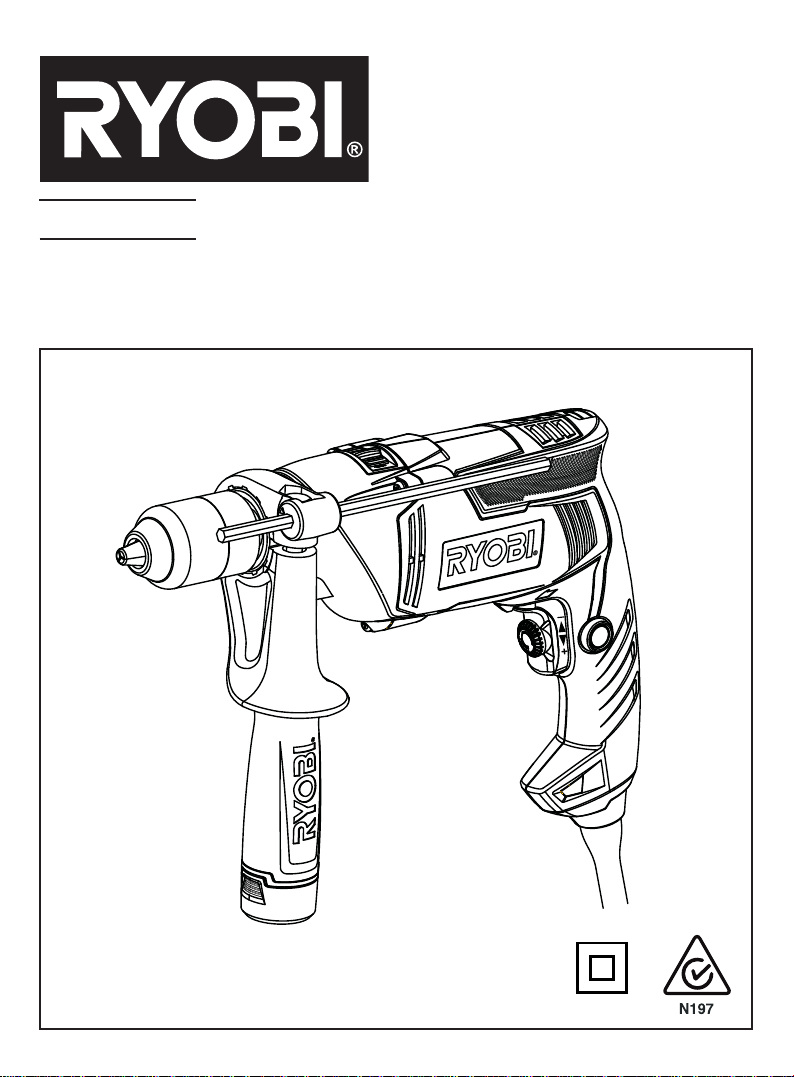

Page 1

EID1050RB

IMPACT DRILL

OWNER'S OPERATING MANUAL

Page 2

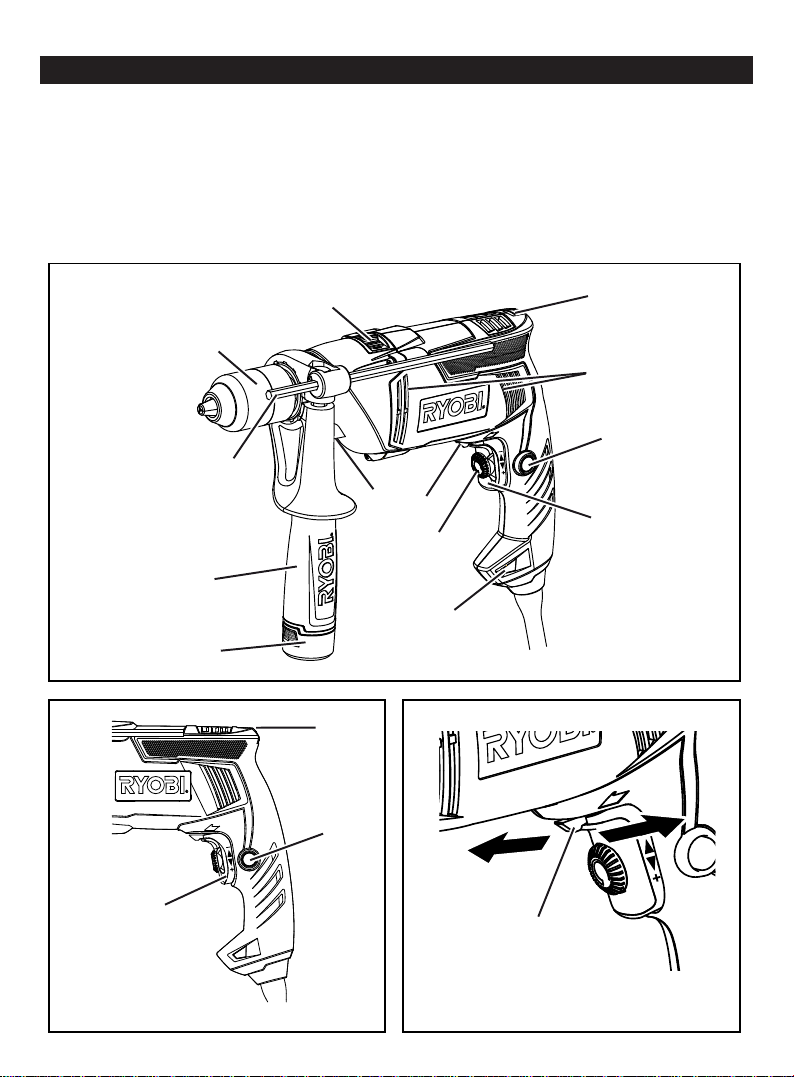

1. Trigger Switch

2. Forward / Reverse Selector

3. Keyless Chuck

4. Variable Speed Selector

5. Lock-on Button

6. Drill Mode Shift Knob

7. Depth Gauge

8. Auxiliary Handle

9. Bit (Not included)

DESCRIPTION

10. Air Vents

11. Livetool Indicator™

12. To Tighten Chuck

13. To Loosen Chuck

14. To Tighten Handle

15. To Loosen Handle

16. Bit Storge

17. Spindle Lock

18. Bubble Level

8

16

6

18

3

10

5

7

2

17

1

4

11

18

5

1

2

Fig. 2Fig. 1

Page 3

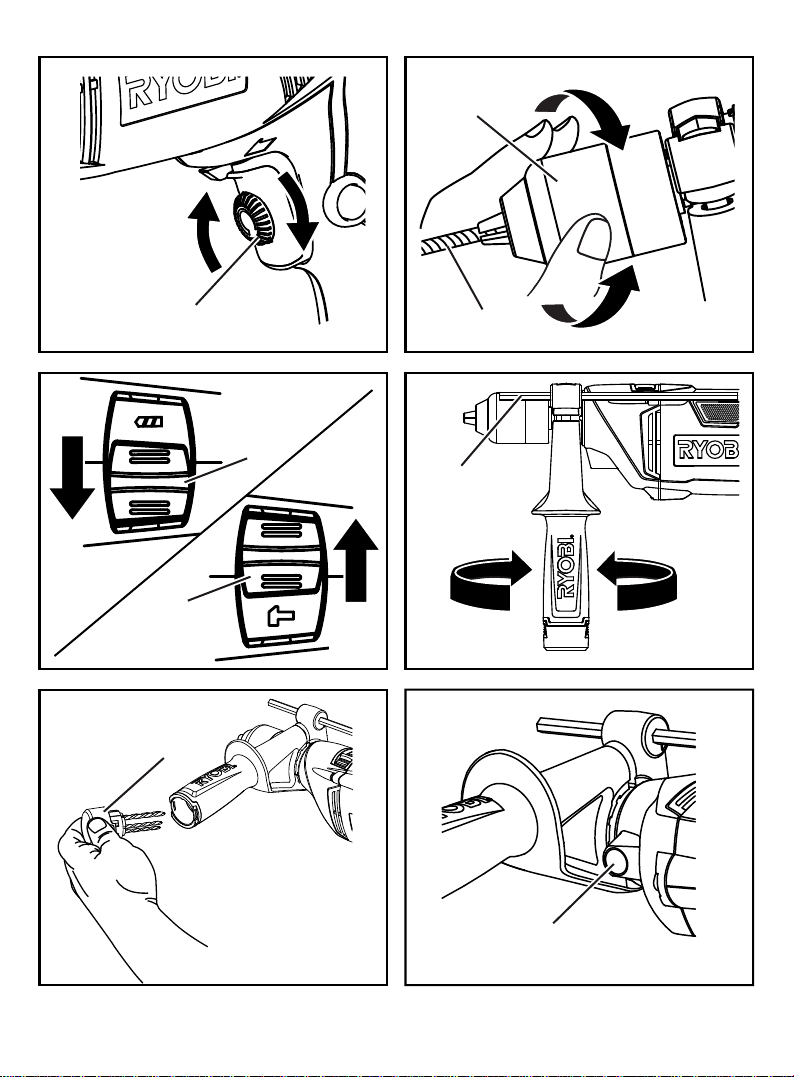

12

3

16

4

6

9

13

Fig. 4Fig. 3

7

6

Fig. 5

15 14

Fig. 6

Fig. 7

17

Fig. 8

Page 4

Important!

It is essential that you read the instructions in this manual before

operating this machine.

Subject to technical modifi cations.

Page 5

English

GENERAL SAFETY RULES

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

The term "power tool'' in the warnings refers

to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

WORK AREA

■ Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

■ Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

■ Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

ELECTRICAL SAFETY

■ Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

■ Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

■ Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

■ Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

■ When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

■ If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

PERSONAL SAFETY

■ Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

■ Use safety equipment. Always wear eye

protection. Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

■ Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch

on invites accidents.

■ Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

■ Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

■ Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

■ If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

POWER TOOL USE AND CARE

■ Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

■ Do not use the power tool if the switch does not

turn it on and off. Any power tool that can not be

controlled with the switch is dangerous and must be

repaired.

■ Disconnect the plug from the power source before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

■ Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

1

Page 6

English

GENERAL SAFETY RULES

■ Maintain power tools. Check for misalignment or

bindling of moving parts, breakage of parts and

any other condition that may affect the power

tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

■ Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

■ Use the power tool, accessories and tool bits etc.,

in accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed. Use of the power

tool for operations different from intended could result

in a hazardous situation.

■ Recommended for the use of a residual current

device with a rated residual current of 30 mA or less.

SERVICE

■ Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

SPECIAL RULES

■ Wear ear protectors with impact drills. Exposure to

noise can cause hearing loss.

■ Use auxiliary handles supplied with the tool. Loss

of control can cause personal injury.

■ Hold the power tool by the insulated grips when

performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. A cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool “live” and

could give the operator an electric shock.

■ This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety. Children

should be supervised to ensure that they do not

play with the appliance.

■ This appliance is not intended for use by young children

or infirm persons. Adequate supervision by a responsible person must be provided to ensure that they do not

play with the appliance.

■ Keep children and visitors away. Visitors should wear

safety glasses and be kept a safe distance from work

area. Do not let visitors contact tool or extension cord.

■ Complies with AS/NZS 60745.2.1 and 60745.1.

SPECIFICATIONS

EID1050RB

Voltage 240 V 50 Hz

Chuck capacity 13 mm (1/2”)

Drilling capacity

in wood 32 mm

in steel 13 mm

in masonry 20 mm

Input 1050 W

No load speed 0 - 3,200 min-1

Blows per minute 0 - 51,000 min-1

Weight 2.86 kg

STANDARD ACCESSORIES

Auxiliary handle and Depth Gauge.

OPERATION

APPLICATIONS

(Use only for the purposes listed below.)

■ Drilling wood, materials and resin boards.

■ Drilling concrete (impact drilling only).

■ Drilling metal: steel, brass, aluminum sheets, stainless

steel & pipe.

SWITCH

See Figure 1 & 3.

■ This tool can be started and stopped by squeezing

and releasing the trigger switch (1).

■ The speed can be adjusted by controlling the force

applied to the trigger.

■ The maximum speed of the drill may be set at different

speeds by adjusting the variable speed selector (4).

■ For continuous operation, press the lock-on button (5)

while squeezing the trigger. Squeeze the trigger again

to release the lock.

CHANGING THE ROTATION DIRECTION

See Figure 2.

■ To change the direction of rotation, stop the tool and

push the forward / reverse selector (2).

■ When the forward selector is pushed in, the bit rotates

clockwise when viewed from the handle end of the tool.

2

Page 7

English

OPERATION

■ When the reverse selector is pushed in, the bit rotates

counterclockwise.

MOUNTING AND REMOVING THE BIT

See Figure 4.

■ Insert the drill bit (9) into the chuck as far as the plain

part of its shank will go.

■ Tighten the chuck securely by rotating the chuck head

in a clockwise direction (12).

■ The bit can be removed by rotating the chuck in a

counterclockwise direction (13).

CHANGING BETWEEN DRILLING AND IMPACT

DRILLING MODE

See Figure 5.

The drilling mode shift knob (6) for changing between

the drilling mode and impact drilling mode is positioned

on the top of the tool.

DRILLING MODE: Shift the knob to the "

showing " " symbol for drilling.

IMPACT DRILLING MODE: Shift the knob to the " "

and showing "

" symbol for impact drilling.

" and

OPERATING

NEVER COVER THE AIR VENTS (10) SINCE THEY

MUST ALWAYS BE OPEN FOR PROPER MOTOR

COOLING.

DRILLING IN WOOD

To prevent ugly splits around the drill hole on the reverse

side of the workpiece, put a piece of scrap timber under

the work piece.

DRILLING IN METAL

Metals such as steel, brass, aluminum sheets, stainless

steel, and pipe may also be drilled. Mark the point to be

drilled with a nail or punch.

Do not use impact drilling mode on these materials.

DRILLING IN CONCRETE

Stone and masonry are generally drilled in the impact

drilling mode.

When drilling in delicate materials such as wall tiles,

it is essential to start with ordinary drilling and, once the

tile is pierced, to continue with impact drilling.

In deep bore holes the drill bit should be pulled out

occasionally in order to remove the debris from the

drill and hole.

AUXILIARY HANDLE AND DEPTH GAUGE

See Figure 6.

Auxiliary handle

The auxiliary handle (8) can be rotated 360º.

Loosen the handle grip by turning in direction (15),

and tighten it at an easy to use position by turning

the grip in direction (14).

Depth gauge

Holes of a fixed depth can be accurately bored by using

the depth gauge (7).

The depth of the hole will be the distance from the end

of the bit to the end of the depth gauge.

By turning the handle grip in direction (14), the depth

gauge can be released and the depth adjusted. After

adjusting the depth, fix the depth gauge again by turning

the handle grip in direction (15).

BIT STORAGE

See Figure 7.

The auxiliary handle also contains a compartment to

store drill bits. To access this compartment unscrew

the end cap below the grey trim on the handle in an

anticlockwise direction.

SPINDLE LOCK

See Figure 8.

For easy changing of the drill bit this drill is equipped with

an automatic spindle lock (17) which holds the spindle

stationary when loosening and tightening the chuck.

BUBBLE LEVEL

See Figure 1.

A bubble vial is located on the top of the motor housing

to help keep the drill bit level during use. This ensures

maximum accuracy in drilling.

Recommendation: Always be supplied via a residual

current device with a rated residual current of 30 mA or

less.

LIVETOOL INDICATOR™

This tool features a Livetool Indicator™ (11) which

illuminates as soon as the tool is connected to the power

supply. This warns the user that the tool is connected and

will operate when the switch is pressed.

3

Page 8

English

MAINTENANCE

After use, check the tool to make sure that it is in good

condition. It is recommended that you take this tool to

a RYOBI Authorised Service Center for a thorough

cleaning and lubrication at least once a year.

DO NOT MAKE ANY ADJUSTMENTS WHILE

THE MOTOR IS IN MOTION. ALWAYS DISCONNECT

THE POWER CORD FROM THE POWER SUPPLY

BEFORE CHANGING REMOVABLE OR CONSUMABLE

PARTS (BLADE, BIT, ETC.), LUBRICATING OR

WORKING ON THE UNIT.

WARNING

To ensure safety and reliability, all repairs should

be performed by an AUTHORISED SERVICE

CENTER or other QUALIFIED SERVICE

ORGANISATION.

SAVE THESE INSTRUCTIONS FOR FUTURE

REFERENCE.

SYMBOL

Safety Alert

V Volts

Hz Hertz

Alternating Current

W Watts

o No load Speed

n

-1

Revolutions or reciprocations per minute

min

Double Insulation

Wear Personal protective equipment

Please read the instructions carefully before

starting the machine.

Recycle raw materials instead of disposing

as waste. The machine, accessories

and packaging should be sorted for

environmentally-friendly recycling

4

Page 9

Loading...

Loading...