Page 1

N197

AP13AK

PLANER THICKNESSER WITH ANTI KICKBACK

OWNER’S OPERATION MANUAL

Page 2

TABLE OF CONTENTS

Table of Contents

Specicatons

Rules for Safe Operation

Loose Parts List

Operation

Adjustment

Maintenance

Troubleshooting

Input

No Load Speed

Min Planing Length

1

1

2-4

4

5

6-9

10

11

PRODUCT SPECIFICATIONS

2000 watt

9000 R.P.M.

127 mm

Max Planing Width

Planing Height

Depth Per Pass

Feeding Speed

Binder

48mm with 2 blades,

9000 R.P.M. ie 18000 C.P.M.

Weight

Look for this symbol to point out important safety precautions. It means attention!!!

Your safety is involved.

Page 1

318 mm

5 - 153 mm

3 mm

8m / min

32 - 30.5 kg

Page 3

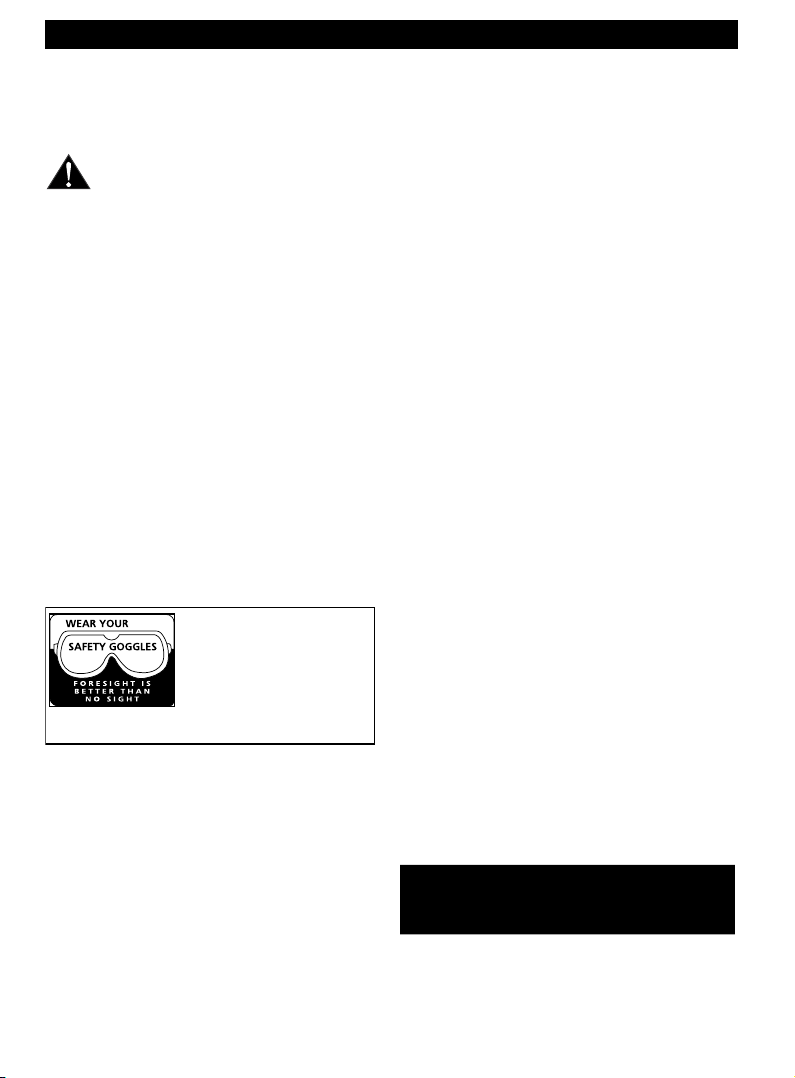

RULES FOR SAFE OPERATION

The purpose of safety rules is to attract your attention to

possible dangers. The safety symbols and the explanations with

them, require your careful attention and understanding.

The safety warnings by themselves do not elimimate any danger.

The instruction or warnings they give are not substitutes for

proper accident prevention measures.

DOUBLE INSULATION

Double insulat ion is a conce pt in s afety i n elect ric pow er tool s,

which eliminates the need for earth groun ding. Whenever

there is elec tric cu rrent in the t ool there are two complete sets

of insulation to pr otect the user. All exposed metal parts are

isola ted from the

in ternal me tal motor components with

protecting insulation.

WARNING: The double insulated system is intended to protect

the user from shock resulting from a break in the tool's internal

wiring. Observe all normal safety precautions related to avoiding

electrical shock.

IMPORTANT:

Servicing of a tool with double insulation requires

extreme care and knowledge of the system and should be

performed only by a qualified service technician. For service we

suggest you return the tool to your nearest Ryobi Authorised

Service Centre for repair. When servicing, use only identical

Ryobi replacement parts.

WARNING:

Do not attempt to operate this tool until you have

read thoroughly and

completely understood the safety rules, etc.

contained in this manual. Failure to comply can result in accidents

involving fi re, elec tric shock or seri ous pers onal injury. Sa ve

owners manual and review frequently for continual safe operation

and for instructing others who may use this tool.

The operation of any tool can result

in foreign objects being thrown int

o

your eyes, which can result in severe

eye damage. Before beginning power

tool opera tion, alwa ys w ear safety

goggles or safety glasses wi th side

shields and a fu ll fac e shi eld wh en

needed. We

recommend Wide Vision Safety Mask for use over

eye glasses or standard safety glasses with side

shields.

1. KNOW YOUR POWER TOOL. Read owners manual carefully.

Learn its applications and limitations as well as the specific

potential hazards related to this tool.

2.

GUARD AGAINST ELECTR ICAL SHOCK BY PREVENTING

BODY CONTACT WITH GR OUNDED SURF ACES.

For example, pipes, radiators, ranges, refrigerator enclosures.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

4

.

AVOID DANGEROUS ENVIRONMENT. Don't use power

tools in damp or wet locations or expose to rain. Keep work

area well lit.

5. K

EEP CHILDREN AND

VISITORS AWAY.

Visitors should wear

safety glasses and be kept a safe distance from work area.

Do not let visitors contact tool or extension cord.

6. STORE IDLE TOOLS.

When not in use, tool s should be stored

in a dr y and high or l ocked-up pl ace, out of

reach of children.

7. DON'T FORCE TOOL.

It will do the job bett er and safer at the

rate at

which it was designed.

8. USE RIGHT TOOL.

Don't force a sma ll too l or attachment to

do the job of a heavy duty tool. Don't use tool for any purpose

not intended.

9. DRESS PROPERLY.

Do not wear loose clothing or jewellery.

They can be caught in moving parts. Rubber gloves and

non-skid fo otwear are r ecommended when working outdoors.

Also wear protective hair covering to contain long hair.

10. ALWAYS WEAR SAFETY GLASSES.

Everyday eyeglasses

have only impact resistant lenses, they are not safety glasses.

11.

PROTECT YOUR LUNGS.

Wear a dust mask if operation is dusty.

12. PROTECT YOUR HEARING.

Wear hearing protection during

extended periods of operation.

13. DON'T OVERREACH.

Keep proper footing and balance at all

times. Do not use tool on a ladder or unstable support.

Secure tools

when working at elevated levels.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean

for better and safer pe rformance. F ollow instru ctions for

lubricating

and changing accessories.

15. DISCONNECT TOOLS.

When not in use, before servicing, or

when changing attachments, blades, bits, cutters, etc. all

tools

should be disconnected.

16. REMOVE ADJUSTIN G KEYS AND WR ENCHES. Before

turning it on, Form a habit of checking to see that keys and

adjusting wrenches are removed from tool.

17.

NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal

sparking of the motor could ignite fumes.

18. KEEP HANDLES DRY, CLEAN AND FREE FROM OIL AND

GREASE.

Always use a clean cloth when cleaning. Never use

brake fluids, gasoline, petroleum

based products, or any

strong solvents to

clean your tool.

19. STAY ALERT AND EXERCISE CONTROL. Watch wha t you

are doing and use common sense. Do not operate tool when

you are tired. Do not rush.

20. CHECK DAMAGED PARTS.Before further use of the tool,

a

guard or any other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function.

Check for alignment of moving parts,

binding of moving parts, breakage of parts and any other

conditions that may affect its operation.

A guard or any other

part that is damaged should be properly repaired or replaced

by an authorised service centre.

21. DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON

AND OFF

.

Have defective switches replaced by authoris ed

service centre.

22. DO NOT OPERATE THIS TOOL WHIL E UNDER THE

INFLUENCE OF DRUGS, ALCOHOL OR ANY MEDICA

TION.

23. SU PPLY C ORD. If the supply cord is damaged, it must be

replaced by the manufacturer or its service agent or similarly

qualified person

in order to avoid a hazard.

Due to Ryobi's continued product refinement policy

,

product features and specifications can and will change

without notice. Check current features and specifications with your Ryobi retailer.

SAVE THESE INSTRUCTIONS

SAF ET Y A LER T S YMBOL . I nd ic at es cau ti on or

wa rn ing . M ay be used i n c on ju ncti on wi th

ot he r

symbols or pictures.

WARNING: Failure to obey a safety warning can

result in serious injury to yourself or to others. Always

follow the safety precautions to reduce the risk of fire,

electric shock and personal injury.

Page 2

Page 4

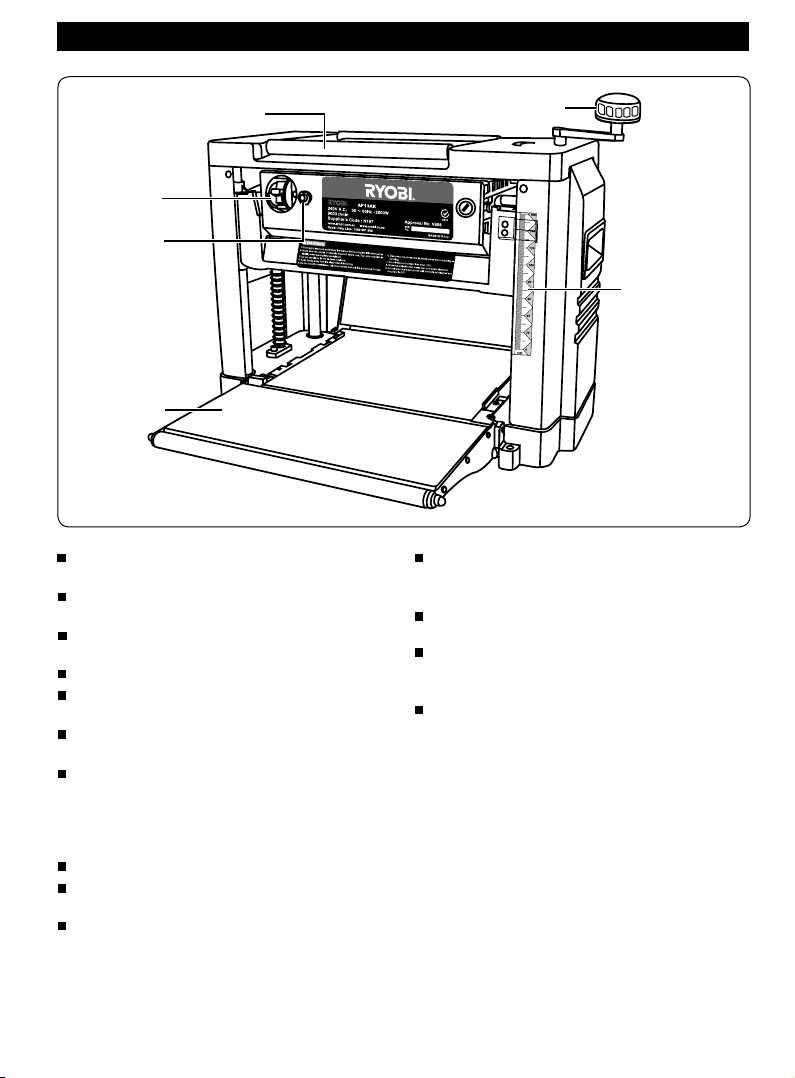

RULES FOR SAFE OPERATION

Stock Rollers

Power

Switch

Overload

Switch

Table

Extention

Always wear eye protection when operating the

machine.

Check to make sure all holding screws are tight

before starting machine.

Always stop the motor and disconnect from power

source before making any adjustments.

Be sure all guards are in place before operation.

Read owner’s manual thoroughly and familiarise

yourself with the machine before operation.

Do not force work through the machine. Allow the

planer to apply the proper feed rate.

Check feed rollers occasionally to be sure

sawdust and chips are not lodged between any

components. If rollers are not seated rmly, the

feed rolls will not hold timber rmly against the

bed, allowing kickback.

Only plane wood boards.

Use sound timber, with no loose knots and as few

tight knots as possible.

Never stand directly in line with either the infeed

or outfeed sides. Always stand off to one side of

the machine.

Hand Crank

Depth Scale

Make sure the workpiece is free of from nails,

screws stones and other foreign objects which

could damage the blades.

Make sure the blades are attached correctly as

described in the instructions.

Use caution when handling the blades and

cutterhead assembly. The blades are sharp and

can easily cut your hand.

Allow the cutterhead to reach full speed before

using.

Page 3

Page 5

RULES FOR SAFE OPERATION

Anti-Kickback Pawls

Device which, when properly installed and maintained,

is designed to stop the workpiece from being kicked

back toward the front of the Blade during a Planer

operation.

Avoiding kickback

Always use the correct Blade depth setting.

Inspect the work for knots or nails before

beginning a cut. Knock out any loose knots with a

hammer, never cut into a loose knot or nail.

Always use clear, sharp, and properly-set blades.

Never make planer with dull blades.

To avoid pinching the Blade, support the work

properly before beginning a planer operation.

When making a planer operation, use steady,

even pressure, never force to plane.

Do not plane wet or warped timber.

LOOSE PARTS LIST

1

2

3

4

Always hold your workpiece rmly with both

hands, keep your body in a balanced position to

be ready to resist kickback. Never stand directly

in line with timber.

5

6

9

7

8

10

• Properly assembled

blade setting guage.

1) “C” Circlip ......................................................................................................................................... 4 pieces

2) Blade Setting Guide ..........................................................................................................................2 pieces

3) Blade Setting Guage Shaft .................................................................................................................1 piece

4) Base Lock Screw ......................8mm x 50(L)................................................................................... 4 pieces

5) Elevation Knob Lock Screw ......6mm x 15(L)..................................................................................... 1 piece

6) Cutterhead Raising Hand Crank ........................................................................................................1 piece

7) Allen Wrenches ............................................................................................................................... 4 & 5mm

8) Open End Wrench ..........................8 x 10..........................................................................................1 piece

9) Dust Chute..........................................................................................................................................1 piece

10) Philip Screws...................................................................................................................................4 pieces

Page 4

Page 6

OPERATION

MOVING THE PLANER (Fig. 1)

The planer can be carried using the handles on either

side of the frame. Make sure the table extensions are

closed before moving the planer.

Fig. 1

MOUNTING THE PLANER ONTO THE WOOD

BASE (Fig. 2a&2b)

When the planer is not mounted on a planer stand,

it is suggested that it be mounted onto two pieces of

timber. This will ensure maximum stability.

Choose two pieces of wood according to the sizes

shown on the gure below . Mount the planer onto

the wood surface.

Use four long, furnished screws to mount the planer

base onto the wood (Fig. 2a)

2-Ø9

Ø9

50.8

ON / OFF SWITCH (Fig. 4)

Your Planer Thicknesser has a rocker style

switch with a removable locking key to prevent

unauthorised use. If you intend to be away from

the machine for a long period of time and there

is any chance of it’s use by others, especially

children, remove the locking key with the switch in

the OFF position. Store the locking key in a safe,

inconspicuous place in your workshop. To turn

the planer on, insert the locking key and turn the

switch to the ON position. The planer will then be

operable. To turn the planer off, turn the switch to

the OFF position. (Fig. 4)

WARNING:

Always be sure the switch is in the off position

50.8

before connecting the planer to the power source.

Fig. 3

Mounting

Hole

Planer Base

Hole

Ø15

15

m8 crew

Fig. 2a

Fig. 2b

STOCK ROLLERS (Fig. 3)

Two rollers are built on top of the planer, providing

convenient handling of stock for consecutive cutting

operations. Stock placed on the top of the machine

can be easily pulled to the operator for planing.

CIRCUIT OVERLOAD SWITCH

The machine is provided with an overload switch

for overload protection. If an overload occurs, the

switch will pop out. If this happens, wait several

minutes and press the switch to reset the machine.

(Fig. 4)

On/Off Switch

On/Off Switch

Locking Key

Page 5

Circuit Overload

Switch

Fig. 4

Page 7

ADJUSTMENT

ADJUST DEPTH OF CUT (Fig. 5)

WARNING:

Never plane more than 3mm in one pass and

never attempt to plane a board under 127mm

(5”) in length. Always wear a protective face

shield.

To adjust the depth of cut, turn the cutterheadraising hand crank in the direction marked on top

of the planer. The depth of cut adjustment can

be read from the depth scale. The adjustment

gradation is 2mm per revolution of the hand

crank.(Fig. 5)

Always start your work by making a light planing

cut. The depth of cut on subsequent passes may

be increased by up to 3mm, but remember that a

light cut creates a ner nish than a heavier cut.

The thickness of timber running through the planer

is controlled by the distance you adjust the cutting

blade from the table.

• Do not plane timber which is less than 5mm thick.

• Do not plane timber which is thicker than 153mm (6”).

Cutterhead Raising

Hand Crank

When you have properly adjusted the depth of

cut scale, test your reading by planing a piece of

scrap timber. After planing, measure the planed

thickness and double check it against the scale

reading. The two measurements should be the

same, re-adjust your depth of cut scale to read the

planed thickness if necessary.

Screws

Chip Deector

Safety Guard

Fig. 6

Depth

Scale

Plastic Pointer

Fig. 5

ADJ USTING THE D EPTH OF CUT SCALE

(Fi g 6&7)

For safe operation of your planer, it is very important

that the depth of cut scale is read accurately. To adjust

the depth of cut scale, follow the steps outlined below:

Try to feed a board for planing.

Compare the measured thickness of the board to

the reading on the depth of cut scale.

If the reading on the depth of cut scale is incorrect,

loosen the screw which tightens the plastic pointer

and adjust accordingly (Fig. 5)

Page 6

Screws

Fig. 7

Page 8

ADJUSTMENT

REMOVING THE PLANER BLADES (Fig. 7a)

To remove the planer blades, follow the steps outlined

below:

WARNING:

Unplug your planer from the power source before

removing the planer blades.

Remove the chip guard by removing the wing nut

on each side.

Loosen the lock bar (B) and blade by turning the

lock screws (A) clockwise. The blades are spring

loaded, and will push out when the assembly is

loosened. (Fig. 7a)

Take out the blade (C), and then the blade lock

bar (B).

Fig. 7a

INSTALLING THE PLANER BLADES (Fig. 7a)

SETTING THE BLADE HEIGHT (Fig. 8&8a)

To obtain a blade projection of 1.5mm, place the

blade setting gauge (E) on the cutterhead with both

guides resting rmly against the blade. (Fig. 8)

Loosen the assembly by turning the 7 screws (A)

clockwise with an open end wrench.

When the blade is pressed to the required height

by guides on the gauge, retighten the assembly by

turning the screws counter clockwise. Make sure

all seven lock screws are tightened securely.

WARNING:

The blade edge is very susceptible to chipping.

Use caution when handling the gauge near the

blades to avoid damaging them.

WARNING:

The assembly must be tightened securely to

prevent accidents during planing.

WARNING:

Unplug your planer from the power source before

removing the planer blades.

To install the planer blades, follow the steps outlined

below:

Remove the blades according to the instructions

for “ REMOVING THE PLANER BLADES”

Fit the blade lock bar (B) into the slot on the

cutterhead.

Fit the blade into the slot on the cutterhead, and

tighten the lockbar blade assembly by turning the

screws counter clockwise. Make sure the blade is

facing the correct direction.

Set the blade heights according to the instructions

as shown below. The blade height must be reset

every time the blades are taken out for any

reason.

Be sure to replace the chip guard after blades

are installed.

Fig. 8

Fig. 8a

Page 7

Page 9

ADJUSTMENT

34mm

135

°

33mm

100mm

3mm

15mm

70mm

100mm

120

°

30mm

20mm

33m

m

5mm

MAKING THE CUTTERHEAD AND WORKTABLE

PARALLEL (Fig. 9~12)

Plane a workpiece and measure thickness after the

cut. If the thickness is not the same on both sides of

the workpiece, perform the following action.

Adjust the cutter shaft and the worktable so they are

parallel. The tools used for checking are shown below

. Please use hardwood to make a tool guage block

according to the size shown in the gure 9. Make the

adjustments as per the following procedures.

Remove height adjustment handle and both top

and side covers by removing allen screws (Fig.11)

to expose height adjustment lock nuts. (Fig.12)

Loosen adjustment lock nut. (Fig.12)

Adjust height nut up or down as required to suit

guage block. (Fig.10)

When desired height setting is reached, tighten

lock nuts inposition. (Fig.12)

Reassemble side and top covers and replace

height adjustment handle.

Fig. 10

Height Adjustment

Crank Handle

Allen

Screws

Height

Adjustment Nut

Fig. 11

Fig. 12

Fig. 9

Page 8

Page 10

ADJUSTMENT

NOTE: Remove gauge block before starting machine.

Thickness planing is the sizing of the material to a

desired thickness, while creating a smooth surface

parallel to the opposite side of the board.

The art of thickness planing consists mainly of using

good judgement about the depth of cut in various

situations. You must take into account:

1) The width of the timber

2) The hardness of the board

3) The dampness of the board

4) The straightness of the board

5) The grain direction

6) The grain structure

How these factors can effect the quality of the work

can only be learned through experience. Whenever

working with a new type of wood, or one with unusual

problems, always make test cuts on scrap material

prior to working on the actual piece.

FOR ADDITIONAL PLANING

If additional planing is needed to obtain the desired

thickness or nish, hand crank the cutterhead no more

than 3mm (at any one time) and complete another

pass.

WARNING:

Never plane more than 3mm in one pass and

never attempt to plane a board under 127mm

(5” ) in length. Always wear a protective face

shield.

INSTALLING THE DUST CHUTE

Currently, the planer is assembled with a steel

cover , which is xed by 2 wing nuts (Fig. 13 & 13a)

Wing Nuts

Steel Cover

Fig. 13a

To install the dust chute , remove the steel cover

rst by unscrewing the 2 wing nuts.

Fix the dust chute with 4 philip screws (Fig 13b)

Dust Chute

Screws

Fig. 13b

Wing Nuts

Fig. 13

Page 9

Page 11

MAINTENANCE

LUBRICATION

The recommended lubrication for roller chains

used in medium to low operation is to simply wipe

the chain clean. When there is an excess build up

of dust or wood shavings etc., coat chain with a

light lm of oil but never pour the oil directly on the

chain. Over -oiling tends to hasten the collection

of dust and woodshavings and works them into

members of the chain leading to increased wear

and premature replacement. This applies to the

speed reduction and height adjustment chains as

well as the elevation screws.

The bearings on the cutterhead are factory lubricated

and sealed. They require no further attention.

PERIODIC MAINTENANCE

Build-up of sawdust and other debris can cause

your machine to plane inaccurately. Periodic

cleaning is mandatory for precision planing and

highly recommended.

Close tting parts, such as the lockbars and the

planer cutterhead slots, should be cleaned with

a brush; removing clinging foreign matter. Then

replace all parts in their respective positions

slightly dampened with oil.

Remove resin and other accumulations from feed

rollers and table with a non-amable solvent.

Page 10

Page 12

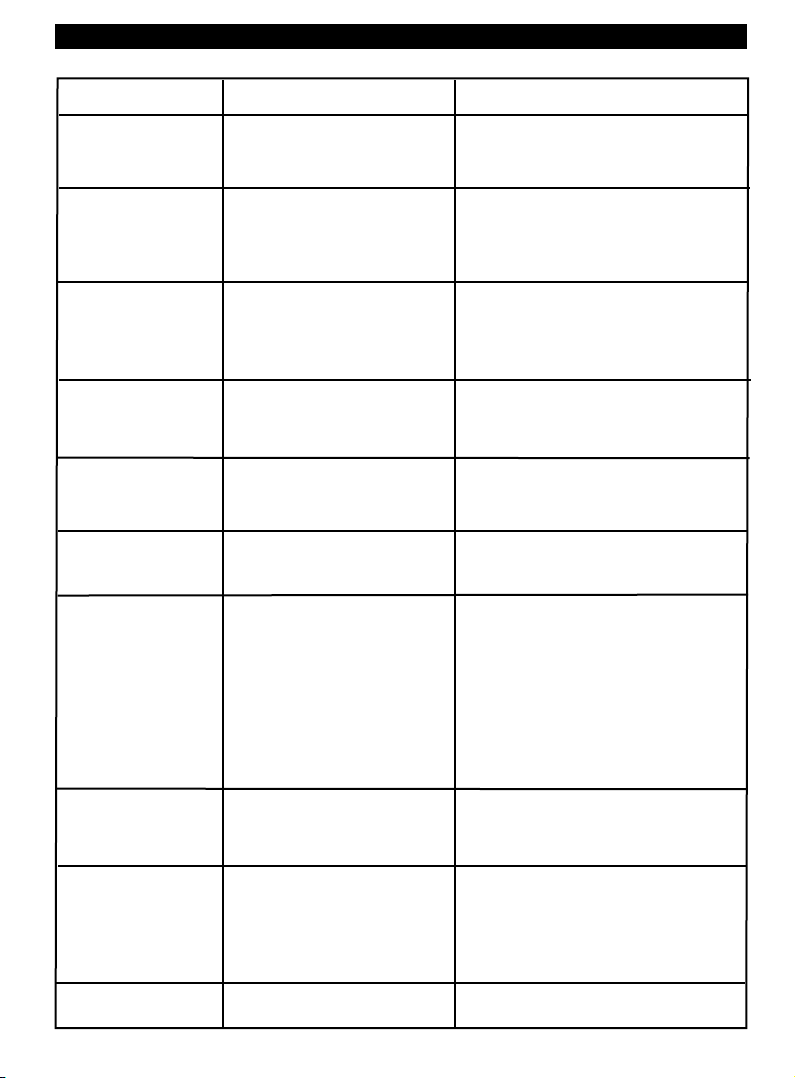

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

FUZZY GRAIN 1. Planing wood with high moisture

content.

2. Dull Blades.

TORN GRAIN 1. Too heavy a cut.

2. Blades cutting against the grain.

3. Dull Blades.

RO U G H / R AI S E D

GRAIN

UNEVEN DEPTH OF

CUT SIDE TO SIDE

BO ARD T HIC K NES S

D O E S N ' T M AT C H

DEPTH OF CUT SCALE

CH AIN JUM P ING

MACHINE WON'T

START / RESTART

1. Dull Blades.

2. Tool heavy a cut.

3. Moisture content too high

4. Cutterhead bearings damages.

1. Blade projection not uniform.

2. Cutterhead not levelled to planer

bed.

1. Depth of cut scale incorrect.

1. Sprockets misaligned.

2. Sprockets worn.

1. Not plugged in.

2. Circuit breaker / fuse.

3. Motor failure.

4. Loose wire.

5. Overload reset has not reset.

6. Motor starter failure.

1. Dry the wood

2. Sharpen Blades.

1. Review proper depth of cut

2. Feed wood with the grain, or turn

workpiece around.

3. Sharpen Blades.

1. Sharpen Blades.

2. Review proper depth of cut

3. Dry the wood.

4. Replace bearings.

1. Adjust Blade projection.

2. Level cutterhead to table.

1. Adjust depth of cut scale.

1. Align sprockets.

2. Replace sprockets.

1. Check power source.

2. Check power source.

3. Have motor checked.

4. Have motor checked by authorised

Ryobi service agent.

5. Allow machine to cool down and restart.

6. Have motor starter checked by authorised

Ryobi service agent.

REPEATED CIRCUIT

TRIPPING RESULTING

IN MOTOR STOPPAGE

POOR F E E D I N G O F

TIMBER

WORKPIECE JAMMED

1. Extension cord too long or too thin.

2. Blades too dull.

3. Low voltage running.

1. Planer table dirty.

2. Feed roller damaged

3. Sprocket damaged.

4. Gear box malfunction.

1. Inadequate Blade setting height. 1. Set the Blade to the correct height.

Page 11

1. Use a shorter or thicker extension cord.

2. Sharpen or replace Blades.

3. Check voltage.

1. Clean off pitch and residue, and lubricate

planer table.

2. Replace.

3. Replace.

4. Check gear box.

Page 13

NOTE

Page 12

Page 14

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

GUARANTEE

Subject to the guarantee condition below, this Ryobi tool

(hereinafter called “the product”) is guaranteed by Ryobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of original purchase covering

bot h parts and labour. Under the terms of this

guarantee, the replacement shall be the opinion of

the Company or its authorised agent. Should service

bec om e necessar y during the warra nty period,

the owner should contact the RYOBI HELPLINE

1300 361505, or the Ryobi retailer from where the

product was purchased.In order to obtain guarantee

service, the owner must present the sales docket and

Guarantee Certicate to conrm date of purchase. This

product is sold by the dealer or agent as principal and

the dealer has no authority from the Company to give

any additional guarantee on the Company’s behalf

except as herein contained or herein referred to.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in th e opinio n of the Company) and such

guarantee does not cover damage, malfunction or

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Contact during normal business hours.

Tel: (02) 9792 9800 - Fax: 1800 807 993 - www.ryobi.com.au

BRISBANE: All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquiries Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville,Vic. 3178

Tel : (03) 9764 8656

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - www.ryobi.co.nz

Contact during normal business hours.

failure resulting from misuse, neglect, abuse, or

used for a purpose for which it was not designed

or is not suited and no rep ai rs , al te ra ti ons or

modi ca ti ons h av e been attempted by other than

an Authorised Service Agent. This guarantee will not

apply if the tool is damaged by accident or if repairs

arise from normal wear and tear.

The Company accepts no additional liability pursuant to

th i s g uar a nte e fo r t h e c o st s of tra vel l ing or

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included

in this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller

in certain circumstances. Nothing herein shall have the

effect of excluding, restricting or modifying any

condition, guarantee, right or liability imposed, to the

exten t only that such exclusi on , re st riction or

modication would render any term herein void.

HOBART: All enquiries Tel : 1300 361 505

ADELAIDE: All enquiries Tel : 1300 361 505

PERTH:

33-35 Sorbonne Cres., Canning Vale,W.A. 6155.

Tel : (08) 9455 7775

This Guarantee Form Should Be Retained By The Customer At All Times

For your record and to assist in establishing date of purchase (necessary for in-guarantee service)

pleas e ke ep your p ur chase d oc ke t and thi s form comp le te d with th e followi ng p articular s.

Purchased From

Address Of Dealer

Date Model No Serial No

Present This Form With Your Purchase Docket When Guarantee Service Is Required.

Loading...

Loading...