Page 1

BIRD'S EYE VIEW CAMERA SYSTEM

Installation and

User Guide

RVS-77550

Page 2

BIRD'S EYE VIEW CAMERA SYSTEM

Contents

Introduction ..........................................................................................................................................4 1.

Installation Principles ...........................................................................................................................4 2.

2.1.

Installer Qualifications ..........................................................................................................4

2.2. Positive Switch Signals Required ........................................................................................4

2.3. Reverse Wiring.....................................................................................................................4

2.4. Turn Signal Wiring................................................................................................................4

System Package..................................................................................................................................8 3.

3.1.

Component List ....................................................................................................................8

3.2. Optional Shrouds for Specific Mounting Requirements .......................................................8

Installation Diagram ............................................................................................................................11 4.

Electronic Control Unit (ECU) ........................................................................................................... .12 5.

5.1.

ECU Installation Locations ................................................................................................ 10

5.1.1. ECU Installation Requirements ............................................................................ 11

5.1.2. Installing the ECU ................................................................................................ 12

Installing the Push-button Remote Control (optional) ...................................................................... 15 7.

Installing Cameras ............................................................................................................................ 16

8.1.

Determining Camera Locations ........................................................................................ 16

8.2. Installing Side Cameras Below Mirrors ............................................................................. 17

8.2.1. Selecting Symmetrical Side Camera Locations ................................................... 18

8.2.2. Under Mirror and Door Mount Option .................................................................. 19

8.2.3. Removing Mirror Glass ........................................................................................ 20

8.2.4. Mounting Cameras on Doors ............................................................................... 21

8.3. Camera Installation Procedure ......................................................................................... 23

8.3.1. Camera Assembly ................................................................................................ 24

Connecting to Signals and Power .................................................................................................... 25 9.

Testing and Calibration .................................................................................................................... 25

Connecting to a DVR (optional)........................................................................................................ 26

Installing in Fleet Vehicles ................................................................................................................ 27

12.1.

Conventional School Buses .............................................................................................. 28

12.2. Conventional Transit Buses .............................................................................................. 29

12.3. Para Transit or Short School Buses ................................................................................. 30

12.4. Fire Trucks ........................................................................................................................ 31

Using the System ............................................................................................................................. 32 13.

Specifications ................................................................................................................................... 34

8.

10.

11.

12.

14.

Warranty ........................................................................................................................................... 35

Contact Rear View Safety................................................................................................................. 36 16.

BIRD'S EYE VIEW CAMERA SYSTEM

15.

Page 3

1. Introduction

This guide describes how to install and use the Bird's Eye View Camera System. The

RVS-77550 provides drivers with a real-time, 360-degree picture of the area around their

vehicle to eliminate blind spots, help improve pedestrian safety, prevent vehicle damage,

and avoid liability costs.

For a description of how the system works, please see section 13 “Using the System” on

page 32.

2. Installation Principles

2.1. Installer Qualifications

Installation of the Bird's Eye View Camera System is for certified personnel only. For more

information, contact Seon Service and Support (please see the back page of this guide for

details).

BIRD'S EYE VIEW CAMERA SYSTEM

The installation process involves drilling into the exterior of a vehicle to mount cameras.

Ensure you read this document carefully, and verify the correct mounting locations prior to

drilling.

Important: The installed system will not operate correctly until it has been calibrated. For

more information, see the Bird's Eye View Camera System Calibration

Guide included with the product Installation and Calibration kit.

Check that you received all system components (for more information, see section 3.1 on

page 6), and inspect the units for any scratches or damage before installing.

2.2. Positive Switch Signals Required

The three signal attachments must be positive switching inputs, the Electronic Control Unit

(ECU) cannot accept a negative switching signal. The signals must be clean and not multipurpose. In many new commercial fleet vehicles the body control module (BCM) decides

when vehicle lighting turns on and off. While this has some efficiency in the scheme of

things, it does alter how we test for the correct wire.

Page 4 of 36

Page 4

BIRD'S EYE VIEW CAMERA SYSTEM

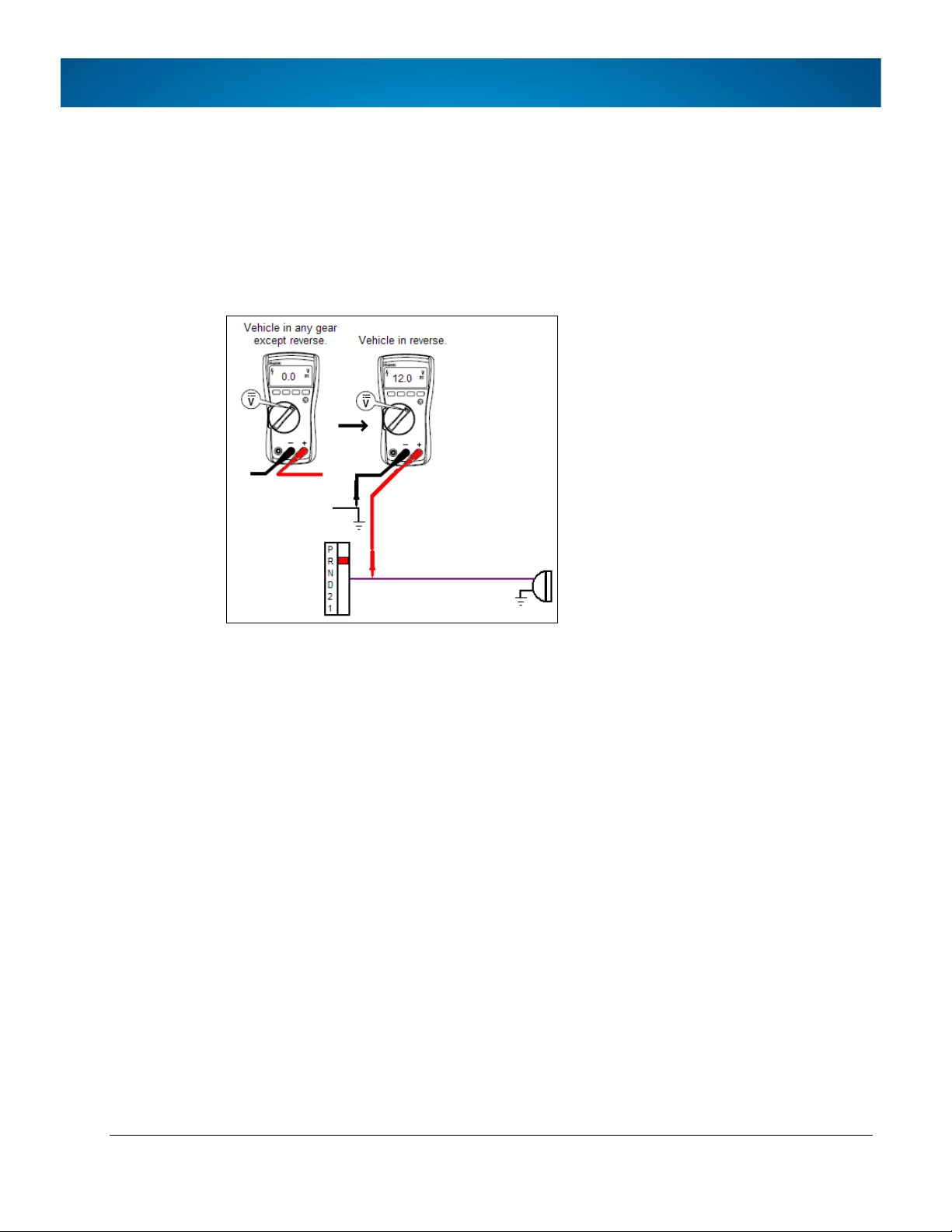

2.3. Reverse Wiring

The reverse signal is typically straightforward: connect to the wire that shows 12v when the

reverse lever is activated and reverse lights come on.

We highly recommend that a vehicle operator assists whenever testing the reverse signal to

ensure control of the vehicle.

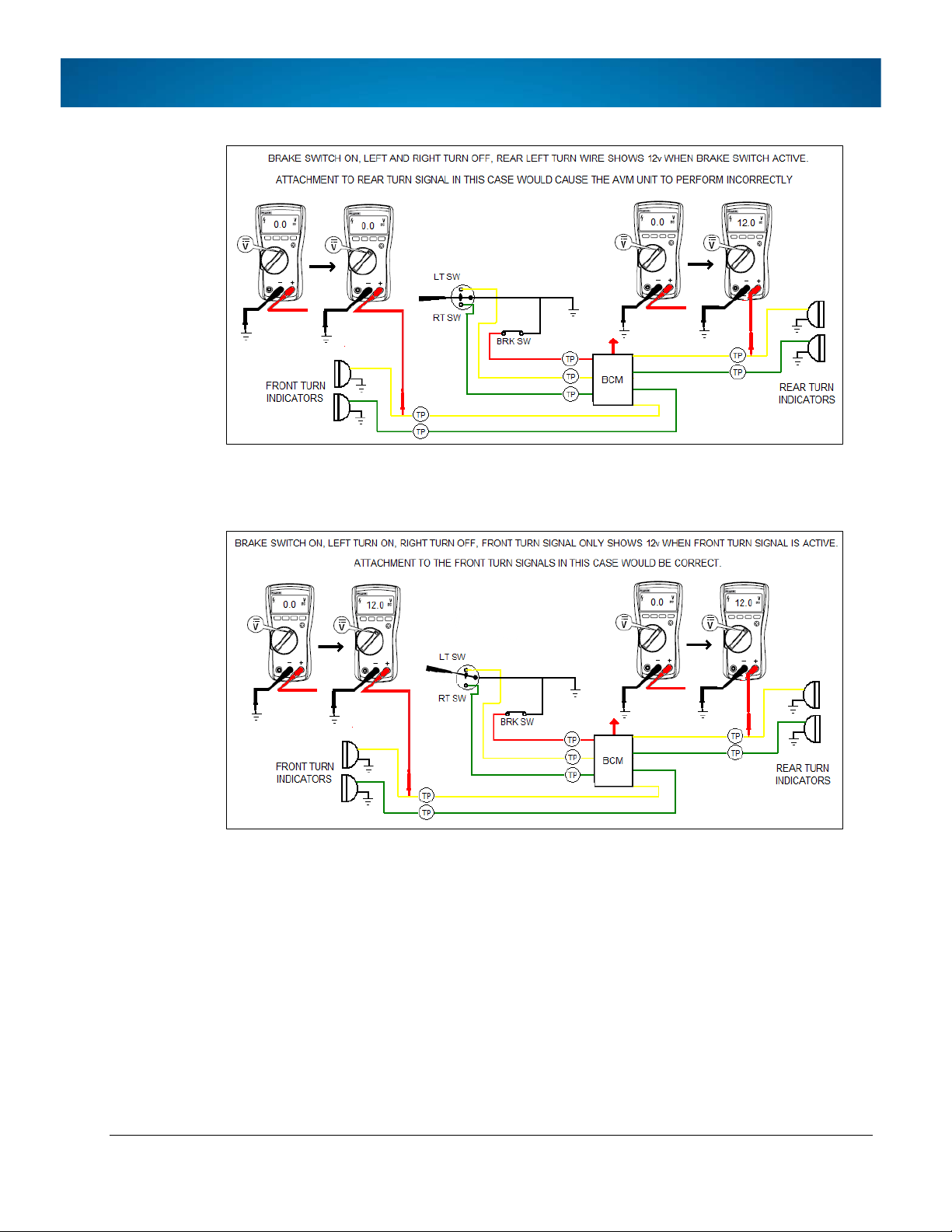

2.4. Turn Signal Wiring

The left and right turn signal wiring can be somewhat different in newer commercial

vehicles. There is no longer a requirement to have the rear turn signals a different color

(amber) than the brake lights (red) - they may all simply be red. This fact, combined with the

addition of a Body Control Module, allows the vehicle manufacturer to use the left and right

turn wires to display a brake signal, simply by activating them both at the same time. This

also allows the use of a single bulb and a single wire to do both. The ECU can detect and

ignore when both left turn and right turn signals are active at the same time, but it cannot

detect either turn signal independently.

Therefore, when applying the brake and activating a turn signal while navigating a turn, the

turn would go undetected, as the brake has already applied 12v to both left turn and right

turn:

Page 5 of 36

Page 5

BIRD'S EYE VIEW CAMERA SYSTEM

The correc

lights, as there is no brake output to those lights:

t attachment point to a vehicle wired in this manner is to the front turn signal

Page 7 of 36

Page 6

3. System Package

The typical contents are shown below (actual contents for your system may vary, depending

on the options selected):

BIRD'S EYE VIEW CAMERA SYSTEM

3.1. Component List

This identifies the components in the image that follows:

1. Electronic Control Unit (ECU), 4 screws

(SD Card for calibration not included)

2.

3. Power connection cables, fuses and fuse holders (1A, 3A)

4. Monitor video-in cable to connect to ECU

5. Reverse signal wire

6. Left and right signal wires

7. INTERFACE harness

8. VIDEO harness

9. POWER harness

10. Remote controller button and extension cable (optional)

11. Video output cables to monitor and DVR (optional)

Page 8 of 36

Page 7

BIRD'S EYE VIEW CAMERA SYSTEM

12. Camera extension cables (x4)

13. Camera, mounting plates, covers, drill template and screws (x4)

14. Screw covers (2 per camera)

Page 9 of 36

Page 8

BIRD'S EYE VIEW CAMERA SYSTEM

3.2. Optional Shrouds for Specific Mounting Requirements

While the inView 360 Around Vehicle Monitoring system ships with a standard commercial

kit as shown above, the following shrouds may be used in particular installations.

These mounting shrouds are special order only and do not come as part of the standard

package.

The optional shrouds are plastic, while the shrouds included in the standard commercial kit

are all metal.

Page 10 of 36

Page 9

4. Installation Diagram

BIRD'S EYE VIEW CAMERA SYSTEM

Page 11 of 36

Page 10

5. Electronic Control Unit (ECU)

5.1. ECU Installation Locations

When deciding on a mounting location for the ECU, ensure you take into account that the

calibration process will require access to each side of the unit:

• to insert and remove the SD card

• to plug and unplug the power connector

Install it in a covered, dry, but accessible location. Also consider cable lengths when laying

out the location of the unit.

Keep in mind the length of the monitor cable, as it isn’t shipped with a video cable extension,

and the supplied video cable will need to reach the ECU from the monitor position.

Here are a few ideal locations:

BIRD'S EYE VIEW CAMERA SYSTEM

Page 12 of 36

Page 11

5.1.1. ECU Installation Requirements

Ventilation

Install the ECU away from any sort of heat outlet, heater, or AC

Secure surfaces

Do not mount the ECU to a plastic panel or other surface that

Mounting

The ECU can be installed horizontally, vertically, or upside down.

Clearance around

Allow sufficient clearance: at least six (6) inches in front of the ECU

Power, Signal,

Provide enough slack on the power cable to prevent any force

blower.

Do not operate the ECU in a closed-in area or restrict ventilation in

any way.

The ECU requires air circulation to maintain optimum operating

temperature and provide best performance.

Do not expose the ECU to moisture.

cannot support the ECU’s weight or is subject to constant

vibration.

BIRD'S EYE VIEW CAMERA SYSTEM

orientation

the ECU and

(optional) DVR

Camera cables

and two (2) inches on each side for removal of the security front

cover and easy access to the hard drive and USB ports.

Allow sufficient clearance behind the DVR for power, signal, and

camera cables.

from being exerted on the connectors.

A single 4-inch diameter loop is sufficient.

Avoid right angle bends in the Ethernet cables.

Page 13 of 36

Page 12

BIRD'S EYE VIEW CAMERA SYSTEM

5.1.2. Installing the ECU

Install with SD card (UPDATE) slot accessible, and leave room to connect cables in the back.

1. Choose a location as described above, and use the unit to mark drill positions.

2. Drill screw holes.

3. Mount the ECU with 4 screws, supplied with an optional install plate for easier

removal if needed.

Page 14 of 36

Page 13

BIRD'S EYE VIEW CAMERA SYSTEM

7. Installing the Push-button Remote Control (optional)

The remote controller has a blue button and a 1x2 connector for the extension cable, which

then connects to the BUTTON (1x4 male) connector on the INTERFACE harness.

1. Choose

2. Drill a 7/16” hole.

3. Thread the switch through the hole.

4. Tighten the nut to the underside of the switch.

5. Connect to the extension cable.

6. Run the extension cable to the ECU.

7. Connect the cable to the 1x4 BUTTON connector on the ECU INTERFACE harness.

a location on the switch panel.

Page 15 of 36

Page 14

8. Installing Cameras

8.1. Determining Camera Locations

Important: Confirm that camera positions will capture the required video before drilling

1. Attach the cameras temporarily with tape or velcro.

2. Connect them to the ECU and power on the system.

3. Calibrate the camera views in the Seon Calibration software (for details, see the

4. When positions are confirmed, install the cameras.

BIRD'S EYE VIEW CAMERA SYSTEM

holes in the vehicle.

inView 360 Calibration Guide included with the product Installation and

Calibration kit).

The cameras see a 150 degree range of video. They need to be mounted as high up and as

close to the centers of the vehicle sides as possible for maximum view overlap during the

calibration stage.

Page 16 of 36

Page 15

BIRD'S EYE VIEW CAMERA SYSTEM

8.2. Installing Side Cameras Below Mirrors

All four cameras in the Seon package are the same, and require 150 degrees of unimpeded

view from a parallel perspective of the vehicle. The view must not include side mirrors.

This is critical in placing the cameras, as shadowing can occur if the camera image that would

typically capture the ground is catching the protruding side mirrors, as in the case shown

below. The effect tends to produce parallel lines (shadow lines) in the calibrated software,

and it gives an undesirable appearance.

The first step in understanding camera placement for a 360-degree view system is to

recognize the range of the cameras being installed: the effective angle range of the inView

360 cameras is 150 degrees parallel to the side of the vehicle.

Imagine inverting a protractor and placing it on top of the vehicle image. This will give a close

estimate to help you choose where to look for an acceptable place to mount the camera.

As a rough template, we recommend you make a simple template similar to the pink version

pictured above, cut it out and simply lay it on an image of the vehicle. If you do not have an

image, you can take a picture on your smart phone.

This isn’t meant to be an exact measurement of where to place the camera to avoid mirrors it is to give you an idea of the areas that should work.

Page 17 of 36

Page 16

BIRD'S EYE VIEW CAMERA SYSTEM

When working on a new vehicle for the first time, the cameras should be temporarily

attached to the vehicle, and the side images examined to determine if the camera image can

see the side mirrors. The rule of thumb is typically that the shorter a vehicle is, the lower the

cameras may need to be to avoid the mirrors in the image.

Once po

both sides of the vehicle and find areas that are an option.

tential areas for side camera placement are established, the next step is to look at

8.2.1. Selecting Symmetrical Side Camera Locations

Side ca

While the driver’s side of the van pictured above appears to have a lot of options, the

passenger side has far fewer. The passenger side has a sliding door, and all electrical

connections are made into this door by contacts when the door is closed.

mera locations must be symmetrical to calibrate the system.

The section beyond this door toward back is also unacceptable as a mounting location, as

the door slides over this area, and would likely hit a camera mounted there. Therefore, the

only symmetrical position available would be somewhere on or within the forward green

section, or underneath the mirrors.

Page 18 of 36

Page 17

BIRD'S EYE VIEW CAMERA SYSTEM

All four cam

body as possible while minimizing image capture of the vehicle itself or protruding

equipment, to avoid shadowing.

eras must be mounted at the furthest point toward the outside of the vehicle

8.2.2. Under Mirror and Door Mount Option

While the under-mirror mount does appear to solve some shadowing issues created by body

panel mounting, it is not for a novice installer.

It requires disassembling the door panel, removing and disassembling mirror housings,

running wiring through the door into the vehicle, and in some cases dealing with moles in

the doors.

Do not attempt the above, unless you are experienced at this level.

This application is not possible in all types of power or standard mirrors: the mirror itself

should meet the criteria below before it is determined that placement is viable:

Page 19 of 36

Page 18

BIRD'S EYE VIEW CAMERA SYSTEM

• The mirror must have adequate extra space inside the mirror housing.

• The mirror must be flat on the bottom, and have enough surface area to

allow for mounting the cover. A 1 1/8” (28mm) diameter hole is required to

accommodate the camera.

• The mirror housing must have a pathway to run the camera cable wiring.

• Some door wiring is connected at the jam with a large Molex; the customer

must be OK with an alternate (possibly less attractive) routing for this cable.

The first step in installing cameras in mirrors is to remove the glass from the mirrors.

This can be a daunting task, and rarely are two models alike. It is glass that is being

unclipped, and it can be broken care is not taken.

The mirror glass will be attached most often with 4-6 tiny clips, similar to what is

pictured above. These clips are plastic and can be broken easily. It is recommended

that attempting to pry the glass off not be done in a cold environment, as the plastic

is far more brittle at lower temperatures.

8.2.3. Removing Mirror Glass

1. Get under the mirror and tilt the glass all the way in at the top, exposing as much

area as possible; if you can, identify a small rectangular area between the glass

and the round plastic turret that the clips are hanging on to.

2. Using a large flat head screwdriver, slide the tip in the rectangular area and

attempt to gently pry the mirror free. Be sure to hold the mirror as you are doing

this.

Page 20 of 36

Page 19

BIRD'S EYE VIEW CAMERA SYSTEM

If the

mirror does not pop free easily, do not force it.

3. Examine the mechanism further and consider if a different pry location might be

better.

4. Once the glass has been detached, proceed to removing the interior door panel

and the outside mirror housing.

5. If there is adequate room to drill the hole and mount the camera into the bottom

of the housing without impeding the motor, tilt mechanism, or manual cable,

then proceed with mounting the camera into the mirror.

The camera itself must be parallel to the side of the vehicle.

A common mistake is thinking screw holes in the under-mirror mount are 90

degrees perpendicular to the side of the vehicle – they are not.

8.2.4. Mounting Cameras on Doors

If you determine that under-mirror mounts are not an option and the side cameras must go

on the front door area, the standard industrial shrouds can be used to do this.

A thorough examination of the inside of the door, the window, window travel, and door

mechanism must be made when choosing a location for the side cameras.

An incorrect location can very easily lead to windows being ruined and/or scratched,

mechanisms being impeded, and wires being frayed or just snapped off all together. We

recommend plugging window switches back in and testing the up and down motion with the

door panel off prior to drilling any holes.

Regardless of whether the camera is mounted under the mirrors or in the door body, the

wiring must feed into the vehicle.

Page 21 of 36

Page 20

BIRD'S EYE VIEW CAMERA SYSTEM

Typically this is done through the existing rubber door boot. While it is typically not easy to

get extra wiring through this boot, it can usually be done. A more significant challenge often

comes at the door side of the boot. Many domestic manufacturers have opted to install a

Molex plug at this end.

Determine if there is enough empty space available in the plug to drill and slide the camera

wiring through. If not, you must find an alternate location to run the wiring into the vehicle.

This could mean drilling a new hole in the door jam to accommodate the wire entry.

It is imperative to find a location to minimize the frequent motion stress this wire will be

under. It is also very important that any wiring entering the vehicle body drop below the

entry point of the vehicle. If the wire strings into the vehicle downward without a ‘drip loop’,

water will follow the wire into the vehicle.

Upon reassembly of the Molex back into the vehicle, ensure all electrical door items are

operational.

Page 22 of 36

Page 21

8.3. Camera Installation Procedure

Camera position

Test position before mounting - be sure the location will

Mount to secure surfaces only - do not mount the

Mounting orientation

Ensure cameras are horizontally level.

Mirrors

Mount at a height where camera views will not be

Follow these guidelines:

work (for important details, see the previous section).

BIRD'S EYE VIEW CAMERA SYSTEM

Mounting surface

1. On th

2. At the mid-point of the vehicle widths and lengths, select a location.

3. Use Velcro or tape to adhere the camera to the vehicle for testing before drilling

4. Once positions have been verified, use the supplied camera drill templates to

e floor with a clear area around the vehicle of at least 6 feet in each

direction, use tape to make a rectangle enclosing the vehicle that includes the

maximum length and width.

holes (for more information, see the Calibration Guide included with the

Installation and Calibration Kit).

mark drill positions.

camera to movable or flexible surfaces.

obstructed by mirrors.

5. Drill the holes and remove the drill template from the vehicle surface.

Page 23 of 36

Page 22

BIRD'S EYE VIEW CAMERA SYSTEM

8.3.1. Camera Assembly

The cameras are sealed, and must be attached to the cover and mounting plate. Take care

not to lose any critical hardware - replacement screws may be very hard to source if they are

lost.

1. Collec

2. Attach the camera to the base plate with the 2 small screws.

3. Thread the camera cable through the hole and fit the grommet on the cable

4. Remove the adhesive on the back plate.

5. Place the base on the vehicle surface. Align to the drilled holes.

6. Remove the adhesive on the camera lens.

7. Place the camera cover over the camera.

8. Fasten the cover to the vehicle with the two black screws.

9. Cover the screws with the black round adhesive screw covers.

10. Seal the camera base with waterproof caulk.

11. Inside the vehicle, connect the camera cable to the extension cable.

t the camera, mounting plate and 2 small screws, cover plate and 2 black

screws, and screw covers.

hole’s edges.

12. Run the extension cable to the ECU and connect them.

13. Repeat for each camera.

Page 24 of 36

Page 23

9. Connecting to Signals and Power

The inView 360 Around Vehicle Monitoring system requires six electrical connections to the

vehicle:

• Power for ECU and Monitor

• Ignition (switched or accessory) for ECU and Monitor

• Vehicle ground

• Left turn signal

• Right turn signal

• Reverse for ECU and Monitor

All required system inputs are 12v (or 24v) positive inputs.

1. Run wires from the ECU POWER harness to left turn, right turn, and reverse

signals. All signals must be positive.

2. Run wires from the ECU POWER harness to ignition, power, and ground.

BIRD'S EYE VIEW CAMERA SYSTEM

3. Install 3A fuse on the power connection.

4. Install 1A fuse on the ignition connection.

10. Testing and Calibration

Power on the system and check the basic functionality (for details, see section 13,

“Using the System” on page 32:

Note: The 360 view itself will not display correctly until you calibrate the system

(see step 3, below).

1. Test that the monitor comes on and switches views when the turn signals and

reverse gear are engaged.

2. If your system includes the optional remote control, test that the button switches

views.

3. Calibrate the system according to the procedures described in the inView 360

Calibration Guide (included with the Installation and Calibration Kit).

Page 25 of 36

Page 24

11. Connecting to a DVR (optional)

While the system has a monitor to assist with driving and parking, Seon also offers the ability

to install a DVR and record the viewed image, in the same way that the DVR records a single

camera. An adapter (ARMF MicroFit to composite RCA) is all that is required to do this.

Recording the 360 camera view has some significant advantages: in the case of an accident,

it could provide critical video, and help establish what led to the crash. Center and lanedividing lines are typically visible on the monitor and in the recorded image.

Some DVRs such as the Seon TL-HD have a power output that can be utilized, allowing the

system to continue to record the 360-degree image after the vehicle ignition has been

turned off.

Follow these steps:

1. Connect the ARMF cable`s 2x3 MicroFit to an unused DVR camera socket.

BIRD'S EYE VIEW CAMERA SYSTEM

2. Connect one of the ARMF cable’s RCA connectors to a CVBS cable’s RCA

connector.

3. Connect the CVBS cable to a 2x1 connector on the VIDEO harness, connected to

the ECU.

4. Power on and test that the 360 video is displaying as a DVR camera input.

Page 26 of 36

Page 25

12. Installing in Fleet Vehicles

In this guide, “fleet vehicles” refers to vehicles of approximately 20-foot length such as

standard size work vans, mini work vans, bucket trucks, etcetera.

The majority of fleet vehicles require the standard Seon commercial kit. There may be some

exceptions to the mount for the front (forward-facing) camera, but the side and rear

cameras should be appropriate.

The side camera images must not capture the side mirrors. There are 150 degrees of

effective parallel view to the side of the vehicle where the side mirrors should not be in the

in the image. This should be tested by taping the camera to the side of the vehicle and

capturing the image.

If the calibration pads are in view with the side camera, and the side mirrors are not, the

image is typically acceptable. It is the goal to have the side cameras as high as possible, while

missing the side mirrors entirely.

BIRD'S EYE VIEW CAMERA SYSTEM

Recommended Shrouds:

• Front - Standard Optional (front or top)

• Rear - Standard

• Sides - Standard

For more information, see section 3.2, “Optional Shrouds for Specific Mounting

Requirements” on page 8.

Page 27 of 36

Page 26

BIRD'S EYE VIEW CAMERA SYSTEM

12.1. Conventional School Buses

Installation in most full-size school buses is fairly straightforward. Due to vehicle length, the

side and rear cameras may be installed around the top perimeter. These are typically

standard wire runs when installing surveillance cameras inside the bus.

The front camera may also be installed on top in the transit-style (flat nose) school bus, but

the mirror locations should be assessed prior to determining this.

In the conventional school bus example below, the front camera is installed in the front grill,

to avoid the hood. Regardless, all wire runs in this type of vehicle should be straightforward.

Recommended Shrouds:

• Front - Standard

• Rear - Standard

• Sides - Standard

Page 28 of 36

Page 27

BIRD'S EYE VIEW CAMERA SYSTEM

12.2. Conventional Transit Buses

Installing the system in a standard 40-foot transit bus is very similar to the process for a 40foot school bus. The wire runs for this vehicle are fairly standard. We advise testing the front

view prior to mounting the camera up high.

In most cases, public transit vehicles will have fold down bike racks on the front of the

vehicle, limiting the option to install below the windshield.

Typically, the ECU can be installed in the overhead compartment above the operator or radio

cabinet.

The system is not compatible with the negative-switching turn signals found in many full size

transit vehicles: the positive-switching signals must be located. Most modern full size transit

vehicles have multiplex circuitry – this likely requires running a reverse trigger wire to the

back of the vehicle and tapping the output from the node there. There will generally not be

anything useful in the front section.

mmended Shrouds:

Reco

• Front - Standard

• Rear - Standard

• Sides – Standard

Page 29 of 36

Page 28

BIRD'S EYE VIEW CAMERA SYSTEM

12.3. Para Transit or Short School Buses

Installing the system in a cutaway transit vehicle may be more involved than a full size transit

vehicle. Due to the domestic chassis portion of the vehicle being narrower than the rear

body, the cameras must be mounted on the rear body. Due to the length of the vehicle and

the mirrors protruding from the sides, the cameras will most likely require being installed

below the side windows.

Because of the materials used and the way the bus is constructed, to properly mount the

cameras, a hole must usually be drilled from the outside into the vehicle. It is very unlikely

there is a way to wire between these panels after the bus is assembled. Therefore, a flat

conduit is required to shroud the wiring after it enters the cab of the vehicle. This is far from

ideal, and should be discussed with the customer before proceeding. The camera location is

necessary for successful calibration (for more information, see the inView 360 Calibration

Guide, included with the Installation and Calibration kit).

Recommended Shrouds:

• Front - Standard Optional (front or top)

• Rear - Standard

• Sides – Standard

For mo

Requirements” on page 8.

re information, see section 3.2, “Optional Shrouds for Specific Mounting

Page 30 of 36

Page 29

BIRD'S EYE VIEW CAMERA SYSTEM

12.4. Fire Trucks

Note: This product is designed for a standard-length fire truck, and is not compatible with

a tractor-trailer version due to the pivot of the forward-facing camera.

Installing the system in a fire truck requires temporary placement of the side cameras prior

to drilling and mounting. Due to the construction of most fire trucks, side cameras will likely

not be mounted in the center of the vehicle, and instead will be more toward the front. We

highly recommend mounting the cameras high enough to see past the rear of the fire truck,

but low enough so as not to see the side mirrors in the image.

Most fire trucks have no access back through the rear portion of the body to wire anything regardless of fire truck type (utility, pumper, or ladder truck). The rear camera and reverse

wiring must be picked up at the rear of the fire truck, and run with the factory wiring

underneath the vehicle, then up into the cab-over section.

All wiring should be covered with convoluted tubing. This is a heavy industrial vehicle,

sometimes used in very harsh conditions. The system must be installed at a facility where a

lift is available, as well as the properly trained people to operate it.

Recom

mended Shrouds:

• Front - Standard

• Rear - Standard

• Sides - Standard

Page 31 of 36

Page 30

13. Using the System

Start the vehicle:

Shift into reverse gear:

Activate left turn signal:

Activate right turn signal:

360-degree stitched

Forward camera view

Rear camera view

Left-side camera view

Right-side camera view

When you turn on the ignition, the monitor displays a split-screen: the left side is a blended

(stitched) 360-degree “bird’s eye” view of all 4 camera images, and the right side shows the

forward camera. The image on the right changes, based on vehicle operation:

BIRD'S EYE VIEW CAMERA SYSTEM

view (4 cameras)

(with guide lines)

In the 36

0 view, the picture of the vehicle itself (seen from above) is a static image, selected

during system configuration. For more information, see the inView 360 Calibration Guide

included with the product Installation and Calibration kit.

Page 32 of 36

Page 31

Activating a turn signal or shifting the vehicle into reverse gear over-rides the current view.

Front full view:

Rear full view:

Cancelling the turn signal or shifting out of reverse returns to the default (360/forwardfacing) view.

Remote Control (Optional)

Use the optional switch (blue push-button) to cycle through the four split-screen displays

shown on the previous page, as well as full-screen images for the front and rear cameras:

BIRD'S EYE VIEW CAMERA SYSTEM

Page 33 of 36

Page 32

14. Specifications

Input Voltage

12V ~ 24V (Free Voltage)

Power Consumption

13W (ECU + 4 cameras), 0.6W per camera

Video Input

NTSC, Front/Rear/Left/Right Camera (4CH)

Video Output

NTSC, CVBS (SD) 2CH

Operating Temperature

-30°C ~ +75°C

Storage Temperature

-40°C ~ +75°C

Camera View

150° (Horizontal)

Resolution

800 x 480 (Optimized for monitor)

Frame Rate

30 FPS

Camera Cable Length

20”

Extension Cable Lengths

Front: 26’

Cut Off Requirement

< 8V accessory voltage

Weight

Entire kit: ECU, cameras, monitor, cables = 8 lbs.

Dimensions

ECU: 4.54” x 6.24” x 1.34”

Specifications for the inView 360 Around Vehicle Monitoring system are subject to change

without notice.

BIRD'S EYE VIEW CAMERA SYSTEM

Side: 39.5’

Rear: 52’

Cameras: 2.3” L x 2” H x 2” W

Page 34 of 36

Page 33

15. Warranty

BIRD'S EYE VIEW CAMERA SYSTEM

BIRD'S EYE VIEW CAMERA SYSTEM cameras are covered by a 1-year warranty (from the

date of purchase) on parts and repair labor.

Page 35 of 36

Page 34

BIRD'S EYE VIEW CAMERA SYSTEM

16. Contact Rear View Safety

Rear View Safety , INC. | 1797 Atlantic Avenue | Brooklyn NY 11233

800.764.1028 | Sales@RearViewSafety.com | www.RearViewSafety.com

Page 36 of 36

Loading...

Loading...