DOUBLE

INSULATED

CAUTION: Carefully read through this entire owner’s manual before using your

grinder.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

Your new grinder has been engineered and manufactured to Ryobi’s high standard for dependability,

ease of operation and operator safety. Properly cared for, it will give you years of rugged, trouble free

performance.

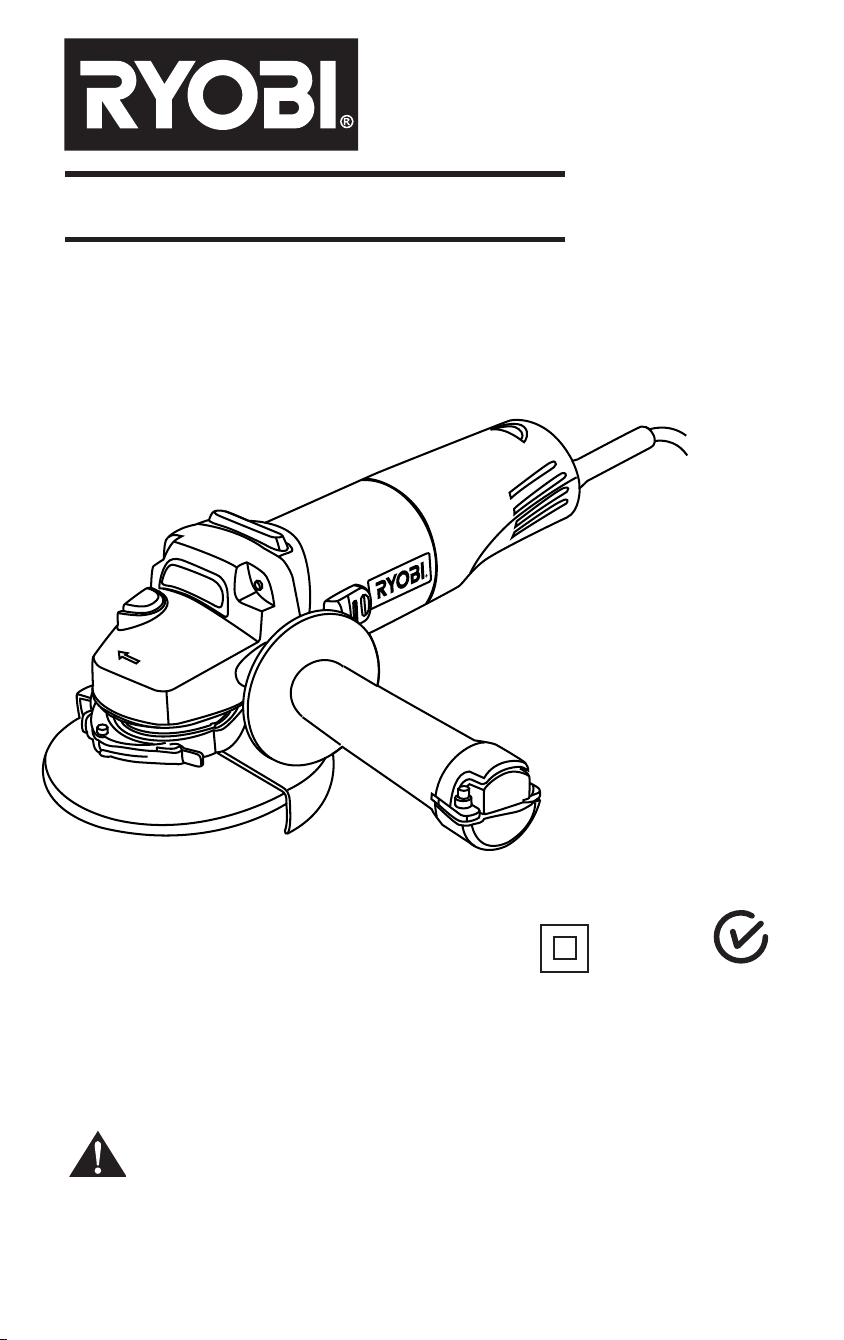

THANK YOU FOR BUYING A RYOBI ANGLE GRINDER

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions.

If you use your grinder properly and only for what it is intended, you will enjoy years of safe, reliable

service.

Thank You again for buying Ryobi tools.

EAG95100 / EAG8012C

ANGLE GRINDER

OWNER'S OPERATING MANUAL

N197

RULES FOR SAFE OPERATION

The purpose of safety rules is to attract your attention to possible

dangers. The safety symbols and the explanations with them,

require your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instruction or warnings they give are not substitutes for proper

accident prevention measures.

SAFETY ALERT SYMBOL. Indicates caution or

warning. May be used in conjunction with other

symbols or pictures.

WARNING: Failure to obey a safety warning can

result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the

risk of fire, electric shock and personal injury.

WARNING: Do not attempt to operate this tool until

you have read thoroughly and understood

completely, safety rules, etc. contained in this

manual. Failure to comply can result in accidents

involving fire, electric shock or serious personal

injury. Save owners manual and review frequently

for continuing safe operation and instructing others

who may use this tool.

The operation of any tool can result in

foreign objects being thrown into your

eyes, which can result in severe eye

damage. Before beginning power tool

operation, always wear safety goggles

a full face shield when needed. We recommend Wide Vision

Safety Mask for use over eyeglasses or standard safety

glasses with side shields.

1. KNOW YOUR POWER TOOL. Read owners manual carefully.

Learn its applications and limitations as well as the specific

potential hazards related to this tool.

2. GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING

BODY CONTACT WITH GROUNDED SURFACES. For

example, pipes, radiators, ranges, refrigerator enclosures.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

4. AVOID DANGEROUS ENVIRONMENT . Don't use power tools

in damp or wet locations or expose to rain. Keep work area

well lit.

5. KEEP CHILDREN AND VISITORS AWAY. Visitors should

wear safety glasses and be kept a safe distance from work

area. Do not let visitors contact tool or extension cord.

6. STORE IDLE TOOLS. When not in use, tools should be stored

in a dry and high or locked-up place, out of reach of children.

7. DON'T FORCE TOOL. It will do the job better and safer at

the rate at which it was designed.

8. USE RIGHT TOOL. Don't force small tool or attachment to

do the job of a heavy duty tool. Don't use tool for purpose not

intended.

9. DRESS PROPERLY. Do not wear loose clothing or jewellery.

They can be caught in moving parts. Rubber gloves and nonskid footwear are recommended when working outdoors. Also

wear protective hair covering to contain long hair.

or safety glasses with side shields and

10.ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses

have only impact resistant lenses, they are not safety glasses.

11. PROTECT YOUR LUNGS. Wear a dust mask if operation is

dusty.

12.PROTECT YOUR HEARING. Wear hearing protection during

extended periods of operation.

13.DON'T OVERREACH. Keep proper footing and balance at

all times. Do not use tool on a ladder or unstable support.

Secure tools when working at elevated levels.

14.MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean

for better and safer performance. Follow instructions for

lubricating and changing accessories.

15.REMOVE ADJUSTING KEYS AND WRENCHES. Form a

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

16.NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal

sparking of the motor could ignite fumes.

17.KEEP HANDLES DRY , CLEAN AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum based products, or any

strong solvents to clean your tool.

18.STAY ALERT AND EXERCISE CONTROL. Watch what you

are doing and use common sense. Do not operate tool when

you are tired. Do not rush operation of tool.

19.CHECK DAMAGED PARTS. Before further use of the tool,

a guard or any other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation. A guard or

any other part that is damaged should be properly repaired

or replaced by an authorised service centre.

20.DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON

AND OFF. Have defective switches replaced by authorised

service centre.

21.DO NOT OPERATE THIS TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL OR ANY

MEDICATION.

22.THE APPLIANCE IS NOT INTENDED FOR USE BY YOUNG

OR INFIRM PERSONS WITHOUT SUPERVISION. YOUNG

CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT

THEY DO NOT PLAY WITH THE APPLIANCE.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Due to continued product

refinement policy, product features

and specifications can and will

change without notice. Check

current features and specifications

with your retailer.

5

12

4

3

1

2

Fig. 2

Fig. 4

Fig. 3 b

9

Fig. 1

Fig. 3 a

Fig. 3 c

2

2

11

11

Fig. 5

2

DESCRIPTION

1. Grinding wheel

2.Tool

- less wheel guard

3.Aux

iliary handle

4. Spindle lock button

5. Switch

6.Inner disc flange

7. Outer clamp nut

8. Spindle shaft

9. Wrench

10. Diamond blade (optional)

Wheel guard lock lever

11.

12.

PowerLight

TM

INSTRUCTIONS FOR SAFE HANDLING

Make sure that the tool is only connected to the voltage marked on

the name plate.

Never use the tool if its cover or any bolts are m

bolts have been r

parts in good working order.

Always secure tools when working in elevated positions.

Never touch the blade, grinding wheel or other moving parts

during use.

Never start a tool when its rotating component is in contact with the

work piece.

Neve r lay a too l dow n be fore its m oving p arts hav e come to a

complete stop.

CCESSORIES : The use of a

A

those recommended in this manual might present a hazard.

REP LACEM ENT P ARTS : W hen s

replacement parts.

Do not use wheels having a maximum permissible speed below

12100 RPM.

emoved, replace them prior to u se. Maintain all

ccessories or attachments other than

issing. If the cover or

erv icing use o nly i dentical

ANGLE GRINDER SAFETY PRECAUTIONS

Check that the speed marked on the grindi ng wheel is equal to or

greater than the rated speed of the tool.

Ensure that the d

with the tool and that the wheel fits the spindle.

Grinding wheels must be stored in a dry place.

Grindingwheels must not beused forany o

Grinding wheels must be stored and h

with the manufacturer’s instruction.

nspect the g

I

racked. Chips or cracks can cause the wheelsto shatter, resulting

or c

in possible serious injury.

Ensure that the wheel is fitted in accordance with this manual.

Ensure that the g

before u se and run the tool at n

osition. Stop immediately if there is considerable vibration or if

safe p

other defects are detected. If this condition occurs, check the tool to

determine the cause.

Do not use s

hole grinding wheels.

Check that the work piece is properly supported.

Use only g

Ensure that sparks r

not hit people, or ignite flammable substances.

1 Always use protective safety glasses and ear protectors.

Use other personal protective equipment such as gloves, apron and

helmet when necessary.

Neverplacethetoolonthefloororothers

Grinding wheels continue to rotate after the tool is switched off.

Never touch the wheel or place it on the floor or other s

it is rotating.

The flange and

Donotremovethesoftpaperinthecentr

the paper has been p

rubber between grinding wheel and flange.)

Use the tool only for a

water or use the tool as a fixed tool.

Grip the tool securely with both hands while operating.

imensions of the g rinding whee l are comp atible

perationother than grinding.

andled with carein accordance

rinding wheel before use to ensure that it is not chipped

rinding wheel is correctly mounted and tightened

eparate reducing bushings or adapters to adapt lar ge

rinding wheels approved by authorized service centre

esulting from use do not create a hazard e.g. do

outer clamp nut must have same outer diameter.

o-load s peed for 30 secon ds in a

urfaceswhileitisrunning.

urfaces while

reviously removed, insert some soft paper or

pproved applications. Never use coolants or

eofthegrindingwheel.(If

SPECIFICATIONS

Grinding wheel 100 mm (4”)

Voltage* 240 V

Input 900 W

Spindle

No Load speed 11000 min

Disc bore size 16 mm 22.2 mm

Net weight 2.34 kg 2.4 kg

* Be sure to checkthe nameplate onthe product,because thevoltage

is subject to change depending on the area in which the product

is to be used.

EAG95100

thread M10 x 1.5

-1

EAG8012C

125 mm (5")

240 V

W

800

M14 x 2

11000 min

-1

STANDARD ACCESSORIES

Aux. handle, Wrench

rindi ng whee l is included i n the s tandard accesso ries fo r some

A g

count ries.

APPLICATIONS

(Use only for the purposes listed below.)

Grinding

Cutting - for Diamond blade only (optional).

NOISE BUILD-UP

Noise (sound pres sure level) in the workplace can exceed 85 dB (A). In

this case, soundinsulation and hearingprotection measuresmust be taken

by the operator.

AUXILIARY HANDLE

The auxiliary side handle on this angle grinder houses the wheel lock nut

wrench. To remove the wheel lock nut wrench from the auxiliary handle, pull

it out by the two lugs on the wrench. When finished with the wrench, slide it

back in to the auxiliary handle with the lugs facing out.

SWITCH (Fig.2)

This tool is started and stopped by sliding and releasing the switch (5).

For the convenience of continuous operation, slide the switch along and it

will be locked.

To release the lock, press the rear end of the switch

WARNING!

To ensure safety and reliability, all repairs should be performed by

anAUTHORIZEDSERVICEC

ORGANIZATION.

Attach the inner disc flange (6), the diamond blade/flat wheels (10) and

the outer clamp nut (7) upside down, the raised part of the flange does

not face to the spindle shaft (8).

Be sure the inner disc flange is properly seated on the spindle shaft.

Depress the spindle lock button (4) located on the right side of gear case.

Using the wrench (9) provided, tighten the outer clamp nut in a clockwise

direction.

ENTRE orotherQUALIFIEDSERVICE

MOUNTING THE GRINDING WHEEL BLADE (Fig.3b & 3c)

Attach the inner disc flange(6) and the wheel on the spindle(8) before

fitting the outer clamp nut. Ensure that the disc(1) is correctly seated over

the boss on the inner disc

Depress the spindle lock button (4) located on the right side of gear case.

Using the wrench (9) provided, tighten the outer clamp nut in a clockwise

direction.

WARNING!

Check carefully whether or not there are cracks in the wheel.

Replace a cracked wheel immediately.

flange and outer clamp nut..

TOOL - LESS WHEEL GUARD

Release the wheel guard lock lever (11) then turn the tool - less wheel

guard (2) to the desired position.

PowerLight

This tool feautres a PowerLight

is connected to the power supply. This warns the user that the tool is connected

to live power and will oprerate when the switch is pressed.

TM

TM

(12) which illuminates as soon as the tool

OPERATING (Fig.4)

KEEP SAFETY GUARDS IN PLACE.

NEVER CO VER THE AI R VENT S SINCE T HEY MUST ALWA YS BE

OPEN FOR PROPER MOTOR COOLING.

The keyto e

between the disc and work p

angle, u

full speed before s

of p

fficient operating is controlling the pressure and surface contact

sually 10 to 20 degrees with the work piece. Allow the disc to reach

ressure on a small area which may gouge or burn work surface.

iece. Flat surfaces are ground at an acute

tarting to grind. Too great an angle causes concentration

MAINTENANCE

After use, check the tool to make sure that it is in good condition.

ecommended that you take this tool to a Ryobi Authorized Service

It is r

Centre for a through cleaning and lubrication at least once a year.

DO N OT MA KE ANY A

MOTION.

ALWAYS DISCONNECT THE POWER CORD FROM THE POWER SUPPLY

BEFORE CH ANG ING REM OVA BLE OR CON SUM ABL E P ARTS

(D

IAMOND BLADE, GRINDING WHEEL ETC.), LUBRICATING OR

WORKING ON THE UNIT.

DJU STMEN TS W HILE T HE MO TOR I S I N

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

3

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

GUARANTEE

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Contact during normal business hours.

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Contact during normal business hours.

Subject to the guarantee condition below, this Ryobi tool

(hereinafter called “the product”) is guaranteed by Ryobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of original purchase covering

both parts and labour. Under the terms of this

guarantee, the repair or replacement of any part shall

be the opinion of the Company or its authorised agent.

Should service become necessary during the warranty

period, the owner should contact the RYOBI HELPLINE

1300 361 505 or contact the retailer from whom the

product was purchased.

In order to obtain guarantee service, the owner must

present the sales docket and Guarantee Certificate

to confirm date of purchase. This product is sold by the

dealer or agent as principal and the dealer has no

authority from the Company to give any additional

guarantee on the Company’s behalf except as herein

contained or herein referred to.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in the opinion of the Company) and such

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or used

for a purpose for which it was not designed or is not

suited and no repairs, alterations or modifications

have been attempted by other than an Authorised

Service Agent. This guarantee will not apply if the tool is

damaged by accident or if repairs arise from normal

wear and tear.

The Company accepts no additional liability pursuant to

this guarantee for the costs of travelling or

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included in

this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller in

certain circumstances. Nothing herein shall have the effect

of excluding, restricting or modifying any condition,

guarantee, right or liability imposed, to the extent only

that such exclusion, restriction or modification

would render any term herein void.

BRISBANE : All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquiries Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville,Vic. 3178

Tel : (03) 9764 8656

HOBART: All enquiries Tel : 1300 361 505

ADELAIDE: All enquiries Tel : 1300 361 505

PERTH: 33-35 Sorbonne Cres. Canning Vale, W.A. 6155

Address Of Dealer

Present This Form With Your Purchase Docket When Guarantee Service Is Required.

Tel: (02) 9792 9800 - Fax: 1800 807 993 - www.ryobi.com.au

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - www.ryobi.co.nz

Tel : (08) 9455 7775

This Guarantee Form Should Be Retained By The Customer At All Times

For your record and to assist in establishing date of purchase (necessary for in-guarantee service)

please keep your purchase docket and this form completed with the following particulars.

Date Model No Serial No

Loading...

Loading...