Ryobi 775R, 41ED775A034 Owner’s Manual

OPERA TOR "SMA NUA L

THANK YOU

Thank you for buying this quality product. This modern

outdoor power tool will provide many hours of useful

service. You will find it to be a great labor-saving device.

This operator's manual provides you with easy-to-

understand operating instructions. Read the whole

manual and follow all the instructions to keep your new

outdoor power tool in top operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS AND

SPECIFICATIONS

All information, illustrations and specifications in this

manual are based on the latest product information

available at the time of printing. We reserve the right to

make changes at any time without notice.

Copyright © 2003 MTD SOUTHWEST INC

All Rights Reserved.

SpeedSpool ® is a registered trademark of MTD

SOUTHWEST INC.

SERVICE INFORMATION

Service on this unit both within and after the warranty

period should be performed only by an authorized and

approved service dealer.

• Call 1-800-345-8746 in the United States. or

1-800-668-1238 in Canada, to obtain a list of

authorized service dealers near you

Or

• Go to www.RyobiOutdoor.com on the World Wide

Web for a list of authorized service dealers

DO NOT RETURN THE UNIT TO THE RETAILER.

NOTE: PROOF OF PURCHASE WILL BE REQUIRED

FOR WARRANTY SERVICE.

Make sure you carefully read and understood this

manual before starting or operating this equipment.

THIS PRODUCT IS COVERED BY ONE OR MORE US

PATENTS, OTHER PATENTS PENDING.

I, California Proposition 65 Warning: ............... 3

II. Rules for Safe Operation ..................... 3-7

A. Important Safety Information ................. 4

B. Safety and International Symbols ............. 5

C. Know Your Unit ........................... 7

III. Assembly Instructions ........................ 8

A. Installing and Adjusting the J-Handle .......... 8

B. Installing the Cutting Attachment Shield ........ 8

IV, Oil and Fuel Information ....................... 9

V, Starting/Stopping Instructions ................. 10

Vl.

Operating Instructions .................... 11-12

A. Operating the EZ-Link TM System ............. 11

B, Holding the Trimmer ...................... 12

C. Adjusting Trimming Line Length ............. 12

D, Tips for Best Trimming Results .............. 12

E, Decorative Trimming ...................... 12

VII.

Maintenance and Repair Instructions ......... 13-19

A, Maintenance Schedule .................... 13

B, Line Installation ......................... 13

C, Installing a Prewound Reel ................. 14

D. Cleaning the SpeedSpool ® ................. 15

E, SpeedSpool ® Replacement Parts ............ 16

F, Air Filter Maintenance ..................... 16

G, Spark Arrestor Maintenance ................. 17

H, Carburetor Adjustment .................... 18

I. Replacing the Spark Plug .................. 18

J. Cleaning ................................ 19

K, Storage ................................ 19

L. Long Term Storage ....................... 19

M, Transporting .............................. 19

N, Accessories/Replacement Parts ............. 19

VIII.

Troubleshooting Chart ....................... 20

IX.

Specifications .............................. 21

X.

Warranty .................................. 24

Xl.

Parts List ........................... Back Cover

CONTENTS OF CARTON

• A Model 775r Trimmer

A J-Handle and Hardware

A Cutting Attachment Shield with Hardware

° SpeedSpool ® Bump Head Cutting Attachment

° Operator's Manual

° Product Registration Card

° Bottle of 2-Cycle Oil

A This item will either be installed on the unit or in the

hardware pack

2

THE ENGINE EXHAUST FROM THIS

PRODUCT CONTAINS CHEMICALS

KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER, BIRTH DEFECTS

OR OTHER REPRODUCTIVE HARM.

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon and Washington. All U.S.

Forest Land and the state of California (Public Resources Codes 4442 and 4443), Oregon and Washington require, by

law that certain internal combustion engines operated on forest brush and/or grass-covered areas be equipped with a

spark arrestor, maintained ineffective working order, or the engine be constructed, equipped and maintained for the

prevention of fire. Check with your state or local authorities for regulations pertaining to these requirements. Failure to

follow these requirements could subject you to liability or a fine. This unit is factory equipped with a spark arrestor. If

it requires replacement, ask your LOCAL SERVICE DEALER to install the Accessory Part #182747 Spark Arrestor Kit.

Read the Operator's Manual(s) and follow all warnings and safety instructions. Failure to do so can

result in serious injury to the operator and/or bystanders.

FOR QUESTIONS, CALL 1-800-345-8746 IN U.S. OR 1-800-668-1238 in CANADA

The purpose of safety symbols isto attract your

attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention

and understandingl The safety warnings do not by

themselves eliminate any danger: The instructions or

warnings they give are not substitutes for proper

accident prevention measuresl

SYMBOL MEANING

SAFETY ALERT SYMBOL: Indicates

danger, warning or caution. Attention is

required in order to avoid serious personal

injury. Maybe used in conjunction with

other symbols or pictographs.

NOTE:Advises you of information or instructions vital

to the operation or maintenance of the

equipment.

SYMBOLMEANING

DANGER: Failure to obey a safety warning I

will result in serious injury to yourself or to I

others: Always follow the safety I

precautions to reduce the risk of fire, I

electric shock and personal injury. J

WARNING: Failure to obey a safety

warning can result in injury to yourself and

others. Always follow the safety

precautions to reduce the risk of f re.

electric shock and personal injury.

CAUTION: Failure to obey a safety warning

may result in property damage or personal

injury to yourself or to others. Always follow

the safety precautions to reduce the risk of

fire, electric shock and personal injury.

¸¸¸¸¸¸¸¸¸¸3

• IMPORTANT SAFETY INFORMATION •

READ ALL INSTRUCTIONS

WARNING: When using the unit, you must I

follow the safety rules. For your own safety[

and that of bystanders, please read these

instructions before operating the unit. I

Please keep the instructions for later use. ]

BEFORE OPERATING

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

• Do not operate this unit when tired, ill or under the

influence of alcohol, drugs or medication.

• Children under the age of 15 must not use the unit;

teens may operate the unit with adult guidance.

• Inspect the unit before use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are in

place and secure. Replace cutting attachment parts

that are cracked, chipped or damaged in any way.

Make sure the cutting attachment is properly installed

and securely fastened. Be sure that the cutting

attachment shield is properly attached, and positioned

as recommended. Failure to do so can result in

personal injury to the operator and bystanders, as well

as damage to the unit.

• Use only 0.080 inch (2.03 mm) diameter Genuine

Factory PartsTM replacement line. Never use metal-

reinforced line, wire, chain or rope. These can break

off and become dangerous projectiles.

• Be aware of risk of injury to the head, hands and feet.

• Clear the area to be cut before each use. Remove

rocks, broken glass, nails, wire, string and other

objects which may be thrown or become entangled in

the cutting attachment. Clear the area of children,

bystanders and pets; keep them outside a 50-foot

(15 m.) radius, at a minimum. Even then, they are still

at risk from thrown objects. Encourage bystanders to

wear eye protection. Ifyou are approached, stop the

unit immediately.

• Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments

or repairs before using the unit.

• This unit was not designed to be used as a

brushcutter. Do not attach or operate this unit with any

type of brushcutting blade or brushcutting attachment.

SAFETY WARNINGS FOR GAS TRIMMERS

WARNING: Gasoline is highly flammable, [

and its vapors can explode if ignited. Take I

the following precautions. J

Store fuel only in containers specifically designed and

approved for the storage of such materials.

Always stop the engine and allow it to cool before

filling the fuel tank. Never remove the fuel tank cap or

add fuel when the engine is hot. Never operate the unit

without the fuel cap securely in place. Loosen the fuel

tank cap slowly to relieve any pressure in the tank.

Add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. Remove the fuel cap

slowly, and only after the engine stops. Do not smoke

while fueling or mixing fuel. Wipe up any spilled fuel

from the unit immediately.

Avoid creating a source of ignition for spilled fuel. Do

not start the engine until fuel vapors dissipate.

Move the unit at least 30 feet (9.1 m) from the fueling

source and site before starting the engine. Do not

smoke. Keep sparks and open flames away from the

area while adding fuel or operating the unit.

WHILE OPERATING

Never start or run the unit inside a closed room or

building. Breathing exhaust fumes can be fatal.

Operate this unit only in a well-ventilated outdoor area.

Wear safety glasses or goggles that meet ANSI Z87.1

standards and are marked as such. Wear ear/hearing

protection when operating this unit. Wear a face or

dust mask if the operation is dusty.

Wear heavy long pants, boots, gloves and a long

sleeve shirt. Do not wear loose clothing, jewelry, short

pants, sandals or go barefoot. Secure hair above

shoulder level.

The cutting attachment shield must always be in place

while operating the unit. Do not operate unit without

both trimming lines extended, and the proper line

installed. Do not extend the trimming line beyond the

length of the shield.

This unit has a clutch. The cutting attachment remains

stationary when the engine is idling. If it does not, have

the unit adjusted by an authorized service technician.

Adjust the J-handle to your size in order to provide the

best grip.

Be sure the cutting attachment is not in contact with

anything before starting the unit.

Use the unit only in daylight or good artificial light.

Avoid accidental starting. Be in the starting position

whenever pulling the starter rope. The operator and

unit must be in a stable position while starting. Refer

to Starting/Stopping Instructions.

Use the right tool. Only use this tool for its intended

purpose.

4 ZZZZZZ

• Do not overreach. Always keep proper footing and

balance.

• Always hold the unit with both hands when operating.

Keep a firm grip on both handles or grips.

• Keep hands, face, and feet at a distance from all

moving parts. Do not touch or try to stop the cutting

attachment when it rotates.

° Do not touch the engine, gear housing or muffler.

These parts get extremely hot from operation, even

after the unit is turned off.

• Do not operate the engine faster than the speed

needed to cut, trim or edge. Do not run the engine at

high speed when not cutting.

• Always stop the engine when cutting is delayed or

when walking from one cutting location to another.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Do not operate before repairing damage. Do

not operate the unit with loose or damaged parts.

• Stop the unit, switch the engine to off, and disconnect

the spark plug for maintenance or repair.

• Use only Genuine Factory Parts TM replacement parts

and accessories for this unit. These are available from

your authorized service dealer. Use of any

unauthorized parts or accessories could lead to

serious injury to the user, or damage to the unit, and

void your warranty.

° Keep unit clean of vegetation and other materials.

They may become lodged between the cutting

attachment and shield.

• To reduce fire hazard, replace a faulty muffler and

spark arrestor. Keep the engine and muffler free from

grass, leaves, excessive grease or carbon build up

OTHER SAFETY WARNINGS

• Never store a fueled unit inside a building where fumes

may reach an open flame or spark.

* Allow the engine to cool before storing or transporting.

Be sure to secure the unit while transporting.

• Store the unit in a dry area, locked up or up high to

prevent unauthorized use or damage, out of the reach

of children.

Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use, see Cleaning and Storage

instructions.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

SAVE THESE INSTRUCTIONS

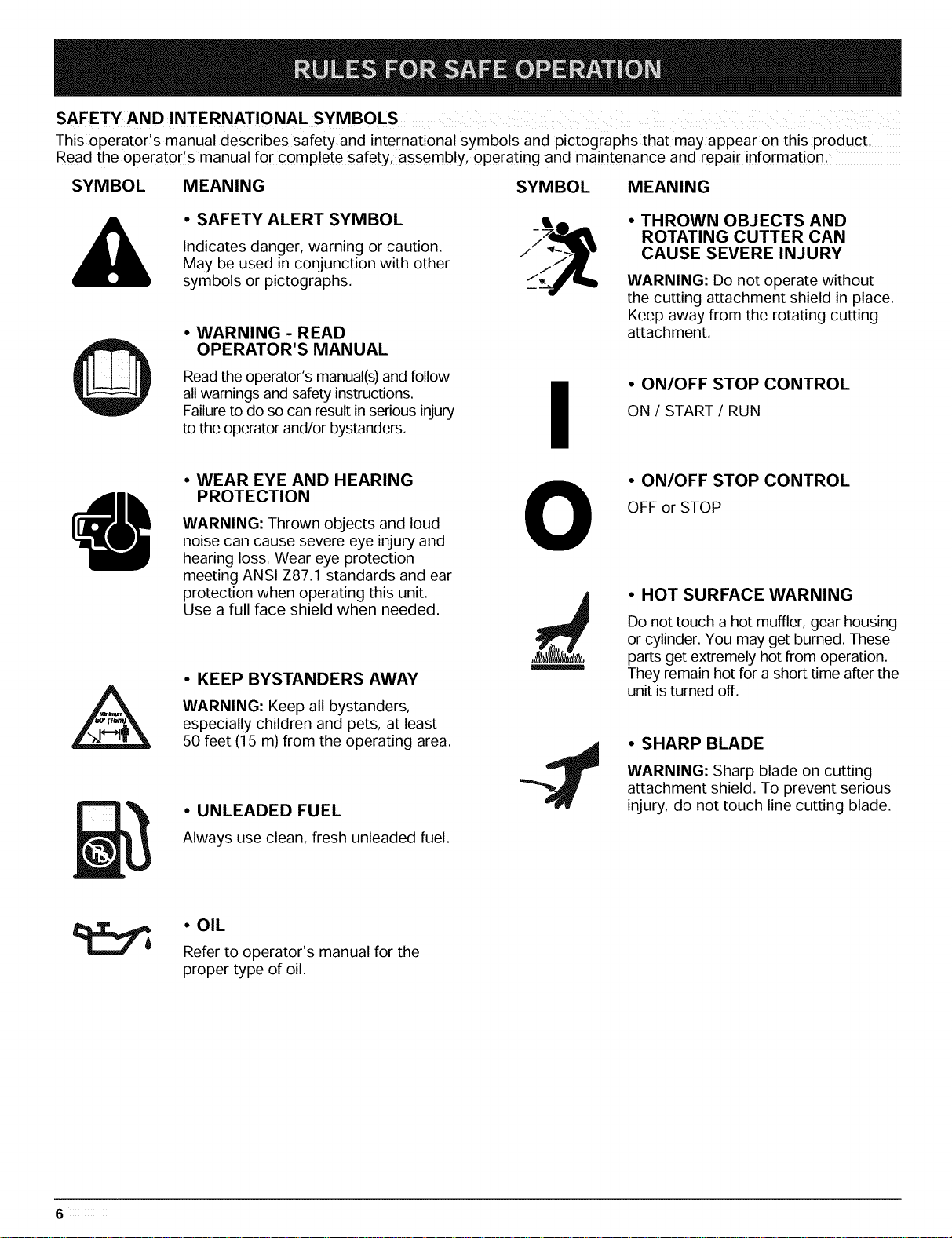

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product,

Read the operator!s manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• THROWN OBJECTS AND

Indicates danger, warning or caution. /

• SAFETY ALERT SYMBOL -//_7_

May be used in conjunction with other

symbols or pictographs. _/_'_

• WARNING - READ

OPERATOR'S MANUAL

ROTATING CUTTER CAN

CAUSE SEVERE INJURY

WARNING: Do not operate without

the cutting attachment shield in place.

Keep away from the rotating cutting

attachment.

Read the operator's manual(s)and follow

all warnings and safety instructions.

Failureto do so can result in serious injury

to the operator and/or bystanders.

• WEAR EYE AND HEARING

PROTECTION

WARNING: Thrown objects and loud

noise can cause severe eye injury and

hearing loss. Wear eye protection

meeting ANSI Z87.1 standards and ear

protection when operating this unit.

Use a full face shield when needed.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders,

especially children and pets, at least

50 feet (15 m) from the operating area.

• UNLEADED FUEL

• ON/OFF STOP CONTROL

ON / START / RUN

I

• ON/OFF STOP CONTROL

OFF or STOP

O

• HOT SURFACE WARNING

Do not touch a hot muffler, gear housing

or cylinder. You may get burned. These

parts get extremely hot from operation.

They remain hot for a short time after the

unit is turned off.

• SHARP BLADE

WARNING: Sharp blade on cutting

attachment shield. To prevent serious

injury, do not touch line cutting blade.

Always use clean, fresh unleaded fuel.

• OIL

Refer to operator's manual for the

proper type of oil.

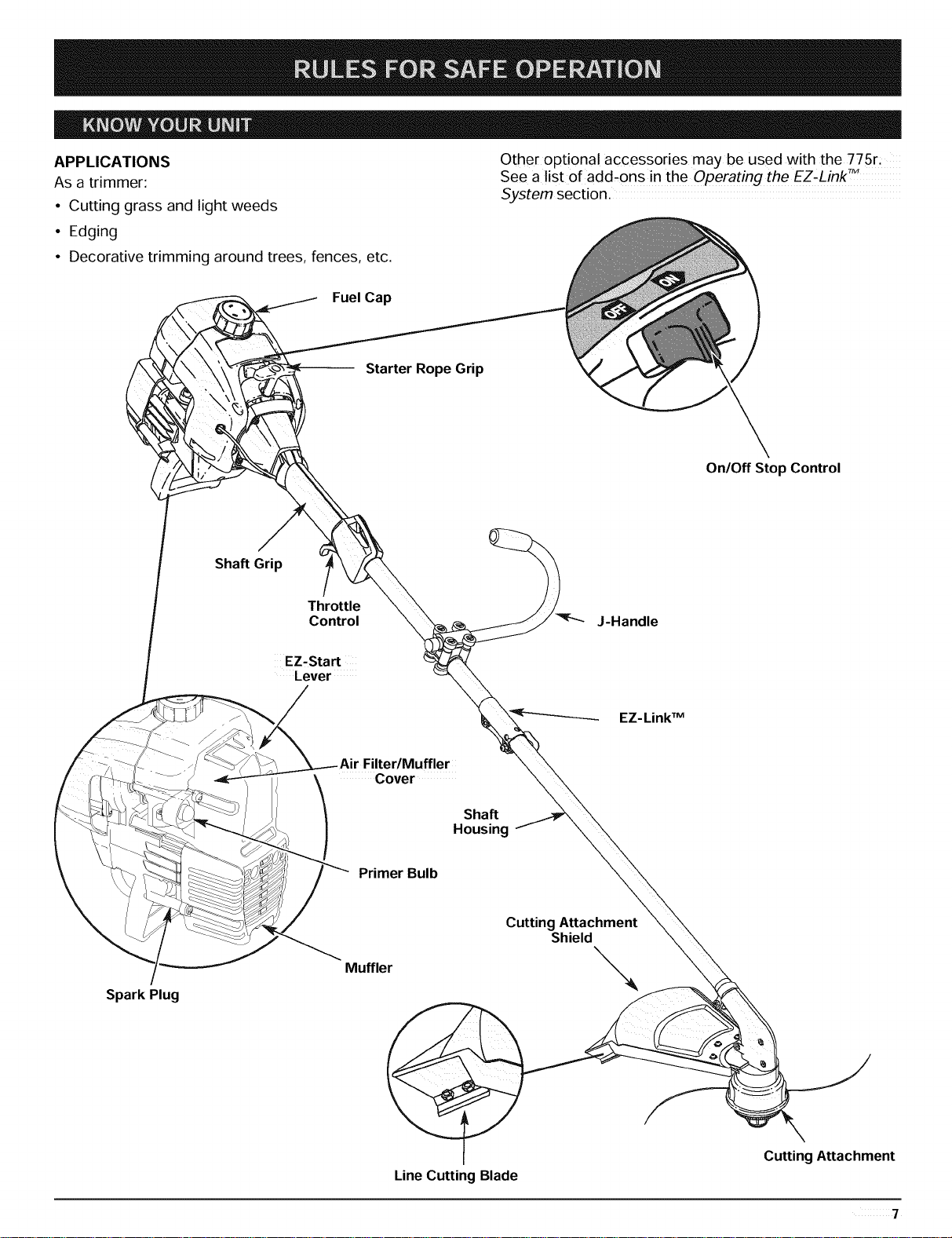

APPLICATIONS

Asatrimmer:

• Cuttinggrassandlightweeds

• Edging

• Decorative trimming around trees, fences, etc.

Fuel Cap

Starter Rope Grip

Shaft Grip

Throttle

Control J-Handle

Otheroptionalaccessoriesmaybeusedwiththe775r:

Seealistofadd-onsintheOperating the EZ.Link "M

System section.

On/Off Stop Control

Spark Plug

EZ-Start

Lever

EZ-Link TM

Air Filter/Muffler

Cover

Shaft

Housing

Primer Bulb

Cutting Attachment

Shield

Muffler

Line Cutting Blade

Cutting Attachment

¸¸¸¸¸¸¸¸¸¸7

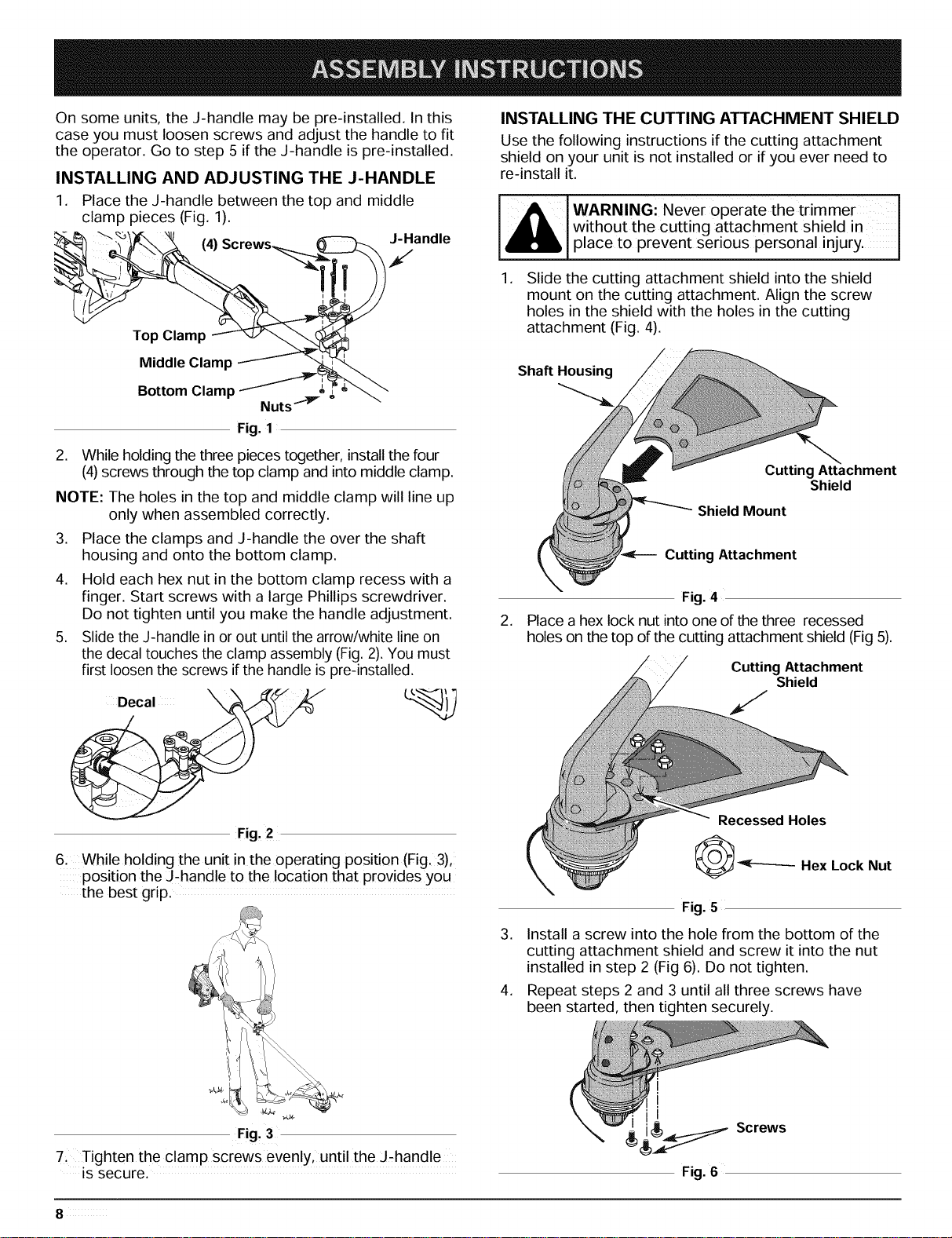

On some units, the J-handle may be pre-installed. In this

case you must loosen screws and adjust the handle to fit

the operator. Go to step 5 if the J-handle is pre-installed.

INSTALLING AND ADJUSTING THE J-HANDLE

.

Place the J-handle between the top and middle

clamp pieces (Fig. 1).

(4) J-Handle

/

Top Clamp

Middle Clamp

Bottom Clamp e

2. While holding the three pieces together, install the four

(4) screws through the top clamp and into middle clamp.

NOTE: The holes in the top and middle clamp will line up

only when assembled correctly.

.

Place the clamps and J-handle the over the shaft

housing and onto the bottom clamp.

4. Hold each hex nut in the bottom clamp recess with a

finger. Start screws with a large Phillips screwdriver.

Do not tighten until you make the handle adjustment.

5. Slide the J-handle in or out until the arrow/white line on

the decal touches the clamp assembly (Fig. 2). You must

first loosen the screws ifthe handle is pre-installed.

Nuts _

Fig. 1

INSTALLING THE CUTTING ATTACHMENT SHIELD

Use the following instructions if the cutting attachment

shield on your unit is not installed or if you ever need to

re-install it.

WARNING:Never operate the trimmer !

without the cutting attachment shield in

place to prevent serious personal injury. J

.

Slide the cutting attachment shield into the shield

mount on the cutting attachment. Align the screw

holes in the shield with the holes in the cutting

attachment (Fig. 4).

Shaft Housing

Cutting Attachment

Shield

Shield Mount

Cutting Attachment

Fig. 4

.

Place a hex lock nut into one of the three recessed

holes on the top of the cutting attachment shield (Fig 5).

Cutting Attachment

Shield

Fig. 2

6: While holding the unit in the operating position (Fig. 3),

position the J-handle to the location that provides you

the best grip.

3. Install a screw into the hole from the bottom of the

cutting attachment shield and screw it into the nut

installed in step 2 (Fig 6). Do not tighten.

4. Repeat steps 2 and 3 until all three screws have

been started, then tighten securely.

Fig, 3

7. Tighten the clamp screws evenly, until the J,handle

IS secure. Fig. 6

8

Fig. 5

Loading...

Loading...