Page 1

227RJ 232RJ 240RJ

Operator's manual

Read through the Operator‘s manual carefully and

understand the content before using the machine.

101 91 68-26

Page 2

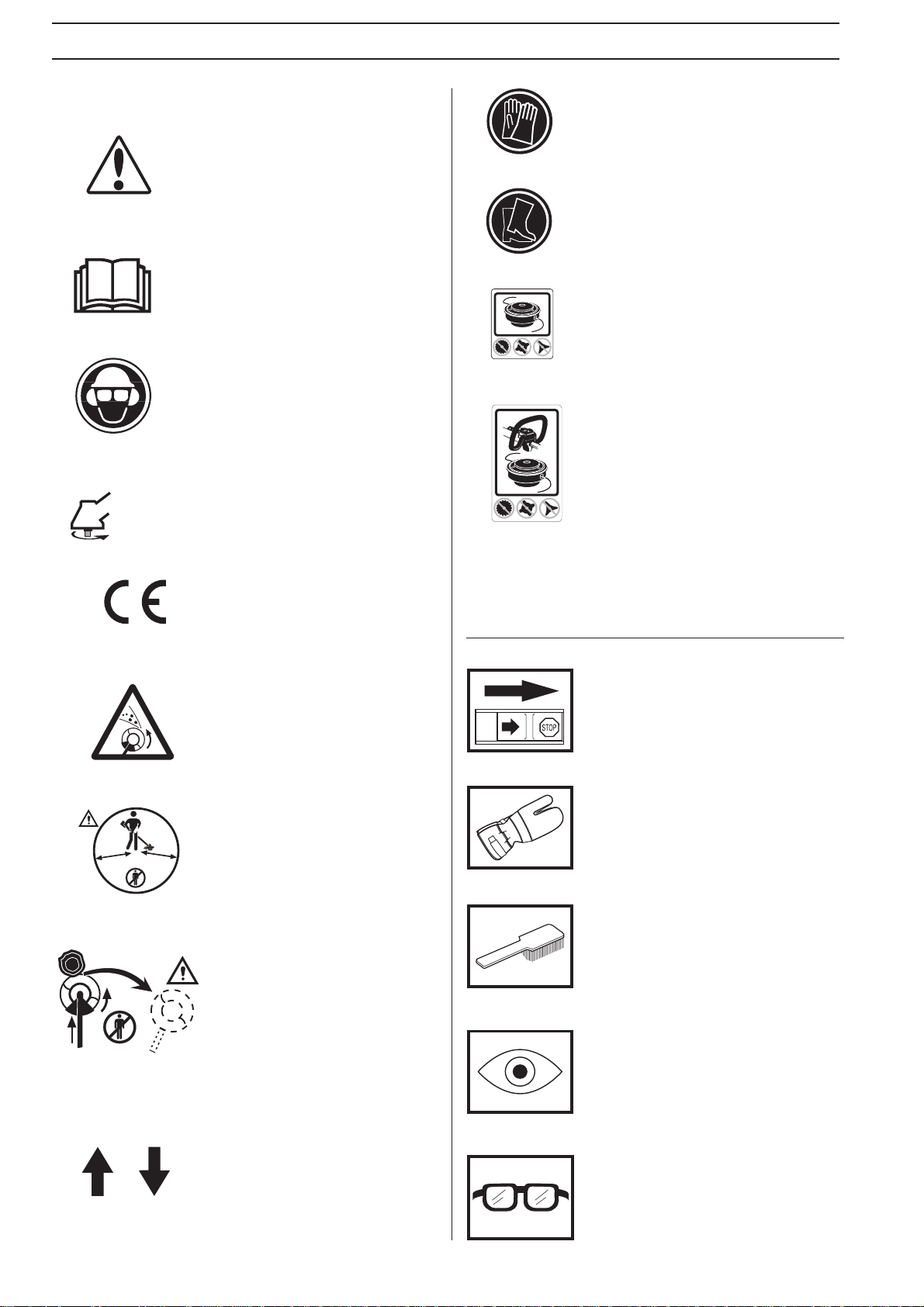

SYMBOL EXPLANATION

Symbols

max

10000 rpm

WARNING! Clearing saws,

brushcutters and trimmers can be

dangerous!

Careless or incorrect use can result in

serious or fatal injury to the operator

or others.

Read through the Operator‘s Manual

carefully and understand the content

before using the machine.

Always use

• A protective helmet where there is

a risk of falling objects

• Ear protection

• Approved eye protection

• Max. speed of output axle, rpm

• Always wear approved protective

gloves.

• Use anti-slip and stable boots.

• Only use non-metallic, flexible

cutting elements, that is trimmer

head with trimmer cord.

• Only intended for the trimmer

head.

15 m

50FT

15 m

50FT

• This product is in accordance with

applicable CE directives.

• Beware of thrown objects and

ricochets.

• The operator of the machine shall

ensure, while working, that no

persons or animals come closer

than 15 metres.

• Blade can thrust violently when

coming in contact with any object.

Blade thrust can cause amputation

of arms or legs. Keep people and

animals 50 feet away. Never use

blades unless recommended

handlebar, shoulder strap,

attaching hardware and blade

deflector are installed.

Other symbols/decals on the machine refer to

special certification requirements for certain

markets.

Checks and/or maintenance should

be carried out with the engine

switched off, with the stop switch in

the STOP position.

Always wear approved protective

gloves.

Regular cleaning required.

Ocular control.

2 – English

• Arrows which show limits for

handle mounting.

Approved eye protection must always

be used.

Page 3

CONTENTS

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify the

design and appearance of products without prior notice.

WARNING!

!

Under no circumstances may the design

of the machine be modified without the

permission of the manufacturer. Always

use genuine accessories. Non-authorised

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

List of contents

SYMBOL EXPLANATION

Symbols ............................................................................... 2

CONTENTS

List of contents .................................................................... 3

SAFETY INSTRUCTIONS

Personal protective equipment ............................................. 4

The machine‘s safety equipment .......................................... 4

Control, maintenance and service of the machine‘s safety

equipment...................................................................... 7

Cutting equipment .............................................................. 9

General safety instructions ................................................. 10

General working instructions............................................. 11

Basic working techniques................................................... 11

WHAT IS WHAT?

What is what on the trimmer?............................................ 13

ASSEMBLY

Assembling the J-handle .................................................... 14

Assembly of the blade and trimmer head............................ 14

Assembling the spray guard and trimmer head

Superauto II................................................................. 14

Assembling the blade guard and grass blade ....................... 15

Assembling other guards and cutting equipment................ 15

FUEL HANDLING

Fuel mixture ...................................................................... 16

Fuelling.............................................................................. 16

START AND STOP

Control before starting....................................................... 17

Start and stop..................................................................... 17

MAINTENANCE

Carburettor........................................................................ 18

Muffler .............................................................................. 20

Cooling system .................................................................. 20

Spark plug.......................................................................... 20

Air filter............................................................................. 21

Angle gear.......................................................................... 21

Maintenance schedule........................................................ 21

TECHNICAL DATA

227RJ ................................................................................ 23

232RJ ................................................................................ 23

240RJ ................................................................................ 23

English – 3

Page 4

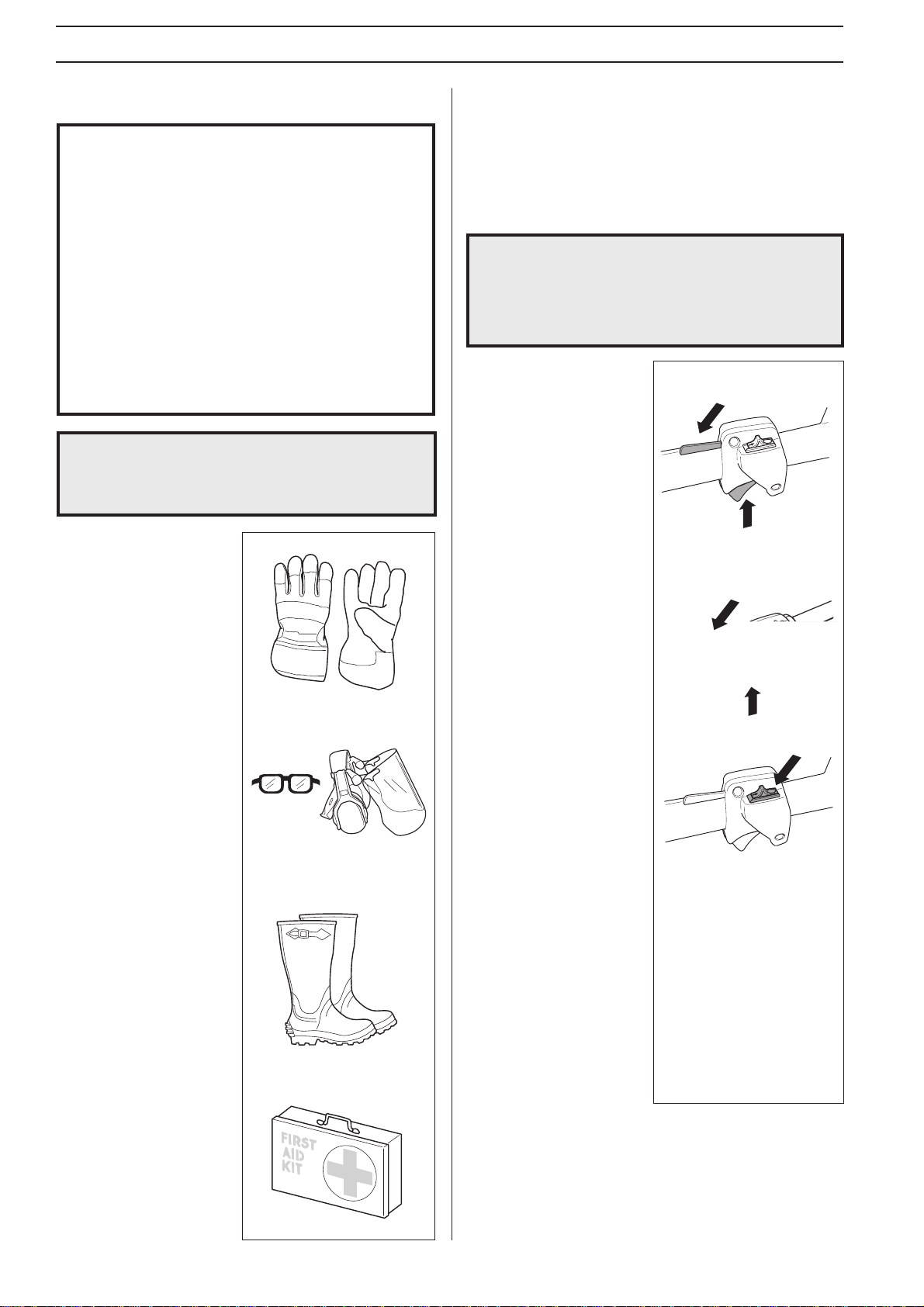

SAFETY INSTRUCTIONS

Personal protective equipment

MPORTANT INFORMATION

• A clearing saw, brushcutter or trimmer used

incorrectly or carelessly can become a dangerous

tool, that can cause serious or fatal injury to the

operator or others. It is extremely important that

you read and understand the content of this

manual.

• When using a trimmer, personal protective

equipment approved by the appropriate

authorities must be used. Personal protective

equipment does not eliminate the risk of

accidents, however, it can reduce the effects of an

injury in the event of an accident. Ask your dealer

for help when choosing protective equipment.

WARNING!

!

GLOVES

Gloves should be worn

when necessary, e.g., when

assembling cutting

equipment.

EAR PROTECTION

Ear protection offering

sufficient dampening effect

should be used.

EYE PROTECTION

Blows from branches or

objects thrown by the

rotating cutting equipment

can damage the eyes.

BOOTS

Use anti-slip and stable

boots.

Remove your hearing protection as soon as

you stop the engine, so that you can hear

any noises or warning signals.

The machine‘s safety equipment

This section describes the machine‘s safety equipment, its

function and how checks and maintenance are carried out to

ensure that it operates correctly. (See the chapter “What is

what“ to locate where this equipment is positioned on your

machine.)

WARNING!

!

Never use a machine with defective safety

equipment. Follow the control,

maintenance and service instructions

described in this section.

1. Throttle trigger

lock

The throttle trigger lock is

designed to prevent the

throttle from accidentally

being engaged. When the

trigger lock (A) is pressed

into the handle (= when you

hold the handle) the throttle

(B) is released. When the

grip on the handle is

released the throttle and the

throttle trigger lock return

to their original positions.

This takes place via two

independent return spring

systems. This means that the

throttle is automatically

locked in its “idling“

position.

A

B

A

B

2. Stop switch

The stop switch should be

used to stop the engine.

"

CLOTHING

Wear clothes made of a

strong fabric and avoid

loose clothing that can

catch on shrubs and

branches. Always wear

heavy, long pants. Do not

wear jewelry, short pants,

sandals or go barefoot.

Secure hair so it is above

shoulder level.

FIRST AID KIT

A first aid kit should be

carried by operators of

clearing saws, brushcutters

or trimmers.

4 – English

Page 5

SAFETY INSTRUCTIONS

3. Cutting

attachment guard

This guard is intended to

prevent objects from being

thrown towards the

operator and to protect the

operator from

unintentionel contact with

the cutting attachment.

WARNING!

Under no circumstances may the cutting

!

equipment be used without an approved

guard fitted. See the c hapter

data”

. If the wrong guard or a defective

guard is fitted this can cause serious

personal injury.

4. Vibration

damping system

Your machine is equipped

with a vibration damping

system, which is designed

to give as vibration-free

and comfortable use as

possible.

Use of incorrectly wound

cord or incorrect cutting

equipment increases the

level of vibration.

The machine’s vibration

damping system reduces

the transfer of vibrations

between the engine unit/

cutting equipment and the

machine’s handle unit.

“Technical

!

WARNING!

Over exposure to vibrations can result in

blood-vessel or nerve injury to persons

suffering with blood circulation problems.

Seek medical attention if you experience

physical symptoms that can be related to

over exposure to vibrations. Examples of

such symptoms are “numbness“, lack of

feeling, “tickling“, “pricking“, “pain“ lack of

or a reduction in normal strength, changes

in the colour of the skin or its surfaces.

These symptoms normally appear in the

fingers, hands or wrists.

English – 5

Page 6

SAFETY INSTRUCTIONS

5. Muffler

The muffler is designed to

give the lowest possible noise

level and to direct the engine‘s

exhaust fumes away from the

operator. Muffler fitted with

catalytic converter is also

designed to reduce harmful

exhaust components.

In countries that have a warm

and dry climate the risk of fire

is obvious. We have therefore

fitted certain mufflers with a

spark arrest screen. Make sure

that your muffler is fitted

with this kind of screen.

It is extremely important that

the instructions for checking,

maintaining and servicing the

muffler are followed. (see the

section “Control, maintenance

and service of the machine‘s

safety equipment“).

WARNING!

!

Mufflers fitted with catalytic converters

become extremely hot during use and

after stopping. This also applies at idling

speeds. Contact can result in burns to

the skin. Be observant to the risk of fire!

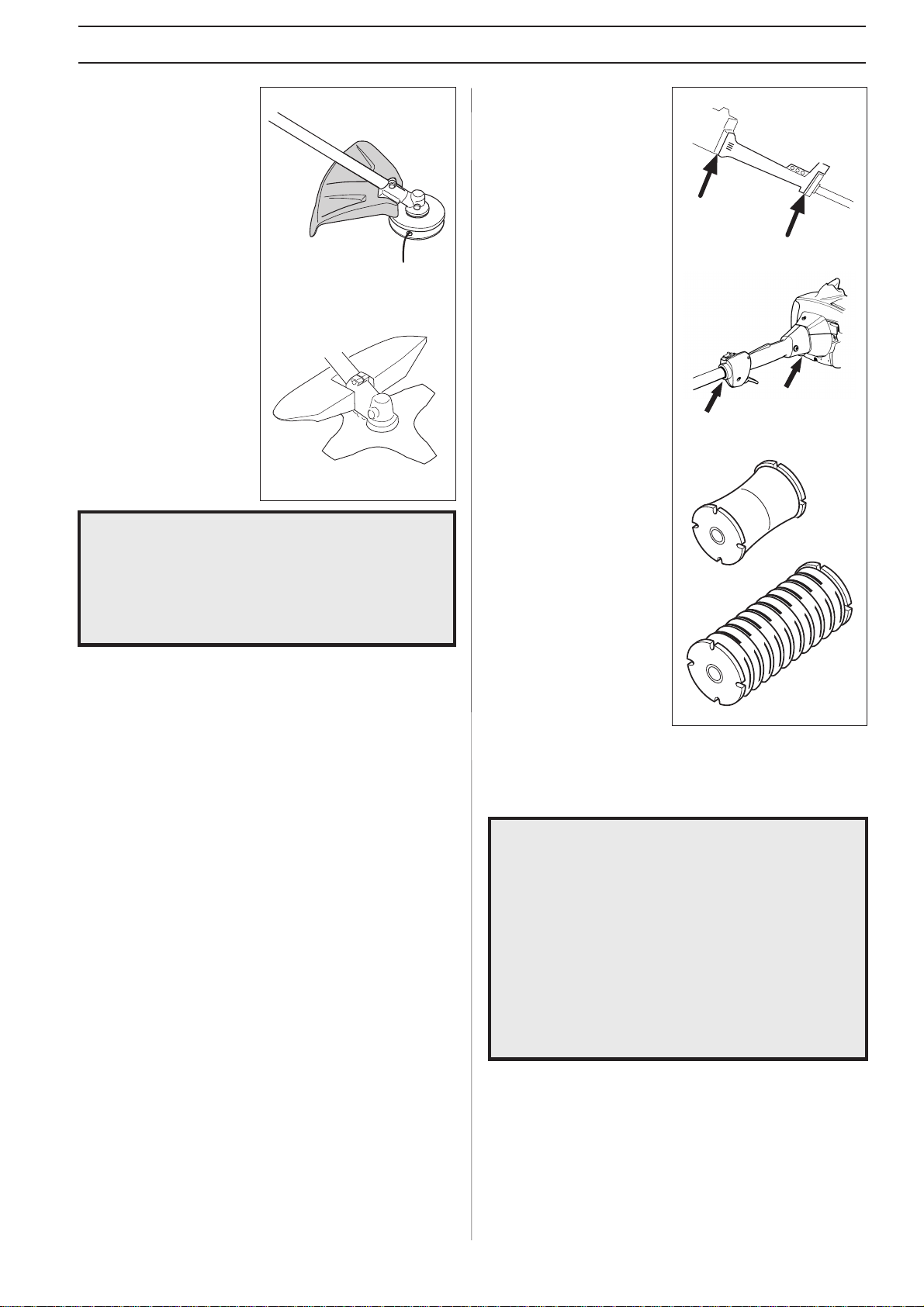

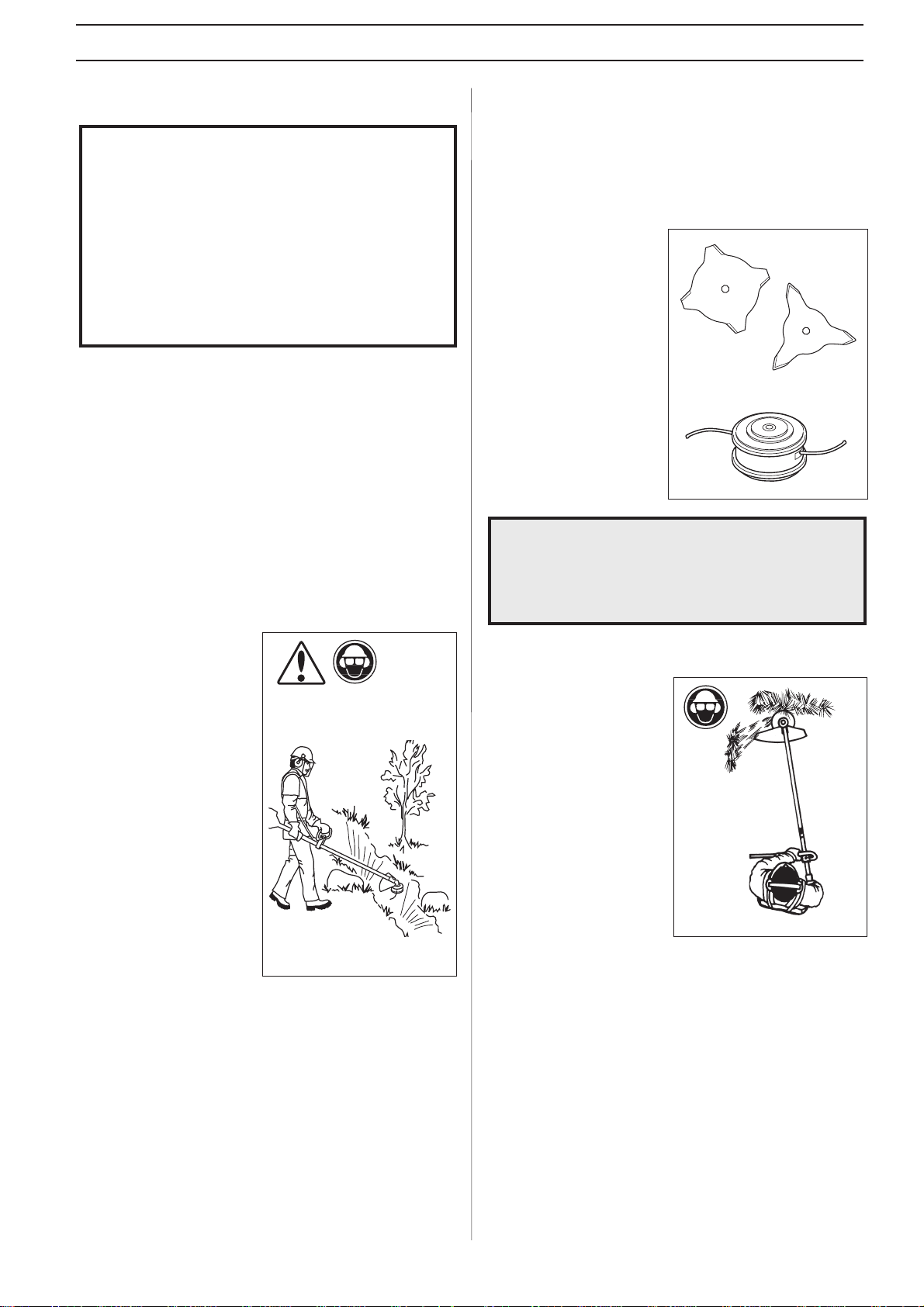

6. Cutting

equipment

1) Grass blades are

intended for brush cutting.

2) The trimmer head is

intended for trimming

grass.

7. Locking nut

A locking nut is used to

secure some types of cutting

equipment on the output

shaft.

1

2

!

WARNING!

Bear in mind that exhaust fumes:

• contain carbon monoxide, which can

cause carbon monoxide poisoning.

Therefore never start or run the machine

indoors.

• are hot and can contain sparks that can

cause fires. Never start the machine

indoors or close to inflammable material.

6 – English

Page 7

SAFETY INSTRUCTIONS

Control, maintenance and service of

the machine‘s safety equipment

IMPORTANT INFORMATION

• All service and repairs to the machine require

special training.

• This applies especially to the machine‘s safety

equipment. If the machine does not meet any of

the controls listed below you should contact your

service workshop.

• The purchase of one of our products

guarantees that professional repair and servicing

will be carried out on it. If the point of purchase is

not one of our servicing dealers, please ask for

details of the closest service workshop.

1. Throttle trigger

lock

• Check that the throttle is

locked in the “idling

position“ when the

throttle trigger lock is in

its original position.

• Press in the throttle

trigger lock and make sure

it returns to its original

position when released.

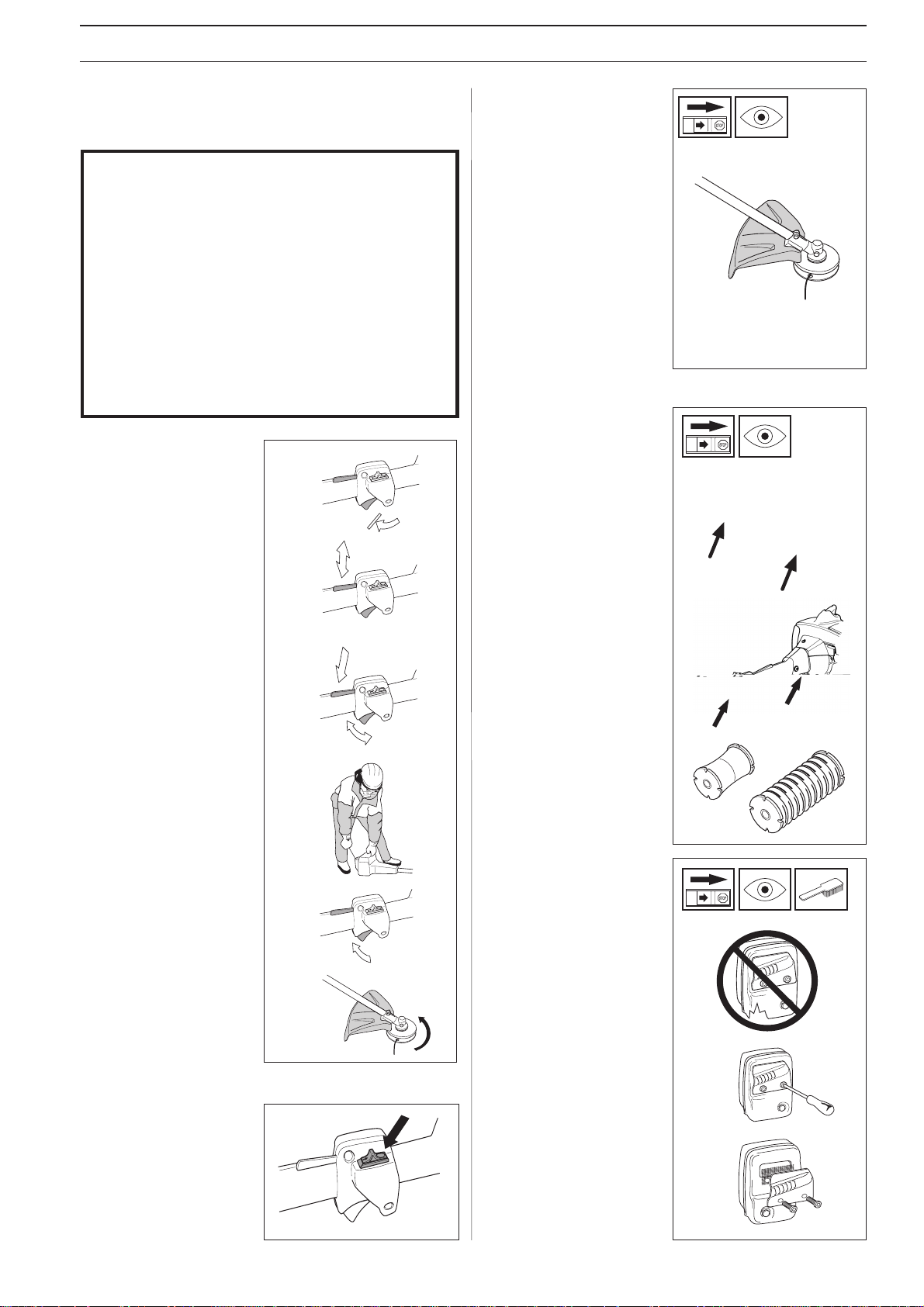

3. Cutting

attachment guard

• Ensure that the spray

guard is undamaged and

is not cracked.

• Replace the guard if it

has been exposed to

impact or is cracked.

• Always use the prescribed

blade an guard

combination, see chapter

"Technical data".

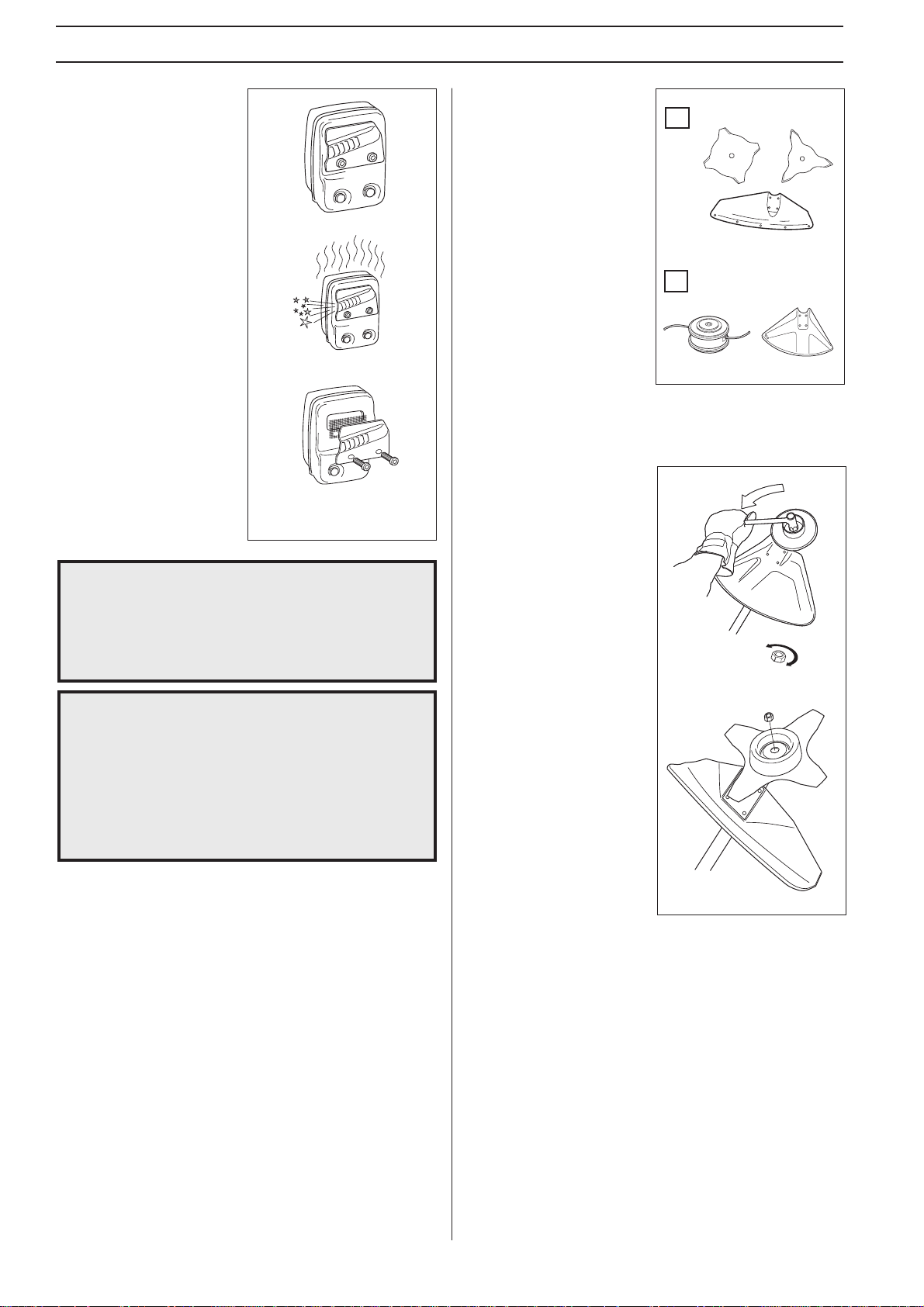

4. Vibration

damping system

• Check the vibration

damping element

regularly for material

cracks and distortion.

• Check that the vibration

damping element is

undamaged and securely

attached.

• Ensure that the throttle

and throttle trigger lock

move easily and that their

return spring systems

function.

• See section "Start". Start

the machine and apply

full throttle. Release the

throttle and check that the

cutting equipment stops

and remains at a standstill.

If the cutting equipment

rotates with the throttle in

the idling position then

the carburettor‘s idling

setting must be checked.

See chapter

“Maintenance“.

2. Stop switch

• Start the engine and make

sure that the engine stops

when the stop switch is

moved to the stop

position.

#

5. Muffler

1.Never use a machine that

has a defective muffler.

2.Check regularly that the

muffler is secure.

3.If your muffler is fitted

with a spark arrest screen

then it should be cleaned

regularly. A blocked

screen leads to the engine

overheating with serious

damage as a result. Never

use a muffler with a

defective spark arrest

screen.

English – 7

Page 8

SAFETY INSTRUCTIONS

6. Cutting equipment

This section describes how through correct maintenance and

through using the right type of cutting equipment you can:

• Reduce the machine‘s tendency to kickback

• Obtain maximum cutting capacity.

• Increase the service life of the cutting equipment.

The three basic rules:

1)Only use the cutting

and guard equipment

we recommend! See

chapter “Technical

data“.

2)Keep the blade‘s teeth

well and correctly

sharpened! Follow our

instructions and use the

recommended filing

gauge. An incorrectly

sharpened or damaged

blade increases the risk

of an accident.

3)Check the cutting

equipment with regard

to damage and crack

formation. Damaged

cutting equipment

should always be

replaced.

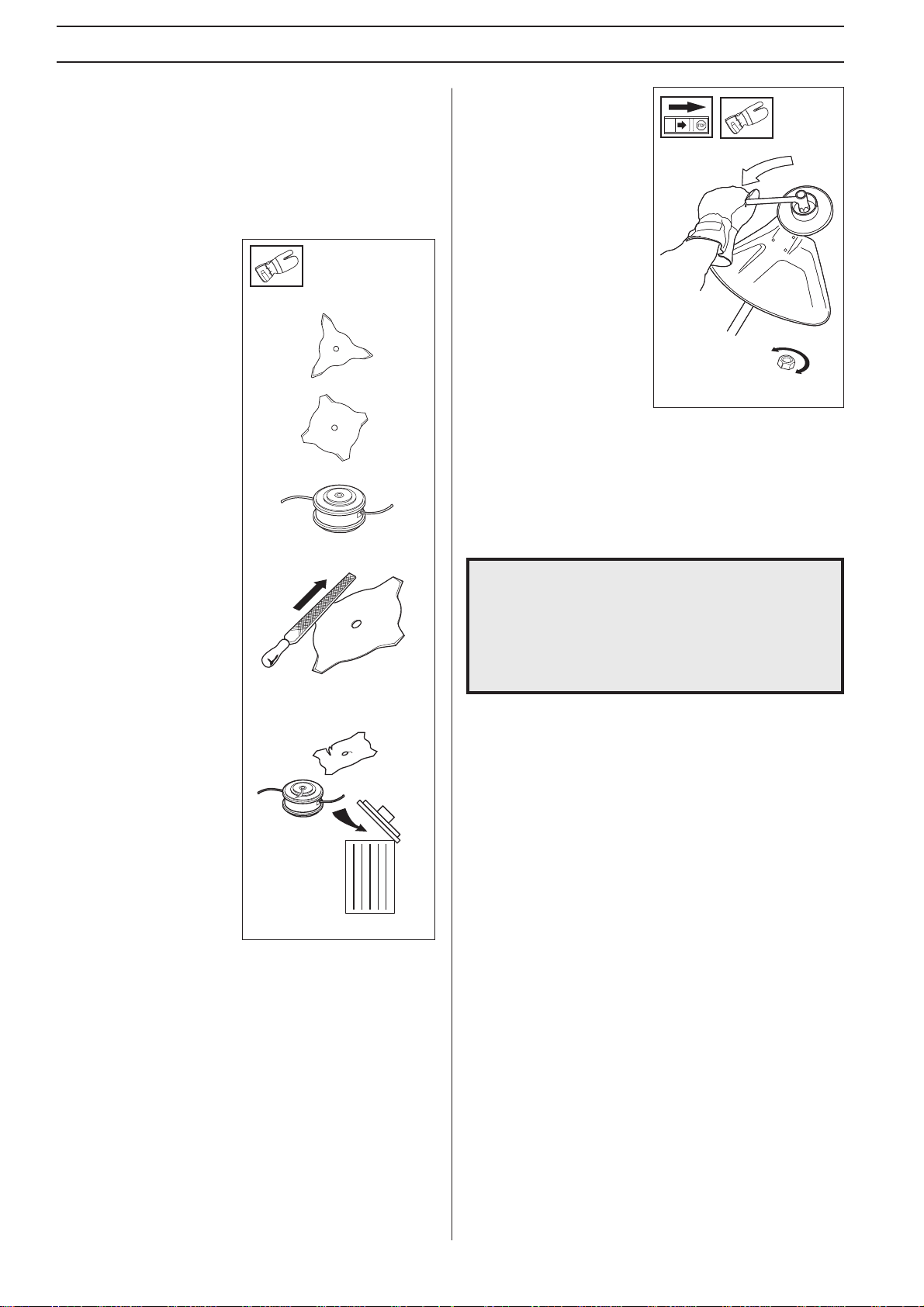

7. Locking nut

• Protect your hand from

injury when assembling,

use the blade guard as

protection when tightening

with a socket spanner.

Tighten the nut by turning

against the direction of

rotation. Loosen the nut by

turning in the direction of

rotation. (NOTE! the nut

has a left-hand thread).

• Tighten the nut using a

socket spanner, 35 - 50

Nm (3.5 - 5 kpm).

NOTE!

The locking nut‘s nylon lock must not be so worn that it can

be turned by hand. The lock shall hold at least 1.5 Nm. The

nut should be replaced after it has been put on approx. 10

times.

WARNING!

Never use a machine with defective

!

safety equipment. The safety equipment

should be maintained as described in this

section. If your machine does not meet

any of these controls you should contact

your service workshop.

8 – English

Page 9

SAFETY INSTRUCTIONS

Cutting equipment

IMPORTANT INFORMATION

The section describes how through correct

maintenance and through using the right type of

cutting equipment you can reduce the machine‘s

tendency to kickback, obtain maximum clearing

capacity and increase the service life of the cutting

equipment.

• Only use the cutting and guard equipment we

recommend! See chapter

•

Refer to the instructions for the cutting equipment

for the correct winding of cord and for the

selection of the right cord diameter.

• Keep the blade’s teeth well and correctly

sharpened! Follow our recommendations. Also

refer to the instructions on the blade packaging.

WARNING!

Incorrect cutting equipment or an

!

incorrectly sharpened blade increases

the risk of kickback.

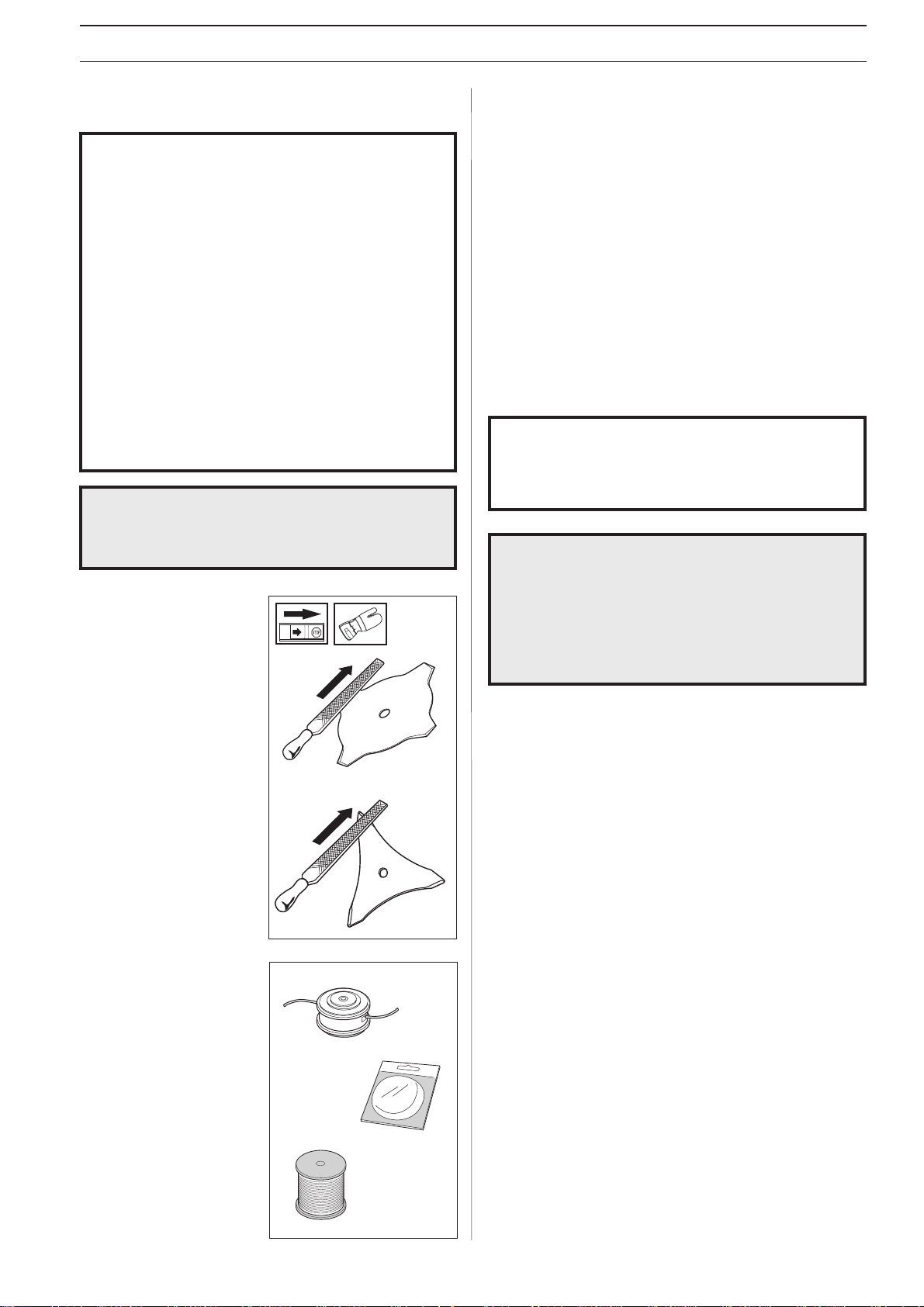

Filing the grass

blade

• See the cutting

equipment’s packaging for

correct filing instructions.

“Technical data“.

• Generally smaller machines require a small trimmer head

and vice versa. This is because when clearing using a cord

the engine must throw out the cord radially from the

trimmer head and also meet resistance from the grass being

cleared.

• The length of the cord is also important. A longer cord

requires greater engine power than a shorter cord of the

same diameter.

• Make sure the knife positioned on the trimmer guard is

intact. This is used to cut the cord to the correct length.

• To increase the life of the cord it can be soaked in water for

a few days. This will make the line tougher and it will keep

longer.

IMPORTANT INFORMATION

Always ensure the trimmer cord is wound tightly

and evenly around the drum, otherwise harmful

vibrations will occur.

WARNING!

!

Always stop the engine before starting

work on any part of the cutting equipment.

This continues to rotate even after the

throttle has been released. Ensure that the

cutting equipment has stopped completely

and remove the cable from the spark plug

before you start to work on it.

• The blades are sharpened

using a single cut flat file.

• Sharpen all edges equally

to maintain the balance of

the blade.

Trimmer head

• Only use a trimmer head

and trimmer cord that is

recommended. These

have been tested by the

manufacturer to suit a

particular engine size.

This is especially

important when a fully

automatic trimmer head

is used. Only use the

cutting equipment we

recommend! See chapter

“Technical data“.

English – 9

Page 10

SAFETY INSTRUCTIONS

General safety instructions

Fuel safety

• Always use a fuel container

with an anti-spill valve.

• Never fill the machine

while the engine is

running. Always stop the

engine and let it cool for a

few minutes before

refuelling.

• Provide good ventilation

when filling or mixing fuel

(petrol and 2-stroke oil).

• Move the machine at least

3 m from the filling

position before starting.

• Never start the machine:

a)If you have spilt fuel on it.

Wipe up all spillage.

b)If you have spilt fuel on

yourself or your clothes.

Change your clothes.

c)If there is a fuel leak.

Make regular checks for

leakage from the fuel cap

and the fuel supply pipes.

Transport and storage

• Store and transport the machine and fuel so that any leakage

or fumes do not risk coming into contact with sparks or

naked flames. For example, electric machines, electric

motors, electrical switches/power switches, heaters or the

like.

• When storing and transporting fuel approved containers

intended for this purpose must be used.

• When storing the machine for long periods the fuel tank

must be emptied. Contact your local petrol station to find

out how to dispose of excess fuel.

10 – English

Page 11

SAFETY INSTRUCTIONS

General working instructions

IMPORTANT INFORMATION

• This section takes up the basic safety

precautions for working with the trimmer.

• If you encounter a situation where you are

uncertain how to proceed you should ask an

expert. Contact your dealer or your service

workshop.

• Avoid all usage which you consider to be

beyond your capability.

Basic safety precautions

1.Observe your surroundings:

• To ensure that people, animals or other things cannot affect

your control of the machine.

• To ensure that the above mentioned do not come into

contact with the cutting equipment or objects that can be

thrown by the cutting equipment.

• NOTE! Never use a machine without the possibility of

calling for help in the event of an accident.

Basic working techniques

• Always drop to idling speed after each working operation.

Longer periods running at full throttle without loading the

engine (that is without resistance, which the engine feels

from the cutting equipment when trimming) can lead to

serious engine damage.

Designations

• Brush cutting is a general

term for clearing grass.

Grass blades are used for

this purpose.

• Grass trimming is a

general term for light

clearing, e.g. around

edges or around trees. A

trimmer head or plastic

blade is used.

WARNING!

!

Sometimes branches, grass or wood can

get caught between the guard and cutting

equipment. Always stop the engine when

cleaning.

2.Avoid usage in

unfavourable weather

conditions. For example,

thick fog, heavy rain,

strong winds or extreme

cold, etc. To work in bad

weather conditions is

tiring and can create

dangerous circumstances,

e.g. slippery surfaces.

3.Make sure you can walk

and stand safely. Look out

for any obstacles with

unexpected movement

(roots, stones, branches,

pits, ditches, etc.). Take

great care when working

on sloping ground.

4.The engine should be switched off before moving. When

moving over longer distances and transporting the transport

guard should be used.

5.Never put the machine down with the engine running unless

you have good sight of it.

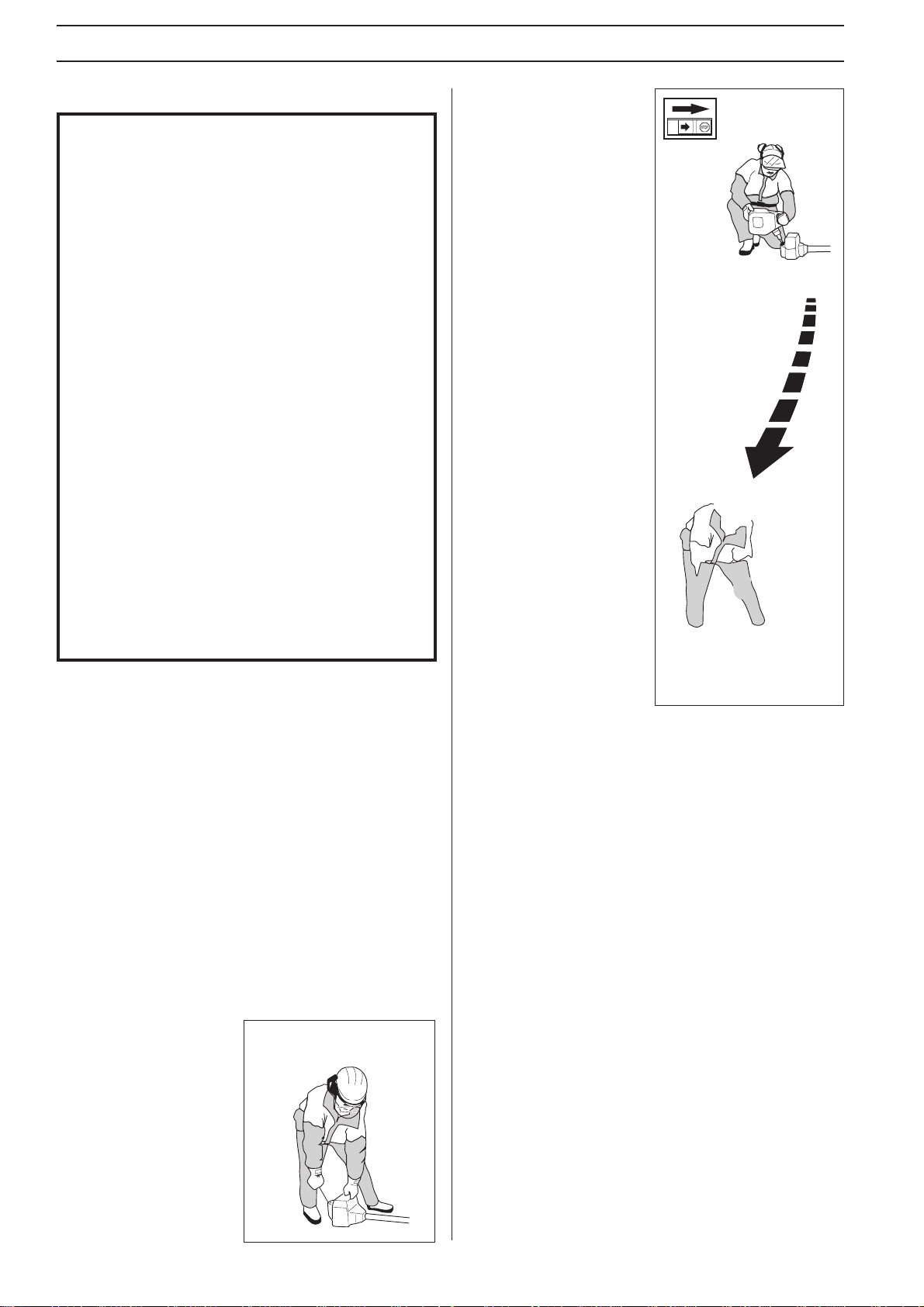

Brush cutting using a grass blade

• A blade is used for all

types of high or thick

grass.

• The grass is cut down

with a sideways, swinging

movement, where the

movement from right-toleft is the clearing stroke

and the movement from

left-to-right is the return

stroke. Let the blade work

on the left-hand side

(between 8 and 12

o’clock).

• If the blade is angled to the left when clearing the grass will

collect in a line, which makes collection easier, e.g. when

raking.

• Try to work rhythmically. Stand firmly with your feet apart.

Move forward after the return stroke and stand firmly again.

• Let the support cup rest lightly against the ground. It is used

to protect the blade from hitting the ground.

• Reduce the risk of material wrapping around the blade by

following these instructions:

a) Always work at full throttle.

b) Avoid the previously cut material during the return

stroke.

• Stop the engine, loosen the harness and place the machine

on the ground before you start to collect the cut material.

English – 11

Page 12

SAFETY INSTRUCTIONS

Trimming

• The trimmer is ideal to

cut grass that is difficult

to reach using a normal

lawn mower. Keep the

cord parallel to the

ground when cutting.

Avoid pressing the

trimmer head against the

ground as this can ruin

the lawn and damage the

tool.

• Do not allow the

trimmer head to

constantly come into

contact with the ground

during normal cutting

procedures. Constant

contact can cause damage

and wear to the trimmer

head.

Sweeping

• The rotating cord‘s

fanning effect can be

used for quick and easy

cleaning. Hold the cord

parallel to and above the

area to be swept and

move the trimmer from

side to side.

• When cutting and

sweeping you should use

full throttle to obtain the

best results.

12 – English

Page 13

WHAT IS WHAT?

What is what on the trimmer?

1. Trimmer head

2. Grease filler cap

3. Angle gear

4. Spray guard

5. Shaft

6. Loop handlebar

7. Throttle

8. Stop switch

9. Throttle trigger lock

10. Suspension for harness

11. Cylinder cover

12. Starter handle

13. Fuel tank

14. Choke

15. Air purge

16. Air filter cover

17. Clutch cover

18. Handlebar adjustment

19. Locking nut

20. Support flange

21. Drive disc

22. Transport guard

23. Socket spanner

24. Operator‘s Manual

25. Harness

26. Allen key

27. Locking pin

28. Support cup

29. Blade

English – 13

Page 14

ASSEMBLY

Assembling the J-handle

• Unscrew the handle and

plastic cover from the

handlebar bracket.

• Place the loop handlebar

with the handlebar holder

on the handlebar bracket.

Fit the handle and plastic

cover. Do not tighten too

tight.

• Put on the harness and

hang the trimmer in the

suspension hook. Now

finely adjust so that the

trimmer gives a

comfortable working

position when it‘s

attached to the harness.

Tighten the handle.

Assembling the spray guard and

trimmer head Superauto II

• Fit the guard (A) intended

for use with the trimmer

head. Secure using the 4

bolts (L) and the support

plate (M) as set out in the

diagram.

• Fit the drive disc (B) on the

output axle.

• Turn the blade axle until

one of the holes in the

drive disc aligns with the

hole in the gear housing.

• Insert the locking pin (C)

in the hole so that the axle

is locked.

• The trimmer head must be

split to be fitted (see the

diagram). Proceed as

follows:

G

F

I

M

L

K

J

I

K

B

C

WARNING

Only grass blades or trimmer heads/

!

plastic blades may be used when the Jhandle is fitted. Clearing blades must

never be used with the J-handle.

Assembly of the blade and trimmer

head

It is extremely important

that the disc drive’s/support

flange’s guide engages

correctly in the cutting

equipment’s centre hole

when assembling the cutting

equipment. Cutting

equipment assembled

incorrectly can result in

serious and/or fatal personal

injury.

WARNING!

Under no circumstances may the cutting

!

equipment be used without an approved

guard fitted. See the chapter

data”

. If the wrong guard or a defective

guard is fitted this can cause serious

personal injury.

“Technical

• Insert your finger into the

centre hole of the cover (I)

at the same time as you

hold the cover with your

other fingers. Press the two

catches (J) that extend from

the cut-out on the bottom

section (K) using the

thumb and index finger of

your other hand. Press

apart the trimmer head

using the fingers on the

cover.

• Place the cover (I) and the

support flange (F) on the

output axle.

• Fit the nut (G). The

tightening torque of the

nut is 35-50 Nm (3,5-5

kpm). Use the socket

spanner in the tool kit.

Hold the handle of the

spanner as close to the

trimmer guard as possible. The nut is tightened when the

spanner is turned against the direction of rotation (left-hand

thread).

• Fit the trimmer head‘s bottom section (K) on the cover (I)

by pressing the two sections together with the cut-outs on

the bottom section aligned with the catches on the cover.

• To dismantle follow the instructions in the reverse order.

A

14 – English

Page 15

ASSEMBLY

• Fit the guard (A)

intended for use with

the trimmer head.

Secure using four bolts

(L) and the support plate

(M) as shown in the

diagram.

A

L

B

• Fit the disc drive (B) on

the output axle.

• Turn the blade axle until

one of the disc drive’s

holes aligns with the

corresponding hole in

the gear housing.

• Insert the locking pin

(C) into the hole to lock

the axle.

• Screw on the trimmer

head (H) in the

direction of rotation.

C

M

• Dismantling takes place

in the reverse order.

English – 15

Page 16

FUEL HANDLING

Fuel mixture

NOTE!

The machine is fitted with a two-stroke engine and must

always be run on a mixture of petrol and two-stroke oil. It is

important to measure the quantity of oil accurately, to ensure

the correct mixture ratio. Small discrepancies in the amount of

oil have a great bearing on the proportions of the fuel mixture

when mixing small amounts of fuel.

WARNING!

!

Petrol

NOTE!

Always use an oil-mixed

quality petrol (at least 90

octane). If your machine is

equipped with a catalytic

converter, (see “technical

data”) an unleaded, oil

mixed quality petrol

should always be used. A

leaded petrol will destroy

the catalytic converter

• The lowest

recommended octane

rating is 90. If you run

the engine on a petrol

with a lower octane

rating than 90 so-called

“knocking“ can occur.

This leads to an

increased engine

temperature, which can

result in a serious engine

breakdown.

• When working at

continuous high revs a

higher octane rating is

recommended.

Two-stroke oil

• For the best results use HUSQVARNA two-stroke oil,

which has been specially produced for clearing saws and

chain saws.

Mixing ratio 1:50 (2%).

Always provide good ventilation when

handling fuel.

Mixture

• Always mix petrol and oil in a clean container intended for

petrol.

• Always start by filling half the quantity of petrol required.

Then add the entire oil quantity. Mix (shake) the fuel

mixture. Fill the remaining quantity of petrol.

• Mix (shake) the fuel mixture carefully before filling in the

machine‘s fuel tank.

• Do not mix more than max. one month’s supply of fuel.

• If the machine is not used for a long period of time, the fuel

tank should be emptied and cleaned.

WARNING!

!

The catalytic converter muffler gets very hot

during and after use. This also applies

during idling. Be aware of the fire hazard,

especially when handling the saw near

flammable substances or vapours.

Fuelling

WARNING!

!

• Clean around the fuel

cap. Contamination in

the tank can disrupt

operations.

• Ensure that the fuel is

well mixed by shaking the

container before filling

the tank.

The following precautions reduce the risk

of fire:

Do not smoke or place any sources of heat

in the vicinity of the fuel. Never refuel

when the engine is running. Always stop

the engine and let it cool for a few minutes

before refuelling. Open the fuel cap slowly

when fuelling so that any over pressure is

released slowly. Tighten the fuel cap

carefully after refuelling. Always move the

machine from the fuelling place before

starting.

Min. 3 m

(10 ft)

• If HUSQVARNA two-stroke oil is not available you can use

a high quality two-stroke oil intended for air cooled engines.

Contact your dealer when selecting an oil.

Mixing ratio: 1:33 (3%).

• Never use two-stroke oil intended for water cooled outboard

motors, so-called outboard motor oil.

• Never use oil intended of four-stroke engines.

16 – English

Gasolin

Benzin

Essence

Gasolina

Lit.

5

10

15

20

US

gallon

1

2 1/2

5

Huile • Aceite

2% (1:50)

0,10

0,20

0,30

0,40

2% (1:50)

2 1/2

6 1/2

12 7/8

Oil • Öl

Lit.

US

fl. oz.

3% (1:33)

0,15

0,30

0,45

0,60

3% (1:33)

3 3/4

9 3/4

19 1/4

Page 17

START AND STOP

Control before starting

For reasons of safety follow

these recommendations!

• Check the blade to ensure

that no cracks have formed

at the bottom of the teeth

or by the centre hole. The

most common reason why

cracks are formed is that

sharp corners have been

formed at the bottom of

the teeth while sharpening

or that the blade has been

used with dull teeth.

Discard a blade if cracks

are found.

• Check that the support

flange is not cracked due

to fatigue or due to being

tightened too much.

Discard the support flange

if it is cracked.

• Ensure the locking nut has

not lost its captive force.

The nut lock should have

a locking force of at least

1.5 Nm. The tightening

torque of the locking nut

should be 35-50 Nm.

• Check that the guard is

not damaged or cracked.

Replace the guard if it is

exposed to impact or is

cracked.

• Check that the trimmer

head and spray guard are

not damaged or cracked.

Replace the trimmer head

or spray guard if they are

exposed to impact or are

cracked.

• Never use the machine

without a guard or spray

guard nor with a defective

guard.

Start and stop

WARNING!

The complete clutch cover with shaft must

!

be fitted before the machine is started,

otherwise the clutch can become loose

and cause personal injury.

Always move the machine from the filling

area before starting. Place the machine on

a flat surface. Ensure the cutting

equipment cannot come into contact with

any object. Make sure no unauthorised

persons are in the working area,

otherwise there is a risk of serious

personal injury. The safety distance is 15

metres.

Cold engine

IGNITION:

Set the stop switch to the

start position.

CHOKE:

Set the choke control in the

choke position.

AIR PURGE:

Press the air purge

diaphragm repeatedly until

fuel begins to fill the

diaphragm. The diaphragm

need not be completely

filled.

Warm engine

Use the same starting

procedure as for the cold

engine, but do not set the

choke control in the choke

position. The start throttle

position is obtained by

setting the choke control in

the choke position and then

returning it to its original

position.

Stop

The engine is stopped by

switching off the ignition.

WARNING!

!

Start

Press the machine body

against the ground using

your left hand (NOTE! Not

your foot). Grip the starter

handle, slowly pull out the

cord with your right hand

until you feel some

resistance (the starter pawls

grip), now quickly and

powerfully pull the cord.

Reset the choke control as

soon as the engine fires and

repeat until the engine starts.

When the engine starts

quickly apply full throttle

and the start throttle will

automatically disengage.

NOTE! Do not pull the

starter cord out completely

and do not release the starter

cord from the fully extended

position. This can damage

the machine.

When the engine is started with the choke

in the choke or start position the cutting

equipment starts to rotate immediately.

English – 17

Page 18

MAINTENANCE

Carburettor

Your Husqvarna product has been designed and

manufactured to specifications that reduce harmful

emissions.

After your unit has been run 8-10 tanks of fuel the engine

has broken in. To ensure that your unit is at peak

performance and producing the least amount of harmful

emissions after break in, have your authorized servicing

dealer, who has a revolution counter at his disposal, to adjust

your carburettor for optimum operating conditions.

WARNING!

The complete clutch cover with shaft

!

Operation

• The carburettor governs

the engine‘s speed via the

throttle. Air/fuel is mixed

in the carburettor. The

air/fuel mixture is

adjustable. To take

advantage of the engine‘s

optimal output the

adjustment must be

correct.

• The setting of the

carburettor means that

the engine is adapted to

local conditions, for

example, the climate,

altitude, petrol and the

type of 2-stroke oil.

• The carburettor is

equipped with three

adjustment possibilities:

L = Low speed needle

H = High speed needle

T = Idle speed adjuster

screw

• The fuel quantity in relation to the air flow permitted by

the throttle opening is adjusted using the L and H-needles.

Turning the needles clockwise gives a leaner fuel mixture

(less fuel) and turning them anti-clockwise gives a richer

fuel mixture (more fuel). A leaner mixture gives high revs

while a richer mixture give less revs.

• The T-screw regulates the position of the throttle while the

engine is idling. Turning the screw clockwise gives a higher

idling speed while turning it anti-clockwise gives a lower

idling speed.

must be fitted before the machine is

started, otherwise the clutch can become

loose and cause personal injury.

Basic setting

• The carburettor is set to its basic setting when test run at the

factory. The basic setting is richer than the optimal setting

and should be kept during the machine‘s first working

hours. Thereafter the carburettor should be finely adjusted.

Fine adjustment should be carried out by a skilled

technician.

NOTE! If the cutting attachment rotates/moves while the

engine is idling the T-screw should be turned anti-clockwise

until the cutting attachment stops.

Rec. idling speed: 2 700 rpm.

Recommended max. speed: See “technical data”.

WARNING!

!

If the idling speed cannot be adjusted so

that the cutting attachment stops,

contact your service workshop. Do not

use the machine until it has been

correctly adjusted or repaired.

Fine adjustment

• When the machine has been ”run-in” the carburettor should

be finely adjusted. The fine adjustment should be carried

out by qualified person. First adjust the L-jet, then the

idling screw T and then the H-jet.

Conditions

• Before any adjustments are made the airfilter should be clean

and the airfilter cover fitted. Adjusting the carburettor while

a dirty airfilter is in use will result in a leaner mixture when

the filter is finally cleaned. This can give rise to serious

engine damage.

• Carefully turn the L and H needle to the mid point between

fully turned in and fully turned out.

• Do not attempt to adjust the needles beyond the stops as

damage can occur.

• Now start the machine according to the starting instructions

and run it warm for 10 minutes.

NOTE! If the cutting attachment rotates/moves the T screw

should be turned anti-clockwise until the cutting attachment

stops.

Low speed needle L

Try to find the highest idling

speed, turning the low speed

needle L clockwise

respectively counterclockwise. When the highest

speed has been found, turn

the low speed needle L 1/4

turn counter-clockwise.

NOTE! If the cutting

attachment rotates/moves in

the idling position, turn the

idling speed screw T

counter-clockwise until the

cutting attachment stops.

L

+ 1/4

18 – English

Page 19

MAINTENANCE

English – 19

Page 20

MAINTENANCE

Muffler

NOTE!

Some mufflers are fitted with a catalytic converter. See

“Technical data” to see whether your machine is fitted with a

catalytic converter.

The muffler is designed to

dampen the noise level and

to direct the exhaust fumes

away from the user. The

exhaust fumes are hot and

can contain sparks, which

can result in fire if the

exhaust fumes are directed

towards a dry and

inflammable material. Some

mufflers are equipped with a

special spark arrest screen. If

your machine is fitted with

this type of screen it should

be cleaned regularly. This is

done using a wire brush. On

mufflers without a catalytic

converter the screen should

be cleaned weekly, or

replaced if necessary. On

mufflers fitted with a

catalytic converter the

screen should be checked

and cleaned monthly. If the

screen is damaged it should

be replaced. If the screen is

frequently blocked, this can

be a sign that the function

of the catalytic converter is

impaired. Contact your

dealer to inspect the muffler.

A blocked screen will cause

the engine to overheat

resulting in damage to the

cylinder and piston. Also see

under “Maintenance”.

NOTE!

Never use a machine with a defective muffler.

Cooling system

To maintain as low operating temperature as possible

the engine is equipped with

a cooling system.

The cooling system consists

of:

1.An air intake on the

starter unit.

2.Cooling fins on the

flywheel.

3.Cooling fins on the

cylinder

4.Cylinder cover (leads cold

air onto the cylinder).

Clean the cooling system

using a brush at least once a

week, in difficult conditions

more often.

A dirty or blocked cooling

system leads to the engine

overheating resulting in

damage to the cylinder and

piston.

Spark plug

The condition of the spark

plug is affected by:

• An incorrect carburettor

setting.

• An incorrect fuel

mixture (too much or

faulty oil).

• A dirty air filter.

These factors cause

deposits on the spark plug

electrode that may result in

malfunction or starting

difficulties.

4

3

2

1

0,5 mm

!

20 – English

WARNING!

Mufflers fitted with catalytic converters

become extremely hot during use and

after stopping. This also applies at idling

speeds. Contact can result in burns to

the skin. Be observant to the risk of fire!

If the machine is low on power, difficult to start or runs

poorly while idling always check the spark plug first.

If the spark plug is dirty, clean it and at the same time check

that the electrode gap is 0.5 mm. The spark plug should be

changed after about one month of operation or earlier if

necessary.

NOTE! Always use the recommended type of spark plug. An

incorrect spark plug can damage the cylinder/piston.

Page 21

MAINTENANCE

Maintenance schedule

Below follows some general maintenance instructions.

If you need further information please contact your service

workshop.

Daily maintenance

1.Clean the outside of the

machine.

2.Make sure the throttle

trigger lock and the

throttle function correctly

from a safety point of

view.

3.Check that the stop

switch functions.

4.Check that the cutting

head does not rotate while

idling.

5.Clean the air filter.

Replace if necessary.

6.Check that the guard is

undamaged and not

cracked. Replace the

guards if they have been

exposed to impact or are

cracked.

7.Check that the trimmer

head is undamaged and

not cracked. Replace the

trimmer head if necessary.

8.Check that the locking

nut is tight.

9.Check that all nuts and

screws are tightened.

10. Make sure the harness is

not damaged.

11. Check that the blade is

well centred, is sharp, and

is not cracked. An

uncentred blade causes

vibrations that can result

in damage to the

machine.

12. Check that the blade‘s

transport guard is intact

and that it can be secured

correctly.

English – 21

Page 22

MAINTENANCE

Weekly

maintenance

1.Check the starter, the

starter cord and the return

spring.

2.Make sure that the

vibration damping

elements are not damaged.

3.Clean the outside of the

spark plug. Remove and

check the electrode gap.

Adjust the gap to 0.5 mm

or change the spark plug.

4.Clean the cooling fins on

the flywheel.

5.Clean or replace the

muffler’s spark arrest

screen (not on mufflers

with a catalytic converter).

6.Clean the carburettor area.

7.Clean the cooling fins on

the cylinder and check that

the air intake in the starter

unit is not blocked.

1

maintenance

1.Clean the fuel tank.

1

2

Monthly

2.Clean the carburettor and

the area surrounding it.

3.Clean the fan and the area

3

around it.

4.Check the fuel filter and the

fuel pipe, replace if

necessary.

3

2

4

5

4

5

6

5.Check all cables and

connections.

6.Check the clutch, clutch

springs and the clutch drum

with regard to wear.

Replace if necessary.

7.Change the spark plug.

6

7

8.Check and clean the

7

muffler’s spark arrest screen

if necessary (only mufflers

with a catalytic converter).

8

8.Check that the angle gear

is 3/4 filled with grease.

Fill if necessary using

special grease.

8

22 – English

Page 23

TECHNICAL DATA

Technical data

Engine

Cylinder capacity, cm

Cylinder bore, mm

Stroke length, mm

Idling speed, rpm

Recommended max. speed, rpm

Speed of output axle, rpm

Max. engine output, acc. to ISO 8893

Catalytic converter muffler

Speed-regulated ignition system

Ignition system

Manufacturer/type of ignition system

Spark plug

Electrode gap, mm

Fuel lubrication system

Manufacturer/type of carburettor

Fuel tank capacity, litres

Weight

Weight without fuel, cutting tool and

guard, kg

3

227RJ

26,9

35

28

2 700

11 000-11 700

10 000

1,0 kW/9 000 rpm

Yes

Yes

Walbro CD

Champion RCJ 7Y

0,5

Walbro WT

0,5

6,0

232RJ

30,8

35

32

2 700

11 000-11 700

10 000

1,1 kW/8 400 rpm

Yes

Yes

Walbro CD

Champion RCJ 7Y

0,5

Walbro WT

0,5

6,4

240RJ

36,3

38

32

2 700

11 000-11 700

10 000

1,3 kW/9 000 rpm

Yes

Yes

Walbro CD

Champion RCJ 7Y

0,5

Walbro WT

0,5

6,4

Noise levels

Equivalent noise pressure level at the

user’s ear, measured according to EN

11806 and ISO 7917, dB(A), min/max:

Equivalent noise power level at the user’s

ear, measured according to EN 11806

and ISO 10884, dB(A), min/max:

Vibration levels

Vibration levels on the handles,

measured according to EN 11806 and

ISO 7916, m/s

When idling, left/right handles, min:

When idling, left/right handles, max:

At max. speed, left/right handles, min:

At max. speed, left/right handles, max:

NOTE!

Noise and vibration measurements are made with all the machine’s approved cutting equipment fitted.

The table indicates the highest and lowest values.

93/98

103/109

3,1/2,8

3,5/4,0

2,6/3,3

4,6/5,1

92/98

103/108

2,2/2,0

3,0/3,0

4,5/2,5

6,5/4,5

98/101

106/112

3,1/3,0

4,0/3,8

6,4/8,2

7,7/11,0

English – 23

Page 24

TECHNICAL DATA

Approved accessories 227RJ

Thread blade shaft M10

Plastic knifes

Grass blade

Trimmer head

Approved accessories 232RJ, 240RJ

Thread blade shaft M10

Plastic knifes

Grass blade

Trimmer head

Type

Tricut ∅ 300 mm

Multi 255-3

Grass 255-4

Grass 255-8

Trimmy H II

Trimmy Fix

Trimmy Hit Pro

Superauto II

Type

Tricut ∅ 300 mm

Multi 255-3

Multi 275-4

Grass 255-4

Grass 255-8

Trimmy H II

Trimmy Fix

Trimmy Hit Pro

Superauto II

Cutting attachment guard Art No.

503 74 50-01

503 74 40-01

503 74 40-01

503 74 40-01

503 74 50-01

503 74 50-01

503 74 50-01

503 74 50-01

Cutting attachment guard Art No.

503 74 50-01

503 74 40-01

503 74 40-01

503 74 40-01

503 74 40-01

503 74 50-01

503 74 50-01

503 74 50-01

503 74 50-01

EU declaration of conformity (Only applies to Europe)

(Directive 89/392/EEC, Annex II, A)

We, Husqvarna AB, S-561 82 Huskvarna, Sweden, tel: +46 36-146500, declare under sole responsibility that the

clearings saws Husqvarna 227RJ, 232RJ and 240RJ from 1998’s serial numbers and onwards (the year is clearly stated

in plain text on the type plate with subsequent serial number), are in conformity with the following standards or other

normative documents following the provisions in the COUNCIL’S DIRECTIVES:

- of June 14 1989 “relating to machinery” 89/392/EEC and applicable supplements.

- of May 3 1989 “relating to electromagnetic compatibility” 89/336/EEC, and applicable supplements.

The following standards have been applied: EN292-2, EN ISO 11806.

SMP Svensk Maskinprovning AB, Fyrisborgsgatan 3 S-754 50 Uppsala, Sweden, has carried out voluntary type

approval for Husqvarna AB. The certificates are numbered: SEC/98/632– 227RJ, SEC/94/022 – 232RJ,

SEC/98/611– 240RJ.

Huskvarna 25 November 1999

Bo Andréasson, Development manager.

24 – English

Page 25

Super Auto II

Super Auto II 1

1

3

4

2

5

6

9

7

8

10

English – 25

Page 26

Tri Cut

1

3

4

>20mm

2

5

6

8

7

26 – English

Page 27

Trimmy H II

1

3

2,0-2,4 mm

.080-.095"

2

4

15 cm

6"

5

8

7,5 m

25'

6

~ 3,7 m

12'

7

9

2

15 cm

6"

1

English – 27

Page 28

Trimmy Hit

1

5

23

“Click”

7,0 m

23'

4

6

7

10

8

9

“Click”

11

28 – English

Page 29

Trimmy Hit Junior

1

5

2

6

3

4

~ 2,8 m

9'

5,75 m

19'

15 cm

6"

2,0-2,4 mm

.080-.095"

7

10

15 cm

6"

1.)

8

2.)

“Click”

11

9

12

15 cm

6"

English – 29

Page 30

Trimmy Hit Pro

1

5

6

2

3

4

~ 3,7 m

12'

7,5 m

25'

15 cm

6"

2,0-2,4 mm

.080-.095"

7

10

15 cm

6"

1.)

8

2.)

“Click”

11

9

12

15 cm

6"

30 – English

Page 31

Trimmy Hit VI

1

5

2

6

3

4

7

10

8

9

11

English – 31

Page 32

Trimmy SII

1

3

4

2

7,0 m

23'

~ 3,5 m

11'

2,4-3,3 mm

.095"-.130"

12 cm

5"

5

8

~ 15 cm

6'

6

7

"Clic"

9

35-50 NM

32 – English

Page 33

~ 15 cm

6'

English – 33

Page 34

´*30r¶6<¨

Page 35

English – 35

Page 36

´*30r¶6<¨

2001W19

Page 37

We hope you find the links below useful. For further gardening information visit

www.GardenResources.co.uk

Blower Vacs Brush cutters Brushcutters Chainsaws Chain saws

Cultivators Cylinder lawn

mowers

Electric

chainsaws

Garden tractors Garden vacuums Hayter lawn

Hover mowers Husqvarna

Lawn scarifiers Lawn tractors Leaf blowers Leaf vacuums Petrol chainsaws

Petrol hedge

cutters

Ryobi strimmers Scarifiers Strimmers Westwood lawn

Westwood

tractors

Chainsaws Cultivators Cylinder Lawn

Electric

Chainsaws

Garden

Shredders

Hedgecutters Hover Mowers Husqvarna

Lawn Mowers Scarifiers Lawn Tractors Leaf Blowers Leaf Vacuums

Petrol Chainsaws Petrol Hedge

Rotovators Ryobi Strimmers Garden Patio

Patio Heaters Patio Heater

Gas Greenhouse

Heaters

Christmas

Gardening Gifts

Fertiliser

spreaders

chainsaws

Ride on lawn

mowers

Brush Cutters

Fertiliser

Spreaders

Garden Tractors

Cutters

Covers

Stainless Steel

Patio Heaters

Garden Tractors Ride on Lawn

Brushcutters Blower Vacs Chain Saws

Cylinder mowers Echo chainsaws Echo Strimmers

Garden blowers Garden rollers Garden shredders

Hedge cutters

mowers

Kawasaki brush

cutters

Ride on mowers Rotary mowers Rotavators

Mowers

Garden Blowers Garden Rollers Lawn Rollers

Garden Vacuums Hayter Lawn

Chainsaws

Ride on Lawn

Mowers

Heaters

Garden Heaters

Table Top Patio

Heaters

Mowers

Kawasaki

strimmers

tractors

Echo Chainsaws Echo Strimmers

Mowers

Kawasaki Brush

Cutters

Ride on Mowers

Outdoor Patio

Heaters

Greenhouse

Heaters

Patio Heaters UK

Ride on Mowers

Hedgecutters

Lawn mowers

Westwood ride on

mowers

Hedge Cutters

Kawasaki

Strimmers

Rotary Mowers

Gas Patio Heaters

Green House

Heaters

Patio Heaters with

Covers

Also See

Gardening Tools Direct, for lawn mowers, brush cutters, chainsaws

Gardening Supply for patio heaters, lawn mowers, chainsaws

Garden Tractor, for lawn tractors and ride on mowers

Loading...

Loading...