Russell XN050MA44A, X024LE44D Installation Manual

Apex Packaged

INSTALLATION AND

Refrigeration System

MAINTENANCE MANUAL

Publication IOM H900.1

January, 2009

Table of Contents

Inspection 1

Unit Placement Requirements 2

Installation Instruction 2

Before Unit Start-Up 3

After Start-Up 3

Clearances and Unit Placement 4

Unit Weights 5

Cabinet Footprint 5

Maintenance 6

Sequence of Operation 6

Electronic Controller Operation 7-10

Controller Parameters and Settings 11 - 12

Electrical Wiring Diagrams 13 - 19

Replacement Parts 20

Troubleshooting Guide 21

Warranty 22

Inspection

When the equipment is received, check the quantity of cartons and crates against the bill of lading. Inspect all containers for

visible damage. Report any damage or shortages to the freight company immediately. It is the customers

responsibility to file all claims with the freight company.

Do not return damaged equipment to the factory without prior approval. A returned material authorization (RMA) is

required.

ITEMS RETURNED WITHOUT AN RMA LABEL WILL BE REFUSED!

201 Thomas French Dr., Scottsboro, AL 35769 • Tel: (256) 259 -7400 • Fax: (256) 259 -7474

Part # 08499055

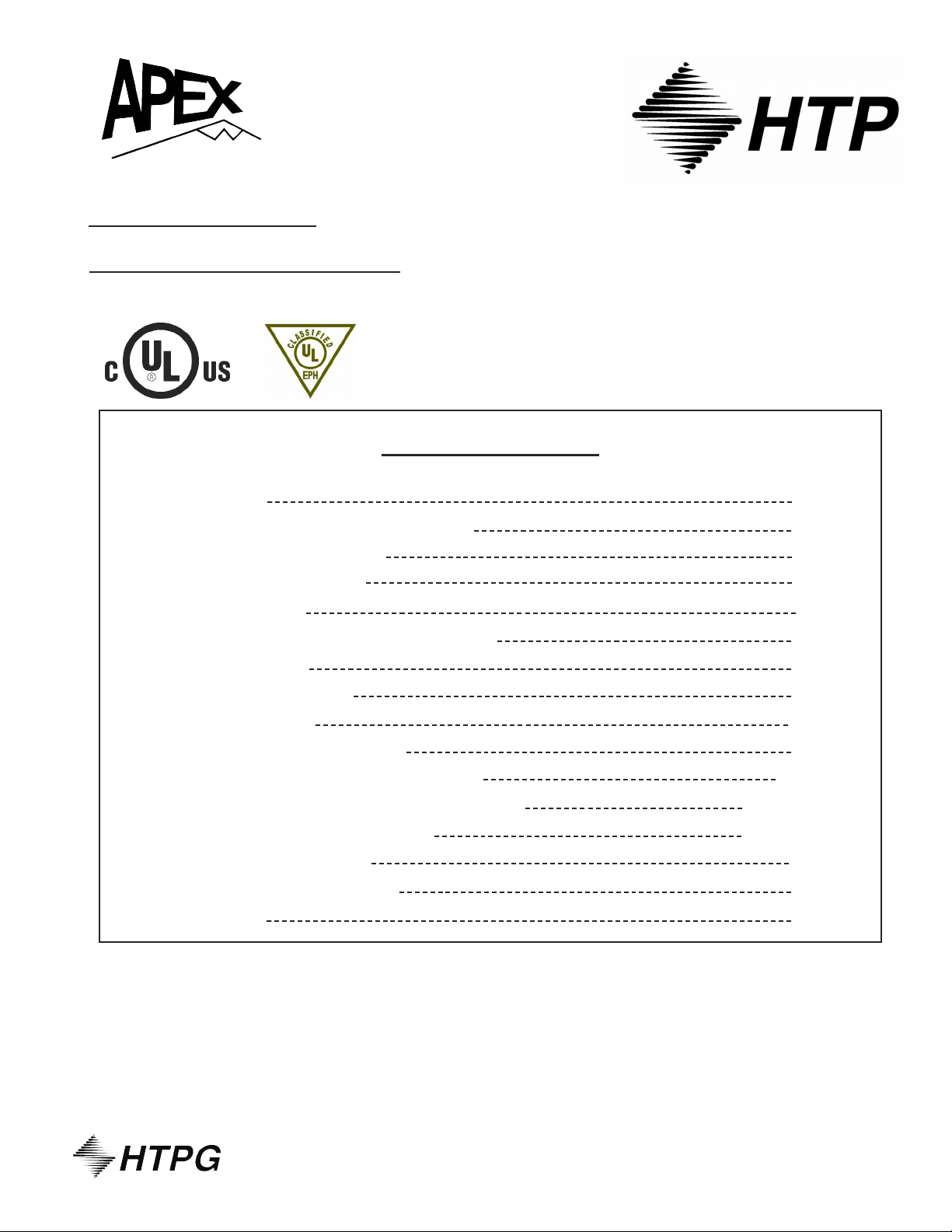

Unit Placement Requirements

ee Figures and Weight tables on pages 4 & 5, and follow these guidelines:

S

1. Make sure that the structural integrity of the box can withstand the weight of the unit(s).

2. Do not remove the shipping skid from the unit until it is ready to be lifted into place on top

of the walk-in.

3. Do not locate the evaporator section of the unit over a door.

4. The unit supply air pattern must cover the entire walk-in.

5. Leave one unit width between sides of unit and walls. Leave two unit widths between units.

6. Provide adequate space at the compressor compartment end of the unit and a minimum of

two feet above the unit for servicing.

7. Adequate airflow must be available for condenser. Do not shield the Apex unit, use top of walk-in for

storage or install the Apex unit in a non-ventilated space. Lack of attention to this detail will cause poor

performance and possibly unit failure.

8. Do not locate unit in the area of steam, hot air or fume exhausts.

9. Indoor units are designed for use in areas that range in temperature from 50°F to 110°F.

10. Indoor units are not designed for outdoor installation.

11. Do not install units in noise sensitive areas. Units must be properly supported to prevent

excessive noise and vibration.

12. Installations that do not conform to all of the requirements in this manual will void the unit

warranty.

Installation Instructions

General

Installation and maintenance are to be performed by qualified personnel who are familiar with local codes and

regulations. Installers should have previous experience with commercial refrigeration equipment.

CAUTION: Avoid contact with sharp edges and coil surfaces. They are potential hazards.

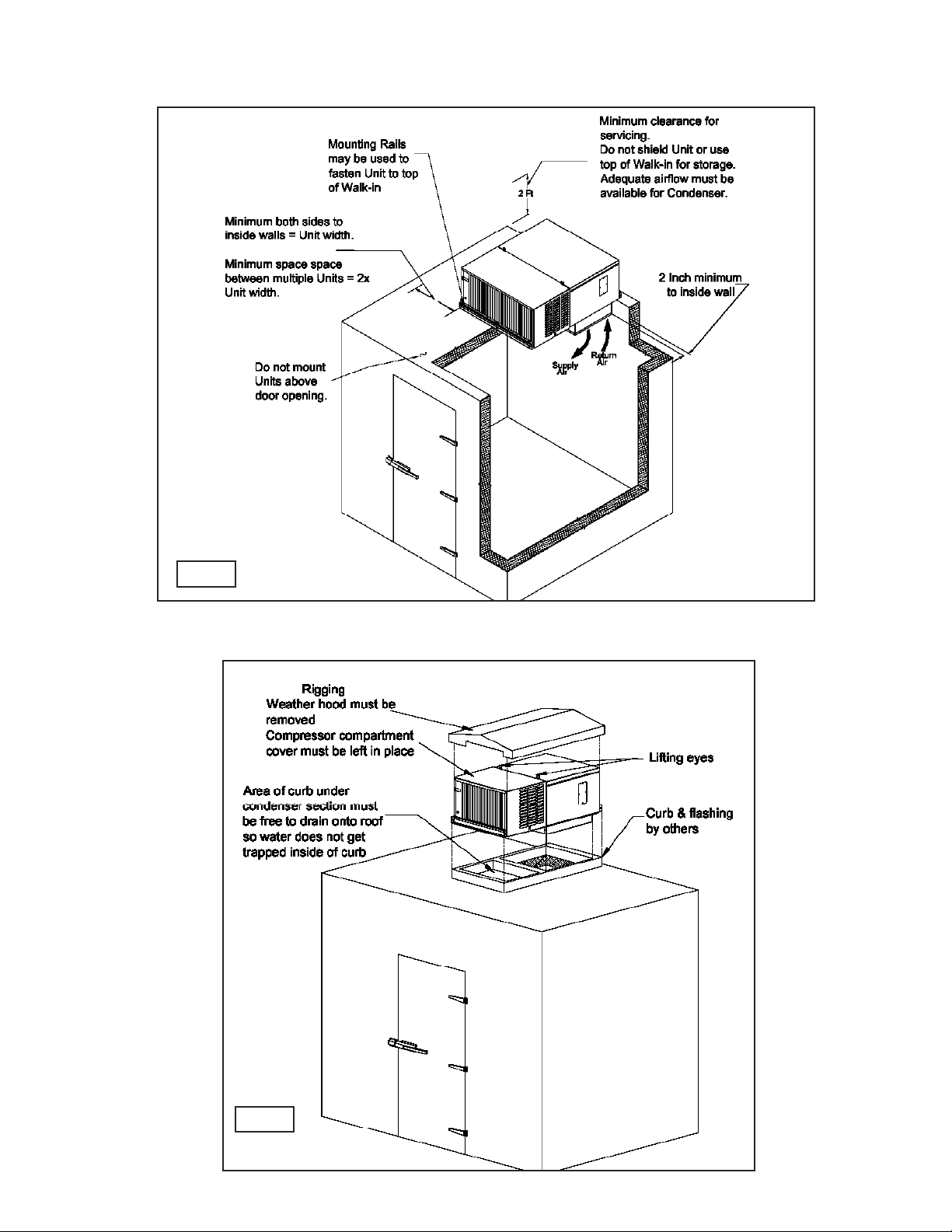

Small cabinet units can be set in place by hand. Medium and large cabinet units have lifting eyes. Use a

spreader bar when rigging to prevent damage to and undo stress on the unit cabinet. Remove the weather

hood from outdoor units. IMPORTANT: The compressor compartment cover must be left on units when

lifting using the lifting eyes.

Indoor Models

1. Inspect packaging for shipping damage. Open package and inspect unit for concealed damage.

2. Follow Figure 1 requirements on page 4.

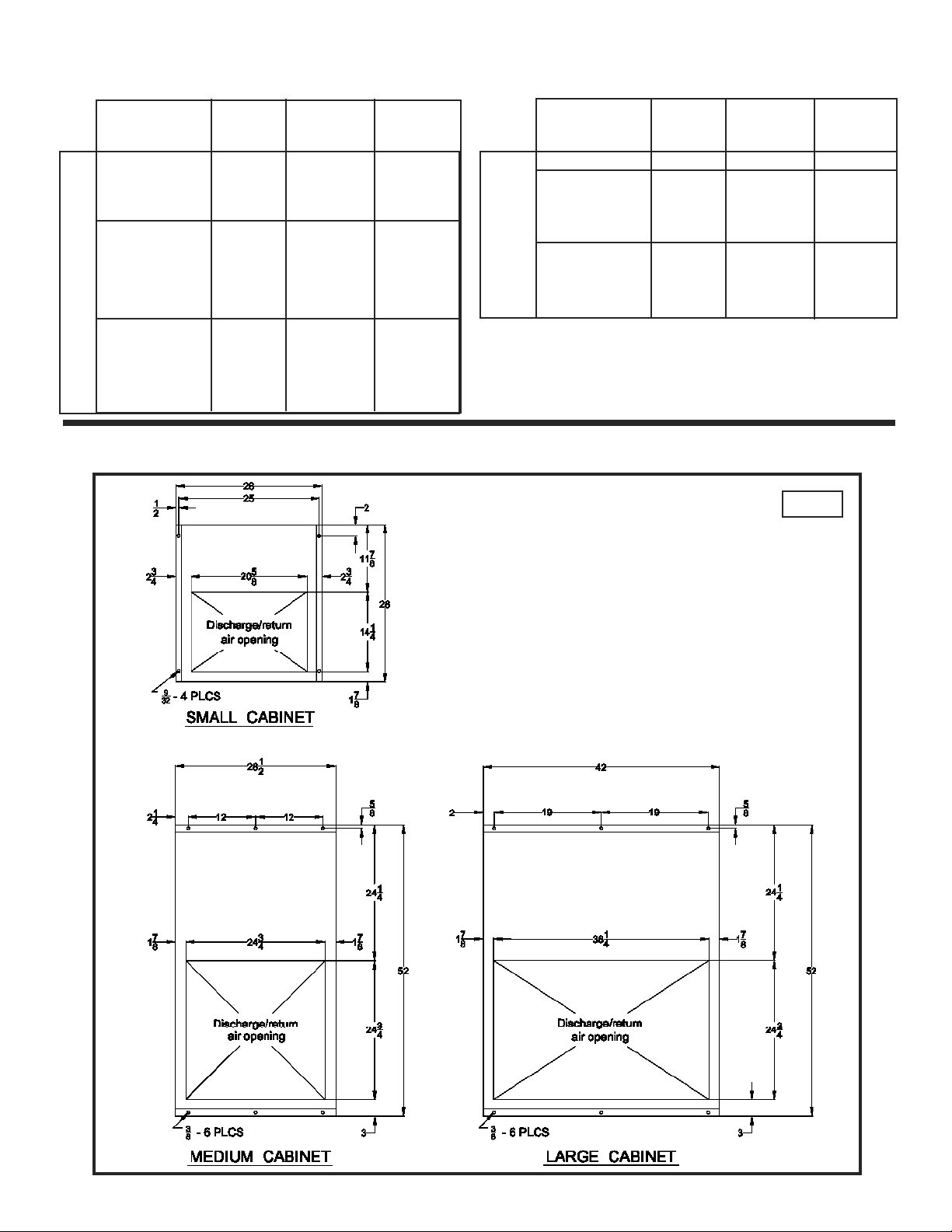

3. Cut a finished opening in the box ceiling to the dimensions shown in the footprint drawings

on page 5. Make sure that the top with the cut-out has the structural integrity to hold the unit.

See table on page 5 for unit weights.

4. Make sure that the surface of the box is clean where the unit gasket will seal around the

opening.

5. Refer to the walk-in box manufacturer's instructions for any procedures that may be necessary

to ensure the integrity of the exposed foam in the panels.

6. Make sure the unit is mounted level - no more than 1/8 inch drop per foot.

7. Place the unit into the provided opening with the evaporator air flow directed toward the door

(See Figure 1 on page 4). Be careful not to damage the grill during installation.

8. Make sure that the condenser air flow is not obstructed.

9. On indoor units, condensate is evaporated by a discharge line loop run through the drain pan

under the compressor, so a drain line is not required.

10. Install the trim pieces around the inside opening.

2

Outdoor Models

Installation is the same as indoor models except as follows:

1. Units must be curb mounted (curb provided by others). To help with curb sizing, see Figure 3 on

page 5 which shows unit footprint dimensions for each cabinet size. (Only medium and large

cabinet units are available for outdoor use.)

2. Make sure curb is level and properly flashed to prevent water leakage into walk-in.

3. Water from rain or snow may get into compressor section of unit. Make sure the curb under this part of

unit is designed with openings so water will not collect inside the curbing.

4. The condensate drain outlet is located on the side of the unit. Field piping may be connected to

the outlet provided it is adequately sloped and heated to prevent freezing, where necessary. The

drain line in the unit is trapped and heated.

5. After connecting electrical power (see Before Unit Start-up), install compressor compartment cover and

weather hood.

Before Unit Start-up

1. Check all mechanical and electrical connections for looseness developed during transit and

tighten as necessary.

2. Adhere to all applicable building and electrical codes when wiring unit.

3. Make sure supply power is correct voltage and phase for unit and is fused properly.

4. If unit is supplied with a power cord, plug unit into power supply.

IMPORTANT:

Do not use extension cords to connect unit to power.

Plug-in to grounded three prong outlet.

Do not remove grounding prong.

Do not use a power adapter.

5. If unit is not supplied with a cord, hard wire to power supply.

After Start-up

1. To protect the compressor (in the event of a brief power interruption), the electronic controller is pro-

grammed for a five minute start-up time delay.

2. See Electronic Controller Operation section to set box temperature (factory settings are 35ºF for coolers

and -10ºF for freezers), and change any control parameters that may have to be changed to fit the appli-

cation. Basic parameters are factory set as follows:

a. Time between defrosts • 6 hours.

b. Defrost termination temperature • 40°F Coolers, 50°F Freezers.

c. Maximum defrost duration before defrost is terminated by time • 50 minutes.

3. Timing for defrosts starts when unit is started, so as set from factory, defrost will occur 6 hours

after start-up and every 6 hours thereafter.

4. Unit defrosting operation should be checked after start-up and periodically thereafter. The

amount and pattern of frosting can vary greatly. Frost build-up is dependent on the temperature

of the room, the type of product being stored, how often new product is brought into the room

and percentage of time the door to the room is open. It may be necessary to periodically change

the number of defrost cycles or adjust the duration of defrost.

3

Clearances and Unit Placement

FIG. 1

Outdoor Rigging

FIG. 2

4

Unit Weights

C

O

O

L

E

R

U

N

I

T

S

Model Number

XN026MA**A*

XN029MA**A*

XN037MA**A*

XN050MA**A*

X*050MA**D*

X*068MA**D*

X*076MA**D*

X*106MA**D*

X*106MA**E*

X*134MA**D*

X*134MA**E*

Cabinet

Size

Small

Small

Small

Medium

Medium

Medium

Medium

Large

Large

Large

Large

INDOOR

NET/SHIP

WT. (lbs.)

120 / 185

120 / 185

125 / 190

210 / 305

210 / 305

220 / 315

220 / 315

295 / 420

305 / 430

310 / 435

310 / 435

OUTDOOR

NET/SHIP

WT. (lbs.)

__

__

__

__

220 / 360

230 / 370

230 / 370

310 / 485

320 / 495

325 / 500

325 / 500

F

R

U

E

N

E

I

Z

T

E

S

R

Cabinet Footprints

Model Number

XN018LE44A*

XN024LE44A*

X*024LE44D*

X*031LE44D*

X*043LE44D*

X*051LE44D*

X*051LE44E*

X*068LE44D*

X*068LE44E*

Cabinet

Size

Small

Medium

Medium

Medium

Medium

Large

Large

Large

Large

INDOOR

NET/SHIP

WT. (lbs.)

140 / 200

210 / 305

210 / 305

245 / 340

245 / 340

315 / 445

315 / 445

320 / 450

320 / 450

OUTDOOR

NET/SHIP

WT. (lbs.)

__

__

225 / 365

255 / 400

255 / 400

330 / 510

330 / 510

335 / 515

335 / 515

FIG. 3

Note:

All dimensions are in inches.

5

Maintenance

The following items should be checked every six months. Make sure all power is shut off to unit before performing any maintenance or service.

1. Tighten all electrical connections.

2. Check all wiring and insulators.

3. Check contactor for proper operation.

4. Check all fan motors. Tighten motor mount screws/nuts and fan set screws.

5. Clean the condenser and evaporator coil surfaces.

CAUTION: Avoid contact with sharp edges and coil surfaces. They are potential hazards.

6. Check the operation of the control system. Make sure all safety controls are operating properly.

7. Make sure evaporator is defrosting properly. See item 4 under "After Start-up".

8. Clean the drain pan and drain lines. Check the drain pan and drain line for proper drainage.

On outdoor units make sure the crankcase and drain line heaters, and thermostat are functioning properly.

9.

Sequence of Operation

Coolers

1. When power is supplied to the unit, the compressor, condenser motor(s) and evaporator

motor(s) will run until the box temperature setting is reached.

2. When the box temperature setting is reached, the compressor and condenser motor(s) shut off but

the evaporator motor(s) continue to run. This will provide an off-cycle defrost of the evaporator coil.

3. When the box temperature rises above the set point and the minimum compressor off-time has

elapsed, the compressor and condenser motor(s) will be re-energized.

4. When a defrost is initiated, as set by the electronic controller parameters, the compressor and condenser

motor(s) are shut off until the defrost sensor reaches the termination temperature.

5. Indoor units are not furnished with crankcase heaters, drain line heaters or condenser fan cycling

controls.

Freezers

1. When power is supplied to the unit, the compressor, condenser motor(s) and evaporator motor(s) will run

until the box temperature setting is reached. For outdoor units, depending on the ambient temperature,

condenser fan motor(s) may be off.

2. When the box temperature setting is reached, the compressor and condenser motor(s) shut off

but the evaporator motors continue to run.

3. When the box temperature rises above the set point and the minimum compressor off-time has

elapsed, the compressor and condenser motor(s) will be re-energized.

4. When a defrost is initiated, as set by the electronic controller parameters, the compressor, condenser

motor(s), and evaporator motor(s) are shut off and the defrost heaters are energized.

5. The unit will stay in defrost until the defrost sensor reaches the termination temperature, then

the defrost heaters will de-energized and the unit will go into the drip mode as set on the controller (see

parameter dd).

6

6. After the drip time, the compressor and condenser motor(s) start but the evaporator motor(s) stay off until

defrost sensor reaches the controller parameter settings.

(see parameters F0, F1 & A0)

7. Then the refrigeration cycle is resumed.

ELECTRONIC CONTROLLER OPERATION

The electronic controller controls all of the functions of the APEX system. The following paragraphs explain the

operation of the controller and how to change the settings of the controller parameters. Table 1 shows a listing

of parameteres and settings.

CONTROLLER DISPLAY

During normal operating conditions, the display shows the value measured by the box temperature probe. In

case of an active alarm, the temperature flashes alternately with the alarm code.

LED INDICATIONS ON DISPLAY

Compressor icon illuminated indicates compressor ON

or

Compressor icon flashing indicates compressor in

a time delay status.

Defrost icon illuminated indicates unit in defrost.

Alarm icon illuminated indicates the presence of

an alarm.

7

Loading...

Loading...