Page 1

1

IMPORTANT

FOR STARTING

INSTRUCTIONS

REFER TO PA GE 10

IMPORTANT MANUAL DO NOT THROW AWAY

OPERATOR’S

MANUAL

Model 310r

Blower

Model 310BVr

Blower Vac

Page 2

2

I. California Emission Regulations ................................3

II. Safety Warnings ......................................................3-5

A. Operational ........................................................3-4

B. Safety and International Symbols ......................4-5

III. Assembly Instructions ............................................6-8

A. Blower Tube and Nozzle Assembly ......................6

B. Installing the Vacuum Bag Assembly

(Optional for Model 310r) ......................................6

C. Installing the Adapter

(Optional for Model 310r) ......................................7

D. Installing the Vacuum Tubes

(Optional for Model 310r)....................................7-8

IV. Oil and Fuel Information ............................................9

V. Starting/Stopping Instructions..................................10

VI. Operating Procedures ..............................................11

A. Typical Operating Positions ................................11

B. Vacuum Operating Procedures

(Optional for Model 310r) ....................................11

VII. Maintenance and Repair ....................................12-16

A. Maintenance Schedule ........................................12

B. Air Filter Maintenance ....................................12-13

C. Carburetor Adjustment ..................................13-15

D. Replacing the Spark Plug ....................................15

E. Inspecting/Cleaning the Muffler......................15-16

VIII. Cleaning and Storage ..............................................17

IX. Specifications ..........................................................17

X. Troubleshooting ........................................................18

XI. California Emission Control Warranty Statement ....19

XII. Warranty Statement ................................................20

SERVICE INFORMATION

Service on this power equipment within and after

the warranty period can be performed by any

Authorized Service Dealer.

Dial 1-800-345-8746 in the United States and

1-800-265-6778 in Canada to obtain the listing

of

servicing dealers in your area.

DO NOT RETURN UNIT TO RETAILER.

NOTE: PROOF OF PURCHASE WILL BE

REQUIRED FOR WARRANTY

SERVICE.

THANK YOU

Thank you for purchasing this quality product. This modern power tool has been designed to provide you with

many hours of useful service. You will find it to be a great

labor-saving device.

This manual has been prepared to provide you with common sense operating instructions and to ensure that you

will get maximum satisfaction. To keep your unit in top

operating condition, use the maintenance and service procedures in this manual.

PRODUCT REFERENCES,

ILLUSTRATIONS AND SPECIFICA TIONS

All information, illustrations and specifications in this manual are based on the latest product information available at

the time of printing. We reserve the right to make changes

at any time without notice.

TABLE OF CONTENTS

INTRODUCTION

MAKE SURE THIS MANUAL IS

CAREFULLY READ AND UNDERSTOOD

BEFORE STARTING OR OPERATING

THIS EQUIPMENT.

California Proposition 65 Warning:

Page 3

3

CALIFORNIA EMISSION REGULATIONS

SAFETY WARNINGS

FUELING AND PRE-OPERATION

• Gasoline is extremely flammable and its vapors can

explode if ignited. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the fuel tank. Keep sparks and open flames

away from the area.

• Store the gasoline and fuel only in containers

designed and approved for the storage of such materials.

• Pressure can build up in the fuel tank. Loosen the fuel

tank cap slowly to relieve any pressure in the tank.

• Add fuel in a clean, well-ventilated area. Wipe up any

spilled fuel immediately. If fuel has been spilled, allow

it to dry completely before starting the engine.

• Move the unit at least 10 ft (3 m) from the fueling point

before starting the engine.

• Thoroughly inspect the unit for loose or damaged

parts before each use. Do not use until adjustments or

repairs are made.

• Avoid accidental starting. Be in the starting position

whenever pulling the starting rope.

• Keep all bystanders, especially children, and pets at

least 30 ft (10 m) away from the area.

DURING OPERATION

• Wear safety glasses or goggles at all times when operating the unit.

• Dress properly. Do not operate the unit when barefoot

or wearing open sandals. Always wear sturdy, rubbersoled footwear. The use of gloves, ear/hearing protection, and long pants are recommended.

• Do not wear loose-fitting clothing, or loose articles

such as scarves, strings, chains, ties, etc. because

they could get drawn into the air intake. Also make

sure long hair does not get drawn into the air intake.

• Keep hands, face and feet away from all moving parts.

• Rotating impeller blades can cause severe injury. Stop

the engine before opening the vacuum door or installing/changing tubes. Do not put hands or any other

object into the vacuum tubes while they are installed

on the unit.

• Do not touch the muffler or cylinder. These parts get

extremely hot from operation and remain hot for a

short time after the equipment is turned off.

• Operate the unit only in a well-ventilated area,

outdoors. Carbon monoxide exhaust fumes can be

lethal in a confined area.

• Inspect the area before starting the unit. Remove all

debris and hard or sharp objects such as rocks, glass,

wire, etc.

• Do not point the blower in anyone’s direction or in the

direction of windows. The blower can propel objects

at high speed.

• Do not wear rubber or other insulated gloves when

using the unit to avoid static electricity shock.

• Do not overreach. Keep proper footing and balance at

all times.

• Never run the unit without the proper equipment

attached. When used as a blower, always install the

blower tube. When used as a vacuum, always install

the suction tubes and collection bag assembly. Make

sure the collection bag is completely zipped when the

NOTE: Advises you of information or

instructions vital to the operation or

maintenance of the equipment.

WARNING: Failure to obey a safety warning

can result in injury to yourself and others.

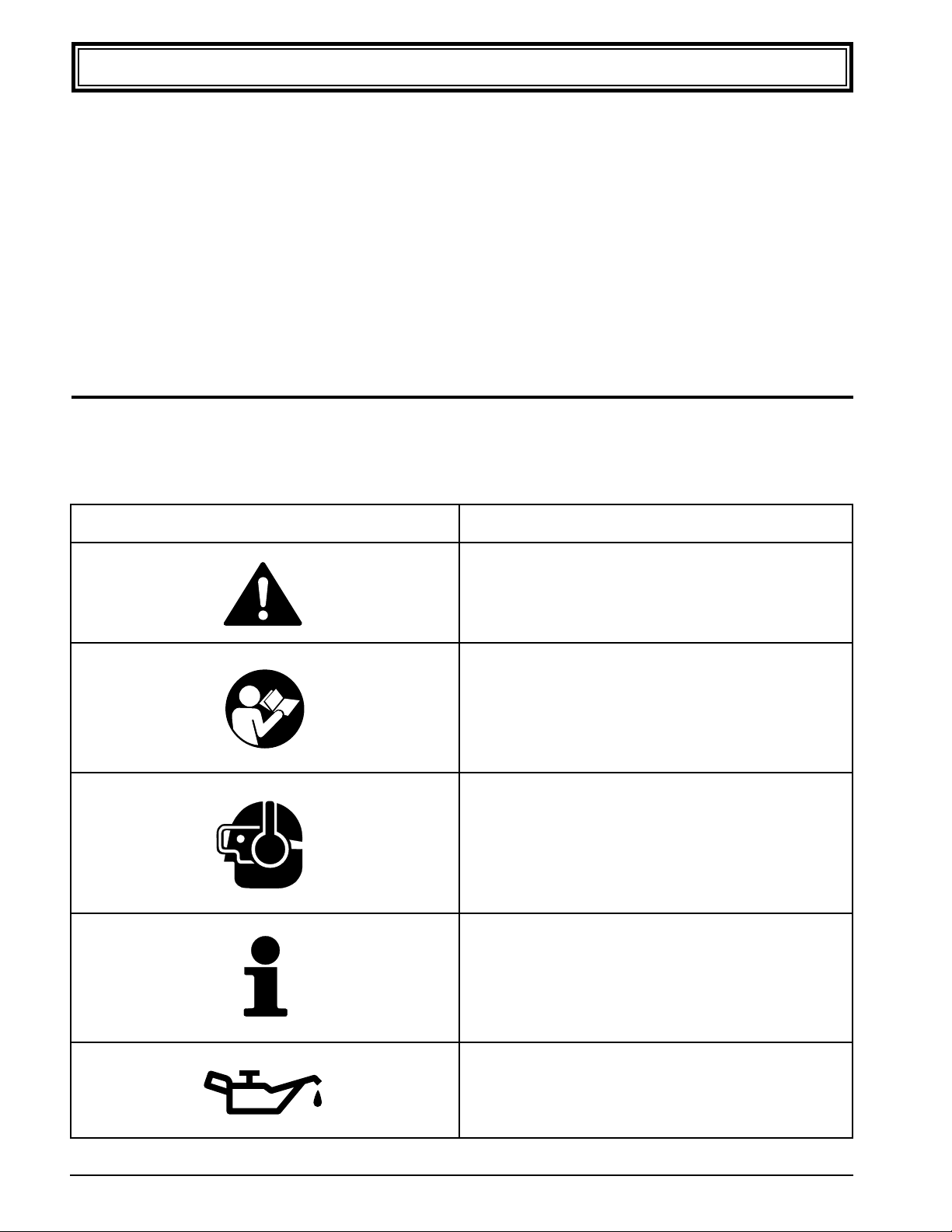

THE PURPOSE OF SAFETY SYMBOLS IS TO ATTRACT

YOUR ATTENTION TO POSSIBLE DANGERS. THE

SAFETY SYMBOLS, AND THE EXPLANATIONS WITH

THEM, DESERVE YOUR CAREFUL ATTENTION AND

UNDERSTANDING. THE SAFETY WARNINGS DO NOT

BY THEMSELVES ELIMINATE ANY DANGER. THE INSTRUCTIONS OR WARNINGS THEY GIVE ARE NOT

SUBSTITUTES FOR PROPER ACCIDENT PREVENTION

MEASURES.

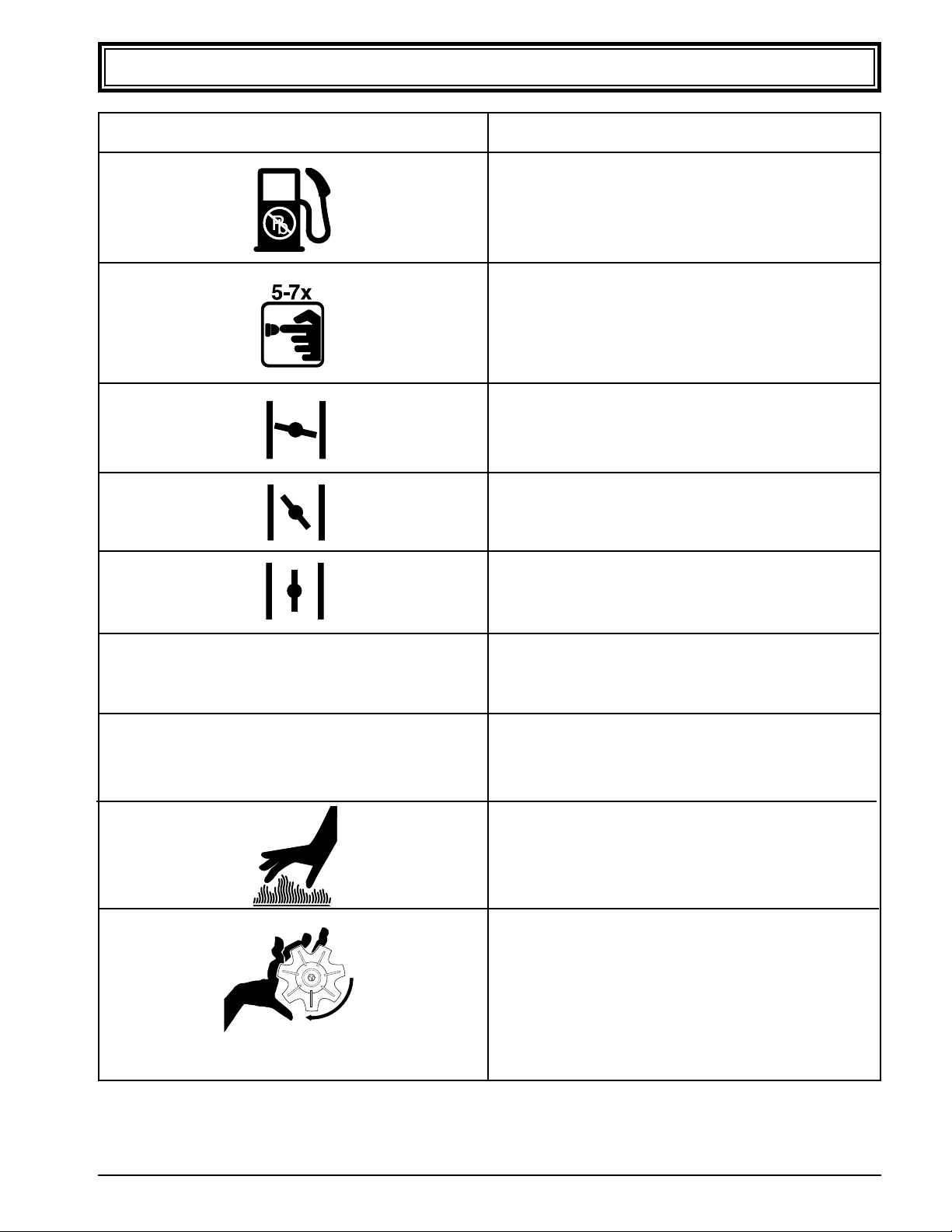

SYMBOL MEANING

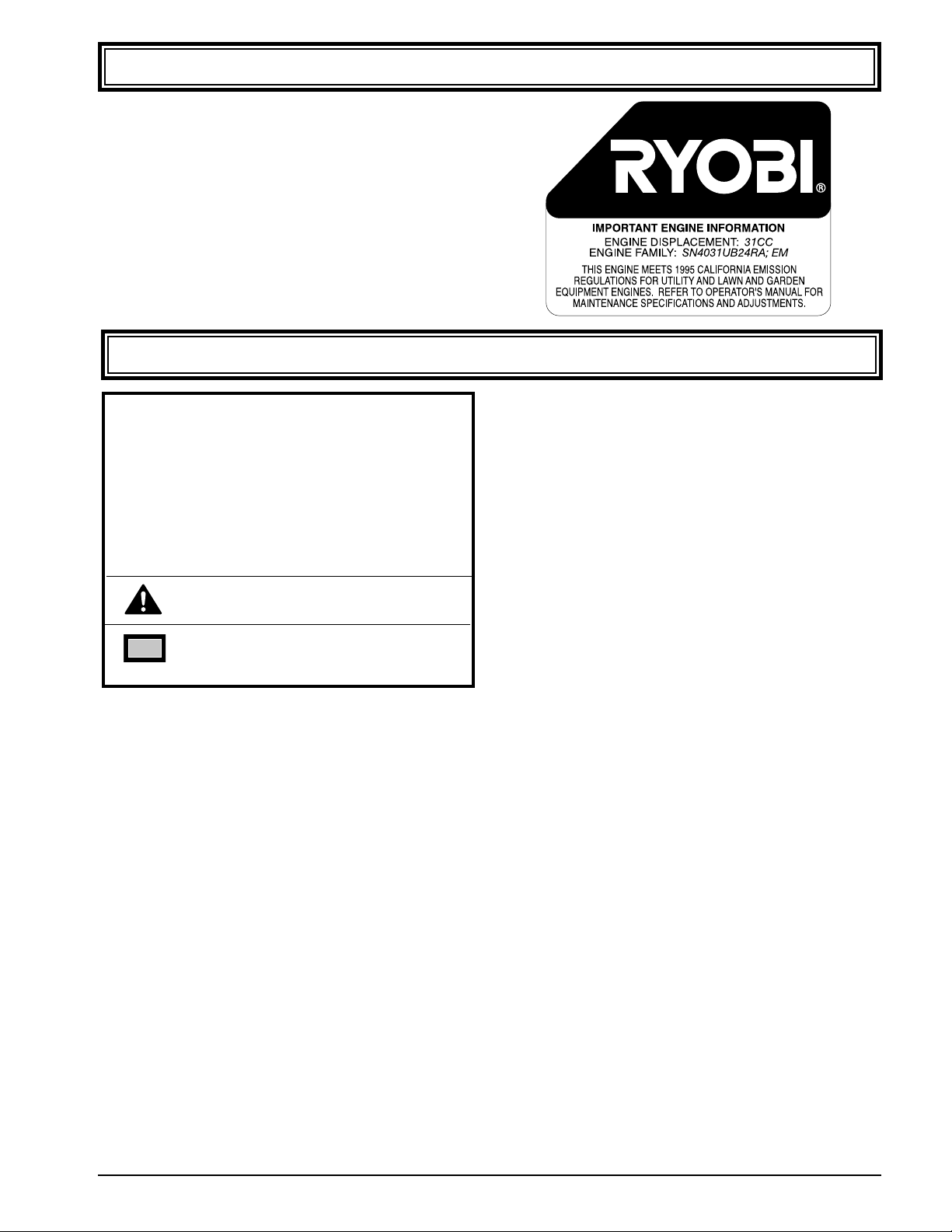

The engine of your lawn and garden care product

meets the 1995 California emissions regulations.

To ensure that your unit continues to meet these

regulations, refer to the following information and

instructions in this operator's manual.

These units are identified by the label on the engine

of your product. A typical identification label is

shown.

Page 4

4

SAFETY WARNINGS (Continued)

unit is running to avoid flying debris.

• Avoid situations that could catch the collection bag on

fire. Do not operate near an open flame. Do not vacuum warm ash from fireplaces, barbeque pits, brush

piles, etc. Do not vacuum discarded cigars or cigarettes unless the cinders are completely cool.

• Use the right tool. Do not use this unit for any job

except that for which it is intended.

• Always remain alert. To prevent injury to yourself and

others, do not operate this unit if you are fatigued.

• Use only genuine replacement parts when servicing

this unit. These parts are available from your authorized dealer. The use of non-standard parts, or other

accessories or attachments not designed for this unit

could result in serious injury to the user or damage to

the unit.

AFTER OPERATION

• Turn off the engine and let it cool before refueling or

before putting the unit in storage.

• Store the unit in an upright position on the feet provided.

• Store the unit in an area free of potential fuel vapor

ignition sources such as open flames (pilot lights) or

electrical sparking devices (switches, electric motors).

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read

the operator's manual for complete safety, assembly, operating and maintenance and repair information.

• SAFETY ALERT SYMBOL.

Indicates caution, warning or danger. May be

used in conjunction with other symbols or pictographs.

• READ OPERATOR'S MANUAL.

Failure to follow operating instructions and safety precautions in operator's manual can result in

serious injury. Read operator's manual before

starting or operating this unit.

• WEAR EYE AND HEARING PROTECTION.

Warning. Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear

ear and eye protection when operating this unit.

• FOR SERVICE INFORMATION, CALL:

USA: 1-800-345-8746

CANADA: 1-800-265-6778

• INDICATES OIL.

Refer to operator's manual for the proper type of

oil.

SIGNIFICATIONSYMBOL

Page 5

5

SAFETY WARNINGS (Continued)

• UNLEADED FUEL.

Always use clean, fresh unleaded fuel.

• PRIMER BULB.

Push primer bulb, fully and slowly, 5 to 7 times.

• CHOKE CONTROL.

FULL CHOKE position.

• CHOKE CONTROL.

PARTIAL CHOKE position.

• CHOKE CONTROL.

RUN position.

• IGNITION / POWER SWITCH.

ON / START / RUN

• IGNITION / POWER SWITCH.

OFF OR STOP

• HOT SURFACE WARNING.

Do not touch a hot muffler, gear box or cylinder.

You may get burned. These parts get extremely

hot from operation and remain hot for a short

time after the unit is turned off.

• BLOWERS AND BLOWER / VACUUMS –

ROTATING BLADES CAN CAUSE SEVERE

INJURY.

Stop the engine or motor before opening the

vacuum door or installing / changing tubes.

Do not put hands or any other objects into the

vacuum tubes while they are installed on this unit.

SYMBOL SIGNIFICATION

I

O

Page 6

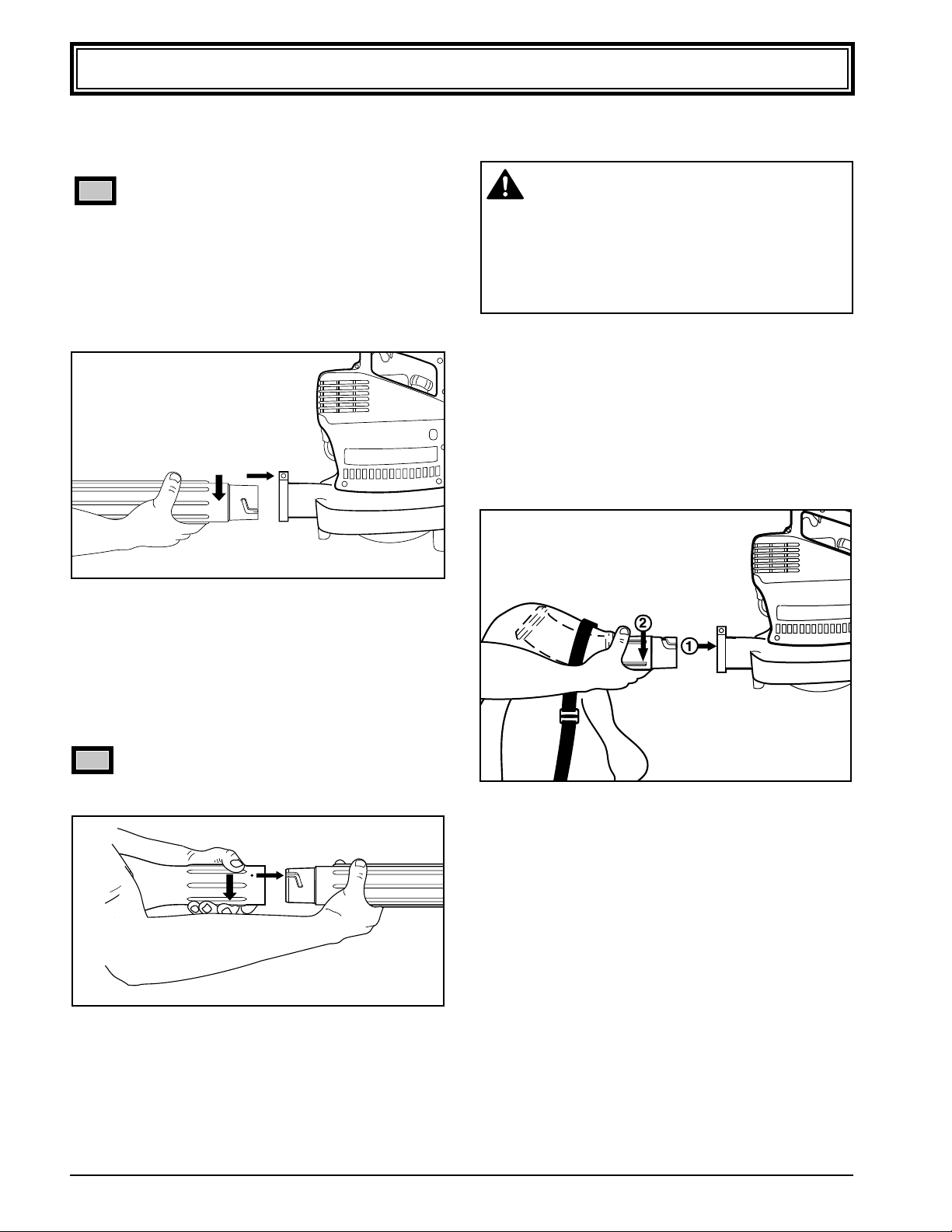

WARNING

Rotating impeller blades can cause severe

injury. Do not attempt to convert the unit while

the engine is running to avoid serious personal

injury. Do not put hands or any other object into

the vacuum tubes while they are installed on

the unit.

1. Remove the blower tubes.

2. Align the grooves in the vacuum bag/elbow tube

assembly with the pins in the blower outlet.

3. Grasping the tube firmly with both hands, push the

vacuum bag/elbow tube assembly into the blower

outlet (Fig. 3). Turn the assembly clockwise until it

snaps into the detent and locks. The curve of the

tube should angle upwards.

6

BLOWER TUBE AND NOZZLE ASSEMBL Y

- BOTH MODELS

NOTE: Do not install tubes while unit is running.

1. Align the grooves in the blower tube with the pins in

the blower outlet.

2. Grasping the tube firmly with both hands, push the

tube into the blower outlet (Fig. 1). Turn the tube

clockwise until it snaps into the detent and locks.

ASSEMBLY INSTRUCTIONS

Fig. 1

3. Align the pins of the blower nozzle with the grooves in

the blower tube (Fig. 2).

4. Grasping the nozzle firmly with both hands, push the

nozzle onto the blower tube. Turn the nozzle

clockwise until it snaps into the detent and locks.

NOTE: The blower tube and nozzle or vacuum

bag must be used at all times to prevent

overheating the engine.

Fig. 2

Fig. 3

INSTALLING THE VACUUM BAG/TUBE

ASSEMBLY (OPTIONAL FOR MODEL 310r)

Page 7

7

ASSEMBLY INSTRUCTIONS (Continued)

INSTALLING THE ADAPTER ONTO THE

UPPER VACUUM TUBE - (OPTIONAL

FOR MODEL 310r)

NOTE: Do not install while unit is running.

1. Turn the blower upside down as shown in Fig. 4.

Hold the blower between your knees to install the

adapter and vacuum tubes.

3. Align the adapter's three (3) slots with the unit's three

(3) hooks. Push firmly so all three (3) hooks snap

through (Fig. 7).

Fig. 7

Fig. 4

Ta b

Fig. 5

2. Push the door lock tab in the direction shown in Fig. 5

and open the door (Fig. 6).

Fig. 6

4. Align the arrow on the upper tube with the arrow on

the adapter. Slide the upper vac tube onto the

adapter (Fig. 8).

NOTE: The arrows must align properly to install

the vacuum tubes correctly.

Fig. 8

Page 8

8

INSTALLING THE VACUUM TUBES (OPTIONAL FOR MODEL 310r)

NOTE: Do not install tubes while unit is running.

1. Align the arrow on the lower vacuum tube with the

arrow on the upper vacuum tube (Fig. 12).

2. Grasping the lower vac tube firmly with both hands,

push the lower vac tube into the upper vac tube. Turn

the lower vac tube clockwise until it snaps into detent

and locks. (The dot on the lower tube aligns with the

dot on the upper tube) when properly assembled.

ASSEMBLY INSTRUCTIONS (Continued)

5. Grasping the upper vac tube firmly with both hands

(Fig. 9), turn the vac tube clockwise (Fig. 10) until

the tabs of the adapter (2) snap into the square

indentations of the upper vac tube (2) (Fig. 11).

NOTE: This assembly requires the use of both

hands because the parts fit together

tightly.

Fig. 9

NOTE: The flat on the upper tube should face the

handle as you install the tube (Fig. 13).

Adapter

Fig. 10

Fig. 11

NOTE: When the tabs lock into the indentations,

the adapter and vacuum tube become a

permanent assembly. The adapter cannot

be removed from the vacuum tube.

Lower Vac Tube

Upper Vac

Tube

Fig. 12

Installing the Vacuum Tubes to the Blower/Vac

NOTE: Do not install tubes while unit is running.

1. Grasp the assembled tube firmly with both hands.

Turn the tube/adapter clockwise as far as possible to

the end of the grooves until it snaps into the detent

and locks (Fig. 13).

NOTE: When the tube is installed correctly, the

flat on the upper tube faces the handle

on the blower/vac (Fig. 13).

Fig. 13

Handle

Flat

Page 9

WARNING

Remove fuel cap slowly to avoid injury

from fuel spray.

NOTE: BE SURE TO READ THESE

INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO START OR OPERATE

THIS UNIT. Using old or improper oil or

fuel, or improperly mixing the oil and fuel

can cause engine damage. This type of

damage will void the engine warranty.

WARNING

Gasoline is extremely flammable and its

vapors can explode if they are ignited. Always

stop the engine and allow it to cool before filling

the fuel tank. Do not smoke while filling the

tank. Keep sparks and open flames away from

the area.

RECOMMENDED OIL TYPE

A 4 oz. (0.118 liter) bottle of 2-cycle engine oil is included

with your product.

RYOBI 2-cycle oil is recommended for this outdoor power

tool. If another brand of 2-cycle oil is used, make sure it is

high quality oil, formulated for 2-cycle, air-cooled engines.

DANGER: Combustible mixture contains petroleum

distillate. Store away from heat or open flame.

Harmful or fatal if swallowed. If swallowed, do

not induce vomiting. CALL PHYSICIAN

IMMEDIATELY. Avoid prolonged contact with

skin. Wash thoroughly after handling.

Do not reuse bottle.

RECOMMENDED FUEL TYPE

Use clean, fresh, unleaded gasoline that is less than 60

days old.

NOTE: Alcohol blended fuel absorbs moisture

(water). As little as 1% moisture in the

fuel can cause fuel and oil to separate

and form acids when stored.

If this type of fuel must be used, use

fresh fuel, (less than 60 days old) and

mix according to the mixing instructions.

DEFINITION OF BLENDED FUELS

Today's fuels are often a blend of gasoline and one or

more oxygenates such as ethanol, methanol or MTBE

(ether).

9

OIL & FUEL INFORMATION

THIS ENGINE IS CERTIFIED TO OPERATE ON UNLEADED GAS AND OIL MIXTURE.

USE OF BLENDED FUELS

If you choose to use a blended fuel or its use is unavoidable, the following precautions are recommended.

1. Always use fresh fuel mix per your operator's manual.

2. Use the special additive STA-BIL® or an equivalent.

3. Always agitate the fuel mix before fueling the unit.

4. Drain the tank and run the engine dry before storing

the unit.

USE OF FUEL ADDITIVES

The use of fuel additive, such as STA-BIL®Gas Stabilizer

or an equivalent, will inhibit corrosion and minimize the

formation of gum deposit. Add 0.8 oz (23 ml) per gallon of

fuel per instructions on container. NEVER add fuel additives directly to the unit's fuel tank. Using a fuel additive

can keep fuel fresh for up to six (6) months.

OIL AND FUEL MIXING INSTRUCTIONS

NOTE: For proper engine operation and maxi-

mum reliability, pay strict attention to the

oil and fuel mixing instructions on the

2-cycle oil container. Use a 32:1 fuel/oil

ratio when you use 2-cycle oil. Using

improperly mixed fuel can severely damage the engine.

Thoroughly mix the proper ratio of 2-cycle engine oil with

unleaded gasoline in a separate fuel can, 32:1. Do not mix

them directly in the engine fuel tank. See the table below

for specific gas and oil mixing ratios.

Page 10

10

5. SQUEEZE THE THROTTLE TRIGGER TO FULL

THROTTLE. Hold the trigger in this position.

6. PULL THE STARTER ROPE BRISKLY until you hear

the engine sounds like it wants to run (normally 2 to 5

pulls).

7. PLACE THE CHOKE LEVER IN THE "PARTIAL"

POSITION. Pull the starter rope briskly 1 to 3 times to

start the engine. See Fig. 15.

NOTE: If the engine does not start immediately,

repeat steps 2 through 7.

8. After the engine warms up for 5 to 10 seconds,

PLACE THE CHOKE LEVER IN THE "RUN" POSITION. See Fig. 15.

STOPPING

To stop the engine, push and hold the stop button until the

engine comes to a complete stop (Fig. 18).

NOTE: To prevent vapor lock, avoid setting the

unit in the sun.

Fig. 17

STARTING/STOPPING INSTRUCTIONS

Fig. 16

STARTING

1. MIX OIL WITH GAS per instructions (page 8).

2. FULLY PRESS AND RELEASE THE PRIMER BULB

UNTIL FUEL IS VISIBLE IN BULB. See Fig. 14 for

the primer bulb location.

4. HOLD THE BLOWER/VAC IN THE STARTING

POSITION (Fig. 16 for blower, Fig. 17 for vacuum).

3. PLACE THE CHOKE LEVER IN THE FULL "CHOKE"

POSITION. See Fig. 15.

Primer

Bulb

Fig. 14

Fig. 15

Fig. 18

Page 11

11

WARNING

DO NOT OPEN THE DOOR WITH THE

ENGINE RUNNING! To do so can result in

serious personal injury caused by contact with

the rotating blades.

NOTE: Do not wear rubber or any other insulated

gloves to avoid static electricity shock.

1. Move the unit slowly back and forth over the debris

to be vacuumed (Fig. 22).

WARNING

Wear goggles or safety glasses at all times when

operating this unit.

TYPICAL OPERATING POSITIONS

1 Use the blower for trees, shrubs, flower beds and

hard-to-clean areas (Fig. 19).

OPERATING PROCEDURES

2. Use the unit around buildings and for other normal

cleaning (Fig. 20).

3. Use the blower for walls, overhangs and screens

(Fig. 21).

Fig. 20

Fig. 21

VACUUM OPERATING PROCEDURES (OPTIONAL FOR MODEL 310r)

Fig. 22

Fig. 19

2. Vacuum a large pile of debris working from the outside of the pile. Do not force the suction tube into the

debris because this can clog the tube.

3. Empty the collection bag after each use. Shake the

bag vigorously while emptying to remove dust from

the bag, which can block the proper amount of air

flow and deteriorate the performance of the vacuum.

NOTE: Use the zipper when emptying the

collection bag. Do not empty the bag

through the nozzle.

Page 12

12

NOTE: CLEAN AND RE-OIL THE AIR FILTER

EVERY 10 HOURS OF OPERATION.

Your unit's air filter is one of the most

important areas to maintain. If it is not

maintained as follows, you will void the

warranty.

1. Press the filter cover with your finger and remove the

cover from the air filter base (Fig. 23).

MAINTENANCE SCHEDULE

These required maintenance procedures should be performed at the frequency stated in the table to ensure that

your unit continues to meet the 1995 California emission regulations. They should also be included as part of

any seasonal tune-up.

MAINTENANCE AND REPAIR INSTRUCTIONS

FREQUENCY MAINTENANCE REQUIRED REFER TO:

Before

Starting

Engine

Every

10 Hours

Every

25 Hours

Every

50 Hours

Fill fuel tank with correct oil and fuel mixture.

Clean and re-oil air filter.

Inspect and clean muffler.

Check spark plug condition and gap.

Page 9

Page 15

Page 16

Page 13

AIR FILTER MAINTENANCE

Fig. 23

2. Remove the air filter from the air filter cover assembly

(Fig. 24).

Fig. 24

3. Wash the filter in detergent and water (Fig. 25). Rinse

the filter thoroughly and allow it to dry.

Fig. 25

Page 13

13

Fig. 26

Fig. 27

Fig. 28

6. Carefully reinstall the air filter. Be sure the filter is

sealed properly before placing it on the air filter base

(Fig. 28).

5. Squeeze the filter to spread the oil (Fig. 27).

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

4. Apply clean oil to the filter enough to saturate the

filter (Fig. 26).

CARBURETOR ADJUSTMENT

This unit is equipped with a diaphragm-type carburetor

that has been carefully calibrated at the factory. In most

cases, no further adjustment is required.

NOTE: To meet the 1995 California emission

regulations, the carburetor has

adjustment needle limiter caps to restrict

the amount of adjustment.

The condition of the air filter is important to the operation

of the blower. A dirty air filter will restrict the air flow, which

upsets the fuel-air mixture in the carburetor. The resulting

symptoms are often mistaken for an out-of-adjustment

carburetor. Therefore, check the condition of the air filter

before adjusting the carburetor. Refer to Air Filter

Maintenance.

If the following conditions are experienced, it may be necessary to adjust the carburetor:

• The engine will not idle

• The engine hesitates or stalls on acceleration

• The loss of engine power that is not corrected by

cleaning the air filter and muffler

NOTE: Careless adjustments can seriously

damage your unit.

Adjusting the Carburetor

1. Clean the air filter if it is dirty. Refer to Air Filter

Maintenance.

2. Make the initial settings with the engine stopped.

These initial settings should allow you to start and

warm up the unit before making the final adjustments.

Initial Idle Speed Setting

a) Remove the air filter cover and insert a screwdriver

through the opening in the air filter base (Fig. 29).

b) For Walbro carburetors: Back the idle speed screw

(Fig. 30 - page 14) out (counterclockwise) until it

does not contact the carburetor throttle lever. Then

turn the screw in (clockwise) until it just begins to

move the throttle lever; then continue turning 2 full

turns.

c) For Zama carburetors: Back the idle speed screw

(Fig. 31 - page 14) out (counterclockwise) until it

does not contact the throttle valve located inside of

the carburetor. This is accomplished by carefully

watching for the movement of the throttle lever to

stop. Then turn the screw in (clockwise) until it just

begins to move the throttle lever, then continue

turning 1 1/2 turns.

Page 14

3. Initial High Speed Mixture and Idle Speed Mixture

Needle Settings: Insert the screwdriver through the

hole at the back of the top handle (Fig. 32). Turn both

the high speed mixture and idle speed mixture

needles out (counterclockwise) until the limiter

caps stop.

4. Start the engine and let it run for a minute.

5. Release the throttle trigger and let the engine idle. If

the engine stops, turn the idle speed screw (Figs. 30

and 31) in (clockwise) 1/8 turn at a time (as required)

until the engine idles.

NOTE: Forcing the limiter caps with a

screwdriver will damage the needle tips

and the seat in the carburetor body.

6. Final Idle Speed Screw and Idle Speed Mixture

Needle Settings: Adjust the idle speed screw and idle

speed mixture needle for smoothest engine idle.

a. Turn the idle speed mixture needle (Figs. 30 and

31) in (clockwise) until you hear the fastest idle;

then turn the needle out (counterclockwise) 1/8

turn.

b. Squeeze the throttle trigger. If the engine falters

or hesitates as it accelerates, turn the idle speed

mixture needle (Figs. 30 and 31) out

(counterclockwise) 1/16 turn at a time until the

engine accelerates rapidly.

c. If the idle speed changes significantly because of

Steps a and b, readjust the idle speed screw

(refer to Step 2).

7. Final High Speed Mixture Needle Adjustment:

a. High speed mixture needle adjustment is not

recommended without a precision high speed

tachometer.

b. The factory presets the high speed mixture

needle at 1-1/4 turns out from the closed

position. Your unit should perform well at this

setting. If additional adjustment of the high speed

mixture needle is required, contact your local

authorized service dealer.

14

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

Fig. 31

Fig. 29

Fig. 30

WALBRO CARBURETOR

Throttle

Lever

Idle Speed

Screw

High Speed

Mixture Needle

Idle Speed

Mixture Needle

Idle Speed

Screw

Throttle

Lever

High Speed

Mixture Needle

Idle Speed Mixture Needle

ZAMA CARBURETOR

NOTE: If the limiter caps are removed at any

time, your unit will no longer meet the

1995 California emission regulations and

you will void the warranty.

Page 15

NOTE: If the carburetor adjustments do not help

the unit to run properly, contact your

authorized service dealer.

15

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

INSPECTING/CLEANING THE MUFFLER

The muffler should be removed every 25 hours of operation to inspect for excessive carbon build-up. Excessive

deposits around the exhaust ports or exhaust holes will

cause poor engine performance.

Use the following procedure to remove, inspect and clean

and reinstall the muffler.

Fig. 34

WARNING

Make sure the muffler is cool before inspecting

and cleaning it.

1. Remove the muffler mounting bolts (Fig. 34).

2. Remove the muffler (with heat shield) and gasket.

Discard the old gasket.

Fig. 32

REPLACING THE SPARK PLUG

Use a Champion RDJ7Y spark plug (or equivalent). Correct

air gap is .025 in (0.635 mm). Remove plug after every 50

hours of operation and check its condition.

1. Stop the engine and pull the wire off of the spark

plug.

2. Clean around the spark plug and remove it from the

cylinder head.

NOTE: Replace a cracked, fouled or dirty spark

plug. Do not sand blast, scrape or clean

electrodes because the engine could be

damaged by grit entering thecylinder.

3. Set the air gap at .025 in (0.635 mm) using a wire

feeler gauge (Fig. 33). Install a correctly gapped spark

plug into the cylinder head. Torque to 110-120 in•lb

(12.3-13.5 N•m).

Fig. 33

Exhaust Exit Tube Removal

The exhaust exit tube is removable on blower and

blower/vac mufflers. To remove the exhaust exit tube:

1. Remove the screws securing the exhaust exit tube to

the muffler body (Fig. 35).

2. Remove the exhaust exit tube and gasket.

Muffler Mounting Bolts

.025 in

(0.635 mm)

Page 16

16

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

If carbon build-up cannot be cleaned, replace the muffler.

3. Inspect the muffler mounting holes for elongation.

Replace the muffler if the holes are elongated.

Muffler Reassembly

1. Install a new gasket*. Make sure the arrow stamped

into the gasket is to your right. Tuck the tab (with the

arrow) between the cylinder and plastic shroud

(Fig. 38).

2. Install the muffler with the muffler mounting bolts (see

Fig. 35) and torque the bolts to 80-90 in•lb

(9-10.1 N•m).

Inspection and Cleaning

1. Check the inlet port of the muffler and outlet port of

the cylinder for excessive carbon deposits (Fig. 36).

Clean as required.

Fig. 35

Fig. 36

2. Inspect the baffle inside the muffler for carbon buildup. Clean baffle by scraping carbon as required. Use a

piece of wire to clear obstructions from the small

holes in baffle (Fig. 37).

Fig. 37

Fig. 38

* Some earlier units have a muffler gasket with slots.

Muffler Gasket

Inlet Port

Exhaust

Exit Tube

Screws

Page 17

17

ENGINE

Manufacturer ..........................Ryobi Outdoor Products,

Inc.

Type ..........................................2-Cycle, Air-Cooled

Displacement............................31 cc (1.9 cu. in)

Bore ..........................................1.37 in (34.79 mm)

Stroke ......................................1.25 in (31.75 mm)

Operating RPM ........................7200-7500

Ignition ......................................Electronic Ignition

Lubrication................................Fuel/Oil Mix

Carburetor ................................Diaphragm, All Position

Ignition Switch ..........................Push Button

Starter ......................................Auto Rewind

Muffler ......................................Baffled With Guard

Clutch ......................................None

Throttle......................................Manual Spring Return

Bearings....................................Needle & Ball

Crankshaft ................................Cantilevered

Connecting Rod........................Steel

Fuel Tank ..................................Clear Sight

Fuel Tank Capacity ..................18 fl. oz (0.51 L)

BLOWER

Max. Blower Velocity................150 mph (241.4 kmh)

Max. Blower Volume ................324 cfm (9.18 cmm)

Operating Weight......................12 lbs (5.22 kg)

BLOWER / VACUUM

Vacuum Bag Capacity..............1.4 bushels (0.066m3)

SPECIFICATIONS

WARNING

Always turn off your unit before you clean

or perform any maintenance on it.

Cleaning

Use a small brush to clean off the outside of the unit. Do

not use strong detergents on plastic housing or handle.

They can be damaged by household cleaners that contain

aromatic oils such as pine and lemon, and by solvents

such as kerosene.

Storage

If the unit will be stored for an extended period of time,

use the following storage procedure.

1. Drain all fuel from the fuel tank. Make sure that the

fuel is drained into a container with the same 2-cycle

fuel mixture. Do not use fuel that has been stored for

more than 60 days. Dispose of the old fuel/oil mix in a

safe manner and use a fresh mix.

2. Start the engine and allow it to run until it stalls.

3. Allow the engine to cool. Remove the spark plug and

put approximately 1 ounce of any high quality motor

oil or 2-cycle oil into the cylinder. Pull the starter rope

slowly to distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of

the oil from the cylinder before attempting to start the unit after storage.

4. Thoroughly clean the unit and inspect it for any loose

or damaged parts. Repair or replace the damaged

parts and tighten any loose screws, nuts or bolts.

The unit is now ready for storage.

5. Store the unit in a dry, well-ventilated area.

CLEANING AND STORAGE

Page 18

18

TROUBLESHOOTING

PROBLEM CAUSE ACTION

Engine Will Not Start Choke in incorrect position Refer to starting/stopping instructions

on page 10

Empty fuel tank Fill fuel tank

Primer bulb wasn't pushed Press primer bulb fully and slowly until

enough fuel is visible in bulb

Engine flooded Use starting procedure WITHOUT

USING CHOKE

Engine Will Not Idle Carburetor misadjusted Adjust carburetor

Engine Will Not Accelerate Carburetor misadjusted Adjust carburetor

Throttle wire has come loose Thread throttle wire through the

carburetor throttle lever. Tighten screw.

Engine Lacks Power or Stalls Dirty air filter Clean or replace air filter

No oil in fuel Add oil to fuel

If further assistance is required, contact your local authorized service dealer.

Page 19

19

The California Air Resources Board and Ryobi America Corp. (RAC), is pleased

to explain the emission control system warranty on your 1995 lawn and garden

equipment engine. In California, new lawn and garden equipment engines must be

designed, built and equipped to meet the State's stringent anti-smog standards.

RAC must warrant the emission control system on your lawn and garden equipment engine for the periods of time listed below provided there has been no abuse,

neglect or improper maintenance of your lawn and garden equipment engine.

Your emission control system may include parts such as the carburetor or fuel

injection system, the ignition system, and catalytic converter. Also included may be

hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, RAC will repair your lawn and garden equipment engine at no cost to you including diagnosis, parts and labor.

The 1995 and later utility and lawn and garden equipment engines are warranted

for two years. If any emission-related part on your engine is defective, the part will

be repaired or replaced by RAC.

OWNER'S WARRANTY RESPONSIBILITIES:

• As the lawn and garden equipment engine owner, you are responsible for the

performance of the required maintenance listed in your operator's manual.

RAC recommends that you retain all receipts covering maintenance on your

lawn and garden equipment engine, but RAC cannot deny warranty solely for

the lack of receipts or for your failure to ensure the performance of all

scheduled maintenance.

• As the lawn and garden equipment engine owner, you should however be aware

that RAC may deny you warranty coverage if your lawn and garden equipment

engine or a part has failed due to abuse, neglect, improper maintenance or

unapproved modifications.

• You are responsible for presenting your lawn and garden equipment engine to

an Ryobi Authorized Service Center as soon as a problem exists. The warranty

repairs should be completed in a reasonable amount of time, not to exceed 30

days.

If you have any questions regarding your warranty rights and responsibilities, you

should call 1-800-345-8746.

MANUFACTURER'S WARRANTY COVERAGE:

• The warranty period begins on the date the engine or equipment is delivered to

the retail purchaser.

• The manufacturer warrants to the initial owner and each subsequent purchaser,

that the engine is free from defects in material and workmanship which cause

the failure of a warranted part for a period of two years.

• Repair or replacement of warranted part will be performed at no charge to

the owner at an Authorized Ryobi Service Center. For the nearest location,

please contact Ryobi at: 1-800-345-8746.

• Any warranted part which is not scheduled for replacement, as required

maintenance which is scheduled only for regular inspection to the effect of

"Repair or replace as necessary" is warranted for the warranty period. Any

warranted part which is scheduled for replacement as required maintenance will

be warranted for the period of time up to the first scheduled replacement point

for that part.

• The owner will not be charged for diagnostic labor which leads to the

determination that a warranted part is defective, if the diagnostic work is

performed at an Authorized Ryobi Service Center.

• The manufacturer is liable for damages to other engine components caused by

the failure of a warranted part still under warranty.

• Failures caused by abuse, neglect or improper maintenance are not covered

under warranty.

• The use of add-on or modified parts can be grounds for disallowing a warranty

claim. The manufacturer is not liable to cover failures or warranted parts caused

by the use of add-on or modified parts.

• In order to file a claim, go to your nearest Authorized Ryobi Service Center.

Warranty services or repairs will be provided at all Authorized Ryobi Service

Centers.

• Any manufacturer approved replacement part may be used in the performance

of any warranty maintenance or repair of emission related parts and will be

provided without charge to the owner. Any replacement part that is equivalent in

performance or durability may be used in non-warranty maintenance or repair

and will not reduce the warranty obligations of the manufacturer.

• The following components are included in the emission related warranty of the

engine, air filter, carburetor, primer, fuel lines, fuel pick up/fuel filter, ignition

module, spark plug and muffler.

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

Page 20

20 Operator's Manual Part Number 181146 3/95

RYOBI AMERICA CORP. warrants each new RYOBI Product for two (2) years according to the following terms.

This warranty extends to the original retail purchaser only and commences on the

date of original retail purchase.

Any part of the RYOBI Product manufactured or supplied by RYOBI and found in the

reasonable judgement of RYOBI to be defective in material or workmanship will be

repaired or replaced by an authorized RYOBI service dealer without charge for parts

and labor.

The RYOBI Product including any defective part must be returned to an authorized

service dealer within the warranty period. The expense of delivering the RYOBI

Product to the dealer for warranty work and the expense of returning it back to the

owner after repair or replacement will be paid for by the owner. RYOBI’s responsibility in respect to claims is limited to making the required repairs or replacements and

no claim of breach of warranty shall be cause for cancellation or rescission of the

contract of sale of any RYOBI Product. Proof of purchase will be required by the

dealer to substantiate any warranty claim. All warranty work must be performed by

an authorized RYOBI service dealer.

This warranty is limited to ninety (90) days from the date of original retail purchase

for any RYOBI Product that is used for rental or commercial purposes, or any other

income-producing purpose.

This warranty does not cover any RYOBI Product that has been subject to misuse,

neglect, negligence, or accident, or that has been operated in any way contrary to

the operating instructions as specified in the RYOBI Operator’s Manual. This war-

ranty does not apply to any damage to the RYOBI Product that is the result of

improper maintenance or to any RYOBI Product that has been altered or modified so

as to adversely affect the products operation, performance or durability or that has

been altered or modified so as to change its intended use. The warranty does not

extend to repairs made necessary by normal wear or by the use of parts or accessories which are either incompatible with the RYOBI Product or adversely affect its

operation, performance or durability.

In addition, this warranty does not cover:

A. Tune-ups - Spark Plugs, Carburetor Adjustments, Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting Line, Inner Reels, Starter Pulley,

Starter Ropes

RYOBI reserves the right to change or improve the design of any RYOBI Product

without assuming any obligation to modify any product previously manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED IN DURATION TO THE TWO (2) YEAR

WARRANTY PERIOD OR NINETY (90) DAYS FOR PRODUCTS USED FOR ANY

COMMERCIAL PURPOSE. ACCORDINGLY, ANY SUCH IMPLIED WARRANTIES INCLUDING MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR OTHERWISE, ARE DISCLAIMED IN THEIR ENTIRETY AFTER THE EXPIRATION OF THE

APPROPRIATE TWO-YEAR OR NINETY DAY WARRANTY PERIOD. RYOBI’S OBLIGATION UNDER THIS WARRANTY, IS STRICTLY AND EXCLUSIVELY LIMITED TO

THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS, AND ROP DOES NOT

ASSUME OR AUTHORIZE ANYONE TO ASSUME FOR THEM ANY OTHER OBLIGATION. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

RYOBI ASSUMES NO RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL OR

OTHER DAMAGES INCLUDING, BUT NOT LIMITED TO EXPENSE OF RETURNING

THE RYOBI PRODUCT TO AN AUTHORIZED SERVICE DEALER AND EXPENSE OF

DELIVERING IT BACK TO THE OWNER, MECHANIC’S TRAVEL TIME, TELEPHONE

OR TELEGRAM CHARGES, RENTAL OF A LIKE PRODUCT DURING THE TIME

WARRANTY SERVICE IS BEING PERFORMED, TRAVEL, LOSS OR DAMAGE TO

PERSONAL PROPERTY, LOSS OF REVENUE, LOSS OF USE OF THE PRODUCT,

LOSS OF TIME, OR INCONVENIENCE. SOME STATES DO NOT ALLOW THE

EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

This warranty applies to all RYOBI Products manufactured by RYOBI and sold in the

United States and Canada.

To locate your nearest service dealer dial 1-800-345-8746 in the United States or

1-800-265-6778 in Canada.

RYOBI AMERICA CORP.

5201 Pearman Dairy Rd

Anderson, SC 29622-1207 U.S.A.

RYOBI CANADA INC.

275 Industrial Rd

Cambridge, Ontario NIR 6K2 CANADA

Loading...

Loading...