Page 1

Inch

1

0

1

2

3

Inch

1

0

1

2

3

inch

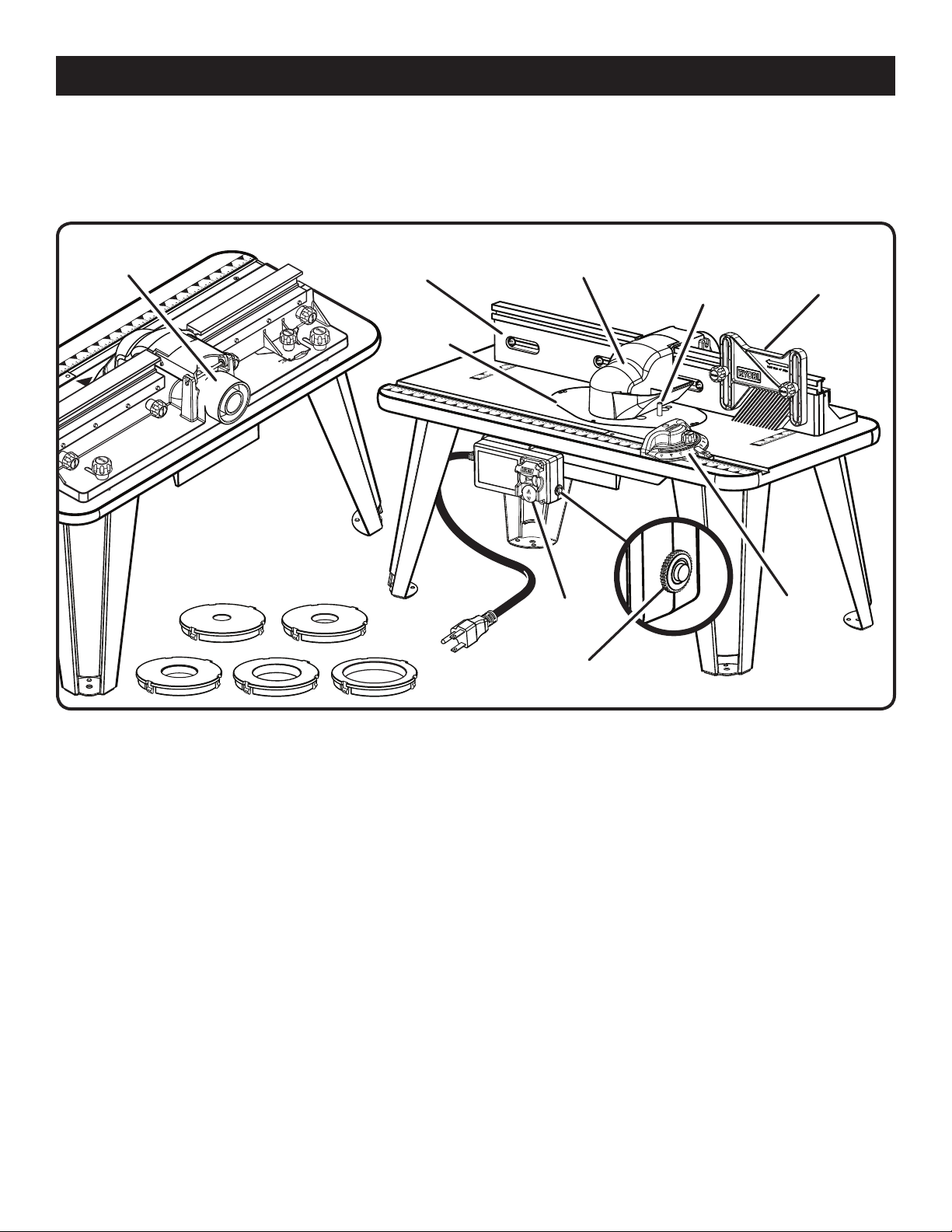

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

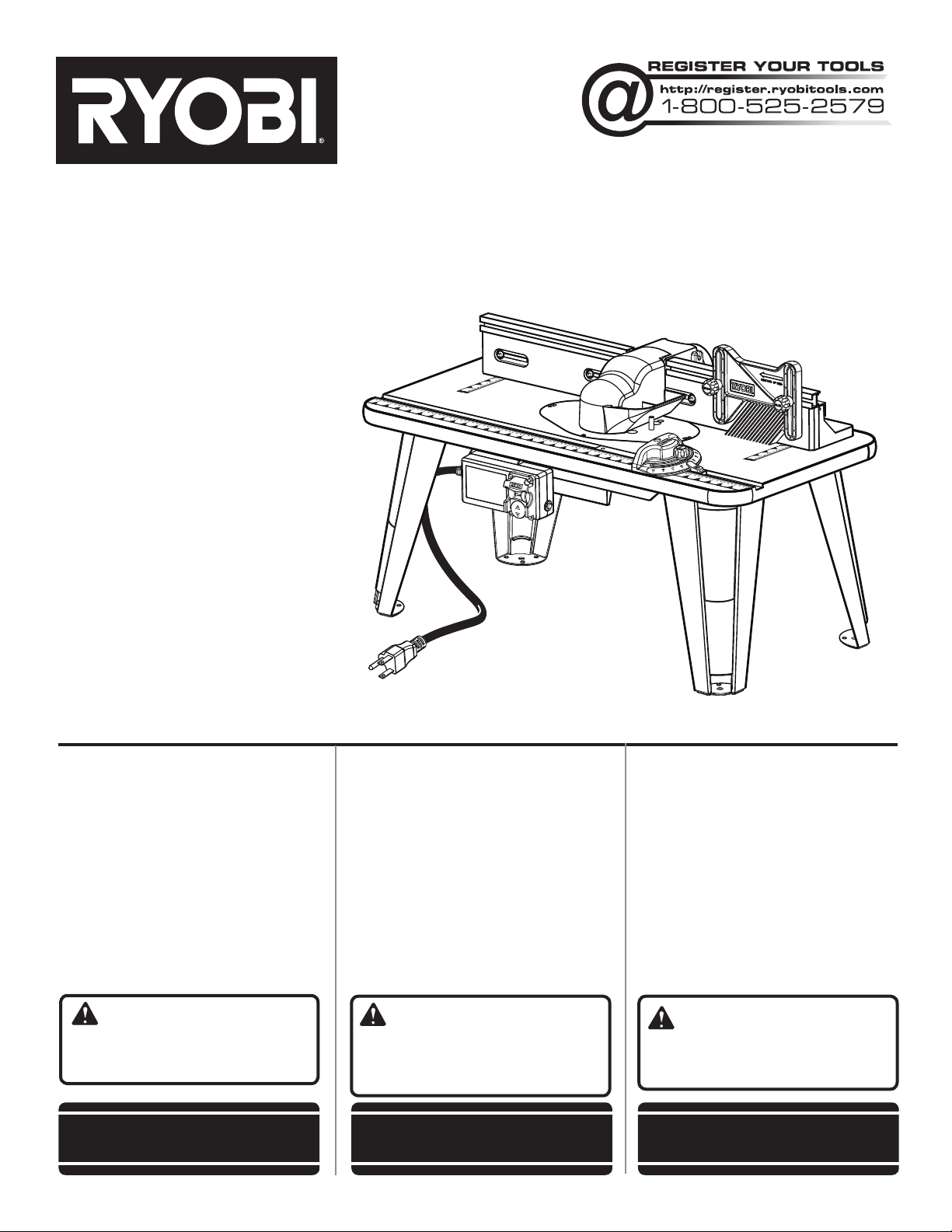

ROUTER TABLE

TABLE À TOUPIE

MESA FRESADORA

A25RT02/A25RT02G

TABLE OF CONTENTS

General Safety Rules .......................2-3

Specific Safety Rules .........................3

Symbols ..............................................4

Electrical ............................................. 5

Features ...........................................6-7

Assembly .......................................8-15

Operation .....................................16-18

Maintenance ..................................... 19

Parts Ordering

and Service .........................Back page

3

2

1

0

1

Inch

TABLE DES MATIÈRES

Règles de sécurité générales ..........2-3

Règles de sécurité particulières .........3

Symboles ............................................4

Caractéristiques électriques ............... 5

Caractéristiques ..............................6-7

Assemblage ...................................8-15

Utilisation .....................................16-18

Entretien ...........................................19

Commande de pièces

et dépannage ....................Page arrière

3

inch

2

1

0

1

Inch

ÍNDICE DE CONTENIDO

Reglas de seguridad generales .......2-3

Reglas de seguridad específicas .......3

Símbolos ............................................4

Aspectos eléctricos ............................ 5

Características ................................6-7

Armado ..........................................8-15

Funcionamiento ...........................16-18

Mantenimiento ..................................19

Pedidos de piezas

y servicio ....................... Pág. posterior

WARNING: To reduce the

risk of injury, the user must read and

understand the operator’s manual

before using this product.

SAVE THIS MANUAL FOR

FUTURE REFERENCE

AVERTISSEMENT :

Pour

réduire les risques de blessures,

l’utilisateur doit lire et veiller à bien

comprendre le manuel d’utilisation avant

d’employer ce produit.

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

ADVERTENCIA: Para reducir

el riesgo de lesiones, el usuario debe leer

y comprender el manual del operador

antes de usar este producto.

GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

Page 2

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

READ ALL INSTRUCTIONS

KNOW YOUR POWER TOOL. Carefully read the router

table operator’s manual and the manual for the particular

router you are using. Learn the applications and limitations as well as the specific potential hazards related to

this tool.

GUARD AGAINST ELECTRICAL SHOCK BY PREVENT-

ING BODY CONTACT WITH GROUNDED SURFACES.

For example: pipes, radiators, ranges, refrigerator enclosures.

KEEP GUARDS IN PLACE and in good working order.

REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents. DO NOT leave tools or pieces of wood

on the tool while it is in operation.

DO NOT USE IN DANGEROUS ENVIRONMENTS. Do

not use power tools in damp or wet locations or expose

to rain. Keep the work area well lit.

KEEP CHILDREN AND VISITORS AWAY. All

visitors should wear safety glasses and be kept a safe

distance from work area. Do not let visitors contact

tool or extension cord while operating.

MAKE WORKSHOP CHILDPROOF with padlocks,

master switches, or by removing starter keys.

DON’T FORCE THE TOOL. It will do the job better and

safer at the feed rate for which it was designed.

USE THE RIGHT TOOL. Do not force the tool or attach-

ment to do a job for which it was not designed.

USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. Use only a cord heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. A wire gauge size

(A.W.G.) of at least 14 is recommended for an extension

cord 25 feet or less in length. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier

the cord.

DRESS PROPERLY. Do not wear loose clothing,

neckties, or jewelry that can get caught and draw you into

moving parts. Rubber gloves and nonskid footwear are

recommended when working outdoors. Also wear protective hair covering to contain long hair.

ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses, they are NOT safety glasses.

SECURE WORK. Use clamps or a vise to hold work

when practical, it is safer than using your hand and frees

both hands to operate the tool.

DO NOT OVERREACH. Keep proper footing and

balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance. Follow

instructions for lubricating and changing accessories.

DISCONNECT TOOLS. When not in use, before servicing,

or when changing attachments, blades, bits, cutters, etc.,

all tools should be disconnected from power source.

AVOID ACCIDENTAL STARTING. Be sure switch is off

when plugging in any tool.

USE RECOMMENDED ACCESSORIES. Consult the

operator’s manual for recommended accessories. The

use of improper accessories may result in injury.

NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped.

CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect

its operation. A guard or other part that is damaged must

be properly repaired or replaced by an authorized service

center to avoid risk of personal injury.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

THE POWER OFF. Don’t leave tool until it comes to a

complete stop.

USE THE RIGHT DIRECTION OF FEED. Feed work into

a blade or cutter against the direction of rotation of blade

or cutter only.

PROTECT YOUR LUNGS. Wear a face or dust mask if

the operation is dusty.

PROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

DO NOT ABUSE CORD. Never carry tool by the cord or

yank it to disconnect from receptacle. Keep cord from

heat, oil, and sharp edges.

ALWAYS USE AN OUTDOOR EXTENSION CORD

MARKED “W-A” OR “W”. These cords are rated for

outdoor use and reduce the risk of electric shock.

NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor could ignite fumes.

2

Page 3

GENERAL SAFETY RULES

INSPECT TOOL CORDS PERIODICALLY. If

damaged, have repaired by a qualified service technician at

an authorized service facility. The conductor with insulation

having an outer surface that is green with or without yellow

stripes is the equipment-grounding conductor. If repair

or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to a

live terminal. Repair or replace a damaged or worn cord

immediately. Stay constantly aware of cord location and

keep it well away from the rotating blade.

INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum-based products, or

any solvents to clean tool.

SPECIFIC SAFETY RULES

FOR YOUR OWN SAFETY, read this router table opera-

tor’s manual and the router manual before operating the

router or using the router table.

ALWAYS USE THE ARTICULATING ROUTER CUTTER

BIT GUARD.

WHEN USING THE ROUTER ON THE ROUTER TABLE,

the router must be plugged into the router table switch

outlet.

KEEP HANDS AWAY FROM CUTTING AREA. Do not

reach underneath the table or in the cutting path with your

hands or fingers at any time while the tool is connected

to a power source.

DO NOT USE AWKWARD HAND POSITIONS.

FIRMLY CLAMP OR BOLT THE ROUTER TABLE TO

A WORK SURFACE so that the router table surface is

approximately hip height.

STAY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate

tool when you are tired. Do not rush.

DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defective switches replaced by an

authorized service center.

DO NOT OPERATE A TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY

MEDICATION.

WHEN SERVICING use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

USE ONLY RECOMMENDED ACCESSORIES listed

in this manual or addendums. Use of accessories that

are not listed may cause the risk of personal injury.

Instructions for safe use of accessories are included

with the accessory.

ALWAYS FEED WORKPIECE AGAINST ROTATION OF

CUTTER.

INSPECT FOR AND REMOVE ALL NAILS FROM LUM-

BER BEFORE ROUTING. Following this rule will reduce

the risk of serious personal injury.

KEEP FINGERS AWAY FROM REVOLVING CUTTER,

USE FIXTURES WHEN NECESSARY.

ALWAYS SUPPORT WORKPIECE FIRMLY AGAINST

TABLE AND FENCE.

IF THE POWER SUPPLY CORD IS DAMAGED, it must

be replaced only by the manufacturer or by an authorized

service center to avoid risk.

SAVE THESE INSTRUCTIONS. Refer to them frequently

and use them to instruct others who may use this tool. If

you loan someone this tool, loan them these instructions

also.

3

Page 4

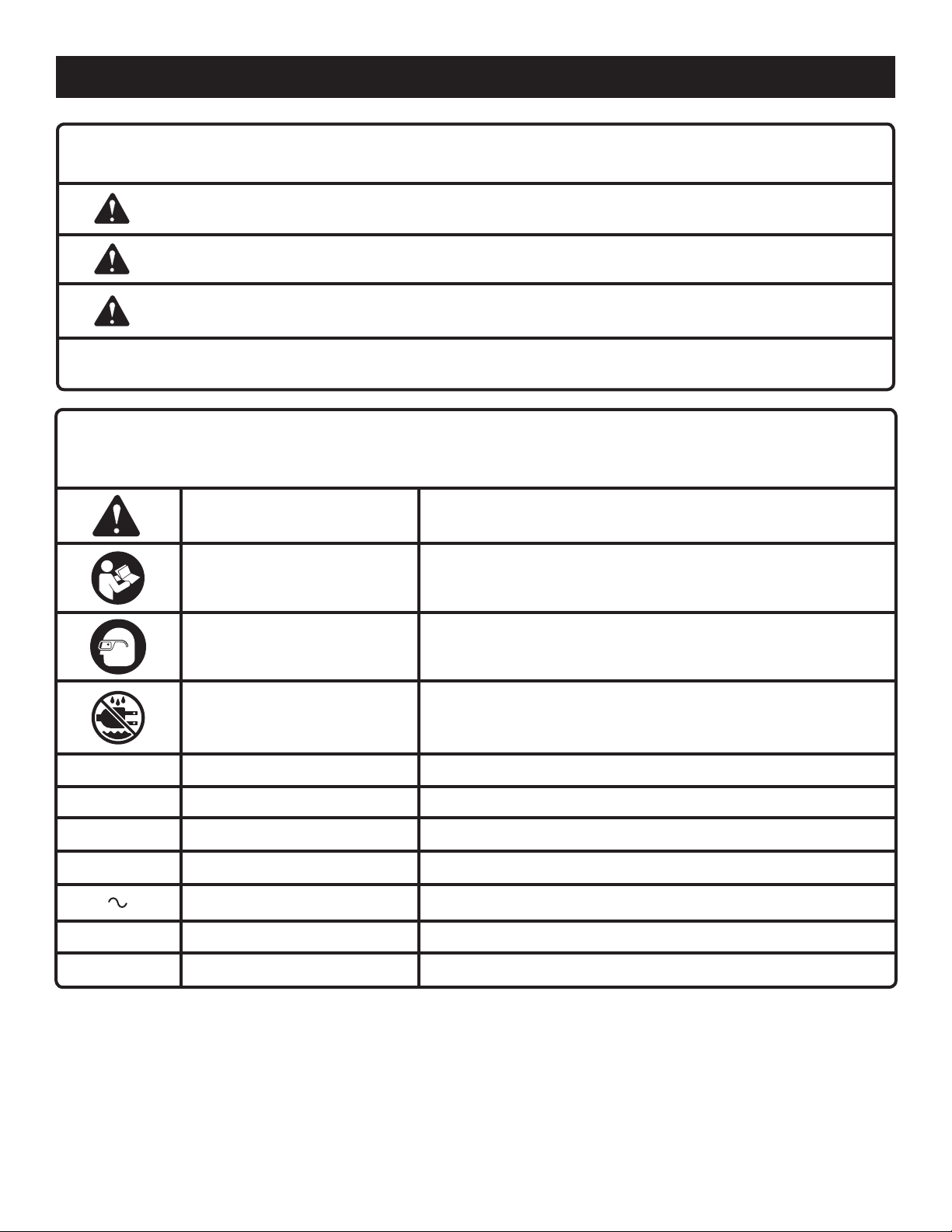

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the product better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Eye Protection

To reduce the risk of injury, user must read and understand operator’s manual before using this product.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

Wet Conditions Alert Do not expose to rain or use in damp locations.

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

min Minutes Time

Alternating Current Type of current

n

o

.../min Per Minute Revolutions, strokes, surface speed, orbits etc., per minute

No Load Speed Rotational speed, at no load

4

Page 5

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding

plugs and 3-pole receptacles that accept the product’s plug.

When using a power product at a considerable distance from

the power source, use an extension cord heavy enough to

carry the current that the product will draw. An undersized

extension cord will cause a drop in line voltage, resulting in

a loss of power and causing the motor to overheat. Use the

chart provided below to determine the minimum wire size

required in an extension cord. Only round jacketed cords

listed by Underwriter’s Laboratories (UL) should be used.

**Ampere rating (on product data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

When working outdoors with a product, use an extension

cord that is designed for outside use. This type of cord is

designated with “W-A” or “W” on the cord’s jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on lumber,

products or other obstructions while you are working with

a power product. Failure to do so can result in serious

personal injury.

SPEED AND WIRING

The no-load speed of this product depends on the router

you are using. This speed is not constant and decreases

under a load or with lower voltage. For voltage, the wiring

in a shop is as important as the motor’s horsepower rating.

A line intended only for lights cannot properly carry a power

product motor. Wire that is heavy enough for a short distance will be too light for a greater distance. A line that can

support one power product may not be able to support two

or three products.

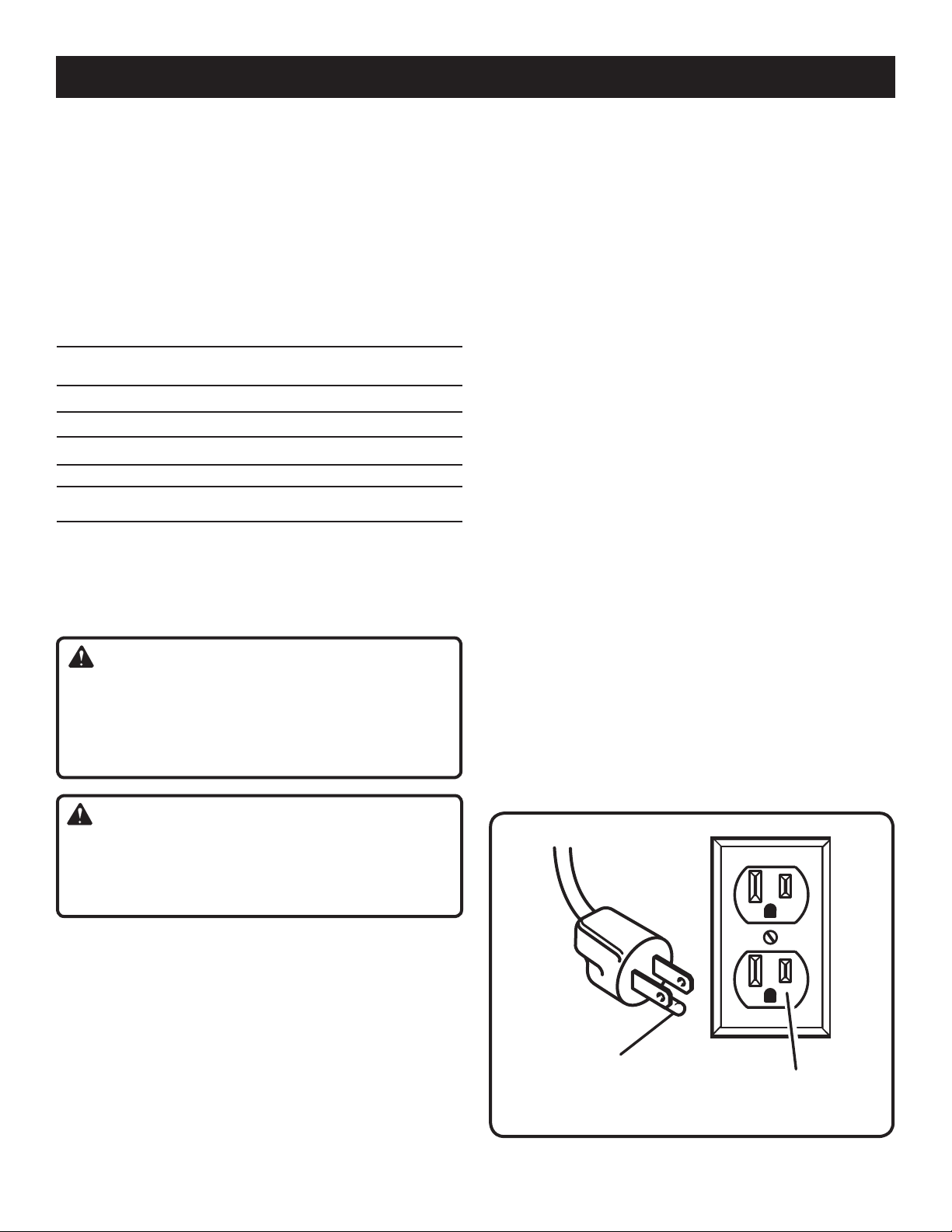

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This product is equipped with an

electric cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor with

insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair

or replacement of the electric cord or plug is necessary, do

not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if

in doubt as to whether the product is properly grounded.

Repair or replace a damaged or worn cord immediately.

This product is intended for use on a circuit that has an outlet

like the one shown in figure 1. It also has a grounding pin

like the one shown.

WARNING:

Check extension cords before each use. If damaged

replace immediately. Never use product with a damaged

cord since touching the damaged area could cause electrical shock resulting in serious injury.

ELECTRICAL CONNECTION

This product is powered by a precision built electric motor.

It should be connected to a power supply that is 120 V, AC

only (normal household current), 60 Hz. Do not operate

this product on direct current (DC). A substantial voltage

drop will cause a loss of power and the motor will overheat.

If the saw does not operate when plugged into an outlet,

double check the power supply.

GROUNDING

PIN

5

120 V GROUNDED OUTLET

Fig. 1

Page 6

FEATURES

PRODUCT SPECIFICATIONS

Table Dimensions ................................16 in. x 32 in. x 1 in.

Maximum Cutter Diameter .................................1-15/16 in.

Fence Length.............................................................. 28 in.

Miter Slot ........................................ 1/4 in. x 3/4 in. x 32 in.

Rating .............................. 120 V, 60 Hz, AC only, 15 Amps

Net Weight .................................................................28 lbs.

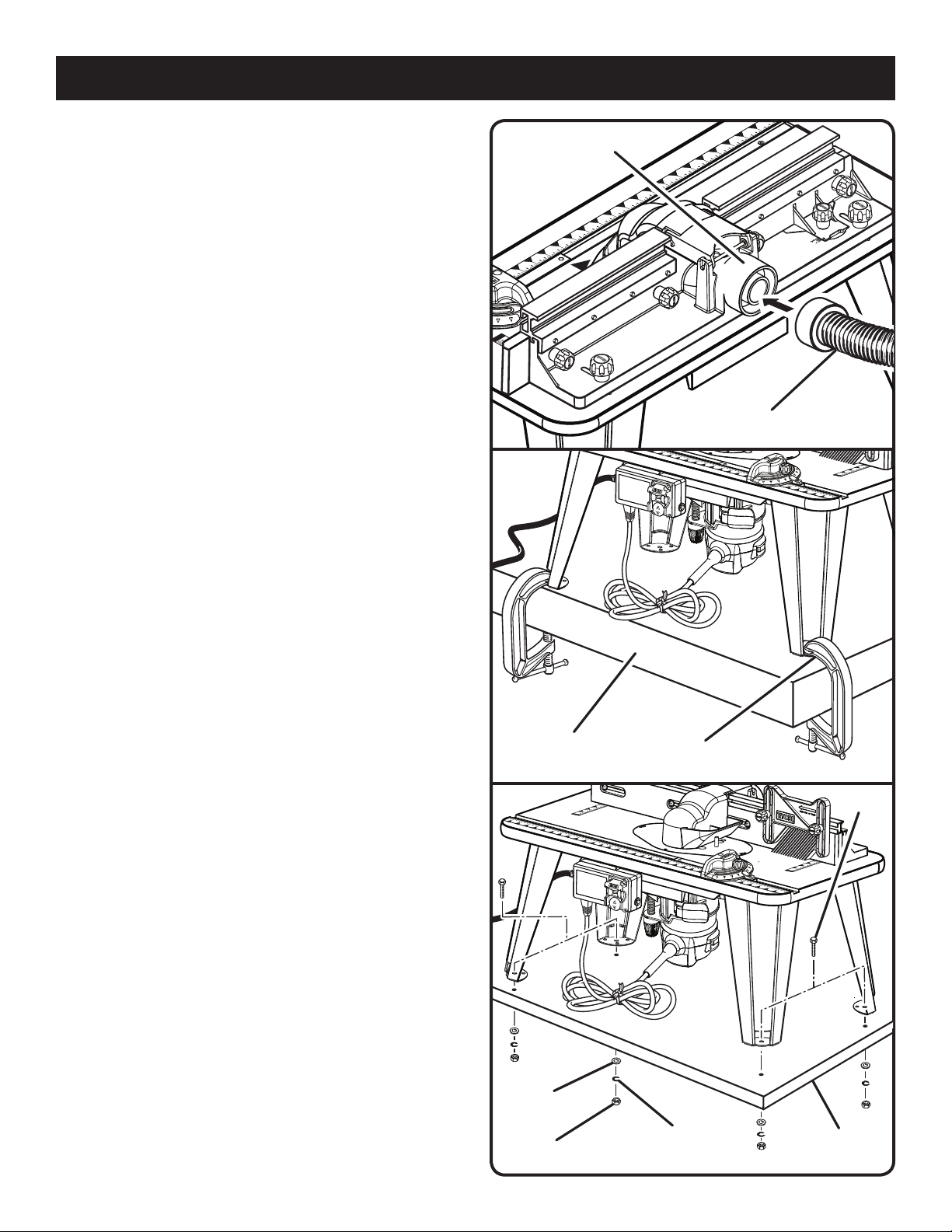

DIRECTION

FEED

VACUUM

PORT

THROAT PLATES

FENCE

ASSEMBLY

INSERT

PLATE

BIT GUARD

STARTING

PIN

3

2

1

0

1

Inch

inch

T

P

E

U

S

E

S

R

H

SWITCH

ASSEMBLY

1

Inch

FEATHER

BOARD

3

2

1

0

MITER

GAUGE

RESET

BUTTON

Fig. 2

KNOW YOUR ROUTER TABLE

See Figure 2.

The safe use of this product requires an understanding of

the information on the product and in this operator’s manual

as well as a knowledge of the project you are attempting.

Before use of this product, familiarize yourself with all

operating features and safety rules.

BIT GUARD

The articulating router cutter bit guard on the fence assembly

provides a barrier to protect the operator from contact with the

cutter and is designed to stay in contact with the workpiece.

FEATHERBOARD

The featherboard allows for safe movement of the workpiece

through the cutter area and is height adjustable.

FENCE ASSEMBLY

The sacrifical MDF fence assembly provides an adjustable

surface to support and guide the work. Molded into the fence

assembly is the vacuum port.

INSERT PLATE

The insert plate can be used in comination with a variety of

routers. It also has pre-drilled countersunk holes that can

be used with a variety of routers.

MITER GAUGE

A miter gauge is used for mitered routing and to help support

wider pieces.

6

Page 7

FEATURES

RESET BUTTON

See Figure 2.

The router table switch is equipped with a reset button that

protects the electronic components of the router table switch

box from overload.

STARTING PIN

When you are unable to use the fence for a guide because

the workpiece is odd-shaped or too small, use the starting

pin for a guide and/or pivot point. Only use piloted cutters

when using the starting pin.

THROAT PLATES

Five throat plates are included with the router table. The

throat plate provides a stable surface around the cutter

and prevents objects from falling through the throat and

damaging the spindle.

VACUUM PORT

The vacuum ports molded into the fence will accept either

a 1-1/4 in. or 2-1/2 in. vacuum attachment.

SWITCH ASSEMBLY

See Figure 3.

This product is equipped with a switch assembly that has a

built-in locking feature. This feature is intended to prevent

unauthorized and possible hazardous use by children and

others.

TO TURN YOUR ROUTER TABLE ON:

Plug the router into either switch box outlet on the router

table and plug the router table into a 120 volt grounded

outlet.

With the switch key inserted into the switch, lift the switch

to turn ON ( l ).

WARNING:

Always remove the switch key when the tool is not in

use and keep it in a safe place. In the event of a power

failure, turn the switch OFF ( O ) and remove the key.

This action will prevent the tool from accidentally starting

when power returns.

WARNING:

ALWAYS make sure your workpiece is not in contact with

the cutter before operating the switch to start the tool.

Failure to heed this warning may cause the workpiece to

be kicked back toward the operator and result in serious

personal injury.

WARNING:

To reduce the risk of accidental starting, ALWAYS make

sure the switch is in the OFF ( O ) position before plugging

tool into the power source.

SWITCH

ON

SWITCH

OFF

NOTE: The router table is equipped with a reset button. See

Figure 2. If, for any reason, the router table will not turn on,

press the reset button and then restart.

TO TURN YOUR ROUTER TABLE OFF:

Press the switch down to turn OFF ( O ).

TO LOCK YOUR ROUTER TABLE:

Press the switch down.

Remove the switch key from the switch and store in a

safe, secure location.

7

SWITCH KEY

SWITCH IN LOCKED POSITION

Fig. 3

Page 8

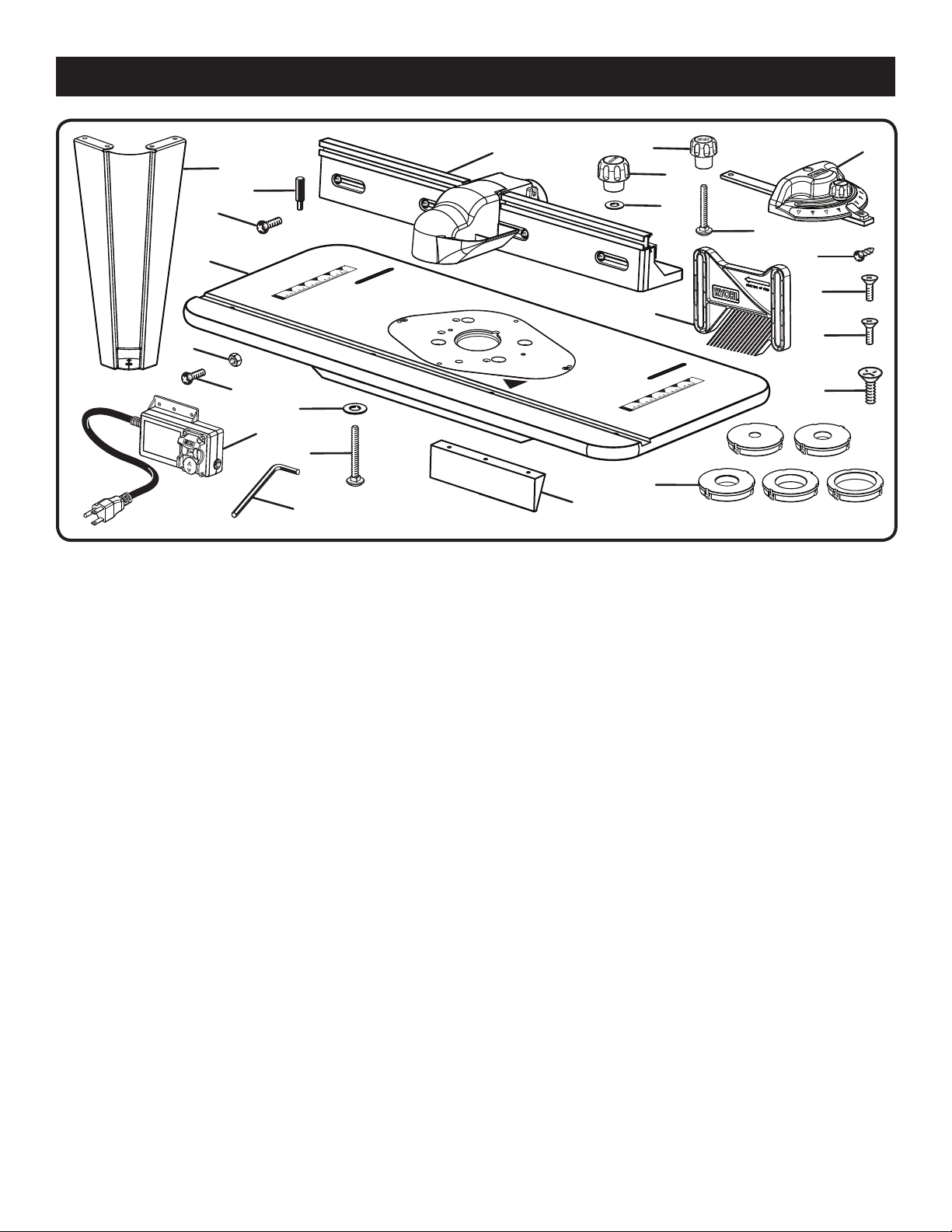

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the loose parts

list are included.

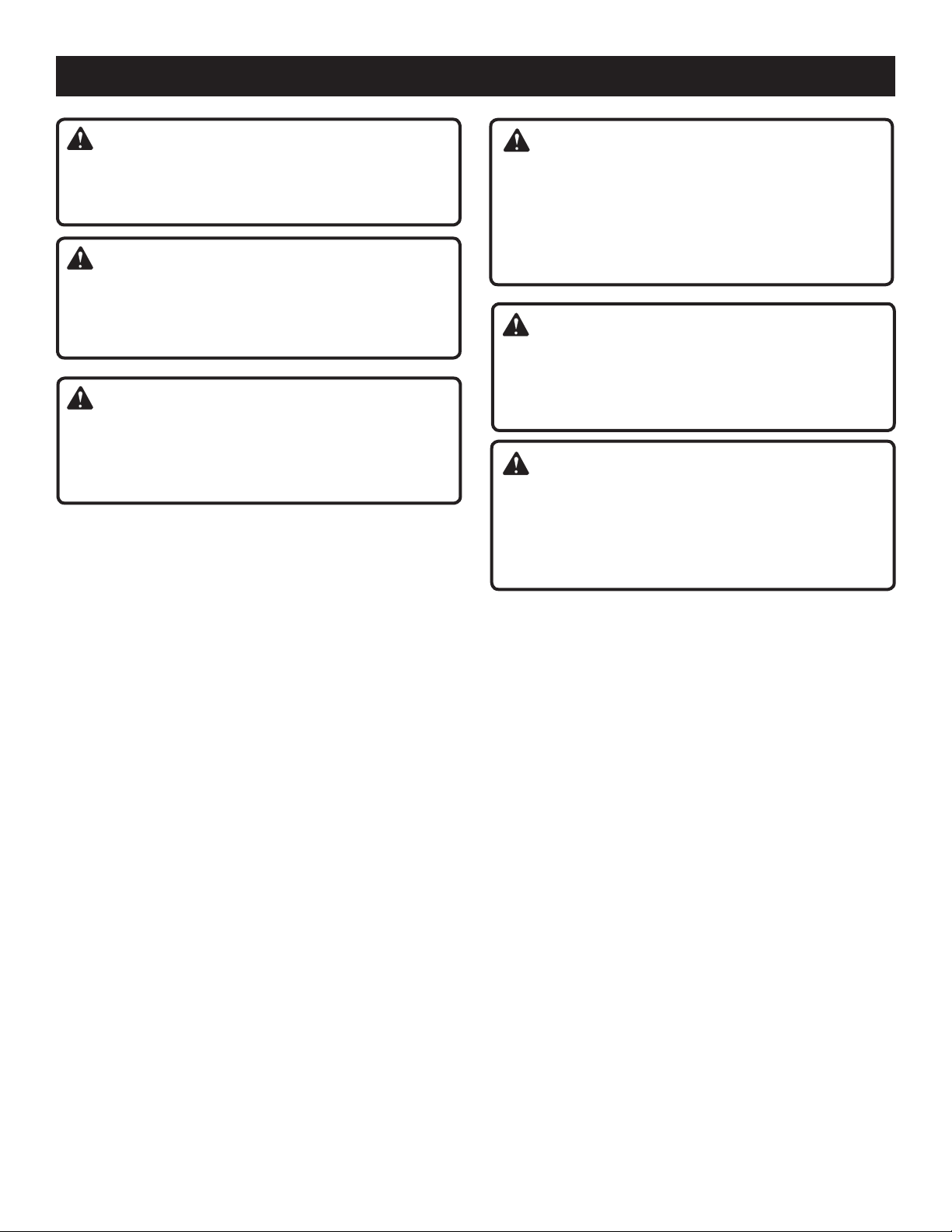

WARNING:

WARNING:

If any parts are damaged or missing do not operate this

tool until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

Do not use this product if any parts on the Loose Parts List

are already assembled to your product when you unpack

it. Parts on this list are not assembled to the product by

the manufacturer and require customer installation. Use

of a product that may have been improperly assembled

could result in serious personal injury.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

WARNING:

Do not attempt to modify this product or create accessories not recommended for use with this product. Any

such alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

WARNING:

The undertable guards must be securely in place before

using the router table. Failure to do so could result in

serious personal injury.

8

Page 9

3

ASSEMBLY

1

2

3

4

0

1

Inch

5

6

8

7

9

10

PACKING LIST

1. Table Leg (4)

2. Starting Pin

3. Table Leg Phillips Head Screw (16)

4. Table Top

5. Switch Box Nut (3)

6. Switch Box Screw (3)

7. Switch Box

8. Carriage Bolt Washer (2)

9. Carriage Bolt (2)

10. Hex Key (1)

11. Under Table Guard (2)

12. Throat Plates (5)

18

23

17

19

22

21

3

2

1

16

15

20

14

3

FEED

DIRECTION

Inch

2

1

0

1

13

12

11

Fig. 4

13. Router Insert Plate Screws (5/16-18 x 3/4 in.) (3)

14. Router Insert Plate Screws (10-24 x 5/8 in.) (3)

15. Router Insert Plate Screws (10-32 x 5/8 in.) (3)

16. Under Table Guard Screw (6)

17. Miter Gauge

18. Fence Assembly

19. Fence Lock Knobs (2)

20. Featherboard

21. Featherboard Bolts (2)

22. Fence Lock Knob Washer (2)

23. Featherboard Lock Knobs (2)

24. Operator’s Manual (not shown)

9

Page 10

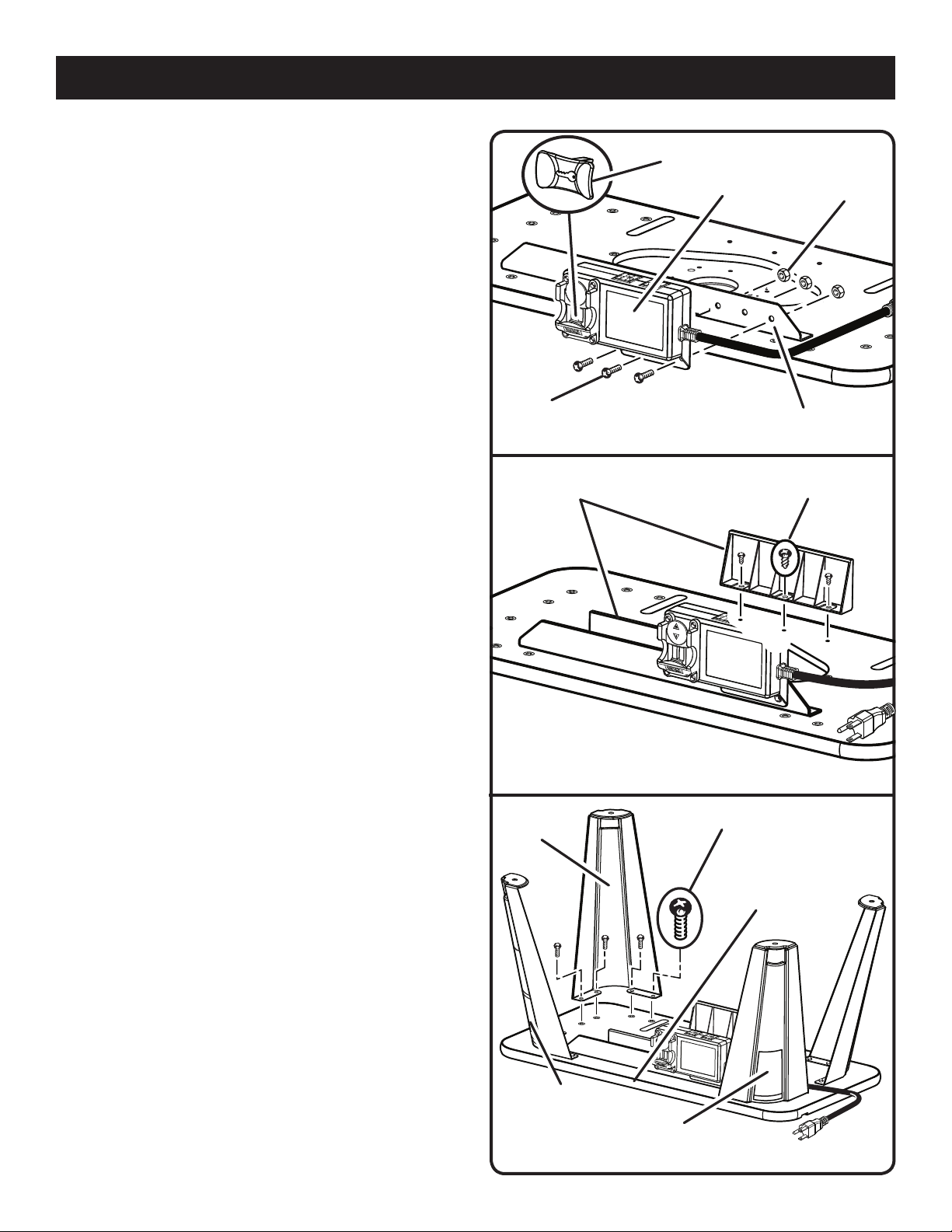

ASSEMBLY

ASSEMBLING THE ROUTER TABLE

Assembling the router table involves attaching the switch

box, the under table guards, the legs, the router/insert plate

assembly, the fence assembly, featherboard, throat plate,

starting pin, and installing the miter gauge to the router table.

ATTACHING THE SWITCH BOX

See Figure 5.

The switch box will come in a bag with the switch box screws

and nuts. Use these screws and nuts in the bag to attach

the switch box.

Place the router table upside down on a flat surface.

Hold the switch box so that the words ON and OFF on

the toggle switch are upside down.

Line up the three holes in the switch box with the three

holes on the outside of the front rail, this is the rail that

is already installed on the front underside of the router

table.

Insert the switch box screws through the holes in the

switch box and through the holes in the front rail.

Install the nuts on the back of the switch box screws.

Holding the screws in place with a screwdriver, tighten

the nuts onto the screws with a wrench or socket.

SWITCH BOX

SCREW

UNDER

TABLE GUARDS

SWITCH KEY

SWITCH BOX

SWITCH

BOX NUT

FRONT RAIL

Fig. 5

UNDER TABLE

GUARD SCREW

ATTACHING THE UNDER TABLE GUARDS

See Figure 6.

The under table guards will come in a bag with the under

table guard screws. Use these screws in the bag to attach

the under table guards.

Place the router table upside down on a flat surface.

Position the under table guards in front of and behind the

insert plate. The front under table guard should have the

open ended side facing the back of the router table.

Align the three holes of the under table guards with the

holes in the table. The front under table guard will be

bolted onto the front rail.

Insert the under table guard screws through the holes

and into the table.

Tighten screws with a screwdriver.

ATTACHING THE TABLE LEGS

See Figure 7.

The table legs will come in a bag with the table leg screws.

Use the table leg screws in the bag to attach the table legs.

Place router table upside down on a flat, level surface

with the front edge closest to you.

Place each leg in a corner of the table. The legs with the

warning labels should go in the front, and the legs without

the warning labels should go in the back.

NOTE: The table leg with the English language warning

should go next to the switch box.

Align the four holes in the legs with the four corresponding

threaded holes in the table.

Insert the table leg screws through the holes and into the

table.

TABLE LEG

RIGHT LEG-

FRENCH / SPANISH

LABEL

TABLE LEG SCREW

LEFT LEG-

ENGLISH LABEL

Fig. 6

FRONT SIDE

Fig. 7

10

Page 11

ASSEMBLY

3

Tighten screws with a screwdriver.

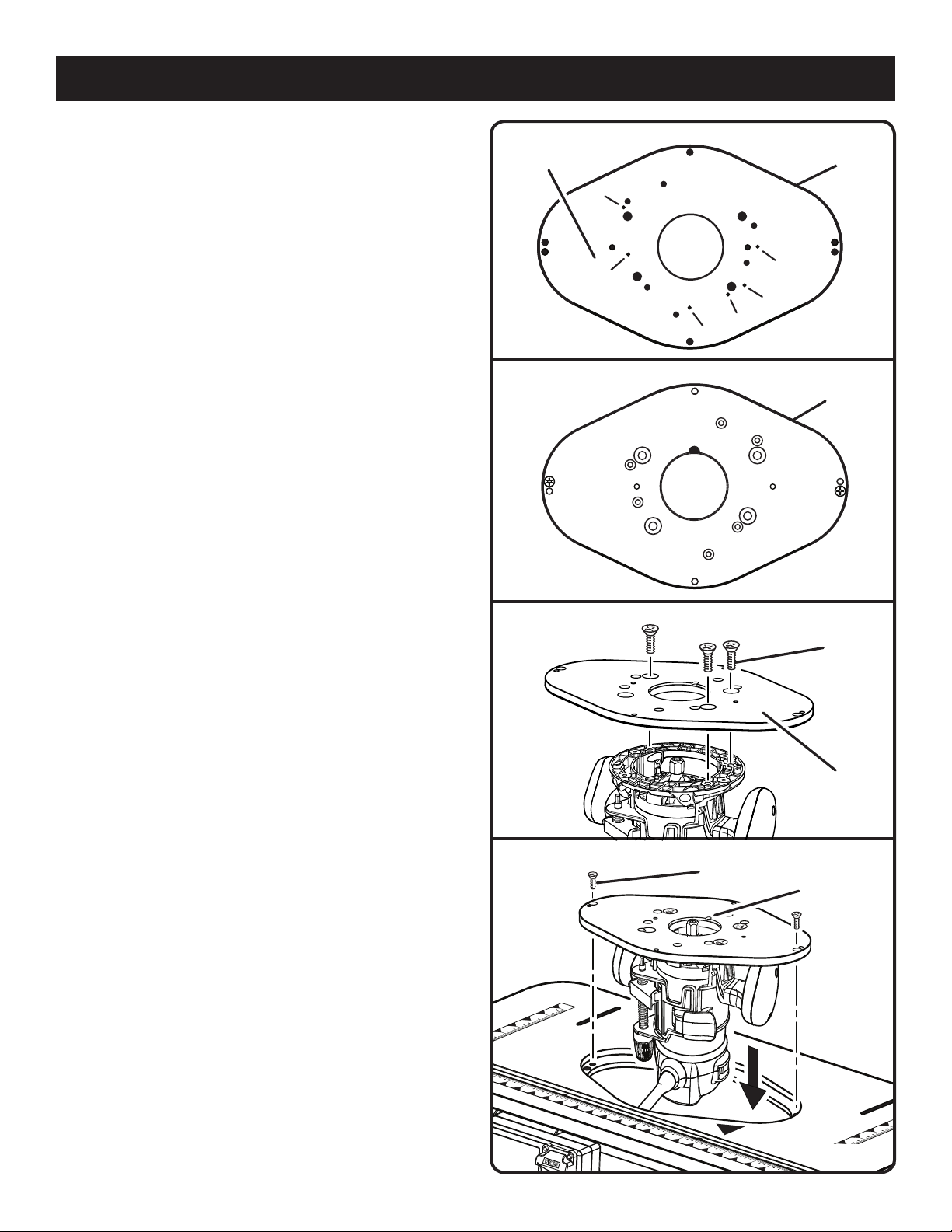

PRE-DRILLING HOLES FOR THROUGH

TABLE DEPTH ADJUSTMENT

See Figure 8.

Since each router will have different placements for through

table depth adjustments, pilot holes have been pre-drilled in

the throat plate to assist in through table adjustments. Only

the models listed below in the key are available for use with

the through table depth adjustment feature.

Remove the throat plate.

Determine which router you have and find the pre-drilled

pilot hole that matches your router. (Refer to the key

below.)

Using a drill and drill bit, drill a hole through the pilot hole

large enough for the depth adjustment tool (not included

with router table, but may be included with your router)

to pass though so through table depth adjustments can

be made.

Figure 8 Key:

RD: RIDGID R2930

RY: Ryobi R163K

ML: Milwaukee 5615-20, 5616-20

PC1: Porter-Cable 890 Series

PC2: Porter-Cable 8529

ATTACHING THE ROUTER TO THE TABLE

For ease of use, assemble the router to the insert plate with

the insert plate removed first, then install the insert plate/

router assembly into the router table.

PRE-DRILLED

PILOT HOLES

RD

ML

A6

A5

B4

NOTCH H

B3

INSERT PLATE

REAR SIDE

PC2

RY

PC1

PC1

Fig. 8

INSERT PLATE

FRONT SIDE

A1

A2

B1

B2

A3

A4

Fig. 9

ROUTER INSERT

PLATE SCREWS

ATTACHING THE ROUTER TO THE INSERT

PLATE

See Figures 9 - 10.

Remove the insert plate.

Remove the subbase plate from the router.

Using the following chart for reference, and using one of

the three included sets of three router insert plate screws,

attach the router to the insert plate with the pilot holes

facing the router and the notch in the insert plate facing

the back of the router table.

NOTE: When attaching insert plate to the router, make

sure the holes in the router base match up with the insert

plate accurately and are not off-center.

INSTALLING THE ROUTER/INSERT PLATE

ASSEMBLY

See Figure 11.

With the insert plate installed on the router, insert router

and insert plate assembly into the router table with the

notch in the insert plate facing the back of the router table

toward the fence assembly.

Install the insert plate screws and leave loose until all

adjustments have been made.

11

INSERT PLATE

Fig. 10

INSERT PLATE

SCREWS

NOTCH

3

2

1

0

1

2

FEED

DIRECTION

1

Inch

Fig. 11

1

0

Page 12

ASSEMBLY

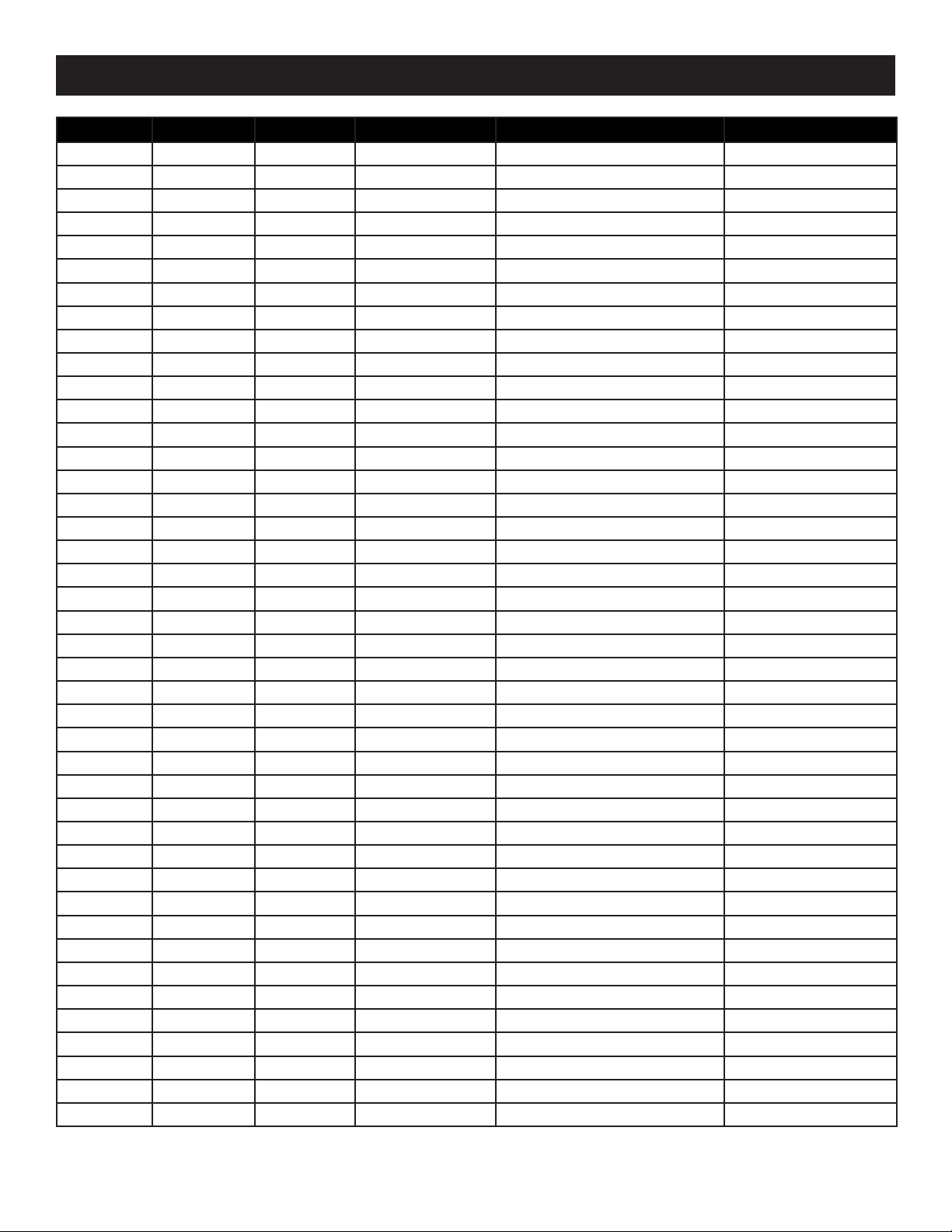

BRAND MODEL BASE TYPE FASTENER SIZE INSERT PLATE HOLES USED NUMBER OF HOLES

Bosch 1617 Fixed 10-24 x 5/8 in. A1, A3, A5 3

Bosch 1617 EVS Fixed 10-24 x 5/8 in. A1, A3, A5 3

Bosch 1617 EVSPK Fixed 10-24 x 5/8 in. A1, A3, A5 3

Craftsman 17504 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 17505 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 17506 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 17508 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 17510 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 17511 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 17515 Plunge 5/16-18 x 3/4 in. B1, B2, B4 3

Craftsman 17517 Plunge 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 17533 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 17533 Plunge 5/16-18 x 3/4 in. B1, B2, B4 3

Craftsman 24833 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Craftsman 24833 Plunge 5/16-18 x 3/4 in. B1, B2, B4 3

Craftsman 27500 Fixed 5/16-18 x 3/4 in. B1, B2, B4 3

Craftsman 26921 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Hitachi M12V Plunge 10-32 x 5/8 in. A1, A3, A5 3

Hitachi KM12VC Fixed 10-32 x 5/8 in. A1, A3, A5 3

Makita RF1101 Fixed 10-24 x 5/8 in. A1, A3, A5 3

Makita RP1101 Plunge 10-24 x 5/8 in. A1, A3, A5 3

Makita RF1101K

Milwaukee 5615-20 Fixed 10-24 x 5/8 in. A1, A3, A5 3

Milwaukee 5616-20 Fixed 10-24 x 5/8 in. A1, A3, A5 3

Porter Cable

Porter Cable

Porter Cable

Porter Cable

Porter Cable

Porter Cable

Porter Cable

RIDGID R2930

Ryobi R160 Fixed 5/16-18 x 3/4 in. B1, B2, B4 3

Ryobi R161K Fixed 5/16-18 x 3/4 in. B1, B2, B4 3

Ryobi R162K Fixed 5/16-18 x 3/4 in. B1, B2, B4 3

Ryobi R163K Fixed 5/16-18 x 3/4 in. B1, B2, B4 3

Ryobi R165U Fixed 5/16-18 x 3/4 in. B1, B2, B4 3

Ryobi R175 Plunge 5/16-18 x 3/4 in. B1, B3 2

Ryobi RE175 Plunge 5/16-18 x 3/4 in. B1, B3 2

Ryobi

Skil 1810 Fixed 10-32 x 5/8 in. A2, A4, A6 3

Skil 1825

693LRPK Plunge only 10-24 x 5/8 in. A1, A3, A5 3

694PK Plunge only 10-24 x 5/8 in. A1, A3, A5 3

694VK Plunge only 10-24 x 5/8 in. A1, A3, A5 3

892 Fixed 10-24 x 5/8 in. A1, A3, A5 3

893PK Fixed 10-24 x 5/8 in. A1, A3, A5 3

7529 Plunge 10-24 x 5/8 in. A1, A3, A5 3

8529 Plunge 10-24 x 5/8 in. A1, A3, A5 3

RE180PL/PL1

All identified trademarks and trade names are the property of their respective owners.

Fixed/Plunge

Fixed/Plunge

Plunge 5/16-18 x 3/4 in. B1, B3 2

Fixed/Plunge

10-24 x 5/8 in. A1, A3, A5 3

10-32 x 5/8 in. A1, A3, A5 3

10-32 x 5/8 in. A2, A4, A6 3

12

Page 13

ASSEMBLY

Inch

1

0

1

2

3

0

1

2

3

FEED

DIRECTION

1

2

3

2

3

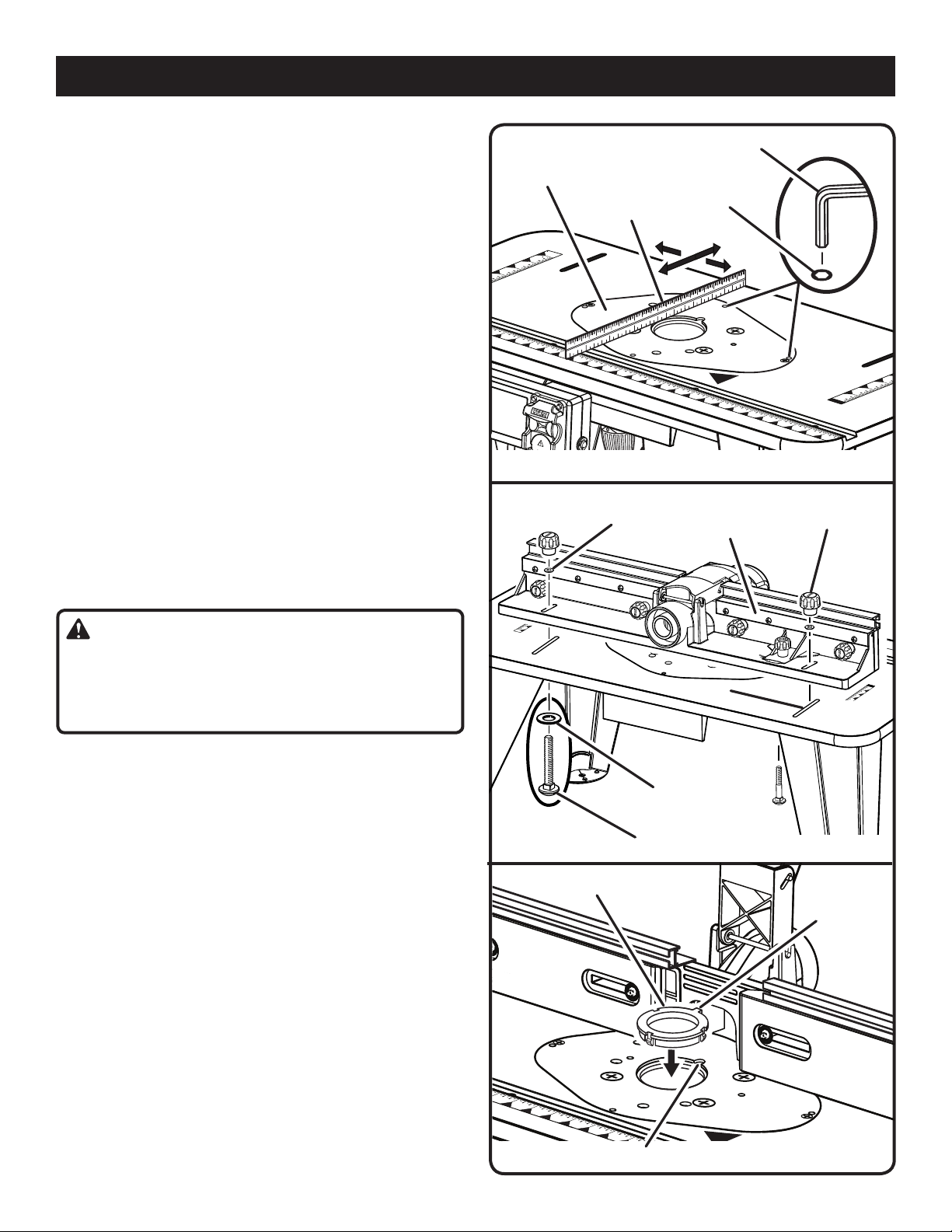

MAKING INSERT PLATE LEVEL

See Figure 12.

Unplug the router table and/or the router.

Check to see if the insert plate mounted assembly is level

with a straight edge or level.

Loosen insert plate screws.

Using the supplied hex key, tighten or loosen the adjust-

ing screws depending on how the insert plate needs to be

adjusted in order to make the insert plate level.

Tighten insert plate screws with a screwdriver.

ATTACHING THE FENCE ASSEMBLY

See Figure 13.

Unplug the router table and/or the router.

Place the router table right side up with the back edge

closest to you.

Slide the carriage bolt washers onto the carriage bolts.

Slide carriage bolts through the slot in the router table

and through the slots in the fence assembly.

Slide the fence lock knob washer over the carriage

bolts.

Install the fence lock knobs over the carriage bolts.

Tighten the fence lock knobs.

WARNING:

INSERT

PLATE

Inch

1

0

1

2

3

0

STRAIGHT

EDGE

FENCE LOCK

KNOB WASHER

HEX KEY

ADJUSTING

SCREWS

FENCE

ASSEMBLY

Fig. 12

FENCE

LOCK KNOBS

Make sure throat plates snap securely into place. Do

not use if snaps are damaged or throat plates do not

snap in securely. Failure to do so could result in serious

SLOT

personal injury.

INSERTING AND REMOVING THROAT

PLATES

See Figure 14.

The throat plate provides a stable surface around the cutter

and prevents objects from falling through the throat plate

and damaging the spindle.

The proper size throat plate depends on the size and shape

CARRIAGE BOLTS

THROAT PLATE

of the cutter. When inserted, the throat plate opening should

be within approximately 1/4 in. of the outermost edge of

the cutter.

Unplug the router table and/or the router.

Select the throat plate you wish to use.

Press throat plate into insert plate slot until it snaps into

place.

To remove, push throat plate out from the bottom of the

insert plate.

CARRIAGE BOLT

WASHER

Fig. 13

TAB

NOTCH

Fig. 14

13

Page 14

Inch

1

0

1

2

3

ASSEMBLY

Inch

1

0

1

2

3

2

3

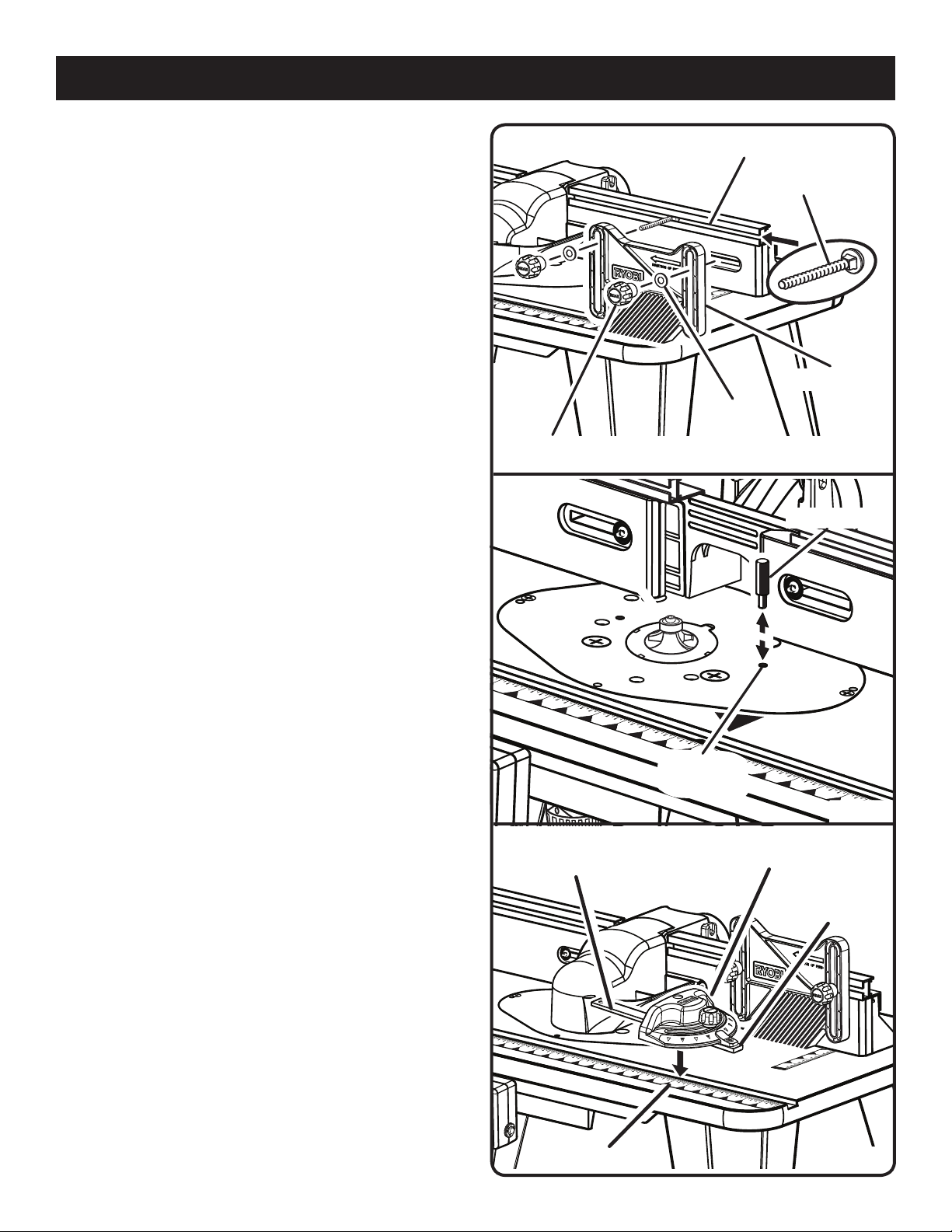

ATTACHING THE FEATHERBOARD

See Figure 15.

Unplug the router table and/or the router.

Insert the featherboard bolts through the slots in the fence

assembly.

Slide the featherboard over the featherboard bolts.

Install the fence lock knobs and carriage bolt washers

over the carriage bolts.

Tighten the fence lock knobs.

INSERTING THE STARTING PIN

See Figure 16.

Place the starting pin on the router table and use it as a pivot

point when cutting small, odd-shaped pieces.

NOTE: It is not necessary to use the fence when you are

using the starting pin, but the bit guard should be used to

cover the cutter. Additionally, only use piloted cutters when

using the starting pin.

Unplug the router table and/or the router.

Place the starting pin into the hole to the right of the router

table throat opening.

Push the pin in to secure.

FENCE LOCK KNOB

SLOT

FEATHERBOARD

CARRIAGE

BOLT

WASHER

BOLT

FEATHERBOARD

Fig. 15

STARTING PIN

INSTALLING THE MITER GAUGE

See Figure 17.

Unplug the router table and/or the router.

With the router table right side up, and the front edge

closest to you, place the miter gauge bar in the slot near

the front of the table with the pointer on the right.

ATTACHING THE VACUUM HOSE

See Figure 18.

The vacuum port molded into the fence will accept either a

1-1/4 in. or 2-1/2 in. vacuum attachment.

FEED

DIRECTION

STARTING

PIN HOLES

Fig. 16

MITER

GAUGE BAR

MITER GAUGE

POINTER

3

2

1

0

1

Inch

SLOT

Fig. 17

14

Page 15

Inch

1

0

1

2

3

ASSEMBLY

CLAMPING THE ROUTER TABLE TO A WORK

BENCH

See Figures 19.

Unplug the router table and/or the router.

Place the router table right side up on a sturdy work

surface; e.g., leg stand, workbench, counter top.

Using a clamp, insert the top front of clamp through the

opening in the router table leg.

Tighten clamp securely.

MOUNTING THE ROUTER TABLE TO A

WORK BENCH

See Figure 20.

Unplug the router table and/or the router.

Place the router table right side up on a sturdy work

surface; e.g., leg stand, workbench, counter top.

Mark the holes with a pencil.

Remove the router table.

Drill four holes through the work surface.

Place the router table back on the work surface, align-

ing the holes in the table legs with the holes in the work

surface.

VACUUM PORT

DIRECTION

FEED

Inch

1

VACUUM HOSE

Fig. 18

inch

3

2

1

0

1

Inch

NOTE: Position the router table surface at approximately

hip height.

Insert four bolts (not included, 1/4-20 recommended) and

tighten securely with flat washers, lock washers, and hex

nuts (not included).

WORK TABLE

2

1

0

1

Inch

CLAMP

Fig. 19

3

inch

Inch

BOLTS

3

2

1

0

1

15

FLAT

WASHER

HEX NUT

LOCK

WASHER

WORK TABLE

Fig. 20

Page 16

OPERATION

WARNING:

Do not allow familiarity with products to make you careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes, resulting in possible

serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

APPLICATIONS

You may use this product for the purposes listed below:

Table mounted dado and mortise operations in wood and

wood composition materials

Fence guided edging operations for cabinetry and

picture framing on wood and wood composition

materials

Piloted cutter operations using the starting pin for

edging patterned surfaces on wood and wood

composition materials

WARNING:

The router or router table should never be connected to

a power supply when you are assembling parts, making

adjustments, installing or removing cutters, cleaning, or

when not in use. Disconnecting the router and router table

will prevent accidental starting that could cause serious

personal injury.

WARNING:

The direction of feed for the workpiece is always against

the sharp edges of the cutter and therefore into the rotation of the cutter. Failure to heed this warning can result

in serious personal injury.

WARNING:

When operating the router with the router table, the

router must only be plugged into and controlled by the

router table switched outlet. To reduce the risk of serious

personal injury, never connect the table mounted router

into another power source.

16

Page 17

OPERATION

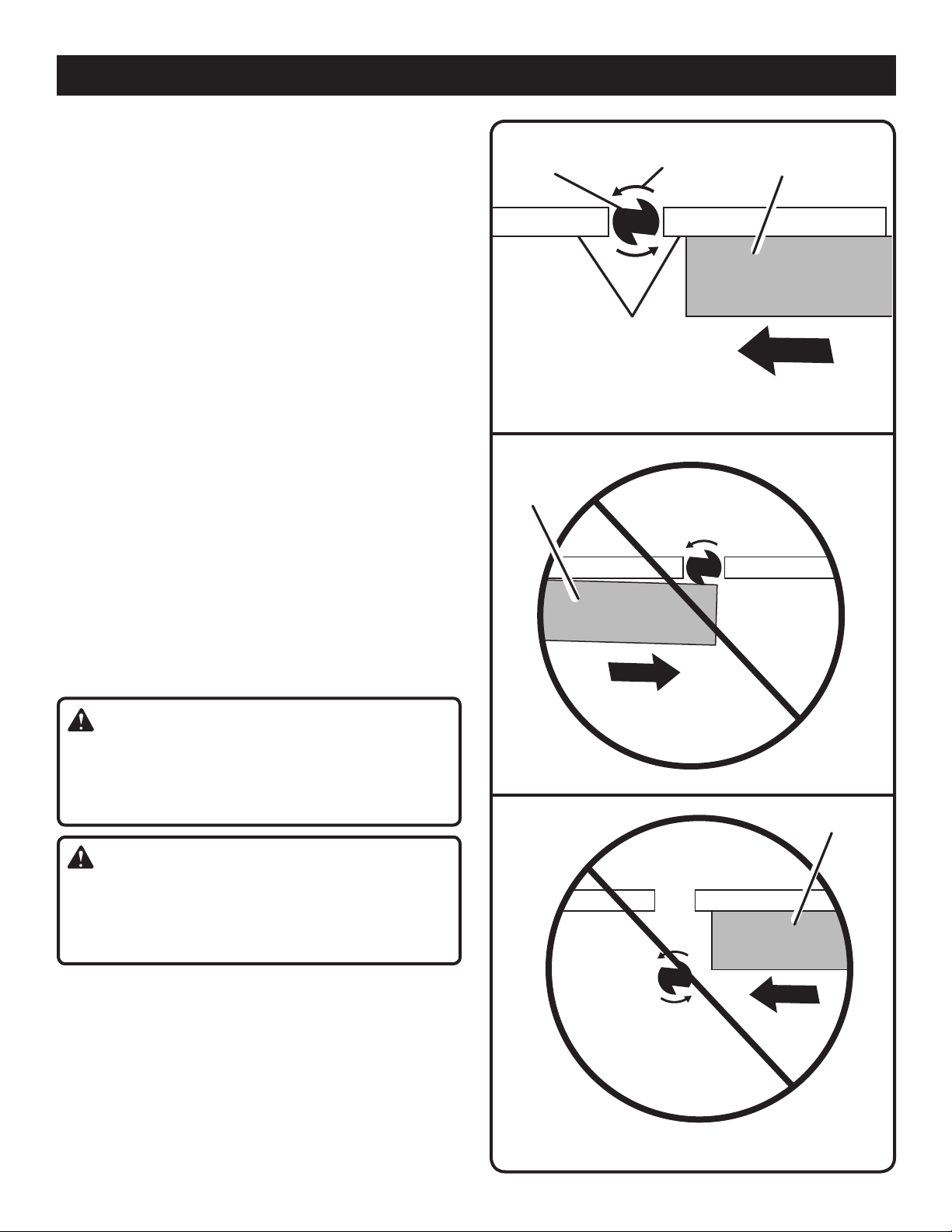

PERFORMING A ROUTING OPERATION

See Figures 21 - 23.

Observe the following rules when using the router:

Read the entire operator’s manual for the router and router

table.

Plug the router table power cord into a power source.

Always control the power to the router with the router

table switch whenever the router is mounted on the table.

Always plug the router into either of the router table

switched outlets. Never plug a router table mounted

router into another power source.

Position the infeed and outfeed fence so they are close

to the maximum diameter of the cutter, but not touching

the cutter.

NOTE: The workpiece must always be tight against the

fence, unless you are using a ball-bearing piloted cutter.

Adjust the infeed fence to support the uncut workpiece

and adjust the outfeed fence to support the workpiece

after the cut. The “0” location on the fence scale denotes

the center of the throat opening of the table.

Reconfirm that all router adjustments are securely locked

before connecting the router table to a power source.

The cutter rotates counterclockwise (as viewed above

the table) on the router table. Always feed the workpiece

against the sharp edges of the cutter.

Make sure the router table switch is off when not in use.

Remove the switch key to ensure the router table is off.

ROUTER BIT

WORKPIECE

DIRECTION OF

ROTATION

FENCE

CORRECT

CLIMB CUTTING

WORKPIECE

DIRECTION OF FEED

Fig. 21

WARNING:

Never feed the workpiece in the same direction of rotation

of the bit. Feeding in this direction can cause the workpiece to climb over the bit and cause serious personal

injury.

WARNING:

When making a side or edge cut, never position the fence

such that the workpiece is located between the cutter

and the fence. Failure to heed this warning can result in

serious personal injury.

INCORRECT

Fig. 22

WORKPIECE

INCORRECT

Fig. 23

17

Page 18

OPERATION

INSERTING/REMOVING CUTTERS

Unplug the router table and/or the router.

Remove the router/insert plate assembly. (See Installing

Router/Insert Plate Assembly in the Assembly section.)

WARNING:

If you are changing a cutter immediately after use, be

careful not to touch the cutter or collet with your hands or

fingers. They will get burned because of the heat buildup

from cutting. Always use a wrench.

Consult the router operator’s manual for proper cutter

removal/installation procedure and replace cutter.

ADJUSTING DEPTH OF CUT

Consult the router operator’s manual for adjusting the depth

of cut.

ADJUSTING THE MITER GAUGE

See Figure 24.

Unplug the router table and/or the router.

Loosen the miter gauge knob.

Rotate the miter gauge to the desired angle.

Tighten the miter gauge knob.

MITER

GAUGE KNOB

3

3

2

1

0

1

Inch

MITER GAUGE

Fig. 24

OUTFEED FENCE

POSITIONING THE FENCE

See Figure 25.

The fence enables you to support and guide the workpiece.

Unplug the router table and/or the router.

Loosen the fence lock knobs.

Position the fence to the desired location.

Tighten the fence lock knobs.

NOTE: The outfeed fence has joining capabilities and can

be adjusted out in increments up to 1/4 in. and enable

you to support the workpiece as it exits the cutter.

WARNING:

When making a side or edge cut, never position the fence

such that the workpiece is located between the cutter

and the fence. Failure to heed this warning can result in

serious personal injury.

A groove can be cut in the workpiece by adjusting the

fence back from the cutter. When cutting a groove,

feed the workpiece from right to left. When widening an

existing groove, make certain that the side being cut is

against the leading edge of the cutter. This would be the

side farthest from the fence when the workpiece is fed

from right to left. As shown in figures 21 - 23.

DIRECTION

FEED

LOOSEN

Inch

1

FENCE LOCK KNOBS

CUTTER

TIGHTEN

FEED

DIRECTION

SCALE

1/4

0

PROPER

DISTANCE

1

0

1

Inch

3

3

2

2

18

SCALE

Fig. 25

Page 19

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc., come in contact with plastic parts. Chemicals can damage, weaken or

destroy plastic which could result in serious personal

injury.

Electric tools used on fiberglass material, wallboard, spackling

compounds, or plaster are subject to accelerated wear and

possible premature failure because the fiberglass chips and

grindings are highly abrasive to bearings, brushes, commutators, etc. Consequently, we do not recommended using this

tool for extended work on these types of materials. However,

if you do work with any of these materials, it is extremely

important to clean the tool using compressed air.

CALIFORNIA PROPOSITION 65

WARNING:

This product and some dust created by power sanding, sawing, grinding, drilling, and other construction activities may

contain chemicals, including lead, known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products and,

• arsenic and chromium from chemically treated lumber.

Your risk from exposure to these chemicals varies, depending on how often you do this type of work. To reduce your

exposure, work in a well-ventilated area and with approved safety equipment, such as dust masks that are specially

designed to filter out microscopic particles.

19

Page 20

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT :

Lire attentivement toutes les instructions. Le non-

respect des instructions ci-dessous peut entraîner un choc

électrique, un incendie et des blessures graves.

LIRE TOUTES LES INSTRUCTIONS

VEILLER À BIEN CONNAÎTRE L’OUTIL. Soigneusement

lire le toupie ajourne le manuel d’utilisation et le manuel

pour le toupie particulier que vous utilisez. Apprendre les

applications et les limites de la scie, ainsi que les risques

spécifiques relatifs à son utilisation.

SE PROTÉGER DES CHOCS ÉLECTRIQUES EN

ÉVITANT TOUT CONTACT DU CORPS AVEC DES

SURFACES MISES À LA TERRE. Par exemple : tuyaux,

radiateurs, cuisinières, réfrigérateurs.

MAINTENIR TOUS LES DISPOSITIFS DE PROTECTION

EN PLACE et en bon état de fonctionnement.

RETIRER LES CLÉS ET OUTILS DE RÉGLAGE. Prendre

l’habitude de vérifier que tous les outils et clés de réglage

ont été retirés de l’outil avant de le mettre en marche.

GARDER LE LIEU DE TRAVAIL PROPRE. Les établis

encombrés et les endroits sombres sont propices aux

accidents. NE PAS laisser d’outils ou de pièces de bois

sur la scie en fonctionnement.

NE PAS UTILISER DANS DES ENVIRONNEMENTS

DANGEREUX. Ne pas utiliser les outils électriques dans

des endroits mouillés ou humides, ne pas les exposer à

la pluie. Garder le lieu de travail bien éclairé.

GARDER LES ENFANTS ET VISITEURS À L’ÉCART. Tous

les visiteurs doivent porter des lunettes de sécurité et se

tenir à bonne distance de la zone de travail. Ne pas laisser

les visiteurs toucher l’outil ou son cordon d’alimentation

pendant le fonctionnement.

ASSURER LA SÉCURITÉ DES ENFANTS en installant

des cadenas et des disjoncteurs ou en retirant les clés

de contact.

NE PAS FORCER L’OUTIL. Il exécutera le travail mieux

et de façon moins dangereuse s’il fonctionne dans les

limites prévues.

UTILISER L’OUTIL APPROPRIÉ. Ne pas utiliser l’outil ou

un accessoire pour effectuer un travail pour lequel il n’est

pas conçu. Ne ne pas utiliser l’outil pour une application

non prévue.

UTILISER UN CORDON PROLONGATEUR ADÉQUAT.

S’assurer que le cordon prolongateur est en bon état.

Utiliser exclusivement un cordon d’une capacité suffisante

pour supporter le courant de fonctionnement de l’outil.

Un cordon de capacité insuffisante causerait une baisse

de la tension de ligne, entraînant une perte de puissance

et une surchauffe. Un calibre de fil (A.W.G) d’au minimum

14 est recommandé pour un cordon prolongateur de

7,5 m (25 pi) ou moins. En cas de doute, utiliser un cordon

du calibre immédiatement supérieur. Moins le numéro de

calibre est élevé, plus la capacité du fil est grande.

PORTER UNE TENUE APPROPRIÉE. Ne pas porter de

vêtements amples, gants, cravate ou bijoux. Ces articles

pourraient être happés et tirer la main ou une partie du

corps dans les pièces en mouvement. Des gants en

caoutchouc et des chaussures antidérapantes sont

recommandées pour le travail à l’extérieur. Les cheveux

longs doivent être ramassés sous un couvre-chef.

ENGAGER LES PIÈCES DANS LE SENS CORRECT. Le

matériau à couper ne doit être engagé que contre le sens

de rotation de la lame.

TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ

À COQUES LATÉRALES. Les lunettes de vue ordinaires

sont munies seulement de verres résistants aux impacts ;

ce ne sont PAS des lunettes de sécurité.

ASSUJETTIR LES PIÈCES. Dans la mesure du possible,

utiliser des serre-joints ou un étau pour maintenir la pièce.

Cette pratique réduit les risques et laisse les deux mains

libres.

NE PAS TRAVAILLER HORS DE PORTÉE. Toujours se

tenir bien campé et en équilibre.

ENTRETENIR SOIGNEUSEMENT LES OUTILS. Garder

les outils bien affûtés et propres pour accroître la sécurité

et les performances. Suivre les instructions de lubrification

et de changement d’accessoires.

DÉBRANCHER TOUS LES OUTILS. Tous les outils

doivent être débranchés lorsqu’ils ne sont pas en usage

et avant toute opération d’entretien ou de changement

d’accessoire, lame, foret, fers, etc.

ÉVITER LES DÉMARRAGES ACCIDENTELS. S’assurer

que le commutateur est en position d’arrêt avant de

brancher un outil.

UTILISER LES ACCESSOIRES RECOMMANDÉS. Voir

les accessoires recommandés dans le manuel d’utilisation.

L’utilisation d’accessoires inadéquats peut causer des

blessures.

NE JAMAIS MONTER SUR L’OUTIL. Un basculement

de l’outil ou le contact accidentel avec l’accessoire de

coupe peut causer des blessures graves.

VÉRIFIER L’ÉTAT DES PIÈCES. Avant d’utiliser l’outil

de nouveau examiner soigneusement les pièces et

dispositifs de protection qui semblent endommagés afin

de déterminer s’ils fonctionnent correctement et s’ils

remplissent les fonctions prévues. Vérifier l’alignement

des pièces mobiles, s’assurer qu’aucune pièce n’est

bloquée ou cassée, vérifier la fixation de chaque pièce et

s’assurer qu’aucun autre problème ne risque d’affecter le

bon fonctionnement de l’outil. Pour éviter les risques de

blessures, toute protection ou pièce endommagée doit

être correctement réparée ou remplacée dans un centre

de réparations agréé.

UTILISER LA BONNE DIRECTION DE NOURRIT. Nourrir

le travail dans une lame ou un coupeur contre la direction

de rotation de lame ou le coupeur seulement.

2

Page 21

RÈGLES DE SÉCURITÉ GÉNÉRALES

NE JAMAIS LAISSER L’OUTIL EN FONCTIONNEMENT

SANS SURVEILLANCE. COUPER L’ALIMENTATION

ÉLECTRIQUE. PAS L’OUTIL DE FEUILLE JUSQU’A

CE QU’IL VIENT A UN ARRET COMPLET.

PORTER UNE PROTECTION RESPIRATOIRE. Porter

un masque facial ou respiratoire si le travail produit de la

poussière.

PORTER UNE PROTECTION AUDITIVE. Porter une

protection auditive durant les périodes d’utilisation

prolongée.

NE PAS MALTRAITER LE CORDON D’ALIMENTATION.

Ne jamais tirer sur le cordon pour le débrancher de la

prise secteur. Garder le cordon à l’écart de la chaleur, de

l’huile et des objets tranchants.

N’UTILISER QUE DES CORDONS PROLONGATEURS

POUR EXTÉRIEUR. Quand l’outil est dehors utilisé,

l’usage seulement rallonges ont marqué W-UN ou le «

W ». Ces cordes sont évaluées pour l’usage extérieur et

réduisent le risque de décharge électrique.

NE JAMAIS UTILISER CET OUTIL DANS UNE

ATMOSPHÈRE EXPLOSIVE. Les étincelles normalement

produite par le moteur pourraient enflammer les vapeurs.

INSPECTER RÉGULIÈREMENT LES CORDONS DE

L’OUTIL. Faire remplacer tout commutateur défectueux

par un technicien qualifié ou un centre de réparations

agréé. Le fil à gaine verte, avec ou sans traceur jaune est

le fil de terre. Si le cordon doit être réparé ou remplacé,

ne pas connecter le fil de terre de l’outil sur une borne

sous tension. Tout cordon endommagé doit être réparé

ou remplacé immédiatement. Toujours rester conscient

de l’emplacement du cordon et veiller à le tenir à l’écart

de la lame en rotation.

INSPECTER RÉGULIÈREMENT LES CORDONS

PROLONGATEURS et les remplacer s’ils sont

endommagés.

GARDER L’OUTIL SEC, PROPRE ET EXEMPT D’HUILE

OU DE GRAISSE. Toujours utiliser un chiffon propre

pour le nettoyage. Ne jamais utiliser de liquide de freins,

d’essence ou de produits à base de pétrole pour nettoyer

l’outil.

RESTER VIGILANT ET GARDER LE CONTRÔLE. Se

montrer attentif et faire preuve de bon sens. Ne pas utiliser

l’outil en état de fatigue. Ne pas se presser.

NE PAS UTILISER L’OUTIL SI LE COMMUTATEUR

NE PERMET PAS DE LE METTRE EN MARCHE OU

DE L’ARRÊTER.Faire remplacer les commutateurs

défectueux dans un centre de réparations agréé.

NE PAS UTILISER CET OUTIL SOUS L’INFLUENCE DE

L’ALCOOL, DE DROGUES OU DE MÉDICAMENTS.

Utiliser exclusivement des pièces identiques à celles

d’origine POUR LES RÉPARATIONS. L’usage de toute

autre pièce pourrait créer une situation dangereuse ou

endommager l’outil.

UTILISER EXCLUSIVEMENT LES ACCESSOIRES

RECOMMANDÉS dans ce manuel ou ses addendas.

L’emploi de tout accessoire non recommandé peut

présenter un risque de blessure. Les instructions de

sécurité d’utilisation sont fournies avec les accessoires.

RÈGLES DE SÉCURITÉ PARTICULIÈRES

POUR VOTRE PROPRE SURETE, lire ce toupie manuel de

utilisation et le manuel de utilisation avant de fonctionner

le routeur ou l’utilisation de la table de toupie.

TOUJOURS UTILISER EL GARDE DE COUPEUR.

EN UTILISANT LE ROUTEUR SUR LA TABLE DE

TOUPIE, le routeur doit être connecté à la sortie de commutateur de table de routeur.

GARDER DES MAINS LOIN DE LA COUPE DE

SECTEUR. Pas la portée au-dessous de la table ou dans

le chemin de coupe avec vos mains ou vos doigts à tout

moment pendant que l’outil est connecté à une source

de pouvoir.

NE PAS UTILISER LES POSITIONS GAUCHES DE

MAIN.

FERMEMENT LE SERRE-JOINT OU VERROUILLE LA

TABLE DE ROUTEUR A UNE SURFACE DE TRAVAIL

pour que la surface de table de routeur est approximativement la hauteur d’hanche.

TOUJOURS GLISSER LA PIÈCE À TRAVAILLER DANS

LE SENS CONTRAIRE DE LA ROTATION DU COUTEAU.

NE PAS APPROCHER SES DOIGTS DU COUTEAU EN

ROTATION, UTILISER DES GABARITS AU BESOIN.

TOUJOURS MAINTENIR FERMEMENT EN PLACE

LA PIÈCE À TRAVAILLER CONTRE LA TABLE ET LE

GUIDE.

SI LE CORDON D’ALIMENTATION EST ENDOMMAGÉ,

il doit être remplacé uniquement pas le fabricant ou par

un centre de réparation agréé pour éviter tout risque.

CONSERVER CES INSTRUCTIONS. Les consulter

fréquemment et les utiliser pour instruire les autres

utilisateurs éventuels. Si cet outil est prêté, il doit être

accompagné de ces instructions.

3

Page 22

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à

l’utilisation de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER :

AVERTISSEMENT :

ATTENTION :

AVIS :

Certains des symboles ci-dessous peuvent être utilisés sur produit. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser produit plus efficacement et de réduire les risques.

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée,

aura pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourraît entraîner des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité) Indique une information importante

ne concernant pas un risque de blessure comme une situation pouvant

occasionner des dommages matériels.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

Symbole d’alerte de sécurité Indique un risque de blessure potentiel.

Lire le manuel d’utilisation

Pour réduire les risques de blessures, l’utilisateur doit lire et veiller à

bien comprendre le manuel d’utilisation avant d’utiliser ce produit.

Protection oculaire

Avertissement concernant

l’humidité

V Volts Tension

A Ampères Intensité

Hz Hertz Fréquence (cycles par seconde)

min Minutes Temps

Courant alternatif Type de courant

n

o

.../min Par minute Tours, coups, vitesse périphérique, orbites, etc., par minute

Vitesse à vide Vitesse de rotation à vide

Toujours porter une protection oculaire avec écrans latéraux certifiée

conforme à la norme ANSI Z87.1.

Ne pas exposer à la pluie ou l’humidité.

4

Page 23

CARACTÉRISTIQUES ÉLECTRIQUES

CORDONS PROLONGATEURS

Utiliser exclusivement des cordons prolongateurs à 3 fils doté

d’une fiche à prise de terre branchés sur une prise triphasée

compatible avec la fiche de l’produit. Lors de l’utilisation d’un

produit électrique à grande distance d’une prise secteur,

veiller à utiliser un cordon prolongateur d’une capacité

suffisante pour supporter l’appel de courant de l’produit.

Un cordon de capacité insuffisante causerait une baisse

de la tension de ligne, entraînant une perte de puissance

et une surchauffe. Se reporter au tableau ci-dessous pour

déterminer le calibre minimum de fil requis pour un cordon

donné. Utiliser exclusivement des cordons à gaine cylindrique

homologués par Underwriter’s Laboratories (UL).

**Intensité nominale (sur la plaquette signalétique de l’produit)

0-2,0 2,1-3,4 3,5-5,0 5,1-7,0 7,1-12,0 12,1-16,0

Longueur Calibre de fil

du cordon (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Utilisé sur circuit de calibre 12 – 20 A

NOTE : AWG = American Wire Gauge

Pour le travail à l’extérieur, utiliser un cordon prolongateur

spécialement conçu à cet effet. Ce type de cordon porte

l’inscription « W-A » ou « W » sur sa gaine.

Avant d’utiliser un cordon prolongateur, vérifier que ses fils

ne sont ni détachés ni exposés et que son isolation n’est ni

coupée, ni usée.

AVERTISSEMENT :

Maintenir le cordon prolongateur à l’écart de la zone de

travail. Lors du travail avec un cordon électrique, placer le

cordon de manière à ce qu’il ne risque pas de se prendre

dans les pièces de bois, produits et autres obstacles. Ne

pas prendre cette précaution peut entraîner des blessures

graves.

VITESSE ET CÂBLAGE

La vitesse n’est pas constante et elle diminue sous une

charge ou en présence d’une baisse de tension. Le câblage

de l’atelier est aussi important que la puissance nominale

du moteur. Une ligne conçue seulement pour l’éclairage

ne peut pas alimenter correctement le moteur d’un produit

électrique. Un fil électrique d’une capacité suffisante pour

une courte distance ne le sera pas nécessairement pour une

distance plus longue. Une ligne dont la capacité est suffisante

pour un produit électrique ne l’est pas nécessairement pour

deux ou trois.

INSTRUCTIONS DE MISE À LA TERRE

En cas de problème de fonctionnement ou de panne, la

mise à la terre fournit un chemin de résistance au courant

électrique, pour réduire le risque de choc électrique. Cet

produit est équipé d’un cordon électrique avec conducteur et

fiche de mise à la terre. Le cordon doit être branché sur une

prise correctement installée et mise à la terre conformément

à tous les codes et réglementations locaux en vigueur.

Ne pas modifier la fiche fournie. Si elle ne peut pas être insérée

dans la prise secteur, faire installer une prise adéquate par

un électricien qualifié. L’usage d’un cordon prolongateur

incorrect peut présenter des risques de choc électrique. Le

fil à gaine verte, avec ou sans traceur jaune est le fil de terre.

Si le cordon doit être réparé ou remplacé, ne pas connecter

le fil de terre de l’produit sur une borne sous tension.

Consulter un électricien qualifié ou le personnel de service si

les instructions de mise à la terre ne sont pas bien comprises,

ou en cas de doute au sujet de la mise à la terre.

Tout cordon endommagé doit être réparé ou remplacé

immédiatement.

Cet produit est conçu pour être branché sur un circuit

comportant une prise telle que celle montrée à la figure 1.

Sa fiche est dotée d’une broche de terre semblable à celle

représentée.

AVERTISSEMENT :

Vérifier l’état des cordons prolongateurs avant chaque

utilisation. Remplacer immédiatement tout cordon

endommagé. Ne jamais utiliser un produit dont le cordon

d’alimentation est endommagé, car tout contact avec la

partie endommagée pourrait causer un choc électrique

et des blessures graves.

CONNEXION ÉLECTRIQUE

Cet produit doit être branchée uniquement sur une

alimentation 120 V, c.a. (courant résidentiel standard),

60 Hz. Ne pas utiliser cet produit sur une source de courant

continu (c.c.). Une chute de tension importante causerait une

perte de puissance et une surchauffe du moteur. Si l’produit

ne fonctionne pas une fois branché, vérifier l’alimentation

électrique.

BROCHE DE

TERRE

5

PRISE SECTEUR 120 V MISE

À LA TERRE

Fig. 1

Page 24

CARACTÉRISTIQUES

FICHE TECHNIQUE

Dimensions de la table ....406,4 mm x 812,8 mm x 25,4 mm

(16 po x 32 po x 1 po)

Diamètre maximum du fer ...............49,21 mm (1-15/16 po)

Longueur du guide .................................. 711,2 mm (28 po)

Rainure du guide d’onglet .............. 6,35 mm x 19,01 mm x

812,8 mm (1/4 po x 3/4 po x 32 po)

Alimentation nominale..120 V, 60 Hz, c.a. seulement, 15 A

Poids net ....................................................12,7 kg (28 lbs.)

ORIFICE

D’ASPIRATION

DIRECTION

FEED

PLAQUES À OUVERTURE

ENSEMBLE DU

GUIDE

PANNEAU

D’INSERTION

3

2

1

0

1

Inch

COMMUTATEUR

ARTICULATING

ROUTER CUTTER /

BIT GUARD

BOUTON DE

RÉARMENT

CHEVILLE DE

DÉPART

inch

T

P

E

U

S

E

S

R

H

GUIDE

3

2

1

0

1

Inch

GUIDE

D’ONGLETE

CALE-

Fig. 2

VEILLER À BIEN CONNAÎTRE LA TABLE À

TOUPIE

Voir la figure 2.

La sécurité d’utilisation de ce produit exige la compréhension

des informations apposées sur l’outil et contenues dans ce

manuel d’utilisation, ainsi que la connaissance du travail

à exécuter. Avant d’utiliser ce produit, se familiariser avec

toutes ses fonctions et règles de sécurité.

PROTECTEUR

Le protecteur fournit une barrière qui protège l’utilisateur d’un

contact avec le fer. Il est conçu pour rester dans le contact

avec la pièce de fabrication.

CALE-GUIDE

Le cale-guide permet de manipuler la pièce à travailler de

façon sécuritaire dans la zone de coupe et sa hauteur est

ajustable.

ENSEMBLE DU GUIDE

L’offert en sacrifice ensemble du guide fournit une surface

ajustable pour soutenir et diriger le travail. Moulé dans l’assemblée de clôture sont l’attachement de vide.

PANNEAU D’INSERTION

Le panneau d’insertion est compatible avec divers types de

toupies. Il a pré-a entraîné aussi des trous noyé qui peuvent

être utilisés avec une assortiment de toupies.

GUIDE D’ONGLET

Un guide d’onglet est prévu pour le toupillage en onglet et

pour aider à soutenir les pièces larges.

6

Page 25

CARACTÉRISTIQUES

BOUTON DE RÉARMEMENT

Voir la figure 2.

Le commutateur est équipé avec un remettre à l’état initial

le bouton qui protège les composants électroniques de la

boîte de commutateur de table de routeur de la surcharge.

CHEVILLE DE DÉPART

Quand vous ne pouvez pas utiliser le guide pour guider lapièce

parce que celle-ci est trop petite ou d’une formeirrégulière,

utilisez la cheville de départ comme guide et/ou pivoter le

point. Utilisez uniquement des fers avec guide quand une

cheville de départ est utilisée.

PLAQUES À OUVERTURE

Cinq plaques à ouverture sont fournies avec la table à toupie.

La plaque à ouverture fournit une surface stable autour du fer

et empêche les objets de tomber et d’endommager la broche.

ORIFICE D’ASPIRATIONR

Les ports de poussière moulés dans la orifice d’aspiration ou

un 31.75 mm (1-1/4 po) ou 63,5 mm (2-1/2 po) l’attachement

de vide.

COMMUTATEUR MARCHE / ARRÊT

Voir la figure 3.

Ce produit est équipé d’un commutateur avec dispositif de

verrouillage intégré. Ce dispositif est conçu pour empêcher

l’utilisation non autorisée et potentiellement dangereuse par

des enfants ou personnes non compétentes.

POUR METTRE LA TABLE À TOUPIE :

Brancher sur le routeur dans la sortie de boîte de

commutateur sur le rable de routeur et bouche la table

de routeur dans le morceauto du de pilote de et/ou un

120 volt sortie fondé.

La clé étant insérée dans le commutateur, le relever pour

mettre la scie en MARCHE ( I ).

AVERTISSEMENT :

Lorsque l’outil n’est pas en usage, toujours retirer la clé

et la ranger en lieu sûr. En cas de panne secteur, mettre

le commutateur en position D’ARRÊT ( O ) et retirer la

clé. Ceci empêchera un démarrage accidentel lorsque

le courant est rétabli.

AVERTISSEMENT :

TOUJOURS s’assurer que la pièce n’est pas en contact

avec la fers avant de mettre le commutateur de l’outil en

position de marche. Ne pas prendre cette précaution peut

causer le rebond de la pièce en direction de l’opérateur

et d’entraîner des blessures graves.

AVERTISSEMENT :

Pour éviter un démarrage accidentel, TOUJOURS

s’assurer que le commutateur est en position D’ARRÊT

( O ) avant de brancher l’outil.

COMMUTATEUR EN

POSITION DE MARCHE

COMMUTATEUR EN

POSITION D’ARRÊT

NOTE : La table de routeur est équipée avec un remet à

l’état initial le bouton.Voir la figure 2. Si, pour n’importe

quelle raison, la table de routeur n’allumera pas, appuiera

le remettre à l’état initial le bouton et alors remet en marche.

POUR ARRÊTER LA TABLE À TOUPIE :

Abaisser le commutateur en position d’ARRÊT ( O ).

POUR VERROUILLER LA TABLE À TOUPIE :

Abaisser le commutateur.

Retirer la clé du commutateur et la ranger en lieu sûr.

CLÉ DE

COMMUTATEUR

7

COMMUTATEUR EN POSITION

VERROUILLÉE

Fig. 3

Page 26

ASSEMBLAGE

DÉBALLAGE

Ce produit nécessite un assemblage.

Avec précaution, sortir le produit et les accessoires de

la boîte. S’assurer que toutes les pièces figurant sur la

bordereau d’expédition sont incluses.

AVERTISSEMENT :

Ne pas utiliser le produit si, en le déballant, vous

constatez que des éléments figurant dans la bordereau

d’expédition sont déjà assemblés. Certaines pièces

figurant sur cette liste n’ont pas été assemblées par le

fabricant et exigent une installation. Le fait d’utiliser un

produit qui a été assemblé de façon inadéquate peut

entraîner des blessures.

Examiner soigneusement le produit pour s’assurer que

rien n’a été brisé ou endommagé en cours de transport.

Ne pas jeter les matériaux d’emballage avant d’avoir

soigneusement examiné le produit et avoir vérifié qu’il

fonctionne correctement.

Si des pièces manquent ou sont endommagées, appeler

le 1-800-525-2579.

AVERTISSEMENT :

Si des pièces manquent ou sont endommagées, ne pas

utiliser cet outil avant qu’elles aient été remplacées.

L’utilisation sûre de ce produit avec les pièces manquent

ou sont endommagées pourrait entraîner des blessures

graves.

AVERTISSEMENT :

Ne pas essayer de modifier cet outil ou de créer des

accessoires non recommandés pour cet outil. De telles

altérations ou modifications sont considérées comme

un usage abusif et peuvent créer des conditions

dangereuses pouvant entraîner des blessures graves.

AVERTISSEMENT :

Ne pas brancher sur le secteur avant d’avoir terminé

l’assemblage. Le non-respect de cet avertissement

peut causer un démarrage accidentel, entraînant des

blessures graves.

AVERTISSEMENT :

Les protecteur inférieurs bien montés en place avant

d’utiliser la table à toupie. Sinon des blessures graves

pourraients’ensuivre.

8

Page 27

ASSEMBLAGE

3

1

2

3

4

1

0

1

Inch

5

6

8

7

9

10

BORDEREAU D’EXPÉDITION

1. Pieds (4)

2. Cheville de départ

3. Vis de pied (16)

4. Table à toupie

5. Écrou de commutateur (3)

6. Vis de commutateur (3)

7. Commutateur

8. Rondelle de boulon à collet carré (2)

9. Boulon à collet carré (2)

10. Cle en hex (1)

11. Protecteurs sous table (2)

12. Plaque à ouverture (5)

18

23

17

19

22

21

3

2

16

15

20

14

3

FEED

DIRECTION

Inch

2

1

0

1

13

12

11

Fig. 4

13. Vis de la plaque d’insertion de la toupie (5/16-18 x 3/4 po) (3)

14. Vis de la plaque d’insertion de la toupie (10-24 x 5/8 po) (3)

15. Vis de la plaque d’insertion de la toupie (10-32 x 5/8 po) (3)

16. Vis de protecteurs sous table (6)

17. Guide d’onglet

18. Ensemble de guide

19. Bouton de verrouillage du guide (2)

20. Cale-guide

21. Boulon à cale-guide (2)

22. Rondelle de bouton de verrouillage du guide (2)

23. Bouton de cale-guide (2)

24. Manual de utilisation (non illustreé)

9

Page 28

ASSEMBLAGE

ASSEMBLAGE DE LA TABLE À TOUPIE

Pour assembler la table à toupie, il faut fixer la boîte d’interrupteur, les protecteurs sous table, les pieds, l’ensemble toupie/

plaque d’insertion, l’ensemble guide, le cale-guide, la plaque

à gorge et la goupille de départ et installer la jauge à onglets

sur la table à toupie.

FIXER LA BOÎTE D’INTERRUPTEUR

Voir la figure 5.

La boîte d’interrupteur est emballée dans un sac qui contient les vis

et les écrous de la boîte d’interrupteur. Utiliser les vis et les boulons

compris dans le sac pour fixer la boîte d’interrupteur.

Placer la table à toupie à l’envers sur une surface plane.

Tenir en place la boîte d’interrupteur de sorte que les mots ON

et OFF figurant sur l’interrupteur à bascule soient à l’envers.

Aligner les trois trous de la boîte d’interrupteur avec les trois

trous de la face extérieure du rail avant; il s’agit du rail déjà

installé sous le devant de la table à toupie.

Insérer les vis de la boîte d’interrupteur dans les trous de la

boîte d’interrupteur et dans les trous du rail avant.

Installer les écrous au bout des vis de la boîte d’interrupteur.

Serrer les vis en place à l’aide d’un tournevis, serrer les écrous

à l’aide d’une clé de serrage ou d’une clé à douille.

FIXER LES PROTECTEURS SOUS TABLE

Voir la figure 6.

Les protecteurs sous table sont emballés dans un sac qui contient les vis des protecteurs sous table. Utiliser les vis comprises

dans le sac pour fixer les protecteurs sous table.

Placer la table à toupie à l’envers sur une surface plane.

Placer les protecteurs sous table devant et derrière la plaque

d’insertion. Le côté ouvert du protecteur sous table avant

doit faire face à l’arrière de la table à toupie.

Aligner les trois trous des protecteurs sous table avec les

trois trous de la table. Le protecteur sous table avant doit

être vissé au rail avant.

Insérer les vis du protecteur sous table dans les trous et

dans la table.

Serrer les vis à l’aide d’un tournevis.

VIS DE

COMMUTATEUR

PROTECTEURS

SOUS TABLE

PIED DE LA

TABLE

CLE DE

COMMUTATEUR

COMMUTATEUR

VIS DE PROTECTEURS

VIS DE PIED DE LA TABLE

ÉCROU DE

COMMUTATEUR

RAIL AVANT

Fig. 5

SOUS TABLE

Fig. 6

FIXER LES PIEDS DE LA TABLE

Voir la figure 7.

Les pieds de la table sont emballés dans un sac qui contient

les vis des pieds de la table. Utiliser les vis comprises dans le

sac pour fixer les pieds de la table.

Placer la table à toupie à l’envers sur une surface égale et

plane, en plaçant le côté avant près de soi.

Placer chacun des pieds à un coin de la table. Les pieds sur

lesquels des étiquettes d’avertissement sont collés doivent

être fixés à l’avant et ceux qui n’en ont pas doivent être fixés

à l’arrière.

NOTE : Le pied de table sur lequel figure un avertissement

en anglais doit être fixé à côté de la boîte d’interrupteur.

Aligner les quatre trous du pied avec les quatre trous filetés

correspondants dans la table.

Insérer les vis de pied de la table par les trous et dans la

table.

Serrer les vis à l’aide d’un tournevis.

10

PIED DROIT-

ETIQUETTE DE

ESPANGNOL /

FRANÇAIS

COTE AVANT

PIED PARTIE-

ETIQUETTE DEANGLAIS

Fig. 7

Page 29

ASSEMBLAGE

3

AVANT-TROUS POUR RÉGLER LA HAUTEUR

DE COUPE SUR LA TABLE

Voir la figure 8.

Puisque les réglages de la hauteur de coupe sur la table varient

en fonction de chaque toupie, des avant-trous ont été percés

dans la plaque à gorge pour faciliter les réglages sur la table.

Seulement les modèles ont énuméré au dessous dans la clef

sont disponible pour l’usage avec le par la caractéristique

d’ajustement de table.

Retirer la plaque à gorge.

Déterminer le type de toupie à installer et trouver l’avant-

trou correspondant au modèle de toupie. (Se référer à les

abréviations figure 8 signifiant au dessous.)