Page 1

OPERATOR'S MANUAL

Zero Clearance Throat Plate

4070333

(For use with BT3000 & BT3100 Table Saws)

Your new throat plate has been engineered and manufactured to Ryobi's high standard for dependability, ease of

operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual.

Thank you for buying a Ryobi accessory kit.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

RULES FOR SAFE OPERATION

Safe operation of this accessory requires that you read

and understand this operator's manual, the operator’s

manual for the table saw and all labels affixed to the tool.

READ ALL INSTRUCTIONS

■ KNOW YOUR ACCESSORY. Read the operator's

manual carefully. Learn the product's applications

and limitations as well as the specific potential hazards related to this product.

■ KEEP THE WORK AREA CLEAN. Cluttered work

areas and work benches invite accidents. DO NOT

leave tools or pieces of wood on the saw while

operating.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

SYMBOL MEANING

■ ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses; they are NOT safety glasses.

■ DO NOT USE THIS PRODUCT WITH OTHER

EQUIPMENT or for other purposes.

■ ALWAYS DISCONNECT THE SAW FROM THE

POWER SUPPLY BEFORE ASSEMBLING THIS

KIT. Make sure the switch is off when reconnecting

the saw to a power supply.

■ BEFORE MAKING A CUT BE SURE ALL ADJUSTMENTS ARE SECURE.

■ SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to instruct other users. If you

loan someone this product, also loan these instructions.

SAFETY ALERT SYMBOL: Indicates danger, warning or caution. May be used in conjunction

with other symbols or pictographs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

NO HANDS: Failure to keep your hands away from the blade will result in serious personal injury.

WET CONDITIONS ALERT: Do not expose to rain or use in damp locations.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

WEAR

YOUR

SAFETY

FORESIGHT IS BETTER

GLASSES

THAN NO SIGHT

The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning tool operation, always wear safety

goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields. Always wear eye protection which is marked to comply with ANSI Z87.1.

SAVE THESE INSTRUCTIONS

2

Page 3

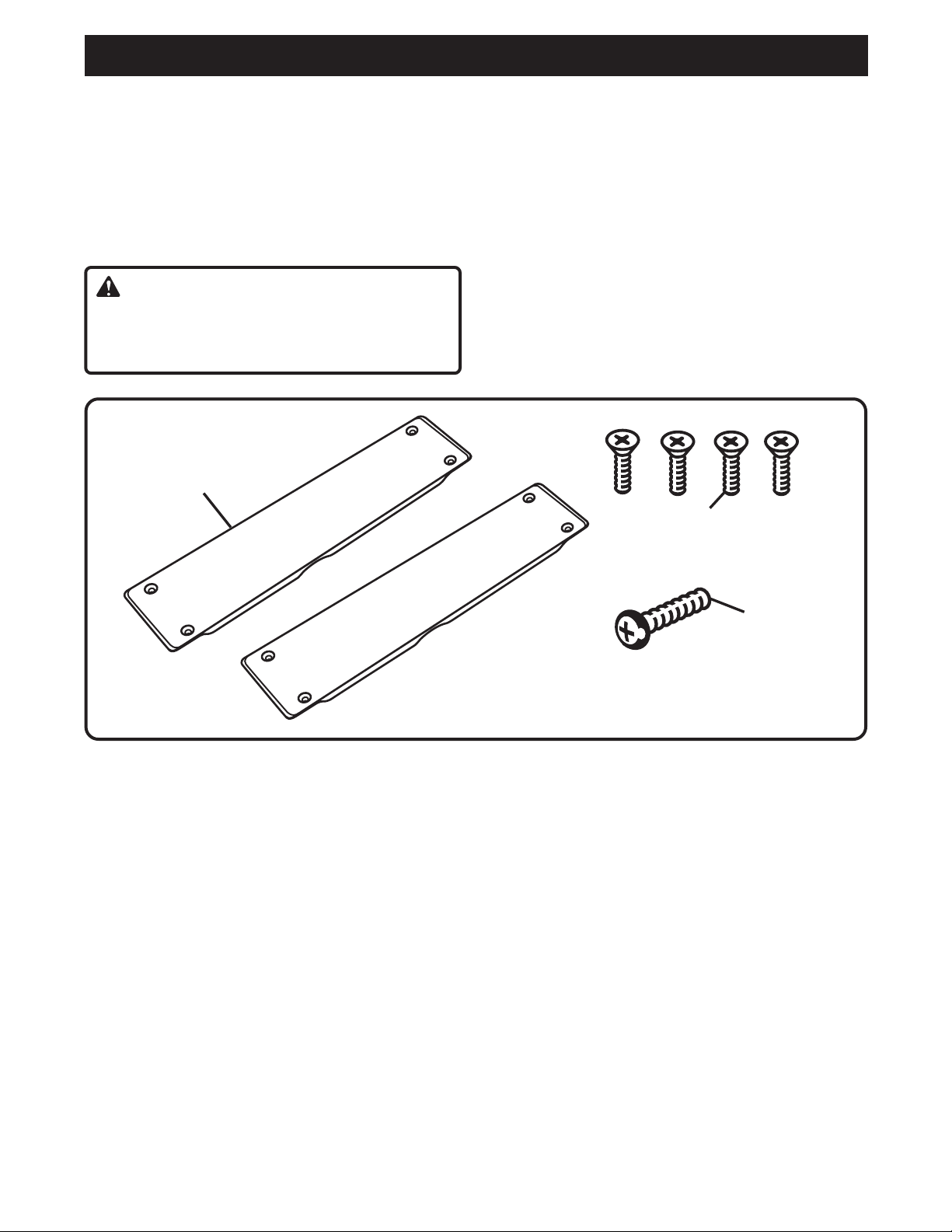

UNPACKING

INFORMATION

■ Remove the loose parts from the box. Make sure

that all items listed in the loose parts list are included.

■ Inspect all parts carefully to make sure no breakage

or damage occurred during shipping.

■ If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

WARNING:

If any parts are missing, replace the missing parts

before assembling the kit. Failure to do so could

result in serious personal injury.

1

LOOSE PARTS LIST

1. Zero clearance throat plates (2)

2. Thread cutting screw - 1 in. (1) (For use with BT3000)

3. Flat head screws - (4)

TOOLS NEEDED

Phillips head screwdriver

3

2

3

Page 4

ASSEMBLY

WARNING:

The table saw should never be connected to a power

supply when you are assembling or disassembling

parts. Disconnecting the table saw will prevent accidental starting that could cause serious personal

injury.

PREPARING THE ZERO CLEARANCE

THROAT PLATE FOR USE WITH A

STANDARD BLADE

To prepare the zero clearance throat plate for use with

a standard blade, cut an opening for the blade guard,

install the throat plate, and then make the zero clearance

cut.

TO CUT AN OPENING FOR THE BLADE GUARD

Figures 1 and 2

Follow these directions to cut an opening for the blade

guard.

■ Set up the original throat plate and properly install

the blade guard assembly on the table saw. Refer to

the table saw operator’s manual.

■ Position the new throat plate on the saw in front of

the blade guard with the crescent-shaped opening to

the right.

■ Measure from the rear of the throat plate, and mark

lines at 6-1/8 in. and 7-1/8 in.

■ Raise the saw blade to a height of 1 in. and position

it to 90° by setting the blade bevel adjustment to 0°.

■ Adjust the rip fence to the right edge of the original

throat plate and lock it firmly in place.

■ Assure the riving knife portion of the blade guard

assembly is aligned directly with the blade.

■ Plug the saw into a power source.

■ Insert the key plate and start the saw.

■ Guide the new throat plate along the left edge of the

rip fence.

■ Make a rip cut from the rear to the mark at 7-1/8 in.

■ Turn the saw off and allow the blade to fully stop

before removing the throat plate from the front.

■ Adjust the rip fence 5/8 in. to the right edge of the

original throat plate and firmly lock in place.

■ Release the blade tilt lock lever and adjust the saw

to a 22-1/2° bevel.

■ Lock the blade tilt lever.

■ Start the saw.

■ Guide the throat plate again along the left edge of

rip fence.

■ Make a bevel rip cut from the rear to the mark at

6-1/8 in.

Fig. 1

6 1/8"

7 1/8"

Fig. 2

WARNING:

Keep hands away from rotating blade during cut.

Failure to heed this warning could result in serious

personal injury.

■ Turn the saw off and allow the blade to fully stop

before removing the throat plate from the front.

■ Remove any remaining material that may still be

attached between the two cuts.

4

Page 5

ASSEMBLY

TO INSTALL THE ZERO CLEARANCE THROAT

PLATE

See Figure 3.

Follow these steps to install the zero clearance throat

plate.

■ Release the blade tilt lock lever and adjust the saw

to 90° cut by setting the bevel angle to 0°.

■ Lock the blade tilt lever.

■ Adjust the saw blade to the lowest position.

■ Remove the key plate and unplug the saw from the

power source.

■ Remove the original throat plate from the saw.

For the BT3000:

screws on the top of the saw. Use the 1" long thread

cutting screw provided to tap the four pre-drilled

holes in the throat plate opening by alternately

screwing and unscrewing the screw into each hole.

Drop a light machine oil in the holes to aid in the

operation.

For the BT3100:

the plate, lift and remove the plate, and then remove

the two screws underneath the plate.

■ Raise carefully the anti-kickback fingers on the blade

guard assembly.

■ Install the zero clearance throat plate by sliding it

under the fingers and surrounding the riving knife

(splitter).

■ Make sure the saw blade is in the lowest position.

■ Secure the zero clearance throat plate with the four

flat head screws provided.

TO MAKE A ZERO CLEARANCE CUT

Remove the three phillips machine

Remove the screw at the front of

See Figure 4.

Follow these steps to make a zero clearance cut.

■ Plug the saw into a power source.

■ Insert the key plate.

■ Choose one of these options:

■

To make a straight zero clearance cut:

a) Turn on the saw.

b) Rotate the blade adjustment handle clock-

wise to raise the blade through the throat

plate.

■

To make a bevel zero clearance cut:

a) Move the rip fence to the right at least 6 in. to

provide clearance for the blade guard assembly in the bevel position.

b) Lower the saw blade fully.

c) Release the blade tilt locking lever.

Fig. 3

Fig. 4

d) Adjust the bevel to the desired angle.

e) Turn on the saw.

f) Rotate the blade adjustment handle clock-

wise to raise the blade through the throat

plate.

■ Turn off the saw.

NOTE: The saw blade must be at 90° (0° bevel setting)

and the lowest setting to allow for installation or removal

of a bevel cut zero clearance throat plate.

CAUTION:

When lowering the blade, always lift the anti-kickback fingers so they do not damage zero clearance

throat plate or hinder lowering of the blade. Do not

lower the blade with the saw on.

5

Page 6

ASSEMBLY

PREPARING THE ZERO CLEARANCE

THROAT PLATE FOR USE WITH A DADO

BLADE

NOTE: Use only the Dado Set, part number 4650306,

with the BT3000 and BT3100 table saws.

WARNING:

Turn saw off, remove key plate and unplug saw from

power source before proceeding. Failure to do so

could result in accidental start-up, resulting in serious injury.

■ Remove the original throat plate from the saw.

For the BT3000:

screws on the top of the saw.

For the BT3100:

the plate and the two screws underneath the plate.

■ Remove the blade guard assembly. Refer to the

table saw operator’s manual.

■ Install the dado blade. Refer to dado set instructions.

■ Lower the saw blade by pushing the locking lever to

the left and rotating the blade adjustment handle

counterclockwise.

NOTE: For the BT3000, use the 1" long thread cutting

screw provided and tap the four pre-drilled holes in

the throat plate opening. Alternate screwing and

unscrewing the screw into each hole until you tap all

four. Drop a light machine oil in the holes to aid in the

operation.

■ Install the new throat plate and secure it with the four

flat head screws.

■ Plug the saw into a power source.

■ Insert the key plate and turn on the saw.

■ Rotate the blade adjustment handle clockwise, cut-

ting the new throat plate until the blade is in the

highest desired position.

■ Turn off the saw and remove the key plate.

■ Unplug the saw from the power source.

Remove the three phillips machine

Remove the screw at the front of

WARNING:

Always put spacers in the proper location when

changing back to the saw blade. Failure to do so

may result in serious injury and damage the tool.

NOTE: The blade guard assembly cannot be used with

the dado blade. Dado cuts are non-through cuts. Make

sure the blade guard assembly is reinstalled for all

through cuts.

6

Page 7

NOTES

7

Page 8

OPERATOR'S MANUAL

Zero Clearance Throat Plate

4070333

WARRANTY

Ryobi warrants its accessories for a period of 90 days from the date of purchase. Batteries and chargers are

warranted for a period of two years from the date of purchase.

PARTS AND SERVICE

For parts or service, contact your nearest Ryobi authorized service center. Be sure to provide all relevant

information when you call or visit. For the location of the authorized service center nearest you, please call

1-800-525-2579 or visit us online at www.ryobitools.com. When ordering parts, always give the model

number:

MODEL NUMBER

4070333

972000-217

9-02

RYOBI TECHNOLOGIES INC.

1428 Pearman Dairy Road Anderson, SC 29625

Post Office Box 1207 Anderson, SC 29622

1-800-525-2579 www.ryobitools.com

Loading...

Loading...