Page 1

EID650FK

IMPACT DRILL

OWNER’S OPERATING MANUAL

N197

4

Page 2

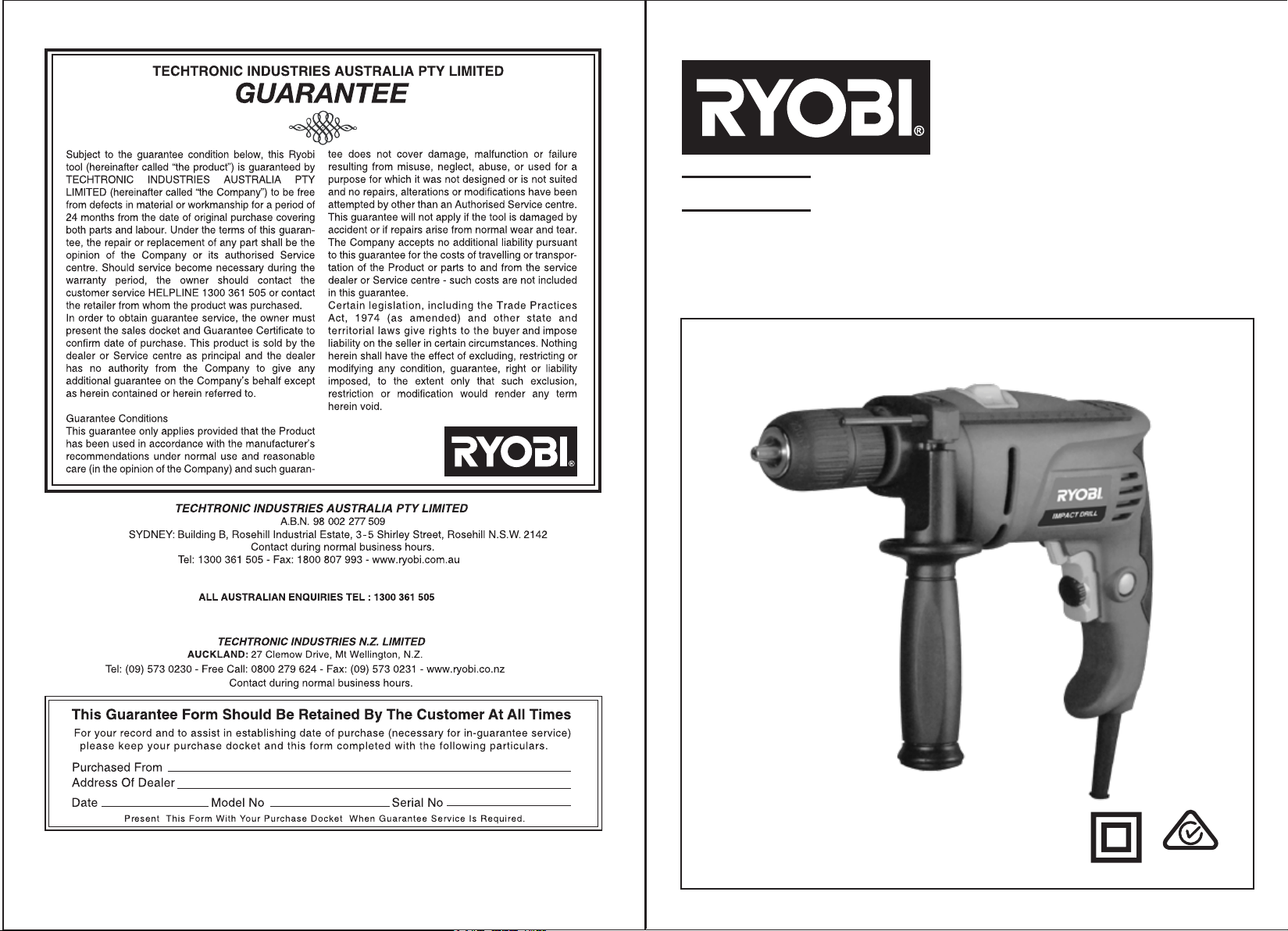

DESCRIPTION

DESCRIPTION

Components list

1. Depth stop

2. Hammer mode switch

3. Keyless chuck

4. Auxiliary handle

1

3

5. Forward / Reverse lever

6. Variable speed control

7. Trigger switch

8. Lock ON button

2

Lock ON

botton

Trigger

switch

Fig. 2

R

Variable speed

control

L

Fig. 4

Fig. 3

Fig. 5

5

8

6

4

7

Fig. 1

Please refer to pages 2 - 3 for instructions

Fig. 6

Fig. 8 Fig. 9

Fig. 7

Page 3

Important!

It is essential that you read the instructions in this manual before

operating this machine.

Subject to technical modifications

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to loose control.

2) Electrical Safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adaptor plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce the risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat,

oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in a serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger on

the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventative

safety measures reduce the risk of starting

the power tool accidently.

1

Page 4

GENERAL POWER TOOL SAFETY WARNINGS

d) Store idle power tools out of the reach of

children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment of binding or moving parts,

breakage of parts and any other condition

that may affect the power tools’ operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool

bits etc., in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

SPECIFIC SAFETY WARNINGS

■ Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body leaves it unstable and may lead to

loss of control.

■ Hold power tools by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live”

wire will also make exposed metal parts of the

tool “live” and shock the operator.

■ Know your power tool. Read operator’s

manual carefully. Learn its applications and

limitations, as well as the specific potential

hazards related to this power tool. Following

this rule will reduce the risk of electric shock, fire

or serious injury.

■ Always wear safety glasses with side

shields. Everyday glasses have only impact

resistant lenses. They are NOT safety glasses.

Following this rule will reduce the risk of eye

injury.

■ Protect your lungs. Wear a face or dust mask

if the operation is dusty.

■ Use auxiliary handle, if supplied with the

tool. Loss of control can cause personal injury.

■ Protect your hearing. Wear hearing

protection during extended periods of

operation.

■ If using an extension lead, ensure that the

male and female plug connection is elevated

and out of the way of any water contact.

WARNING:

This impact drill is designed for light

consumer use. It is NOT designed for trade

or industrial use and is not covered by the

guarantee for use in these applications.

SPECIFICATIONS

Power input:

No load speed:

Blows per minute:

Chuck capacity:

Drill capacity:

650 W

0-2,800 min

0-28,000 b/min

13 mm

Steel: 13 mm

Masonry: 13 mm

Wood: 25 mm

Net weight:

2.00 kg

OPERATION

It is recommended that the tool always be supplied

via a residual current device with a rated residual

current of 30mA or less.

AUXILIARY HANDLE AND DEPTH STOP

Install the auxiliary handle on the head of the

housing and insert the depth stop in the hole

provided. The auxiliary handle can swivel 360° for

the most comfortable position and easiest operation.

The depth stop helps keep an accurate depth when

drilling holes.

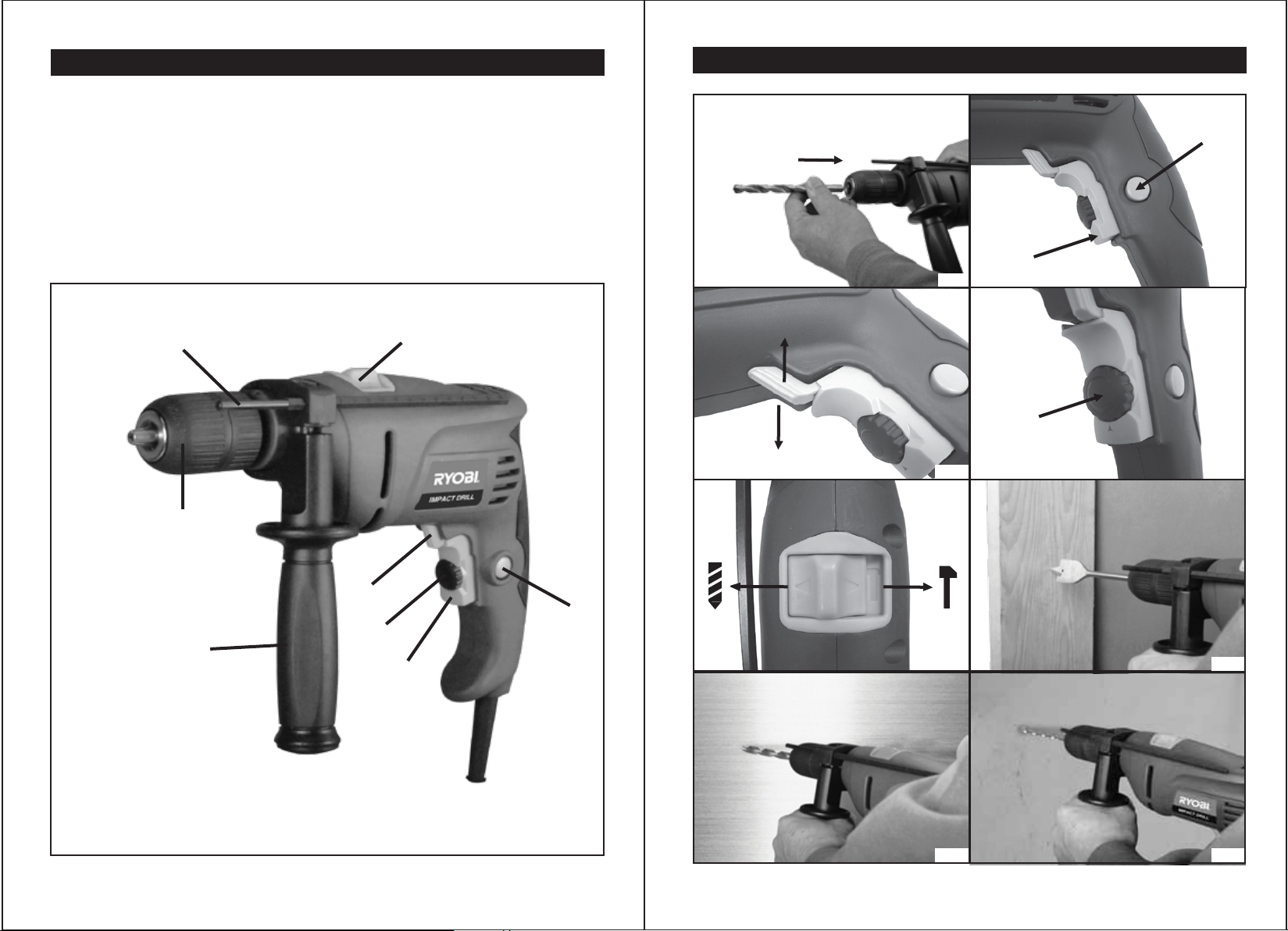

MOUNTING OF THE DRILL BIT

■ When mounting the drill bit, insert the bit into the

chuck as far as it will go and tighten securely.

(Fig.2)

■ To tighten, grasp and hold the collar of the chuck

with one hand, while rotating the chuck body with

your other hand.

NOTE:

Rotate the chuck body in the direction of the

arrow marked GRIP to tighten the chuck

jaws.

■ DO NOT use a wrench to tighten or loosen the

chuck jaws.

OPERATION

■ The bit can be removed by reversing the above

procedure.

SWITCHES (Fig.3)

Your drill starts and stops by squeezing and

releasing the trigger switch. For continuous

operation, press the lock on button while the trigger

switch is fully depressed. To release the lock,

squeeze the trigger switch again.

FORWARD REVERSE SWITCH (Fig.4)

Your drill is fitted with a forward reverse lever which

allows the removal of screws.

■ FORWARD ROTATION: Situate the lever in the

“R” (right) position indicated on your drill.

■ REVERSE ROTATION: Situate the lever in the

“L” (left) position indicated on your drill.

-1

VARIABLE SPEED (Fig.5)

Your drill has a variable speed control mechanism

designed to allow the operator to have control and

adjustment of speed and torque limits. The speed

and torque of your drill can be increased or

decreased by rotating the variable speed control

button.

HAMMER MECHANISM (Fig.6)

The hammer mechanism can be operated with the

machine running. When drilling materials that are

liable to break, such as tiles, it is advisable to start

the drill without impact. For deep holes, the drill bit

should be pulled out occassionally in order to

remove the dust and chips from the hole. To drill

with impact, only use drill bits with a carbide tip and

negative cut angle on the lip. Carbide tip drill bits

should only be sharpened with silicone carbide

wheels. To work WITHOUT HAMMER, as a normal

drill, turn the lever to the point where a drill is

printed. To work WITH HAMMER, push the lever to

APPLICATION

stainless steel and pipe may also be drilled. Mark

the point to be drilled with a nail or a punch before

drilling.

DRILLING IN CONCRETE (Fig.9)

Rock and masonry are generally drilled in hammer

mode. When drilling delicate material such as wall

tiles, it is essential to start with ordinary drilling and

once the tile is pierced, to continue with hammer

drilling. In deep boreholes the drill bit should be

pulled out occassionally in order to remove the dust

and chips from the hole.

WARNING:

Never cover the air vents. They must be

open at all times for proper motor cooling.

MAINTENANCE

■ Do not make any adjustment while the motor is

in motion.

■ Always disconnect the electrical cord from the

power source before changing the drill bit,

brushes, or when working on the unit.

■ After use, check your tool to keep it in top

condition.

■ Clean out accumulated dust.

■ When the carbon brushes are worn to the

standard line, they must be replaced.

SERVICE

Now that you have purchased your tool, should a

need ever exist for repair, parts or service, simply

contact your nearest Ryobi Authorised Service

Centre or other qualified service organisation. Be

sure to provide all pertinent facts when you call or

visit.

the position where a hammer is printed.

WARNING:

The chuck and exposed metal surfaces of

the tool may become “live” if the tool drills

into wiring in a wall. The operator must

always ensure that the area being drilled

does not conceal electrical wiring or

plumbing.

APPLICATION

DRILLING IN WOOD (Fig.7)

To prevent ugly splits around the drill hole on the

reverse side of the workpiece, place a scrap piece

of timber beneath the material to be drilled.

DRILLING IN METAL (Fig.8)

Metals such as steel, brass, aluminium sheets,

2

3

Loading...

Loading...