Russell VC20M44 User Manual

V Series

Air Cooled

Condensing Units

20 to 80 HP

Brochure 520.8

February, 2007

MEA

3050 Enterprise St. • P.O. Box 1030 • Brea, CA 92822-1030 • Tel (714) 529-1935 • FAX (714) 529-7203 www.russellcoil.com

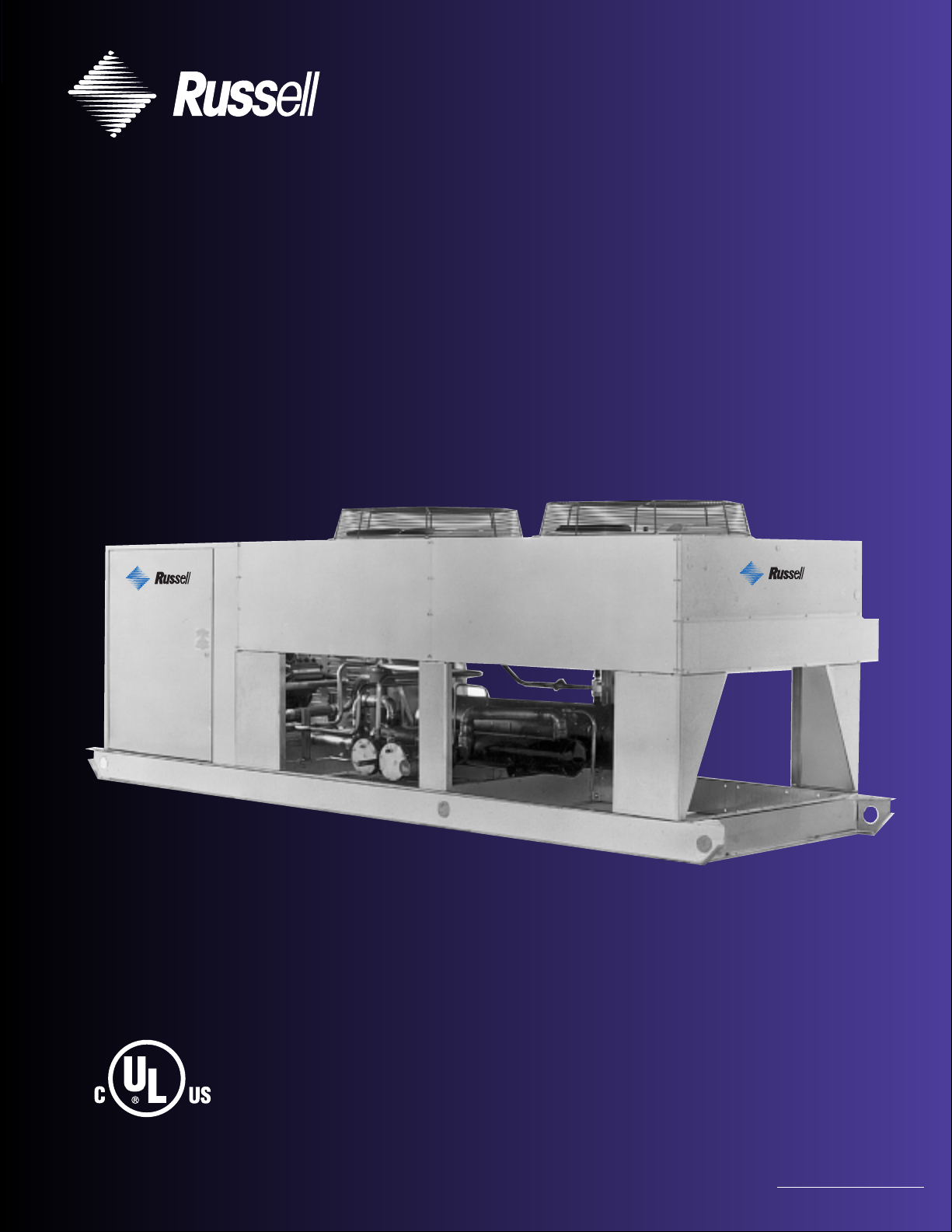

The outdoor housing of the

unit has been re-engineered.

Removing only a few screws

allows complete removal of

the compressor housing top

panel, side panel and corner

post. This gives the mechanic

quick, unrestricted access to

the compressor, all controls

and components located

within the compressor

compartment. Or, just a

single panel can be removed,

depending on the requirements

of the service call.

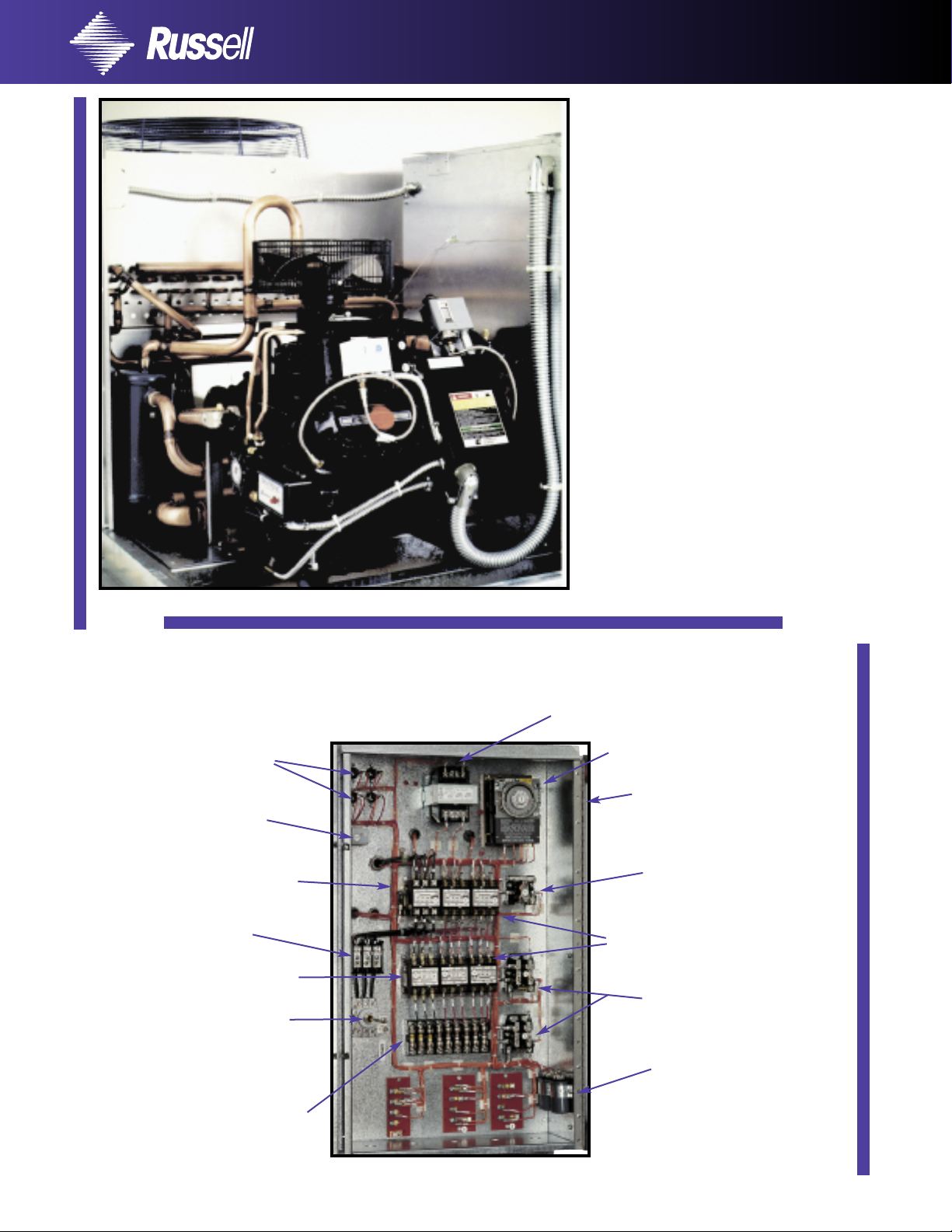

The large control panel has abundant space for the controls you choose. The components are intelligently

arranged and laid out in a logical fashion which is easy to understand and work with. Each control and wire is

clearly marked with a name or number as shown on the wiring diagram which is permanently affixed to the

control panel door.

CONTROL VOLTAGE TRANSFORMER

CONTROL CIRCUIT FUSES

RUSSAVER PRESSURE CONTROL*

COMPRESSOR CONTACTOR

POWER TERMINAL BLOCK

EVAP FAN MOTOR CONTACTOR*

NON-FUSED DISCONNECT SWITCH*

EVAPORATOR

FAN AND HEATER SUB-CIRCUIT FUSING*

DEFROST CLOCK*

HINGED DOOR

BLOCK OUT RELAY*

EVAPORATOR DEFROST CONTACTORS*

EVAPORATOR SEQUENCING

RELAYS*

CONDENSER FAN

MOTOR CAPACITORS

* OPTIONAL ITEMS, SEE PAGE 3

2 15

MODEL NUMBER NOMENCLATURE

V C D 31 L 22

STYLE CONDENSING UNIT REFRIGERANT TYPE

V

22 = R22

FEATURES PACKAGE 44 = R404A / R507

C = Std. piping, Fan cycle control 34 = R134a

L = Std. piping, Flooded control 52 = R502

S = Russ-Saver package

TEMP. RANGE

COMPRESSOR TYPE L= Low temp.

B = Bitzer* M = Medium temp.

C = Carlyle* H = High temp.

D = Copeland Discus

S = Special* NOMINAL H.P.**

V Series

NOMINAL COMPRESSOR HP

SINGLE PARALLEL DUAL

COMP.

20HP 17(2) 7.5 HP 18 (2) 7.5 HP

25HP 21 (2) 10HP 23 (2) 10HP

7HP 24 (2) 12HP 26 (2) 12HP

2

30HP 31 (2) 15HP 32 (2) 15HP

35HP 41 (2) 20HP 42 (2) 20HP

40HP 44 (2) 22HP 46 (2) 22HP

50HP 51 (2) 25HP 52 (2) 25HP

60HP 54 (2) 27HP 56 (2) 27HP

PIPING PIPING

61 (2) 30HP 62 (2) 30HP

71 (2) 35HP 72 (2) 35HP

81 (2) 40HP 82 (2) 40HP

ELECTRICAL

COMPONENTS

CONDENSER

PIPING

COMPONENTS

RECEIVER

HOUSING

LOW AMBIENT

CONTROLS

TESTING

FEATURES AT A GLANCE

Crankcase heater STD STD STD

Oil failure control STD STD STD

High - Low pressure control - manual(high)/automatic(low) reset STD STD STD

Compressor contactor STD STD STD

Control circuit fuses - standard 230/1 STD STD STD

Power terminal block STD STD STD

Copper tubes with Aluminum fins STD STD STD

Subcooling circuit STD STD STD

Fan motor - PSC overload protection STD STD STD

Fan blade - individually balanced STD STD STD

Fan guard - heavy duty resilient wire basket STD STD STD

Suction line vibration eliminator STD STD STD

Replaceable core liquid line filter / drier STD STD STD

Suction line filter (replaceable core some models) STD STD STD

Discharge line vibration eliminator STD STD STD

High Pressure control hoses STD STD STD

Inlet and outlet isolation valves STD STD STD

Pressure relief valve STD STD STD

Mill galvanized steel with removable access panels STD STD STD

Control panel with hinged door STD STD STD

Heavy galvanized steel base rails STD STD STD

Pressure fan cycling control STD STD N/A

Flooded condenser N/A STD N/A

Russ-Saver — All ambient energy saver N/A N/A STD

UL / CUL listed — all models STD STD STD

Leak detection, dielectric and run tests STD STD STD

Dry nitrogen holding charge STD STD STD

MODEL

VC VL VS

OPTIONS: 4 Year extended compressor warranty Hot Gas defrost components

Air defrost time clock Liquid line solenoid valve

Compressor unloading Oil Separator

Copper or coated condenser fins Crankcase pressure regulator

Electric defrost components Sentronic oil safety control

Evaporator sub circuit fusing Stainless steel superhoses

Fused or non fused disconnect Suction accumulator

Heated and insulated receiver— not UL

* Contact factory for details.

RUSS-SAVER

The initial cost of quality refrigeration equipment is a substantial investment. But the costs of

installation and operation are also formidable. Rising to the challenge, Russell engineers

have designed the RUSS-SAVER system to meet the highest standards of performance and

reliability while effectively addressing the problem of these profit draining costs.

· REDUCED INSTALLATION COSTS

The installation of a refrigeration system which uses RUSS-SAVER requires a smaller refrigerant charge than equipment which uses other types of low ambient controls. As the more

expensive zero ozone depleting refrigerants become the refrigerants of choice, the reduced

charge requirements provided by RUSS-SAVER affords

saving benefits.

substantial and immediate cost

· REDUCED OPERATING COSTS

The most expensive part of an

the compressor. Day and night, year after year, the cost of electricity to operate your equipment is unrelenting

The RUSS-SAVER system is designed to take advantage of reduced ambient conditions dur-

ing non-peak requirements. As the outside air temperature decreases, head pressures are

allowed to drop. This action results in the compressor pumping more refrigerant per stroke

while requiring less energy; saving

. These dollars are pulled right from your bottom line.

operating

refrigeration system is the cost of energy to operate

substantial amounts of energy and

your

money!

· RUSS-SAVER even saves money during high ambient conditions.

The sub cooling loop provided in the condenser of the RUSS-SAVER condensing unit

increases the system efficiency 1/2% for each degree of sub cooling provided, thereby making the compressors job easier. Combined with Copelandʼs energy efficient DISCUS compressors, RUSS-SAVERʼs efficiency saves you money during summer operation and even more

during the winter months.

4 13

V Series

RUSS-SAVER

To estimate your average monthly savings:

1) Select a RUSS-SAVER system that meets your refrigeration requirements.

2) Determine the Average Annual Outdoor Air Temperature from the table below.

3) Using the Projected Monthly Savings graph, locate the system nominal horse power at the

bottom of the graph.

4) Go straight up to the appropriate Annual Average Outdoor Temperature curve, then go

horizontally to the left to determine your Estimated Monthly Savings.

5) To calculate your Estimated Monthly Savings for energy costs other than $0.10 KWH, divide

the Estimated Monthly Savings by 0.10 and multiply the result by your local electric utility rate.

6) To determine your Estimated Yearly Savings, multiply the Estimated Monthly Savings by 12.

AVERAGE ANNUAL OUTDOOR AIR TEMPERATURE

STATE & ANNUAL STATE & ANNUAL STATE & ANNUAL STATE & ANNUAL

STATION AVG.oF STATION AVG.oF STATION AVG.oF STATION AVG.oF

AL Mobile 70 IA Des Moines 50 NM Albuquerque 60 VT Burlington 45

AK Juneau 40 KS Wichita 55 NY Buffalo 45 VA Richmond 60

AZ Phoenix 70 KY Louisville 55 New York 55 WA Seattle 50

AR Little Rock 60 LA New Orleans 70 NC Charlotte 60 WV Charleston 55

CA Los Angeles 60 ME Portland 45 ND Bismarck 45 WI Milwaukee 45

SanFrancisco 55 MD Baltimore 55 OH Cleveland 50 WY Cheyenne 45

CO Denver 50 MA Boston 50 Columbus 50

CT Hartford 50 MI Detroit 50 OK Oklahoma City 60 CANADA

DE Wilmington 55 MN Sault St. Marie 40 OR Portland 55 ALB Calgary 40

D.C. Washington 55 Minneapolis 45 PA Philadelphia 50 B.C. Vancouver 50

FL Jacksonville 70 MS Jackson 65 RI Providence 50 MAN Winnipeg 35

Miami 75 MO St. Louis 55 SC Columbia 65 N.B. St. John 45

GA Atlanta 60 MT Great Falls 45 SD Sioux Falls 45 N.F. St. Johnʼs 40

HI Honolulu 75 NE Omaha 50 TN Nashville 60 N.S. Halifax 45

ID Boise 50 NV Reno 50 TX Dallas 65 ONT Toronto 45

IL Chicago 50 NH Concord 45 El Paso 65 QUE Montreal 45

IN Indianapolis 50 NJ Atlantic City 55 UT Salt Lake City 50 YUK Dawson 25

RUSS-SAVER PROJECTED MONTHLY SAVINGS @ $0.10/ KWH

800

AVERAGE ANNUAL TEMPERATURE

45oF

700

o

55

65

75

F

o

F

o

F

600

500

400

300

200

100

0

AVERAGE MONTHLY SAVINGS ($)

20 25 30 35 40 45 50 55 60 65 70 75 80

SYSTEM HORSEPOWER

Loading...

Loading...