Page 1

1

MODEL NO. 975r

IMPORTANT MANUAL DO NOT THROW AWAY

OPERATOR’S

MANUAL

975r

Page 2

2

INTRODUCTION

TABLE OF CONTENTS

THANK YOU

Thank you for purchasing this quality product. This modern

outdoor power tool has been designed to provide you with

many hours of useful service. You will find it to be a great

labor-saving device.

This operator's manual provides you with easy-to-understand operating instructions. Read the entire manual and

follow all of the instructions to keep your new outdoor

power tool in top operating condition.

The other manual that came with your outdoor power tool,

the parts manual, contains all of the information that you

need to order parts.

PRODUCT REFERENCES, ILLUSTRATIONS AND SPECIFICATIONS

All information, illustrations and specifications in this manual are based on the latest product information available at

the time of printing. We reserve the right to make changes

at any time without notice.

I. California Emission Regulations ................................3

II. Safety Warnings ......................................................3-5

III. Assembly Instructions ................................................6

A. Adjusting the J-Handle ..........................................6

B. Installing the Shoulder Strap ................................6

IV. Oil and Fuel Information..........................................7-8

V. Starting/Stopping Instructions....................................9

VI. Operating Instructions ........................................10-11

A. Operating Split Boom Coupler ............................10

B. Adjusting the Trimming Line Length ..................11

C. Decorative Trimming ............................................11

D. Edging ..................................................................11

VII. Maintenance and Repair Instructions ................12-21

A. Maintenance Schedule ........................................12

B. Line Installation ..............................................12-14

C. Air Filter Maintenance ..........................................15

D. Carburetor Adjustment ..................................16-17

E. Inspecting/Cleaning the Muffler ..........................17

F. Checking Spark Arrester Screen ..........................18

G. Replacing the Spark Plug ....................................19

H. Checking/Adjusting Valve Clearance ............19-20

I. Cleaning and Storage ..........................................21

VIII. Specifications ..........................................................21

IX. Troubleshooting Chart ..............................................22

X. California Emission Control Warranty Statement ....23

XI. Warranty ..................................................................24

SERVICE INFORMATION

Service on this power equipment within and after

the warranty period can be performed by any

Ryobi Authorized Service Dealer.

Dial 1-800-345-8746 in the United States and

1-800-265-6778 in Canada to obtain the listing of

servicing dealers in your area.

DO NOT RETURN UNIT TO RETAILER.

MAKE SURE THIS MANUAL IS CAREFULLY

READ AND UNDERSTOOD BEFORE STARTING

OR OPERATING THIS EQUIPMENT.

NOTE: PROOF OF PURCHASE WILL BE

REQUIRED FOR WARRANTY

SERVICE.

THIS PRODUCT IS COVERED BY ONE OR MORE OF THE US PATENTS LISTED BELOW:

5,241,932; 5,176,116; 4,779,405; 4,651,422; 4,589,742; 4,505,040; 4,463,498; 4,356,605; 4,342,235;

4,223,441. OTHER PATENTS PENDING.

NOTE: For users on U. S. Forest Land and in the states of California, Maine, Oregon and Washington. All

U.S. Forest Land and the state of California (Public Resources Codes 4442 and 4443), Oregon and

Washington require, by law that certain internal combustion engines operated on forest brush and/or grasscovered areas be equipped with a spark arrester, maintained in effective working order. Check with your

state or local authorities for regulations pertaining to these requirements. Failure to follow these

requirements could subject you to liability or a fine. This unit is factory-equipped with a spark

arrester. The replacement part number for the spark arrester is 180890.

California Proposition 65 Warning:

Page 3

3

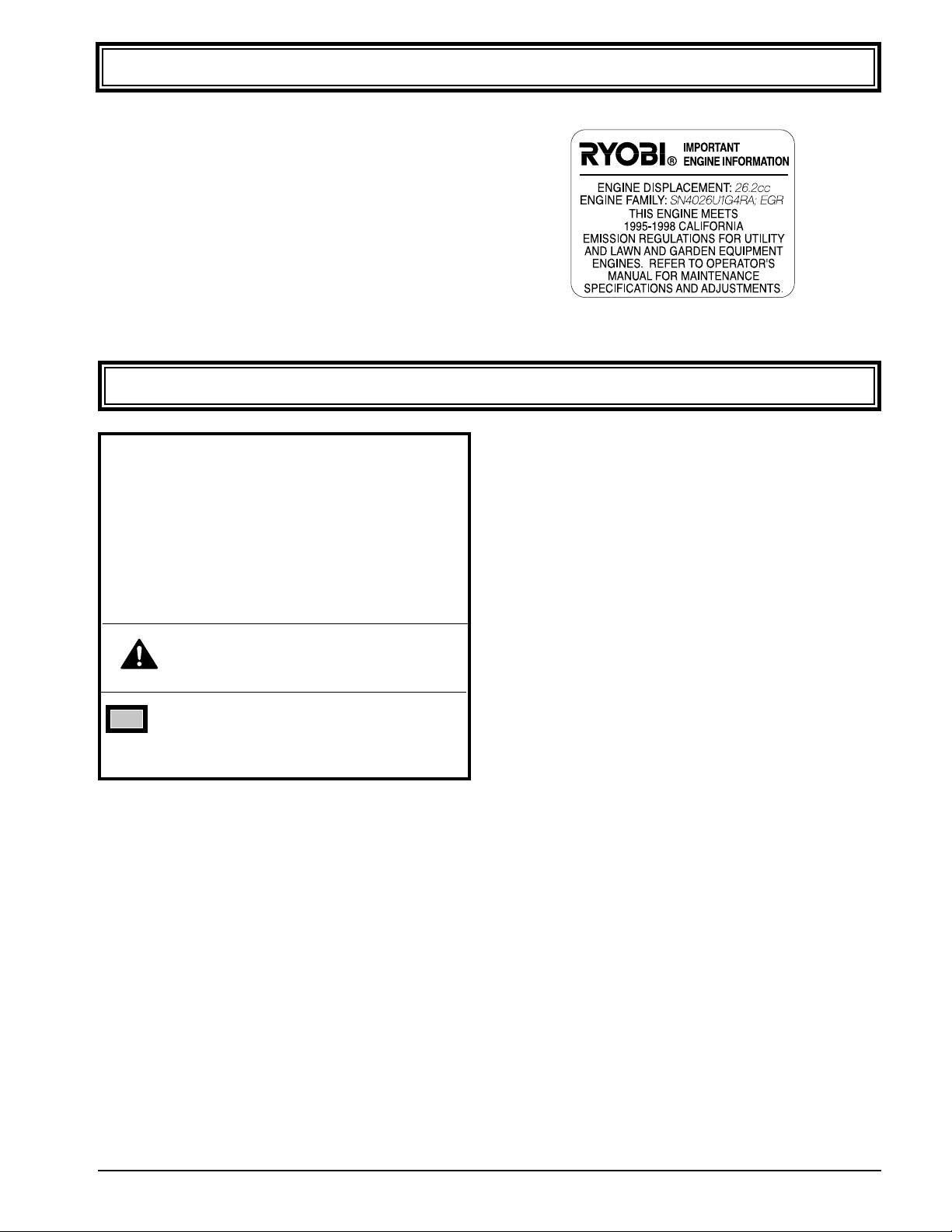

CALIFORNIA EMISSION REGULATIONS

The engine of your lawn and garden care product

meets the 1995-1998 California emissions regulations.

To ensure that your unit continues to meet these

regulations, refer to the following information and

instructions in this operator's manual.

These units are identified by the label on the engine of

your product. A typical identification label is shown.

NOTE: Advises you of information

or instructions vital to the

operation or maintenance

of the equipment.

WARNING: Failure to obey a safety

warning can result in injury

to yourself and others.

THE PURPOSE OF SAFETY SYMBOLS IS TO ATTRACT

YOUR ATTENTION TO POSSIBLE DANGERS. THE

SAFETY SYMBOLS, AND THE EXPLANATIONS WITH

THEM, DESERVE YOUR CAREFUL ATTENTION AND

UNDERSTANDING. THE SAFETY WARNINGS DO NOT

BY THEMSELVES ELIMINATE ANY DANGER. THE

INSTRUCTIONS OR WARNINGS THEY GIVE ARE NOT

SUBSTITUTES FOR PROPER ACCIDENT PREVENTION

MEASURES.

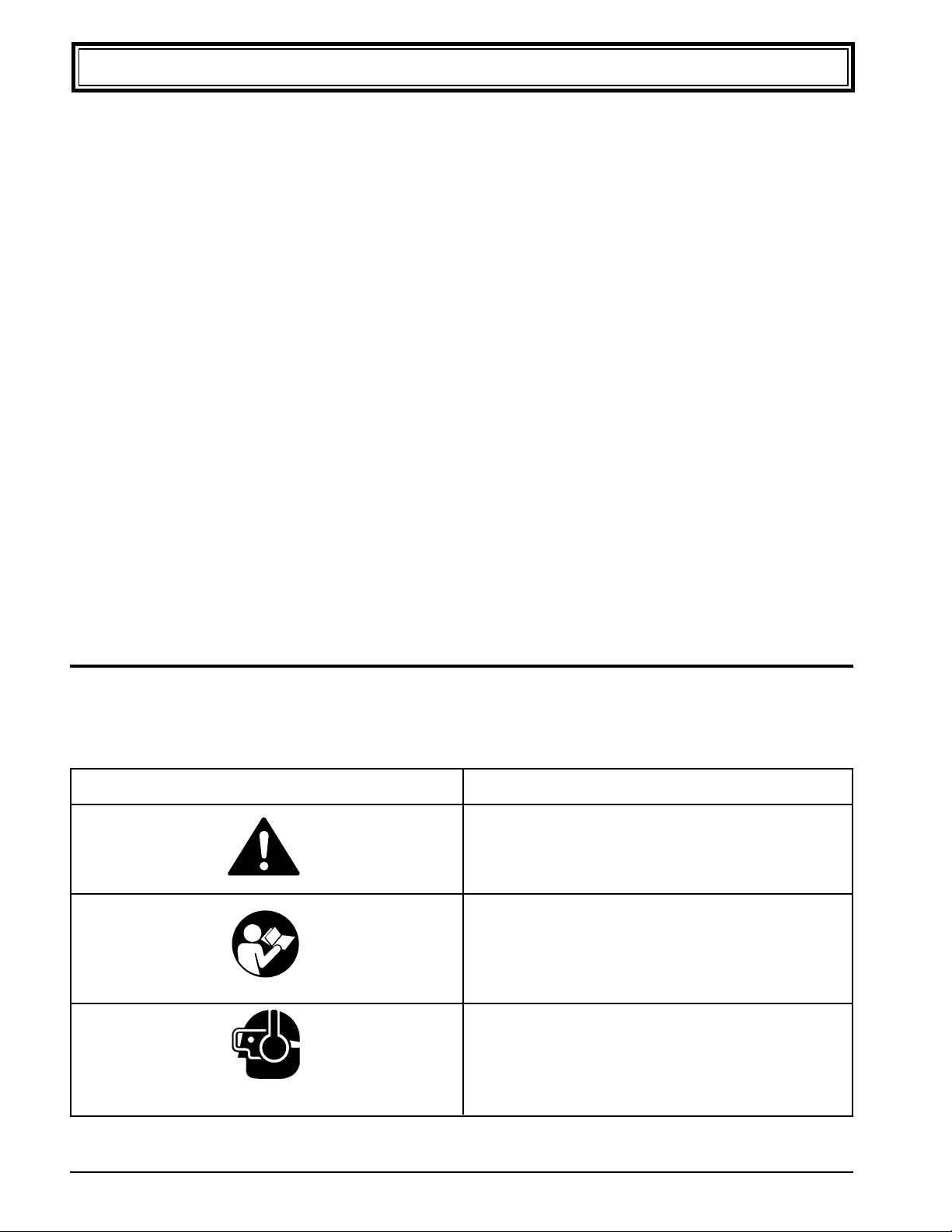

SYMBOL MEANING

SAFETY WARNINGS

FUEL AND PRE-OPERATION AL

• Fuel is extremely flammable and its vapors can

explode if ignited. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the fuel tank. Keep sparks and open flames

away from the area.

• Store fuel only in containers designed and approved

for the storage of such materials.

• Pressure can build up in the fuel tank. Loosen the fuel

tank cap slowly to relieve any pressure in the tank.

• Add fuel in a clean, well-ventilated area. Wipe up any

spilled fuel immediately. If fuel has been spilled, allow

it to dry completely before starting the engine.

• Move the trimmer at least 3 m (10 ft) from the fueling

point before starting the engine.

• Thoroughly inspect the trimmer for loose or damaged

parts before each use. Do not use until adjustments or

repairs are made.

• Avoid accidental starting. Be in the starting position

whenever pulling the starting rope.

• Keep all bystanders, especially children, and pets at

least 10 m (33 ft) away from the area.

• Carefully inspect the areas to be cut. Remove all

debris that could become entangled in the string or

blade. Also remove any objects that could be thrown

during cutting.

• Before starting, make sure the string head is not in

contact with anything.

• Check the oil before each use.

Page 4

4

OPERATIONAL

• Wear safety glasses / goggles at all times when operating this trimmer.

• Dress properly. Do not operate this trimmer when

barefoot or wearing open sandals. Always wear sturdy, rubber-soled footwear. The use of gloves,

ear/hearing protection and long pants are recommended.

• Do not wear loose fitting clothing or articles such as

scarves, strings, chains, ties, etc. because they could

get drawn into the air intake. Also make sure long hair

does not get drawn into the air intake.

• Keep hands, face, and feet away from all moving

parts. Do not attempt to touch or stop the string

when it is rotating.

• Do not touch the muffler or cylinder. These parts get

extremely hot from operation and remain hot for a

short time after the equipment is turned off.

• Always hold the trimmer with both hands when operating. Keep a firm grip on both the front and rear handles or grips.

• Operate this trimmer only in a well-ventilated area outdoors. Carbon monoxide exhaust fumes can be

lethal in a confined area.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Repair any damage before further operation

is attempted. Do not operate the trimmer with loose

or damaged parts.

• Use the right tool. Do not use this trimmer for any job

except that for which it is intended.

• Do not force the tool at a rate faster than it is able to

cut effectively.

• Do not overreach. Keep proper footing and balance at

all times.

• Always remain alert. To prevent injury to yourself and

others, do not operate this trimmer if you are fatigued.

• Do not operate the unit while under the influence of

drugs, alcohol or any medication.

• Do not operate the engine faster than the speed necessary to cut, trim or edge. Do not run the engine

at high speed when not cutting.

• The string guard must be in place at all times while

operating the trimmer.

• Always stop the engine when cutting is delayed or

when walking from one cutting location to another.

• Use only genuine replacement parts when servicing

this trimmer. These parts are available from your

authorized dealer. The use of non-standard parts, or

other accessories or attachments not designed for

this trimmer, could result in serious injury to the user

or damage to the trimmer and void the warranty.

OTHER SAFETY WARNINGS

• Store the trimmer in an appropriate and dry location

to prevent unauthorized use and damage.

SYMBOL SIGNIFICATION

• SAFETY ALERT SYMBOL.

Indicates caution, warning or danger. May be

used in conjunction with other symbols or

pictographs.

• READ OPERATOR'S MANUAL.

Failure to follow operating instructions and safety

precautions in operator's manual can result in

serious injury. Read operator's manual before

starting or operating this unit.

• WEAR EYE AND HEARING PROTECTION.

Warning. Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear

ear and eye protection when operating this unit.

SAFETY WARNINGS (Continued)

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read

the operator's manual for complete safety, assembly, operating and maintenance and repair information.

Page 5

5

SAFETY WARNINGS (Continued)

O

I

SYMBOL

SIGNIFICATION

• FOR SERVICE INFORMATION, CALL:

USA: 1-800-345-8746

CANADA: 1-800-265-6778

• IGNITION / POWER SWITCH.

ON / START / RUN

• IGNITION / POWER SWITCH.

OFF OR STOP

• INDICATES OIL.

Refer to operator's manual for the proper type of

oil.

• UNLEADED FUEL.

Always use clean, fresh unleaded fuel.

• PRIMER BULB.

Push primer bulb, fully and slowly, 5 to 7 times.

• CHOKE CONTROL.

FULL CHOKE position.

• CHOKE CONTROL.

PARTIAL CHOKE position.

• CHOKE CONTROL.

RUN position.

• THROWN OBJECTS AND ROTATING

CUTTER CAN CAUSE SEVERE INJURY.

Warning. Do not operate without guard in place.

Keep away from rotating cutter.

Page 6

6

ASSEMBLY INSTRUCTIONS

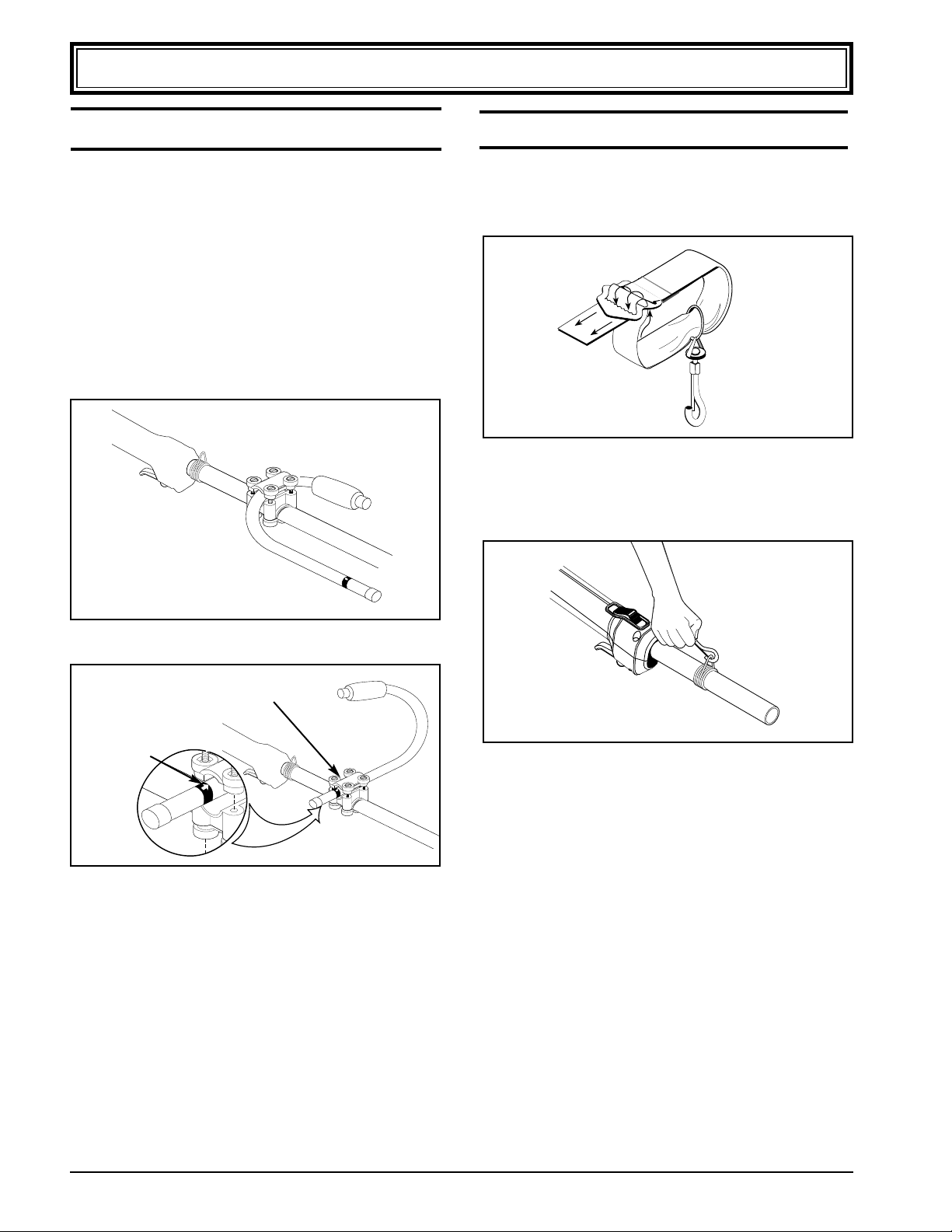

INSTALLING THE SHOULDER STRAP

ADJUSTING THE J-HANDLE

The J-handle is shipped completely assembled on this

model (Fig. 1). Use the following instructions to adjust the

J-handle to the correct operating position.

1. Loosen the four (4) mounting screws on the

J-handle. It is not necessary to remove the screws.

2. Slide the J-handle through the clamp until the arrow /

white line on the decal touches the clamp assembly

(Fig. 2).

3. Position the handle grip as desired (forward and back)

and tighten the mounting screws evenly.

1. Take the end of the shoulder strap without the buckle

and push it through the ring on the snap.

2. Loop the strap through the buckle (Fig. 3).

Fig. 3

3. Snap the shoulder strap onto the wire connector

(Fig. 4). Adjust the length of the strap as desired.

Fig. 4

Fig. 1

Fig. 2

Handle

Position

Decal

Clamp Assembly

Handle Position as Shipped

Page 7

7

OIL & FUEL INFORMATION

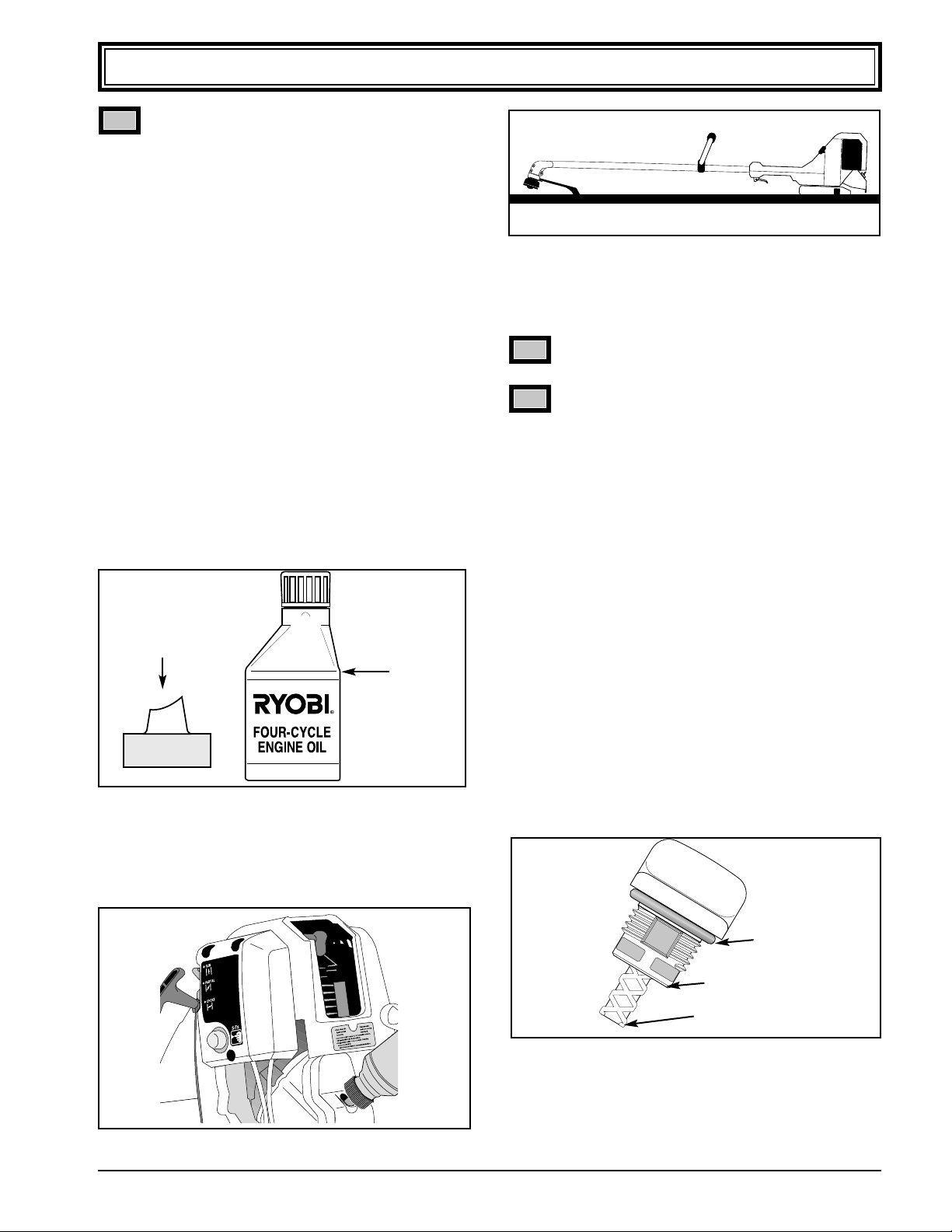

ADDING OIL TO CRANKCASE - INITIAL

USE

Your unit is supplied with one bottle of oil, which contains

100 ml (3.4 fluid oz) of SAE 30 SF, SG, SH oil (Fig. 5).

1. Open the bottle of oil.

2. Install the funnel spout.

Fig. 5

NOTE: BE SURE TO READ THESE

INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO START OR OPERATE

THIS UNIT. Using old or improper oil or

fuel can cause engine damage. This type

of damage will void the engine warranty.

RECOMMENDED OIL TYPE

Using the proper type and weight of oil in the crankcase is

extremely important. Check the oil before each use and

change the oil regularly. Failure to use the correct oil, or

using dirty oil, can cause premature engine wear and failure.

Use high-quality SAE 30 weight oil of API (American

Petroleum Institute) service class SG, SF, SH.

Fig. 6

3. Remove the oil fill plug / dipstick from the crankcase.

Pour the entire bottle of oil into the crankcase (Fig. 6).

Make sure the engine is level (Fig. 7) for when the oil is

poured into the crankcase.

Fig. 7

Fig. 8

NOTE: DO NOT ADD OIL TO THE FUEL.

4. Reinstall oil fill plug / dipstick into the crankcase.

NOTE: Save the bottle and funnel spout for

future use.

CHECKING THE OIL

The importance of checking and maintaining the proper oil

level in the crankcase cannot be overemphasized. Check

oil BEFORE EACH USE as follows:

1. Make sure the engine is stopped, level (Fig. 7) and is

cool so the oil has had time to drain into the

crankcase.

2. To keep dirt, grass clippings, etc. out of the engine,

clean the area around the oil fill plug / dipstick before

removing it.

3. Remove the oil fill plug / dipstick; wipe the oil off.

Reinsert it into the crankcase. Thread the oil fill plug /

dipstick into the crankcase.

4. Remove the oil fill plug / dipstick and check the oil

level. The oil level should be up to the top of the dipstick (Fig. 8).

5. If the level is low, add the oil to the top of the dipstick

(Fig. 8). Always check the level with the dipstick

before adding more oil.

Funnel Spout

100 ml

(3.4 oz)

Level

Full (100 ml/3.4 oz)

O-ring

Add Oil

Page 8

RECOMMENDED FUEL TYPE

WARNING

Fuel is extremely flammable and its vapors can

explode if they are ignited. Always stop the

engine and allow it to cool before filling the fuel

tank. Do not smoke while filling the tank. Keep

sparks and open flames away from the area.

Fill the fuel tank using clean, fresh, unleaded gasoline.

NOTE: Alcohol blended fuel absorbs moisture

(water). As little as 1% moisture in the

fuel can cause fuel to separate and form

acids when stored. If this type of fuel

must be used, use fresh fuel (less than

60 days old).

DEFINITION OF BLENDED FUELS

Today's fuels are often a blend of gasoline and one or

more oxygenates such as ethanol, methanol or MTBE

(ether).

USE OF BLENDED FUELS

If you choose to use a blended fuel or its use is unavoidable, the following precautions are recommended.

1. Always use fresh fuel.

2. Use the special additive STA-BIL® (by Gold Eagle) or

an equivalent.

3. Drain tank and run engine dry before storing the

unit.

USE OF FUEL ADDITIVES

The use of fuel additive such as STA-BIL®Gas Stabilizer

or an equivalent, will inhibit corrosion and minimize the formation of gum deposit. Add 23 ml (0.8 oz) per gallon of

fuel per instructions on container. NEVER add fuel additives directly to the unit's fuel tank. Using a fuel additive

can keep fuel fresh for up to six (6) months.

8

OIL & FUEL INFORMATION (Continued)

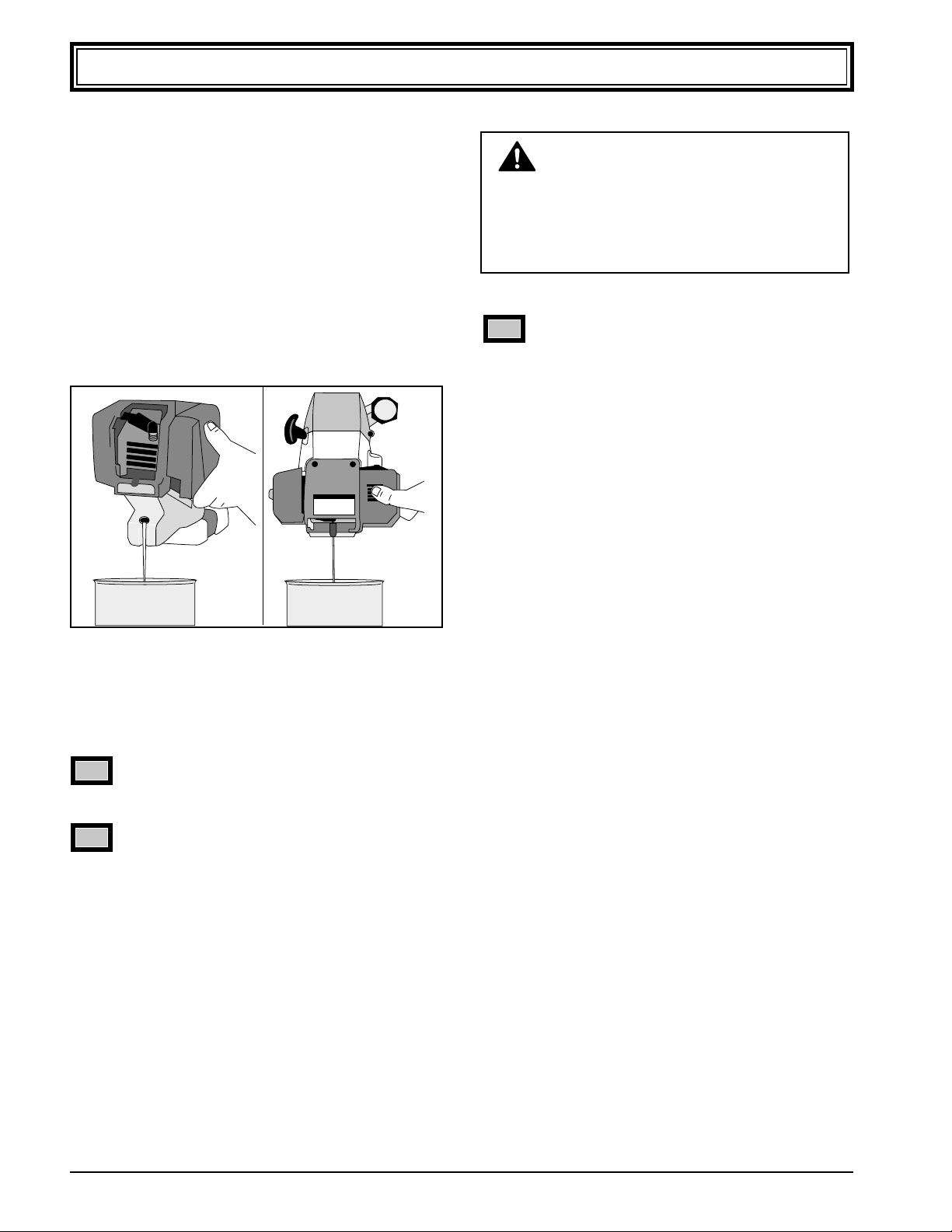

CHANGING THE OIL

For a new engine, change the oil after the first 10 hours of

operation. Thereafter, change the oil after every 25 hours

or before storing for an extended period of time.

Change the oil while the engine is still warm. The oil will

flow freely and carry away more impurities.

Change the oil as follows:

1. Remove the oil fill plug / dipstick.

2. Pour the oil into a container by tipping the trimmer in

a vertical position (Fig. 9). Be sure to allow ample time

for complete drainage. Dispose of oil properly.

NOTE: Make sure the O-ring is in place on the

oil fill plug when checking and changing

the oil.

NOTE: To prevent extensive engine wear or

damage, always maintain the proper oil

level in the crankcase. Never operate the

engine with oil level below the bottom of

the dipstick.

3. Fill the crankcase, with new oil of the proper type, to

the top of the dipstick. Use the bottle saved from the

initial use.

4. Reinstall the oil fill plug / dipstick and tighten securely.

Fig. 9

Page 9

9

1. CHECK THE OIL LEVEL IN THE CRANKCASE, FILL

THE FUEL TANK AND PUT THE IGNITION SWITCH

IN THE "RUN" (I) POSITION. See Figure 11 for the

location of the ignition switch.

2. FULLY PRESS AND RELEASE THE PRIMER BULB

5 TO 7 TIMES. See Fig. 12 for the primer bulb location.

3. PLACE THE CHOKE LEVER IN THE FULL “CHOKE”

POSITION. See Fig. 12.

NOTE: For a warm engine, go directly to Step 5

(place the choke lever directly in the

"PARTIAL" choke position). See Fig. 12.

4. WITH THE UNIT ON THE GROUND, PULL THE

STARTER ROPE QUICKLY UNTIL THE ENGINE

SOUNDS LIKE IT WANTS TO RUN (no more than

5 pulls). See Fig. 13.

5. PLACE THE CHOKE LEVER IN THE “PARTIAL”

POSITION (Fig. 12). PULL THE STARTER ROPE

QUICKLY UNTIL THE ENGINE STARTS (no more

than 5 pulls). See Fig. 13.

6. If the engine does not start, repeat steps 2 to 5.

7. RUN THE ENGINE FOR 30 SECONDS, WITH THE

THROTTLE LEVER FULLY SQUEEZED (Fig. 11), TO

WARM UP. PLACE THE CHOKE LEVER IN THE

“RUN” POSITION (Fig. 12).

NOTE: In colder weather, run the engine for 2 to 3

minutes to warm up.

8. TO STOP THE ENGINE, PUT THE IGNITION SWITCH

IN THE "STOP" (O) POSITION. See Fig. 11.

NOTE: When storing the unit, place the unit flat on

the floor instead of hanging it by the guard

or the cutting head (Fig. 10).

STARTING/STOPPING INSTRUCTIONS

Fig. 12

Fig. 11

Fig. 13

Fig. 10

Throttle Trigger

Ignition Switch

STOP

(O)

RUN

(I)

RUN

Position

CHOKE

LEVER

PARTIAL

CHOKE

Position

FULL

CHOKE

Position

PRIMER

BULB

Throttle

Trigger

Starter

Rope

Page 10

10

OPERATING SPLIT BOOM®COUPLER

Models 925r and 975r are equipped with a Split Boom

®

coupler, which enables optional attachments to be installed

on this unit.

The optional attachments are:

Sweeper/Blower ......................................SB130 or SB720r

Vacuum ......................................................LV130 or LV720r

Edger ........................................................LE130 or LE720r

Cultivator ................................................GC130 or GC720r

Straight Shaft Trimmer ............................SS720r or SS725r

Curved Shaft Trimmer ............................CS720r or CS725r

Tree Pruner................................................................TP720r

Snow Thrower Attachment ......................................ST720r

Removing the Lower (Attachment) Boom

NOTE: To make removing the boom easier, place

the unit on the ground or on a table.

1. Loosen the thumb screws (Fig. 14).

2. Push the release button in (Fig. 14).

3. Pull the lower boom straight out of the coupler

(Fig. 15).

OPERATING INSTRUCTIONS

Fig. 14

Installing the Lower (Attachment) Boom

1. Loosen the thumb screws. This will allow the lower

boom to be inserted into the coupler (Fig. 15).

2. Remove the protective cover or hanger from the lower

(attachment) boom. Push the lower (attachment)

boom into the coupler (Fig. 15).

3. Before locking the release button into the coupler,

rotate the boom 90 degrees; then rotate the lower

boom back 90 degrees. This will ensure the drive

shafts in both the upper and lower booms are

engaged.

4. Locate and lock the release button into the hole in the

coupler (Fig. 14).

5. Check the sight hole to make sure both ends of the

boom are together (Fig. 16). Tighten the thumb screws

before using the unit.

Fig. 15

Fig. 16

Release Button

Coupler

Thumb Screw

Thumb Screw

Lower Boom

Coupler

Upper

Boom

Thumb Screws (2)

Release

Button

Thumb

Screws (2)

Sight Hole

Coupler

Page 11

NOTE: Always keep the trimming line fully

extended. Line release becomes more

difficult as cutting line becomes shorter.

Each time the head is bumped, about 25.4 mm (1 in) of

trimming line is released. A blade in the weed guard will

cut the line to the proper length if excess line is released.

For best results, tap the head on bare ground or hard soil.

11

OPERATING INSTRUCTIONS (Continued)

ADJUSTING THE TRIMMING

LINE LENGTH

WARNING

Wear safety glasses/goggles when operating

this trimmer.

NOTE: Always operate the trimmer in an upright

position and with the string guard

installed.

Your trimmer is equipped with a bump head that allows the

operator to release more trimming line without stopping the

engine. To release additional line, lightly tap the trimming

head on the ground (Fig. 17) while operating the trimmer at

high speed.

Fig. 17

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences, etc., Decorative

trimming is easy because both models are equipped with

a Split Boom®coupler.

Loosen the wing screws on the Split Boom®coupler and

push the release button (see Fig. 14 on page 10). Rotate

the boom to a 30-degree angle and retighten the wing

screws (Fig. 18).

Fig. 18

EDGING

The Split Boom®coupler can be used for edging (Fig. 19).

Loosen the wing screws, rotate the boom to a 90-degree

angle and retighten the wing screws.

NOTE: When edging, twist the boom, not the

engine, to the proper angle.

This model accepts attachments. One of the available

attachments is an edger. See page 10 for the list of other

available attachments.

Page 12

12

FREQUENCY MAINTENANCE REQUIRED REFER TO:

MAINTENANCE SCHEDULE

These required maintenance procedures should be performed at the frequency stated in the table.

They should also be included as part of any seasonal tune-up.

Every

50 Hours

Every

25 Hours

Every

10 Hours

Daily or

Before

Starting

Engine

Check spark plug condition and gap.

Check rocker arm to valve clearance.

Check spark arrester screen.

Change oil.

Change oil after initial use.

Clean and re-oil air filter.

Check oil level.

Fill fuel tank.

Page 19

Page 19-20

Page 18

Pages 7-8

Pages 7-8

Page 15

Pages 7-8

Page 8

MAINTENANCE AND REPAIR INSTRUCTIONS

The Correct Line to Use

WARNING

Always use Ryobi replacement line. Do not

use metal-reinforced line.

It is very important to use the correct size line. Line with a

diameter of 0.080 in (2.03 mm) for Model 975r. The

engine may overheat and fail if you use a larger line.

LINE INSTALLATION FOR

THE SPEED SPOOL

™

The trimming line in the speed spool may be replaced by

two different methods:

• Winding the existing inner reel with new line

• Installing a prewound inner reel

Winding the Existing Inner Reel with New

Line

NOTE: Before installing new trimming line onto

the existing inner reel, remove any old

line from the speed spool by pulling the

line out of the line exiting or locking

holes (see Figs. 20 and 21 for location of

holes).

1. Line up the arrow on the inner reel with the arrow on

the outer spool (Fig. 19).

Arrow

Bump

Knob

Arrow

Outer

Spool

Fig. 19

TOP VIEW OF SPEED SPOOL

Inner

Reel

Page 13

13

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

IMPORTANT!

Always use the correct line length when

installing trimming line on the unit. If longer line

is used than specified in this manual, the line

may not release properly.

Ryobi premeasured replacement line is recommended. See "Replacement Parts" for part

numbers.

4. Pull the line away from the spool until the line is tight

against the inner reel (Fig. 22).

5. Repeat the procedure with the second eyelet and use

the same amount of line as specified in step 2 on

page 13.

6. Wind the inner reel counterclockwise until approxi-

mately four (4) inches of line remains outside of the

eyelets in the outer spool (Fig. 23).

Fig. 22

Fig. 23

7. If winding the line becomes difficult or the line jams,

pull the ends of the line away from the spool and continue winding the inner reel counterclockwise

(Fig. 24).

Fig. 24

Fig. 21

3. Insert the line into the locking hole no more than 1/2

inch (12.7 mm) (Fig. 21). Do not push the line too far

into the inner reel. A small loop is formed when the

line is inserted correctly (Fig. 21).

2. Insert 10 feet (2.5 m) of trimming line straight into one

of the two eyelets and push it up through the line

exiting hole in the inner reel (Fig. 20). Do not bend

the line when inserting it into the eyelet.

Eyelet

Trimming LIne

Line

Exiting

Hole

Fig. 20

Locking

Hole

Loop

Page 14

14

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

Installing a Prewound Reel

1. Insert the ends of the two trimming lines into the eyelets in the outer spool (Fig. 25), then grasp the ends

and pull firmly to release the line from the holding

slots in the outer spool.

2. Hold the inner reel in place and install the spring,

foam seal, and tighten the Bump Knob in the clock-

wise direction. Line installation is now complete.

Fig. 25

Releasing the Inner Reel

If the speed spool does not operate correctly when

bumping the head on the ground, use the following

instructions.

1. Pull the ends of the line firmly away from the spool to

release the inner reel (Fig. 26). If this procedure does

not release the inner reel, follow the "Cleaning the

Speed Spool" instructions below.

Fig. 26

Cleaning the Speed Spool™

If the speed spool becomes difficult to wind or does not

operate correctly when bumping the head on the

ground, use the following instructions.

1. Remove the Bump Knob, foam seal, spring, inner reel,

and trimming line from the outer spool (Fig. 27).

Fig. 27

Inner Reel

Bump Knob/

Foam Seal/Spring

Assembly

Fig. 29

Shaft

3. Clean the shaft and the inner surface of the outer

spool. To clean the shaft underneath the plunger,

press down on the plunger (Fig. 29). Remove any dirt

and/or debris from the shaft.

4. Install the inner reel and line, spring, foam seal, and

Bump Knob into the outer spool (See Fig. 27).

NOTE: The inner reel must be completely dry

before reinstalling it into the outer spool.

Fig. 28

2. Remove any debris or grass from the Bump Knob/

foam seal/spring assembly, and inner reel. Wash the

inner reel with warm soap and water (Fig. 28).

Inner Reel

Page 15

15

NOTE: CLEAN AND RE-OIL THE AIR FILTER

EVERY 10 HOURS OF OPERATION.

Your unit’s air filter is one of the most

important areas to maintain. If it is not

maintained, you will void the warranty.

Before cleaning, make sure the unit is

turned off.

1. Remove the three (3) screws (Torx®T-25) on the carburetor/air filter cover assembly. Remove the air filter

cover (Fig. 30).

NOTE: The choke lever should be in the

"PARTIAL" position to remove and

install the air filter cover.

2. Remove the air filter (Fig. 31).

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

Fig. 31

Fig. 33

Fig. 30

AIR FILTER MAINTENANCE

3. Wash the filter in detergent and water (Fig. 32). Rinse

the filter thoroughly and allow it to dry.

Fig. 32

4. Apply enough clean SAE 30 oil to saturate the filter

(Fig. 33).

6. Reinstall the filter (see Fig. 31), air filter cover and

screws (see Fig. 30). Torque the screws to 2.8-3.4

N•m (25-30 in•lb).

NOTE: If the unit is operated without the

air filter cover installed, you will void the

warranty.

Fig. 34

5. Squeeze the filter to spread the oil (Fig. 34).

Air Filter

Choke Lever

Screws

Screw

Page 16

16

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

4. Start the engine and let it run for three (3) to five (5)

minutes with the throttle trigger fully squeezed.

5. Release the throttle trigger and let the engine idle. If

the engine stops, turn the idle speed screw (Fig. 36)

in (clockwise) 1/8 turn at a time (as required) until

the engine idles.

6. Final High Speed Mixture Needle Adjustment:

a. While squeezing the throttle trigger fully, set the

high speed mixture needle at the optimum setting

(Fig. 36). See “Definition of Optimum Setting” on

page 17.

7. Final Idle Speed Mixture Needle Adjustment: Adjust

the idle speed mixture needle for smoothest engine

idle using the following procedure. Do not squeeze

the throttle trigger when adjusting the idle speed mixture needle.

a. Set the idle speed mixture needle at

the optimum setting (Fig. 36). See

“Definition of Optimum Setting”.

b. Turn the idle speed mixture needle out

(counterclockwise) to the rich side of

optimum.

The engine should idle and accelerate smoothly.

This unit is equipped with a diaphragm-type carburetor

that has been carefully calibrated at the factory. In most

cases, no further adjustment will be required.

NOTE: To meet the 1995 California emission

regulations, the carburetor has

adjustment needle limiter caps to

restrict the amount of adjustment.

The condition of the air filter is important to the operation

of the trimmer. A dirty air filter will restrict the air flow,

which upsets the fuel-air mixture in the carburetor. The

resulting symptoms are often mistaken for an out-ofadjustment carburetor. Therefore, check the condition of

the air filter before adjusting the carburetor. Refer to

Air Filter Maintenance.

If the following conditions are experienced, it may be necessary to adjust the carburetor:

• The engine will not idle

• The engine hesitates or stalls on acceleration

• The loss of engine power that is not corrected by

cleaning the air filter, muffler, spark arrester screen or

adjusting the valve clearance

• The engine operates in an erratic or fuel rich condition

The carburetor has three basic adjustments: the idle

speed, idle speed mixture and high speed mixture.

NOTE: The string guard and line spool must be

installed and the cutting line extended

to its full cutting length when making

carburetor adjustments.

Adjusting the Carburetor

1. Clean the air filter if it is dirty. Refer to Air Filter

Maintenance.

2. Make the initial settings with the engine stopped.

These initial settings should allow you to start and

warm up the trimmer before making the final adjustments.

Initial Idle Speed Setting: Back the idle speed screw

(Fig. 35) out (counterclockwise) until it does not

contact the carburetor throttle lever. Then turn the

screw in (clockwise) until it just begins to move the

throttle lever; then continue turning 2 full turns.

3. Initial High Speed Mixture and Idle Speed Mixture

Settings: Turn both the high speed and idle speed

mixture needles halfway between the allowable

movement of the limiter caps.

CARBURETOR ADJUSTMENT

Fig. 35

Throttle

Lever

Idle Speed

Screw

High Speed

Mixture Needle

Idle Speed

Mixture Needle

Page 17

NOTE: If the carburetor adjustments do not

help the unit to run properly, contact

your authorized service dealer.

NOTE: If the limiter caps are removed at any

time, your unit will no longer meet the

1995 California emission regulations and

you will void the warranty.

17

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

2. Remove the muffler and muffler gasket. Discard the

old gasket (Fig. 38).

CARBURETOR ADJUSTMENT

(Continued)

INSPECTING/CLEANING THE MUFFLER

The muffler should be removed every 25 hours of operation to inspect for excessive carbon build-up. Excessive

deposits around the exhaust ports or exhaust holes will

cause poor engine performance.

Use the following procedure to remove, inspect, clean and

reinstall the muffler.

Removing Muffler

1. Remove the three (3) muffler mounting bolts from the

cylinder (Fig. 37).

8. Final Idle Speed Adjustment: Adjust the idle speed

by turning the idle speed screw in (clockwise) or out

(counterclockwise) until the cutting head does not

rotate. Do not squeeze the throttle trigger when

adjusting the idle speed screw.

Definition of Optimum Setting for Idle Speed

Mixture and High Speed Mixture

Adjustments

Always set the idle speed mixture needle and high speed

mixture needle at the optimum setting. To find the optimum setting, use the following instructions.

1. Turn the adjusting needle out (counterclockwise)

from the preliminary setting until the engine speed

decreases (rich). Note the position of the needle.

2. Turn the adjusting needle in (clockwise). The engine

speed may increase, then it will decrease as the needle is turned in (lean). Note the position of the needle.

3. Set the adjusting needle midway between the rich

and lean settings, which is the highest engine speed

(Fig. 36).

Fig. 38

Fig. 37

Fig. 36

Muffler Mounting

Bolt

Muffler Mounting

Bolt

Muffler

Muffler Gasket

Rich

Lean

Adjust to

Midpoint

Page 18

18

CHECKING SPARK ARRESTER SCREEN

This unit is equipped with a spark arrester screen. Every

50 hours of operation, check the spark arrester screen

for debris and / or deposits.

Check the spark arrester screen as follows:

1. Remove the screw (Fig. 39).

2. Remove the cover (Fig. 39).

3. Push the spark arrester screen out of the cover.

WARNING

Make sure the muffler is cool before

checking the spark arrester screen to

prevent injury.

Muffler Reassembly

1. Install a new muffler gasket and place the muffler baffle in place (Fig. 40).

2. Install the muffler with the three (3) mounting bolts.

Install the lower bolt first to ease the installation of the

top two (2) bolts (Fig. 41).

NOTE: The 5 mm nut must be held in the slot

next to the spark plug before installing

the top rear muffler bolt.

NOTE: Be careful not to crossthread the muffler

mounting bolts.

Torque the muffler mounting bolts to 40-45 in•lb

(4.5-5.0 N•m).

Fig. 40

Fig. 41

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

4. Inspect the spark arrester screen.

If the screen is clean, reinstall the screen, cover and

screw. If the screen is plugged, replace it.

5. Torque the screw to 1.7-2.2 N•m (15-20 in•lb).

Fig. 39

Cover

Screw

Spark Arrester

Screen

Muffler Mounting

Bolt

Muffler Mounting

Bolt

Muffler

Muffler Gasket

Page 19

19

REPLACING THE SPARK PLUG

Use a Champion RDZ19H spark plug or equivalent.

Correct air gap is 0.635 mm (0.025 in). Remove plug after

every 50 hours of operation and check its condition.

1. Stop the engine and pull the wire off of the spark

plug.

2. Clean around the spark plug and remove it from the

cylinder head.

NOTE: Replace a cracked, fouled or dirty spark

plug. Do not sand blast, scrape or clean

electrodes because the engine could be

damaged by grit entering the cylinder.

3. Set the air gap at 0.635 mm (.025 in) using a wire

feeler gauge (Fig. 42). Install a correctly gapped spark

plug into the cylinder head. Torque to 11.3-12.3 N•m

(100-110 in•lb).

Fig. 42

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

CHECKING / ADJUSTING VALVE TO

ROCKER ARM CLEARANCE

Every 50 hours of operation, remove the rocker arm

cover and check the valve to rocker arm clearance, using

a flat feeler gauge.

NOTE: The engine must be cold when checking

or adjusting the clearance.

Check / adjust the clearance as follows:

1. Remove the four (4) screws from the engine cover

(Figs. 43 and 44).

2. Remove the engine cover.

Fig. 44

Fig. 43

.025 in

(0.635 mm)

Screw

Screws

Page 20

20

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

Fig. 45

4. Position the crankshaft so the piston is at the top of

the compression stroke (the rocker arms are free and

loose).

5. Measure the clearance between the valve stems and

rocker arms, using a flat feeler gauge (Fig. 46).

Fig. 46

The recommended valve to rocker arm clearance for both

the intake and exhaust is 0.076 mm-.0152 mm (.003-.006

in).

6. If the clearance is not within specification, adjust as follows:

a. Turn the adjusting nut (Fig. 47), using an 8 mm

(5/16 in) wrench or nut driver.

To increase the rocker arm to valve clearance,

turn the adjusting nut counterclockwise.

To decrease the rocker arm to valve clearance,

turn the adjusting nut clockwise.

b. Recheck the clearance with a flat feeler gauge

and readjust as necessary (see Fig. 46).

7. Reinstall the rocker arm cover using a new gasket.

Torque the rocker arm cover screw to 2.2-3.4 N•m

(20-30 in•lb) (see Fig. 45).

CHECKING / ADJUSTING VALVE TO

ROCKER ARM CLEARANCE (Continued)

3. Remove the rocker arm cover and gasket, using a T-

25 Torx® screwdriver (Fig. 45).

Fig. 47

8. Reinstall the engine cover and screws (see Figs. 43

and 44 on page 19).

Torque the top screws to 1.1-1.3 N•m (10-12 in•lb).

Torque the front screw to 1.1-1.7 N•m (10-15 in•lb).

Torque the rear screw with washer to 2.8-3.4 N•m

(25-30 in•lb).

Flat Feeler Gauge

Valve

Rocker Arm

Adjusting Nuts

Page 21

21

MAINTENANCE AND REPAIR

INSTRUCTIONS (Continued)

WARNING

Always turn off your trimmer before you clean

or perform any maintenance on it.

Cleaning

Use a small brush to clean off the outside of the trimmer.

Do not use strong detergents on plastic housing or handle.

They can be damaged by household cleaners that contain

aromatic oils such as pine and lemon, and by solvents

such as kerosene. Wipe off any moisture with a soft cloth.

Storage

If the trimmer will be stored for an extended period of time,

use the following storage procedure.

1. Drain all fuel from the fuel tank. Do not use fuel that

has been stored for more than 60 days.

2. Start the engine and allow it to run until it stalls. This

ensures that all fuel has been drained from the carburetor.

3. Drain the oil from the crankcase and add fresh oil. Pull

the starter rope a few times to lubricate the engine.

4. Thoroughly clean the unit and inspect for any loose or

damaged parts. Repair or replace damaged parts and

tighten loose screws, nuts or bolts.

The unit is now ready for storage.

5. Store the trimmer in a dry, well-ventilated area, and

place the unit flat on the floor (Fig. 48).

CLEANING AND STORAGE

SPECIFICATIONS

ENGINE

Engine Type ..........................................Air-Cooled, 4-Cycle

Displacement ............................................................26.2 cc

Bore ............................................................32 mm (1.26 in)

Clutch Type ........................................................Centrifugal

Stroke ......................................................32.6 mm (1.28 in)

Operating RPM......................................................7500 rpm

Ignition Type ................................Electronic / with governor

Ignition Switch ..................................................Slide Switch

Spark Plug ............................................Champion RDZ19H

Spark Plug Gap ....................................0.635 mm (0.025 in)

Fuel Tank Capacity ........................................450 ml (16 oz)

Oil Capacity ....................................................100 ml (3 oz)

DRIVE SHAFT & CUTTING HEAD

Drive Shaft ....................................................................Steel

Drive Shaft Housing......................Steel Tube, Split Boom®

Operating Weight......................................7.14 kg (15.8 lbs)

Throttle Control ........................................Finger-Tip Trigger

Shoulder Strap ........................................................Optional

Line Spool Diameter ......................................76.2 mm (3 in)

Trimming Line Diameter..........................2.03 mm (0.080 in)

Cutting Path Diameter ..................................406 mm (16 in)

COLD TORQUE SPECIFICATIONS

Spark Plug ..........................11.3-12.3 N•m (100-110 in•lb)

Rocker Arm Cover Screw ............2.2-3.4 N•m (20-30 in•lb)

Engine Cover Screws (Top)..........1.1-1.3 N•m (10-12 in•lb)

Engine Cover Screw (Front) ........1.1-1.7 N•m (10-15 in•lb)

Engine Cover Screw (Rear)..........2.8-3.4 N•m (25-30 in•lb)

Air Filter Cover Screws ................2.8-3.4 N•m (25-30 in•lb)

Spark Arrester Screen Screw. ....1.7-2.2 N•m (15-20 in•lb)

Fig. 48

Page 22

22

TROUBLESHOOTING

PROBLEM CAUSE ACTION

Engine Is Difficult to Ignition switch is “STOP (O)" Turn switch to “RUN (I)”

Start or Will Not Start

Primer bulb wasn’t pushed enough Press primer bulb fully and slowly 5-7 times

Engine is not choked Use starting procedure, USING

"FULL" CHOKE" (Page 9)

Empty fuel tank Fill fuel tank

Engine flooded Use starting procedure, USING

"PARTIAL" CHOKE (Page 9)

Valve clearance is out of Use adjust valve to rocker arm

adjustment clearance procedure (Pages 19 and 20)

Plugged spark arrester screen Clean or replace spark arrester screen (Page 18)

Spark plug fouled Clean spark plug and regap or replace

Engine Will Not Idle Air filter is plugged Clean and re-oil air filter or replace (Page 15)

Carburetor misadjusted Adjust carburetor (Pages 16-17)

Engine Will Not Accelerate Carburetor misadjusted Adjust carburetor (Pages 16-17)

Engine Lacks Power or Stalls Dirty air filter Clean and re-oil air filter or replace (Page 15)

When Cutting

Valve clearance is out of Use adjust valve to rocker arm

adjustment clearance procedure (Pages 19-20)

Dirty spark arrestor screen Clean or replace screen

Carburetor misadjusted Adjust carburetor (Pages 16-17)

Not enough fuel in fuel tank Fill fuel tank

Cutting Head Will Not Advance Cutting head out of line Refill with new cutting line (Pages 13-14)

Line

Inner reel bound up Replace inner reel (Pages 13-14)

Cutting head dirty Clean inner reel and outer spool (Pages 13-14)

Indexing teeth worn or burred Replace inner reel and outer spool

(Pages 13-14)

Line welded Disassemble cutting head, remove the welded

section and rewind the line

Line twisted when refilled Disassemble cutting head and rewind reel

Not enough line is exposed Push the Bump Knob and pull out the line until

a minimum of 102 mm (4 in) is outside of the

cutting head

Starter Rope Is Difficult to Pull Oil accumulated in combustion Remove the spark plug

or Engine Locks chamber

Unit operated with low or no oil Drain the oil from the spark plug hole

Pull the starter rope several times to remove

any excess oil from the cylinder

Clean the spark plug and wipe off excess oil

with a dry cloth

Reinstall the spark plug

Check oil before starting

If further assistance is required, contact your local authorized service dealer or call 1-800-345-8746.

Page 23

23

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Ryobi Outdoor Products (ROP), are pleased to

explain the emission control system warranty on your 1995 and later lawn and garden

equipment engine. In California, new lawn and garden equipment engines must be

designed, built and equipped to meet the State's stringent anti-smog standards. ROP

must warrant the emission control system on your lawn and garden equipment engine for

the periods of time listed below provided there has been no abuse, neglect or improper

maintenance of your lawn and garden equipment engine.

Your emission control system may include parts such as the carburetor or fuel injection

system, the ignition system, and catalytic converter. Also included may be hoses, belts,

connectors and other emission-related assemblies.

Where a warrantable condition exists, ROP will repair your lawn and garden equipment

engine at no cost to you including diagnosis, parts and labor.

The 1995 and later utility and lawn and garden equipment engines are warranted for two

years. If any emission-related part on your engine is defective, the part will be repaired or

replaced by ROP.

OWNER'S WARRANTY RESPONSIBILITIES:

• As the lawn and garden equipment engine owner, you are responsible for the performance of the required maintenance listed in your operator's manual. ROP recommends

that you retain all receipts covering maintenance on your lawn and garden equipment

engine, but ROP cannot deny warranty solely for the lack of receipts or for your failure

to ensure the performance of all scheduled maintenance.

• As the lawn and garden equipment engine owner, you should however be aware that

ROP may deny you warranty coverage if your lawn and garden equipment engine

or a part has failed due to abuse, neglect, improper maintenance or unapproved

modifications.

• You are responsible for presenting your lawn and garden equipment engine to an Ryobi

Authorized Service Center as soon as a problem exists. The warranty repairs should be

completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should

call 1-800-345-8746.

MANUFACTURER'S WARRANTY COVERAGE:

• The warranty period begins on the date the engine or equipment is delivered to the

retail purchaser.

• The manufacturer warrants to the initial owner and each subsequent purchaser, that the

engine is free from defects in material and workmanship which cause the failure of a

warranted part for a period of two years.

• Repair or replacement of warranted part will be performed at no charge to the owner at

an Authorized Ryobi Service Center. For the nearest location, please contact Ryobi at:

1-800-345-8746.

• Any warranted part which is not scheduled for replacement, as required maintenance

which is scheduled only for regular inspection to the effect of "Repair or replace as necessary" is warranted for the warranty period. Any warranted part which is scheduled for

replacement as required maintenance will be warranted for the period of time up to the

first scheduled replacement point for that part.

• The owner will not be charged for diagnostic labor which leads to the determination that

a warranted part is defective, if the diagnostic work is performed at an Authorized Ryobi

Service Center.

• The manufacturer is liable for damages to other engine components caused by the failure of a warranted part still under warranty.

• Failures caused by abuse, neglect or improper maintenance are not covered

under warranty.

• The use of add-on or modified parts can be grounds for disallowing a warranty claim.

The manufacturer is not liable to cover failures or warranted parts caused by the use of

add-on or modified parts.

• In order to file a claim, go to your nearest Authorized Ryobi Service Center. Warranty

services or repairs will be provided at all Authorized Ryobi Service Centers.

• Any manufacturer approved replacement part may be used in the performance of any

warranty maintenance or repair of emission related parts and will be provided without

charge to the owner. Any replacement part that is equivalent in performance or durability may be used in non-warranty maintenance or repair and will not reduce the warranty

obligations of the manufacturer.

• The following components are included in the emission related warranty of the engine,

air filter, carburetor, primer, fuel lines, fuel pick up/fuel filter, ignition module, spark plug

and muffler.

Page 24

24

assuming any obligation to modify any product previously manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED IN DURATION TO THE TWO (2) YEAR WARRANTY PERIOD OR NINETY (90) DAYS FOR PRODUCTS USED FOR ANY COMMERCIAL PURPOSE. ACCORDINGLY, ANY SUCH IMPLIED WARRANTIES INCLUDING MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR OTHERWISE, ARE DISCLAIMED IN

THEIR ENTIRETY AFTER THE EXPIRATION OF THE APPROPRIATE TWO-YEAR OR NINETY DAY WARRANTY PERIOD. RYOBI’S OBLIGATION UNDER THIS WARRANTY, IS STRICTLY AND EXCLUSIVELY LIMITED TO THE REPAIR OR REPLACEMENT OF DEFECTIVE

PARTS, AND ROP DOES NOT ASSUME OR AUTHORIZE ANYONE TO ASSUME FOR THEM

ANY OTHER OBLIGATION. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG

AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

RYOBI ASSUMES NO RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL OR OTHER

DAMAGES INCLUDING, BUT NOT LIMITED TO EXPENSE OF RETURNING THE RYOBI

PRODUCT TO AN AUTHORIZED SERVICE DEALER AND EXPENSE OF DELIVERING IT

BACK TO THE OWNER, MECHANIC’S TRAVEL TIME, TELEPHONE OR TELEGRAM

CHARGES, RENTAL OF A LIKE PRODUCT DURING THE TIME WARRANTY SERVICE IS

BEING PERFORMED, TRAVEL, LOSS OR DAMAGE TO PERSONAL PROPERTY, LOSS OF

REVENUE, LOSS OF USE OF THE PRODUCT, LOSS OF TIME, OR INCONVENIENCE.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT

APPLY TO YOU.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

This warranty applies to all RYOBI Products manufactured by RYOBI and sold in the United

States and Canada.

To locate your nearest service dealer dial 1-800-345-8746 in the United States or

1-800-265-6778 in Canada.

Limited Two-Year Warranty

RYOBI OUTDOOR PRODUCTS warrants each new RYOBI Product for two (2) years according to the following terms.

This warranty extends to the original retail purchaser only and commences on the date of

original retail purchase.

Any part of the RYOBI Product manufactured or supplied by RYOBI and found in the reasonable judgement of RYOBI to be defective in material or workmanship will be repaired or

replaced by an authorized RYOBI service dealer without charge for parts and labor.

The RYOBI Product including any defective part must be returned to an authorized service

dealer within the warranty period. The expense of delivering the RYOBI Product to the dealer for warranty work and the expense of returning it back to the owner after repair or replacement will be paid for by the owner. RYOBI’s responsibility in respect to claims is limited to

making the required repairs or replacements and no claim of breach of warranty shall be

cause for cancellation or rescission of the contract of sale of any RYOBI Product. Proof of

purchase will be required by the dealer to substantiate any warranty claim. All warranty work

must be performed by an authorized RYOBI service dealer.

This warranty is limited to ninety (90) days from the date of original retail purchase for any

RYOBI Product that is used for rental or commercial purposes, or any other income-producing purpose.

This warranty does not cover any RYOBI Product that has been subject to misuse, neglect,

negligence, or accident, or that has been operated in any way contrary to the operating instructions as specified in the RYOBI Operator’s Manual. This warranty does not apply to any

damage to the RYOBI Product that is the result of improper maintenance or to any RYOBI

Product that has been altered or modified so as to adversely affect the products operation,

performance or durability or that has been altered or modified so as to change its intended

use. The warranty does not extend to repairs made necessary by normal wear or by the use

of parts or accessories which are either incompatible with the RYOBI Product or adversely

affect its operation, performance or durability.

In addition, this warranty does not cover:

A. Tune-ups - Spark Plugs, Carburetor Adjustments, Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting Line, Inner Reels, Starter Pulley,

Starter Ropes, Drive Belts

RYOBI reserves the right to change or improve the design of any RYOBI Product without

RYOBI OUTDOOR PRODUCTS

550 N. 54th Street

Chandler, AZ 85226 U.S.A.

RYOBI CANADA INC.

275 Industrial Rd

Cambridge, Ontario NIR 6K2 CANADA

Loading...

Loading...