SPECIFICATIONS :

Motor I

nput................................. 900 watt

No Load Speed ........................ 12,000 rpm

Adjustable Height ..................... 5 - 35 mm

Adjustable Angle .......................

0

o

- 90

o

Blade Size ................................ 100 x 22 x 4 mm

Biscuit Size ............................... #0, #10, #20

Net Weight ................................ 2.65 kg

SAVE THIS MANUAL FOR FUTURE REFERENCE.

DOUBLE

INSULATED

Pay close attention to the Rules for Safe Operation, Warnings and Cautions.

If you use your Biscuit Joiner properly and only for what it is intended, you will enjoy years

of safe, reliable service.

Thank You again for buying Ryobi tools.

THANK YOU FOR BUYING A RYOBI BISCUIT JOINER

N197

OWNER'S OPERATING MANUAL

900 WATT BISCUIT JOINER

MODEL EBJ900K

CAUTION: Carefully read through this entire owner's manual before using your

Biscuit Joiner

Your new Biscuit Joner has been engineered and manufactured to Ryobi's high standard for

dependability, ease of operation and operator safety. Properly cared for, it will give you years of

rugged, trouble free performance.

The operation of any tool can result

in foreign objects being thrown

into your eyes, which can result

in severe eye damage . Befo re

beginning power tool operatio n,

alw ay s wear safe ty goggles or

safety glasses with side shields and a full face shield

when needed. We recommend Wide Vision Safety Mask

for use over eyeglasses or standard safety glasses with

side shields.

The purpose of safety rules is to attract your attention to

possible dangers. The safety symbols and the explanations

with them, require your careful attention and understanding.

The safety warnings do not by themselves eliminate any

danger. The ins truction or warnings they give are not

substitutes for proper accident prevention measures.

RULES FOR SAFE OPERATION

SAFETY ALERT SYMBOL. Indicates caution

or warning. May be used in conjunction with

other symbols or pictures.

WARNING: Failure to obey a safety warning

can result in ser ious injury to yourself or to

others. Always follow the safety precauti ons

to reduce the risk of re, electric shock and

personal injury.

WARNING: Do not attempt to operate this tool

until you have read thoroughly and understood

completely, safety rules, etc. contained in this

manual. Failure to comply can result in accidents

involving re, electric shock or serious personal

injury. Save owners manual and review frequently

for continuing safe operation and instructing

others who may use this tool.

9. DRESS PROPERLY. Do not wear loos e clot hing or

jewellery. They can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended when

working outdoors. Also wear protective hair covering to

contain long hair.

10. A

LWAYS WE AR SA F ET Y GLAS SES . Eve r yd a y

eyeglasses have only impact resistant lenses, they are

not safety glasses.

11. PROTECT YOUR LUNGS. Wear a dust mask if operation

is dusty.

12. P

ROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

13. D

ON'T OVERREACH. Keep proper footing and balance at

all times. Do not use tool on a ladder or unstable support.

Secure tools when working at elevated levels.

14. MAINT

AIN TOOLS WITH CARE. Keep tools sharp and

clean for better and safer performance. Follow instructions

for lubricating and changing accessories.

15. REMOVE

ADJUSTING KEYS AND WRENCHES. Form a

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

16. NE

VER USE IN AN EXPLOSIVE ATMOSPHERE. Normal

sparking of the motor could ignite fumes.

17. KEEP

HANDLES DRY, CLEAN AND FREE FROM OIL

AND GREASE. Always use a clean cloth when cleaning.

Nev er use brak e flu ids, gas ol ine, pet ro leum based

products, or any strong solvents to clean your tool.

18. ST

AY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate tool

when you are tired. Do not rush operation of tool.

19. C

HECK DAMAGED PARTS. Before further use of the

tool, a guard or any other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect

its operation. A guard or any other part that is damaged

should be properly repaired or replaced by an authorised

service centre.

20. D

O NOT USE TOOL IF SWITCH DOES NOT TURN IT ON

AND OFF. Have defective switches replaced by authorised

service centre.

21. D

O NO T OPER ATE TH I S TOO L WHI LE UN D ER

THE INFLU ENC E OF DRUG S, ALCO HOL OR AN Y

MEDICATION.

22. T

HE APP L IA N CE IS NO T INTE NDE D FOR US E

BY YOU NG OR I NFI RM PE RS O NS WI TH O UT

SU PE RV IS ION . YOU NG CHIL DR EN SHOU LD BE

SUPERVISED TO ENSURE THAT THEY DO NOT PLAY

WITH THE APPLIANCE.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Due to continued product

renement policy, product features

and specications can and will

change without notice. Check

current features and specications

with your retailer.

1. KNOW YOUR POWER TOOL. Read owner s manual

carefully. Learn its applications and limitations as well as

the specic potential hazards related to this tool.

2. G

UA RD AG AIN ST ELE CT R IC A L SHO CK B y

PRE VEN TING BODY CONTACT WITH GRO UND ED

SUR FACE S. For exam ple , pipes, radiato rs, rang es,

refrigerator enclosures.

3. K

EEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

4. A

VOID DANGEROUS ENVIRONMENT. Don't use power

tools in damp or wet locations or expose to rain. Keep work

area well lit.

5. KEEP

CHILDREN AND VISITORS AWAY. Visitors should

wear safety glasses and be kept a safe distance from work

area. Do not let visitors contact tool or extension cord.

6. ST

ORE IDLE TOOLS. When not in use, tools should be

stored in a dry and high or locked-up place, out of reach of

children.

7. DON'T

FORCE TOOL. It will do the job better and safer at

the rate at which it was designed.

8. USE

RIGHT TOOL. Don't force small tool or attachment to

do the job of a heavy duty tool. Don't use tool for purpose

not intended.

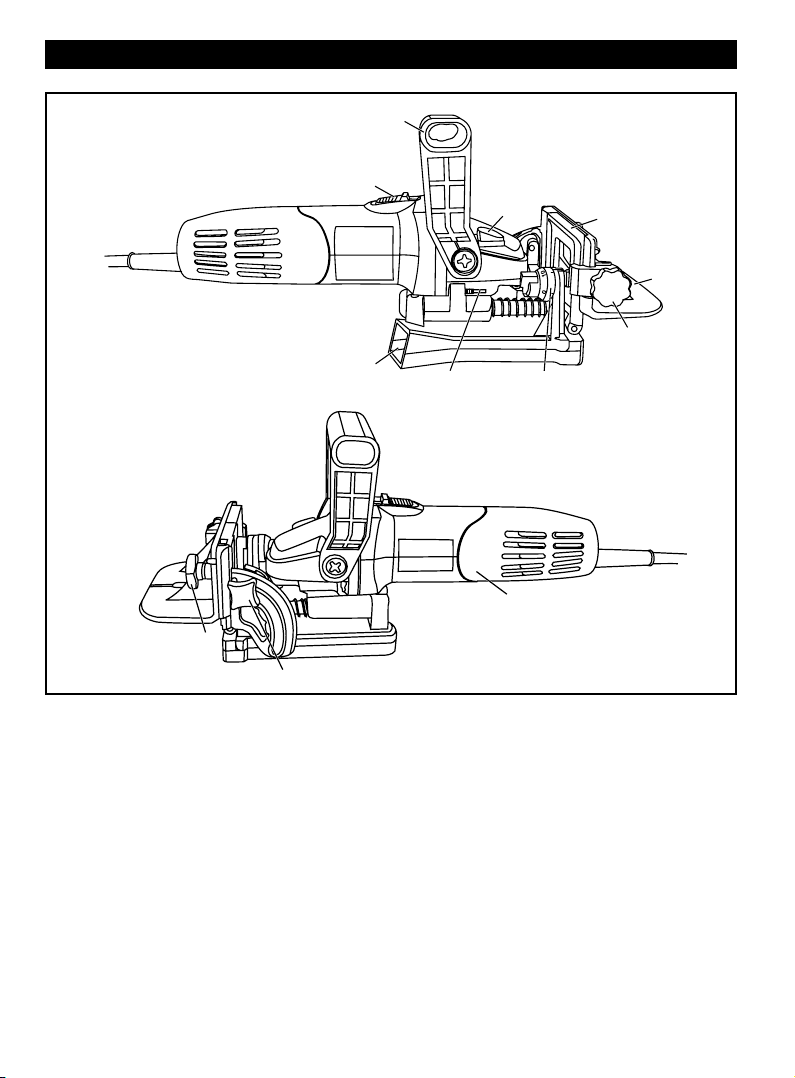

Page 1

9

4

3

5

6

1

8

7

2

FEATURES

Page 2

7. Depth Adjustment Rod

8. Arbor Lock

9. Dust Port

10. Height Adjustment Knob

11. Angle Lock Knob

12. Motor Housing

12

11

10

1. Power Switch

2. Handle

3. Fixed Fence

4. Adjustable Fence

5. Height Lock Knob

6. Depth Selector

The adjustable fence will cut joints at angles from 0 to 90 at

a xed cut height of 9mm (5/16") (the center of a 25.4mm

board). To utilize the adjustable fence (4), remove the xed

fence by loosening the height lock knob and rotating the

height adjustment knob until the xed fence comes clear

of the top of the joiner fence. Loosen the angle lock knob

(11) and move the adjustable fence to the desired angle

and re-tighten the knob. When using the adjustable fence

for 90 degree cuts. it is recommended that you verify the

angle of cut with a measuring tool such as a combination

square or other device. Angle cuts of other degrees should

also be vered with additional measuring tools.

Plunge Depth Adjustment (Fig. 3)

The depth of cut can be set to match the dimensions of the

particular size biscuit you use. The numbers on the depth

selector (6) coincide with the three most common sizes

of biscuits, 0-10-20. The letter "M" stands for maximum

depth capacity of the tool (18 mm).

To select a depth, align the appropriate number with the

mark on the tool's housing. Rotate the depth adjustment

dial to the desired position and it "clicks" into place.

Use your bi scuit joine r only for the purposes listed

below:

Cutting and jointing of timber

Edge jointin g long boards of ei ther natural wood or

manufactured sheeting

APPLICATIONS

Page 3

The Biscuit Jointer is designed for the cutting and jointing

of timber. It provides an accurate, effective and convenient

alternative to the other means of jointing (such as doweling)

and can be particularly useful for edge jointing long boards

of either natural wood or manufactured sheeting.

The 100mm (4") TCT blade is plunged into the wood

to the required depth, which is pre-set depending on

the biscuit to be used. Commonly availa ble bi scui ts

are #20 (12 mm wide), #10 (10 mm wide) and #0 (8

mm wide). Glue is applied and the biscuit inserted into

the semicircular slot that is left by the blade. As the glue

sets, it expands the biscuit, resulting in an extremely

strong joint. The adjustable fence allows the height and

angle of the blade to be positioned to suit different joint

requirements. The depth of cut can be dialed up on the

pre-set control dial, depending on the biscuit to be used.

As with dowels, two biscuits can be used, one above the

other, for extra strength.

FEATURES

Before making any adjustments, unplug the tool.

Fence Adjustments (Fig. 1~2)

The joiner comes with two fence options. The joiner comes

with the xed fence (3) attached. This allows cuts at 90

degrees to a cut height of a maximum of 35mm (1-3/8").

To adjust the cut height. loosen the height lock knob (5)

and rotate the height adjustment knob (10) to achieve the

desired cut height. Tighten the height lock knob rmly using

nger pressure only.

ADJUSTMENTS

ADJUSTMENTS

Fig. 2

Fig. 1

Fig. 3

Page 4

Making a Normal Biscuit Cut (Fig. 6~7)

Position your work pieces together and draw a reference

mark at 90

o

to the center point of each proposed joint

location. Space the joints about 4 inches apart.

Separate your work material and clamp each piece securely

to a stable work bench or work table.

Set the biscuit depth selector (6) to correspond with the size

of biscuit you are using. Generally #20 biscuits suit most

applications. If you are using stock that is 16mm thick or

less, you will need smaller biscuits.

Adjust the height of the fence as required and if using the

xed fence rmly tighten height lock knob (5) using nger

pressure only. If using the adjustable fence rmly tighten

angle lock knob (11).

Place one hand on the handle (2) and the other hand on

the motor housing (12).

Place the cutting guide at the center point of each slot in

turn and press the fence against the edge of the work piece

(see gure 6). Make sure the jointer fence is ush to both

sides of your work surface.

Switch on the power switch and push the motor housing

towards the work material. Once the cut is made pull the

motor housing back and allow the return spring to retract the

blade from the slot. Turn the power switch off. Repeat the

procedure until all slots are cut in your work piece.

Cut the slots in the matching pi ece of work material,

again lining up the center point of each slot and to make

the cuts.

Once all the cuts are complete dry t your biscuits into

your joints and test t your materials to ensure proper

alignment.

Remove the biscuits and insert glue into the slots using a

nozzle applicator or thin wood scrap. It is also helpful to

apply a small amount of glue to the biscuits themselves

before inserting them into the slot.

Place the biscuits in position and clamp your work materials

together until the joint line becomes invisible. Keep your

work materials clamped until the biscuits swell and the

glue sets.

It is possible that thick pieces of timber may require two biscuits

at each location, one at a height of about 1/3 the thickness of

the wood, and the other at about 2/3 the tickness.

NOTE: Unlike other saws and drills, mastering the biscuit joiner

does take some practice. Remember that the ultimate goal is

to achieve a parallel set of cuts in your work surface. If you

nd yourself making uneven cuts, you are probably working

too fast. Make sure of these points:

When the tool powers on it might vibrate out of position.

Prior to making a cut make sure the center of the tool is

aligned with the center of your cut mak.

Make sure the height lock knob is rmly tightened.

Go slow - visually make sure you have the joiner lined up

with your cut mark and most importantly that the fence is

ush with both the top and side edge or your work material

prior to making the cut. Once these are accomplished then

make the cut. Patience and practice are the keys to creating

perfect joints.

OPERATION

ADJUSTMENTS

Fine Depth Adjustment (Fig. 4)

All biscuits are manufactured to slightly different sizes, so

you might need to adjust the depth of cut on the tool. The

depth adjustment rod (7) can be rotated to increase or

decrease the depth of cut.

Biscuit jointers can be used for making various types of strong,

accurate joints in pieces of timber or wood sheeting.

To cut the biscuit slot the body of the jointer is moved toward

the material after alignment, by utilizing the various features of

the Biscuit Joiner you can create a wide range of different types

of joints. Always make a reference line to line up the machine

with the center of the material to be plunged to ensure accurate

biscuit placement (Figure. 5 - Please note in the picture the

center of the adjustable fence is omitted in order to better

explain the joining process).

OPERATION

Crescentshaped slot

Layout line

Fig. 5

Fig. 4

MAINTENANCE

Replacing the blade

Pull out the power plug.

Remove the xed fence and raise the adjustable fence to

the o degree position.

Turn the machine over and unscrew the two screws in the

base plate. Pivot the base plate open.(see Fig. 8)

Now, with the arbor lock (8) in the top of the gearbox housing

depressed, rotate the blade by hand until the blade locks.

Loosen the blade ange anti-clockwise using the pin wrench

supplied.(see Fig. 9)

Remove the outer blade ange.

Remove the blade leaving the inner ange in place.

Mount the new blade, insert the outer blade ange and

fasten.

Important: The cutting bevel of the teeth (i.e. the direction

of rotation of the saw blade) has to conform to the direction

of the arrow marked on the housing.

Make sure the blade lock is released.

Important: After replacing the blade, make sure the blade

runs freely by turning the saw head by hand.

Close the base and re-install the two screws.

Before using the machine again, check that the safety

devices are in good working order.

Plug the machine into a main socket outlet and run the

machine without actually cutting any work material. This is

to make sure the blade is spinning freely.

Fig. 6

OPERATION

Page 5

Fig. 8

Fig. 7

Fig. 9

Dust Extraction (Fig. 10)

You can use the dust bag provided or with the aid of the

adaptor accessory, connect the tool to a vacuum system.

The plastic dust extraction assembly ts in the dust port (9)

on the joiner. You can then attach a vacuum hose or the

supplied dust bag, to the adaptor.

Please note, when the bag becomes full, the dust will backup into the adaptor and the dust port. To clean them, turn off

and unplug the tool and remove the packed dust.

Maintenance

Do not allow brake uid, gasoline, and other petroleum

base products come in contact with the plastic parts of the

joiner. They contain chemicals that can damage, weaken

or destroy the housing of the tool and thus compromising

the integrity of the double insulation.

Keep the machine's air vents unclogged and clean at all

times. Remove dust and dirt regularly from the machine.

Cleaning is best done with compressed air or a rag. Relubricate all exposed moving parts at regular intervals.

Fig. 10

MAINTENANCE

Page 6

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

GUARANTEE

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Contact during normal business hours.

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Contact during normal business hours.

Subject to the guarantee condition below, this Ryobi tool

(hereinafter called “the product”) is guaranteed by Ryobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of original purchase covering

both parts and labour. Under the terms of this

guarantee, the repair or replacement of any part shall

be the opinion of the Company or its authorised agent.

Should service become necessary during the warranty

period, the owner should contact the RYOBI HELPLINE

1300 361 505 or contact the retailer from whom the

product was purchased.

In order to obtain guarantee service, the owner must

present the sales docket and Guarantee Certificate

to confirm date of purchase. This product is sold by the

dealer or agent as principal and the dealer has no

authority from the Company to give any additional

guarantee on the Company’s behalf except as herein

contained or herein referred to.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in the opinion of the Company) and such

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or used

for a purpose for which it was not designed or is not

suited and no repairs, alterations or modifications

have been attempted by other than an Authorised

Service Agent. This guarantee will not apply if the tool is

damaged by accident or if repairs arise from normal

wear and tear.

The Company accepts no additional liability pursuant to

this guarantee for the costs of travelling or

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included in

this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller in

certain circumstances. Nothing herein shall have the effect

of excluding, restricting or modifying any condition,

guarantee, right or liability imposed, to the extent only

that such exclusion, restriction or modification

would render any term herein void.

BRISBANE : All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquiries Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville,Vic. 3178

Tel : (03) 9764 8656

HOBART: All enquiries Tel : 1300 361 505

ADELAIDE: All enquiries Tel : 1300 361 505

PERTH: 33-35 Sorbonne Cres. Canning Vale, W.A. 6155

Address Of Dealer

Present This Form With Your Purchase Docket When Guarantee Service Is Required.

Tel: (02) 9792 9800 - Fax: 1800 807 993 - www.ryobi.com.au

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - www.ryobi.co.nz

Tel : (08) 9455 7775

This Guarantee Form Should Be Retained By The Customer At All Times

For your record and to assist in establishing date of purchase (necessary for in-guarantee service)

please keep your purchase docket and this form completed with the following particulars.

Date Model No Serial No

Loading...

Loading...