release the trigger lock

button and continue to squeeze the trigger for

continued operation.

STOPPING THE CHAIN SAW

1. Release the trigger to stop the chain saw.

2. Upon release of the trigger, the trigger lock button

will be automatically reset to the lock position.

This cordless chain saw is not designed for cutting

trees larger than 5 in. (127 mm) in diameter.

This cordless chain saw is designed for limbing and

pruning type cutting, as well as cutting trees up to 5 in.

(127 mm) in diameter only.

Do not attempt to make any cut that would require

removal of the SAFE-T-TIP.

TRIGGER LOCK

BUTTON

TRIGGER

TRIGGER LOCK

BUTTON

TRIGGER

Fig. 9

PREPARATION FOR CUTTING

PROPER GRIP ON HANDLES

Figures 10, 11, and 12.

Refer to “Important Safety Instructions” earlier in this

manual for appropriate safety equipment.

1. Wear non-slip gloves for maximum grip and protection.

2. Hold the saw firmly with both hands. Always keep

your left hand on the front handle and your right

hand on the rear handle so that your body is to the

left of the chain line.

Fig. 10

15

Page 16

OPERATION

WARNING:

Never use a left-handed (cross-handed) grip, or

any stance which would place your body or arm

across the chain line.

3. Maintain a proper grip on the saw whenever the

unit is running. The fingers should encircle the

handle and the thumb is wrapped under the handlebar. This grip is least likely to be broken (by a

kickback or other sudden reaction of the saw). Any

grip in which the thumb and fingers are on the

same side of the handle, is dangerous because a

slight kick of the saw can cause loss of control.

WARNING:

Do not operate the throttle trigger with your left

hand and hold the front handle with your right

hand. Never allow any part of your body to be in

the chain line while operating a saw.

CHAIN LINE

Fig. 12

PROPER GRIP

IMPROPER

GRIP

Fig. 11

16

Page 17

OPERATION

PROPER CUTTING STANCE

See Figure 13.

■ Weight should be balanced with both feet on solid

ground.

■ Keep left arm with elbow locked in a "straight arm"

position to withstand any kickback force.

■ Your body should always be to the left of the chain

line.

■ Thumb should be on underside of handlebar.

BASIC CUTTING PROCEDURE

Practice cutting a few small logs using the following

technique to get the "feel" of using your saw before

you begin a major sawing operation.

1. Take the proper stance in front of the wood with the

saw off.

2. Squeeze the trigger and let the chain accelerate to

full speed before entering the cut.

3. Begin cutting with the saw against the log.

4. Keep the unit running the entire time you are

cutting, maintain a steady speed.

5. Allow the chain to cut for you; exert only light

downward pressure. If you force the cut, damage to

the bar, chain, or unit can result.

6. Release the trigger as soon as the cut is completed, allowing the chain to stop. If you run the

saw without a cutting load, unnecessary wear can

occur to the chain, bar, and unit.

7. Do not put pressure on the saw at the end of the

cut.

CHAIN LINE

STRAIGHT ARM

POSITION

Fig. 13

■ Always cut with both feet on solid ground to prevent

being pulled off balance.

■ Do not cut above chest height, as a saw held

higher is difficult to control against kickback forces.

■ Do not fell trees near electrical wires or buildings.

Leave this operation for professionals.

■ Cut only when visibility and light are adequate for

you to see clearly.

TREE FELLING

Unusual Hazardous Tree Felling Conditions

Do not fell trees during periods of high wind or heavy

precipitation. Wait to do your cutting until the hazard

has ended.

WORK AREA PRECAUTIONS

■ Cut only wood or materials made from wood; no

sheet metal, no plastics, no masonry, no non-wood

building materials.

■ Never allow children to operate your saw. Allow no

person to use this chain saw who has not read this

Operator's Manual or received adequate instructions for the safe and proper use of this chain saw.

■ When felling a tree, keep everyone - helpers,

bystanders, children, and animals a safe distance

from the cutting area. During felling operations, the

safe distance should be a least twice the height of

the largest trees in the felling area. During bucking

operations, keep a minimum distance of 15 feet

(4.5 m) between workers.Trees should not be felled

in a manner that would endanger any person, strike

any utility line or cause any property damage. If the

tree does make contact with any utility line, the

utility company should be notified immediately.

WARNING:

Do not cut down trees having an extreme lean or

large trees that have rotten limbs, loose bark, or

hollow trunks. Have these trees pushed or

dragged down with heavy equipment, then cut

them up.

WARNING:

Do not cut trees near electrical wires or

buildings.

WARNING:

Check the tree for damaged or dead branches

that could fall and hit you during felling.

17

Page 18

OPERATION

WARNING:

Periodically glance at the top of the tree during

the backcut to assure the tree is going to fall in

the desired direction.

WARNING:

If the tree starts to fall in the wrong direction, or

if the saw gets caught or hung up during the fall,

leave the saw and save yourself!

■ Felling a tree - When bucking and felling operations

are being performed by two or more persons, at the

same time, the felling operation should be separated from the bucking operation by a distance of

at least twice the height of the tree being felled.

Trees should not be felled in a manner that would

endanger any person, strike any utility line or cause

any property damage. If the tree does make

contact with any utility line, the utility company

should be notified immediately.

■ Before any cuts are started, pick your escape route

(or routes in case the intended route is blocked);

clear the immediate area around the tree and make

sure there are no obstructions in your planned path

of retreat. Clear path of safe retreat approximately

135° from planned line of fall. The retreat path

should extend back and diagonally to the rear of the

expected line of fall.

■ Before felling is started consider the force and

direction of the wind, the lean and balance of the

tree, and the location of large limbs. These things

influence the direction in which the tree will fall. Do

not try to fell a tree along a line different from its

natural line of fall.

■ The chain saw operator should keep on the uphill

side of the terrain as the tree is likely to roll or slide

downhill after it is felled.

■ Remove dirt, stones, loose bark, nails, staples, and

wire from the tree where felling cuts are to be

made.

■ Notched Undercut. Cut a notch about 1/3 the

diameter of the tree, perpendicular to the direction

of fall. Make the cuts of the notch so they intersect

at a right angle to the line of fall. This notch should

be cleaned out to leave a straight line. To keep the

weight of the wood off the saw, always make the

lower cut of the notch before the upper cut.

Figure 15.

See Figure 14.

See

PLANNED LINE OF FALL

PLANNED PATH OF SAFE RETREAT

135° FROM PLANNED LINE OF FALL

PLANNED

LINE OF FALL

135°

135°

2 IN. (5 CM) OR 1/10 DIA

90°

SAFE

RETREAT

ZONE

SAFE

RETREAT

ZONE

45°

90°

45°

SAFE

RETREAT

ZONE

Fig. 14

HINGE

NOTCH -

APPROX. 1/3

DIAMETER OF

TRUNK

18

BACK CUT

2 IN. (5 CM)

Fig. 15

Page 19

OPERATION

■ Felling Backcut. The backcut is always made

level and horizontal, and at a minimum of 2 inches

(5 cm) above the horizontal cut of the notch.

Figures 15 and 16.

■ Never cut through to the notch. Always leave a

band of wood between the notch and backcut

(approximately 2 inches (5 cm) or 1/10 the diameter

of the tree). This is called "hinge" or “hingewood.”

It controls the fall of the tree and prevents slipping

or twisting or shoot-back of the tree off the stump.

See Figures 15 and 16.

■ On large diameter trees, stop the back cut before it

is deep enough for the tree to either fall or settle

back on the stump. Then insert soft wooden or

plastic wedges into the cut so they do not touch the

chain. The wedges can be driven in, little by little, to

help jack the tree over.

NOTE: When bucking or felling with a wedge, it

may be necessary to remove the SAFE-T-TIP®

anti-kickback device to allow the bar to be drawn

through the cut. After the cut is complete, the tip

should be reinstalled immediately.

■ As tree starts to fall, stop the chain saw and put it

down immediately. Retreat along the cleared path,

but watch the action in case something falls your

way. Be alert for overhead limbs or branches that

may fall and watch your footing.

See Figure 17.

WARNING:

Never cut through to the notch when making a

backcut. The hinge controls the fall of the tree,

this is the section of wood between the notch

and backcut.

See

WEDGE

Fig. 17

BUCKING

See Figures 18 through 21.

Bucking is the term used for cutting a fallen tree to the

desired log length.

■ Always make sure your footing is secure and your

weight is distributed evenly on both feet.

■ Cut only one log at a time.

■ Support small logs on a saw horse or another log

while bucking.

■ Keep a clear cutting area. Make sure that no objects

can contact the guide bar nose and chain during

cutting, this can cause kickback. To avoid the danger, keep the SAFE-T-TIP® anti-kickback device

attached while cutting. Refer to “Precautions Against

Kickback” earlier in this manual.

KICKBACK

BACK CUT

HINGE

NOTCH

Fig. 18

Fig. 16

19

Page 20

OPERATION

■ When bucking on a slope, always stand on the uphill

side of the log. To maintain complete control of the

chain saw when cutting through the log, release the

cutting pressure near the end of the cut without

relaxing your grip on the chain saw handles. Do not

let the chain contact the ground. After completing the

cut, wait for the saw chain to stop before your move

the chain saw. Always stop the motor before moving

from tree to tree.

■ Sometimes it is impossible to avoid pinching (with

just standard cutting techniques) or difficult to predict

which way a log will settle when cut. To avoid

pinching while cutting, rotate or move the log so that

the pinch is eliminated.

See Figure 19.

BUCKING LOGS UNDER STRESS

See Figures 20 and 21.

When the log is supported along its entire length, it

should be cut from the top or overbucking.

When the log is supported on one end, cut 1/3 the

diameter from the underside or underbucking. Then

make the finishing cut by overbucking to meet the first

cut.

As the log is being cut, it will tend to bend. The saw

can become pinched or hung in the log if you make the

first cut deeper than 1/3 of the diameter of the log.

Give special attention to logs under stress to prevent

the bar and chain from pinching.

When bucking on a slope, always stand on the uphill

side of the log as shown in Figure 19. When “cutting

through”, to maintain complete control of the chain

saw, release the cutting pressure near the end of the

cut without relaxing your grip on the chain saw

handles. Do not let the chain contact the ground. After

completing the cut, wait for the saw chain to stop

before your move the chain saw. Always stop the

motor before moving from tree to tree.

See Figure 19.

Fig. 19

LOG SUPPORTED AT ONE END:

LOAD

FINISHING CUT

1ST CUT

1/3 DIA

LOG SUPPORTED AT BOTH ENDS:

LOAD

1ST CUT 1/3 DIA

20

FINISHING CUT

Fig. 20

Page 21

OPERATION

TYPES OF CUTTING USED

See Figure 21.

OVERBUCKING

Begin on the top side of the log with the bottom of the

saw against the log; exert light pressure downward.

Note that the saw will tend to pull away from you.

WARNING:

Never climb into a tree to limb or prune. Do not

stand on ladders, platforms, a log or in any

position which can cause you to lose your

balance or control of the saw.

UNDERBUCKING

Begin on the under side of the log with the top of the

saw against the log; exert light pressure upward.

During underbucking, the saw will tend to push back at

you. Be prepared for this reaction and hold the saw

firmly to maintain control.

OVERBUCKING

UNDERBUCKING

LIMBING

See Figure 22.

Limbing is removing branches from a fallen tree.

■ Work slowly, keeping both hands on the chain saw

with a firm grip. Always make sure your footing is

secure and your weight is distributed evenly on

both feet.

■ Leave the larger support limbs under the tree to

keep the tree off the ground while cutting.

■ Limbs should be cut one at a time. Remove the cut

limbs from the work area often to help keep the

work area clean and safe.

■ Branches under tension should be cut from the

bottom up to avoid binding the chain saw.

■ Keep the tree between you and the chain saw while

limbing. Cut from the side of the tree opposite the

branch you are cutting.

2

3

1

Fig. 21

4

CUT LIMBS ONE AT A TIME AND LEAVE SUPPORT

LIMBS UNDER TREE UNTIL LOG IS CUT

Fig. 22

21

Page 22

OPERATION

PRUNING

See Figure 23.

Pruning is trimming limbs from a live tree.

■ Work slowly, keeping both hands on the chain saw

with a firm grip. Always make sure your footing is

secure and your weight is distributed evenly on

both feet.

■ Do not cut from a ladder, this is extremely dangerous. Leave this operation for professionals.

■ Do not cut above chest height as a saw held higher

is difficult to control against kickback.

■ When pruning trees it is important not to make the

finishing cut next to the main limb or trunk until you

have cut off the limb further out to reduce the

weight. This prevents stripping the bark from the

main member.

1. Underbuck the branch 1/3 through for your first

cut.

2. Your second cut should overbuck to drop the

branch off.

3. Now make your finishing cut smoothly and

neatly against the main member so the bark will

grow back to seal the wound.

LOAD

FIRST CUT

1/3 DIAMETER

FINISHING CUT

SPRINGPOLE

SECOND CUT

Fig. 23

WARNING:

If the limbs to be pruned are above chest height,

hire a professional to perform the pruning.

SPRINGPOLES

See Figure 24.

A springpole is any log, branch, rooted stump, or

sapling which is bent under tension by other wood so

that it springs back if the wood holding it is cut or

removed. On a fallen tree, a rooted stump has a high

potential of springing back to the upright position

during the bucking cut to separate the log from the

stump. Watch out for springpoles, they are dangerous.

Fig. 24

WARNING:

Springpoles are dangerous and could strike the

operator, causing the operator to lose control of

the chain saw. This could result in severe or

fatal injury to the operator.

22

Page 23

MAINTENANCE

ASSEMBLING BAR AND CHAIN

See Figures 25, 26, 27, 28 and 29.

CAUTION:

Remove the battery pack from the chain saw and

make sure the chain has stopped before you do

any work on the saw.

WARNING:

The safety instructions in this section are to

protect the user from serious personal injury.

CAUTION:

Always wear gloves when handling the bar and

chain; these components are sharp and may

contain burrs.

SPROCKET

CHAIN TENSION

PIN HOLE

CHAIN

CHAIN

COVER

ADJUSTING

PIN

BAR

WASHER

CHAIN

COVER

SCREW

Fig. 25

WARNING:

Never touch or adjust the chain while the motor

is running. The saw chain is very sharp, always

wear protective gloves when performing

maintenance to the chain.

1. Remove the battery pack before you do any work

on the chain saw.

2. Remove the hex key from the storage area and use

it to remove the chain cover screw, washer and

chain cover from the chain saw.

3. Remove the bar and chain from the mounting

surface.

4. Remove the old chain from the bar.

5. Lay out the new saw chain in a loop and straighten

any kinks. The cutters should face in the direction

of chain rotation. If they face the opposite direction,

turn the loop over.

6. Place the chain drive links into the bar groove.

Position the chain so there is a loop at the back of

the bar. Hold the chain in position on the bar and

place the loop around the sprocket of the chain

saw. Fit the bar flush against the mounting surface

so that the bar stud is in the long slot of the bar.

NOTE: When placing the bar on the bar stud,

assure that the adjusting pin is in the chain tension

pin hole.

CHAIN DRIVE

LINKS

BAR

GROOVE

Fig. 26

23

Page 24

MAINTENANCE

7. Replace the chain cover, washer and chain cover

screw. Tighten the chain cover screw finger tight

only. The bar must be free to move for tension

adjustment.

8. Remove all the slack from the chain by turning the

chain tensioning screw clockwise until the chain

seats snugly against the bar with the drive links in

the bar groove.

9. Lift the tip of the guide bar up to check for sag.

Release the tip of the guide bar and turn the chain

tensioning screw 1/2 turn clockwise. Repeat this

process until sag does not exist.

10. Hold the tip of the guide bar up and tighten the bar

mounting screw securely.

11. Chain is correctly tensioned when there is no sag

on the underside of the guide bar, the chain is

snug, but it can be turned by hand without binding.

NOTE: If chain is too tight, it will not rotate.

Loosen the chain cover screw slightly and turn

tension adjuster 1/4 turn counterclockwise. Lift the

tip of the guide bar up and retighten chain cover

screw securely. Assure that the chain will rotate

without binding.

12. Place the hex key back into the storage area.

LIFT THE TIP OF

THE GUIDE BAR

UP TO CHECK

FOR SAG

Fig. 28

CHAIN

TENSIONING

SCREW

Fig. 27

HEX KEY

Fig. 29

24

Page 25

MAINTENANCE

CHAIN TENSION

See Figures 30 and 31.

1. Stop the engine before setting the chain tension.

Make sure the guide bar screw is loosened to finger

tight, turn the chain tensioner clockwise to tension

the chain. Refer to “Assembling the Bar and Chain”

earlier in this manual for additional information.

A cold chain is correctly tensioned when there is no

slack on the underside of the guide bar, the chain is

snug, but it can be turned by hand without binding.

2. Chain must be re-tensioned whenever the flats on

the drive links hang out of the bar groove.

3. During normal saw operation, the temperature of

the chain will increase. The drive links of a correctly

tensioned warm chain will hang approximately

.050 in. (1.25 mm) out of the bar groove.

NOTE: New chain tends to stretch, check chain

tension frequently and tension as required.

CAUTION:

Chain tensioned while warm, may be too tight

upon cooling. Check the “cold tension” before

next use.

APPROX. .050 (1.25 mm)

Fig. 31

FLATS

Fig. 30

25

Page 26

CHAIN MAINTENANCE

See Figures 32 and 33.

MAINTENANCE

CUTTING

CORNER

CAUTION:

Remove the battery pack and make sure the

chain has stopped before you do any work on the

saw.

Use only low-kickback chain on this saw. This fastcutting chain will provide kickback reduction when

properly maintained.

For smooth and fast cutting, chain needs to be maintained properly. The chain requires sharpening when

the wood chips are small and powdery, the chain must

be forced through the wood during cutting, or the chain

cuts to one side. During maintenance of your chain,

consider the following:

■ Improper filing angle of the side plate can increase

the risk of a severe kickback.

■ Raker (depth gauge) clearance.

■ Too low increases the potential for kickback.

■ Not low enough decreases cutting ability.

■ If cutter teeth have hit hard objects such as nails

and stones, or have been abraded by mud or sand

on the wood, have service dealer sharpen chain.

NOTE: Inspect the drive sprocket for wear or damage

when replacing the chain. If signs of wear or damage

are present in the areas indicated, have the drive

sprocket replaced by a Ryobi Service dealer.

TOP PLATE

RIVET HOLE

HEEL

CHECK FOR WEAR OR

DAMAGE

GULLET

SIDE PLATE

DEPTH GAUGE

TOE

Fig. 32

Fig. 33

HOW TO SHARPEN THE CUTTERS

See Figure 34 and 35.

Be careful to file all cutters to the specified angles and

to the same length, as fast cutting can be obtained

only when all cutters are uniform.

1. Wear gloves for protection. Properly tension the

chain prior to sharpening. Refer to “Chain Tension

Section” earlier in this manual. Do all of your filing

at the mid-point of the bar.

2. Use A 5/32 in. diameter round file and holder.

3. Keep the file level with the top plate of the tooth. Do

not let the file dip or rock.

4. Using light but firm pressure, stroke towards the

front corner of the tooth.

Lift file away from the steel on each return stroke.

Fig. 34

26

Page 27

MAINTENANCE

5. Put a few firm strokes on every tooth. File all left

hand cutters in one direction. Then move to the

other side and file the right hand cutters in the

opposite direction. Occasionally remove filings from

the file with a wire brush.

WARNING:

Improper chain sharpening increases the

potential of kickback.

WARNING:

Failure to replace or repair damaged chain can

cause serious injury.

WARNING:

The saw chain is very sharp, always wear

protective gloves when performing maintenance

to the chain.

LEFT HAND

CUTTERS

RIGHT HAND

CUTTERS

CORRECT TOP PLATE

FILING ANGLE

30°

Fig. 35

INCORRECT TOP PLATE

FILING ANGLE

LESS

THAN 30°

MORE

THAN 30°

TOP PLATE FILING ANGLE

See Figure 36.

■ CORRECT 30° - File holders are marked with guide

marks to align file properly to produce correct top

plate angle.

■ LESS THAN 30° - For Cross Cutting.

■ MORE THAN 30° - Feathered Edge Dulls Quickly.

SIDE PLATE ANGLE

See Figure 37.

■ CORRECT- 80

diameter file is used in file holder.

■ HOOK- “Grabs” and dulls quickly. Increases

potential of KICKBACK.

Results from using a file with diameter too small, or

file held too low.

■ BACKWARD SLOPE- Needs too much feed

pressure, causes excessive wear to bar and chain.

Results from using a file with diameter too large, or

file held too high.

DEPTH GAUGE CLEARANCE

o

Produced automatically if correct

See Figure 38.

1. The depth gauge should be maintained at a clear-

ance of .025 in. (0.6 mm). Use a depth gauge tool for

checking the depth gauge clearances.

2. Every time the chain is filed, check the depth gauge

clearance.

CORRECT SIDE

PLATE FILING

ANGLE

80°

INCORRECT SIDE PLATE

FILING ANGLE

HOOK

RAKER CLEARANCE

.025 in. (0.6 mm)

Fig. 36

BACKWARD

SLOPE

Fig. 37

Fig. 38

27

Page 28

MAINTENANCE

Use a Flat File and a Depth Gauge Jointer to lower all

gauges uniformly. Depth gauge jointers are available in

.020 in. to .035 in. (0.5 mm to 0.9 mm). Use a .025 in.

(0.6 mm) depth gauge jointer. After lowering each

depth gauge, restore original shape by rounding the

front. Be careful not to damage adjoining drive links

with the edge of the file.

Depth gauges must be adjusted with the flat file in the

same direction the adjoining cutter was filed with the

round file. Use care not to contact cutter face with flat

file when adjusting depth gauges.

GUIDE BAR MAINTENANCE

See Figure 41

When the guide bar shows signs of wear, reverse it

on the saw to distribute the wear for maximum bar

life. The bar should be cleaned every day of use and

checked for wear and damage.

Feathering or burring of the bar rails is a normal

process of bar wear. Such faults should be smoothed

with a file as soon as they occur.

A bar with any of the following faults should be replaced.

■ Wear inside the bar rails which permits the chain to

lay over sideways.

■ Bent guide bar.

■ Cracked or broken rails.

■ Spread rails.

In addition, guide bars with a sprocket at their tip must

be lubricated weekly with a grease syringe to extend

the guide bar life. Using a grease syringe, lubricate

weekly in the lubricating hole.

Turn the guide bar and check that the lubrication holes

and chain groove are free from impurities.

.

See Figures 39 and 40.

See Figure x.

DEPTH GAUGE JOINTER

FLAT FILE

Fig. 39

RESTORE ORIGINAL

SHAPE BY ROUNDING

THE FRONT

Fig. 40

LUBRICATING HOLE

Fig. 41

REVERSING THE GUIDE BAR

See Figures 41, 42, and 43.

1. Remove the SAFE-T-TIP® mounting screw.

2. Remove the SAFE-T-TIP® from the bar.

3. Remove the chain from the bar and turn the bar

over.

NOTE: Bottom of bar should not be on top.

4. Replace the chain on the bar. Refer to “Assembling

the Bar and Chain” earlier in this manual for specific information.

5. Replace the SAFE-T-TIP® on the bar nose.

NOTE: The locking tab fits in the recessed hole in

the bar.

6. Tighten the screw with your finger.

7. From the finger-tight position, tighten the screw an

additional 3/4 of a turn using a wrench.

28

Page 29

MAINTENANCE

CAUTION:

Remove the battery pack and make sure the

chain has stopped before you do any work on

the saw.

WARNING:

Although the guide bar comes with a SAFE-TTIP® anti-kickback device already installed, you

need to check the tightness of the mounting

screw before each use.

SAFE-T-TIP® NOSE GUARD MAINTENANCE

See Figures 42 and 43.

Tighten the mounting screw of the nose guard as

instructed below. These are specially hardened

screws. If the screw cannot be installed tightly, replace

both the screw and the SAFE-T-TIP® before further

operation. Do not replace with an ordinary screw.

In addition to preventing chain contact with solid

objects at the nose of the bar, the SAFE-T-TIP® also

helps keep the chain away from abrasive surfaces

such as the ground. Keep it on the right hand side of

the bar, where it will be between the chain and the

ground during flush with ground cutting.

The mounting screw requires a 5/16 in. wrench (or

adjustable wrench) to achieve the recommended

tightness of 35 to 45 in. lb. (4-5 Nm). A tightness

within this range can be achieved by the following

method.

1. Tighten the screw with your finger.

2. From the finger-tight position, tighten the screw an

additional 3/4 of a turn using a wrench.

MOUNTING SAFE-T-TIP® NOSE GUARD

See Figuress 42 and 43.

1Mount the SAFE-T-TIP® on the bar nose.

NOTE: The tab fits in the recessed hole in the bar.

2. Tighten the screw with your finger.

3. From the finger-tight position, tighten the screw an

additional 3/4 of a turn using a wrench.

MOUNTING SCREW

LOCKING RIVET

SAFE-T-TIP

Fig. 42

TIGHTEN 3/4

OF A TURN

Fig. 43

WARNING:

When servicing use only identical Ryobi

replacement parts. Use of any other parts may

create a hazard or cause product damage.

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types

of commercial solvents and may be damaged by their

use. Use clean cloths to remove dirt, dust, oil, grease,

etc.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.

come in contact with plastic parts. They contain

chemicals that can damage, weaken or destroy

plastic.

29

Page 30

MAINTENANCE

WARNING:

Do not attempt to modify this tool or create

accessories not recommended for use with this

tool. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING:

Any repairs requiring disassembly should only be

performed by a Ryobi Authorized Service dealer.

For the repair center nearest you, call 1-800-

525-2579.

TRANSPORTING AND STORING

See Figure 44.

■ Do not store or transport the chain saw when it is

running. The chain saw should always be idle

before storing or transporting.

■ Always place the guide bar scabbard on the bar

and chain before storing or transporting the chain

saw. Use caution to avoid the sharp teeth of the

chain.

■ Clean the chain saw thoroughly before storing.

Store the chain saw indoors, in a dry place that is

locked and/or inaccessible to children.

■ Keep away from corrosive agents such as garden

chemicals and de-icing salts.

BATTERIES

The battery pack for your chain saw is equipped with

nickel-cadmium rechargeable batteries. Length of

service from each charging will depend on the type of

work you are doing.

The batteries in this tool have been designed to

provide maximum trouble free life. However, like all

batteries, they will eventually wear out. Do not disassemble battery pack and attempt to replace the

batteries. Handling of these batteries, especially when

wearing rings and jewelry, could result in a serious

burn.

To obtain the longest possible battery life, we suggest

the following:

■ Store and charge your batteries in a location where

the temperature is above 50°F but less than 100°F.

■ Never store batteries in a discharged condition.

Recharge them immediately after they are discharged.

■ All batteries gradually lose their charge. The higher

the temperature the quicker they lose their charge.

If you store your chain saw for long periods of time

without using it, recharge it every month or two.

This practice will prolong battery life.

DISPOSAL OF THE EXHAUSTED BATTERY

To preserve natural resources,

please recycle or dispose of properly. This product contains a nickelcadmium battery. Must be disposed

of properly. Local, state, or federal

laws may prohibit disposal of NickelCadmium batteries in ordinary trash.

Consult your local waste authority for

information regarding available recy-

cling and/or disposal options. For more information on

battery recycling call 1-800-8BATTERY.

BATTERY PACK PREPARATION FOR RECYCLING

Fig. 44

WARNING:

Upon removal, cover the battery pack’s terminals

with heavy duty adhesive tape. Do not attempt to

destroy or disassemble battery pack or remove

any of its components. Also, never touch both

terminals with metal objects and/or body parts as

short circuit may result. Keep away from

children. Failure to comply with these warnings

could result in fire and/or serious injury.

30

Page 31

BAR AND CHAIN COMBINATIONS

RECOMMENDED BAR AND CHAIN COMBINATIONS

Bar Part Number - 10 in. (254 mm) 671256002 or 671667002

Chain Part Number 6958301 or 690583002

TROUBLESHOOTING

IF THESE SOLUTIONS DO NOT SOLVE THE PROBLEM CONTACT YOUR AUTHORIZED SERVICE DEALER.

PROBLEM POSSIBLE CAUSE SOLUTION

Bar and chain running

hot and smoking.

Motor runs, but chain is

not rotating.

1. Check chain tension for

over tight condition

2. Chain oil tank empty.

1. Chain tension too tight.

2. Check guide bar and chain

assembly.

3. Check guide bar and chain

for damage.

1. Tension chain. Refer to “Chain Tension”

earlier in this manual.

2. Check oil tank.

1. Retension chain, Refer to “Chain Tension”

earlier in this manual.

2. Refer to “Assembling the Bar and Chain”

earlier in this manual.

3. Inspect guide bar and chain for damage.

31

Page 32

NOTES

32

Page 33

NOTES

33

Page 34

OPERATOR'S MANUAL

18 Volt Cordless Chain Saw

Model No. CS1800

CUSTOMER SERVICE INFORMATION

For parts or service, contact your nearest Ryobi authorized service center. Be sure to provide all relevant

information when you call or visit. For the location of the authorized service center nearest you, please call

1-800-525-2579 or visit us online at www.ryobitools.com.

The model number of this tool is found on a plate attached to the buffer/polisher. Please record the serial

number in the space provided below. When ordering repair parts, always give the following information:

Model No.

Serial No.

CS1800

RYOBI TECHNOLOGIES INC.

1428 Pearman Dairy Road Anderson, SC 29625

Post Office Box 1207 Anderson, SC 29622

www.ryobitools.com

1-800-525-2579

983000-353

10-04

Loading...

Loading...