EJS700RG

JIGSAW

OWNER’S OPERATING MANUAL

DESCRIPTION

1. Switch

2. Lock-on button

3. Safety guard

4. Base

5. Degree marks

6. Saw blade

7. Dust port (connect to dust extraction system, not

included)

8. Roller guide

9. Bevel lock lever

10. Edge guide

11. Edge guide lock screw

12. Quick release lever

2

16

19

11

1

13

17

9

5

4

13. Live tool indicator

14. Overmold handle

15. Laser guide

16. Variable speed control selector

17. Orbital adjustment knob

18. Blade storage area

19. Transparent guard (only used for straight cutting)

20. T o install

21. T o release

22. Lock

23. Unlock

24. Laser guide line

25. LED worklight

14

15

7

3

25

18

8

Fig. 1

7

20

6

18

Fi g. 2

21

Fig. 3

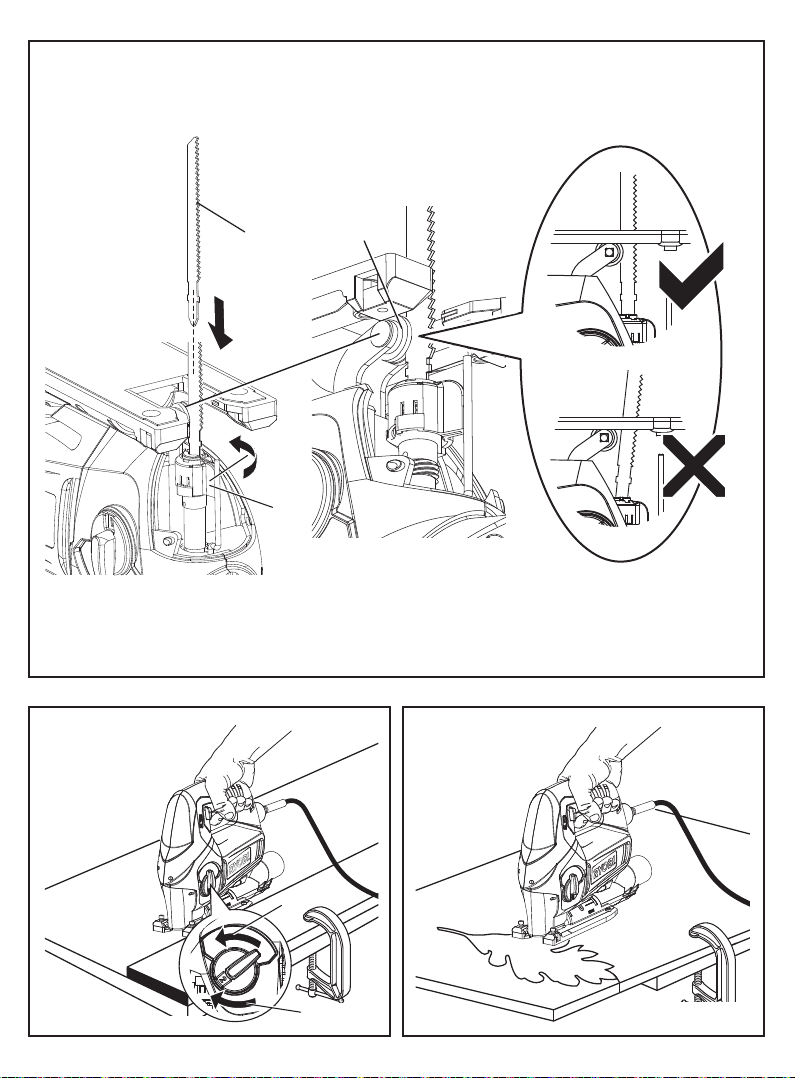

1

3

0

6

8

12

Fig. 4

L

3

0

1

H

Fig. 5

Fig. 6

9

23

4

16

5

22

Fig. 7

Fig. 9

Fig. 8

9

7

4

Fig. 10

15

24

10

Fig. 11 Fig. 12

Important!

It is essential that you read the instructions in this manual before

operating this machine.

Subject to technical modifications.

English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions. Failure

to follow the warnings and instructions may result in electric

shock, fi re and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1. WORK AREA

a. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. ELECTRICAL SAFETY

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adaptor plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f. If operating power tools in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3. PERSONAL SAFETY

a. Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your fi nger on the switch or energising power tools

that have the switch on invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

4. POWER TOOL USE AND CARE

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b. Do not use the power tool if the switch does not

turn it on and off. Any power tool that can not be

controlled with the switch is dangerous and must

be repaired.

c. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

1

English

dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits

etc., in accordance with these instructions and

in the manner intended for the particular type

of power tool, taking into account the working

conditions and the work to be performed. Use

of the power tool for operations different from

intended could result in a hazardous situation.

5. SERVICE

a. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

SPECIAL SAFETY RULES

It is advised to wear a dusk mask.

Wait for the cutter to stop before setting the tool

down. An exposed cutter may engage the surface

leading to possible loss of control and serious injury.

Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live" and

could give the operator an electric shock.

If the replacement of the supply cord is necessary,

this has to be done by the manufacturer or his

agent in order to avoid a safety hazard.

This appliance is not intended for use by persons

(including children) with reduced physical,

sensory or mental capabilities, or lack of

experience and knowledge, unless they have been

given supervision or instruction concerning use

of the appliance by a person responsible for their

safety. Children should be supervised to ensure

that they do not play with the appliance.

This appliance is not intended for use by young

children or infirm persons. Adequate supervision by a

responsible person must be provided to ensure that

they do not play with the appliance.

Keep children and visitors away. Visitors should

wear safety glasses and be kept a safe distance from

work area. Do not let visitors contact tool or extension

cord.

Complies with AS/NZS 60745.

Recommended for the use of a residual current device

with a rated residual current of 30 mA or less.

SAFETY RULES LASER GUIDE

The laser guide radiation used in saw is Class 2M with

maximum <5mW and 650nm wavelengths. These lasers

do not normally present an optical hazard, although staring

at the beam may cause fl ash blindness.

WARNING

DO NOT stare directly at the laser beam. A hazard may

exist if you deliberately stare into the beam, please

observe all safety rules as follows:

The laser shall be used and maintained in accordance

with the manufacturer’s instructions.

Never aim the beam at any person or an object other

than the work piece.

The laser beam shall not be deliberately aimed at

personnel and shall be prevented from being directed

towards the eye of a person for longer than 0.25s.

Always ensure the laser beam is aimed at a sturdy

work piece without reflective surfaces. i.e. wood or

rough coated surfaces are acceptable. Bright shiny

reflective sheet steel or the like is not suitable for laser

use as the reflective surface could direct the beam

back at the operator.

Do not change the laser guide assembly with a

different type. Repair must only be carried out by the

laser manufacturer or an authorised agent.

Save these instructions. Refer to them frequently

and use them to instruct others who may use this

tool. If you loan someone this tool, loan them these

instructions also.

LASER RADIATION

DO NOT STARE INTO THE

BEAM OR VIEW DIRECTLY

WITH OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

2

English

SPECIFICATIONS

Voltage 240 V 50 Hz

Input power 680 W

Stroke per minute 800 - 3000 min

Stroke length 21 mm

Max cutting capacity

Wood 85 mm

Steel 8 mm

-1

FEATURES

KNOW YOUR SAW

Before attempting to use your saw, familiarize yourself

with all operating features and safety requirements.

ELECTRICAL CONNECTION

Your saw has a precision built electric motor. It should be

connected only to a power supply of the type specifi ed by

its rating plate. Do not operate this tool on direct current

(DC). A substantial voltage drop will cause a loss of power

and overheating. If your tool does not operate when

plugged into an outlet, double-check the power supply.

WARNING

Do not allow familiarity with tools to make you careless.

Remember that a careless fraction of a second is

suffi cient to infl ict severe injury.

OPERATION

SWITCH

See Figure 1.

To turn your saw ON, depress the switch.

Release trigger switch to turn your saw OFF.

LOCK-ON BUTTON

See Figure 1.

Your saw is equipped with a lock-on feature, which is

convenient when continuous cutting for extended periods

of time is required. To lock-on, depress the trigger switch,

push in and hold the lock-on button located on the side of

the handle, then release trigger switch. Release lock-on

button and your saw will continue running.

T o release the lock, depress the trigger switch and release.

If you have the lock-on feature engaged during use and

your saw becomes disconnected from power supply,

disengage the lock-on feature immediately.

WARNING

Before connecting your saw to power supply source,

always check to be sure it is not in lock-on position

(depress and release trigger switch). Failure to do so

could result in accidental starting of your saw resulting

in possible serious injury. Also, do not lock the trigger on

jobs where your saw may need to be stopped suddenly.

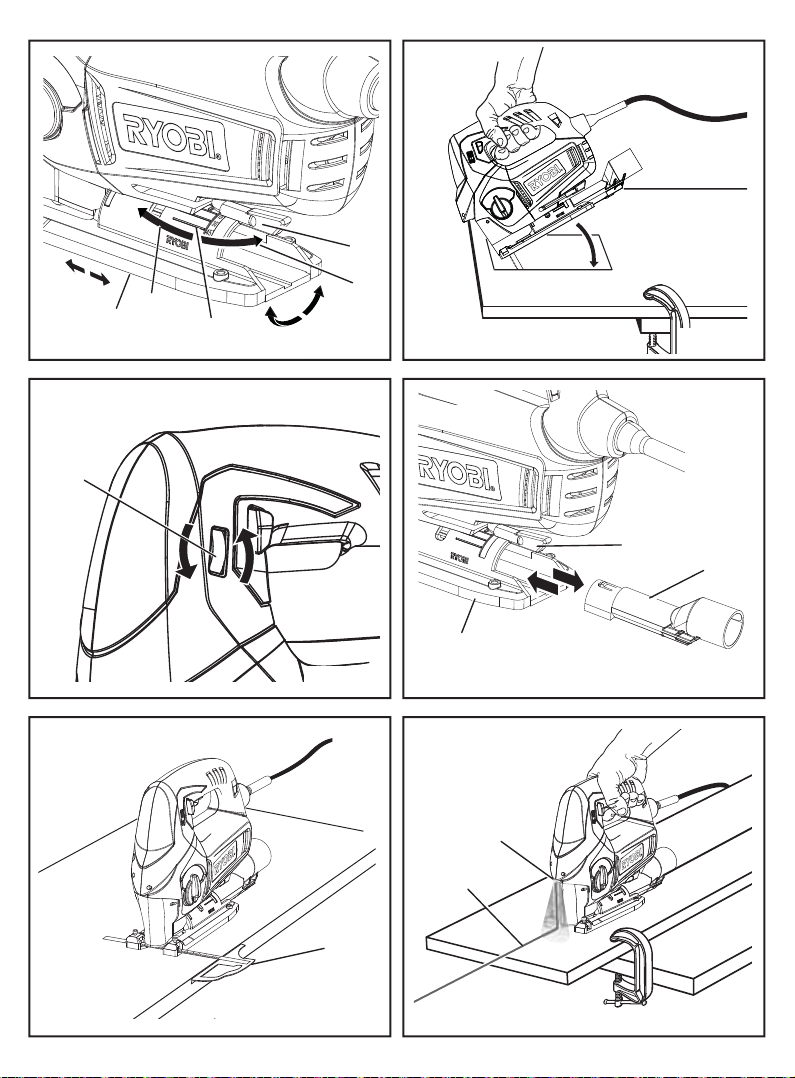

TRANSPARENT GUARD

See Figure 3.

For your protection, a transparent guard has been included

with the saw. It is used to shield wood particles from the

eyes. The transparent guard is attached by placing it in

front of the blade area of the base and snapping it into the

tabs on the sides of the saw base. For removal, simply

pull the tap of the transparent guard. Make sure the saw is

unplugged before installation and removal.

NOTE: The transparent guard can only be used for

straight cutting.

TO INSTALL BLADES

See Figure 3 - 4.

Unplug the tool.

WARNING

Failure to unplug your saw could result in accidental

starting causing possible serious injury.

Turn the tool upside down.

Pull the tap of the transparent guard.

Rotate the quick release lever counter-clockwise and

hold in position.

Insert the saw blade into the groove in the roller guide,

making sure the back of the saw blade is properly

positioned in the groove.

NOTE: Only T-shank saw blades can be used.

Push the saw blade into the blade clamp as far as it

will go.

Release the quick release lever.

Install the transparent guard.

3

English

WARNING

To avoid possible serious injury, always wear safety

goggles or safety glasses with side shields. Keep hands

and fi ngers away, from the motor housing and blade

clamp and do not reach underneath work while blade

is cutting.

WARNING

T o avoid serious personal injury, do not use saw without

safety guard properly in place.

VARIABLE SPEED

See Figure 9.

Your saw has a variable speed control selector designed to

allow operator control and adjustment of speed and power

limits. The speed and power of your saw can be increased

or decreased by rotating the variable speed control selector

in the direction of the arrows.

NOTE: Hold your saw in normal operating position and

turn the variable speed control selector counterclockwise

to increase speed and power. Turn clockwise to decrease

speed and power.

If you wish to lock the switch on at a given speed, depress

the trigger switch, push in and hold the lock-on button, and

release the trigger switch. Next, adjust the variable speed

control selector until the desired speed is reached.

Avoid running your saw at low speeds for extended

periods of time. Running at low speeds under constant

usage may cause your saw to become overheated. If this

occurs, cool your saw by running it without a load and at

full speed.

The following guidelines may be used in determining

correct speed for various applications.

LOW speed is ideal when minimum speed and power

is required, for example starting cuts.

MEDIUM speed is suitable for cutting hard metals,

plastics and laminates.

HIGH speed produces best results when maximum

power is required, for example cutting wood. Soft

metals such as aluminum, brass and copper also

require high speeds.

BLADE STORAGE

See Figure 2.

A convenient feature on your saw is the blade storage.

The blade storage area is located on the back of dust port.

It is convenient for storing extra blades when not in use.

To open: Pull the door down with your thumb or

finger.

Place blades in blade storage area.

To close: Push the door up with your thumb or finger.

WARNING

Do not insert saw blade into air vents. They could come

in contact with electrically live internal parts and cause

electric shock, resulting in serious injury.

WARNING

Your saw should never be connected to power supply

when you are assembling parts, making adjustments,

installing or removing blades or when not in use.

Disconnecting your saw will prevent accidental starting

which could cause serious injury.

GENERAL CUTTING

See Figure 5.

Rest the front of the saw base on the workpiece and align

cutting edge of the blade with the line on your workpiece.

Make sure the power cord is out of the way of saw blade

and not in the line of cut. Start your saw and move it

forward on the work surface. Apply downward pressure to

keep the saw steady and only enough forward pressure to

keep the blade cutting.

WARNING

Do not force your saw. Forcing your saw may overheat

the motor and break saw blades.

ORBITAL MOTION

See Figure 5.

The blade of your saw cuts in orbital motion. This feature is

adjustable and provides faster and more effi cient cutting.

With orbital motion the blade cuts through your work in

the upstroke but does not drag across your work in the

downstroke.

Higher settings (H) should be used when fast cutting

in soft material.

Lower (L) settings should be used when cutting

materials with more resistance.

STRAIGHT CUT

See Figure 5.

A straight cut can be made by clamping a piece of wood or

straightedge to the workpiece and guiding the edge of your

saw against it. Make the cut from one direction only, do not

cut halfway to complete the cut from the opposite end.

4

English

SCROLL CUTTING

See Figure 6.

Scroll cuts can be made with your saw by guiding the

direction of the cut with applied pressure on the handle.

WARNING

Excessive side pressure to the blade could result in broken

blades or damage to the material being cut.

ANGLE CUTTING (BEVEL CUTTING)

See Figure 7.

Bevel cutting angles may be adjusted from 0° to 45° right

or left. Angles for cuts from 0° to 45° in 15° increments

are marked on a scale on both the left and right side of

the base.

The use of a protractor is recommended when accurate

cuts are required.

ADJUSTING THE ANGLE

See Figure 3 and 7.

Release the transparent guard.

Release the bevel lock lever until the base can be

moved.

Slide base forward slightly to release the base from

the tab on the motor housing.

Align the mark on the base of the desired angle with

the edge of the motor housing.

Once the desired angle is reached, slide the base

back until the tab on the motor housing aligns with the

appropriate notch on the rear of the base.

Push the bevel lock lever back to secure the base.

Install the transparent guard.

TO MAKE A PLUNGE CUT

See Figure 8.

WARNING

To avoid loss of control, broken blades, or damage to

the material being cut, always use extreme caution

when making plunge cuts. We do not recommend

plunge cutting on materials other than wood.

Mark the line of cut clearly on the workpiece.

Set the cutting angle at 0°.

Tilt your saw forward so that it rests on the front edge

of the base and blade will not come in contact with the

workpiece when the saw is turned on.

Make sure the blade is inside the area to be cut.

Start your saw by using high speed and slowly lower

the blade into the workpiece until the blade cuts

through the wood.

Continue lowering the blade into the workpiece until

the base rests flat on the work surface, then move the

saw forward to complete the cut.

Use only the 7 teeth per inch blade for this type of

cut.

METAL CUTTING

Many kinds of metals can be cut with your saw. Be careful

not to twist or bend the blades. Do not force.

If the blade chatters or vibrates excessively, use a fi ner

tooth blade or higher speed. If blade heats excessively,

use lower speed. If blade teeth become fi lled or clogged

when cutting soft metals, such as aluminum, use a coarsertooth blade or lower speed. We recommend the use of oil

when cutting metals to keep blades cool, increase cutting

action, and prolong blade life. Clamp the work fi rmly and

cut close to the clamping point to eliminate any vibration of

the workpiece being cut.

When cutting conduit, pipe or angle iron, clamp work in a

vice if possible and saw close to the vice. To cut thin sheet

materials, "sandwich" the material between hardboard or

plywood and clamp the layers to eliminate vibration and

material tearing. By doing this, the material will be cut

smoothly. Lay out your pattern or line of cut on top of the

"sandwich".

IMPORTANT

When cutting metal, keep exposed portion of saw bar

clean and free of metal chips by wiping frequently with

an oily cloth. Use extreme caution in disposing of oily

cloth after completion of job to prevent potential fi re

hazard.

DUSTLESS FEATURE

See Figure 10.

For dustless operation, a dust port has been provided with

your saw. It attaches to the saw base.

This allows the air to fl ow out around the blade blowing

sawdust and chips away from the operators view of the

line of cut.

TO INSTALL:

Unplug your saw.

5

English

WARNING

Failure to unplug your saw could result in accidental

starting causing possible serious injury.

Attach the dust port to the back of the base. You can

hear a click sound when it is locked securely.

Connect exhaust opening to dust collection system.

TO REMOVE:

Unplug your saw.

Directly pull the dust port out.

TO CONNECT DUST EXTRACTION SYSTEM (NOT INCLUDED)

Unplug the tool.

WARNING

Failure to unplug your saw could result in accidental

starting causing possible serious injury.

Connect the nozzle of the dust collection system to

the dust port.

EDGE GUIDE

See Figure 11.

An edge guide is available for use with your saw. It can be

used for making crosscuts and rip cuts.

TO INSTALL:

Unplug your saw.

WARNING

Failure to unplug your saw could result in accidental

starting causing possible serious injury.

Insert arm of the edge guide through the two slots in

the base of your saw.

Adjust edge guide to the desired width and lock in

place with the edge guide screw.

WARNING

When servicing, use only identical replacement parts.

Use of any other part may create a hazard or cause

product damage.

LASER GUIDE

See Figure 12.

Depress the trigger switch to generate a red laser beam

on the work surface in front of the saw. Use the laser to

guide the saw along the line of cut.

LED WORKLIGHT

See Figure 12.

The jigsaw has a built-in LED worklight. This feature is

convenient when working in close or tight areas where

additional light is needed. Whenever the trigger switch is

depressed, the LED worklight will illuminate.

LIVE TOOL INDICATOR

This tool features a live tool indicator which illuminates as

soon as the tool is connected to the supply. This warns the

user that the tool is connected and will operate when the

switch is pressed.

MAINTENANCE

GENERAL

All other parts represent an important part of the class

II insulation system and should be serviced only by a

qualifi ed service technician.

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types

of commercial solvents. Use clean cloths to remove dirt,

carbon dust, etc.

WARNING

Do not at any time let brake fl uids, gasoline, petroleum-

based products, penetrating oils, etc. come in contact

with plastic parts. They contain chemicals that can

damage, weaken or destroy plastic.

It has been found that electric tools are subject to

accelerated wear and possible premature failure when

they are used on fi berglass boats, sports cars, wallboard

or plaster.

The chips and grindings from these materials are highly

abrasive to electric tool parts such as bearings, brushes,

commutators, etc. Consequently, it is not recommended

that this tool be used for extended work on any fi berglass

material, wallboard or plaster. During any use on these

materials it is extremely important that the tool is cleaned

frequently by blowing with an air jet.

LUBRICATION

All of the bearings in this tool are lubricated with a

suffi cient amount of high grade lubricant for the life of

the unit under normal operating conditions. Therefore, no

further lubrication is required.

6

English

CAUTION

Keep extension cords away from the cutting area and

position the cord so that it will not get caught on lumber,

tools, etc., during cutting operation.

WARNING

Check extension cords before each use, if damaged

replace immediately. Never use tool with a damaged

cord as touching the damaged area could cause

electrical shock resulting in serious injury.

Extension cords suitable for use with your saw are

available at your nearest service center.

WARNING

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing

dust. If operation is dusty, also wear a dust mask.

SYMBOL

Safety Alert

V Volts

Hz Hertz

Alternating Current

W Watts

no No load Speed

-

1

min

Revolutions or reciprocations per minute

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

Maximum cutting capacity in wood

Conformity

Double Insulation

Wear ear protection

Wear eye protection

Please read the instructions carefully before

starting the machine.

7

7(&+7521,&,1'8675,(6$8675$/,$37</7'

/HYHO'RQFDVWHU5RDG

'RQFDVWHU9LFWRULD

$XVWUDOLD

7HO)D[1R

Loading...

Loading...