HBGL650

BENCH GRINDER LINISHER

O

WNER’S OPERATION MANUAL

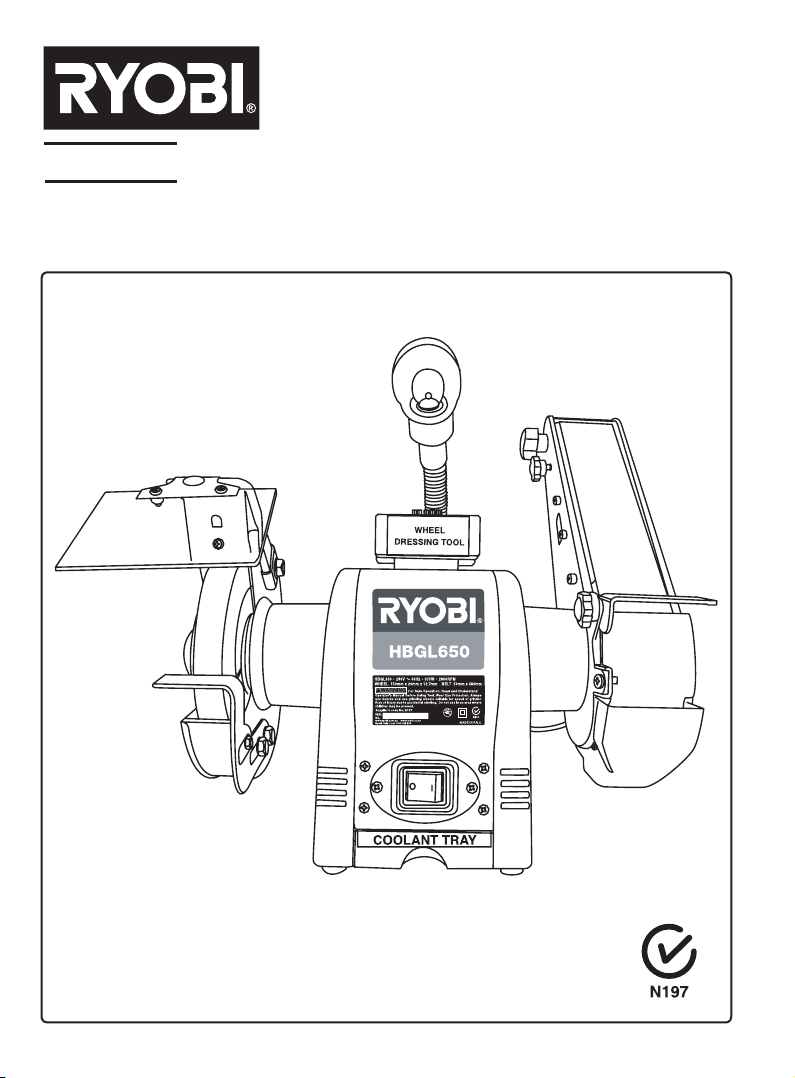

Fig. 0

Fig. 2

Fig.

4

8

9

10

12

A

2

3

4

5

6

7

1

B

13

Fig. 3

Fig. 1

C

11

(2)

(1)

(3)

WHEEL

DRESSING TOOL

WHEEL

DRESSING T

OOL

Fig. 5

Fig. 6

(2)

(2)

(1)

Fig. 8Fig. 7

Fig. 10

Fig.

12

Fig. 11

Fig. 9

(1)

(1)

(1)

(1)

(1)

(1)

(2)

Page 1

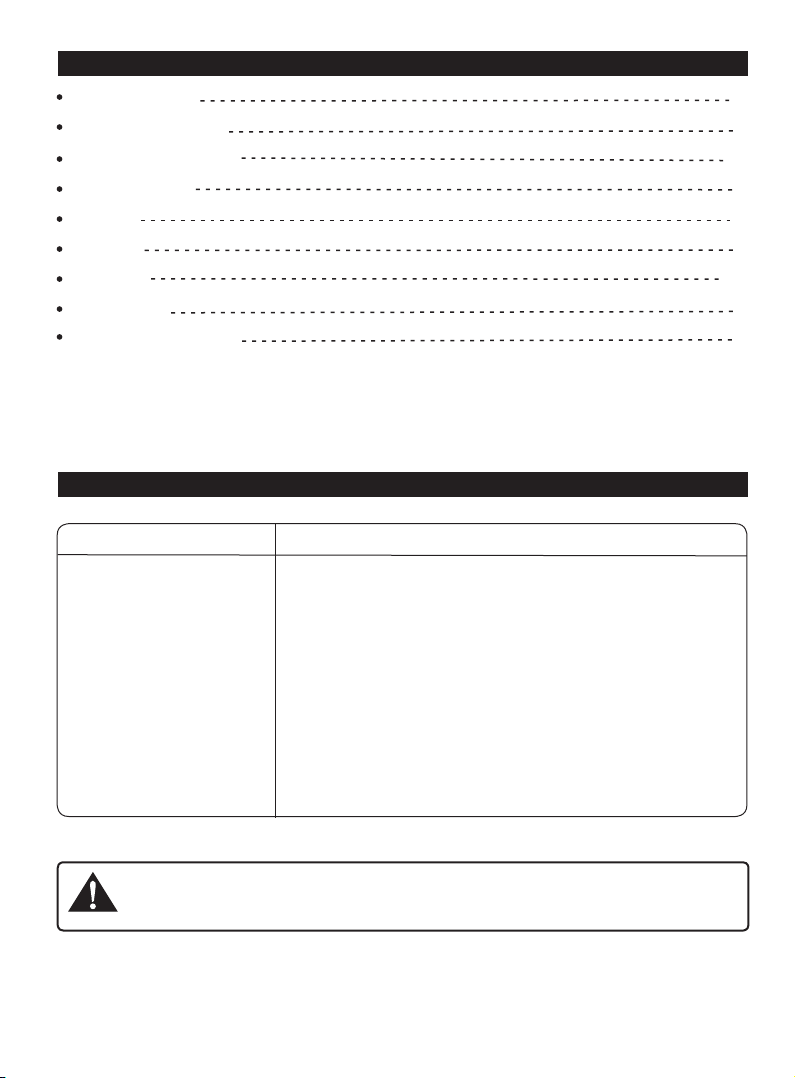

PRODUCT SPECIFICATIONS

Table of Contents

Product Specifications

Rules for Safe Operation

Loose Parts List

Features

Assembly

Operation

Maintenance

Parts Ordering / Service

1

2

3-4

5

5

6

6-7

8

9

TABLE OF CONTENTS

Diameter

Width

Arbor Hole

Belt size

NO Load Speed

Rating

Power

Weight

LOOSE PARTS LIST

PRODUCT SPECIFICATIONS

Wheel

150 mm

20 mm

12.7 mm

50 x 686 mm

2850 RPM

240V ~ 50Hz only

375W

10 kg

Look for this symbol to point out important safety precautions. It means attention!!!

Your safety is involved.

Page 2

Safe operation of this power tool requires that

you read and understand this operator’s manual

and all labels affixed to the tool. Safety is a

combination of common sense, staying alert,

and knowing how your power tool works.

READ ALL INSTRUCTIONS

KNOW YOUR POWER TOOL. Read the

operator’s manual

carefully. Learn the

applications and limitations as well as

specific potential hazards related to this

tool.

GUARD AGAINST ELECTRICAL SHOCK

by pr

eventing body contact with grounded

surfaces. For example:pipes, radiators,

ranges, refrigerator enclosures.

KEEP GUARDS IN PLACE and in working

order. Never operate the tool with any guard

or cover removed. Make sure all guards are

operating properly before each use.

REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking

to see keys and adjusting wrenches are

r

emoved from tool before turning it on.

KEEP THE WORK AREA CLEAN.

Clutter

ed work areas and work benches

invite accidents.

AVOID DANGEROUS ENVIRONMENTS.

Do

not use power tools near gasoline or

other flammable liquids, in damp or wet

locations or expose them to rain. Keep work

area well lighted.

KEEP CHILDREN AND VISITORS AWAY.

All

visitors should wear safety glasses and

be kept a safe distance from work area.

MAKE WORKSHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

DON’T

FORCE THE TOOL. It will do the job

better and safer at the rate for which it was

designed.

USE

THE RIGHT TOOL. Do not force the

tool or attachment to do a job for which it

was not designed.

USE

THE PROPER EXTENSION CORD.

Make

sure your extension cord is in good

condition. When using an extension cord,

be sure to use one heavy enough to carry

the current your product will draw. An

undersized cord will cause a drop in line

voltage resulting in loss of power and

overheating . A wire gauge size (A.W.G.) of

at least 16 is recommended for an extension

cord 8 metres or less in length. If in doubt,

use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

INSPECT EXTENSION CORDS

PERIODICALLY and replace if damaged.

WEAR PROPER APPAREL. Do not wear

loose clothing, neckties, or jewelry that

can get caught in

the tool’s moving parts

and cause personal

injury. Nonslip footwear

is recommended when working outdoors. Wear

protective hair covering to contain long hair.

ALWAYS WEAR SAFETY GLASSES WITH SIDE

S

HIELDS. Everyday eyeglasses have only impact-

resistant lenses; they are NOT safety glasses.

PROTECT YOUR LUNGS. Wear a face or dust

mask if the cutting operation is dusty.

PROTECT YOUR HEARING. Wear hearing

protection during extended periods of operation.

D

ON’T ABUSE CORD. Never carry tool by the cord

or yank it to disconnect from the power supply. Keep

cord away from heat, oil, and sharp edges.

DO NOT OVERREACH. Keep proper footing and

balance at all times.

M

AINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OF F. D

isconnect all tools when not in use,

before servicing, or when changing attachments

etc.

AVOID ACCIDENTAL STARTING. Be sure switch

is of

f when plugging in.

USE RECOMMENDED ACCESSORIES. The use

of impr

oper accessories may cause risk of injury.

USE ONLY GRINDING WHEELS

that is rated

greater than 2850 PRM.

DO NOT use wheels with incorrect size bore.

NEVER use wheel washers or wheel screws

that are defective of incorrect and NEVER touch

grinding wheel or other moving parts.

NEVER STAND ON TOOL.

Serious injury

could occur if the tool is tipped or if the wheel is

unintentionally contacted.

DIRECTION OF FEED.

Be aware of wheel

rotation direction; never grind without the

workrest being properly set.

NEVER

grind more

than one workpiece at a time

CHECK DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged

should be carefully checked to determine that

it will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect its operation. A guard or other part that is

damaged must be properly repaired or replaced

by an authorised service centre to avoid risk of

personal injury.

RULES FOR SAFE OPERATION

KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Always use a clean cloth

when cleaning. Never use brake fluids, gasoline,

petroleum-based products, or any solvents to

clean tool.

INSPECT TOOL CORDS AND EXTENSION

CORDS PERIODICALLY and, if damaged,

have repaired by a qualified service

technician. Stay constantly aware of cord

location and keep it well away from the

rotating wheel.

NEVER USE IN AN EXPLOSIVE

ATMOSPHERE. Normal

sparking of the

motor or sparking from grinding metal could

ignite fumes.

USE OUTDOOR EXTENSION CORDS.

Use

only extension cords with approved

ground connection that are intended for use

outdoors and so marked.

USE ONLY FLANGES furnished with this

bench grinder linisher. IF ANY PART OF

THIS GRINDER LINISHER IS MISSING

or

should break, bend, or fail in any way,

or should any electrical component fail to

perform properly, shut off the power switch,

remove the machine plug from the power

source and have damaged, missing, or failed

parts replaced before resuming operation.

MAKE SURE THE GRINDER LINISHER IS

SECURELY MOUNTED as described in the

operating instructions before connecting the

tool to a power supply.

DO NOT OVERTIGHTEN THE WHEEL NUT.

Excessive

tightening can cause the wheel to

crack during operation.

INSPECT GRINDING WHEEL for visible

defects. Check the wheel for fissures and

cracks, and test for normal operation prior

to use.

ADJUST distance between wheel and work

r

est to maintain 1.6mm. or less separation

as the diameter of the wheel decreases

with use. The value of separation used

in the marking is to be the separation

recommended by the manufacturer but shall

not be more than 3.2mm.

Page 3

RULES FOR SAFE OPERATION

WARNING:

When servicing use only identical Ryobi replacement

parts. Use of any other parts may create a hazard

or cause product damage.

WARNING:

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals

know to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

. lead from lead-based paints.

. crystalline silica from bricks and cement

and other masonry products.

. arsenic and chromium from chemicallytreated timber.

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

DOT NOT EXPOSE

TO RAIN OR USE IN

D

AMP LOCATIONS

ALWAYS EASE THE WORKPIECE

AGAINST THE ABRASIVE WHEEL when

starting to grind. A harsh impact can break

the wheel. Use light pressure when starting

to grind; too much pressure on a cold wheel

can cause the wheel to crack.

NEVER START THE GRINDER LINISHER

when

the wheel is in contact with the

workpiece.

SECURE WORK. Always hold workpiece

firmly against the work rest.

DO NOT USE THE BENCH GRINDER

LINISHER if the flange nut or clamp nut is

missing or if the spindle shaft is bent.

FREQ

UENTLY clean grinding dust from

beneath grinder.

STAY ALERT AND EXERCISE CONTROL.

Watch what

you are doing and use common

sense. Do not operate tool when you are

tired. Do not rush.

SAVE THESE INSTRUCTIONS. Refer

to

them frequently and use them to instruct

other users. If you loan someone this tool,

loan them these instructions also.

Page 4

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

the explanations with them, deserve your careful attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions or warnings they give, are not substitutes for

proper accident prevention measures.

SYMBOL MEANING

SAFETY ALERT SYMBOL:

Indicates danger, warning, or caution. May be used in conjunction with other symbols or

pictographs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal

injury.

WARNING: Failure to obey a safety warning may result in property damage or personal

injury to yourself or to others. Always follow the safety precautions to reduce the risk of

fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal

injury to yourself or to others. Always follow the safety precautions to reduce the risk of

fire, electric shock and personal injury.

NOTE:

IMPORTANT

Servicing requires extreme care and knowledge and

should be performed only by a qualified service

technician. For s

ervice we suggest you return the

tool to your nearest RYOBI AUTHORISED SERVICE

CENTRE

for repair. When servicing,use only identical

Ryobi replacement parts.

WARNING:

Do not attempt to operate this tool until you have

read thoroughly and understand completely all

instructions, safety rules, etc. contained in this

manual. Failure to comply can result in accidents

involving fire, electric shock, or serious personal

injury. Save this operator’s manual and review

frequently for continuing safe operation and

instructing others who may use this tool.

The operation of any tool can result in foreign objects being thrown into your eyes, which

can result in severe eye damage. Before beginning power tool operation,always

wear safety goggles or safety glasses with side shields and a full face shield when

needed. We recommend Wide Vision Safety Mask for use over eyeglasses or

standard safety glasses with side shields.

WARNING:

Advises you of information or instructions vital to the operation or maintenance of the

equipment.

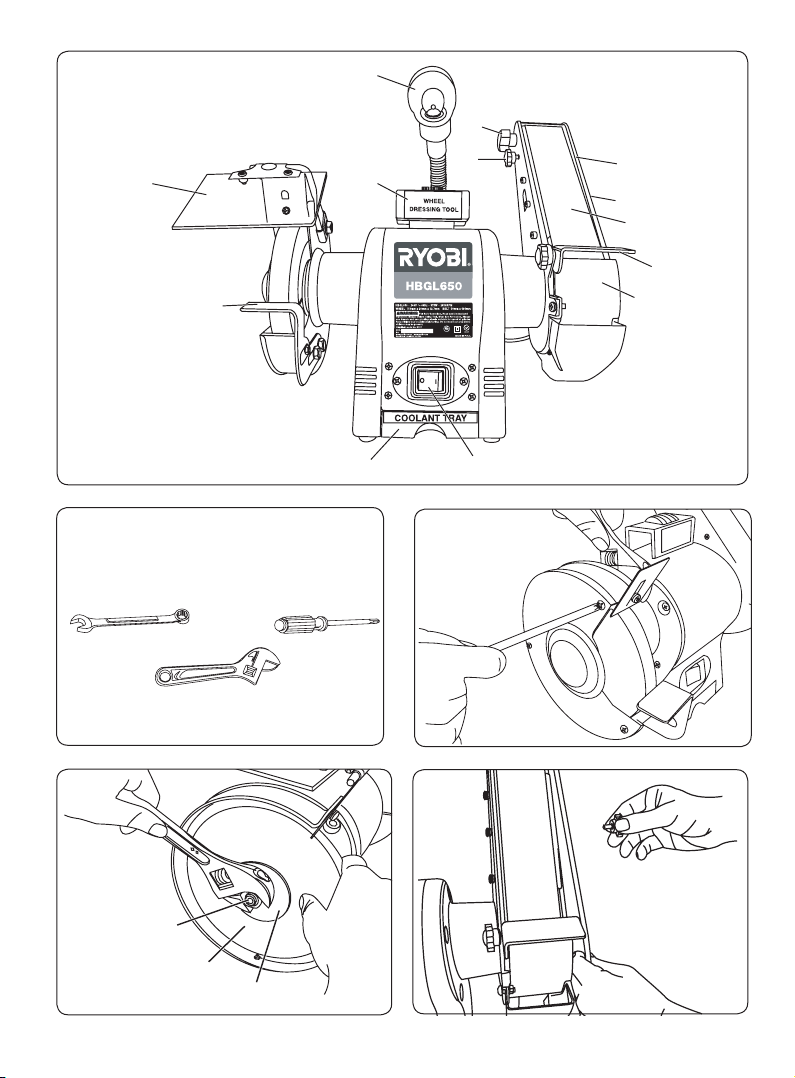

TOOLS NEEDED (NOT INCLUDED)

The following tools are needed for assembly

and alignment:

FEATURES

KNOW YOUR BENCH GRINDER LINISHER

See Figure. 0

Before attempting to use your new tool,

familiarise yourself with all operating features

and safety requirements.Carefully read this

operator’s manual before using your grinder.

POWER SWITCH ( 1)

Your Bench Grinder linisher features an easy

access On/Off switch for convenience and

safety.

MOTOR

P

owered by a precision-built electric induction

motor, your linisher has sufficient power to

handle tough grinding jobs.

GRINDING WHEEL

Equipped with coarse and fine grinding

wheels to suit most applications.

NOTE:New wheels sometimes require dressing

to true up the face of the wheel.

COOLANT TRAY (2)

When

grinding, metal objects become heated

quickly. It is important to keep moving the

object back and forth across the grinding

wheel and to cool the object frequently using

the grinder’s Coolant Tray.

WORK REST(3)

The work rests are independently adjustable

to compensate for wheel wear. Before

grinding, make certain the work rests are

adjusted properly. Generally the object being

ground is done slightly above centre of the

grinding wheel.

Adjust the distance between the wheel and

the work rest to maintain 1.6mm. or less

separation as the diameter of the wheel

decreases with use.

SAFETY EYE SHIELD (4)

The

safety shield is adjustable for operator

convenience. Operating the grinder without

these features attached could result in

serious injury. Do not grind with the safety

shield raised ; always wear safety glasses for

personal protection.

WHEEL DRESSING

TOOL (5)

A buildup of metals, dirt, rust, etc. will become

embedded in the grinding wheel as it wears.

Using the Wheel Dressing Tool to clean the

wheel of these ground-in particles will help

improve the grinder’s performance.

AUTO-ON WORKLIGHT (6)

Your Bench Grinder linisher comes equipped

with a permanently mounted worklight that

automatically lights the work area for safer,

more accurate grinding and sharpening.

LOOSE PART LIST

1. On/ Off Switch

2. Coolant Tray

3. Work Rest

4. Flat Eyeshield

5. Wheel Dressing Tool

6. 12V Light

7.

Belt T

ensioning Lock Knob

8. Belt Tracking Knob

9. Work rest

10. Guard Cover

11. Guard Cover knob

12. Sanding Belt

13.

Safety Guard

A: 7mm, 10mm, and 12mm COMBINATION

WRENCH

B:

PHILLIPS SCREWDRIVER

C: ADJUSTABLE WRENCH

Page 5

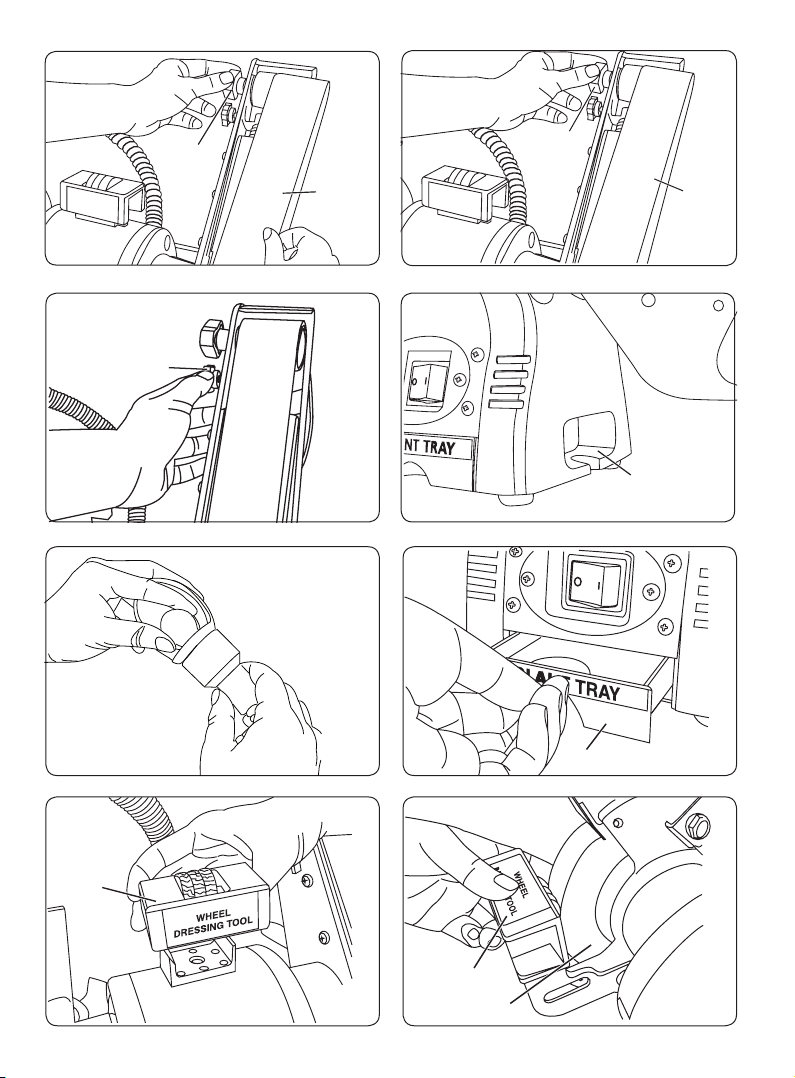

ASSEMBLY

OPERATION

EYESHIELD ADJUSTMENT

The Opti-View eyeshield allows users to

see operation more clearly and precisely.

Eyeshield can be adjusted up and down.

TOOL REST ADJUSTMENT

Tool rests are adjustable to maintain the

correct distance from grinding wheel of

1.6mm.

W

ARNING: Before every use, carefully

inspect the grinding wheel for any cracks

or chips and if any defects are found,

immediately replace the grinding wheel with

a new Ryobi grinding wheel. You should be

aware a defective grinding wheel can and do

explode causing serious injury.

CHANGING THE GRINDING WHEEL

To replace worn grinding wheel, the necessary

steps are listed below:

Disconnect the power supply.

Remove the three screws and nuts holding

the outside wheel guard (1). (Fig. 2)

Hold grinding wheel (1) firmly. Remove the

nut (2) and flange (3) on the shaft by using

proper tool.(Fig. 3)

Take off used wheel and replace with a new

one.

Assemble the flange, nut and outside cover

in reverse order. To ensure good balance,

make sure the surface between the grinding

wheel and the flanges are smooth.

Secure the three screws and nuts holding the

outside wheel guard.

Stand

to the side of the machine. Switch on

Fix tool rests with screws and washers

supplied. Keep tool rests Perpendicular to

grinding wheel and sanding assembly.

Assemble eyeshield and spark deflector

by using bolts, washers and knurled nuts

supplied loose.

Install eyeshield assembly to wheel guard.

the machine and let it run at full speed with no

load for one minute to check the wheel before

using it under load.

Note: Never sharpen or grind anything made of

aluminium, br

ass or copper.

CHANGING THE SANDING BELT

To replace worn sanding belt, remove guard

cover (Fig. 4)

Turn the belt Tensioning Lock Knob (1)

anticlockwise which will loosen the tension

on the belt enabling removal of worn sanding

belt (2). (Fig. 5)

Insert new sanding belt (2) on belt drive

ensuring the direction of rotation printed

on the belt is pointing in the correct upward

position at the rear side and turn the belt

tensioning lock knob (1) clockwise to tighten

and adjust sanding belt.(Fig. 6)

TRACKING THE BELT

Ensure the belt is positioned on the centre of

the two rollers, turning the Belt Tracking Knob

(1) in a clockwise direction will move the belt

to the left, turning the Belt Tracking Knob (1)

in an anticlockwise direction will move the belt

to the right. (Fig.7)

NOTE: Extreme caution should be taken not to

let hands in contact with the belt when Bench

Grinder Linisher is in operation. With the guard

removed, switch on the Bench Grinder Linisher

and adjust the Belt Tracking Knob (1) until the

belt is positioned on the centre of the two rollers,

and reattach the guard (Fig. 7).

NOTE: After initial use the belt may stretch and

re-adjustment of the belt will be required.

Remo

ve top wheel cover bolt. washer and

nut and insert spark deflector. Replace bolt,

washer and nut. Adjust to desired working

position and tighten firmly.

NOTE: The height and angle of the eyeshield

can be adjusted up and down to the user's

requirement.

Page 6

OPERATION

BENCH ATTACHMENT

Fasten Grinder Linisher to work bench before

operating this machine. There is a hole (1) on

either side of the base which should be used

to secure the grinder. (Fig. 8)

2 x 10mm diameter bolts should be used to

secure the Grinder Linisher to the bench or

stand.

A

UTO ON LIGHT

Your Ryobi Bench Grinder Linisher comes

complete with and Auto On Adjustable light

which allows you to illuminate the workpiece

when operating in poorly lit.

The light will automatically come on when

the Grinder Linisher is switched on. When

Grinder Linisher is not in use, switch off the

tool to avoid overheating of the lamp.

WORKLIGHT BULB REPLACEMENT

When the light bulb is worn out and will no

longer work, unfasten the screws which fix

the lamp cover, then gently remove the bulb

from the holder by pushing in and turning

anticlockwise. Contact your dealer for

replacement part. To replace, gently push the

light bulb into the insert and turn clockwise,

then fix the lamp cover in reverse order.

WARNING: Do not use force as this

could lead to the bulb breaking and

serious injury.

COOLANT TRAY

The in-built coolant storage dip tray (1) allows

you to cool overheated workpieces. Simply

pull out the tray and half fill with appropriate

coolant, such as water. (fig. 10)

WARNING: Do not overfill the coolant

tray

WHEEL DRESSING TOOL

After extensive use, the grinding wheel will

accumulate in-ground metal build up. To

clean the wheel detach the Wheel Dressing

Tool (1) from the storage holder. (Fig. 11)

Rest the Wheel Dressing Tool on the tool rest

approx. 5mm from the grinding wheel.

Switch on the Grinder Linisher and wait a few

seconds until the grinding wheel reaches full

speed then slowly move the Dressing Tool

(1) to gently touch against the grinding wheel

(2)holding firmly with two fingers. Do not use

excessive pressure. (Fig. 12)

CAUTION: Do not allow the grinding

wheel and Dressing Tool to touch

before the grinding wheel has reached

full speed as this may cause the

Dressing tool to be flicked from your

grasp causing serious injury.

Page 7

MAINTENANCE

WARNING:

When servicing, use only identical Ryobi

replacement parts. Use of any other part

may create a hazard of cause product

damage.

GENERAL

K

eep the bench grinder linisher clean.

Remove dust from working parts and beneath

the grinder frequently.

Make sure the bench grinder linisher operates

proper

ly. Check screws, nuts, and bolts for

tightness.

EXTENSION CORDS

The

use of any extension cord will cause

some loss of power. To keep the loss to a

minimum and to prevent tool overheating,

use an extension cord that is heavy enough

to carry the current the tool will draw.

A wire gauge size (A.W.G.) of at least 16 is

recommended for an extension cord 8 metres

or less in length. When working outdoors, use

an extension cord that is suitable for outdoor

use. The cord’s jacket will be marked WA.

WARNING:

Check extension cords before each use. If

damaged, replace immediately. Never use

tool with a damaged cord since touching

the damaged area could cause electrical

shock resulting in serious injury.

WHEEL DRESSING TOOL

Dressing a wheel is done to renew sharpness

or to true up the face of the wheel. Set the

work rest of the bench grinder at a slight angle

and brace the wheel dressing tool against it.

Do not make contact with the grinding wheel

until after you have turned on the motor and

the wheel is rotating at full speed. Press the

dressing tool slightly against the rotating

wheel until you get a bite, then move slowly

from side to side across the wheel. A small

bite and many passes is better than a big

bite and one pass. Work cautiously, hold the

dresser with force on the work rest. Do not

use excessive pressure against the grinding

wheel. Proceed slowly until you master the

technique.

WARNING:

Do not use excess force as this could

lead to the grinding wheel breaking and

serious injury.

Page 8

This section covers the most common problems encountered during operation and what to do about them. Do not make any

adjustments until machine is unplugged and moving parts have come to a c

omplete stop.

SYMPTOM POSSIBLE CAUSE

CORRECTIVE ACTION

Motor will not start; fuses or

circuit breakers blow

1, S

hort circuit in line cord or plug

2, Short circuit in motor or loose

connections.

3, I

ncorrect fuses or circuit break-

ers in power line.

1, I

nspect cord or plug for damaged insulation and

shorted wires.

2, Inspect all connections on motor for loose or

shorted terminals or worn insulation.

3, Install correct fuses or circuit breakers.

Motor stalls (resulting in blown

fuses or tripped circuit)

1, S

hort circuit in motor or loose

connections

2, Low voltage.

3, I

ncorrectfusesor circuit breakers

in power line.

4, Motor overloaded.

1, I

nspect connections on motor for loose or shorted

terminals or worn insulation

2, Correct the low voltage conditions.

3, Install correct fuse

s or circuit breakers.

4. Reduce load on motor.

Wa

vy condition on surface of

workpiece.

1, Machine vibrating

2, Workpiece not being held firmly.

3, Wheel face uneven.

4, Wheel is too hard.

1, M

ake su re mac hines is securely mounted on

a solid surface.

2, Usea holdingdevice to firmlyretain the workpiece.

3, Dress the grinding wheel.

4. Use softer wheel, or reduce the feed rate.

Burningspots or c

racks in the

workpiece.

1, Improper type of grinding wheel

2, Improper feed rate.

3, Coolant required.

1, Try a wheel which is softer style or a coarser grit.

2, S

low down the rate of movement of the workpiece

into wheel.

3, Introduce coolant by hand.

Wheel clogs and workpiece

s

hows burn ma

rks

1, W

heel is too hard.

2, Feed rate too slow.

3, Bad wheel dress.

4. Coolant required.

1, Wheel too hard for the material being ground,

select softer bond.

2

, In

crease the rate of movement of the workpiece

into wheel.

3

, Dress thewheel.

4, Int ro duce coolant by hand

Wheel dulls quickly, grit falls

off.

1, D

epth of cut too great.

2, Wheel is soft.

3, Wheel diameter too small.

4, Bad wheel dress.

5, Defective wheel bonding.

1, Slow down the rateof movement of the workpiece

into wheel.

2, Wh

eeltoo softforthe material being ground,select

harderbond.

3, R

eplace the wheel.

4, Dress the wheel.

5, Consult manufacturer of grinding wheel.

Motor overheats. 1, Motor overloaded. 1

, Reduce load on motor

Machine slowswhen operating 1, Depth of cut too great. 1

, Slow down the rate of movement of the workpiece

into wheel.

Li

nes on surface of workpiece. 1, Impurity on wheel surface.

2, W

orkpiece not being held tightly.

1, Dress the grinding wheel.

2. Usea holding device to firmly retain theworkpiece.

Motor will not start

1, Low voltage.

2, Open circuit in motor or loose

connections.

1, Check powe

r line for proper voltage.

2, Inspect all lead connections on motor for loose

or open connections.

TROUBLESHOOTING

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

GUARANTEE

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Contact during normal business hours.

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Contact during normal business hours.

Subject to the guarantee condition below, this Ryobi tool

(hereinafter called “the product”) is guaranteed by Ryobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of original purchase covering

both parts and labour. Under the terms of this

guarantee, the repair or replacement of any part shall

be the opinion of the Company or its authorised agent.

Should service become necessary during the warranty

period, the owner should contact the RYOBI HELPLINE

1300 361 505 or contact the retailer from whom the

product was purchased.

In order to obtain guarantee service, the owner must

present the sales docket and Guarantee Certificate

to confirm date of purchase. This product is sold by the

dealer or agent as principal and the dealer has no

authority from the Company to give any additional

guarantee on the Company’s behalf except as herein

contained or herein referred to.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in the opinion of the Company) and such

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or used

for a purpose for which it was not designed or is not

suited and no repairs, alterations or modifications

have been attempted by other than an Authorised

Service Agent. This guarantee will not apply if the tool is

damaged by accident or if repairs arise from normal

wear and tear.

The Company accepts no additional liability pursuant to

this guarantee for the costs of travelling or

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included in

this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller in

certain circumstances. Nothing herein shall have the effect

of excluding, restricting or modifying any condition,

guarantee, right or liability imposed, to the extent only

that such exclusion, restriction or modification

would render any term herein void.

BRISBANE : All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquiries Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville,Vic. 3178

Tel : (03) 9764 8656

HOBART: All enquiries Tel : 1300 361 505

ADELAIDE: All enquiries Tel : 1300 361 505

PERTH: 33-35 Sorbonne Cres. Canning Vale, W.A. 6155

Address Of Dealer

Present This Form With Your Purchase Docket When Guarantee Service Is Required.

Tel: (02) 9792 9800 - Fax: 1800 807 993 - www.ryobi.com.au

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - www.ryobi.co.nz

Tel : (08) 9455 7775

This Guarantee Form Should Be Retained By The Customer At All Times

For your record and to assist in establishing date of purchase (necessary for in-guarantee service)

please keep your purchase docket and this form completed with the following particulars.

Date Model No Serial No

Loading...

Loading...