Page 1

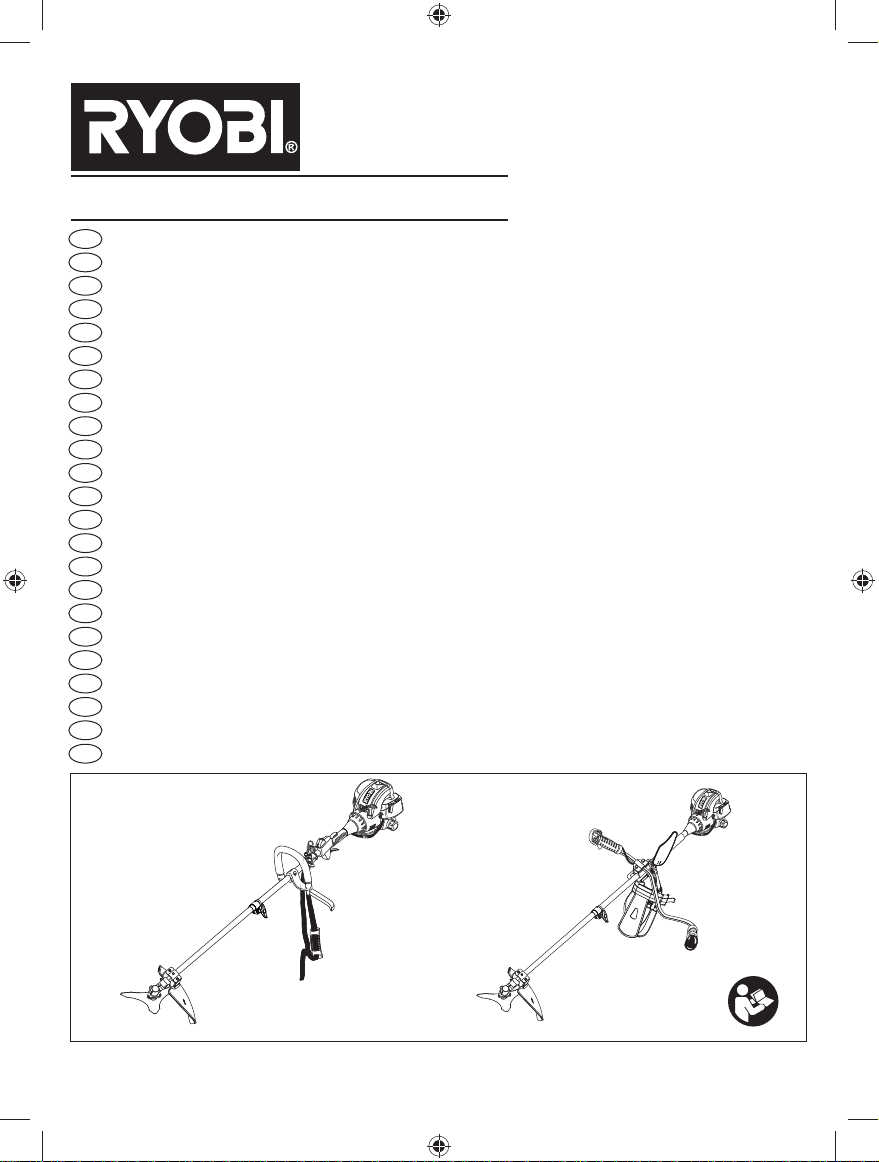

RBC30SESB / RBC30SBSB

FR

COUPE-BORDURES / DÉBROUSSAILLEUSE MANUEL D’UTILISATION 1

EN

STRING TRIMMER / BRUSHCUTTER USER’S MANUAL 13

DE

KANTENSCHNEIDER / FREISCHNEIDEGERÄT BEDIENUNGSANLEITUNG 23

ES

RECORTADORA DE HILO / CORTADORA DE MALEZA MANUAL DE UTILIZACIÓN 35

IT

TAGLIABORDI / DECESPUGLIATORE MANUALE D’USO 46

PT

APARADOR DE RELVA / CORTA-SEBES MANUAL DE UTILIZAÇÃO 58

NL

GRASTRIMMER / BOSMAAIER GEBRUIKERSHANDLEIDING 70

SV

TRIMMER / RÖJSÅG INSTRUKTIONSBOK 82

DA

TRÅDTRIMMER / BUSKRYDDER BRUGERVEJLEDNING 92

NO

TRÅDTRIMMER / KRATTRYDDER BRUKSANVISNING 102

FI

SIIMALEIKKURI/RUOHORAIVURI KÄYTTÄJÄN KÄSIKIRJA 112

HU

SZEGÉLYVÁGÓ / BOZÓTVÁGÓ MOTOROS KASZA HASZNÁLATI ÚTMUTATÓ 122

CS

STRUNOVÁ SEKAČKA / KŘOVINOŘEZ NÁVOD K OBSLUZE 134

RU

ТРИММЕР / КУСТОРЕЗА РУКОВОДСТВО ПО ЗКСПЛУАТАЦИИ 144

RO

TRIMMER / APARAT PENTRU TUNS TUFIŞURI MANUAL DE UTILIZARE 15

PL

PODKASZARKA DO OBRZEŻY/ŚCINACZ KRZEWÓW INSTRUKCJA OBSŁUGI 16

SL

KOSILNICA Z NITKO / OBREZOVALNIK GRMOVJA UPORABNIŠKI PRIROČNIK 17

HR

©I©A»/REZA»ICA KORISNI»KI PRIRU»NIK 18

ET

TRIMMER-VÕSALÕIKUR KASUTAJAJUHEND 197

LT

ŽOLIAPJOVĖ / KRŪMAPJOVĖ NAUDOJIMO VADOVAS 207

LV

ROKAS PĻAUJMAŠĪNA / KRŪMGRIEZIS LIETOTĀJA ROKASGRĀMATA 217

SK

STRUNOVÁ KOSAČKA/KROVINOREZ NÁVOD NA POUŽITIE 227

BG

ТРИМЕР / ТРИМЕР ЗА РАЗЧИСТВАНЕ РЪКОВОДСТВО ЗА УПОТРЕБА 237

RBC30SESB

Important! It is essential that you read the instructions in this manual before mounting and operating

this machine.

RBC30SBSB

Page 2

VL

ȼɚɠɧɨ

6XEMHFWWRWHFKQLFDOPRGLILFDWLRQV6RXVUpVHUYHGHPRGLILFDWLRQVWHFKQLTXHV7HFKQLVFKHbQGHUXQJHQYRUEHKDOWHQ

%DMRUHVHUYDGHPRGLILFDFLRQHVWpFQLFDV&RQULVHUYDGLHYHQWXDOLPRGLILFKHWHFQLFKH7HFKQLVFKHZLM]LJLQJHQYRRUEHKRXGHQ

&RPUHVHUYDGHPRGLILFDo}HVWpFQLFDV0HGIRUEHKROGIRUWHNQLVNHQGULQJHU0HGI|UEHKnOOI|UWHNQLVNDlQGULQJDU

7HNQLVHWPXXWRNVHWYDUDWDDQ0HGIRUEHKROGRPWHNQLVNHHQGULQJHUɦɨɝɭɬɛɵɬɶɜɧɟɫɟɧɵɬɟɯɧɢɱɟɫɤɢɟɢɡɦɟɧɟɧɢɹ

=]DVWU]HĪHQLHPPRG\ILNDFMLWHFKQLF]Q\FK=PČQ\WHFKQLFNêFK~GDMĤY\KUD]HQ\$PĦV]DNLPyGRVtWiVMRJiWIHQQWDUWMXN

3DVLOLHNDQWWHLVĊGDU\WLWHFKQLQLXVSDNHLWLPXV7HKQLOLVHGPXXGDWXVHGY}LPDOLNXG3RGORQRWHKQLsNLPSURPMHQDPD

7HKQLþQHVSUHPHPEHGRSXãþHQH3UiYRQDWHFKQLFNp]PHQ\MHY\KUDGHQpɉɨɞɥɟɠɢɧɚɬɟɯɧɢɱɟɫɤɢɦɨɞɢɮɢɤɚɰɢɢ

Ɉɬɢɡɤɥɸɱɢɬɟɥɧɚɜɚɠɧɨɫɬɟɞɚɩɪɨɱɟɬɟɬɟɢɧɫɬɪɭɤɰɢɢɬɟɜɬɨɜɚɪɴɤɨɜɨɞɫɬɜɨɩɪɟɞɢɞɚɛɨɪɚɜɢɬɟɫ

ɬɚɡɢɦɚɲɢɧɚ

6XEUH]HUYDPRGLILFDĠLLORUWHKQLFH3DWXUDPWLHVƯEDVPDLQƯWWHKQLVNRVUDNVWXUOLHOXPXV

Page 3

EN Some regions have regulations that restrict the use of the product to some operations. Check with your local authority

for advice.

FR La législation de certaines régions restreint l'utilisation du produit à certaines opérations. Contactez les autorités

locales pour de plus amples informations.

DE In einigen Regionen können Vorschriften die Benutzung dieses Produktes auf einige Tätigkeiten beschränken. Lassen

Sie sich von Ihrer örtlichen Behörde beraten.

ES Algunas regiones tienen normativas que restringen el uso del producto para algunas operaciones. Consulte con sus

autoridades locales.

IT In alcune regioni norme speci¿ che limitano l'utilizzo del prodotto ad alcune operazioni. Controllare con le autorità locali

per avere ulteriori informazioni a riguardo.

NL In enkele streken gelden regels die het gebruik van het product tot enkele handelingen beperken. Raadpleeg uw

gemeentebestuur voor advies.

PT Algumas regiões têm normas que restringem o uso do produto para algumas operações. Consulte as autoridades

locais.

DA Nogle områder har regler, som begrænser brugen af produktet til visse formål. Forhør dig hos de lokale myndigheder.

SV En del regioner har regelverk som begränsar produktens användning till vissa funktioner. Kontrollera med lokala

myndigheter.

FI Joillain alueilla vallitsee säädöksiä, jotka rajoittavat tämän tuotteen käyttöä joissain toiminnoissa. Pyydä paikallisilta

viranomaisilta neuvoa.

NO Visse regioner har forskrifter som begrenser bruken av produktet til de¿ nerte operasjoner. Sjekk hos lokale myndigheter

for råd.

RU ȼ ɧɟɤɨɬɨɪɵɯ ɪɟɝɢɨɧɚɯ ɫɭɳɟɫɬɜɭɸɬ ɨɝɪɚɧɢɱɟɧɢɹ ɧɚ ɢɫɩɨɥɶɡɨɜɚɧɢɟ ɧɟɤɨɬɨɪɵɯ ɨɩɟɪɚɰɢɣ ɫ ɞɚɧɧɵɦ ɭɫɬɪɨɣɫɬɜɨɦ.

Ɉɛɪɚɳɚɣɬɟɫɶ ɡɚ ɢɧɮɨɪɦɚɰɢɟɣ ɜ ɦɟɫɬɧɵɟ ɨɪɝɚɧɵ ɜɥɚɫɬɢ.

PL W niektórych regionach obowiązują przepisy ograniczające uĪywanie produktu w przypadku okreĞlonych dziaáaĔ.

Informacje na ten temat moĪna uzyskaü w lokalnych urzĊdach.

CS Místní pĜedpisy mohou omezovat použití výrobku. OvČĜte si u svého orgánu místní správy toto naĜízení.

HU Egyes régiókban olyan elĘírások érvényesek, amelyek korlátozzák a termék bizonyos mĦveletekre való használatát.

További információért forduljon a helyi önkormányzathoz.

RO Unele regiuni au reglementări care restricĠionează utilizarea produsului la unele operaĠiuni. CereĠi sfatul autorităĠii

locale.

LV Dažos reƧionos pastƗv noteikumi, kas ierobežo darbƯbas, kurƗm produkts ir izmantojams. Lai uzzinƗtu vairƗk,

konsultƝjieties ar vietƝjƗm iestƗdƝm.

LT Kai kuriuose regionuose šio gaminio naudojimą tam tikriems darbams apriboja galiojantys Ƴstatymai. Dơl patarimǐ

kreipkitơs Ƴ vietinơs valdžios instituciją.

ET Mõnedes piirkondades on seadused, mis piiravad toote kasutamist teatud tööde tegemiseks. Lisateavet saate

kohalikust omavalitsusest.

HR Neke regije imaju pravila koja ograniþavaju korištenje proizvoda za neke radove. Provjerite kod lokalnih tijela za savjet.

SL V nekaterih regijah predpisi omejujejo uporabo izdelka na doloþene namene. Za nasvet se obrnite na lokalne oblasti.

SK Niektoré regióny majú nariadenia, ktoré obmedzujú použitie produktu na urþité operácie. Poraćte sa s miestnym

úradom.

BG ȼ ɧɹɤɨɢ ɪɟɝɢɨɧɢ ɢɦɚ ɪɚɡɩɨɪɟɞɛɢ, ɨɝɪɚɧɢɱɚɜɚɳɢ ɢɡɩɨɥɡɜɚɧɟɬɨ ɧɚ ɩɪɨɞɭɤɬɚ ɞɨ ɨɩɪɟɞɟɥɟɧɢ ɨɩɟɪɚɰɢɢ. ɉɨɢɫɤɚɣɬɟ

ɫɴɜɟɬ ɨɬ ɦɟɫɬɧɢɬɟ ɜɥɚɫɬɢ.

Page 4

Assembly

EN

ATTACHING THE HANDLE

(Fig. 2a)

■ Remove the bolts and bracket from the front handle.

■ Place the handle bar.

NOTE: The throttle trigger must be mounted to the operator's

right side.

■ Replace the bolts and bracket.

■ Adjust the handle bar for best operator control and comfort.

■ Tighten the two bolts securely with the combination wrench

supplied.

ATTACHING THE BLADE GUARD AND GRASS

DEFLECTOR

Blade guard

(Fig. 2b)

■ To attach the blade deflector to the mounting bracket, align the

screw holes on the blade deflector to the bolts on the mounting

bracket.

■ Using the combination wrench supplied, tighten the two bolts

securely.

WARNING:

– The blade deflector should remain fitted to the product at

all times.

– When using the line trimmer bump head, the grass deflector

must be attached to the blade guard.

– When using the brushcutter blade, the grass deflector must

be removed from the blade guard.

Grass defl ector

(Fig 2b)

■ To attach the grass deflector to the blade deflector, align the 3

screws on the grass deflector to the screw holes on the blade

deflector.

■ Using the combination wrench supplied, tighten the two bolts

securely.

NOTE: When using the line trimmer bump head, the grass

deflector must be attached to the blade guard.

INSTALLING THE REELEASY™ LINE TRIMMER HEAD

(Fig. 2c)

■ Stop the engine and disconnect the spark plug wire.

■ Remove the bump head from the drive connector.

■ Open the ReelEasy™ Line Trimmer Head by depressing the

latches on each side.

NOTE: The contents of the line trimmer head are spring loaded,

so keep your other hand over the line trimmer head cover while

depressing the latches.

■ Remove the line trimmer head cover, bump knob, and line spool

and set aside.

■ Place the cutting head housing on the drive shaft.

■ Make sure the housing is fully seated.

■ Install the hex bolt to secure the line trimmer head to the drive

shaft.

■ Tighten by using the hex-shaped opening on the inside of the

bump knob.

NOTE: Only use the bump knob to tighten the bolt. The use of

other tools may allow over tightening of the bolt, which could

damage the line trimmer head.

■ Reinstall the bump head spring into the line trimmer head and

push down to seat.

■ Reinstall the line spool.

■ For the curved shaft attachment with the ReelEasy™ cutting

head the spool should be placed so “For curved shaft” is visible

on the line spool.

■ Replace the bump knob by inserting it into the centre of the

line spool.

■ Replace the line trimmer head cover, aligning latches with

openings in the line trimmer head.

■ Press cover and line trimmer head together until both latches

snap into openings securely.

■ Install line as described in the next section of this manual.

INSTALLING LINE IN REELEASY™ LINE TRIMMER

HEAD

(Fig. 2c)

■ Use a 2.4 mm diameter monofilament string.

■ Stop the engine and disconnect the spark plug wire.

■ Cut one piece of string approximately 6 m in length.

■ Rotate the knob on the string head until the line on knob aligns

with the arrows on the top of string head.

■ Insert one end of the string into the eyelet located on the side of

the string head and push until string comes out through eyelet

on the other side.

■ Continue to push string through the string head until the middle

section of the string is inside the string head and string outside

the string head is evenly divided on each side.

■ Rotate the knob on the line trimmer head to wind the line.

■ If using a curved shaft attachment, the knob should be rotated

counterclockwise.

■ Wind the string until approximately 20 cm remains protruding

from the string head.

■ Replace the spark plug boot.

ATTACHING THE SHOULDER STRAP

(Fig. 2d)

■ Connect the latch on the shoulder strap to the strap hanger.

■ Adjust the strap hanger to a comfortable position.

NOTE: Always use the shoulder strap/harness with your unit.

CONVERTING FROM STRING TRIMMER TO

BRUSHCUTTER

(Fig. 2e)

Page 5

EN

WARNING: Always stop the engine and disconnect the spark plug

wire from the spark plug.

Removing the bump head

■ Place the holding pin through the slot in the upper flange

washer and the hole in the gear head.

■ Unlock the spool retainer as shown and remove the spool.

■ Remove the bump head from the drive connector.

■ Place the holding pin through the slot in the upper flange

washer and the hole in the gear head.

■ Turn the connector clockwise to remove.

■ Remove the washer.

WARNING: When using the brushcutter blade, the grass defl ector

must be removed from the blade guard.

Installing the blade

■ Place the upper flange washer over the gear shaft with the

hollow side towards the gear head.

■ Centre the blade on the upper flange, making sure the blade

sits flat.

■ Install the cupped washer with the raised centre away from the

blade.

■ Place the holding pin through the slot in the upper flange

washer and the hole in the gear head.

■ Replace the blade nut and tighten securely by turning clockwise.

Assembly

CONVERTING FROM BRUSHCUTTER TO STRING

TRIMMER

WARNING: Always stop the engine and disconnect the spark plug

wire from the spark plug.

Removing the blade

■ Place the holding pin through the slot in the upper flange

washer and the hole in the gear head.

■ Remove the blade nut, washers, and blade.

■ Attach the grass deflector to the blade deflector; align the 3

screws on the grass deflector to the screw holes on the blade

deflector.

■ Using the combination wrench supplied, tighten the two bolts

securely.

WARNING: When using the line trimmer bump head, the grass

defl ector must be attached to the blade guard.

Installing the bump head

■ Place the upper flange washer over the gear shaft with the

hollow side towards the gear head.

■ Place the holding pin through the slot in the upper flange

washer and the hole in the gear head.

■ Place the bump head on the drive connector.

■ Tighten securely with wrench.

Page 6

English (Original instructions)

SYMBOLS

Important: Some of the following symbols may be used on your tool. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and more safely.

SYMBOLS EXPLANATION

Indicates danger, warning or caution. it means attention!!!

Your safety is involved.

Your manual contains special messages to bring attention to potential safety concerns as well as

operating and servicing information. Please read all the information carefully to ensure satisfaction

and safe use.

Wear eye, hearing and head protection when operating this equipment.

Danger of Ricochet. Keep all bystanders, especially children and pets, at least 15m from the

operating area.

Tri-Arc blade is appropriate for this unit and is suited for cutting pulpy weeds and vines.

This unit is not intended for use with a toothed saw type blade.

Rotational direction and maximum speed of the shaft for the cutting attachment.

Wear non-slip safety footwear when using this equipment.

Wear non-slip, heavy-duty gloves.

Do not smoke when mixing fuel or filling fuel tank.

Use unleaded petrol intended for motor vehicle use with an octane rating of 91([R+M]/2) or higher.

Use 2-stroke lubricant for air cooled engines.

Mix the fuel mix thoroughly and also each time before refuelling.

CE Conformity s to all regulatory standards in the country in the EU where the product is

purchased.

13

Page 7

English (Original instructions)

Thank you for buying a Ryobi trimmer/brushcutter.

Your new trimmer/brushcutter has been engineered and

manufactured to Ryobi’s high standard for dependability,

ease of operation, and operator safety. Properly cared for,

it will give you years of rugged, trouble-free performance.

INTENDED USE

This product is only intended for use outdoors in a well

ventilated area.

The product is intended for cutting long grass, pulpy

weed, or brush and similar vegetation at or about ground

level. The cutting plane should be approximately parallel

to the ground surface. The product should not be used

to trim hedges, bushes or other vegetation where the

cutting plane is not parallel to the ground surface.

WARNING

To reduce the risk of injury, the user must read

and understand the operator’s manual.

WARNING

Do not attempt to operate this trimmer/brushcutter

until you have read thoroughly and understood

completely all instructions, safety rules etc

contained in this manual. Failure to comply may

result in accidents involving fire, electric shock

or serious personal injury. Save operator’s

manual and review frequently for continuing safe

operation, and instructing others who may use

this tool.

READ ALL INSTRUCTIONS.

GENERAL SAFETY RULES

■ For safe operation, read and understand all

instructions before using the trimmer/brushcutter.

Follow all safety instructions. Failure to follow all

safety instructions listed below, can result in serious

personal injury.

■ Do not allow children or untrained individuals to use

this unit.

■ Never start or run the engine in a closed or poorly

ventilated area; breathing exhaust fumes can kill.

■ Clear the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire,

or string which can be thrown or become entangled in

the string head or blade.

■ Wear full eye and hearing protection while operating

this unit.

■ Wear heavy long pants, boots, and gloves. Do not

wear loose fitting clothing, short pants, jewellery of

any kind, or use with bare feet.

■ Secure long hair so it is above shoulder level to

prevent entanglement in any moving parts.

■ Keep all bystanders, children, and pets at least 15 m

away.

■ Do not operate this unit when you are tired, ill, or

under the influence of alcohol, drugs, or medication.

■ Do not operate in poor lighting.

■ Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or

exposure to hot surfaces.

■ Keep all parts of your body away from any moving part.

■ Do not touch area around the muffler or cylinder of

the trimmer/brushcutter, these parts get hot from

operation.

■ Always stop the engine and remove the spark plug

wire before making any adjustments or repairs except

for carburetor adjustments.

■ Inspect the unit before each use for loose fasteners,

fuel leaks, etc. Replace any damaged parts before use.

■ The string head or blade will rotate during carburetor

adjustments.

■ It has been reported that vibrations from hand-held

tools may contribute to a condition called Raynaud’s

Syndrome in certain individuals. Symptoms may

include tingling, numbness and blanching of the

fingers, usually apparent upon exposure to cold.

Hereditary factors, exposure to cold and dampness,

diet, smoking and work practices are all thought to

contribute to the development of these symptoms.

It is presently unknown what, if any, vibrations or

extent of exposure may contribute to the condition.

There are measures that can be taken by the operator

to possibly reduce the effects of vibration:

a) Keep your body warm in cold weather. When

opera-ting the unit wear gloves to keep the hands

and wrists warm. It is reported that cold weather is

a major factor contributing to Raynaud’s Syndrome.

b) After each period of operation, exercise to increase

blood circulation.

c) Take frequent work breaks. Limit the amount of

exposure per day.

If you experience any of the symptoms of this condition,

immediately discontinue use and see your physician

about these symptoms.

■ Keep the tool well maintained, fasteners tightened

and worn parts replaced.

■ Mix and store fuel in a container approved for fuel.

■ Mix fuel outdoors where there are no sparks or flames.

Wipe up any fuel spillage. Move 9 m away from

refueling site before starting engine.

14

Page 8

English (Original instructions)

■ Stop the engine and allow to cool before refueling or

storing the unit.

■ Allow the engine to cool; empty the fuel tank and

secure the unit from moving before transporting in a

vehicle.

SPECIFIC SAFETY RULES FOR TRIMMER USE

■ Replace string head if cracked, chipped, or damaged

in any way. Be sure the string head or blade is

properly installed and securely fastened. Failure to do

so can cause serious injury.

■ Make sure all guards, straps, deflectors and handles

are properly and securely attached.

■ Use only the manufacturer's replacement line in the

cutting head. Do not use any other cutting attachment.

■ Never operate unit without the grass deflector in

place and in good condition.

■ Maintain a firm grip on both handles while trimming.

Keep string head below waist level. Never cut with

the string head located over 76 cm or more above the

ground.

SPECIFIC SAFETY RULES FOR

BRUSHCUTTER AND BLADE USE

■ After engine stops, keep rotating blade in heavy

grass or pulpy weeks until it stops.

■ Do not operate the brushcutter unless the blade

guard is firmly secured in place and in good condition.

■ Use heavy gloves while installing or removing blades.

■ Always stop the engine and remove the spark plug

wire before attempting to remove any obstruction

caught or jammed in the blade or before removing

and installing the blade.

■ Do not attempt to touch or stop the blade when it is

rotating.

■ A coasting blade can cause injury while it continues

to spin after the engine is stopped or throttle trigger

released. Maintain proper control until the blade has

completely stopped rotating.

■ Replace any blade that has been damaged. Always

make sure blade is installed correctly and securely

fastened before each use. Failure to do so can cause

serious injury.

■ Use only the manufacturer's replacement TRI-ARC

blade intended for use on this brushcutter. Do not use

any other blade.

■ The TRI-ARC blade is suited for cutting pulpy weeds

and vines only. Do not use for any other purpose.

Never use the TRI-ARC blade to cut woody brush.

■ Exercise extreme caution when using the blade with

this unit. Blade thrust is the reaction that may occur

when the spinning blade contacts anything it cannot

cut. This contact may cause the blade to stop for an

instant, and suddenly “thrust” the unit away from the

object that was hit. This reaction can be violent enough

to cause the operator to lose control of the unit.

Blade thrust can occur without warning if the blade

snags, stalls, or binds. This is more likely to occur

in areas where it is difficult to see the material being

cut. For cutting ease and safety, approach the weeds

being cut from the right to the left. In the event an

unexpected object or woody stock is encountered,

this could minimize the blade thrust reaction.

■ Never cut any material over 13 mm diameter.

■ Always wear the shoulder strap when using the

brushcutter and adjust to a comfortable operating

position. Maintain a firm grip on both handles while

cutting with a blade. Keep the blade away from body

and below waist. Never use the brushcutter with the

blade located 76 cm or more above the ground level.

■ Cover the blade with the blade protector before

storing the unit, or during transportation. Always

remove the blade protector before using the unit.

If not removed, the blade protector could become a

thrown object as the blade begins to turn.

15

Page 9

English (Original instructions)

SPECIFICATIONS

RBC30SESB RBC30SBSB

Weight (kg)

- Without fuel, cutting attachment and harness 5.69 6.03

- Without fuel with bump head 5.97 7.13

- Without fuel with blade 5.97 7.13

Fuel tank volume [cm

Cutting swath (mm)

- Bump head 457 457

- Blade 260 260

Recommended torque for blade (Nm) >=13 >=13

Engine displacement (cm

Line diameter for ReelEasy

TM

Head (mm) 2.4 2.4

Maximum engine performance

(in accordance with ISO 8893) (kW) 0.75 0.75

Maximum rotational frequency

of the the spindle (minEngine speed (rotational frequency)

at recommended max. spindle

rotational frequency (minEngine speed (rotational frequency)

at idle (minFuel consumption (in accordance

with ISO 8893) at max. engine performance [kg/h or (L/h)] 0.42 or (0.58) 0.42 or (0.58)

Specific fuel consumption

(in accordance with ISO 8893)

at max. engine performance [g/kW.h or (L/kW.h)] 560 or (0.77) 560 or (0.77)

3

or (L)] 415 or (0.415) 415 or (0.415)

3 /

cc) 30 30

1

) 10,000 10,000

1

) 12,000 12,000

1

) 2,800-3,800 2,800-3,800

16

Page 10

English (Original instructions)

DESCRIPTION

1. Primer Bulb

2. Choke lever

3. Fuel Cap

4. Starter Grip

5. Throttle Lock

6. On / Off Switch

7. Throttle Trigger

8. Rear Handle (RBC30SESB)

9. Front Handle (RBC30SESB)

10. Shoulder Strap (RBC30SESB) / Harness

(RBC30SBSB)

11. Shaft

12. Blade Guard

13. Tri-arc Blade

14. Grass Deflector

15. Cutting Line

16. Idle Speed Screw

17. Knob

18. Hanger Cap

19. Trigger Handle (RBC30SBSB only)

20. Left Handle (RBC30SBSB only)

21. Throttle interlock (RBC30SBSB only)

22. ReelEasy

23. Latch

TM

24. Bolt (RBC30SBSB only)

25. Clamp (RBC30SBSB only)

26. Combination wrench (RBC30SBSB only)

27. Bracket (RBC30SBSB only)

28. Bike handle (RBC30SBSB only)

29. Wrench

30. Clamp

31. Screw

32. Bracket (RBC30SESB only)

33. Securing bolt (RBC30SESB only)

34. Pin (RBC30SESB only)

ASSEMBLY

Please refer to Fig. 2a - 2d.

Unpacking

This product requires assembly.

■ Carefully remove the tool and any accessories from

the box. Make sure that all items listed in the packing

list are included.

■ Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

■ Do not discard the packing material until you have

carefully inspected and satisfactorily operated the tool.

WARNING

If any parts are damaged or missing, do not

operate this tool until the parts are replaced.

Failure to heed this warning could result in

serious personal injury.

WARNING

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING

To prevent accidental starting that could cause

serious personal injury, always disconnect the

engine spark plug wire from the spark plug when

assembling parts.

WARNING

Never attach or adjust any attachment while

power head is running. Failure to stop the engine

may cause serious personal injury.

WARNING

Be certain the knob is fully tightened before

operating equipment; check it periodically for

tightness during use to avoid serious injury.

OPERATION

FUEL AND REFUELING

HANDLING THE FUEL SAFELY

WARNING

Check for fuel leaks. If any are found, correct

them before using the product to prevent fire or

burn injury.

■ Always handle fuel with care, it is highly flammable.

■ Always refuel outdoors where there are no sparks

and flames. Do not inhale fuel vapors.

■ Do not let petrol or lubricant come in contact with

your skin.

■ Keep petrol and lubricant away from the eyes. If

petrol or lubricant comes in contact with the eyes,

wash them immediately with clean water. If irritation is

still present, see a doctor immediately.

■ Clean up spilled petrol immediately.

■ Always transport and store fuel in a container

approved for petroleum.

MIXING THE FUEL

■ This product is powered by a 2-stroke engine and

requires pre-mixing petrol and 2-stroke lubricant. Premix unleaded petrol and 2-stroke engine lubricant in a

clean container approved for petrol.

■ This engine is certified to operate on unleaded petrol

intended for automotive use with an octane rating

17

(Fig. 3)

Page 11

English (Original instructions)

of 91 ([R + M] / 2) or higher.

■ Do not use any type of pre-mixed petrol / lubricant

from fuel service stations, this includes the premixed petrol / lubricant intended for use in mopeds,

motorcycles, etc.

■ Use full synthetic 2-stroke lubricant only. Do not use

automotive lubricant or 2-stroke outboard lubricant.

■ Mix 2% full synthetic 2-stroke lubricant into the petrol.

This is a 50:1 ratio.

■ Mix the fuel thoroughly and also each time before

fueling.

■ Mix in small quantities. Do not mix quantities larger

than usable in a 30 day period. Full synthetic 2-stroke

lubricant containing a fuel stabilizer is recommended.

FILLING THE TANK

WARNING

Check for fuel leaks. If any are found, correct

them before using the product to prevent fire or

burn injury.

■ Clean surface around fuel cap to prevent

contamination.

■ Loosen fuel cap slowly to release pressure and to

keep fuel from escaping around the cap.

■ Carefully pour fuel mixture into the tank. Avoid spillage.

■ Prior to replacing the fuel cap, clean and inspect

the gasket.

■ Immediately replace fuel cap and hand tighten.

Wipe upany fuel spillage. Move 9 m away from

refueling site before starting engine.

Note: It is normal for smoke to be emitted from a new

engine during and after first use.

WARNING

Always shut off engine before fueling. Never add

fuel to a machine with a running or hot engine.

Move at least 9 m from refueling site before

starting engine. Do not smoke.

STARTING AND STOPPING (Fig. 4a - 4b)

WARNING

Never start or run the engine inside a closed or

poorly ventilated area; breathing exhaust fumes

can kill.

■ Set the switch (6) to the "I" position before trying to

start unit.

TO START A COLD ENGINE:

1. Lay the trimmer on a flat, bare surface.

2. Press the primer bulb (1) 10 times.

NOTE: After the 7th press, the fuel should be visible

in the primer bulb. If not, continue pressing until the

fuel is visible.

3. Set the choke lever (2) to

4. Hold down the throttle lock (5) and then squeeze the

throttle trigger (7).

NOTE: Lock the throttle in position by depressing the

throttle interlock button (21) for RBC30SBSB.

5. Hold the foam handle tightly with left hand and pull

the starter grip (4) upwards with right hand in a quick,

firm and consistent motion until the engine attempts

to start. Do not pull the starter grip more than 4 times.

6. Set the choke lever to

7. Pull the starter grip until the engine starts. Do not pull

the starter grip more than 6 times.

NOTE: If the engine does not start, repeat the

procedure from step 3.

8. Allow the engine to run for 10 seconds, then set the

choke lever to

position.

TO START A WARM ENGINE:

1. Press the primer bulb 10 times.

2. Set the choke lever to

3. Hold down the throttle lock and then squeeze the

throttle trigger.

NOTE: Lock the throttle in position by depressing the

throttle interlock button for RBC30SBSB.

4. Hold the foam handle tightly with left hand and pull

the starter grip upwards with right hand in a quick,

firm and consistent motion until the engine starts.

choke position.

choke position.

choke position.

1 Litre + 20 ml =

2 Litres + 40 ml =

3 Litres + 60 ml = 50:1 (2%)

4 Litres + 80 ml =

5 Litres + 100 ml =

TO STOP THE ENGINE:

■ Press and hold the switch in the stop “ O ” position until

the engine stops.

OPERATING THE TRIMMER (Fig. 5)

RBC30SESB : Hold the trimmer with the right hand on the

18

Page 12

English (Original instructions)

rear handle and the left hand on the front handle.

RBC30SBSB: Hold the trimmer with the right hand on the

trigger handle and the left hand on the left handle.

Keep a firm grip with both hands while in operation. Trimmer

should be held at a comfortable position with the trigger

handle about hip height.

Always operate trimmer at full throttle. Cut tall grass

from the top down. This will prevent grass from wrapping

around the shaft housing and string head which may

cause damage from overheating. If grass becomes

wrapped around the string head, stop the engine,

disconnect the spark plug wire, and remove the grass.

Prolonged cutting at partial throttle will result in lubricant

dripping from the silencer.

CUTTING TIPS (Fig. 6)

When cutting, make sure the cutter head is at a slight

angle as shown while still approximately parallel to the

ground surface. In tall grass, cut from the top down to

ensure the moving parts do not get tangled with the long

grass / brush.

Move the head in steady strokes from left to right as you

work through the grass / brush.

ADVANCING THE LINE (Fig. 7)

FOR REELEASYTM ONLY

If the line becomes short, tap the head on the ground

as shown to extend more line. Take care not to ‘crash’ it

against a hard surface.

OPERATING THE BRUSHCUTTER (Fig. 5)

RBC30SESB: Hold the brushcutter with the right hand on

the rear handle and the left hand on the front handle.

RBC30SBSB: Hold the brushcutter with the right hand on

the trigger handle and the left hand on the left handle.

Keep a firm grip with both hands while in operation.

Brushcutter should be held at a comfortable position with

the trigger handle about hip height. Maintain your grip and

balance on both feet. Position yourself so that you will

not be drawn off balance by the kick-back reaction of the

cutting blade.

Adjust the shoulder strap to position the brushcutter at

a comfortable operating position and to assure that the

shoulder strap will reduce the risk of operator contact

with the blade.

Exercise extreme caution when using the blade

with this unit. Blade thrust is the reaction which

may occur when the spinning blade contacts

anything it cannot cut. This contact may cause

the blade to stop for an instant, and suddenly

“thrust” the unit away from the object that was hit.

This reaction can be violent enough to cause the

operator to lose control of the unit. Blade thrust may

occur without warning if the blade snags, stalls or binds.

This is more likely to occur in areas where it is difficult to

see the material being cut. For cutting ease and safety,

approach the weeds being cut from the right to the left.

In the event that an unexpected object or woody stock is

encountered, this could minimise the blade thrust reaction.

CUTTING TECHNIQUE - BLADE (Fig. 8)

WARNING

Extreme care must be taken when using blades

to ensure safe operation. Read the safety

information for safe operation using the blade,

refer to “Specific Safety Rules for Brushcutter

and Blade Use” earlier in this manual.

MAINTENANCE

WARNING

Use only original manufacturer's replacement

parts, accessories and attachments. Failure to

do so can cause possible injury, poor performance and may void your warranty.

■ The cutting attachment must not work in idle mode.

If this requirement is not satisfied, the clutch has

to be adjusted or the machine needs an urgent

maintenance by a qualified technician.

■ You may make adjustments and repairs described

here. For other repairs, have the trimmer serviced by

an authorized service agent.

■ Consequences of improper maintenance may

include excess carbon deposits resulting in loss of

performance and discharge of black lubricant residue

dripping from the muffler.

■ Make sure all guards, straps, deflectors and handles

are properly and securely attached to avoid the risk of

personal injury.

STRING REPLACEMENT (Fig. 9)

FOR REELEASYTM ONLY

■ Ensure the unit is in the off position

■ Remove the spark plug lead to prevent accidental

starting.

■ Use a 2.4mm diameter monofilament string.

■ Cut one piece of string approximately 6 m in length.

■ Rotate the knob on the string head until the line on

knob aligns with the arrows on the top of string head.

19

Page 13

English (Original instructions)

■ Insert one end of the string into the eyelet located

on the side of the string head and push until string

comes out through eyelet on the other side. Continue

to push string through the string head until the middle

section of the string is inside the string head and

string outside the string head is evenly divided on

each side.

■ Rotate the knob on the string head clockwise to wind

the string.

■ Wind the string until approximately 20cm remains

protruding from the string head.

BLADE PROTECTOR (Fig. 10)

Always place the blade protector on the blade when the

unit is not in use. The blade protector has clips round the

edges to snap over the blade and keep it in place. Wear

gloves and be cautious when handling the blade.

NOTE: Always remove the blade protector before

using the unit. If not removed, the blade protector could

become a thrown object as the blade begins to turn.

CLEANING THE EXHAUST PORT AND

SILENCER

Depending on the type of fuel used, the type and amount

of lubricant used, and/or your operating conditions, the

exhaust port and silencer may become blocked with

carbon deposits. If you notice a power loss with your

petrol powered tool, a qualified service technician will

need to remove these deposits to restore performance.

SPARK ARRESTOR

It is recommended to clean or replace the spark arrestor

every 25 hours to ensure proper performance of your

product. Spark arrestors may be in different locations

depending on the model purchased. Please contact

your nearest service dealer for the location of the spark

arrestor for your model.

ATTACHING THE HANGER CAP (Fig. 11)

To use the hanger cap, push in the button and place the

hanger cap over the lower end of the attachment. Slightly

rotate the cap from side to side until the button locks into

place.

NOTE: The secondary hole in the attachment shaft can

be used for hanging purposes as well.

CLEANING THE AIR FILTER SCREEN (Fig. 12)

For proper performance and longer life, keep the air filter

screen clean.

■ Remove the air filter cover by pushing down the latch

while gently pulling out the cover.

■ Brush the air filter screen lightly.

■ Replace the air filter cover by inserting the tabs of the

cover into the slots on the air filter base, then push

the cover up until it latches securely in place.

FUEL CAP

WARNING

A leaking fuel cap is a fire hazard and must be

replaced immediately.

SPARK PLUG (Fig. 13)

This engine uses a Champion RCJ-6Y or equivalent

spark plug with 0.63 mm electrode gap. Use an exact

replacement.

STORAGE (1 MONTH OR LONGER)

■ Drain all fuel from tank into a container approved

for fuel. Run engine until it stops.

■ Clean all foreign material from the trimmer. Store it in

a well-ventilated place that is inaccessible to children.

Keep away from corrosive agents such as garden

chemicals and de-icing salts.

■ Abide by all ISO and local regulations for the safe

storage and handling of fuel. Excess fuel should be

used up in other 2-stroke engine powered equipment.

20

Page 14

English (Original instructions)

TROUBLESHOOTING

IF THESE SOLUTIONS DO NOT SOLVE THE PROBLEM, CONTACT YOUR AUTHORISED SERVICE DEALER.

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will not start.

Engine starts but will not

ac cel er ate.

Engine starts but will only run at

high speed at half choke.

Engine does not reach full speed

and emits ex ces sive smoke.

Engine starts, runs, and Idle speed screw on Contact a servicing dealer.

accelerates but will not idle.

Blade continues to rotate Carburetor requires. Contact a servicing dealer.

at idle speed. adjustment.

Line will not advance. 1. Line welded to itself. 1. Lubricate with silicone spray.

2. Not enough line on 2. Install more line. Refer to “Line Replacement”

spool. earlier in this manual.

3. Line worn too short. 3. Pull lines while alternately pressing down on

4. Line tangled on spool. 4. Remove line from spool and rewind. Refer to

“Line Replacement” earlier in this manual.

5. Engine speed too slow. 5. Advance line at full throttle.

No spark.

No fuel.

Engine is flooded.

Starter rope now harder to

pull than when new.

Old fuel.

Engine requires

approximately three minutes

to warm up.

Carburetor requires

adjustment.

Check lubricant fuel mixture.

Air filter is dirty.

Spark arrestor screen is dirty.

carburetor requires adjustment

The spark plug may be damaged, remove it and check

for dirt and cracks. Replace with a new spark plug.

Push primer bulb until bulb is full of fuel. If bulb does

not fill, primary fuel delivery sys tem is blocked. Con tact

a servicing dealer. If prim er bulb fills, engine may be

flooded, proceed to next item.

Remove spark plug, turn unit so spark plug hole is

aimed at the ground. Rotate the choke dial to “

” position and pull starter cord 10 to 15 times. This

will clear excess fuel from en gine.

which splashed on the product. Clean and reinstall

spark plug. Clean up any spilled fuel and move at

least 9m away before restarting. Pull starter three times

with choke dial at “

choke dial to “

pro ce dure. If engine still fails to start, repeat pro ce dure

with a new spark plug.

Contact a servicing dealer.

Only use fresh fuel mixed with recommended oil. Fuel over

30 days old may prevent the unit from starting.

Allow engine to completely warm up. If engine does

not accelerate after three minutes, contact a ser vic ing

dealer.

Contact a ser vic ing dealer.

Use fresh fuel and the correct 2-stroke lubricant mix.

Clean air filter. Refer to Clean ing the Air Filter Screen

earlier in this manual.

Contact a servicing dealer.

and releasing bump head.

”. If en gine does not start, rotate

” position and repeat normal starting

Remove any fuel

21

Page 15

English (Original instructions)

TROUBLESHOOTING

IF THESE SOLUTIONS DO NOT SOLVE THE PROBLEM, CONTACT YOUR AUTHORISED SERVICE DEALER.

PROBLEM POSSIBLE CAUSE SOLUTION

Grass wraps round shaft 1. Cutting tall grass at 1. Cut tall grass from the top down.

housing and string head. ground level.

2. Operating trimmer at 2. Operate trimmer at full throttle.

part throttle.

Bump knob hard to turn. Screws threads dirty or Clean threads and lubricate with grease - if no

damaged. improvement, replace bump knob.

Lubricant drips from muffler. 1. Operating trimmer at 1. Operate trimmer at full throttle.

part throttle.

2. Check lubricant/fuel mixture. 2.

3. Air filter dirty. 3. Clean per instruction in Maintenance Section.

Use fresh fuel and the correct full synthetic 2-stroke lubricant

mix.

22

Page 16

EN Inspection after dropping or other impacts: Thoroughly inspect the product and identify any affections or damage with

it. Any part that is damaged should be properly repaired or replaced by an authorized service centre.

FR Véri¿ cation après une chute ou autres chocs: Véri¿ ez minutieusement l'appareil et repérez tout dommage éventuel.

Toute pièce endommagée doit être correctement remplacée ou réparée par un service après-vente agréé.

DE Inspektion nach einem Fall oder anderen Schlägen: Inspizieren Sie das Produkt gründlich und identi¿ zieren jegliche BeeinÀ ussung

oder Beschädigung. Jedes beschädigte Teil sollte durch den autorisierten Kundendienst ordnungsgemäß repariert oder ausgetauscht

werden.

ES Inspección tras caídas u otros impactos: Inspeccione cuidadosamente el producto para identi ¿ car cualquier problema o

daño. Cualquier pieza dañada debe ser sustituida o reparada adecuadamente por un centro de servicio autorizado.

IT Controllare l'utensile dopo che è caduto o dopo altri tipi di impatti: Ispezionare il prodotto e identi¿ care eventuali difetti

o danni. Riparare eventuali parti danneggiate o farle sostituire da un centro servizi autorizzato.

NL Controleer het apparaat nadat u het hebt laten vallen of bij impact: Controleer het apparaat grondig en ga alle defecten

of schade na. Een beschadigd onderdeel moet door een geautoriseerd onderhoudscentrum goed worden gerepareerd of

vervangen.

PT Inspecção após quedas ou outros impactos: Inspeccione cuidadosamente o produto para identi¿ car qualquer problema

ou dano. Qualquer peça dani¿ cada deve ser substituída ou reparada adequadamente por um centro de serviço autorizado.

DA Inspektion efter tab eller andre slagpåvirkninger: Produktet skal inspiceres grundigt, og evt. påvirkninger eller skader

skal lokaliseres. Enhver del, som bliver beskadiget, skal repareres ordentligt eller udskiftes på et autoriseret servicecenter.

SV Inspektion efter att produkten tappats eller utsatts för stötar: Kontrollera produkten noggrant för att identi¿ era eventuella

skador på den. Skadade delar skall repareras ordentligt eller bytas ut av en auktoriserad service¿ rma.

FI Tarkastaminen pudottamisen ja muiden iskujen jälkeen: Tarkista tuote huolella ja paikanna kaikki vauriot ja viat.

Valtuutetun huoltopisteen on korjattava tai vaihdettava vioittuneet osat asianmukaisesti.

NO Inspeksjon etter fall og andre former for støt: Det sekundære hullet i tilbehørsskaftet kan også brukes til hengeformål.

Enhver del som er skadet må repareres eller skiftes ut ved et autorisert serviceverksted.

RU Ɉɫɦɨɬɪ ɩɨɫɥɟ ɩɚɞɟɧɢɹ ɢɥɢ ɞɪɭɝɢɯ ɭɞɚɪɨɜ: ȼɧɢɦɚɬɟɥɶɧɨ ɨɫɦɨɬɪɢɬɟ ɭɫɬɪɨɣɫɬɜɨ ɧɚ ɨɬɫɭɬɫɬɜɢɟ ɩɨɜɪɟɠɞɟɧɢɣ ɢ

ɩɨɥɨɦɨɤ. ȼ ɫɥɭɱɚɟ ɩɨɜɪɟɠɞɟɧɢɹ ɤɚɤɨɣ-ɥɢɛɨ ɞɟɬɚɥɢ ɧɟɨɛɯɨɞɢɦɨ ɨɛɪɚɬɢɬɶɫɹ ɜ ɚɜ

ɜɵɩɨɥɧɟɧɢɹ ɧɚɞɥɟɠɚɳɟɝɨ ɪɟɦɨɧɬɚ ɢɥɢ ɡɚɦɟɧɵ.

PL Sprawdzenie po upuszczeniu lub innych uderzeniach: NaleĪy dokáadnie sprawdziü produkt w celu stwierdzenia

wszelkich uszkodzeĔ.

CS Prohlídka po pádu þi jiných úderech: Výrobek ĜádnČ prohlédnČte a zjistČte vady þi poškození. Jakýkoliv poškozený díl je

nutné správnČ opravit nebo nechat vymČnit v autorizovaném servisním stĜedisku.

HU Leesés vagy más ütés utáni átvizsgálás: Alaposan vizsgálja át a terméket, és keresse meg az esetleges behatásokat

vagy sérüléseket. A sérült alkatrészeket egy hivatalos szervizközpontban kell megjavíttatni vagy kicseréltetni.

RO InspecĠia după cădere sau alte impacturi: InspectaĠi amănunĠit produsul úi identi¿ caĠi orice defecĠiuni sau pagube ale

acestuia. Orice piesă deteriorată trebuie să ¿ e reparată în mod corespunzător sau înlocuită de un service autorizat.

LV P Ɨrbaude pƝc nosviešanas vai citiem triecieniem: RnjpƯgi pƗrbaudiet produktu un nosakiet jebkƗdas radušƗs vainas vai

bojƗjumus. Jebkura bojƗta detaƺa jƗnodod remontam vai nomaiƼai pilnvarotƗ apkopes centrƗ.

LT Patikrinimas Ƴ

detalĊ leidžiama remontuoti arba keisti tik autorizuotame aptarnavimo centre.

ET Kontrollige pärast mahakukkumist või saadud lööki: Kontrollige saag hoolikalt üle ja tehke kindlaks võimalikud rikked ja

vigastused. Vigastatud osad tuleb lasta pädeval hooldajal parandada või asendada.

HR Provjerite nakon pada ili drugih udara: Temeljito provjerite proizvod i identi¿ cirajte sve utjecaje ili ošteüenja. Svaki

ošteüeni dio trebao bi pravilno popraviti ili zamijeniti ovlašteni servisni centar.

SL Pregled, þe naprava pade ali prejme drug udarec: Temeljito preglejte izdelek in opazujte, ali je morda poškodovan. Vsak

poškodovani del mora ustrezno popraviti ali zamenjati pooblašþeni servisni center.

SK Kontrola po páde þi iných nárazoch: Dôkladne skontrolujte produkt a zistite na Ėom prípadné poruchy, þi poškodenia.

AkýkoĐvek poškodený diel sa musí náležite opraviĢ alebo vymeniĢ v autorizovanom servisnom centre.

BG ɉɪɨɜɟɪɤɚ ɫɥɟɞ ɢɡɩɭɫɤɚɧɟ ɢɥɢ ɞɪɭɝɢ ɭɞɚɪɢ: ȼɧɢɦɚɬɟɥɧɨ ɩɪɨɜɟɪɟɬɟ ɩɪɨɞɭɤɬɚ ɢ ɭɫɬɚɧɨɜɟɬɟ ɞɚɥɢ ɟ ɡɚɫɟɝɧɚ

ɩɨɜɪɟ

rankiui nukritus ar po kitǐ smnjgiǐ: Atidžiai patikrinkite prietaisą, ar jis nepažeistas. Bet kurią apgadintą

ɞɚ ɩɨ ɧɟɝɨ. ȼɫɹɤɚ ɩɨɜɪɟɞɟɧɚ ɱɚɫɬ ɬɪɹɛɜɚ ɞɚ ɛɴɞɟ ɩɨɩɪɚɜɟɧɚ ɢɥɢ ɡɚɦɟɧɟɧɚ ɨɬ ɭɩɴɥɧɨɦɨɳɟɧ ɫɟɪɜɢɡɟɧ ɰɟɧɬɴɪ.

ɬɨɪɢɡɨɜɚɧɧɵɣ ɫɟɪɜɢɫɧɵɣ ɰ

ɟɧɬɪ ɞɥɹ

ɬ, ɢɥɢ ɢɦɚ

Page 17

ClEaN aNd rEplaCE thE foam filtEr (fig. 14)

EN

■ Remove the air box cover from the engine.

■ Remove the air filter.

■ Clean the foam filter. If damaged, replace immediately.

■ Reinstall the foam filter.

■ Reinstall the air filter.

fr

NEttoyEz Et rEmplaCEz lE filtrE EN moussE

(fig. 14)

■ Retirez le couvercle de la boîte à air du moteur.

■ Retirez le filtre à air.

■ Nettoyez en place le filtre en mousse. Si elles sont

endommagées, faites-les remplacer immédiatement.

■ Remettez en place le filtre en mousse.

■ Remettez le filtre à air.

dE

rEiNiguNg dEs luftfiltErsiEBEs (aBB. 14)

■ Entfernen Sie den Deckel des Luftfilterkastens von dem

Motor.

■ Entfernen Sie die den Luftfilter

■ Reinigen sie den Schaumstofffilter. Ersetzen Sie es

unverzüglich, falls es beschädigt sein sollte.

■ installieren Sie den Schaumstofffilter.

■ Den Luftfilter wieder einbauen.

limpiE y sustituya El filtro dE Espuma (fig.14)

Es

■ Retire la tapa de la caja de aire del motor.

■ Retire el filtro de aire

■ Limpie el filtro de espuma. Si están dañadas, substitúyalas

cuanto antes.

■ Vuelva a instalar el filtro de espuma.

■ Vuelva a instalar el filtro de aire.

it

pulirE E sostituirE il filtro pEr la sChiuma

(fig. 14)

■ Rimuovere il coperchio della scatola dell’aria dal motore.

■ Rimuovere il filtro dell’aria

■ Pulire il filtro in poliuretano. Se appaiono danneggiate,

richiederne l’immediata sostituzione.

■ Reinstallare il filtro in poliuretano.

■ Reinstallare il filtro dell’aria.

maak dE sChuimfiltEr sChooN EN vErvaNg

Nl

dEzE (afB. 14)

■ Verwijder het omstelklepdeksel van de motor.

■ Verwijder de luchtfilter.

■ Reinig de schuimfilter. Bij beschadiging, moeten zij

onmiddellijk worden

■ vervangen.

■ Herbevestig de schuimfilter.

■ Plaats het luchtfilter terug.

limpE E suBstitua o filtro dE Espuma (fig. 14)

pt

■ Retire a tampa da caixa de ar do motor.

■ Retire o filtro de ar.

■ Limpe o filtro de espuma. Se estiverem danificadas, mande

substitui-las imediatamente.

■ Volte a instalar o filtro de espuma.

■ Reinstale o filtro de ar.

da

rENs og udskift skumfiltrEt (fig. 14)

■ Fjern luftdækslet fra motoren.

■ Fjern luftfilteret.

■ Rens skumfilteret. Beskadigede skumfilteret skal udskiftes

omgående.

■ Genmonter skumfilteret.

■ Montér luftfilteret igen.

rENgör oCh sätt tillBaka skumfiltrEt (fig.

sv

14)

■ Ta bort luftlådeskyddet från motorn.

■ Ta bort luftfiltret.

■ Rengör skumgummifiltret. Byt omedelbart ut om den är

skadad.

■ Sätt tillbaka skumgummifiltret.

■ Sätt tillbaka filtret.

fi

puhdista ja vaihda vaahtosuodatiN (kuva 14)

■ Poista imukotelon kansi moottorista.

■ Irrota ilmansuodatin

■ Puhdista vaahtomuovisuodatin. Mikäli ne ovat vialliset,

vaihda ne välittömästi.

■ Asenna vaahtomuovisuodatin.

■ Asenna ilmansuodatin uudelleen.

rENgjør og sEtt tilBakE skumfiltErEt (fig.

No

14)

■ Fjern luftboksdekslet fra motoren.

■ Fjern luftfilteret.

■ Rengjør skumfilteret. Hvis skadet må den øyeblikkelig skiftes

ut.

■ Reinstaller skumfilteret.

■ Sett på plass filteret igjen.

Очистите и устанОвите на местО

ru

пенОпластОвый фильтр(рис . 14)

■ Снимите крышку воздушной камеры с двигателя.

■ Снимите воздушный фильтр.

■ Очистите на пенопластовый фильтр. В случае

повреждения сразу же замените его.

■ Yстановите на пенопластовый фильтр.

■ Установите воздушный фильтр.

Page 18

Une projection de la lame

FR

survenir sans prévenir.

Continued movement of saw

EN

blade after cutting through log.

Die Klinge kann ohne

DE

Vorwarnung zurückschlagen.

ES

Puede producirse un

rebote inesperado

La lama potrà rimbalzare

IT

senza avvertenze se scatta

O impulso da lâmina pode

PT

ocorrer sem aviso

Het maaiblad kan plots

NL

terugslaan

Återkast kan uppstå utan

SV

förvarning

Klinge-tilbageslag kan ske

DA

uden varsel

Slike reaksjoner kan oppstå

NO

uten forvarsel

Tällainen takapotku saattaa

FI

tapahtua varoittamatta

A vágókés hirtelen

HU

kilökődését okozhatja

Odmrštění nože může

CS

nastat bez varování

Отскок режущего

RU

лезвия может произойти

неожиданно

Accelerarea lamei poate să

RO

apară fără avertisment

Zjawisko odrzutu może

PL

wystąpić bez ostrzeżenia

SL

Pride lahko do povratnega

udarca rezila

Odbacivanje noža može se

HR

dogoditi bez upozorenja

Tera põrkumine võib

ET

ilmneda ilma hoiatamata

Geležtės sviedimas gali

LT

pasireikšti be įspėjimo

Asmens rāviens var

LV

negaidīti rasties

Ak sa ostrie zachytí,

SK

zapadne alebo zovrie,

môže bez výstrahy dôjsť k

Обратен тласък може да

BG

възникне изненадващо

Gardez vos mains à

l'écart des lames.

Risk of getting cut,

operate carefully.

Halten Sie die Hände

von den Klingen fern!

Mantenga las manos

alejadas de las hojas.

Tenere le mani lontane

dalle lame.

Mantenha as mãos

afastadas das lâminas.

Houd handen weg van

snijbladen.

Håll händerna borta från

bladen.

Hold hænderne på

afstand af knivene.

Hold hendene vekke fra

kniven.

Pidä kädet kaukana

teristä.

Tartsa a kezeit távol a

késektől.

Udržujte ruce mimo

nože.

Не касайтесь режущих

полотен.

Ţineţi mâinile departe

de lame.

Nie zbliżać rąk do

ostrzy.

Roke držite proč od

rezil.

Držite ruke dalje od

oštrica.

Hoidke käed

lõiketeradest eemal.

Rankas laikykite toliau

nuo geležčių.

Neturiet rokas asmeņu

tuvumā.

Ruky nedávajte do

blízkosti ostrí.

Дръжте ръцете си далеч

от остриетата.

Position marche

Run position

Laufstellung

Posición de

funcionamiento

Posizione di corsa

Posição de

funcionamento

Stand draaien

Körläge

Arbejdsstilling

Kjørestilling

Käyntiasento

Be pozíció

Pracovní poloha

Положение вкл

Poziţia mers

W pozycji "działanie"

Položaj teka

Položaj uključeno

Tööasend

Veikimo padėtis

Ieslēgts stāvoklis

Poloha zapnuté

Включено положение

Mettez le levier de starter en

position "FULL".

Set the choke lever to “FULL”

choke position.

Stellen Sie den Chokehebel

auf die "VOLL" Position.

Coloque la palanca del

estrangulador en posición

“FULL”.

Posizionare la leva dell'aria sulla

posizione “FULL” (Pieno).

Defina a alavanca de controlo

para a posição de “FULL”.

Zet de chokehendel in de

chokestand "FULL".

Ställ in chokespaken i

"FULL"-läge.

Indstil chokerhåndetaget i

chokerposition “FULL” (=fuld).

Sett chokespaken til ”FULL”

chokeposisjon.

Aseta rikastinvipu asentoon

"FULL".

Állítsa a fojtókart „FULL”

(TELJES) fojtás állásba.

Nastavte páku sytiče do

polohy „FULL“.

Установите рычажок дросселя

в положение "FULL" (Полные

обороты).

Setaţi maneta şocului la

poziţia „FULL”.

Ustaw dźwignię ssania w

położeniu „FULL”.

Ročico dušilne lopute

premaknite v položaj »FULL«

(polna zadušitev).

Postavite polugu čoka u

položaj čoka “FULL” (PUNO).

Seadke õhuklapi hoob

asendisse "SULETUD".

Nustatykite droselio svirtį į

“Full” droselio padėtį.

Iestatiet droseles sviru

pozīcijā “FULL” (pilna slodze).

Nastavte páčku sýtiča do

polohy „FULL“.

Поставете дроселния лост на

позиция “FULL” (Пълно).

Mettez le levier de starter en

position "HALF".

Set the choke lever to "HALF"

choke position.

Stellen Sie den Chokehebel

auf die "HALB" Position.

Coloque la palanca del

estrangulador en la posición

“HALF”.

Posizionare la leva dell'aria

sulla posizione “CHOKE”.

Defina a alavanca de controlo

para a posição de “HALF”.

Zet de chokehendel in de

chokestand "HALF".

Ställ in chokespaken i

"HALF"-läge.

Indstil chokerhåndetaget i

chokerposition “HALF” (=halv).

Sett chokespaken til ”HALF”

(halv) chokeposisjon.

Aseta rikastinvipu asentoon

"HALF".

Állítsa a fojtókart „HALF”

(FÉL) fojtás állásba.

Nastavte páku sytiče do

polohy „HALF“.

Установите рычажок дросселя

в положение "HALF" (Половина

оборотов).

Setaţi maneta şocului la

poziţia „HALF”.

Ustaw dźwignię ssania w

położeniu „HALF”.

Ročico dušilne lopute

premaknite v položaj »HALF«

(polovična zadušitev).

Postavite polugu čoka u

položaj čoka “HALF” (POLA).

Seadke õhuklapi hoob

asendisse "POOL".

Nustatykite droselio svirtį į

“Half” droselio padėtį.

Iestatiet droseles sviru

pozīcijā "HALF" (pusslodze).

Nastavte páčku sýtiča do

polohy „HALF“.

Поставете дроселния лост на

позиция “HALF” (Наполовина).

Page 19

Mettez le contacteur

FR

d'allumage en position "I"

(MARCHE).

Set the ignition switch to the

EN

"I" (ON) position.

Schalten Sie den Zündungsschalter

DE

auf die "I" (AN) Position.

Ponga el interruptor de

ES

encendido en la posición “I”

(ENCENDIDO).

Posizionare l'interruttore di

IT

accensione su “I” (ON).

Coloque o interruptor de

PT

ignição na posição "I" (ON),

ligado.

Plaats de ontstekingsschakelaar

NL

in de stand "I" (AAN).

Sätt tändningskontakten i

SV

läge "I" (PÅ).

Sæt tændingskontakten i

DA

pos. "I" (=ON).

Sett tenningsbryteren til

NO

"I"-posisjon (ON) .

Aseta käynnistyskytkin

FI

asentoon "I" (Päällä).

A gyújtáskapcsolót állítsa „I”

HU

(BE) állásba.

Nastavte spínač zapalování

CS

do polohy "I" (Zap.).

Установите ключ зажигания

RU

в положение "I" (ВКЛ.).

Setaţi comutatorul de aprindere

RO

în poziţia "I" (PORNIT).

PL

Ustawić przełącznik zapłonu

w położeniu ( I ) (ON).

Stikalo za vžig prestavite v

SL

položaj »I« (VKLOP).

Postavite prekidač paljenja

HR

u položaj "I" (Uključeno).

Seadke süütelüliti asendisse

ET

"I" (SEES).

Uždegimo jungiklį nustatykite į „I“

LT

(įjungta) padėtį.

Aizdedzes slēdzi iestatiet

LV

pozīcijā “I” (Iesl.).

Prepnite spínač zapaľovania

SK

do polohy „I“ (zapnuté).

Поставете стартиращия ключ в

BG

позиция „I“ (включено).

Pressez la poire d'amorçage

à 10 reprises.

Press the primer bulb 10

times.

Drücken Sie die

Einspritzpumpe 10 Mal.

Pulse el cebador 10 veces.

Premere la pompetta 10

volte.

Pressione o cartucho

principal 10 vezes.

Druk 10 keer op de

brandstofbalg.

Tryck på primerknappen 10

gånger.

Pres spædebolden ind 10

gange.

Trykk på primerballongen

10 ganger.

Paina pumppauspalloa 10

kertaa.

Nyomja meg az adagolószivattyú

gombját 10-szer.

Stiskněte 10-krát hlavičku

startéru.

Нажмите 10 раз кнопку

подсоса.

Apăsaţi pompa de amorsare

de 10 ori.

Naciśnij pompkę ręczną

paliwa 10 razy.

10-krat pritisnite črpalni

mehurček.

Pritisnite pumpicu za gorivo

10 puta.

Suruge etteandekuplile 10

korda.

Paspauskite užvedimo

lemputę 10 kartų.

Nospiediet degvielas

pumpīti 10 reizes.

Stlačte primárnu banku

10-krát.

Натиснете помпата за

подкачване на горивото 10 пъти.

Tirez sur la poignée du lanceur

jusqu'à ce que le moteur

démarre.

Pull the starter grip until the

engine starts.

Den Startergriff ziehen bis der

Motor anspringt.

Tire de la palanca de arranque

hasta que el motor arranque.

Tirare la leva di avvio fino a che

non si avvia il motore.

Puxe a pega de arranque até que

o motor arranque.

Trek aan de startkoord tot de

motor start.

Dra i startsnöret tills motorn

startar.

Træk i starthåndtaget, til motoren

starter.

Dra starterhåndtaket inntil

motoren starter.

Nykäise käynnistimen kahvasta

siten, että moottori käynnistyy.

Húzza az indítófogantyút addig,

amíg a motor be nem indul.

Tahejte za rukojeť spouštěče, až

se spustí.

Дергайте за ручку стартера,

пока двигатель не запустится.

Trageţi mânerul starterului până

când motorul porneşte.

Pociągnij za uchwyt rozrusznika

tak, aby uruchomić silnik.

Zagonski ročaj povlecite

tolikokrat, da se motor zažene.

Povucite ručku za pokretanje dok

se motor ne pokrene.

Tõmmake starteri käepidemest

kuni mootor käivitub.

TRAUKITE rankinį starterį tol, kol

variklis užsiveda.

Pavelciet palaišanas rokturi līdz

dzinējs sāk darboties.

Poťahujte rukoväť štartéra, kým

sa motor nespustí.

Издърпайте ръкохватката на стартера,

докато двигателят се стартира.

Squeeze the throttle lock and throttle trigger

to run.

Enfoncez le verrouillage de l'accélérateur ainsi

la gâchette de l'accélérateur pour démarrer.

Auslösersicherung und Gashebel zum Betrieb

drücken.

Deslice el bloqueo del acelerador y el gatillo

del acelerador para arrancar el motor.

Premere il dispositivo di blocco e la valvola a

farfalla si avvierà.

Druk op de snelheidsvergrendeling en de

snelheidsregelaar om te draaien.

Deslize o bloqueio do acelerador e o gatilho

do acelerador para arrancar o motor.

Pres gaslåsen og gasudløseren ind for at

starte.

Tryck in gaslåset och gasreglaget för körning.

Käytä laitetta puristamalla kaasuttimen

lukitusta ja kaasuliipaisinta.

Klem inn avtrekkerlåsen og avtrekkeren for

å kjøre.

Нажмите рычажок блокировки и курковый

выключатель.

Nacisnąć przycisk blokady przepustnicy i przycisk

uruchamiania przepustnicy, aby uruchomić urządzenie.

Stiskněte zámek spouště a spoušť plynu pro

chod.

Húzza meg a gázrögzítőt és a gázkart a

működtetéshez.

Strângeţi opritorul acceleraţiei şi declanşatorul

acceleraţiei pentru a porni.

Nospiediet droseļaizbīdņa fiksatoru un

droseles regulatoru, lai uzsāktu darbību.

Jei norite prietaisą įjungti, nuspauskite

perjungiklio užraktą ir droselinį perjungiklį.

Vajutage töötamiseks seguklapi

lukustusnupule ja gaasipäästikule.

Za pokretanje stišćite bravu sklopke gasa i

sklopku.

Za zagon stisnite zaklep ročice za plin in

ročico za plin.

Zariadenie sa spustí stlačením poistného

tlačidla a regulačného spínača.

Стиснете фискатора и дросела, за да

заработил.

Page 20

FR

Temps d'attente 10 secondes.

EN

Waiting time 10 seconds.

DE

Wartezeit 10 Sekunden.

ES

Tiempo de espera 10 segundos.

IT

Tempo di attesa 10 secondi.

PT

Tempo de espera 10 segundos.

NL

Wachttijd 10 seconden.

SV

Väntetid 10 sekunder.

DA

Ventetid 10 sekunder.

NO

Ventetid 10 sekunder.

FI

Odotusaika 10 sekuntia.

HU

Várakozási idő 10 másodpercig.

CS

Čekací doba 10 sekund.

RU

Необходимо подождать 10 секунд.

RO

Timp de aşteptare 10 secunde.

PL

Czas oczekiwania 10 sekund.

SL

Čas čakanja 10 sekund.

HR

Vrijeme čekanja 10 sekundi.

ET

Ooteaeg 10 sekundi.

LT

Laukimo laikas 10 sekundžių.

LV

Gaidīšanas laiks 10 sekundes.

SK

Doba čakania 10 sekúnd.

BG

Време на изчакване 10 секунди.

Pour arrêter le moteur, placez l'interrupteur sur

“O”, en position ARRÊT .

To stop the engine, move the ignition switch to

the “O” stop position .

ZumAbstellen des Motors den Zündschalter in

die “O” Stoppstellung bringen .

Para parar el motor, desplace el interruptor de

encendido a la posición “O” de parada .

Per arrestare il motore, portare l’interruttore di

accensione in posizione “O” .

Para parar o motor, coloque o interruptor de

ignição na posição “O” de paragem .

Om de motor af te zetten, zet u de

contactschakelaar in de stopstand “O” .

För att stanna motorn, flytta tändningen till läget

"O" stopp .

Motoren standser, når tændingskontakten

sættes på “O” .

For å stoppe motoren, trykker du bryteren til

“O”-stillingen .

Pysäytä moottori siirtämällä virtalukko ”O”pysäytysasentoon .

A motor leállításához helyezze a kapcsolót "O"

állásba, KI pozícióba .

Motor nářadí se vypíná nastavením vypínače

do polohy "O", tj. do polohy "VYPNUTO" .

Чтобы остановить мотор поставьте

выключатель на "О", в положение ВЫКЛ .

Pentru a opri motorul, puneţi întrerupătorul în

poziţia "O", în poziţia OPRIT .

Aby zatrzymać silnik, ustawić wyłącznik na

pozycję "O", w pozycji ZATRZYMANIE .

Da bi zaustavili motor, pomaknite stikalo za

vžig v položaj “O” za zaustavitev .

Da biste zaustavili motor, stavite sklopku u

položaj “O”, na ZAUSTAVLJENO .

Mootori seiskamiseks seadke lüliti asendisse

“O” .

Kad išjungtumėte variklį, perjunkite jungiklį į

“O”, išjungimo padėtį .

Dzinēju aptur, pagriežot slēdzi izslēguma

stāvoklī, kas apzīmēts ar “O” .

Motor vypnete prepnutím spínača zapaľovania

do polohy “O” (vypnuté) .

Двигателят се изключва, като поставите

превключвателя на "O" в положение за СПИРАНЕ .

Le niveau de puissance sonore garanti est

111 d B

.

Guaranteed sound power level is 111 d B.

Der garantierte Schallleistungspegel

beträgt 111 d B.

El nivel de potencia sonoro garantizado es

de 111 d B.

Il livello garantito di potenza sonora è di

111 d B.

O nível de potência sonoro garantido é

de 111 d B.

Het gegarandeerd geluidsniveau bedraagt

111 d B.

Garanterad ljudnivå är 111 d B.

Det garanterede lydeffektniveau er 111 dB.

Garantert lydeffektnivå er 111 dB.

Taattu äänenteho on 111 dB.

Garantált hangteljesítményszint: 111 d B.

Zaručená hladina akustického výkonu je

111 d B.

Гарантируемый уровень звуковой

мощности составляет

Nivelul de putere sonoră garantat este

de 111 d B.

Maksymalny poziom natężenia hałasu

wynosi 111 d B.

Zajamčena raven zvočne moči je 111 d B.

Jamčena razina zvučne snage 111 d B.

Garanteeritud helivõimsuse tase on 111

dB

.

Garantuotas garso galios lygis yra 111 d B.

Garantētais skaņas jaudas līmenis ir

111 d B.

Garantovaná hladina akustického výkonu

je 111 d B.

Гарантираното ниво на шум е 111 d B.

111 d B.

Page 21

Conformité GOST-R

FR

GOST-R Conformity

EN

GOST-R-Konformität

DE

Conformidad con GOST-R

ES

Conformità GOST-R

IT

Conformidade GOST-R

PT

GOST-R-conformiteit

NL

GOST-R-konformitet

SV

GOST-R Overensstemmelse

DA

GOST-R samsvar

NO

GOST-R-vastaavuus

FI

GOST-R megfelelőség

HU

Shoda GOST-R

CS

Соответствие требованиям GOST-R

RU

Conform GOST-R

RO

Zgodność GOST-R

PL

Skladnost GOST-R

SL

HR

Sukladno GOST-R

ET

GOST-R vastavus

GOST-R suderinimas

LT

LV

GOST-R atbilstība

SK

GOST-R konformita

BG

GOST-R Съответствие

Page 22

English Français Deutsch Español Italiano Nederlands Português

Dansk Svenska Suomi Norsk Русский

Model Modell Malli Modell Модель RBC30SESB RBC30SBSB

Vibration (ISO22867): Vibration (ISO22867): Vibration (ISO22867): Vibrasjon (ISO22867): Вибрация (ISO22867):

Forhåndtag Främre handtag Etukädensija Fremre håndtak Передняя ручка

Tomgang Tomgångskörning Tyhjäkäynnillä Tomgang На холостом ходу 3.5/6.6 m/s²

Tophastighed Racing Huipponopeudella Rusing При работе 20.0/20.6 m/s²

Ækvivalent total

vibrationsniveau

Baghåndtag Bakre handtag Takakädensija Bakre håndtak Задняя ручка

Tomgang Tomgångskörning Tyhjäkäynnillä Tomgang На холостом ходу 6.4/7.4 m/s²

Tophastighed Racing Huipponopeudella Rusing При работе 15.0/20.6 m/s²

Ækvivalent total

vibrationsniveau

Usikkerhed Osäkerhet Epätarkkuus Usikkerhet Погрешность 1.5 m/s²

Vibration (ISO22867): Vibration (ISO22867): Vibration (ISO22867): Vibrasjon (ISO22867): Вибрация (ISO22867):

Venstre håndtag Vänster handtag Vasen kahva Venstre håndtak Левой ручки

Tomgang Tomgångskörning Tyhjäkäynnillä Tomgang На холостом ходу 1.5/1.9 m/s²

Tophastighed Racing Huipponopeudella Rusing При работе 10.8/3.6 m/s²

Ækvivalent total

vibrationsniveau

Højre håndtag Höger handtag Oikea kahva Høyre håndtak Правой ручки

Tomgang Tomgångskörning Tyhjäkäynnillä Tomgang На холостом ходу 4.4/6.1 m/s²

Tophastighed Racing Huipponopeudella Rusing При работе 12.4/11.6 m/s²

Ækvivalent total

vibrationsniveau

Usikkerhed Osäkerhet Epätarkkuus Usikkerhet Погрешность 1.5

Støjniveau Ljudnivå Melutaso Støynivå Уровень шума

Lydtryksniveau på

operatørposition

Tomgang Tomgångskörning Tyhjäkäynnillä Tomgang На холостом ходу 84.6/84.5 dB(A) 86.5/86.6 dB(A)

Tophastighed Racing Huipponopeudella Rusing При работе 104.5/103.1 dB(A) 104.8/104.3 dB(A)

Ækvivalent A-vægtet

lydtryksniveau

A-vægtet lydeffektniveau A-vägd ljudeffektsnivå A-painotettu äänenteho A-vektet lydeffektnivå Уровень A-взвешенной

Tomgang Tomgångskörning Tyhjäkäynnillä Tomgang На холостом ходу 93.5 dB(A) 93.6 dB(A)

Tophastighed Racing Huipponopeudella Rusing При работе 109.5 dB(A) 109.5 dB(A)

Ækvivalent A-vægtet

lydeffektniveau

Usikkerhed Osäkerhet Epätarkkuus Usikkerhet Погрешность 2.5 dB(A) 2.5 dB(A)

Model Modèle Model Modelo Modello Model Modelo

Vibration (ISO 22867): Vibrations (ISO22867): Vibrationen (ISO22867): Vibración (ISO22867): Vibrazione (ISO22867): Trillingen (ISO22867): Vibration (ISO22867):

Front handle Poignée avant Vorderer Haltegriff Mango delantero Manico anteriore Voorste handvat Pega frontal

Idling Au ralenti Leerlauf Al ralentí Al minimo Motor in vrijloop Ao ralenti

Racing En fonctionnement Hohe Drehzahl En funcionamiento In funzione Draaiende motor Em funcionamento

Equivalent vibration

total value

Rear handle Poignée arrière Hinterer Haltegriff Mango trasero Manico posteriore Achterste handvat Pega traseira

Idling Au ralenti Leerlauf Al ralentí Al minimo Motor in vrijloop Ao ralenti

Racing En fonctionnement Hohe Drehzahl En funcionamiento In funzione Draaiende motor Em funcionamento

Equivalent vibration

total value

Uncertainty Incertitude Unsicherheit Incertidumbre Incertezza Onzekerheid Incerteza

Vibration (ISO 22867): Vibrations (ISO22867): Vibrationen (ISO22867): Vibración (ISO22867): Vibrazione (ISO22867): Trillingen (ISO22867): Vibration (ISO22867):

Left handle Poignée gauche Linker griff Empuñadura izquierda Impugnatura sinistra Linker handgreep Punho esquerdo

Idling Au ralenti Leerlauf Al ralentí Al minimo Motor in vrijloop Ao ralenti

Racing En fonctionnement Hohe Drehzahl En funcionamiento In funzione Draaiende motor Em funcionamento

Equivalent vibration

total value

Right handle Poignée droite Rechter griff Empuñadura derecha Impugnatura destra Rechter handgreep Punho direito

Idling Au ralenti Leerlauf Al ralentí Al minimo Motor in vrijloop Ao ralenti

Racing En fonctionnement Hohe Drehzahl En funcionamiento In funzione Draaiende motor Em funcionamento

Equivalent vibration

total value

Uncertainty Incertitude Unsicherheit Incertidumbre Incertezza Onzekerheid Incerteza

Noise level (ISO 22868): Niveau sonore Lärmpegel Nivel sonoro Livello sonoro Geluidsniveau Nível sonoro

Emission sound pressure

level at the operator

position

Idling Au ralenti Leerlauf Al ralentí Al minimo Motor in vrijloop Ao ralenti

Racing En fonctionnement Hohe Drehzahl En funcionamiento In funzione Draaiende motor Em funcionamento

Equivalent A-weight

emission sound pressure

level

A-weighted sound

power level

Idling Au ralenti Leerlauf Al ralentí Al minimo Motor in vrijloop Ao ralenti

Racing En fonctionnement Hohe Drehzahl En funcionamiento In funzione Draaiende motor Em funcionamento

Equivalent A-weight

sound power level

Uncertainty Incertitude Unsicherheit Incertidumbre Incertezza Onzekerheid Incerteza

Valeur totale équivalente

des vibrations

Valeur totale équivalente

des vibrations

Valeur totale équivalente

des vibrations

Valeur totale équivalente

des vibrations

Niveau de pression

sonore émis au niveau de

l'utilisateur

Niveau de pression

sonore équivalent

pondéré A

Niveau de puissance

sonore pondéré-A

Niveau de puissance

sonore équivalent

pondéré A

Entspricht Gesamtwert der

Vibration

Entspricht Gesamtwert der

Vibration

Entspricht Gesamtwert der

Vibration

Entspricht Gesamtwert der

Vibration

Schalldruckpegel in der

Position des Benutzers

Entspricht A-Bewertung

Emissionsschalldruckpegel

A-bewerteter

Schallleistungspegel

Entspricht A-Bewertung

Schallleistungspegel

Valor total de vibración

equivalente

Valor total de vibración

equivalente

Valor total de vibración

equivalente

Valor total de vibración

equivalente

Nivel de presión acústica

de emisión en la posición

del operador

Nivel de potencia acústica

de emisión ponderado A

Nivel de potencia acústica

ponderada en A

Nivel de potencia

acústica sonora

ponderado A

Valore totale delle

vibrazioni equivalenti

Valore totale delle

vibrazioni equivalenti

Valore totale delle

vibrazioni equivalenti

Valore totale delle

vibrazioni equivalenti

Livello di emissioni

pressione sonora alla

posizione dell'operatore

Livello di emissioni

di pressione sonora

equivalente ponderato A

Livello di potenza sonora

pesato A

Livello di potenza sonora

equivalente ponderato A

Equivalente totale

trillingswaarde

Equivalente totale

trillingswaarde

Equivalente totale

trillingswaarde

Equivalente totale

trillingswaarde

Emissie geluidsdrukniveau

in de bedienpositie

Equivalent A-gewicht

emissie geluidsdrukniveau

A-gewogen geluidsniveau Nível de potência sonora

Equivalent A-gewicht

geluidsniveau

Valor total da vibração

equivalente

Valor total da vibração

equivalente

Valor total da vibração

equivalente

Valor total da vibração

equivalente

Nível de emissão de

pressão sonora na

posição do operador

Nível de emissão

de pressão sonora

equivalente à

ponderação A

ponderada A

Nível de potência

sonora equivalente à

ponderação A

Page 23

EN

GUARANTEE

In addition to any statutory rights resulting from the purchase, this product is

covered by a guarantee as stated below.

1. The guarantee period is 24 months for consumers and commences on the

date when the product was purchased. This date has to be documented