Page 1

Instruction Manual

Wired and Wireless Obstacle

Detection Sensor Systems

Page 2

Table of Contents

Contact us 3

Product Overview 4

Product Features 4-5

Package Contents (Hardware) 6

About the Monitor 7-8

About the ECU 8-9

About the Sensors 10

Sensor Installation 11

Sensor Installation (In-Bumper Flush Mount) 12-14

TABLE OF CONTENTS

Sensor Installation (SE Version) 15-18

Alternate Sensor Mounting Locations 18-20

ECU Installation Location & Sensor Connection 21-22

ECU Installation (Specic to Wired Systems) 22

ECU Installation (Specic to Wireless Systems on Trailers) 22

Monitor Installation 23

Monitor Function Setup 23-24

Setting Stop-line Adjustment 24

Installation Test (in order shown) 25-26

System Operation 26-27

Warranty 28

Disclaimer 29

2

Rear View Safety

Page 3

If you have questions about this product, contact:

Rear View Safety

1797 Atlantic Avenue

Brooklyn, NY 11233

Tel: 1.800.764.1028

IN NO EVENT SHALL SELLER OR MANUFACTURER BE

LIABLE FOR ANY DIRECT OR CONSEQUENTIAL DAMAGES OF

ANY NATURE, OR LOSSES OR EXPENSES RESULTING FROM

ANY DEFECTIVE PRODUCT OR THE USE OF ANY PRODUCT.

Contact us

Reverse With Condence ™

3

Page 4

Product Overview

SenseStat® is a unique family of Obstacle Detection Sensor Systems

(ODSS) that uti-lize the latest ultrasonic technology to detect objects

that are up to eight (8) feet from the rear of a vehicle. These backup alert, reverse-sensing systems, are available in both wired and

wireless congurations designed for multiple commercial vehicle appli-cations. SenseStat uses a Sensor-scanning algorithm that reads

each of four (4) sepa-rate Sensors providing the ability to Monitor

4-zones across the width of a vehicle. The result is a greater degree

of “blind spot” coverage in helping to prevent backing acci-dents, improper back-ups and allows for convenient tractor/trailer exchange

with all SenseStat equipped trucks.

Product Features

• Automatic activation when in reverse – Drivers don’t have to remember to turn onthe system. It’s there for you every time you put

your vehicle in reverse.

• Easy trailer switch (Wireless Only)– For tractor trailer rigs, just con-

PRODUCT OVERVIEW

nect to anySenseStat-equipped trailer, press the Monitor’s sync button and you’re connected andready to roll.

• Flexible Sensor placement – If overheads or low-hanging wires are

a concern,SenseStat Sensors can be installed at the top corners of

your vehicle: front orback. They can also be split between truck top

and bumpers.

4

Rear View Safety

Page 5

• Virtual bumper – For lift trucks or vehicles with extended bumpers,

SenseStat’s Stop-line Adjustment will adjust your stopping distance

(zero point) away from the actualbumper by whatever distance you

need. This allows for accurate stopping with allow-ance for overhanging ladders, folding lifts or other protrusions.

• Long trailers, extended cabs or busses – By installing the wireless

system, youeliminate the need for long wire runs through sometimes-complex wiring routes.

• SenseStat SE— oers a rugged housing for the systems four Sensors.

These heavy-duty, 2” x 3.2” x 1.4” shock-absorbent housings adapt to a

wide variety of vehiclesrequiring either a vertical or horizontal installation. Protect your systems against roughhandling, roadwear, construction sites and other conditions that might aect your in-vestment in

safety.

Power Input 10.5~24VDC

Power Consumption ECU: 200mA Max, LED Monitor: 250mA Max

Distance Detection 0.72~8.20 (ft) / 0.22~2.5 (M)

Detection Tolerance +/- 0.8 inches / +/- 0.02M (at 25°C )

Operating Temp -30°C to +75°C

Storage Temp -30°C to +80°C

Product Features

Dimensions ECU: 4.33” (L) x 3.62” (W) x 1.25” (H)

Monitor: 2.95”(L) x 3.54” (W) x 1.57” (H)

Weight ECU: 1 lb / .45 kg, Monitor: 22 lb / 1kg

Reverse With Condence ™

5

Page 6

Package Contents (Hardware)

• Monitor

• Wired (P/N: MA-ODSS-4D)

• Wireless (P/N: MA-ODSS-4DWA)

• ECU

• Wired (P/N: MA-ODSS-ECU)

• Wireless (P/N: MA-ODSS-ECUWA)

• Sensor with Rubber Boot (P/N: MA-ODSS-M17S)

• Sensor and Metal Under Bumper Sensor Mounts (P/N: MA-ODSS-M17SM)

• Box Truck Extension Cables - If Purchased as Box Truck Wired System

(P/N: MA-ODSS-4M17-BTC)

• One (2) 10M Extension Cable

• One (1) 1.2M “Y” Power Cable

• Straight Antenna (Mounts directly to ECU) - Wireless Only (P/N: MA-ODSS.SA)

• Straight Antenna with 10’ of Attached Cable - Wireless Only

(P/N: MA-ODSS-EA10)

• Mounting Bracket (P/N: MA-ODSS-EAMB)

Optional Items and Accessories

PACKAGE CONTENTS (HARDWARE)

• 5M Sensor Extension Cable (P/N: MA-ODSS-M17-SCE)

• Both Wired and Wireless Systems

• Connects between ECU and Sensor

• SE Enhanced Sensor Mounts - If Purchased as SE System or can

be added later

• SE Mount with Sensor (P/N: MA-ODSS-M17SE)

• SE Mount only (P/N: MA-ODSS-M17SE-M)

6

Rear View Safety

Page 7

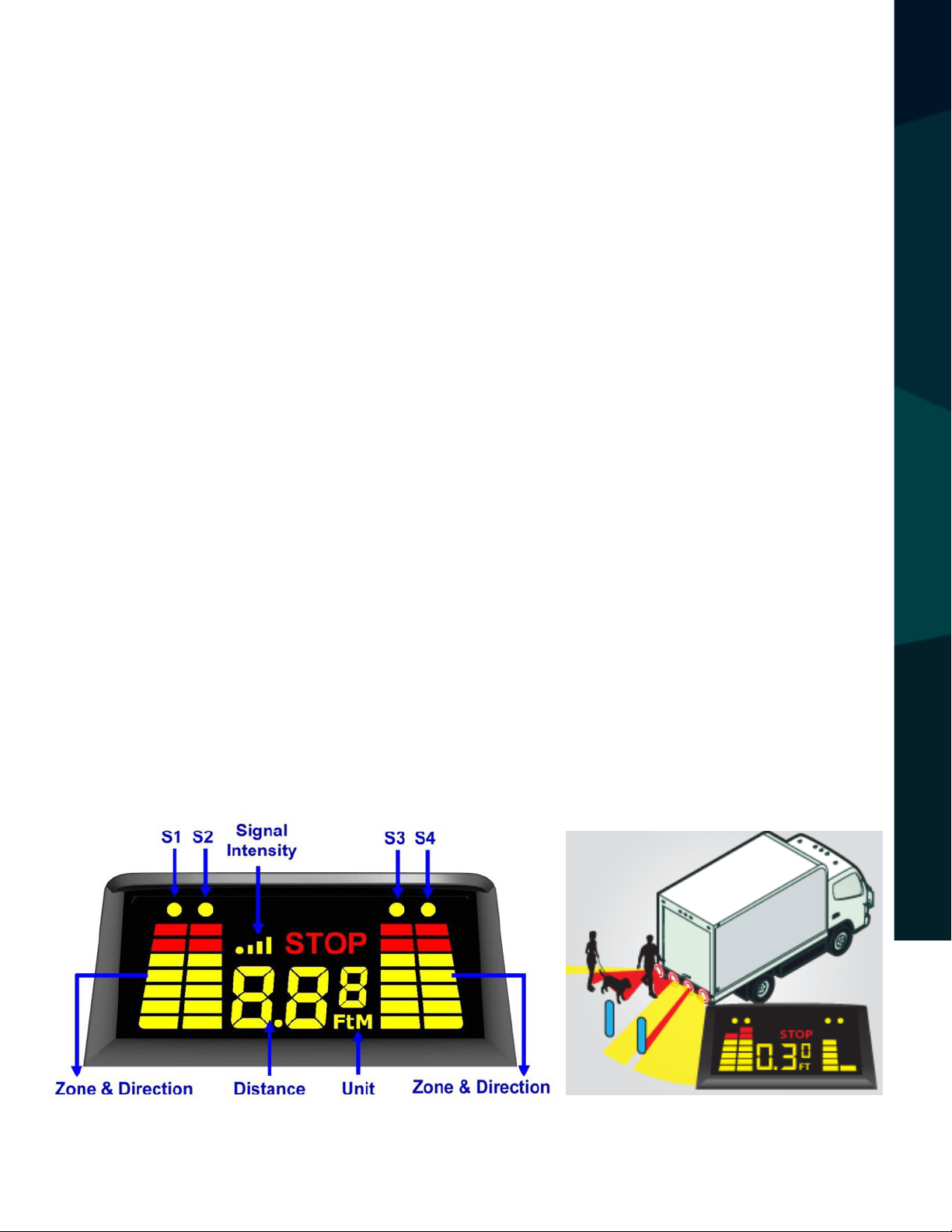

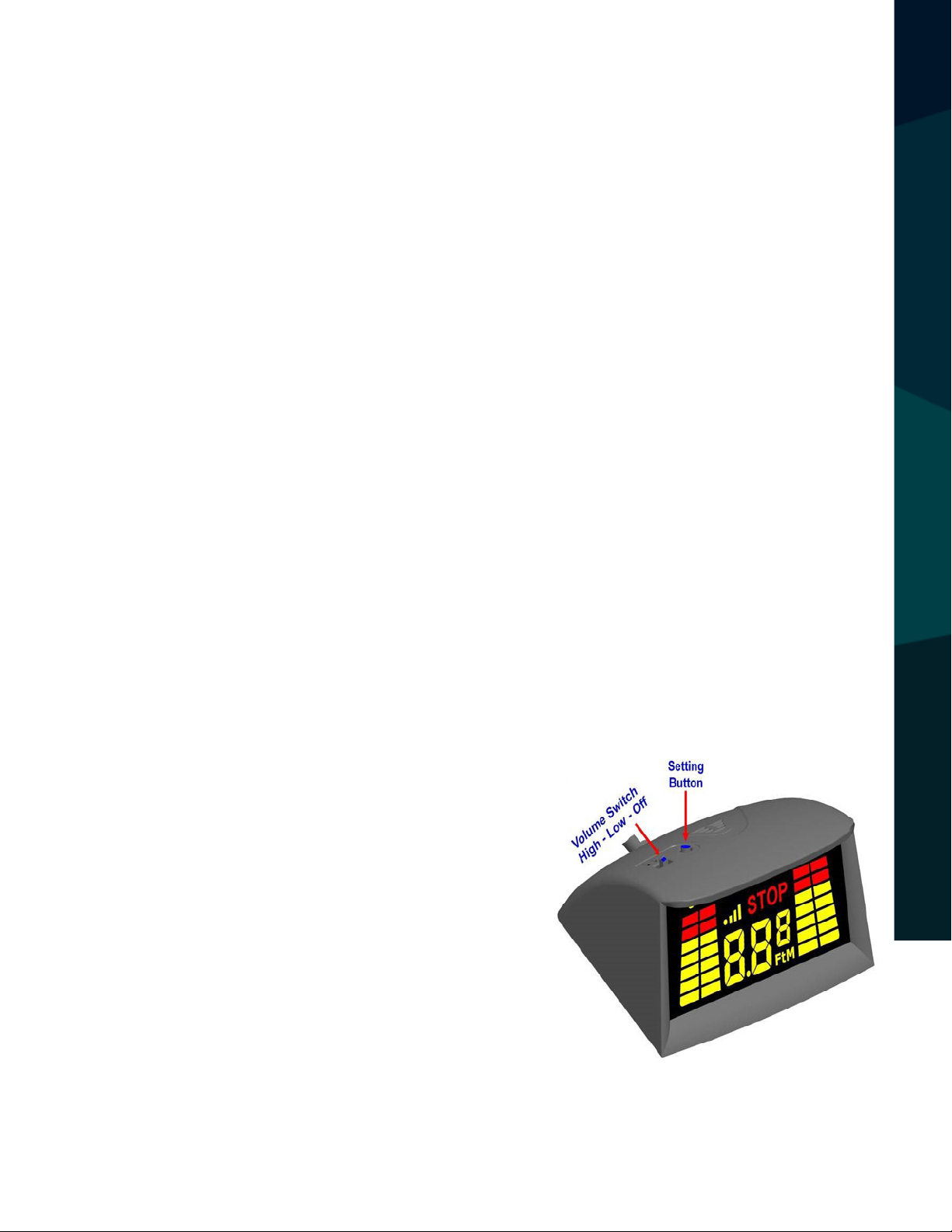

About the Monitor

The Monitor consists of a bright LED display having 4 individual bar

(Sensor) indicators and a distance meter. The advanced capabilities

of the system are designed such that the dash-mounted display will

indicate the distance (in feet & inches or meters) of the Sensor that is

closest to an object. The yellow dot at the top of the Sensor (S1, S2, S3

or S4) that is closest to an object will ash while that Sensors distance

to the object is indicated on the display. As the vehicle is moving, if an

object becomes closer to a dierent Sensor, the yellow dot over that

Sensors bar will ash and indicate its distance to the new closest object.

See the table on page 15 for more information on when the Monitor

will provide visual and audible warnings

ABOUT THE MONITOR

Reverse With Condence ™

7

Page 8

About the Monitor

• Indication of Sensors: S1, S2, S3, S4 indicate Sensor locations from left to

right (see Fig 8)

• Indication of Direction and Zone: The 4 LED column bars show the Direction

and Zone (Sensor) of the obstacle

• Indication of Distance: Shows the distance from the Sensor to the obstacle in

meters or in feet & inches of the Sensor that is closest to an object

• Signal Intensity: Shows the wireless signal strength (when applicable).

• Unit: Displays the unit of measurement being used, feet or metersIndication

of Sensors: S1, S2, S3, S4 indicate Sensor locations from left to right (see Fig 8)

• Indication of Direction and Zone: The 4 LED column bars show the Direction

ABOUT THE MONITOR

and Zone (Sensor) of the obstacle

• Indication of Distance: Shows the distance from the Sensor to the obstacle in

meters or in feet & inches of the Sensor that is closest to an object

• Signal Intensity: Shows the wireless signal strength (when applicable).

• Unit: Displays the unit of measurement being used, feet or meters

NOTE: See the table on page 15 for more information on when the Monitor will

provide visual and audible warnings.

About the ECU

The Electronic Control Unit (ECU) is an intelligent microcontroller system with

four (4) individual Sensor inputs, all contained in a waterproof enclosure. There

are four (4) integrated cables labeled S1, S2, S3 and S4, which will connect to

the four (4) each Sensor Units. There are two mounting holes for securing the

ECU at the rear of the vehicle. Since the ECU is watertight, it can be installed

underneath the vehicle to facili-tate the installation. Two antenna options are

8

Rear View Safety

Page 9

available for the Wireless ECU to assist with the installation depending on

your mounting location and needs pertaining to your vehicle. See the install

section of this manual for further information.

Fig 2: Wired ECU

Fig 3: Wireless ECU Fig 4: Wireless Antennas

ABOUT THE ECU

Reverse With Condence ™

9

Page 10

About the Sensors

The Sensor Unit consists of a waterproof ultrasonic transducer designed for

high accu-racy measurement of up to 8 feet or approximately 2.5 meters. The

standard mount consists of a rubber sleeve, set in a metal mounting bracket

for mounting under the bumper. The Sensors can also be mounted directly

in the bumper using the rubber boot or on the face of the bumper using the

optional SE Sensor Mount (see Fig 14). The Sensors are labeled S1, S2, S3 &

S4 to match the waterproof threaded connect-ors which have an O-ring seal.

Fig 5: Sensor in Metal Bracket Fig 6: Sensor, Rubber Sleeve &

ABOUT THE SENSORS

Fig 7: Waterproof Threaded Sensor Connectors

10

Metal Bracket

Rear View Safety

Page 11

Sensor Installation

1) The width of vehicles vary. It is important to install the Sen-sors at

the appropriate dis-tance and location along the rear bumper or equivalent (see Fig 8). Assuming that the width of vehicle is L, then the space

between Sensors is 1/4L (Sensors must be mounted S1, S2, S3, S4, from

left to right).

• Sensors S1 and S4 should be located approximately 1/8L from either

side of the vehicle. S2 and S3 will be located 1/4L from S1 and S4.

If the Sensors are mounted on a DOT type bumper, the Sensor locations

are deter-mined by the vehicle width (L), not the width of the bumper.

2) Sensors should be mounted at an absolute minimum of 16 inches

SENSOR INSTALLATION

(40cm) to 32 inches (80cm) from the ground (20 inches (50cm) is a

good choice, if available). See Alternate Sensors Mounting Locations,

Fig 22, for other options.

Reverse With Condence ™

11

Page 12

Sensor Installation (In-Bumper Flush Mount)

For vehicles equipped with a bumper that can accommodate the Sensors,

carefully drill a 25mm hole and insert the Rubber Jacket, properly orientated

“UP”, in the hole rst. Then insert the Sensor, again properly orientated “UP”

(see Fig 9). Depending on the thickness and construction of the bumper, the

hole diameter may need to be varied. The Rubber Jacket is designed to seat

properly into a 25mm hole with a 1/8 inch (3.2mm) thick metal bumper. If

this is not the case, the anges on the Rubber Jacket must be taken into consideration. It is suggested that a test hole be utilized to conrm a proper t.

Fig 9: UP

SENSOR INSTALLATION

Sensor Installation (Standard Metal Under Bumper Bracket)

Installing the Under Bumper

• With a drill bit (M5), make 2 holes spaced 2.1875 inches (2 3/16” or

55.6mm) apart in the bumper or equivalent. They should be set back no

more than 0.6 inches (15mm) from the front edge of the bumper. It is recommended to always take your own measurements to ensure proper installa-tion.

12

Rear View Safety

Page 13

• Attach the Sensors on the bumper or simi-lar vehicle xture (metal bar, etc.)

with the enclosed mounting hardware.

• Some bumpers may not be exactly parallel to the ground. When needed, the

Sensor’s vertical angle can be adjusted by placing a shim between the bracket

and bumper.

• See Fig 11, Fig 12 and Fig 13 for addition-al Information on Sensor conguration.

SENSOR INSTALLATION

Fig 10: Under-bumper Assembly & Mount for Standard

Metal Bracket Sensor

Reverse With Condence ™

13

Page 14

Fig 11: Sensor “UP” Indicator Fig 11: Se Fig 12: Rear of Metal

Bracket Assembly (oriented “UP”)

nsor “UP” Indicator

SENSOR INSTALLATION

Fig 12: Rear of Metal

Bracket Assembly

(oriented “UP”)

14

Fig 14: SE Mount

Rear View Safety

Page 15

Sensor Installation (SE Version)

The SE Mount is an enhanced mounting method that further protects the Sensors while providing alternate mounting op-tions. The solid rubber compound

SE Mount is designed to securely and conveniently attach the SenseStat Sensor

to your vehicle. To facilitate the installation, 2 each #6-32 Stain-less Steel Hex

Screws (2 inches in length) are provided, along with the appropriate washers

and hex nuts. To proper-ly ax the SE Mount, use only the hardware provided,

mak-ing sure to use the Flat Washer (0.375 inch outside diame-ter) in the front

of and in back of each unit. If the screw is not long enough, be sure to use #6-32

Stainless Steel Socket Hex Screws only.

1) Begin by examining the rear of the vehicle for the best location to secure the

Sensors. Below, in Fig 15 and Fig 16, are examples of how the SE Mount can be

orient-ed either horizontally or vertically. Depending on any space constraints,

decide which orientation is best suited for your vehicle. If you encounter any

diculty in doing so, please contact RVS Technical Support for assistance. The

formula, Fig 8, will still be followed for spacing of the sensors.

SENSOR INSTALLATION (SE VERSION)

Fig 15: SE Sensor Mounted Horizontally

Reverse With Condence ™

15

Page 16

Fig 16: SE Sensor Mounted Vertically

2) Once the location and orientation are determined, mark and drill the

2 (two) Sensor mount holes (0.156” or 5/32”) to accommodate the #6-32

screws. Refer to Fig 17 for the proper hole spacing which is 2.20” or 56mm

center to center.

3) Before attaching the SE Sensors to the vehicle, the Sensor Element must

be inserted into the center hole by pressing it into the front of the SE Mount. If

the Sen-sor is already inserted into the SE Sensor Mount, it may need to be rotated depending on the orientation. If the Sensor is mounted in the Standard

Metal Bracket remove it carefully pressing the rear of the Sensor for-ward out

of the Rubber Boot.

SENSOR INSTALLATION (SE VERSION)

4) Depending on the orientation of the SE Mount, the Sensor must be positioned (rotated) such that the “UP” Indicator (Fig 11) is pointing upward prior

to mounting to the vehicle. There is a slight angle (approximately 3 degrees)

on the face of the Sensor (indicated by the dotted line in Fig 13). This angle

helps to compensate for weight added to trucks which causes the back end to

lower. As a result, the Sensor may point slightly toward the ground. This could

cause the Sensor to detect reected signals from the ground if the angle was

too extreme.

16

Rear View Safety

Page 17

5) View the backside of the SE Mount prior to attaching to the vehicle to

determine the best way to route the Sensor Element wires. There are three (3)

wire slot guides available as indicated in Fig 19.

Depending on the type of installation, the Sensor Element wires can also

run through a large center hole as long

there is a similar size hole in the

6) Attach the SE Mount with the correctly oriented Sensor to the vehicle with the

enclosed mounting hardware. Make sure

that the face of the Sensor is perpen-dic-

SENSOR INSTALLATION (SE VERSION)

ular to the ground. In situations where the

face of the Sensor is not per-pendicular to

the ground, the Sensor’s vertical angle can

be adjusted by placing a shim between the

SE Mount and the bumper.

7) Make sure the Sensors are securely fastened by tightening the Stainless

Steel Nylon Lock Nuts to prevent the screws from loosening due to vehicle vibration.

Fig 17: SE Mount Drill

Hole Spacing

Fig 18: SE Mount

and Hardware

Reverse With Condence ™

17

Page 18

Fig 19: Backside of SE Sensor Mount

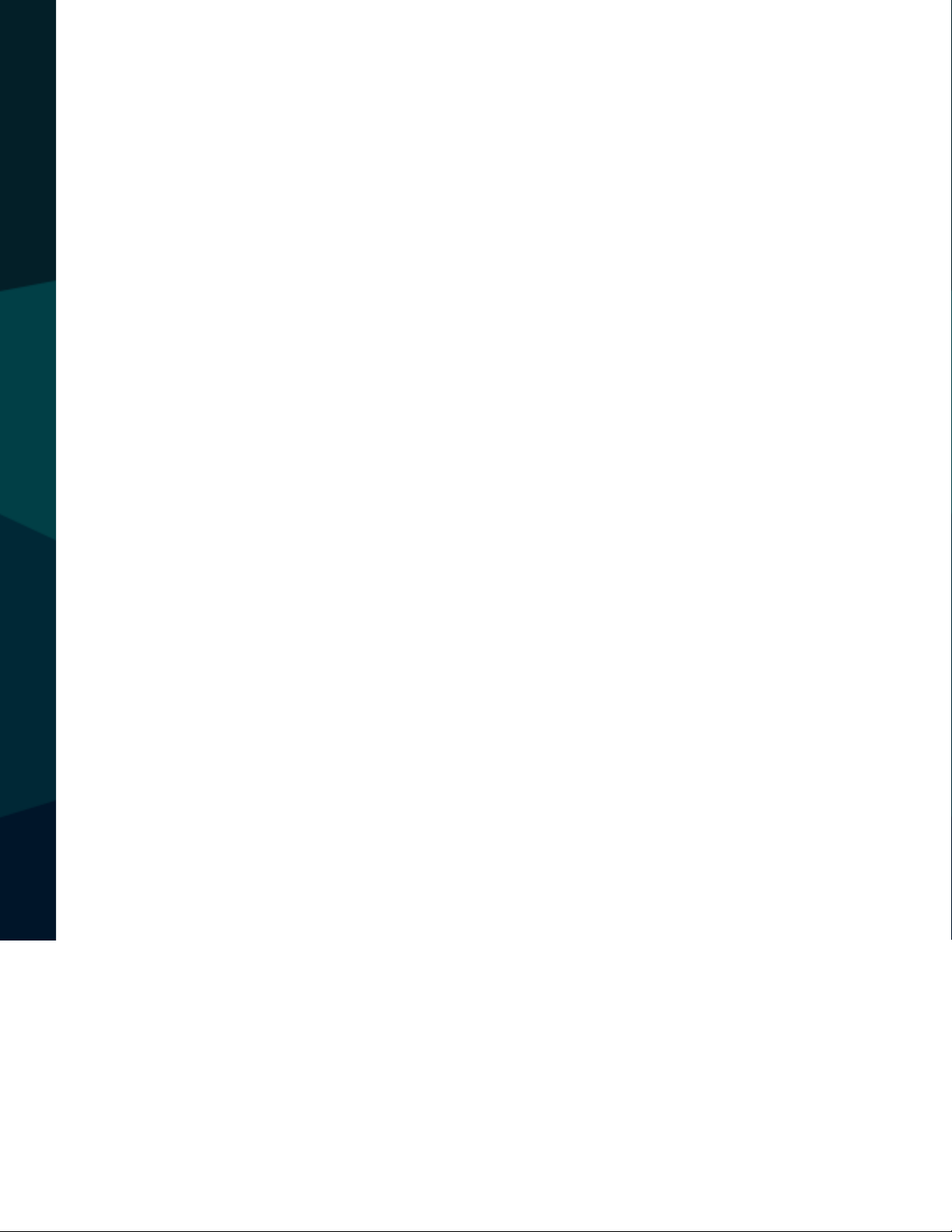

Alternate Sensor Mounting Locations

The system is designed to be installed with

all 4 (four) Sensors aligned across the rear of

the vehicle, preferably at a height ranging

from 16” to 32” from the ground. When the

Sensors are installed in a dierent layout

(for example to detect a building overhang

ALTERNATE SENSOR MOUNTING LOCATIONS

as shown on the right), please consider the

following:

• Each Sensor detects objects in a circular

area approximately 20” in diameter. The

Sensor eld of coverage can be seen below

in Fig 21.

• When the Sensors are placed on two

18

Fig 20

Rear View Safety

Page 19

dierent levels (per the example to the right) install S1 and S4 on the top and

S2 and S3 on the bottom of the vehicle.

• It is recommended that the face of all Sensors should be on the same plane to

ensure the accuracy of the system.

CAMERA SPECIFICATIONS

Sensors can also be mounted across the front of the vehicle to detect building

overhangs or to detect objects out of view.

NOTE: SenseStat is a tool to help the driver. The driver should always know

what is in front of or behind them and physically check the area themselves.

Fig 22: Alternate Sensor Mounting Locations

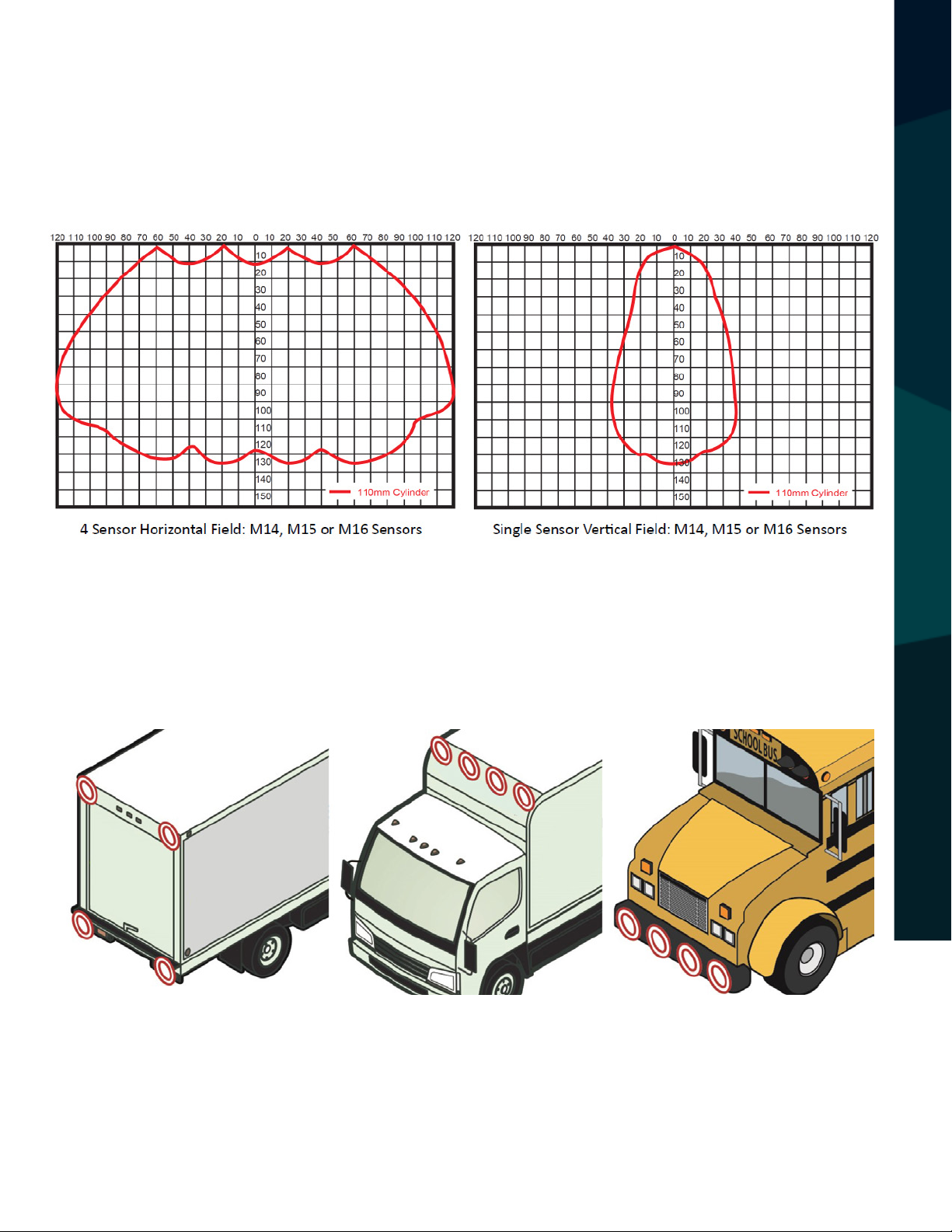

CAUTION: Using less than 4 (four) Sensors across the width of a bumper will create limited coverage resulting in blind zones! It is strongly suggested that these blind zones

are mapped out to educate the driver regarding the system limitations. See Fig 23.

Reverse With Condence ™

19

Page 20

Having all four Sensors in line, on the same plane, provides the best result. If

you break the Sensor con-guration up, for example two on top and two on

bottom, you create a bigger gap between the Sensors, causing a large blind

zone area. This blind zone area can lead to objects or people being undetected by the Sensors.

MONITOR SPECIFICATIONS

Fig 23: Sensor Conguration and Blind Zones

20

Rear View Safety

Page 21

ECU Installation Location & Sensor Connection

1) Depending on the vehicle type, select an appropriate location to mount

the water-tight ECU on the rear undercarriage of the truck chassis (see Fig 24).

Make sure the ECU is installed 4 inches (10cm) away from any objects (metal or electrical) that may aect the wireless

transmission (if applicable).

2) If Wireless, connect either antenna to the ECU. If using the Straight

Antenna, the ECU should be mounted in an open area and free from obstruction. Do not place the ECU in the frame of the vehicle or any enclosed area.

The Straight Antenna will screw onto the ECU and the ECU should be mounted

ECU INSTALLATION LOCATION & SENSOR CONNECTION

so that the antenna is pointing towards the road. If us ing the External Mount

Antenna, the ECU can be mounted in various places, including tucked into

the frame of the vehicle. The External Mount Antenna comes with 10 feet of

attached cable to allow the antenna to be mounted in another location using the included mounting bracket (see Fig 4). Again, this antenna should be

mounted in an open area to ensure proper transmission. It is recommended to

mount the antenna on the same side of the vehicle as the monitor, with the

anten-na pointing to the front of the vehicle.

Fig 25: Mounting

Tabs and Hardware

Fig 24: Mounting the ECU

Reverse With Condence ™

21

Page 22

3) Secure with the two (2) enclosed mounting bolts (M6x10). Be sure to

secure the ECU tightly to prevent the unit from becom-ing loose due to road

vibration. See Fig 25.

4) The ECU provides 12 inches of cable built into the ECU. In order to connect

the Sensors to the ECU, four (4) exten-sion cables have been provided (see

Fig 26). Securely fasten these extension cables to the vehicle using cable

ties, drilling holes, using existing pathways or using the frame of the vehicle.

Securely tighten the watertight extension cables, to both the ECU and the

Sensors, to the same numbered ECU cable connectors labeled S1, S2, S3 &

S4., from left to right.

5) Powering the ECU will vary depending on Wired or Wireless and the

vehicle itself. NOTE: RVS recom-mends the connections to be soldered and

covered with heat shrink tubing. If you choose to use a crimp, please ensure

the crimp is of the correct size to t both the wire gauge sizes

of the RVS product and the existing vehicle wiring.

ECU Installation (Specic to Wired Systems)

When installing the ECU with a wired system, the ECU will obtain power

from the Monitor’s power connection in the cab of the vehicle, typically a

reverse +12VDC. Installation will require an included extension cable to be

MONITOR SPECIFICATIONS

ran the length of the vehicle’s body, which will then plug into the ECU and

provide power to the ECU and Sensors.

ECU Installation (Specic to Wireless Systems on Trailers)

When installing the ECU on cargo trailers, the above procedure is the same

except for the source of power. Many box trailers do not have reversing lights

to power the ECU when backing up. In which case the ECU can be powered

22

Rear View Safety

Page 23

by a continuous source such as the running lights or ABS system and the Monitor will be powered o of a reverse +12VDC in the cab, to ensure operation

while in reverse.

Monitor Installation

1) Mount the LED Monitor in a location that is easily viewed by the driver

using the enclosed Double Sided Adhesive Pad.

2) If Wireless, connect the LED Monitor power cable (red wire) to +12VDC

and the ground (black wire) to the vehicle electrical ground. The +12VDC

could come from ignition, the battery or the fuse panel. The Monitor is typically powered constantly, due to the ECU being powered while in reverse. With

this method of installation, the Monitor will remain dormant, with a blank

screen, until the ECU sends information to the Monitor.

3) If Wired, connect the Monitor/systems power connection to a +12VDC

source that’s on only while in reverse, to prevent constant beeping and distance indication.

Monitor Function Setup

A) Adjusting Volume: The Volume Switch is

located on the top of the Monitor. Adjust the

alarm volume at one of 3 levels: High, Low or

MONITOR INSTALLATION

O (refer to Fig 27).

B) Setting Metric or Feet: By pushing the

Setting Button twice, the distance can be

displayed either in meters or in feet.

C) Truck & Trailer Exchange (Wireless Only):

Reverse With Condence ™

Fig 27: Monitor Switch

& Button

23

Page 24

This function is designed for vehicles which may work with a multitude of

trailers. The Monitor works with the ECU as a default setting, however, when

the Monitor of the vehicle has to work with another set of ECU/

Sensors (installed in another trailer), you must Fig 27: Monitor Switch &

Button sync to the new ECU and Sensors by pressing and holding the Setting

Button when the reverse gear is engaged (or however the ECU is powered),

until the Monitor shows the ECU ID number, then let go.

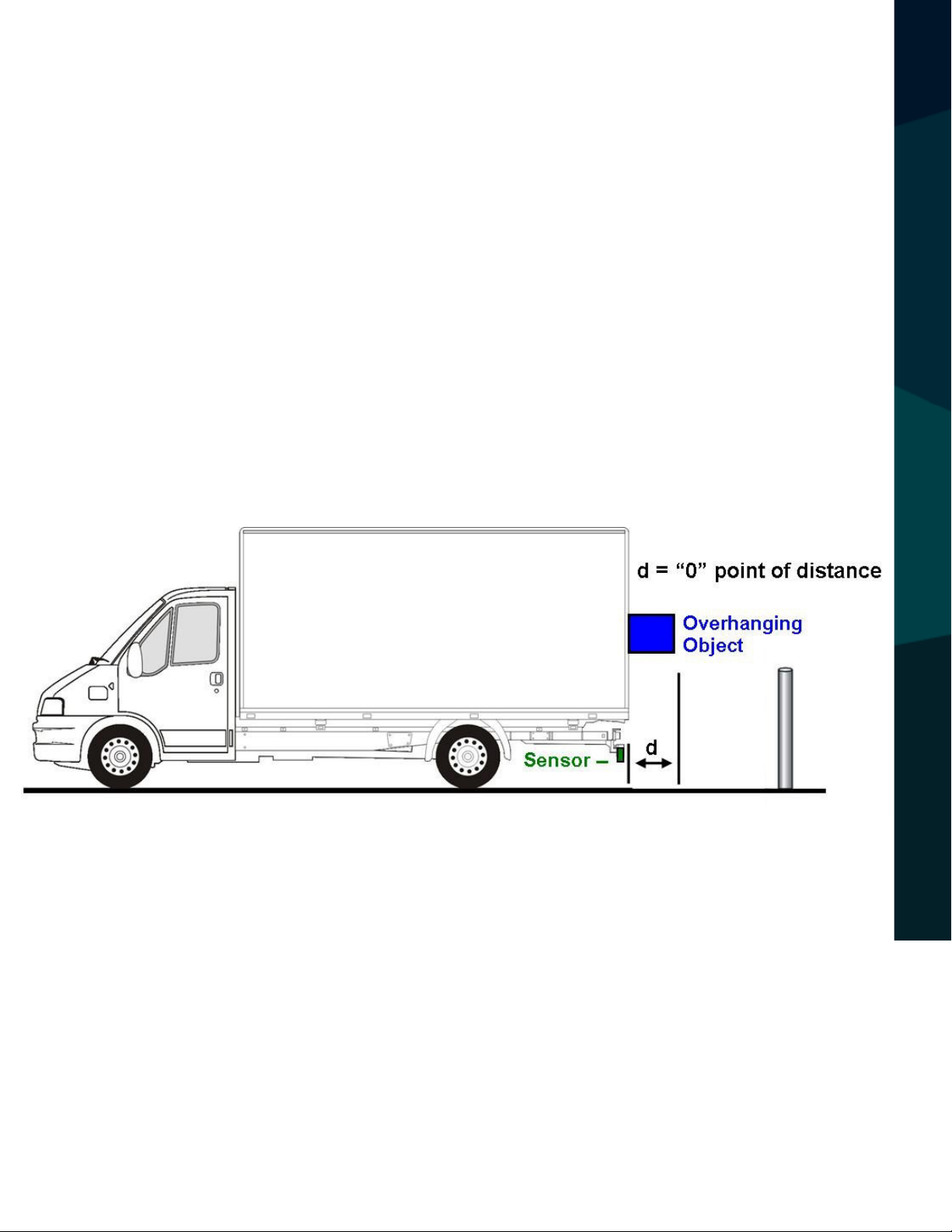

D) Understanding Stop-line Adjustment: This function is designed for

adjusting the stop line of the obstacle detection system. Obstacle Sensor

systems usually report the distance from the bumper to obstacles, so the

bumper or exactly the Sensor surface is the “0” point of distance (indicated as

"d" in Fig 28). With this function, the so-called “0” point itself can be extended from 0 (zero) up to 31 inches (0.8m), enabling you to change the stop line

accordingly. In some circumstances, for instance, when the vehicle has a rear

carrier or similar item, the “0” point should be extended. By doing so, the

Sensor system doesn’t report the carrier, but reports the accurate distance

from the obstacle to the carrier, instead of to the bumper. See the following

procedure for setting the Stop-line Adjustment.

Setting Stop-line Adjustment

SETTING STOP-LINE ADJUSTMENT

A) Press and hold Setting Button, before and while turning the vehicle key

to the ACC position. In 3 seconds, the warning unit will indicate the numeric

value of the previous “0” point of distance.

B) Each time you press the button, the displayed “0” point of distance (d)

increases by 1”, up to 35” (0.01m, up to 0.8m), and then starts at 0 (zero) again.

However if you press and hold the button for about 2 seconds, the value will

increase automatically, hold the button until the value reaches the desired

24

Rear View Safety

Page 25

corrected distance and ne tune as needed. Refer to Fig 28 below for further

clarication.

C) After the button is released, wait for 5 seconds, the new value will be effective automatically.

NOTE: Be aware that the Stop-line Adjustment remains as programmed

and does not re-set automatically. Stop-line Adjustment does not prevent the sensor from detecting an object. If the sensor is detecting

the overhanging object, it will continue to do so after

Stop-line Adjustment.

INSTALLATION TEST (IN ORDER SHOWN)

Fig 28: Stop-line Adjustment

Installation Test (in order shown)

A) Initial Test: With the vehicle in park and your foot on the brake, shift the

vehi-cle into reverse. The display (which remains blank at all other times) will

turn on and begin the Automatic Self-Test. It will be helpful to have an observer assist you in testing the unit the rst time by having them carefully walk

Reverse With Condence ™

25

Page 26

behind the vehicle. When doing so, each of the individual four (4) Sensor icons

will indicate (by ashing) when the assistant is closet to a particular Sensor.

The distance in feet and inches will also indicate when the individual is within

8 feet of a Sensor.

B) Volume Adjustment: Slide the Volume Switch (found on top of the LED

Moni-tor) to preferably the “High” volume setting in order to make sure it is

suciently loud.

C) Backing Test: Once the above is completed, test the system by placing

the vehicle in reverse with nothing behind it for at least 8 feet. The LED Monitor will turn on and run a Self-Test (see Automatic Self-Test under Systems

Operation). Once completed (takes about 2 seconds), the icon and distance

measurement will not display since no object is within 8 feet of the Sensors.

Begin backing up and as soon as an object is detected the Sensor icons and

distance measurement will appear on the LED Monitor. One of the four (4)

Sensor icons will be ashing (the one that is closest to an object) and the distance to that object is displayed as well.

NOTE: Audibly indicates only when an object is within 5’7” of Sensor 2 & 3

(two center Sensors) and 3’3” inches of Sensor 1 & 4 (two outer Sensors).

SYSTEM OPERATION

System Operation

A) Automatic Self-Test: Whenever the system is enabled (by placing the

vehicle in reverse), it will perform a self-test. Any Sensors that are blocked or

inoperable will display an error message denoted by E1, E2, E3 or E4 (Sensors

numbered left to right facing the back of the vehicle). After the self-test, the

system will automatically remove the icon display of any inoperable Sensor(s)

26

Rear View Safety

Page 27

and begin operating (even when a Sensor is malfunctioning). For example, if E4

were malfunctioning, the re-maining three Sensors would be displayed.

B) Inoperable Sensor: If any of the Sensor icons are not displayed, attend to

the repair of that Sensor immediately. In the case of an inoperable Sensor, do

not back up without walking around the vehicle rst and proceed with extreme

caution.

C) Blocked Sensor: Carefully remove any snow, ice or dirt that may have built

up on an inoperable Sensor. When placed in reverse the system will retest the

Sensors indicating if the problem still exists.

D) Minimum Detection Distance: The minimum detection and display distance is 8.7 inches (22cm); a person (or an object) can be detected most reliably

within 67 inches (1.7M) behind the vehicle or less.

E) Relative Accuracy: The display indicates the distance with 1.0 inch accuracy and shows the relative location of the obstacle (4 zones). For example, if

there is an object within range of the left side rear of the vehicle, the S1 icon

will indicate by ashing and displaying the distance in feet and inches. If the

object is moving to the right, the display will adjust in real time to indicate this

movement.

F) Detection Range: The middle Sensors (S2 & S3) start audible warning from

67 inches (1.7M); the corner Sensors (S1 & S4) start audible alarm at 39 inches

(1.0M).

SYSTEM OPERATION

CAUTION: The system will never alert you to any obstacles behind a malfunctioning Sensor; the icon for that Sensor will not be displayed on the Monitor.

Reverse With Condence ™

27

Page 28

ONE YEAR WARRANTY

REAR VIEW SAFETY, INC. WARRANTS THIS PRODUCT AGAINST MATERIAL DEFECTS FOR A

PERIOD OF ONE YEAR FROM DATE OF PURCHASE. WE RESERVE THE RIGHT TO REPAIR OR

REPLACE ANY SUCH DEFECTIVE UNIT AT OUR SOLE DISCRETION. REAR VIEW SAFETY, INC.

IS NOT RESPONSIBLE FOR A DEFECT IN THE SYSTEM AS A RESULT OF MISUSE, IMPROPER

INSTALLATION, DAMAGE OR MISHANDLING OF THE ELECTRONIC COMPONENTS. REAR VIEW

SAFETY, INC. IS NOT RESPONSIBLE FOR CONSEQUENTIAL DAMAGES OF ANY KIND.

THIS WARRANTY IS VOID IF: DEFECTS IN MATERIALS OR WORKMANSHIP OR DAMAGES

RESULT FROM REPAIRS OR ALTERATIONS WHICH HAVE BEEN MADE OR ATTEMPTED BY

OTHERS OR THE UNAUTHORIZED USE OF NONCONFORMING PARTS; THE DAMAGE IS DUE

TO NORMAL WEAR AND TEAR, THIS DAMAGE IS DUE TO ABUSE, IMPROPER MAINTENANCE,

NEGLECT OR ACCIDENT; OR THE DAMAGE IS DUE TO USE OF THE REAR VIEW SAFETY, INC.

SYSTEM AFTER PARTIAL FAILURE OR USE WITH IMPROPER ACCESSORIES.

WARRANTY PERFORMANCE

DURING THE ABOVE WARRANTY PERIOD, SHOULD YOUR REAR VIEW SAFETY PRODUCT

EXHIBIT A DEFECT IN MATERIAL OR WORKMANSHIP, SUCH DEFECT WILL BE REPAIRED WHEN

THE COMPLETE REAR VIEW SAFETY, INC. PRODUCT IS RETURNED, POSTAGE PREPAID AND

INSURED, TO REAR VIEW SAFETY, INC. OTHER THAN THE POSTAGE AND INSURANCE

REQUIREMENT, NO CHARGE WILL BE MADE FOR REPAIRS COVERED BY THIS WARRANTY.

WARRANTY DISCLAIMERS

NO WARRANTY, ORAL OR WRITTEN, EXPRESSED OR IMPLIED, OTHER THE ABOVE WARRANTY

IS MADE WITH REGARD TO THIS REAR VIEW SAFETY, INC. REAR VIEW SAFETY, INC. DISCLAIMS

WARRANTY

ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE OR

PURPOSE AND ALL OTHER WARRANTIES IN NO EVENT SHALL REAR VIEW SAFETY. INC.

LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL, OR PUNITIVE DAMAGES OR FOR

ANY COSTS, ATTORNEY FEES, EXPENSES, LOSSES OR DELAYS ALLEGED TO BE AS A

CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN ANY PRODUCT INCLUDING,

BUT NOT LIMITED TO, ANY CLAIMS FOR LOSS OF PROFITS.

28

Rear View Safety

Page 29

DISCLAIMER

REAR VIEW SAFETY AND/OR ITS AFFILIATES DOES NOT GUARANTEE OR PROMISE THAT THE

USER OF OUR SYSTEMS WILL NOT BE IN/PART OF AN ACCIDENT OR OTHERWISE NOT COLLIDE

WITH AN OBJECT AND/OR PERSON. OUR SYSTEMS ARE NOT A SUBSTITUTE FOR CAREFUL

AND CAUTIOUS DRIVING OR FOR THE CONSISTENT ADHERENCE TO ALL APPLICABLE TRAFFIC

LAWS AND MOTOR VEHICLE SAFETY REGULATIONS. THE REAR VIEW SAFETY PRODUCTS ARE

NOT A SUBSTITUTE FOR REARVIEW MIRRORS OR FOR ANY OTHER MOTOR VEHICLE

EQUIPMENT MANDATED BY LAW. OUR CAMERA SYSTEMS HAVE A LIMITED FIELD OF VISION

AND DO NOT PROVIDE A COMPREHENSIVE VIEW OF THE REAR OR SIDE AREA OF THE VEHICLE.

ALWAYS MAKE SURE TO LOOK AROUND YOUR VEHICLE AND USE YOUR MIRRORS TO CONFIRM

REARWARD CLEARANCE AND THAT YOUR VEHICLE CAN MANEUVER SAFELY. REAR VIEW

SAFETY AND/OR ITS AFFILIATES SHALL HAVE NO RESPONSIBILITY OR LIABILITY

FOR DAMAGE AND/OR INJURY RESULTING FROM ACCIDENTS OCCURRING WITH VEHICLES

HAVING SOME OF REAR VIEW SAFETY PRODUCTS INSTALLED AND REAR VIEW SAFETY AND/

OR ITS AFFILIATES, THE MANUFACTURER, DISTRIBUTOR AND SELLER SHALL NOT BE LIABLE

FOR ANY INJURY, LOSS OR DAMAGE, INCIDENTAL OR CONSEQUENTIAL, ARISING OUT OF THE

USE OR INTENDED USE OF THE PRODUCT. IN NO EVENT SHALL REAR VIEW SAFETY AND/OR

ITS AFFILIATES HAVE ANY LIABILITY FOR ANY LOSSES WHETHER DIRECT OR INDIRECT, IN

CONTRACT, TORT OR OTHERWISE INCURRED IN CONNECTION WITH THE SYSTEMS,

INCLUDING BUT NOT LIMITED TO DAMAGED PROPERTY, PERSONAL INJURY AND/OR LOSS OF

LIFE. NEITHER SHALL REAR VIEW SAFETY AND/OR ITS AFFILIATES HAVE ANY

RESPONSIBILITY FOR ANY DECISION, ACTION OR INACTION TAKEN BY ANY PERSON IN

RELIANCE ON REAR VIEW SAFETY SYSTEMS, OR FOR ANY DELAYS, INACCURACIES AND/OR

ERRORS IN CONNECTION WITH OUR SYSTEMS FUNCTIONS.

DISCLAIMER

Reverse With Condence ™

29

Page 30

If you have any questions

about this product, contact:

Rear View Safety, Inc.

1797 Atlantic Avenue

Brooklyn, NY 11233

800.764.1028

30

Better Cameras. Better Service.

IT’S OUR GUARANTEE.

Rear View Safety

Loading...

Loading...