Page 1

OWNER’S OPERATING MANUAL

210mm COMPOUND MITRE SAW

MODEL CMS812

IMPORTANT NOTICE:

This Mitre Saw is designed for light consumer use. It is NOT designed for trade

or industrial use and is not covered by warranty for use in these applications.

THANKYOU FOR BUYING A RYOBI MITRE SAW

Your new Mitre Saw has been engineered and manufactured to Ryobi's high standard for dependability,

ease of operation and operator safety. Properly cared for, it will give you years of rugged, trouble free

performance.

CAUTION: Carefully read through this entire owner's manual before using your drill.

Pay close attention to the Rules for Safe Operation, Warnings and Cautions. If you use your saw properly and

only for what it is intended, you will enjoy years of safe, reliable service.

Thank you again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

SPECIFICATIONS:

• Power Input .......................... 1200 watts

• No Load Speed...................... 4500 r.p.m.

• Blade Size .............................. 210mm

• Blade Bore Size .................... 16mm

• TCT Blade .............................. 24 tooth

• Cutting Capacities:

90° Cross Cut ........................50mm x 120mm

Bevel Cut................................25mm x 120mm

45° Compound Mitre Cut......25mm x 90mm

Mitre Cut ................................55mm x 85mm

• Weight .................................... 7kg

STANDARD ACCESSORIES:

• Dust Bag

Page 2

RULES FOR SAFE OPERATION

The purpose of safety rules is to attract your attention to

possible dangers. The safety symbols and the explanations with

them, require your careful attention and understanding.

The safety warnings by themselves do not elimimate any danger.

The instruction or warnings they give are not substitutes for

proper accident prevention measures.

SAFETY ALERT SYMBOL Indicates caution or

warning. May be used in conjunction with

other symbols or pictures.

WARNING: Failure to obey a safety warning

can result in serious injury to yourself or to

others. Always follow the safety precautions to

reduce the risk of fire, electric shock and

personal injury.

DOUBLE INSULATION

Double insulation is a concept in safety in electric power tools,

which eliminates the need for earth grounding. Whenever

there is electric current in the tool there are two complete sets

of insulation to protect the user. All exposed metal parts are

isolated from the internal metal motor components with

protecting insulation.

WARNING: The double insulated system is intended to protect

the user from shock resulting from a break in the tool's internal

wiring. Observe all normal safety precautions related to avoiding

electrical shock.

IMPORTANT: Servicing of a tool with double insulation requires

extreme care and knowledge of the system and should be

performed only by a qualified service technician. For service we

suggest you return the tool to your nearest Ryobi Authorised

Service Centre for repair. When servicing, use only identical

Ryobi replacement parts.

WARNING: Do not attempt to operate this tool until you have

read thoroughly and completely understood the safety rules, etc.

contained in this manual. Failure to comply can result in

accidents involving fire, electric shock or serious personal injury.

Save owners manual and review frequently for continual safe

operation and for instructing others who may use this tool.

The operation of any tool can result

in foreign objects being thrown into

your eyes, which can result in severe

eye damage. Before beginning

power tool operation, always wear

safety goggles or safety glasses with

side shields and a full face shield

when needed. We recommend Wide Vision Safety Mask for

use over eye glasses or standard safety glasses with side shields.

1. KNOW YOUR POWER TOOL. Read owners manual carefully.

Learn its applications and limitations as well as the specific

potential hazards related to this tool.

2. GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING

BODY CONTACT WITH GROUNDED SURFACES.

For example, pipes, radiators, ranges, refrigerator enclosures.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

4. AVOID DANGEROUS ENVIRONMENT. Don't use power

tools in damp or wet locations or expose to rain. Keep work

area well lit.

5. KEEP CHILDREN AND VISITORS AWAY. Visitors should wear

safety glasses and be kept a safe distance from work area.

Do not let visitors contact tool or extension cord.

6. STORE IDLE TOOLS. When not in use, tools should be stored

in a dry and high or locked-up place, out of reach of children.

7. DON'T FORCE TOOL. It will do the job better and safer at the

rate at which it was designed.

8. USE RIGHT TOOL. Don't force a small tool or attachment to

do the job of a heavy duty tool. Don't use tool for any purpose

not intended.

9. DRESS PROPERLY. Do not wear loose clothing or jewellery.

They can be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when working outdoors.

Also wear protective hair covering to contain long hair.

10. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses

have only impact resistant lenses, they are not safety glasses.

11. PROTECT YOUR LUNGS. Wear a dust mask if operation is dusty.

12. PROTECT YOUR HEARING. Wear hearing protection during

extended periods of operation.

13. DON'T OVERREACH. Keep proper footing and balance at all

times. Do not use tool on a ladder or unstable support.

Secure tools when working at elevated levels.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean

for better and safer performance. Follow instructions for

lubricating and changing accessories.

15. DISCONNECT TOOLS. When not in use, before servicing, or

when changing attachments, blades, bits, cutters, etc. all

tools should be disconnected.

16. REMOVE ADJUSTING KEYS AND WRENCHES. Before

turning it on, Form a habit of checking to see that keys and

adjusting wrenches are removed from tool.

17. NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal

sparking of the motor could ignite fumes.

18. KEEP HANDLES DRY, CLEAN AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never use

brake fluids, gasoline, petroleum based products, or any

strong solvents to clean your tool.

19. STAY ALERT AND EXERCISE CONTROL. Watch what you

are doing and use common sense. Do not operate tool when

you are tired. Do not rush.

20. CHECK DAMAGED PARTS. Before further use of the tool, a

guard or any other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts and any other

conditions that may affect its operation. A guard or any other

part that is damaged should be properly repaired or replaced

by an authorised service centre.

21. DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON

AND OFF. Have defective switches replaced by authorised

service centre.

22. DO NOT OPERATE THIS TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL OR ANY MEDICATION.

23. SUPPLY CORD. If the supply cord is damaged, it must be

replaced by the manufacturer or its service agent or similarly

qualified person in order to avoid a hazard.

Due to Ryobi's continued product refinement policy,

product features and specifications can and will change

without notice. Check current features and specifications with your Ryobi retailer.

SAVE THESE INSTRUCTIONS

Page 2

Page 3

Your Compound Mitre Saw has been shipped completely

assembled except for the blade.

• Remove all loose parts from the carton. Separate and check

with the list of loose parts. See figure 1.

• Remove the packing materials from around your saw.

• Carefully lift saw from the carton and place it on a level

work surface. Although small, this saw is heavy. To avoid

back injury, get help when needed.

• Do not discard the packaging materials until you have

carefully inspected the saw, identified all loose parts and

satisfactorily operated your new saw.

• Your saw has been shipped with the saw arm locked in the

down position. To release saw arm, pull out the lock down

pin.

• Lift the saw arm by the handle. Hand pressure should

remain on the saw arm to prevent sudden rise upon release

of the lock down pin.

• Examine all parts to make sure no breakage or damage has

occurred during shipping.

If any parts are damaged or missing, do not attempt to plug in

the power cord and turn the switch on until the damaged or

missing parts are obtained and are installed correctly.

UNPACKING

FEATURES

TOOLS NEEDED

WARNING: If any parts are missing, do not

operate this tool until the missing parts are

replaced. Failure to do so could result in

serious personal injury

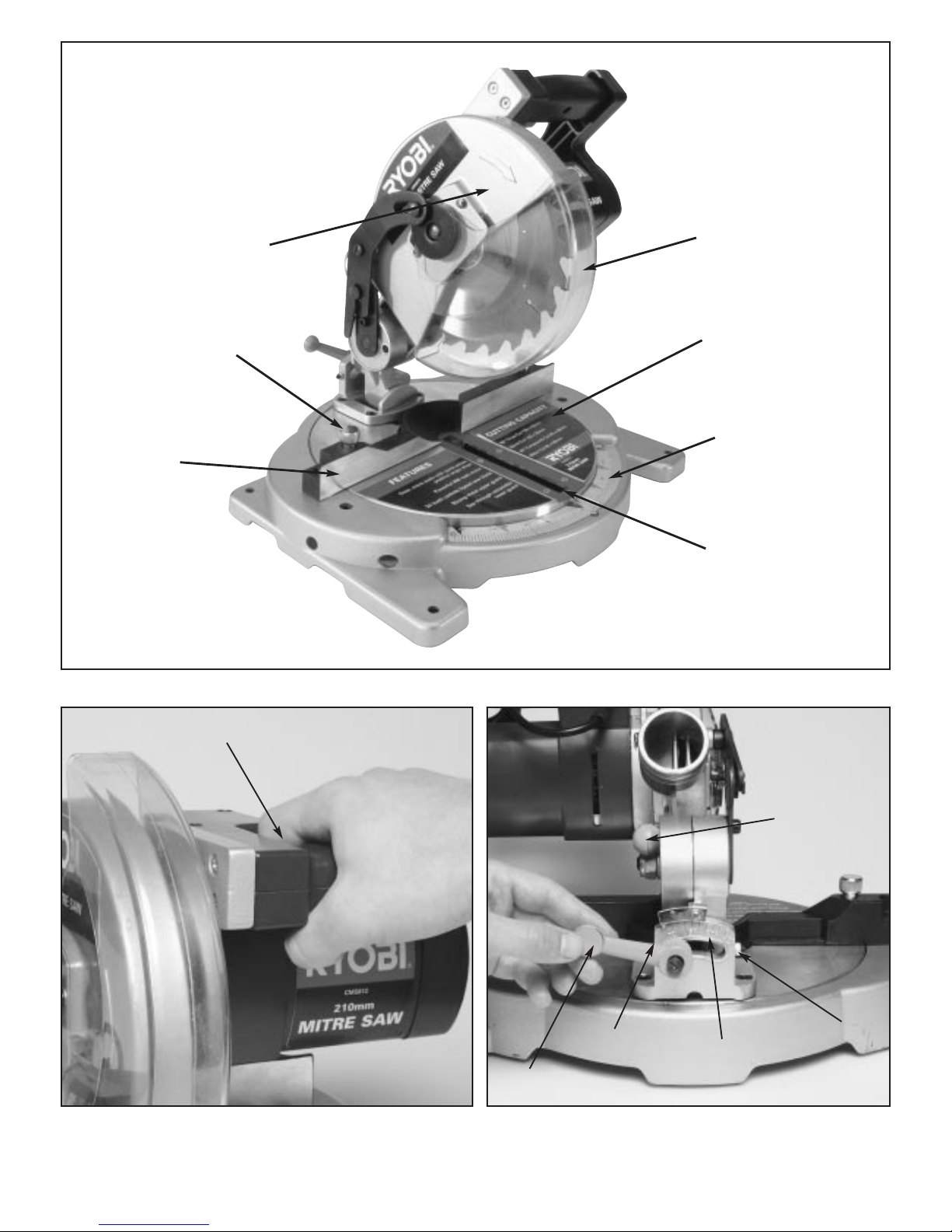

■ KNOW YOUR COMPOUND MITRE SAW

Before attempting to use your saw, familiarise yourself with all

the operating features (Fig 2, 2a & 2b) and safety

requirements.

■ 1200 WATT MOTOR

Your CMS812 Compound Mitre Saw has a powerful 1200 watt

motor with sufficient power to handle tough cutting jobs. It is

made with all ball bearings, and has externally accessible

brushes for ease of servicing.

■ 210mm BLADE

A 210mm saw blade is included with your compound mitre

saw. It will cut materials up to 55mm thick or 120mm wide,

depending upon the thickness of the material and the setting

at which the cut is being made.

WARNING: Do not allow familiarity with

your saw to make you careless. Remember

that a careless fraction of a second is

sufficient to inflict severe injury.

The following tools (not included) are needed for checking adjustments of your saw and for installing the blade.

Fig.1

Page 3

Page 4

Arbor

The shaft on which a blade or cutting tool is mounted.

Bevel Cut

A cutting operation made with the blade at any angle other

than 90° to the mitre table.

Cross Cut

A cutting or shaping operation made across the grain of the

workpiece.

Compound Mitre Cut

A compound mitre cut is a cut made using a mitre angle and a

bevel angle at the same time.

Freehand

Performing a cut without using a fence, mitre guage, fixture,

work clamp, or other proper device to keep the work piece

from twisting or moving during the cut.

Gum or Resin

A sticky, sap based residue from wood products.

Mitre Cut

A cutting operation made with the blade at any angle other

than 90° to the fence.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in one

minute.

Saw Blade Path

The area along which the blade travels.

Set

The distance that the tip of the saw blade tooth is bent (or set)

outward from the side of the blade.

Throw-Back

Throwing of a workpiece in a manner similar to a kickback.

Usually associated with a cause other than the kerf closing,

such as a workpiece not being against the fence, being

dropped into the blade, or being placed inadvertently in

contact with the blade.

Through Sawing

Any cutting operation where the blade extends completely

through the thickness of the workpiece.

Workpiece

The item on which the cutting operation is being done. The

surfaces of a workpiece are commonly referred to as faces,

ends and edges.

Zero Clearance Throat Plate

A plastic throat plate inserted in the mitre table that allows for

blade clearance. When you make your first cut with your

compound mitre saw, the saw blade cuts a slot through the

throat plate the exact width of the blade. This provides for a

zero clearance kerf that minimises workpiece tear out.

No Hands Zone

The area between the marked lines on the left and right side

of the mitre table base. This zone is identified by no hands

zone labels placed inside the marked lines on the mitre table

base.

GLOSSARY OF TERMS FOR WOODWORKING

MAINTENANCE

Page 4

WARNING: When servicing, use only identical Ryobi

replacement parts. Use of any other part may create a

hazard or cause product damage.

■ GENERAL

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, carbon dust, etc.

It has been found that electric tools are subject to accelerated

wear and possible premature failure when they are used on

fibreglass boats, sports cars, wallboard, spackling compounds,

or plaster. The chips and grinding from these materials are

highly abrasive to electric tool pars such as bearings, brushes,

commutators, etc. Consequently, it is not recommended that

this tool be used for extended work on any fibreglass

material, wallboard, spackling compounds, or plaster. During

any use on these materials it is extremely important that the

tool is cleaned frequently by blowing with an air jet.

■ LUBRICATION

All of the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrication

is required.

■ EXTENSION CORDS

The use of any extension cord will cause some loss of power.

To keep power loss to a minimum and to prevent tool

overheating, use an extension cord that is heavy enough to

carry the current the tool will draw.

A wire gauge size (A.W.G.) of at least 16 is recommended for

an extension cord 50 feet or less in length. When working

outdoors, use an extension cord that is suitable for outdoor

use.

If the supply cord is damaged, it shall be replaced by the

manufacturer or its service agent in order to avoid a hazard.

Disconnect from the supply immediately, if the supply cable is

damaged.

Take care not to expose this tool to rain.

WARNING: Do not at any time let brake fluids,

gasoline, petroleum based products,

penetrating oils, etc. come into contact with

plastic parts. They contain chemicals that can

daamage, weaken or destroy plastic.

CAUTION: Keep extension cords away from the

cutting area and position the cord so that it will

not get caught on timber, tools, etc. during

cutting operation.

WARNING: Check extension cords before each

use. If damaged, replace immediately. Never use

tool with a damaged cord since touching the

damaged area could cause electrical shock

resulting in serious injury.

WARNING: Always wear safety goggles or

safety glasses with side sheilds during power

tool operation or when blowing dust.

If operation is dusty, also wear a dust mask.

Page 5

Page 5

Upper Blade Guard

Mitre Table Lock Knob

Rear Fence

Lower Blade Guard

Mitre Table

Mitre Scale

Throat Plate

■ CMS812 210mm Compound Mitre Saw

Fig.2

Fig.2a Fig.2b

Trigger Switch

Bevel Scale

45° Stopper

0° Stopper

Bevel Lock

Handle

Lock Down Pin

Page 6

Page 6

■ LOCK DOWN PIN

Your CMS812 features a lock down pin for easier

transportation. To unlock the head pull the pin out and pull the

saw arm to the upright position. (Fig 3)

■ 0 - 45° MITRE ADJUSTMENT

Your CMS812 mitre cuts from 0° to 45° both right and left,

with automatic locking of the index stopper at 5° increments.

Unlock both mitre table lock knobs and move the mitre table

to the desired cutting angle and then lock the mitre table by

securing both mitre table lock knobs. (Fig 4)

■ ON/OFF SWITCH & SAFETY GUARD

■ FENCE

The fence on your compound mitre saw has been provided to

securely hold your workpiece against when making all cuts.

■ SELF-RETRACTING LOWER BLADE GUARD

The lower blade guard provides protection from each side of

the blade. It retracts over the upper blade guard as the saw is

lowered into the workpiece.

■ ELECTRICAL CONNECTION

Your saw has a precision built electric motor. It should be

connected to a power supply that is 240 volts AC, 50-60 Hz,

only (normal household current). Do not operate this tool on

direct current (DC). A substantial voltage drop will cause a loss

of power and the motor will overheat. If your tool does not

operate when plugged into an outlet, double-check the power

supply.

WARNING: Failure to unplug your CMS812

could result in accidental starting causing

possible serious personal injury.

Fig.3

Fig.4

WARNING: The operation of any power tool can

result in foreign objects being thrown into your

eyes, which can result in severe eye damage.

Before beginning power tool operation, always

wear safety goggles or safety glasses with side

shields and a full face shield when needed. We

recommend a Wide Vision Safety Mask for use

over eyeglasses or standard safety glasses with

side shields

WARNING: Do not attempt to modify this tool

or create accessories not recommended for use

with this tool. Any such alteration or

modification is misuse and could result in

hazardous condition leading to possible serious

personal injury.

ADJUSTMENTS

■ REPLACING BLADE (Fig 5)

1. Unscrew the two screws holding the lower guard retraction

arm and remove the retraction arm. (Fig 5)

2. Unscrew the two phillips headed screws holding the lower

perspex guard and remove the guard. (Fig 5)

3. Place a piece of scrap timber under the blade and pull the

saw arm head down until the teeth of the blade lock into the

scrap timber. This will then allow you to unscrew the blade

bolt. Remove the outer flange and blade.

WARNING: To prevent accidental starting that

could cause possible serious personal injury,

assemble all parts to your saw before

connecting it to the power supply. Saw should

never be connected to power supply when you

are assembling parts, making adjustments,

installing or removing blades, or when not in

use.

DANGER: A 210 mm blade is the maximum

blade capacity of your saw. Never use a blade

that is too thick to allow outer blade washer to

engage with the flats on the spindle. Larger

blades will come in contact with the blade

guards, while thicker blades will prevent the

blade screw from securing the blade on the

spindle. Either of these situations will result in a

serious accident and can cause personal injury.

WARNING: Failure to unplug your saw could

result in accidental starting causing possible

serious personal injury.

WARNING: If the inner blade washer has been

removed, replace it before placing blade on

spindle, Failure to do so could cause an accident

since blade will not tighten properly.

Page 7

Page 7

SPECIAL NOTE

Your CMS812 mitre cutting and bevel

cutting angles have been preset at the

factory but can and will be misaligned

by rough handling and transportation.

It is essential that your new saw be

realigned before use.

Please adhere to the following resetting

instructions.

■ SQUARING THE BLADE SAW TO THE FENCE

Pull the saw arm all the way down and engage the lock down

pin to hold the saw arm in the transport position. (Fig 6)

Unlock the mitre table lock knobs. Rotate the mitre table until

the pointer is positioned at 0° position and lock the mitre table

by securing both mitre table lock knobs. (Fig 7)

Lay a set square on the mitre table and against the rear fence

and blade. If the rear fence and blade do not align adjust as

follows. (Fig 8)

Unscrew the four allen screws securing the rear pivot point to

the base and align correctly. (Fig 10)

CAUTION: Always install the blade with the

blade teeth pointing in a downward direction.

Fig.5

Screws

Phillips

Head

Screws

Fig.6

Fig.7

Fig.8

Fig.9

Fig.10

Allen Screws

Page 8

Page 8

■ SQUARING THE BLADE TO THE MITRE TABLE

Pull the saw arm all the way down and engage the lock down

pin to hold the saw arm in the transport position. (Fig 11)

Unlock the bevel lock knob and move the saw arm to the 0

position and lock the bevel lock knob. (Fig 12)

Lay the set square on the mitre table and against the blade and

if the blade and mitre table do not align adjust as follows.

(Fig 13)

Unscrew the 0° bevel positioning allen screw at the rear as

shown. (Fig 14)

Correctly align the blade and mitre table using the set square

and lock the bevel lock knob. (Fig 15)

Reset the 0° bevel positioning allen screw so where the saw

arm is moved to the 0° bevel position the allen screw bottoms

out and adjust the pointer to the 0° position (Fig 16)

■ SQUARING THE BLADE TO THE TABLE AT 45°

Repeat this procedure for squaring the blade to the mitre table

at 45° (Fig 17)

Move the saw arm to the 45° bevel position. (Fig 18)

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Fig.18

0° Bevel Positioning

allen screw

45° Bevel Positioning

allen screw

Page 9

Page 9Page 9

If the saw arm cannot reach a full 45° position, the 45° bevel

positioning allen screw will have to be reset (Fig 18) so that

when the saw arm is moved to the 45° bevel position the allen

screw bottoms out. Check 45° angle with a 45° set square

(Fig 19) from the table to the blade. If the table and blade do

not align, readjust the 45° positioning screw (Fig 20) so that it

bottoms out at 45° and realign the bevel indication pointer

correctly (Fig 21)

■ APPLICATIONS

(Use only for the purposes listed below)

• Cross Cutting wood & plastics

• Cross Cutting mitres, joints, etc. for picture frames,

moldings, door casings and fine joinery.

NOTE: The crosscut blade provided is for most wood cutting

operations. For fine joinery and picture frame cuts or cutting

plastic, use a blade suitable, available from your nearest

hardware store.

■ CUTTING WITH YOUR COMPOUND MITRE

SAW

■ CROSSCUTTING

A crosscut is made by cutting across the grain of the

workpiece. A 90° crosscut is made with the mitre table set at

the zero degree position. Mitre crosscuts are made with the

mitre table set at some other angle other than zero.

■ TO CROSSCUT WITH YOUR MITRE SAW

• Pull out the lock pin and lift the saw arm to its full

height.

• Unlock the mitre table.

• Rotate the mitre table until the pointer aligns with

the desired angle on the mitre scale.

• Lock the mitre table handle.

NOTE: You can quickly locate 5° increments left or right on the

scale. The mitre table can be seated in one of the positive stop

notches, located in the mitre table frame.

• Place the workpiece flat on the mitre table with one edge

securely against the fence. If the board is warped, place the

convex side against the fence and clamp. If the concave

edge of a board is placed against the fence, the board could

collapse on the blade at the end of the cut, jamming the

blade. (Fig 22)

Fig.19

Fig.20

Fig.21

WARNING: Before starting any cutting

operations, clamp or bolt your compound mitre

saw to a workbench. Never operate your mitre

saw on the floor or in a crouched position.

Failure to heed this warning can result in serious

personal injury

OPERATIONS

WARNING: Use a clamp to secure your

workpiece on one side of the blade only. The

workpiece must remain free on one side of the

blade to prevent the blade from binding in

workpiece. The workpiece binding blade will

cause motor stalling and kickback. This

situation could cause an accident resulting in

serious personal injury.

Fig.22

Page 10

Page 10

• When cutting long pieces of timber or molding, support the

opposite end of the stock.

• Align cutting line on the workpiece with the edge of saw

blade.

• Grasp the stock firmly with one hand and secure it against

the fence.

• Before turning on the saw, perform a dry run of the cutting

operation just to make sure that no problems will occur

when the cut is made.

• Grasp the saw handle firmly, then squeeze the switch

trigger. Allow several seconds for the blade to reach

maximum speed.

• Slowly lower the blade into and through the workpiece.

• Release the switch trigger and allow the saw blade to stop

rotating before raising the blade out of the workpiece.

■ BEVEL CUT

A bevel cut is made by cutting across the grain of the

workpiece with the blade angled to the fence and mitre table.

A bevel cut is made with the mitre table set at zero degree

position and the blade set at an angle between 0° and 45°

(Fig 23)

■ TO BEVEL CUT WITH YOUR MITRE SAW

• Pull out the lock pin and lift the saw arm to its full height.

• Loosen the mitre table locking knobs.

• Rotate the mitre table until the pointer aligns with zero on

the mitre scale.

• Lock the mitre table by securing the two mitre table lock

knobs.

• Loosen the bevel lock handle and move the saw arm to the

left to the desired bevel angle.

• Bevel angles can be set from 0° to 45°

• Align the indicator point with the desired angle.

• Once the saw arm has been set at the desired angle,

securely tighten the bevel lock handle.

• Place the workpiece flat on the mitre table with one warped,

place the convex against the fence. If the board is warped,

place the convex side against the fence. If the concave edge

of the board is placed against the fence, the board could co

lapse on the blade at the end of the cut, jamming the blade.

• When cutting long pieces of timber or molding, support the

overhanging end(s) of the stock.

• Align the cutting line on the workpiece with the edge of saw

blade.

• Grasp the stock firmly with one hand and secure it against

the fence.

• Before turning on the saw, perform a dry run of the cutting

operation just to make sure that no problems will occur

when the cut is made.

• Grasp the saw handle firmly, then squeeze the switch

trigger. Allow several seconds for the blade to reach

maximum speed.

• Slowly lower the blade into and through the workpiece.

• Release the switch trigger and allow the saw blade to stop

rotating before raising the blade out of workpiece.

■ COMPOUND MITRE CUT

A compound mitre cut is a cut made using a mitre angle and a

bevel angle at the same time. This type of cut is used to make

picture frames, cut moulding, make boxes with sloping sides,

and for certain roof framing cuts.

To make this type of cut the mitre table must be rotated to the

correct angle and the saw arm must be tilted to the correct

bevel angle. Care should always be taken when making

compound mitre setups due to the interaction of the two angle

settings.

Adjustments of mitre and bevel settings are interdependent

with one another. Each time you adjust the mitre setting you

change the effect of the bevel setting. Also, each time you

adjust the bevel setting you change the effect of the mitre

setting.

It may take several settings to obtain the desired cut. The first

angle setting should be checked after setting the second

angle, since adjusting the second angle affects the first.

Once the two correct settings for a particular cut have been

obtained, always make a test cut in scrap wood before making

a finish cut in good wood. (Fig 24)

WARNING: To avoid serious personal injury

keep your hands outside the no hands zone; at

least 75mm from blade. Never perform any

cutting operation freehand (without holding

workpiece against the fence). The blade could

grab the workpiece if it slips or twists

WARNING: To avoid serious personal injury,

always push the mitre table clamp back down

before making a cut. Failure to do so could

result in movement of the mitre table while

making a cut causing serious personal injury.

WARNING: To avoid serious personal injury,

keep your hands outside the no hands zone; at

least 75mm from the blade. Never perform any

cutting operation free-hand (without holding

workpiece against the fence). The blade could

grab the workpiece if it slips or twists.

Fig.23

Page 11

■ TO MAKE A COMPOUND CUT WITH YOUR

MITRE SAW

• Pull out the lock pin and lift the saw arm to its full height.

• Loosen the mitre table locking knobs.

• Rotate the mitre table until the pointer aligns with the

desired angle on the mitre scale and lock both mitre table

lock knobs.

NOTE: You can quickly locate 5° increments left or right on the

scale. The mitre table can be seated in one of the positive stop

notches, located in the mitre table frame.

• Loosen the bevel lock handle and move the saw arm to the

left to the desired bevel angle.

• Bevel angles can be set from 0° to 45°

• Align the indicator point with the desired angle.

• Once the saw arm has been set at the desired angle,

securely tighten the bevel lock handle.

• Recheck mitre angle setting. Make a test cut in scrap

material

• Place the workpiece flat on the mitre table with one edge

securely against the fence. If the board is warped, place the

convex side against the fence. If the concave edge of the

board is placed against the fence, the board could collapse

on the blade at the end of the cut, jamming the blade.

(Fig 25).

• When cutting long pieces of timber or molding, support the

opposite end of the stock with a roller stand or with work

surface level with the saw table.

• Align the cutting line on the workpiece with the edge of the

saw blade.

• Grasp the stock firmly with one hand and secure it against

the fence.

• Before turning on the saw, perform a dry run of the cutting

operation just to make sure that no problems will occur

when the cut is made.

• Grasp the saw handle firmly, then squeeze the switch

trigger. Allow several seconds for blade to reach maximum

speed.

• Slowly lower the blade into and through the workpiece.

• Release the switch trigger and allow the saw blade to stop

rotating before raising the blade out of workpiece.

Page 11

Fig.24

WARNING: To avoid serious personal injury,

always lock the mitre table before making a cut.

Failure to do so could result in movement of the

mitre table while making a cut.

WARNING: To avoid serious personal injury,

always keep your hands outside the no hands

zone; at least 75mm from the blade. Never

perform a cutting operation freehand (without

holding the workpiece against the fence). The

blade could grab the workpiece if it slips or

twists.

Fig.25

Page 12

Page 12

■ CUTTING CROWN MOLDING

Your compound mitre saw does an excellent job of cutting

crown molding. In general, compound mitre saws do a better

job of cutting crown molding than any other tool made.

In order to fit properly, crown molding must be compound

mitred with extreme accuracy.

The two contact surfaces on a piece of crown molding that fit

flat against the ceiling and the wall of a room are at angles

that, when added together equal exactly 90°.

Most crown molding has a top rear angle (the section that fits

flat against the ceiling) of 52° and a bottom rear angle (the

section that fits flat against the wall) of 38°.

■ LAYING MOLDING FLAT ON THE MITRE

TABLE

To use this method for accurately cutting crown molding for a

90° inside or outside corner, lay the molding with its broad

back surface flat on the mitre table and against the fence.

When setting the bevel and mitre angles for compound

mitres, remember that the settings are interdependent,

changing one angle changes the other angle as well.

Keep in mind that the angles for crown moldings are very

precise and difficult to set. Since it is very easy for these

angles to shift, all settings should first be tested on a scrap

molding. Also most walls do not have angles of exactly 90°,

therefore, you will need to finetune your settings.

Page 13

Page 13

When cutting crown molding by this method the bevel angle

should be set at 33.85°. The mitre angle should be set at

31.62° either right or left, depending on the desired cut for the

application. See the chart below for correct angle settings and

correct positioning of crown molding on mitre table.

The settings in the chart below can be used for cutting all

standard crown moulding with 52° and 38° angles. The crown

moulding is placed flat on the mitre table using the compound

features of your mitre saw.

■ CUTTING WARPED MATERIAL

(See Figures 26 & 27)

When cutting warped material, always make sure it is

positioned on the mitre table with the convex side against the

fence as shown in figure 26.

If the warped material is positioned the wrong way as shown

in figure 27, it will pinch the blade near the completion of the

cut.

Bevel

Angle Type of Cut

Setting

Left Side, inside corner

1. Top edge of moulding against fence

2. Mitre table set right 31.62°

3. Save left end of cut

Right Side, inside corner

1. Bottom edge of moulding against fence

2. Mitre table set left 31.62°

3. Save left end of cut

Left Side, outside corner

1. Bottom edge of moulding against fence

2. Mitre table set left 31.62°

3. Save right end of cut

Right Side, outside corner

1. Top edge of moulding against fence

2. Mitre table set left 31.62°

3. Save right end of cut

33.85°

33.85°

33.85°

33.85°

RIGHT

Fig.26

WRONG

Fig.27

WARNING: To avoid a kickback and to avoid

serious personal injury, never position the

concave edge of bowed or warped material

against the fence.

Page 14

Page 14

NOTES:

Page 15

HOME USE WARRANTY

24 Months Home Use Warranty

Subject to the warranty conditions below, this RYOBI

tool, (hereinafter called "the product"), is warranted for

home use only by Ryobi Australia Pty. Ltd. (hereinafter

called "The Company") to be free from defects in

material or workmanship for a period of 24 months from

the date of original purchase covering both parts and

labour. Under the terms of this warranty, the repair or

replacement of any part shall be the opinion of the

Company or its authorised agent. Should service

become necessary during the warranty period, the

owner should return the product to their nearest

authorised RYOBI Service Centre. In order to obtain

warranty service, the owner must include the Sales

Docket and Warranty Certificate to confirm date of

purchase. This Product is sold by the dealer or agent as

principal and the dealer has no authority from the

Company to give any additional warranty or guarantee

on the Company's behalf except as herein contained or

herein referred to.

Warranty Conditions

This warranty only applies provided that the Product has

been used in accordance with the manufacturer's

recommendations under normal use and reasonable

care (in the opinion of the Company) and such warranty

does not cover consumable components, damage,

malfunction or failure resulting from misuse, neglect,

abuse, or used for a purpose for which it was not

designed or is not suited and no repairs, alterations or

modifications have been attempted by other than an

Authorised Service Agent. This guarantee will not apply

if the tool is damaged by accident or if repairs arise from

normal wear and tear. The Company accepts no

additional liability pursuant to this warranty for the costs

of travelling or transportation of the Product or parts to

and from the service dealer or agent - which costs are

not included in this warranty. Certain legislation,

including the Trade Practices Act, 1974 (as amended)

and other state and territorial laws give rights to the

buyer and impose liability on the seller in certain

circumstances. Nothing herein shall have the effect of

excluding, restricting or modifying any condition,

warranty, right or liability imposed, to the extent only

that such exclusion, restriction or modification would

render any term herein void.

30 Day Satisfaction Guarantee

If the owner is not completely satisfied with the

performance of the product, for quality reasons, the

Product should be returned to the Authorised RYOBI

Dealer from whom it was purchased within 30 days of

the original date of purchase for refund or exchange.

RYOBI AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Contact during normal business hours.

Tel: (02) 9792 9888 - Fax: 1800 807 993 - Email: info@ryobi.aust.com

Web Site: www.ryobi.com.au

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 503 Mt Wellington Highway, Mt Wellington, N.Z.

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - Email: info@ryobi.co.nz

Contact during normal business hours.

BRISBANE: All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquires Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville.Vic. 3178

Tel : (03) 9764 8655

HOBART: All enquiries Tel : 1300 360 216

ADELAIDE: All enquiries Tel : 1300 360 216

PERTH: 33-35 Sorbonne Cres.,Canning Vale. W.A. 6155.

Tel : (08) 9455 7775

THIS WARRANTY FORM SHOULD BE RETAINED BY THE CUSTOMER AT ALL TIMES.

For your record and to assist in establishing date of purchase (necessary for in-warranty service),

please keep your purchase docket and this form, completed with the following particulars.

PURCHASED FROM :........................................................................................................................................................

ADDRESS OF DEALER : ..................................................................................................................................................

DATE: ................................MODEL NO.: ....................................................SERIAL NO.: ................................................

Present this form with your Purchase Docket when Warranty Service is required.

Loading...

Loading...