Page 1

I NSTALLATION/OPERATION MANUAL

XP-50DHD

XP-OPAL50DHD

TM

XP-65DHD

XP-OPAL65DHD

XP-103DHD

High Definition, 1080p Flat Panel Plasma Display

with

and

Digital High Definition

with Vivix IIITM Technology

TM

Controller/Scaler/Processor

Page 2

Page 3

RuncoCare™ Standard Two Year Limited

Warranty

Congratulations on your purchase of a Runco® product! With proper installation, setup and care, you should enjoy many years

of unparalleled video performance.

This RuncoCare Standard Limited Warranty is provided free of charge by Runco International with the purchase of a covered

Runco product. The following sets forth Runco’s Standard Limited Warranty applicable to all Runco projectors, processors,

LCD and plasma display products, with the exception of the following models: XP-103DHD, SC-1, SC-1a and VW-100HD1.

The following terms and conditions of the RuncoCare Standard Limited Warranty represent a contract between us, Runco

International and you, the customer who has purchased a Runco product. This contract applies to purchases of covered

Runco products occurring on or after September 1, 2008. Runco reserves the right to change the terms of this contract, and

such changes shall apply to purchases of covered Runco products that occur on or after any future effective date.

RuncoCare Standard Features

• Two-year protection from defects in material and workmanship

• Access to 24x7 phone support

• Complimentary, second-day one-way shipping

Warranty Coverage

Y

Runco warrants its products to be free from defects in material and workmanship during the warranty period provided below.

If, in Runco’s determination, a product proves to be defective in material or workmanship during the warranty period, Runco

will repair the product, replace the product with a similar new or like new product, or refund a prorata share of the purchase

price (calculated based on the remainder of the warranty period and the then-current MSRP2 of a similar product), if repair or

replacement of the product is determined by Runco to not be feasible.

Length of Warranty

Runco products are warranted for two (2) years from the date of shipment from Runco. Lamps are warranted six (6) months

from the date of shipment or 1000 hours, whichever comes first. All other accessories, which includes, but is not limited to,

cables, remotes, carrying cases, lens cap and other peripherals sold with the Runco product, are warranted for ninety (90)

days from the date of shipment. Repaired product or replacement lamp is subsequently warranted for the remaining portion (if

any) of the original warranty term or 90 days from the date the product was shipped to you, whichever is longer.

Eligibility

This RuncoCare Standard Limited Warranty is valid only for the first customer who purchases the covered product from an

authorized Runco dealer or distributor. This warranty is not transferable. You may be required to provide proof of purchase in

order to receive warranty services.

PRE

IMINAR

L

1. Runco may update this list of products excluded from this warranty from time to time at Runco’s sole discretion, but updates to

the list of covered products will not apply on a retroactive basis.

2. MSRP is defined as the most recent product price listed on Runco’s price list.

PlasmaWall XP Series Installation/Operation Manual iii

Page 4

RuncoCare Claim Procedure

In the event of a product defect, please follow the warranty claim procedure provided below:

1. The Customer is required to contact a Runco dealer or Runco Technical Support via E-mail at support@runco.com or via

phone at (toll free) 800-23RUNCO (800-237-8626). If the customer is located outside North America, call +3589 4200 554

in Europe for product service.

2. Be prepared to provide the date of purchase, the place of purchase, serial number, product model number, description of

the problem and troubleshooting steps already attempted.

3. Runco Technical Support staff will attempt to correct any minor issues that may be causing the problem. If Runco is

unable to fix the problem to the customer’s satisfaction, Runco will issue a Return Material Authorization (RMA) if it is

determined that the claim was made within the coverage period of the Standard Limited Warranty.

4. The customer will need to return the defective product to the Runco repair depot location specified by the Runco technical

support representative. The customer will need to properly package the defective product, consisting of the product only,

and not include any accessories (e.g., cables, remotes, carrying cases, lens, lens cap and other peripherals) and return it

to the Runco repair depot specified by the technical support representative. It is the customer’s responsibility to properly

package the hardware, include all appropriate materials, and return it to the location specified by the Runco technical

support department. The customer will need to address and resolve any shipping damage claims directly with the shipping

company.

5. The customer is responsible for providing a suitable box to ship the defective product to an authorized Runco repair depot.

Boxes may be purchased from a Runco technical support representative.

6. The customer is responsible for paying freight charges to ship the defective product to an authorized Runco repair depot.

7. Runco will pay freight charges to return the repaired/replacement product to the customer from the Runco repair depot.

8. Once an RMA has been created, the customer may contact serviceorders@runco.com for follow-up questions or

confirmation status of the claim process.

IMINAR

L

Y

Warranty Exclusions

This RuncoCare Standard Limited Warranty does not include or is limited by the following:

1. Products not purchased from an authorized Runco dealer

2. Rental costs incurred by the customer in the event of product defect or failure

3. Any product with a defaced, modified, or removed serial number

4. Damage, deterioration, or malfunction resulting from:

a Accident, abuse, misuse, neglect, improper ventilation, fire, water, disaster, lightning, or other acts of nature, smoke

exposure (cigarette or otherwise), unauthorized product modification (including use of an unauthorized mount), or failure

to follow instructions supplied with the product

b Repair or attempted repair by anyone not authorized by Runco

c Any damage to the product due to shipment

d Removal or installation of the product

e Causes external to the product, such as electric power fluctuations or failure

f Use of supplies or parts not meeting Runco’s specifications

g Normal wear and tear

h Expected lamp degradation and normal decrease in lamp output over a period of time or as the lamp is consumed

i Customer caused defects, including but not limited to, scratched/defaced/altered plastics

PRE

iv PlasmaWall XP Series Installation/Operation Manual

Page 5

j Failure to follow maintenance procedures as outlined in the product’s user guide where a schedule is specified for

regular cleaning of the product

k Opening the product and/or tampering with internal circuitry

l Products lost, stolen or discarded

m Any damage or dissatisfaction associated with latent images, “burnin,” or any other damage determined by Runco to be

the result of customer use patterns

n Any other cause, which does not relate to a product defect in material or workmanship

5. Removal, installation, and setup service charges are excluded from this Standard Limited warranty

6. Runco’s warranty does not cover black uniformity issues or other LCD issues associated with usage outside the Runco

recommended guidelines and specifications for the product

7. Second day shipment delivery time and availability may vary based on origin and destination and Runco is unable to deliver

to PO Box and FPO Box addresses

Extended Service Options

Runco offers extended and expanded service plans. For information on additional product protection, please E-mail

serviceorders@runco.com or call (toll free) 800-23RUNCO (800-237-8626).

Online Product Registration

Y

Please visit http://www.runco.com/info.html to register product.

IMINAR

Limitation of Implied Warranties

L

RUNCO PROVIDES NO WARRANTIES, EXPRESS OR IMPLIED, EXCEPT THOSE EXPRESSLY PROVIDED HEREIN. RUNCO

EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

PRE

PlasmaWall XP Series Installation/Operation Manual v

Page 6

Exclusion of Damages

RUNCO’S MAXIMUM AGGREGATE LIABILITY HEREUNDER IS LIMITED TO THE COST OF REPAIR OR REPLACEMENT OF

THE PRODUCT.

1. RUNCO SHALL NOT BE LIABLE FOR DAMAGE TO OTHER PROPERTY CAUSED BY ANY DEFECT IN THE PRODUCT,

DAMAGES BASED UPON INCONVENIENCE, LOSS OF USE OF THE PRODUCT, LOSS OF TIME, LOSS OF PROFITS,

LOSS OF BUSINESS OPPORTUNITY, LOSS OF GOODWILL, INTERFERENCE WITH BUSINESS RELATIONSHIPS, OR

OTHER COMMERCIAL LOSS, EVEN IF THE CUSTOMER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

2. RUNCO SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, INDIRECT, SPECIAL, OR PUNITIVE

DAMAGES ANY OTHER DAMAGES, WHETHER INCIDENTAL, INDIRECT, CONSEQUENTIAL OR OTHERWISE.

3. RUNCO SHALL NOT BE LIABLE FOR ANY CLAIM AGAINST THE CUSTOMER BY ANY OTHER PARTY.

Y

Effect of Local Law

This warranty gives you specific legal rights, and you may have other rights, which vary from locality to locality. Some localities

do not allow limitations on implied warranties and/or do not allow the exclusion of incidental or consequential damages, so the

above limitations and exclusions may not apply to you.

COPYRIGHT AND TRADEMARKS:

© Copyright 2009 Runco International, LLC (“Runco”). This document contains proprietary information protected by copyright,

trademark and other intellectual property laws. All rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic or other means, in any form, without prior written permission of Runco.

IMINAR

The trademarks reproduced in this Runco Owner’s Manual and used on the Runco Products are either owned by Runco or are

licensed by Runco. You may not reproduce or use the trademarks without the prior written consent of Runco.

THX and the THX logo are trademarks of THX Ltd. which may be registered in some jurisdictions. All rights reserved.

Runco Products are manufactured under one or more of the following patents: US. Patent 6755540 and Other Patents

Pending.

L

PRE

vi PlasmaWall XP Series Installation/Operation Manual

Page 7

Important Safety Instructions

Thank you for your purchase of this quality Runco product! For best performance, please read this manual carefully as it is your

guide through the menus and operation.

WARNING

CAUTION

RISK OFELECTRIC SHOCK

DO NOTOPEN

TO REDUCE THE RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVER (OR BACK)

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

7. Do not block any of the ventilation openings. Install in accordance with the manufacturer’s instructions.

CAUTION:

SERVICE PERSONNEL.

This symbol is intended to alert the user to the presence of

uninsulated “dangerous voltage” within the product’s enclosure

that may be of sufficient magnitude to constitute a risk of electric

shock.

This symbol is intended to alert the user to the presence of

important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

Y

IMINAR

L

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including amplifiers) that

produce heat.

9. Do not defeat the safety purpose of the polarized or grounding type plug. A polarized plug has two blades with one wider

than the other. A grounding type plug has two blades and a third grounding prong. The wide blade or the third prong is

provided for your safety. When the provided plug does not fit into your outlet, consult an electrician for the replacement of

the obsolete outlet.

PRE

10. Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles and the point

where they exit from the apparatus.

11. Only use the attachments/accessories specified by Runco.

12. Use only with a cart, stand, tripod, bracket or table specified by the manufacturer or sold with the apparatus.

When a cart is used, use caution when moving the cart/apparatus to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when unused for long periods of time.

14. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in

any way, such as power supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus,

the apparatus has been exposed to rain or moisture, does not operate normally, or has been dropped.

PlasmaWall XP Series Installation/Operation Manual vii

Page 8

Compliance Information

DECLARATION OF CONFORMITY:

Manufacturer’s Name: Runco International, LLC

Manufacturer’s Address: 1195 NW Compton Drive, Beaverton, OR 97006-1992

hereby declares that the products Model Numbers:

XP-50DHD, XP-OPAL50DHD, XP-65DHD, XP-OPAL65DHD and XP-103DHD

conform with the provisions of:

Council Directive 2004/108/EC on Electromagnetic Compatibility;

EN 55022 “Limits and methods of measurements of radio interference characteristics of information technology equipment”

1998;

EN 55024 “Limits and methods of measurements of immunity characteristics of information technology equipment” 1998;

Including:

• EN 61000-4-2 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 2:

Electrostatic discharge immunity test”

• EN 61000-4-3 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 3: Radiated,

Radio-Frequency, Electromagnetic Field Immunity Test”

• EN 61000-4-4 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 4: Electrical

fast transient/burst immunity test”

• EN 61000-4-5 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 5: Surge

immunity test”

• EN 61000-4-6 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 6: Conducted

disturbances induced by radio-frequency fields immunity test”

• EN 61000-4-8 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 8: Conducted

disturbances induced by power frequency magnetic fields immunity test”

• EN 61000-4-11 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 11: Voltage

dips, short interruptions and voltage variations immunity tests”

PRE

IMINAR

L

Y

And:

• EN 61000-3-2 “Electromagnetic compatibility (EMC) Part 3, Section 2: Limits for harmonic current emissions (equipment

input current up to and including 16 A per phase)” 2000;

• EN 61000-3-3 “Electromagnetic compatibility (EMC) Part 3, Section 3: Limitations of voltage changes, voltage

fluctuations and flicker in public low-voltage supply systems, for equipment with rated current up to and including 16 A

and not subject to conditional connection” 1995;

Council Directive 2006/95/EC and amended by M1 and C1 on Low Voltage Equipment Safety;

EN 60950 “Safety of information technology equipment, including electrical business equipment”

The Technical Construction file required by this Directive is maintained at the corporate headquarters of Planar Systems, Inc.,

1195 NW Compton Drive, Beaverton, OR 97006.

Date of Declaration: September 2009

viii PlasmaWall XP Series Installation/Operation Manual

Page 9

FCC PART 15:

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

INDUSTRY CANADA (ICES-003):

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Y

IMPORTANT RECYCLE INSTRUCTIONS

IMINAR

Lamp(s) inside this product contain mercury. This product may contain other electronic waste that can be

hazardous if not disposed of properly. Recycle or dispose in accordance with local, state, or federal Laws.

For more information, contact the Electronic Industries Alliance at WWW.EIAE.ORG.

For lamp specific disposal information check WWW.LAMPRECYCLE.ORG.

DISPOSAL OF OLD ELECTRICAL AND ELECTRONIC EQUIPMENT (Applicable throughout the European

Union and other European countries with separate collection programs)

This symbol found on your product or on its packaging, indicates that this product should not be treated as

household waste when you wish to dispose of it. Instead, it should be handed over to an applicable collection

point for the recycling of electrical and electronic equipment. By ensuring this product is disposed of correctly,

you will help prevent potential negative consequences to the environment and human health, which could

otherwise be caused by inappropriate disposal of this product. The recycling of materials will help to conserve

natural resources. This symbol is only valid in the European Union. If you wish to discard this product, please

contact your local authorities or dealer and ask for the correct method of disposal.

PRE

L

PlasmaWall XP Series Installation/Operation Manual ix

Page 10

Notes:

Y

IMINAR

L

PRE

x PlasmaWall XP Series Installation/Operation Manual

Page 11

1Table of Contents

RuncoCare™ Standard Two Year Limited Warranty ................................................... iii

Important Safety Instructions ....................................................................................... vii

Compliance Information .............................................................................................. viii

1. Introduction ............................................................................................................... 1

About This Manual .......................................................................................................1

Target Audience .....................................................................................................1

If You Have Comments About This Manual.............................................................1

Textual and Graphic Conventions ...........................................................................1

Using This Manual ........................................................................................................ 2

Related Documents ................................................................................................2

Description, Features and Benefits ...............................................................................3

Key Features and Benefits ......................................................................................3

Parts List ...............................................................................................................4

2. Controls and Functions ............................................................................................ 5

PlasmaWall at a Glance ................................................................................................5

Controls and Indicators...........................................................................................5

Connectors.............................................................................................................7

DHD Controller Front Panel ..........................................................................................8

DHD Controller Rear Panel .........................................................................................10

Outputs ................................................................................................................10

PRE

Inputs ...................................................................................................................11

PlasmaWall Remote Control Unit ................................................................................ 12

IMINAR

L

Y

3. Installation ...............................................................................................................15

Remote Control ..........................................................................................................15

Notes on Batteries ................................................................................................15

Notes on Remote Control Operation ..................................................................... 15

Quick Setup ...............................................................................................................16

PlasmaWall XP Series Installation/Operation Manual xi

Page 12

Table of Contents

Installation Considerations ..........................................................................................17

Special Requirements for the XP-103DHD ............................................................17

High-Altitude Operation ........................................................................................17

Mounting the PlasmaWall on a Wall or Table Stand/Floor Pedestal .......................17

Ambient Light .......................................................................................................18

Ventilation............................................................................................................. 18

Audio/Video Synchronization Issues...................................................................... 20

Other Considerations ............................................................................................21

Connections to the PlasmaWall and DHD Controller ................................................... 22

Connecting the PlasmaWall to the DHD Controller................................................22

Y

Connecting Source Components to the DHD Controller .......................................24

RS-232 Controller Connection ..............................................................................29

Connecting 12-volt Trigger Outputs to External Equipment...................................30

Connecting an External IR Receiver to the DHD Controller....................................31

Connecting AC Power .......................................................................................... 32

4. Operation .................................................................................................................33

Turning on the Power .................................................................................................33

Setting the Computer Display Properties ....................................................................33

Using the On-Screen Menus ......................................................................................35

Main Menu............................................................................................................36

Input Source.........................................................................................................37

Aspect Ratio......................................................................................................... 37

Picture.................................................................................................................. 40

Input Position........................................................................................................45

PRE

5. Maintenance and Troubleshooting ........................................................................ 59

Memory Presets .................................................................................................. 47

Information ...........................................................................................................48

Calibration ............................................................................................................49

Service ................................................................................................................. 53

Cleaning .....................................................................................................................59

Cleaning the Display Panel Body and Remote Control ..........................................59

Cleaning the Screen.............................................................................................. 59

IMINAR

L

Cleaning the Vents................................................................................................59

Troubleshooting Tips ..................................................................................................60

xii PlasmaWall XP Series Installation/Operation Manual

Page 13

Table of Contents

6. External Control ......................................................................................................63

Serial Communications ...............................................................................................63

RS-232 Connection and Port Configuration ..........................................................63

Serial Command Syntax .......................................................................................63

Using Discrete IR Codes ............................................................................................68

IR Command Protocol ..........................................................................................68

IR Command List..................................................................................................69

7. Specifications .......................................................................................................... 71

PlasmaWall Specifications ..........................................................................................71

DHD Controller Specifications .................................................................................... 72

PlasmaWall Dimensions .............................................................................................73

Supported Timings .....................................................................................................76

IMINAR

L

PRE

Y

PlasmaWall XP Series Installation/Operation Manual xiii

Page 14

Table of Contents

Notes:

Y

IMINAR

L

PRE

xiv PlasmaWall XP Series Installation/Operation Manual

Page 15

1List of Figures

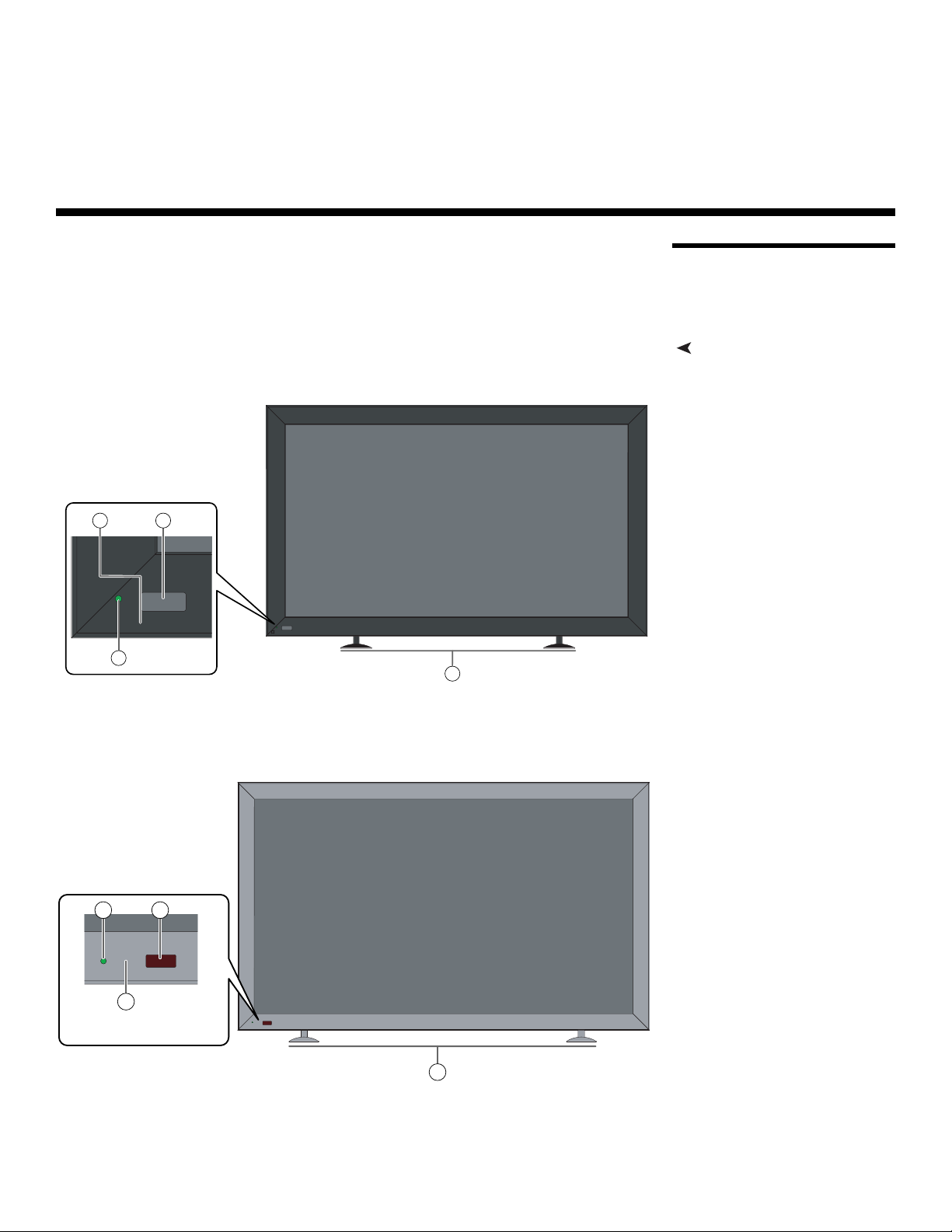

2-1. PlasmaWall XP-50DHD and XP-OPAL50DHD Front-Panel Controls and Indicators ......5

2-2. PlasmaWall XP-65DHD and XP-OPAL65DHD Front-Panel Controls and Indicators ......5

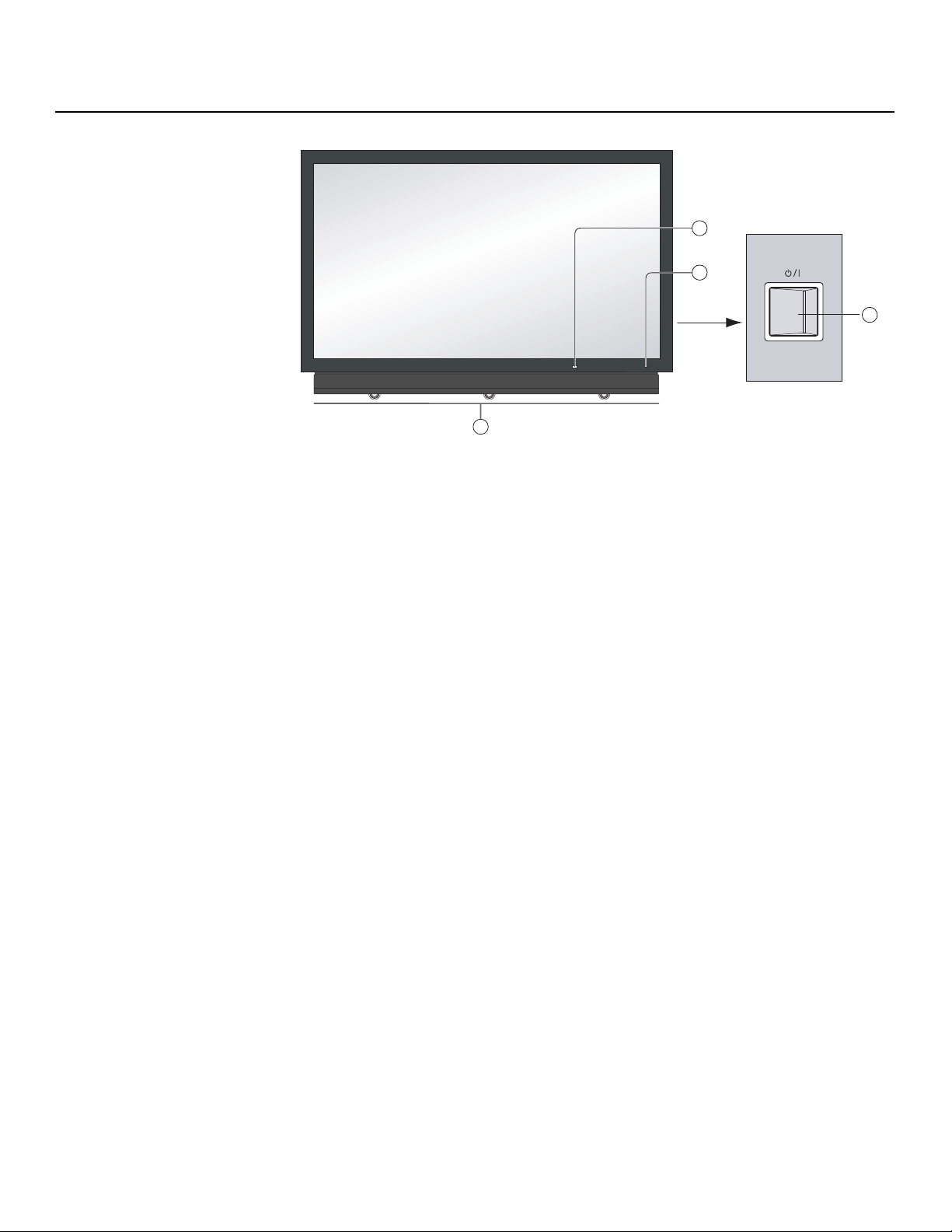

2-3. PlasmaWall XP-103DHD Front-Panel Controls and Indicators ......................................6

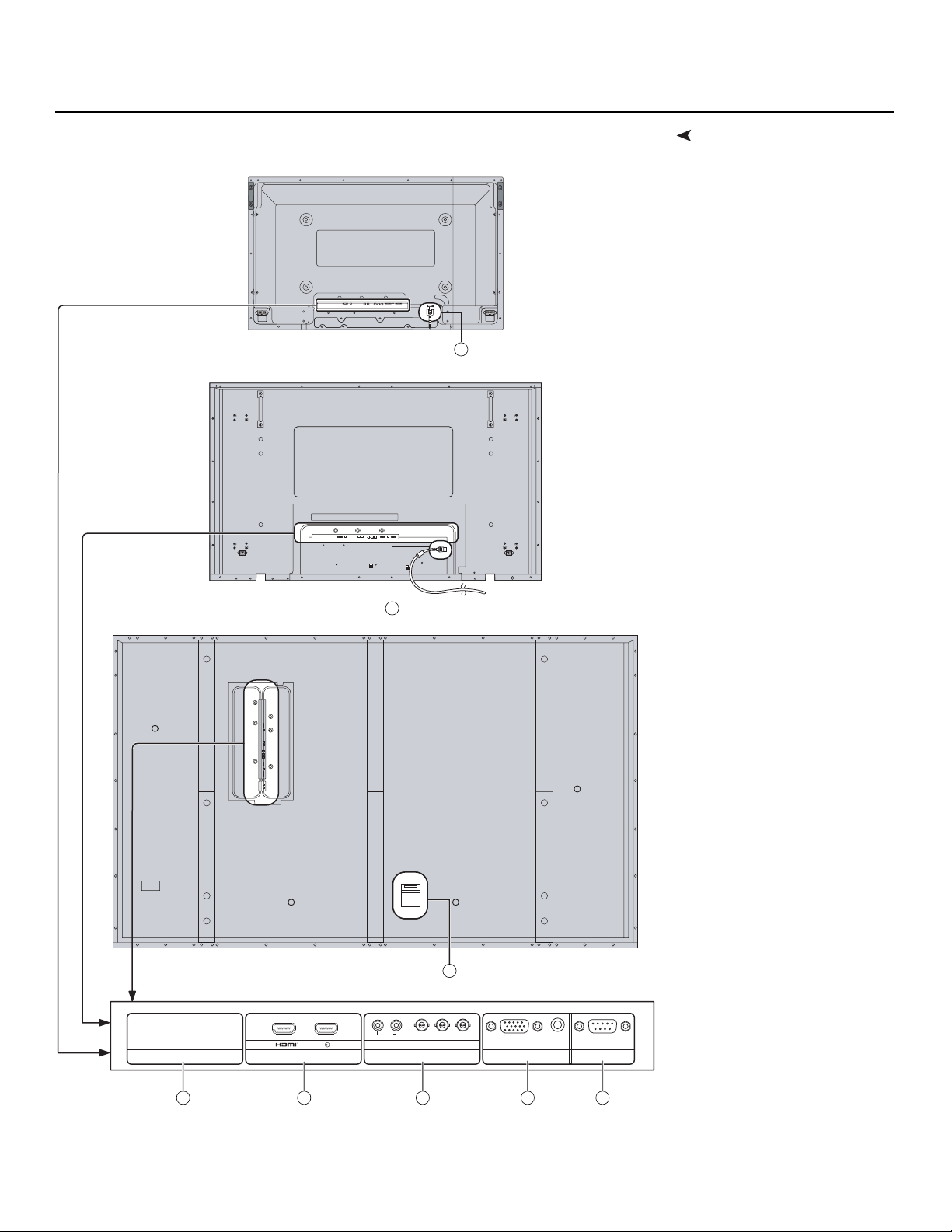

2-4. PlasmaWall Rear Panel................................................................................................. 7

2-5. DHD Controller Front Panel ..........................................................................................8

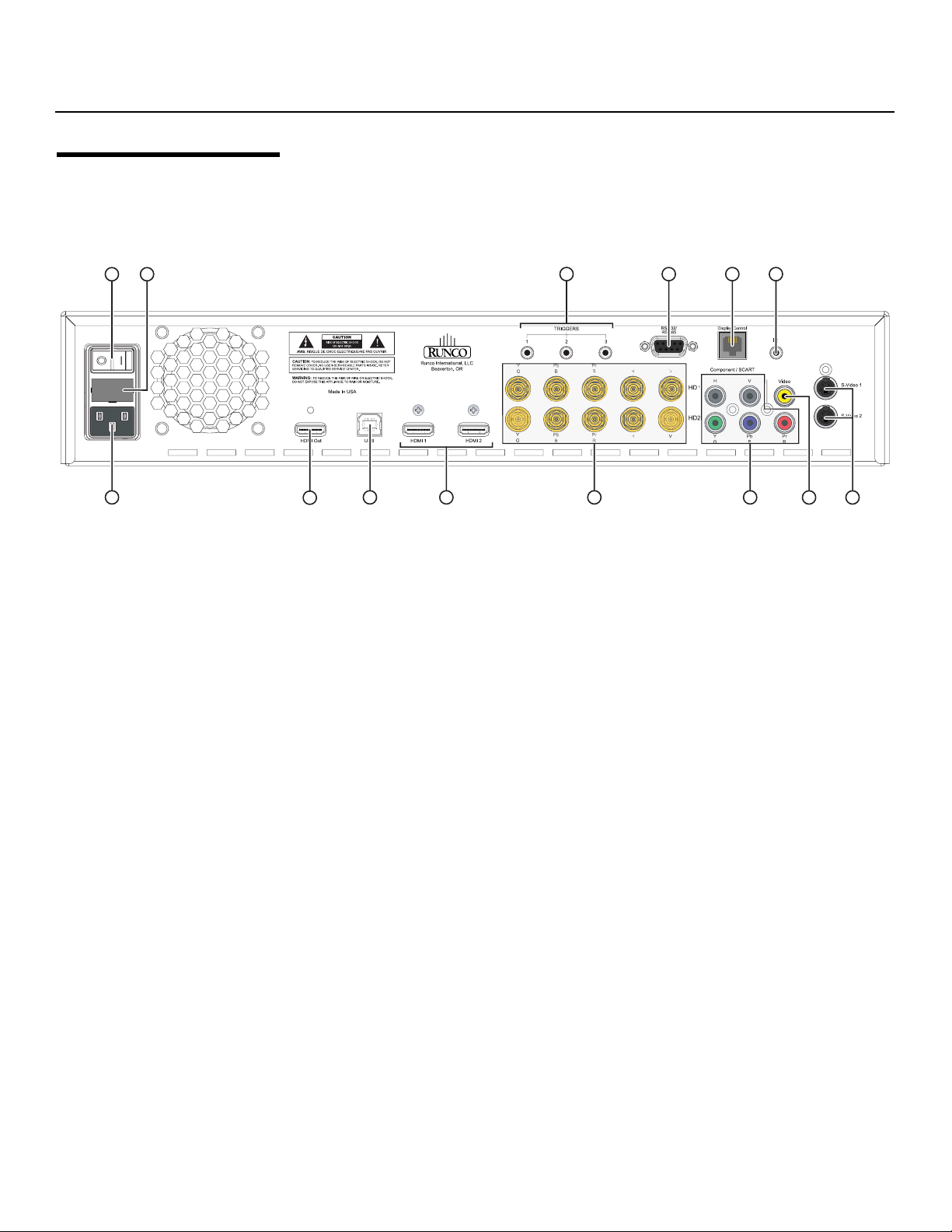

2-6. DHD Controller Rear Panel .........................................................................................10

2-7. DHD Controller/PlasmaWall Remote Control ..............................................................12

3-1. Available Range of the Remote Control ......................................................................15

3-2. Ventilation Requirements for Enclosure Mounting (XP-50DHD, XP-OPAL50DHD,

XP-65DHD and XP-OPAL65DHD)...............................................................................19

3-3. Ventilation Requirements for Enclosure Mounting (XP-103DHD) .................................19

3-4. Connecting the PlasmaWall to the DHD Controller .....................................................22

3-5. RS-232 Connection from the DHD Controller to the PlasmaWall ................................23

3-6. HDMI Source Connections ......................................................................................... 24

3-7. Component Video Source Connections...................................................................... 25

3-8. RGBHV Source Connections......................................................................................26

3-9. SCART RGBS Source Connections............................................................................27

3-10. S-Video and Composite Video Source Connections .................................................28

3-11. RS-232 Control System Connection.........................................................................29

3-12. Connecting 12-volt Trigger Outputs..........................................................................30

PRE

3-13. External IR Receiver Connection...............................................................................31

3-14. AC Power Connection ..............................................................................................32

IMINAR

L

Y

4-1. PlasmaWall OSD Menu Structure ...............................................................................35

4-2. Typical PLUGE Pattern for Adjusting Brightness ......................................................... 40

4-3. Typical Gray Bar Pattern for Adjusting Contrast ..........................................................41

4-4. Typical Color Bar Pattern for Adjusting Color Saturation and Tint................................42

4-5. Typical Test Pattern for Adjusting Sharpness..............................................................44

4-6. Overscan Modes ........................................................................................................46

4-7. CIE 1931 Chromaticity Diagram .................................................................................50

6-1. RC5 Message Format ................................................................................................ 69

7-1. PlasmaWall Model XP-50DHD and XP-OPAL50DHD Dimensions

(with Optional Table Stand) .........................................................................................73

PlasmaWall XP Series Installation/Operation Manual xv

Page 16

List of Figures

7-2. PlasmaWall Model XP-65DHD and XP-OPAL65DHD Dimensions

(with Optional Table Stand) .........................................................................................74

7-3. PlasmaWall Model XP-103DHD Dimensions (with Floor Stand) ................................... 75

Y

IMINAR

L

PRE

xvi PlasmaWall XP Series Installation/Operation Manual

Page 17

1. Introduction

This Owner’s Manual describes how to install, set up and operate a Runco PlasmaWall XP

Series Flat-Panel Plasma Display Monitor and DHD Controller (Model XP-50DHD,

XP-OPAL50DHD, XP-65DHD, XP-OPAL65DHD or XP-103DHD).

Throughout this manual, the Runco PlasmaWall XP Series Flat-Panel Plasma Display

Monitor and DHD Controller are referred to collectively as the “PlasmaWall.” Except where

otherwise indicated, the information in this manual applies to all PlasmaWall models.

Y

most out of the PlasmaWall.

Runco has made every effort to ensure that this manual is accurate as of the date it was

printed. However, because of ongoing product improvements and customer feedback, it

may require updating from time to time. You can always find the latest version of this and

other Runco product manuals on-line, at www.runco.com.

Runco welcomes your comments about this manual. Send them to info@runco.com.

Text Conventions: The following conventions are used in this manual, in order to clarify

the information and instructions provided:

• Remote control button identifiers are set in upper-case bold type; for example, “Press

EXIT to return to the previous menu.”

• Computer input (commands you type) and output (responses that appear on-screen) is

shown in monospace (fixed-width) type; for example: “To change the aspect ratio to

Letterbox, type LETTERBOX <Enter>.”

• All keys with functional names are initial-capped, set in bold type and enclosed in angle

brackets. These keys are the following: <Enter>, <Spacebar>, <Control>, <Esc>

and <Tab>.

• <Enter> indicates that you may press either the RETURN or ENTER key on your

computer keyboard if it has both keys.

PRE

IMINAR

L

1.1 About This Manual

Target AudienceRunco has prepared this manual to help home theater installers and end users get the

If You Have Comments About This Manual...

Textual and Graphic Conventions

In addition to these conventions, underlining, boldface and/or italics are occasionally used

to highlight important information, as in this example:

Note

PlasmaWall XP Series Installation/Operation Manual 1

A carriage return must be used after each command or string.

Page 18

Introduction

Graphic Conventions: These symbols appear in numerous places throughout the

manual, to emphasize points that you must keep in mind to avoid problems with your

equipment or injury:

TIPS highlight time-saving short cuts and helpful guidelines for using

Tip

certain features.

1.2

Using This Manual

Note

Caution

NOTES emphasize text with unusual importance or special

significance. They also provide supplemental information.

CAUTIONS alert users that a given action or omitted action can

degrade performance or cause a malfunction.

Y

WARNING

DANGER!

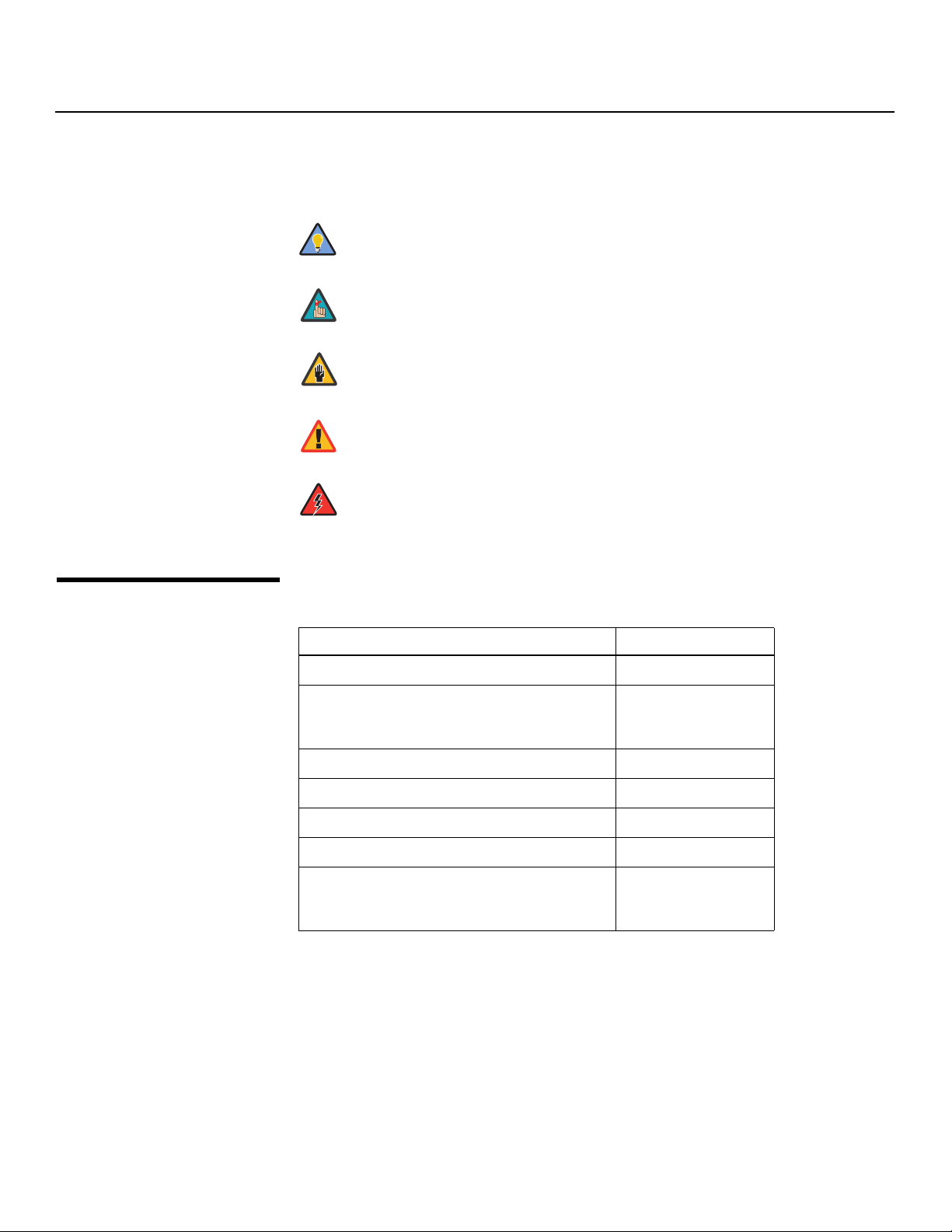

Use the following table to locate the specific information you need in this manual.

WARNINGS appear when a given action or omitted action can result

in damage to the equipment, or possible non-fatal injury to the user.

DANGER appears when a given action can cause severe injury or

death.

IMINAR

If you need... ... Turn to page:

Information about obtaining service iv

General information about the PlasmaWall XP

Series Flat-Panel Plasma Display Monitor and

DHD Controller

L

3

Installation instructions 15

PRE

Related Documents The following are related Runco documents available from your Runco dealer or

➤

First-time configuration instructions 33

Advanced configuration instructions 49

Troubleshooting tips 60

Specifications for the PlasmaWall XP Series

Flat-Panel Plasma Display Monitor and DHD Controller

representative, or from www.Runco.com:

• 42"/50" Plasma Display Wall-Mount Kit Installation Instructions

• 65" Flat-Panel Plasma Display Wall-Mount Kit Installation Instructions

• 103" Flat-Panel Wall-Mount Kit Installation Instructions

• Runco XP-103DHD Installation Site Pre-Qualification

2 PlasmaWall XP Series Installation/Operation Manual

71

Page 19

Introduction

The PlasmaWall XP Series Flat-Panel Plasma Display Monitor and DHD Controller

establish a higher threshold for flat panel display products. The PlasmaWall XP Series is

available in three sizes, including our largest and highest-resolution plasma ever, at 103

inches diagonal and 1920 x 1080 (1080p) native resolution.

The PlasmaWall takes picture quality to a whole new level, boasting our brightest picture,

best contrast ratio, deepest black levels and most spot-on high definition colorimetry ever!

In addition, sophisticated 16-bit digital video processing, a new milestone, results in 4096

steps of graduation for seamless images completely devoid of the primitive "solarization"

and "stair stepping" characteristics previously plaguing digital flat panel displays.

The PlasmaWall features all of the Runco technologies you have come to expect from the

World's Finest Home Theater Products. Discrete, multiple aspect ratio control includes

VirtualWide™ for viewing 4:3 content in widescreen without appreciable picture

degradation, as well as ISF(ccc) calibration modes to easily maintain ISF standards. The

automation interface includes RS-232 control with discrete aspect ratio, input and power

on/off selection.

The included Digital High-Definition (DHD) Video Controller/Scaler/Processor provides a

pure digital signal path from input to output as well as a broad array of video input

choices, all available from its position in the equipment rack, with only digital video and

command cables running to the display itself.

The PlasmaWall not only represents a leap forward in high definition flat-panel technology,

but our engineering advances in plasma design ensure that it will enjoy a long life in any

installation, with operation extending to as much as 60,000 hours. At less than 5-3/4

inches thin, the PlasmaWall provides unlimited installation flexibility as well.

IMINAR

Y

1.3 Description, Features and Benefits

L

• 16:9 Native Resolution: 1920 x 1080

• Models XP-OPAL50DHD and XP-OPAL65DHD feature Runco-exclusive Optical Path

Alignment (OPAL) technology, which delivers extreme glare reduction and enhanced

contrast for high ambient light environments

• Multiple Aspect Ratios with VirtualWide™ Mode

• Includes the new DHD Video Controller/Scaler/Processor

• Less than 5-3/4 inches thin

• High-altitude compliant to 9,000 feet (2,743 meters)

• Exceptional detail and artifact-free video enhancement

•ViVix III™ video processing with 3:2 film detection circuitry

PRE

Key Features and BenefitsThe PlasmaWall offers these key features and benefits:

PlasmaWall XP Series Installation/Operation Manual 3

Page 20

Introduction

Parts List Your PlasmaWall is shipped with the following items. If any items are missing or damaged,

➤

please contact your Runco dealer or Runco Customer Service at (800) 23-RUNCO.

• PlasmaWall XP Series Flat-Panel Plasma Display Monitor and DHD Controller

• AC Power Cords (2)

• Remote Control Unit and two (2), AAA-size batteries

• RJ-11 Telephone Cable, 50 feet (15.24 meters)

• Serial Port Adapter, RJ-11 Female to DB-9 Female

• Rack-mount hardware for the DHD Controller

• PlasmaWall XP Series Installation/Operation Manual (this document)

• PlasmaWall XP Series Quick Setup Guide

Optional Accessories – XP-50DHD and XP-OPAL50DHD:

• Wall Mount Kit (part number 956-0081-00)

• Table Stand (part number 956-0082-00)

Optional Accessories – XP-65DHD and XP-OPAL65DHD:

• Wall Mount Kit (part number 956-0103-00)

• Table Stand (part number 956-0105-00)

Optional Accessories – XP-103DHD:

• Wall Mount Kit (part number 997-5371-00)

• Floor Stand (part number 997-5269-00)

Y

IMINAR

L

PRE

4 PlasmaWall XP Series Installation/Operation Manual

Page 21

indicators.

(behind

2

front bezel)

2. Controls and Functions

2.1 PlasmaWall at a Glance

Controls and IndicatorsFigure 2-1, Figure 2-2 and Figure 2-3 show the PlasmaWall front-panel controls and

Y

4

IMINAR

3

Figure 2-1. PlasmaWall XP-50DHD and XP-OPAL50DHD Front-Panel Controls and Indicators

L

1

PRE

3 4

2

(behind

front bezel)

1

Figure 2-2. PlasmaWall XP-65DHD and XP-OPAL65DHD Front-Panel Controls and Indicators

PlasmaWall XP Series Installation/Operation Manual 5

Page 22

Controls and Functions

4

3

2

Y

1

Figure 2-3. PlasmaWall XP-103DHD Front-Panel Controls and Indicators

1. DISPLAY STAND

Optional accessory for table-top installations.

2. POWER BUTTON

Connects or disconnects the display panel from the AC power source.

3. STANDBY/ON INDICATOR

- Lights green to indicate normal operation;

- Lights red to indicate that the PlasmaWall is in standby mode.

4. REMOTE CONTROL SENSOR

Receives the signals from the remote control.

IMINAR

L

PRE

6 PlasmaWall XP Series Installation/Operation Manual

Page 23

Controls and Functions

ConnectorsFigure 2-4 shows the rear-panel connector locations on the PlasmaWall.

XP-50DHD /

XP-OPAL50DHD

XP-65DHD /

XP-OPAL65DHD

PRE

6

Y

6

IMINAR

L

XP-103DHD

AB

SLOT1 SLOT3

1 2 3 4 5

Figure 2-4. PlasmaWall Rear Panel

PlasmaWall XP Series Installation/Operation Manual 7

AV IN

SLOT2

AUDIO

RL

COMPONENT/RGB IN

PR/CR/R PB/CB/B

6

Y/G

AUDIO

SERIALPC IN

Page 24

Controls and Functions

1. SLOT 1

Not used.

2. SLOT 2 (Dual HDMI input)

Two, HDCP-compliant digital video inputs. Connect the HDMI output from the

DHD Controller to input “A” in this slot.

3. SLOT 3 (COMPONENT/RGB input)

Not used.

4. PC IN

Not used.

5. RS-232C (9-pin, male D-Sub)

Connect the Display Control (RS-232 OUT) port on the DHD Controller to this input.

2.2

DHD Controller Front Panel

3

XP-50DHD

HDMI 1

16:9 1080i/60

PRE

1

2

6. POWER INPUT

Connect the PlasmaWall to AC power here.

Y

Figure 2-5 shows the controls and indicators on the DHD Controller front panel; the

paragraphs that follow describe them.

91011

L

3

IMINAR

standby

n

p

u

t

i

o

a

r

t

e

n

i

e

t

r

a

654 87

i

r

o

i

t

m

n

e

p

n

u

u

t

Figure 2-5. DHD Controller Front Panel

1. RUNCO ICON

Lights blue to indicate that the controller is on or powering up.

2. IR SENSOR

Receives IR commands from the remote control.

3. VACUUM FLUORESCENT DISPLAY

Can be used instead of the On-Screen Display (OSD). Displays currently-selected

menu or – if no menu is selected – the connected display device model, current

source, input resolution and aspect ratio.

4. ON/STANDBY BUTTON

Press once to toggle from standby mode to on mode. Press it again to return to

standby mode. For a discrete on or off command, you can use the direct access

buttons on the remote control.

8 PlasmaWall XP Series Installation/Operation Manual

Page 25

5. LEFT BUTTON

Used to direct-select inputs or move the menu cursor left in the OSD. When no menu

is present on-screen, the LEFT button toggles through the different sources, in this

order:

HDMI 2 - HDMI 1 - SCART - HD 2 - HD 1 - Component - S-Video 2 - S-Video 1 Composite

6. DOWN BUTTON

Use to direct-select aspect ratios or move the menu cursor down in the OSD. When

no menu is present on-screen, this button toggles through the different aspect ratios,

in this order:

16:9 - 4:3 - Letterbox - VirtualWide - Cinema - Virtual Cinema - Native

7. RIGHT BUTTON

Used to direct-select inputs or move the menu cursor right in the OSD. When no

menus are present on-screen, the RIGHT button toggles through the different

sources, in this order:

Composite Video - S-Video 1 - S-Video 2 - Component - HD 1 - HD 2 - SCART HDMI

8. MENU BUTTON

Press the MENU button to bring up the main menu, or to exit the current menu and

return to the previous one.

9. UP BUTTON

Use to direct-select aspect ratios or move the menu cursor up in the OSD. When no

menus are present on-screen, the UP button toggles through aspect ratios in the

following order:

Native - Virtual Cinema - Cinema - VirtualWide - Letterbox - 4:3 - 16:9

10. ENTER BUTTON

When an item is highlighted on the OSD, the ENTER button selects the item.

11. STANDBY LED

Lights amber when the DHD Controller is in standby mode; otherwise it is off.

Video

1 - HDMI 2

IMINAR

L

Controls and Functions

Y

PRE

PlasmaWall XP Series Installation/Operation Manual 9

Page 26

Controls and Functions

2.3

DHD Controller Rear Panel

1213

Figure 2-6. DHD Controller Rear Panel

Outputs 1. HDMI Out

Figure 2-6 shows the rear connector panel on the DHD Controller.

1

➤

2. Display Control

2

3

1011

Y

414

Connect this to the SLOT 2/INPUT A connector on the PlasmaWall (see Figure 2-4).

5 6

789

IMINAR

Connect this to the SERIAL input on the PlasmaWall, using the provided

L

communication cable and adapter.

3. TRIGGERS

Connection for up to three (3), 12-volt trigger-controlled devices. Output current is

limited to 250 milliamperes (mA).

PRE

10 PlasmaWall XP Series Installation/Operation Manual

Page 27

A standard, USB Series “B” connection to a personal computer. (For future use.)

5. HDMI 1 / HDMI 2 (Digital)

HDCP-compliant digital video inputs for connecting an HDMI or DVI source.

6. HD1 / HD2 (5 x Analog BNCs)

Two inputs (five BNCs per input) for connecting standard-definition (SD = 480i/576i),

enhanced-definition (ED = 480p/576p) or high-definition (HD = 720p/1080i/1080p)

component video sources, or RGBHV sources such as personal computers.

7. Component / SCART (5 x RCA connectors)

SD/HD input for connecting SDTV, EDTV or HDTV component video sources, or

RGBHV sources. Also provides RGB input for SCART RGBS sources.

8. Video

Standard, composite video input for connecting a VCR, camcorder or other

composite video source. Also provides composite sync input for SCART RGBS

sources.

9. S-Video 1 / S-Video 2

Two, standard S-Video inputs for connecting a DVD player, satellite receiver or Super

VHS (S-VHS) VCR.

10. IR

Wired input from a Niles- or Xantech-compatible, infrared (IR) repeater system. It is a

3.5-mm, mini phono jack, wired as follows:

Ring = No connection

Tip = IR Input

Sleeve = Ground

11. RS-232 / RS-485

A female, 9-pin D-sub connector for interfacing with a PC or automation/control

system. (Currently, only RS-232 interface is supported.)

IMINAR

L

Controls and Functions

Inputs4. USB

Y

12. MAIN AC FUSE

This is the main AC input fuse (5mm x 20mm, 500 mA, 250V slow-blow).

13. MAIN POWER SWITCH

Disconnects or applies power to the DHD Controller.

14. POWER INPUT (100 to 240 VAC)

Connect the DHD Controller to power here.

PRE

PlasmaWall XP Series Installation/Operation Manual 11

Page 28

Controls and Functions

2.4

PlasmaWall Remote Control Unit

Figure 2-7 shows the PlasmaWall remote control, and the paragraphs that follow describe

its functionality.

2

1

3

Y

7

9

10

(not available on

some models)

L

4

5

6

8

11

IMINAR

12

13

RETURN

EXIT

HDMI

16 : 9

4 : 3

HDMI

1

2

14

PRE

(“CUST 2” on

some models)

Figure 2-7. DHD Controller/PlasmaWall Remote Control

CUST

1

12 PlasmaWall XP Series Installation/Operation Manual

THX

SVC

Page 29

1. IR OUTPUT INDICATOR

Lights when a button is pressed to indicate that an IR signal is being transmitted.

2. ON / OFF

Press to turn the display on or off.

3. ENTER

Press to select a highlighted menu item or confirm a changed setting.

4. Cursor Buttons ( , , , )

Use these buttons to select items or settings, adjust settings or switch display

patterns.

When no menu is present on-screen, the UP and DOWN buttons toggle through the

available aspect ratios, in this order:

UP Button = Native - Virtual Cinema - Cinema - VirtualWide - Letterbox - 4:3 - 16:9

DOWN Button = 16:9 - 4:3 - Letterbox - VirtualWide - Cinema - Virtual Cinema -

Native

Likewise, the LEFT and RIGHT buttons toggle through the different source inputs, in

this order:

LEFT Button = HDMI 2 - HDMI 1 - SCART - HD 2 - HD 1 - Component - S-Video 2 S-Video 1 - Composite

RIGHT Button = Composite Video - S-Video 1 - S-Video 2 - Component - HD 1 HD

5. RETURN / EXIT

Press this button to exit the current menu and return to the previous one.

Video

2 - SCART - HDMI 1 - HDMI 2

Controls and Functions

Y

Note

6. LIGHT

Press to illuminate the buttons.

7. MENU

Press this button to access the OSD controls, or to exit the current menu and return

to the previous one.

8. VIDEO (1)

Press to select Composite video input as the source or to enter the numeric

character

9. COMP (Component) (2)

Press to select Component/SCART video input as the source or to enter the numeric

character “2.”

“1.”

Not all remote control units have this button. If yours does not, use

the MENU button (see below) to exit the current menu.

PRE

IMINAR

L

PlasmaWall XP Series Installation/Operation Manual 13

Page 30

Controls and Functions

10. Aspect Ratio Selection Buttons

Use the red buttons to select an aspect ratio directly or to enter numeric characters,

as follows:

16:9 (3)

For viewing 16:9 DVDs or HDTV programs in their native aspect ratio.

4:3 (6)

Scales the input signal to fit 4:3 display mode in the center of the screen.

LETBOX (Letterbox) (9)

For viewing LaserDisc movies or non-anamorphic DVDs on a 16:9 screen.

V-WIDE (VirtualWide)

Enlarges a 4:3 image horizontally in a NON-linear fashion to fit 16:9 full screen display.

CINEMA

For viewing 2.35:1 source material. The upper and lower portions are masked.

SVC

Selects the Virtual Cinema aspect ratio.

11. S-VID 1 (4) / S-VID 2 (5) (S-Video)

Press to select an S-Video input or to enter the numeric character “4” or “5.”

Y

12. HD 1 (7) / HD 2 (8)

Press to select a HD (RGBHV or YPbPr component) input or to enter the numeric

character “7” or “8.”

13. HDMI 1 / HDMI 2 (0)

Press to select a Digital Video input. Press HDMI 2 to enter the numeric character

“0.”

14. Memory Preset Buttons:

ISF NIGHT

Press to recall settings for the current input from the “ISF Night” memory preset.

PRE

ISF DAY

Press to recall settings for the current input from the “ISF Day” memory preset.

CUST 1

Press to recall settings for the current input from the “Custom 1” memory preset.

THX (XP-65DHD and XP-OPAL65DHD) / CUST 2 (XP-50DHD, XP-OPAL50DHD

and XP-103DHD)

Press to recall settings for the current input from the “THX” or “Custom 2” memory

preset.

IMINAR

L

14 PlasmaWall XP Series Installation/Operation Manual

Page 31

3. Installation

To install batteries in the remote control:

1. Press down the tab on the cover and

pull the cover in the direction of the

arrow.

2. Insert the included batteries. Ensure

that the polarities correctly match the

and markings inside the battery

compartment.

3. Insert the lower tab of the cover into the

opening, and press down the cover until

it clicks in place.

IMINAR

• Do not mix an old battery with a new one or different types of batteries.

• If you will not use the remote control for a long time, remove the batteries to avoid

damage from battery leakage.

L

3.1 Remote Control

Y

Notes on Batteries• When installing batteries, make sure that the battery polarities are correct.

The remote control can be used to control the PlasmaWall within the ranges shown in

Figure 3-1.

PRE

3

HDMI 1

16:9 1080i/60

Approx.

40 feet

(12.2 meters)

Approx.

30º

RETURN

EXIT

HDMI

1

CUST

1

Approx.

16 : 9

4 : 3

HDMI

2

CUST

SVC

2

30º

Figure 3-1. Available Range of the Remote Control

PlasmaWall XP Series Installation/Operation Manual 15

t

i

o

a

r

standby

t

e

n

i

i

n

p

u

t

m

r

e

n

e

p

n

u

u

t

r

a

o

i

t

Notes on Remote Control Operation

Page 32

Installation

• Do not drop the remote control or expose it to moisture or high temperature.

• The remote control may malfunction under a fluorescent lamp. If that occurs, move the

plasma display away from the fluorescent lamp.

• Make sure that there is nothing obstructing the infrared beam between the remote

control and the IR receiver on the plasma display.

The signal from the remote control can be reflected by walls or

Note

• If the effective range of the remote control decreases, or it stops working, replace the

batteries with new ones.

• Ambient conditions may possibly impede the operation of the remote control. If this

happens, point the remote control at the plasma display and repeat the operation.

other surfaces.

Y

3.2 Quick Setup

Table 3-1 gives a quick overview of the PlasmaWall installation process. The sections

following this one provide detailed instructions.

Note

Table 3-1. Installation Overview

IMINAR

L

Step Procedure

1 Mount the PlasmaWall on a wall, table stand or floor ped-

estal

2 Connect the DHD Controller to the PlasmaWall 22

PRE

3 Connect signal sources to the DHD Controller 24

4 Connect external controller to DHD Controller RS-232 port

(optional)

5 Apply power to the PlasmaWall 33

6 If using the PlasmaWall with a computer, adjust computer

display properties

Installation must be performed by a qualified custom video

installation specialist.

For Details, refer to

page...

17

29

33

7 Display calibration: adjust the following for each input and

display mode (resolution and frame rate); save settings

when finished:

• Aspect ratio

• Brightness

• Contrast

• Color level

• Tint

• Sharpness

• White Balance

16 PlasmaWall XP Series Installation/Operation Manual

36

Page 33

Installation

Proper installation of your PlasmaWall will ensure the highest possible picture quality.

Whether you are installing the PlasmaWall temporarily or permanently, you should take the

following into account to ensure that it performs optimally.

The extremely large size and high power consumption of the XP-103DHD place unique

demands upon both the installation personnel and the installation site, over and above

those of the 50-inch and 65-inch PlasmaWall models.

Installing the XP-103DHD requires the following:

• Several people familiar with complex mechanical installations.

• Specialized equipment.

• A dedicated 220VAC circuit.

• A “carry-in” path with sufficient clearances.

• An installation location that can support the weight of both the plasma panel and

mounting hardware (floor pedestal or wall mount).

These and other installation requirements are detailed in a document called Runco

XP-103DHD Installation Site Pre-Qualification, available from your Runco dealer or

representative, or from www.Runco.com. Before proceeding with an XP-103DHD

installation, obtain, read and make sure you understand everything in this document.

interaction between ambient air pressure and the plasma gases contained inside of the

panel, reliable operation of your plasma display cannot be assured during operation at

certain high-altitude locations.

IMINAR

Y

L

Runco has found all PlasmaWall models to operate reliably at altitudes of up to 9,000 feet

MSL (mean sea level).

3.3 Installation Considerations

Special Requirements for the XP-103DHD

High-Altitude OperationDue to the design of all plasma glass panels made by every manufacturer, and the

At higher elevations, each panel may react differently, depending upon the altitude, air

pressure, humidity and other meteorological factors. If you are planning to use this

product at a location above 9,000 feet, please contact Runco technical support for further

information.

To install the PlasmaWall, you will need either an optional table stand, floor pedestal or

wall-mounting kit. (The XP-103DHD must be either wall-mounted or attached to a floor

pedestal.)

If you do decide to wall-mount the PlasmaWall, ensure that the wall-mount bracket is

installed according to the instructions included with it. The wall must be capable of

supporting a redundant weight factor five (5) times the weight of the display, or be

reinforced.

Runco recommends that this be done by a custom installation specialist.

Note

PlasmaWall XP Series Installation/Operation Manual 17

PRE

Use only a Runco-approved wall-mount kit, table stand or floor

pedestal that is specifically designed for your display. Refer to

Parts List on page 4 for ordering information.

Mounting the PlasmaWall on a Wall or Table Stand/Floor Pedestal

Page 34

Installation

You can attach your optional mounts or stand to the PlasmaWall in either of two ways:

• While it is upright.

• As it lies flat with the screen face

down. Place the protective sheet,

which was wrapped around the

plasma monitor when it was

packaged, between the screen and

your work surface to avoid

scratching or otherwise damaging

the screen surface.

Y

Ambient Light In general, minimize or eliminate light sources directed at the display. Contrast ratio in your

Ventilation If you are mounting the PlasmaWall in an enclosure, leave sufficient space on all sides

➤

images will be noticeably reduced if light directly strikes the display, such as when a shaft

of light from a window or floodlight falls on the image. Images may then appear washed

out and less vibrant.

➤

between it and surrounding objects, as shown in

to disperse, maintaining the proper operating temperature.

IMINAR

L

Figure 3-2 or Figure 3-3. This allows heat

PRE

18 PlasmaWall XP Series Installation/Operation Manual

Page 35

Wall

Installation

50mm (2")

Figure 3-2. Ventilation Requirements for Enclosure Mounting (XP-50DHD, XP-OPAL50DHD, XP-65DHD and XP-OPAL65DHD)

Wall

300mm

(11.8")

50mm (2")

300mm

(11.8")

(2")

mm

Wall

50mm (2")

(2") 50

mm

50

IMINAR

L

(11.8")

Wall

300mm

Y

PRE

200mm

(7.87")

(11.8")

300mm

Figure 3-3. Ventilation Requirements for Enclosure Mounting (XP-103DHD)

PlasmaWall XP Series Installation/Operation Manual 19

Page 36

Installation

Audio/Video

Synchronization Issues

Due to its extraordinarily high level of video processing performance, the DHD Controller

➤

may distribute video signals with a perceptible level of audio latency. In order to easily

solve this issue, Runco recommends using the DHD Controller with a high-quality audio

receiver that has the ability to effectively synchronize audio and video signals.

Most mainstream audio receiver/switchers have the ability to synchronize the audio and

video to the Advanced Television Systems Committee (ATSC) prescribed tolerances.

According to the ATSC, the sound program should never lead the video program by more

than 15 milliseconds, and should never lag behind the video program by more than 45

milliseconds.

In addition, many A/V receivers introduce additional latency that needs to be

compensated for during the installation.

latency given different signal input timings.

Table 3-2. Possible Audio Latency for Various Input/Output Timings

Input Timing Possible Audio Latency (milliseconds)

480i 133

480p 83

576i 160

576p 100

720p/50 100

720p/60 83

IMINAR

1080i/25 160

L

1080i/30 133

1080p/24 125

Table 3-2 shows the amount of possible audio

Y

1080p/50 80

1080p/60 67

PRE

20 PlasmaWall XP Series Installation/Operation Manual

Page 37

damage and prolong operating life:

• Keep the ambient temperature constant and below 35°C (95°F). Keep the display away

from heating and/or air conditioning vents. Changes in temperature may cause drifts in

the display circuitry, which may affect performance.

• Keep the PlasmaWall away from devices that radiate electromagnetic energy such as

motors and transformers. Common sources of these include slide projectors,

speakers, power amplifiers and elevators.

• Handle the unit carefully when installing or carrying it. Use the built-in handles; DO NOT

touch or hold the screen face.

• Set the unit away from heat, excessive dust, and direct sunlight.

• Protect the inside of the unit from liquids and small metal objects. In case of accident,

unplug the power cord and have it serviced by an authorized Service Center.

• Do not hit or scratch the panel surface as this causes flaws on the surface of the

screen.

• For correct installation and mounting it is strongly recommended to use a trained,

authorized dealer.

• To avoid sulfurization, it is strongly recommended not to place the unit in a dressing

room in a public bath or hot spring bath.

Y

Installation

Other ConsiderationsHere are some other considerations and tips that can help improve your installation, avoid

IMINAR

L

PRE

PlasmaWall XP Series Installation/Operation Manual 21

Page 38

Installation

3.4

Connections to the PlasmaWall and DHD Controller

Connecting the

PlasmaWall to the DHD

Controller

Proceed as follows to connect the PlasmaWall to the DHD Controller, your video sources,

external controller(s) – if present – and AC power.

When connecting your equipment:

• Turn off all equipment before making any connections.

• Use the correct signal cables for each source.

• Ensure that the cables are securely connected. Tighten the thumbscrews on

connectors that have them.

Connect the DHD Controller to the PlasmaWall as shown in Figure 3-4 and described in

➤

the sections that follow.

Y

PlasmaWall

(XP-65DHD shown here)

Rear Panel

IMINAR

L

SLOT1

PRE

AB

AV IN

SLOT2 SLOT3

HDMI OUT

AUDIO

RL

PR/CR/R PB/CB/B

COMPONENT/RGB IN

Y/G

Communication

Adapter (provided)

AUDIO

SERIALPC IN

RS-232

Cable and

Display Control

(RS-232 OUT)

Figure 3-4. Connecting the PlasmaWall to the DHD Controller

22 PlasmaWall XP Series Installation/Operation Manual

Page 39

Digital Video Connection: The PlasmaWall has a dual HDMI input board, labeled HDMI

(SLOT 2). Connect the HDMI output from the DHD Controller to input “A” on this board,

using an HDMI-to-HDMI cable.

RS-232 Connection: Connect the Display Control (RS-232) output from the DHD

Controller to the SERIAL input on the PlasmaWall. Use a standard, modular telephone

cable with RJ11 plugs at both ends. On the PlasmaWall end, use the provided

RJ11-to-DB9 adapter. This adapter is wired as shown in

Figure 3-5.

Installation

To/From

DHD

Controller

RJ-11 Male

6

1

1, 5, 6

6-position

4

3

2

RCV DATA

XMT DATA

SIG GND

REQUEST TO SEND

CLEAR TO SEND

NO CONNECTION

1

6

2

3

5

8

7

1, 4,

6, 9

DB-9 Female

PlasmaWall

1 5

6 9

SERIAL

IMINAR

L

Figure 3-5. RS-232 Connection from the DHD Controller to the PlasmaWall

Y

PRE

PlasmaWall XP Series Installation/Operation Manual 23

Page 40

Installation

Connecting Source

Components to the DHD

Controller

Connect your video sources to the DHD Controller as shown and described in the

➤

sections that follow.

HDMI Source Connections: See Figure 3-6.

Use the HDMI inputs whenever possible. This ensures the highest

Tip

Note

video quality because the signal is carried in the digital domain

throughout the entire signal path, from source component output

into the display.

You can also connect computers with DVI output to these inputs.

Refer to

input signals.

Supported Timings on page 76 for a list of compatible

Y

IMINAR

L

PRE

AV OUT

HDMI sources (BD, DVD, DTV Set-Top Box etc.)

HDMI

HDMI

AV OUT

Figure 3-6. HDMI Source Connections

24 PlasmaWall XP Series Installation/Operation Manual

Page 41

Component Video Source Connections: Connect your component video sources to

the HD1, HD2 and/or Component/SCART inputs as shown in

RCA-to-BNC

adapter

Figure 3-7.

Installation

Y

COMPONEN T

VIDEO OUT

BD/DVD

IMINAR

L

PRE

Y PB PR

DTV-Set-Top Box

(DTV-STB)

Figure 3-7. Component Video Source Connections

PlasmaWall XP Series Installation/Operation Manual 25

Page 42

Installation

RGBHV Source Connections: Connect personal computers and/or other RGB sources

to the HD1, HD2 and/or Component/SCART inputs as shown in

Figure 3-8.

Y

IMINAR

L

PRE

Computer

Green

or

Blue

Red

H-Sync

BNC-to-RCA

adapter

RGB Camcorder

V-Sync

Green

H-Sync

Blue

V-Sync

Red

Figure 3-8. RGBHV Source Connections

26 PlasmaWall XP Series Installation/Operation Manual

Page 43

SCART RGBS Source Connections: Connect the green, blue and red outputs from

your SCART source to the Component/SCART input on the DHD Controller. Connect the

sync output from your SCART source to the Video input on the DHD Controller. See

Figure 3-9.

Y

Installation

VCR

SCART-to-RGBS

adapter

DVD/DTV STB

Gaming Console

Figure 3-9. SCART RGBS Source Connections

PRE

L

Green

Blue

Red

Sync

IMINAR

Green

Blue

Red

Sync

PlasmaWall XP Series Installation/Operation Manual 27

Page 44

Installation

Composite and S-Video Source Connections: See Figure 3-10.

Y

VCR

Camcorder

IMINAR

L

Gaming Console

PRE

Figure 3-10. S-Video and Composite Video Source Connections

Composite

S-Video

S-Video

Composite

S-Video

S-Video

28 PlasmaWall XP Series Installation/Operation Manual

Page 45

Installation

Use a straight-through, 9-pin RS-232 cable to connect a PC or control/automation

system (if present) to the RS-232 port on the DHD Controller; see

For more information about using this connection, refer to External Control on page 63.

Figure 3-11.

Y

1

345

2

6

7

2 Receive Data

3 Transmit Data

5 Ground

to Automation/

Control System

or PC

89

IMINAR

(none of the other pins are used)

RS-232 Controller Connection

Figure 3-11. RS-232 Control System Connection

L

PRE

PlasmaWall XP Series Installation/Operation Manual 29

Page 46

Installation

Connecting 12-volt

Trigger Outputs to

External Equipment

If your installation includes equipment that responds to 12-volt triggers, connect it to the

➤

12-volt trigger outputs as shown in

To 12-volt

trigger-activated

device

Figure 3-12. Connecting 12-volt Trigger Outputs

Sleeve = Ground

Figure 3-12.

Tip = +12V

Y

IMINAR

L

PRE

30 PlasmaWall XP Series Installation/Operation Manual

Page 47

Installation

CUST

1

CUST

2

SVC

HDMI

1

HDMI

2

EXIT

RETURN

16 : 9

4 : 3

If infrared signals from the remote control cannot reach the DHD Controller due to

excessive distance or obstructions such as walls or cabinet doors, you can connect an

external IR receiver to the DHD Controller to extend the range of the remote control. See

Figure 3-13.

IR Sensor

Remote Control

Y

IR Repeater

Connecting an External IR Receiver to the DHD Controller

(3.5-mm, mini

phono plug)

L

PRE

Figure 3-13. External IR Receiver Connection

IMINAR

PlasmaWall XP Series Installation/Operation Manual 31

Page 48

Installation

Connecting AC Power Plug the female end of the power cord into the AC receptacle on the rear of the

➤

PlasmaWall. Connect the other end to your AC power source. (The XP-103DHD requires

200-240

XP-50DHD / XP-OPAL50DHD

VAC.)

Y

XP-65DHD / XP-OPAL65DHD

IMINAR

L

XP-103DHD (NOTE: The XP-103DHD requires 200 - 240 VAC)

PRE

Figure 3-14. AC Power Connection

Similarly connect the DHD Controller to a nearby AC outlet.

32 PlasmaWall XP Series Installation/Operation Manual

Page 49

4. Operation

1. Turn on your source components.

2. Press the main power switch on the PlasmaWall (see Figure 2-1, Figure 2-2 or Figure

2-3). Its standby/on indicator lights red.

3. Set the main power switch at the rear of the DHD Controller (see Figure 2-6) to the “on”

position. Its standby/on indicator lights amber.

4. Press the ON button on the remote control (or

the ON/STANDBY (

Controller front panel) to turn on the system. The

power indicator on the DHD Controller lights solid

blue; the standby/on indicator turns off.

5. After a brief warm-up period (approximately 10

seconds), the PlasmaWall will display an image.

To maximize image quality when using the PlasmaWall with a personal computer, you

may need to adjust the display properties of your computer’s video card. To do this on a

Microsoft® Windows®-based PC:

1. Choose Settings from the Windows Start

Menu and click on “Control Panel.”

) button on DHD

Y

IMINAR

L

PRE

4.1 Turning on the Power

4.2 Setting the Computer Display Properties

PlasmaWall XP Series Installation/Operation Manual 33

Page 50

Operation

2. Double click on the Display icon.

3. Click the Settings tab on the display dialog

box.

4. Set the Screen area to 1024x768 pixels.

5. Click the Advanced button and click the

Monitor tab on the dialog box. Set the

Refresh Frequency to 60Hz and click

OK.

IMINAR

L

Y

PRE

Note

WARNING

1. The native resolution of the PlasmaWall is 1920 x 1080. Other

horizontal or vertical resolutions may be scaled upward or

downward to fit the display.

2. With most computers, you can get the best picture at

1024

x 768 @ 60Hz.

To prevent image retention (burn) on your display, ALWAYS use a

screen saver and set it to the shortest possible time.

34 PlasmaWall XP Series Installation/Operation Manual

Page 51

Operation

To display the Main Menu, press the MENU button on the remote control (Figure 2-5) or

DHD Controller front panel (Figure 2-3).

To select a menu item, use the and buttons on the remote control or DHD Controller

front panel to highlight it. Then, to confirm your selection, press ENTER on the remote

control or DHD Controller front panel.

The PlasmaWall OSD menus are arranged hierarchically, as shown in Figure 4-1.

Depending on the selected input source and signal characteristics, some menu options

may not be available.

Input Source

Aspect Ratio

Picture

Input Position

Memory

Presets

Information

Composite

S-Video 1

S-Video 2

Component

HD1

HD2

SCART

HDMI 1

HDMI 2

16:9

4:3

Letterbox

VirtualWide

Cinema

Virtual Cinema

Native

Brightness

Contrast

Color

Tint

Sharpness

Noise Filter

Left/Right

Up/Down

Width

Height

Overscan

Overscan Mode

(Zoom/Crop)

Phase

(RGB/Component/SCART signals

only)

Tracking

(RGB/Component/SCART signals

only)

Recall ISF Night

Recall ISF Day

Recall/Save Custom 1

Recall/Save Custom 2

Reset Custom 1 and Custom 2 to

Factory Default

Signal

System

Field Service

Manufacturing

PRE

Display Color

Input Image

Calibration

Input Color

IMINAR

Save ISF Night

L

Note: Default settings appear in bold type.

Save ISF Day

Copy/Paste

Output Shift

Splash Configure

OSD Position Hor. / Ver. 0, 1, 2 ... 100

Gain

Offset

Y

Gamma

Color Temp

Black Level 0, 1, 2 ... 8

Input Level -100, -99... 0 ... 99, 100

Brightness

Contrast

Color

Tint

Sharpness

Gain -32, -31... 0 ... 31, 32

Offset

Chroma Delay

Noise Filter 0, 1, 2 ... 63

Back / Confirm

Copy Settings

Paste Settings

Left/Right

Up/Down

Width

Height

Owner Name

ISF Calibrated

ISF Other

Splash Timer 5, 6, 7 ... 15 ... 59, 60

Splash Enable On/Off

4.3 Using the On-Screen Menus

-100, -99... 0 ... 99, 100

(Red, Green, Blue)

2.0, 2.1, 2.2, 2.4, 2.5 or

S-Curve

Simple

(5500K, 6500K or 7500K)

-50, -49 ... 0 ... 49, 50

(HD 1, HD 2 and

Component inputs only)

0, 1, 2 ... 7

(S-Video 1, S-Video 2 and

Composite inputs only)

-50, -49 ... 0 ... 49, 50

-50, -49, 48 ... 0

Figure 4-1. PlasmaWall OSD Menu Structure

PlasmaWall XP Series Installation/Operation Manual 35

Page 52

Operation

Service

Color Bars 1

Test Video

Input Names Rename/Restore

Remote Control

Display Device - Configure

Color Space