Page 1

OPERATOR’S MANUAL

CORDLESS IMPACT DRILL-DRIVER

MODEL NO. CBI1442D / CBI1802D

This new cordless Impact drill-driver has been engineered and manufactured to Ryobi's high standard for dependability, ease of

operation, and operator safety.When properly cared for, the drill-driver will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator's manual before

using this product.

Thank you for buying a Ry

obi product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

6

8

10

12

14

6

8

10

12

14

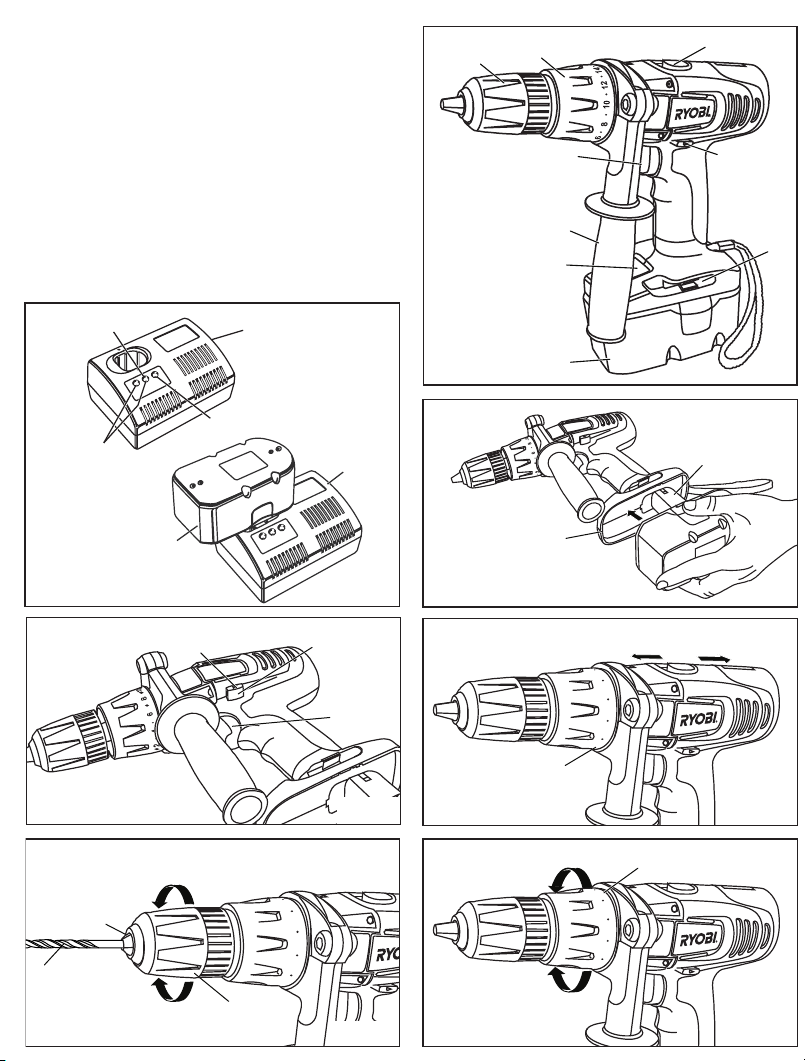

1 .

6

8

10

12

14

Fig. 5

Keyless chuck

2 .

Torque adjustment ring with mode selector

3 .

Two speed gear selector (HI-LO)

4 .

Bit storage area

5 .

Direction of rotation selector (forward/reverse)

6 .

Switch trigger

7.

Battery pack

8 .

Auxiliary handle

9 .

LCD battery capacity indicator

1

2

6

8

9

3

5

4

Green Light

Yellow and

Green Light

Chuck

Drill bit

jaws

Red Light

Battery

pack

Centre position

(lock)

Unlock

(release)

Lock

(tighter)

Battery

Charger

Chuck

sleeve

rotation selector

Battery

charger

Fig. 1

Direction of

Switch

trigger

Fig. 3

7

Battery

Port

To increase

torque

To decrease

torque

To increase

torque

Hi speed(2)

Adjusting ring

Battery

Pack Neck

Fig. 2

Lo speed(1)

Fig. 4

Fig. 6

Page 3

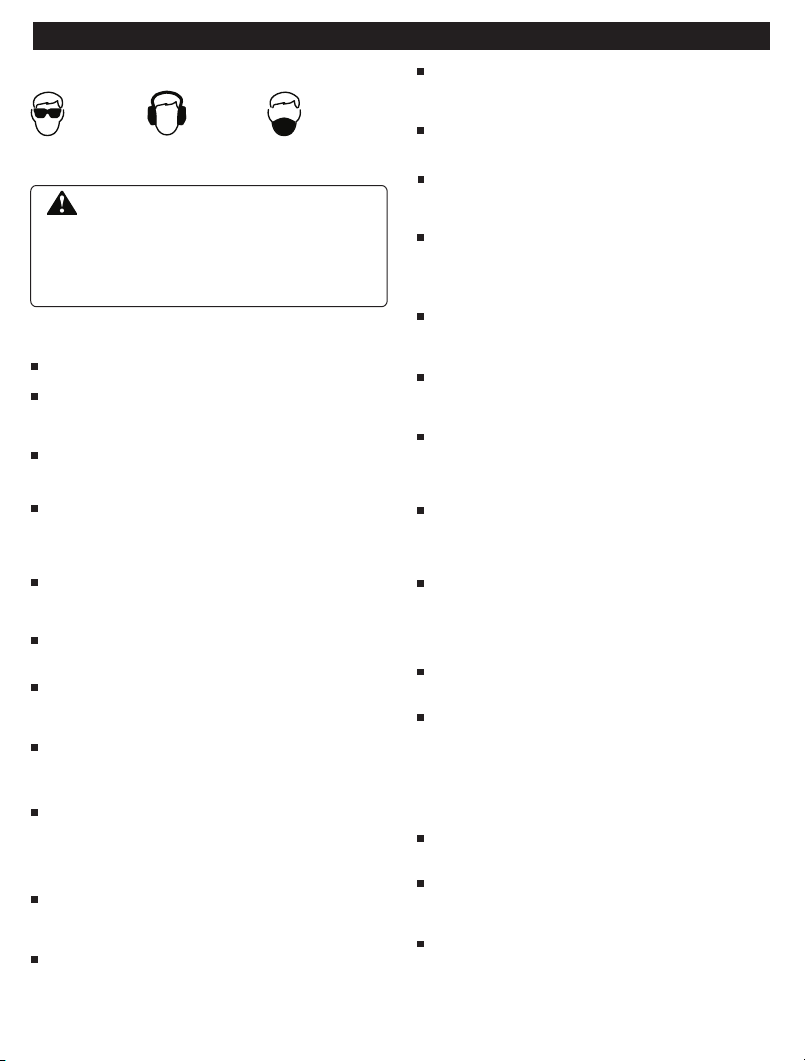

RULES FOR SAFE OPERATION

MEANING OF SAFETY SIGNS

Wear eye

.

protection

GENERAL SAFETY RULES

WARNING:

Read all instructions. Failure to follow all instructions

listed below may result in electric shock, fire and/or

serious injury. The term 'power tool' in all of the warnings

listed below refers to your mains operated (corded)

power tool

S

AVE THESE INSTRUCTIONS

WORK AREA

Keep work area clean and well lit. Cluttered and dark

areas invites accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases,

or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

ELE

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adaptor plugs

with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body

is ea

Do

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

When operating a power tool outdoor

cord suitable for outdoor use. Use of cord suitable of

outdoor use reduces the risk of electric shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention

while operating power tools may result in seriou

injury.

Use safety equipment. Always wear eye protection.

Safety equipment such as dusk mask, non-skid safety

shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Avoid accidental starting. Ensure the switch is in

the off position before plugging in. Carrying power

tools with your finger on the switch or plugging in power

tools that hav

or battery operated (cordless) power tool.

CTRICAL

rthed or grounded.

not expose power tools to rain or wet conditions.

e the switch on invites accidents.

SAFETY

Wear ear

protection.

Wear dust

mask.

s,

use an extension

s

personal

Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to

a rotating part of the power tool may result in personal

injury.

Do not overreach. Keep proper footing and balance

at all times. This enable better control of the power

tool in unexpected situations.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves a

f

rom moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly use. Use of these devices

can reduce dust related hazards.

POWER TOOL USE AND CARE

Do not force the power tool. Use the correct power

tool for your application. The correct power t

do the job better and safer at the rate for which it was

designed.

Do not use the power tool if the switch does not

turn it on and off. Any power tool that can not be

controlled with the switch is dangerous and must be

repaired.

Disconnect the plug from the power source before

making any adjustments, changing accessories,

or storing the power tools. Such preventive safety

measures reduc

a

ccidentally.

Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power

tool. P ower tools are dangerous in the ha nds of

untrained users.

Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

Keep cuttin g too ls sharp and clean. Pro perly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

Use the power tool, accessories and tool bits, etc.,

in accordance with these instructions and in the

manner inte

tool, taking into account the working conditions

and the work to be performed. Use of the power

tool for operations different from intended could result

in a hazardous situation.

BATTERY TOOL USE AND CARE

Ensure the switch is in the off positi on before

inserting battery pack. Inserting the battery pack

into power tools that have the switch on invites accidents

Recharge only with the charger specified by the

m

anufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used

with another battery pack.

Use power tools only with specifically designated

batter y packs. Use of any other ba ttery packs may

create a risk of injury and fire.

Page 2

e the risk of starting the power tool

the

nded f

or the particular type of power

way

ool will

power tools

.

Page 4

RULES FOR SAFE OPERATION

When battery pack is not in use, keep it away from

other metal objects like paper clips, coins, keys,

nails, screws or other small metal objects that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause burns

or a fire.

Under abusive conditions, liquid may be ejected

from the battery, avoid contact. If contact accidentally

occurs, flush with water. If liquid contact eyes,

a

dditionally seek medical help. Liquid ejected from

the battery may caused irritation or burns.

SERVICE

Have your power tool serviced by an authorised

service centre using only identica l replacement

parts. This will ensure that the safety of the power

tool is maintained.

OPERATION

CONTENTS OF BOX

14.4V/18.0V cordless hammer drill, 2 double-ended

bits, 2 battery packs, charger, auxiliary handle.

OPERATING INSTRUCTIONS

CHARGING THE BATTERY PACK (fig. 1)

The battery packs for this tool have been shipped in a

low charge condition to pr event possible problems.

You should, therefore, charge them prior to use.

Note: Batteries will not reach full charge the first time

they are charged. A

by recharging) for the item to fully charge. The battery

charger should only be used indoors.

Make sure power supply is normal house voltage,

240VoHs, 50Hg, AC only.

Place the battery pack into the charger as indicated.

Align raised rib on battery pack with groove in charger.

Press down on battery pack to make sure contacts

on battery pack engage properly with conta

When properly connected, the red light on charger will

turn on.

After normal usage, 1 hour of charging time is required

for the battery to be fully charged.

Note: Normally the red light on the charger will come

on, this indicates charge mode. If the green and yellow

lights come on, remove the battery pack, wait 1 minute

and reinsert battery pack in charger. If the green and

w lights continue to remain on an additional 15

yello

minutes,

the battery pack is damaged and will not accept

charge. A maximum charge time of 1-1 1/2 hours is

required to recharge a completely discharged battery.

The battery pack will become slightly warm to the touch

while charging. This is normal and does not indicate a problem.

Dot not place the charger in an area of extreme heat

or cold. It will work

When the batteries become fully charged, the green

l

ight on charger will turn on. Unplug the charger from

power supply and remove the battery pack.

several cycles (drilling followed

llow

cts in charger.

best at normal room temperature.

MAINTENANCE

Your power to

maintenace. There are no user serviceable parts in

our power tool.

y

Never use water or chemical cleaners to clean your

power tool. Wipe clean with a dry cloth.

Always store your power tool in a dry place.

Keep the motor ventilation slots clean.

If you see some sparks flashing in the ventilation slots,

this is normal and will not damage your power tool.

WORKING H

If your power tool becomes too hot, set the speed to

maximum and run no load for 2-3 minutes to cool the

motor.

Always use a magnetic bit holder when using short

screwdriver bits.

Where possible use a pilot hole before drilling a large

diameter hole.

LED FUNCTION OF CHARGER

Red Fast charging mode

Green and yellow Control charge or defective

Green Fully charged

TO INSTALL BATTERY PACK (fig. 2)

Lock the switch trigger by placing the direction of rotation

selector in the central position.

To install, insert battery pack neck into drill's battery

port, making sure the latches on each side snap into

place and battery pack is secure before beginning

operation.

To remove, locate latches on side of battery pack and

depress both sides to release battery pack from d

L

CD BATTERY CAPACITY INDICATOR

The display is for guidance only. Deviations are possible

for extreme applications. It will be turned on when the

button is pressed, and will be turned off when the button

is released.

Note : Indicator is for reference only and can vary

according to ambience and application. For the LCD

display, it so be read when you push the LCD button

and the drill is on; if

reflect actual battery capacity when you push the LCD

button.

SWITCH (fig. 3)

The drill is starte d and stopped by depr essing and

releasing the switch trigger.

Release the switch trigger to turn the drill OFF.

SWITCH LOCK

The switch trigger can be locked in the OFF position.

This helps to reduce the possibility of accidental starting

when not in use. To lock the sw

direction of rotation selector in the centre position.

Page 3

ol requires no additional lubrication or

INTS FOR Y

OUR DRILL

t

he drill is off, the display does not

itch t

rill.

rigger, place the

Page 5

OPERATION

DIRECTION OF ROTATION

The direction of rotation is controlled by the direction

of rotation selector located above the switch trigger.

With t he dr ill held in n ormal op erati ng posit ion, the

direction of rotation selector should be positioned to

the left for forward direction.

Direction is reversed when the selector is to the right of

the switch. when the selector is in the centre position,

the switch

RIABLE SPEED

VA

This tool has a variable speed switch that delivers

higher speed and torque with increased trigger pressure.

Speed is controlled by the amount of switch trigger

depression.

TWO-SPEED GEAR SELECTOR (fig. 4)

The drill has a two-speed gear train designed for drilling

or driving at LO (1) or HI (2) speeds. A slide switch is

located on top of the drill to select either LO (

(2) speed. When using the drill in the LO (1) speed

range, the speed will decrease and the drill will have

greater power and torque. When using the drill in the

HI (2) speed range, the speed will increase and the

drill will have less power and torque.

INSTALLING AND REMOVING BITS (fig. 5)

Lock the switch trigger by placing the direction of rotation

selector in the central position.

This will

Rotate the chuck sleeve to open or close the chuck

jaws to a point where the opening is slightly larger

than the bit size intended for use. Insert the drill bit

nto the chuck to the full length of the jaws. Tighten the

i

chuck jaws on the drill bit by grasping the drill with one

hand, while rotating the chuck sleeve with the other

hand. To loosen the bit, g

one hand, while rotating the chuck sleeve with the

other hand.

TORQUE ADUSTMENT (fig. 6)

The torque is adjusted by rotating the torque adjustment

ring. The torque is greater when the torque adjustment

ring is set on a higher setting. The torque is less when

the torque adjustment ring is set on a lower setting.

Screwdriving/drilling

Gear level 1 (LO) suits for small

G

The torque is set by means of an adjustment ring.

The contact presusure on the screw has no influence

on the torque. Screwdriving can be carried out from

settings 1-23.

Impact drilling

Turn torque setting to the 'impact drilling' symbol.

DRILLING

When drilling hard smooth surfaces, use a centre punch

to mark the desired hole location.

drill bit from slipping off centre as the hole is started.

Hold the tool firmly and place the tip of the bit at the

point to be drilled. Depress the switch trigger to start

the tool. Move the drill bit into the workpiece, applying

only enough pressure to keep the bit cutting. Do not

force or apply side pressure to elongate a hole.

trigger is locked.

1) o

lock the switch trigger in the OFF position.

rasp and hold the drill with

screws/drilling

ear level 2 (HI) suits for large screws/drilling

This will prevent the

WOOD DRILLING

For maximum performance, use high s

for wood drilling.

Turn the torque adjustment ring on the drill to desired

torque setting.

Begin drilling at a very low speed to prevent the bit

from slipping off the starting point.

Increase the speed as the drill bit bites into the material.

When drilling through holes, place a block of wood

behind the workpiece to prevent ragged or splintered

edges on the back side of the hole.

ETA

L DRILLING

M

For maximum performance, use high speed steel bits

for metal or steel drilling.

Turn the torque adjustment ring on the drill to desired

torque setting.

Begin drilling at a very low speed to prevent the bit

r HI

from slipping off the starting point.

Maintain a speed and pressure which allows cutting

without overheating the bit.

Applying too much pressure will:

• Overheat the drill

• Wear the bear

• Bend or burn bits

• Produce off-center or irregular shaped holes

When drilling large holes in metal, it is recommended

that you drill with a small bit at first, then finish with a

larger bit. Also, lubricate the bit with oil to improve

drilling action and increase bit life.

MASONRY DRILLING

For maximum performance use carbide-tipped masonry

impact bits when drilling holes in brick, tile, concret

e

tc.

Turn the mode selector on the drill to hammer mode.

Rotate the torque selector to drill position.

Apply light pressure and medium speed for best results

in brick.

Apply additiona l pressure and high speed for hard

materials such as concrete.

When drilling holes in tile, practice on a scrap piece to

determine the best speed and pressure.

DISPOSAL OF AN EXHAUSTED BATTERY

To preserve natural resourc

of the battery properly.

This product contains nickel-cadmium batteries. Consult

your local waste authority for information regarding

available recycling and/or disposal options.

PERPARING BATTERY PACK FOR RECYCLING

After removing, cover the battery pack’s terminal with

heavy-duty adhesive tape.

Do not attempt to destroy or take the battery pack

apart or remove any of its

both terminals with metal objects or body parts or a

short circuit may result. Keep away from children. Failure

to comply with these warnings could result in fire and/or

serious injury.

ings

es,

please recycle or dispose

c

omponents. Do not touch

peed steel bits

e,

Page 4

Page 6

SPECIFICATIONS

Drill voltage

Switch

Chuck

No load speed:

Drill mode

Impact mode

Power supply

Torque

No. of Power Pack

Weight

Charger input

Charging time

Battery pack

Charger

14.4V

variable, forward & reverse

13mm keyless (steel max. Ø10mm)

0-350 / 0-1300 /min

0-4550 / 0-16900 bpm

12 x 1.2V Ni-Cd 1500mAh

32Nm

2pcs

2.1 kg (with battery)

AC 240V 50Hz

1 hour (approx.)

130262022

2601050

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use o f an y other part may create a hazard or cau se

product damage.

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged by

their use. Use clean cloths to remove dirt, dust, oil,

grease, etc.

18.0 V

variable, forward & reverse

13mm keyless (steel max. Ø10mm)

0-400 / 0-1400 /min

0-5200 / 0-18200 bpm

15 x 1.2V Ni-Cd 1500mAh

35Nm

2pcs

2.4 kg (with battery)

AC 240V 50Hz

1 hour (approx.)

130262021

2601038

WARNING:

Do not attempt to modify this tool or create accessories

not rec ommen ded for us e wi th t his to ol. Any such

alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

p

ersonal injury.

.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-

ased products, penetrating oils, etc. come in contact

b

w

ith plastic parts. They contain chemicals that can

damage, weaken or destroy plastic.

Do not abuse power tools. Abusive practices can damage

tool as well as workpiece.

Page 5

Page 7

RYOBI HELPLINE

has no

wear and tear.

The Company accepts no additional liability pursuant to

this g u a r a n t e e f o r th e c o s t s o f trav e l l i n g o r

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included

his guarantee.

t

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller in

certain circumstances. Nothing herein shall have the effect

of excluding, restricting or modifying any condition,

guarantee, right or liability imposed, to the extent only

th a t s u c h e x clu s i on, res t r ict i on o r modification

w

ould render any term herein void.

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Tel: (02) 9792 9800 - Fax: 1800 807 993 - www.ryobi.com.au

Tel : (03) 9764 8656

A.B.N. 98 002 277 509

Contact during normal business hours.

HOBART: All enquiries Tel : 1300 361 505

ADELAIDE: All enquiries Tel : 1300 361 505

PERTH: 33-35 Sorbonne Cres. Canning Vale, W.A. 6155

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Loading...

Loading...