Page 1

I NSTALLATION/OPERATION MANUAL

XtremeProjection™ Series

X-200i

Active 3D Home Theater Projector

X-200i

X-200i/CineWide

X-200i/CineWide with AutoScope

Page 2

Page 3

RuncoCare™ Standard Two Year Limited

Warranty

Congratulations on your purchase of a Runco® product! With proper installation, setup and care, you should enjoy many years

of unparalleled video performance.

This Limited Warranty is provided free of charge by Runco International, LLC (“Runco”) with the purchase of a covered Runco

product. This Limited Warranty is applicable to all Runco projectors, processors, LCD display and plasma display products,

with the exception of the following models: XP-103DHD, SC-1 and SC-1a1. This Limited Warranty applies to purchases of

covered Runco products occurring on or after June 1, 2011.

RuncoCare™ Limited Warranty Coverage

Runco warrants its products to be free from defects in material and workmanship during the warranty period provided below. If

a product proves to be defective in material or workmanship during the warranty period, Runco will repair the product, replace

the product with a substantially similar new or like-new product, or refund a prorated share of the purchase price (calculated

based on the remainder of the warranty period and the then-current, most-recent MSRP2 of a similar product), if repair or

replacement of the product is determined by Runco to not be feasible.

Length of RuncoCare™ Warranty Period

Runco products are warranted for two (2) years from the date of shipment from Runco. Lamps are warranted six (6) months

from the date of shipment or 1000 hours of use, whichever comes first. A replacement lamp is warranted for the remaining

portion (if any) of the original warranty period or ninety (90) days from the date it was shipped to you, whichever is longer. All

other accessories, which include but are not limited to cables, remotes, carrying cases, lens cap and other peripherals sold

with the Runco product, are warranted for ninety (90) days from the date of shipment.

RuncoCare™ Eligibility

This Limited Warranty is valid only in the country where the Product was originally purchased and for the buyer who originally

purchased the covered product from the authorized Runco dealer or distributor. This warranty is not transferable; it is not valid

for any subsequent buyer (if any). You may be required to provide proof of purchase in order to receive warranty services.

PRE

IMINAR

L

Y

1. Runco may update this list of products excluded from this warranty from time to time at Runco’s sole discretion, but updates will

not apply on a retroactive basis.

2. MSRP is defined as the most recent product price listed on Runco’s price list.

Runco X-200i Series Installation/Operation Manual iii

Page 4

RuncoCare™ Standard Claim Procedure

• In the event of a product defect, please follow the claim procedure provided below:

A. Register your product if you have not yet done so. Visit http://www.runco.com/support/product-registration/ to

register the product.

B. Contact your original authorized dealer or distributor who sold the product.

C. The dealer/distributor will contact Runco Technical Support via email at support@runco.com or via phone at 1-800-

23-RUNCO (1-800-237-8626).

• The dealer/distributor will provide to Runco proof of purchase, serial number, product model number, description of the

problem and any troubleshooting steps already attempted.

• Runco’s technical support staff will attempt to assist the dealer/distributor in troubleshooting any technical issues that might

be causing the product to malfunction. If Runco is unable to resolve the problem through troubleshooting, a Return Material

Authorization (RMA) number will be issued for the exchange of the defective product if it is determined that the claim is

covered by the warranty. Once an RMA has been created, RMA status is available at serviceorders@runco.com.

• If an RMA is issued, the dealer or customer will need to return the defective product to the Runco repair depot location

specified by the Runco technical support representative. The dealer or customer will need to properly package the defective

product in a suitable shipping container consisting of the product only, and not include any accessories (e.g., cables,

remotes, carrying cases, lens, lens cap and other peripherals). Boxes may be purchased from a Runco technical support

representative.

• The dealer or customer is responsible for paying freight charges and insurance to ship the defective product to the Runco

repair depot location. If there are any shipping damages, the dealer or customer will need to address and resolve any

shipping damage claims directly with the shipping company.

• Runco will not accept a returned product unless an RMA has been issued by Runco.

• For in-warranty repairs, Runco will pay freight charges to return the repaired/replacement product to the dealer/distributor

from the Runco repair depot. For select countries or geographies Runco will ship via an economy express service. Return

delivery time and availability may vary based on origin and destination, and Runco is unable to deliver to PO Box and FPO

Box addresses.

• Note: in the 48 contiguous United States, other options for on-site service or advance exchange for the product may apply,

if you purchased the Runco PremierCare™ Service Plan.

IMINAR

L

Y

What to Include with Your Return

1. Return only the defective product with the lamp (if applicable).

2. Runco will not be responsible for returning or replacing any accessories (e.g., cables, remotes, carrying cases, lens, lens

cap and other peripherals sold with the Runco product) that are returned with the defective product.

3. Repaired or replacement products will be shipped with a lamp (if applicable) but without any accessories.

RuncoCare™ Warranty Exclusions

This Limited Warranty does not include and is limited by the following:

1. Products not purchased from an authorized Runco dealer

2. Rental costs incurred by the customer in the event of product defect or failure

3. Any product with a defaced, modified, or removed serial number

PRE

iv Runco X-200i Series Installation/Operation Manual

Page 5

4. Damage, deterioration, or malfunction resulting from:

A. Accident, abuse, misuse, neglect, improper ventilation, fire, water, disaster, lightning, or other acts of nature, smoke

exposure (cigarette or otherwise), unauthorized product modification (including use of an unauthorized mount), or

failure to follow instructions supplied with the product

B. Repair or attempted repair by anyone not authorized by Runco

C. Any damage to the product due to shipment

D. Removal or installation of the product

E. Causes external to the product, such as electric power fluctuations or failure

F. Use of supplies or parts (including lamps) that are not purchased from Runco or do not meet Runco’s specifications

G. Normal wear and tear

H. Expected lamp degradation and normal decrease in lamp output over a period of time or as the lamp is consumed

I. Customer caused defects, including but not limited to, scratched/defaced/altered plastics

J. Failure to follow maintenance procedures as outlined in the product’s user guide where a schedule is specified for

regular cleaning of the product

K. Opening the product and/or tampering with internal circuitry

L. Products lost, stolen or discarded

M. Any damage or dissatisfaction associated with latent images, “burnin,” or any other damage determined by Runco to

be the result of customer use patterns

N. Any other cause, which does not relate to a product defect in material or workmanship

5. Removal, installation, and set-up service charges are excluded from the warranty.

6. Black uniformity issues or other LCD issues associated with usage outside the Runco recommended guidelines and

specifications for the product.

7. Bright or dark sub pixels that are characteristic of LCD technology and considered by Runco to be acceptable and within

Runco’s manufacturing specifications.

Specifically, it is not uncommon for one or more sub pixels to become bright or dark during or after the manufacturing

process. A bright sub pixel is one that remains in the on position, and a dark sub pixel is one that appears black or off. The

sub pixels are usually hard to see and will not detract from the display quality or usability at normal viewing distance. The

following are Runco’s criteria for identifying bright or dark sub pixels that would be considered unacceptable: a) the

number of bright or dark sub pixels; b) the location of the bright or dark sub pixels; c) the color of the bright sub pixels; and

d) the Runco model size. If sub pixels have been identified as unacceptable by Runco the LCD will be deemed faulty and

will be replaced if reported within the warranty period.

PRE

IMINAR

L

Y

Other Terms and Conditions

1. If the defective product is not properly packaged and is damaged in transit during its return to Runco, you may be invoiced

for either the repair costs, if repairable, or the MSRP of a replacement product and shipping costs incurred by Runco.

2. The repaired or replaced product will assume the remainder of your original product’s warranty term or 90 days from the

date the repaired or replaced product is shipped, whichever is longer.

3. If a replacement product is sent, the replacement becomes the property of the customer and the defective product

becomes the property of Runco.

Runco X-200i Series Installation/Operation Manual v

Page 6

RuncoCare™ Extended Service Options

Runco offers extended and expanded service plans. For information on additional product protection, please ask your

authorized Runco dealer, email serviceorders@runco.com or call (toll free) (800) 23RUNCO (800-237-8626).

Exclusion of Implied Warranties

RUNCO PROVIDES NO WARRANTIES, EXPRESS OR IMPLIED, EXCEPT THOSE EXPRESSLY PROVIDED IN THIS

DOCUMENT. RUNCO EXPRESSLY DISCLAIMS AND EXCLUDES ALL OTHER WARRANTIES, INCLUDING THE IMPLIED

WARRANTIES OF TITLE, NONINFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Limitation of Liability; Exclusion of Damages

Y

RUNCO’S MAXIMUM AGGREGATE LIABILITY IS LIMITED TO THE COST OF REPAIR, REPLACEMENT OR REFUND OF THE

PRODUCT.

RUNCO WILL NOT BE LIABLE FOR DAMAGE TO OTHER PROPERTY OR FOR DAMAGES BASED UPON INCONVENIENCE,

LOSS OF USE OF THE PRODUCT, LOSS OF TIME, LOSS OF PROFITS, LOSS OF BUSINESS OPPORTUNITY, LOSS OF

GOODWILL, INTERFERENCE WITH BUSINESS RELATIONSHIPS, OR OTHER COMMERCIAL OR FINANCIAL LOSS, EVEN IF

RUNCO IS AWARE OF THE POSSIBILITY OF SUCH DAMAGES AND EVEN IF A REMEDY HAS FAILED OF ITS ESSENTIAL

PURPOSE.

RUNCO WILL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, INDIRECT, EXEMPLARY, SPECIAL, PUNITIVE OR

ANY OTHER TYPE OF DAMAGES, WHETHER THE CLAIM IS BASED ON CONTRACT, TORT, PRODUCT LIABILITY,

NEGLIGENCE, STRICT LIABILITY OR ANY OTHER LEGAL OR EQUITABLE THEORY.

RUNCO WILL NOT BE LIABLE FOR ANY CLAIM AGAINST THE CUSTOMER BY ANY OTHER PARTY.

IMINAR

L

Effect of Local Law

This Limited Warranty gives you specific legal rights, and you may have other rights, which vary from locality to locality. Some

localities do not allow limitations on implied warranties and/or do not allow the exclusion of incidental or consequential

damages, so the above limitations and exclusions may not apply to you.

PRE

COPYRIGHT AND TRADEMARKS:

© Copyright 2012 Runco International, LLC (“Runco”). This document contains proprietary information protected by copyright,

trademark and other intellectual property laws. All rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic or other means, in any form, without prior written permission of Runco.

The trademarks reproduced in this Runco Owner’s Manual and used on the Runco Products are either owned by Runco or are

licensed by Runco. You may not reproduce or use the trademarks without the prior written consent of Runco.

Runco Products are manufactured under one or more of the following patents: US. Patent 6755540 and Other Patents

Pending.

vi Runco X-200i Series Installation/Operation Manual

Page 7

Important Safety Instructions

Thank you for your purchase of this quality Runco video product! For the best performance, please read this manual carefully

as it is your guide through the menus and operation.

WARNING

CAUTION

RISK OFELECTRIC SHOCK

DO NOTOPEN

TO REDUCE THE RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVER (OR BACK)

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

CAUTION:

SERVICE PERSONNEL.

This symbol is intended to alert the user to the presence of

uninsulated “dangerous voltage” within the product’s enclosure

that may be of sufficient magnitude to constitute a risk of electric

shock.

This symbol is intended to alert the user to the presence of

important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

Y

7. Do not block any of the ventilation openings. Install in accordance with the manufacturer’s instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including amplifiers) that

produce heat.

9. Do not defeat the safety purpose of the polarized or grounding type plug. A polarized plug has two blades with one wider

than the other. A grounding type plug has two blades and a third grounding prong. The wide blade or the third prong is

provided for your safety. When the provided plug does not fit into your outlet, consult an electrician for the replacement of

the obsolete outlet.

10. Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles and the point

where they exit from the apparatus.

11. Only use the attachments/accessories specified by the manufacturer.

12. Use only with a cart, stand, tripod, bracket or table specified by the manufacturer or sold with the apparatus.

When a cart is used, use caution when moving the cart/apparatus to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when unused for long periods of time.

14. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in

any way, such as power supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus,

the apparatus has been exposed to rain or moisture, does not operate normally, or has been dropped.

15. The +12V trigger only outputs 12Vdc signal for triggering. Do not connect to any other power input or output. This could

cause damage to this unit.

16. Keep the packing material in case the equipment should ever need to be shipped.

17. The lamp becomes extremely hot during operation. Allow the projector to cool down for approximately 45 minutes prior to

removing the lamp assembly for replacement.

18. Do not operate lamps beyond the rated lamp life. Excessive operation of lamps beyond rated life could cause them to

explode in rare occasions.

PRE

IMINAR

L

19. Never look directly into the lens when the lamp is on.

Runco X-200i Series Installation/Operation Manual vii

Page 8

IMPORTANT HEALTH AND SAFETY INFORMATION FOR 3D VIEWING:

Please read and make sure you understand the following safety information before using the product for viewing 3D content.

Provide this information to the end users of this product and ensure that they understand it.

WARNING

It is widely recognized that stereographic display devices can cause discomfort, including, without

limitation, dizziness, nausea, headaches, eye fatigue and eye-strain, in some individuals.

effect and experience will vary by individual, depending on a variety of factors, including his or her

health and vision.

playing games using stereoscopic displays.

young children should ensure their children avoid extensive exposure to electronic stereographic

entertainment.

Runco recommends that users take regular breaks when watching 3D video or

Discontinue use if any discomfort occurs. Parents of

The 3D

Y

The quality and appropriateness of the 3D screen materials onto which the image is projected and

the quality of the 3D content being displayed both have a significant and noticeable impact on the

overall 3D experience.

optimized third-party screen, displaying high-quality 3D content is the best formula for immersive

and comfortable 3D experiences in the home.

proper projector installation and usage instructions.

The glasses that accompany this product are not safe to use as sunglasses, protective eyewear or

any use outdoors or other than only in conjunction with the proper operation of the Runco product

with which they are sold.

the immersive imagery of stereoscopic imagery can increase the risk of tripping or falling the dark.

Special care should be taken.

A properly-calibrated projection system, including glasses and an

Please refer to the remainder of this manual for

It is common to dim the lights in a home theater. Using 3D glasses and

IMINAR

Do not tilt your head while using the 3D glasses.

L

PRE

viii Runco X-200i Series Installation/Operation Manual

Page 9

Compliance Information

DECLARATION OF CONFORMITY:

Manufacturer’s Name: Runco International, LLC

Manufacturer’s Address: 1195 NW Compton Drive, Beaverton, OR 97006-1992

hereby declares that the Products’ Model Numbers:

X-200i, X-200i/CineWide and X-200i/CineWide with AutoScope

conform with the provisions of:

Council Directive 2004/108/EC on Electromagnetic Compatibility;

EN 55022 “Limits and methods of measurements of radio interference characteristics of information technology equipment”

1998;

EN 55024 “Limits and methods of measurements of immunity characteristics of information technology equipment” 1998;

Including:

• EN 61000-4-2 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 2:

Electrostatic discharge immunity test”

• EN 61000-4-3 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 3: Radiated,

Radio-Frequency, Electromagnetic Field Immunity Test”

• EN 61000-4-4 “Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 4: Electrical

fast transient/burst immunity test”

• EN 61000-4-5 "Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 5: Surge

immunity test"

• EN 61000-4-6 "Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 6: Conducted

disturbances induced by radio-frequency fields immunity test"

• EN 61000-4-8 "Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 8: Conducted

disturbances induced by power frequency magnetic fields immunity test"

• EN 61000-4-11 "Electromagnetic compatibility (EMC) Part 4: Testing and measurement techniques Section 11: Voltage

dips, short interruptions and voltage variations immunity tests"

PRE

IMINAR

L

Y

And:

• EN 61000-3-2 "Electromagnetic compatibility (EMC) Part 3, Section 2: Limits for harmonic current emissions (equipment

input current up to and including 16 A per phase)" 2000;

• EN 61000-3-3 "Electromagnetic compatibility (EMC) Part 3, Section 3: Limitations of voltage changes, voltage

fluctuations and flicker in public low-voltage supply systems, for equipment with rated current up to and including 16 A

and not subject to conditional connection" 1995;

Council Directive 2006/95/EC and amended by M1 and C1 on Low Voltage Equipment Safety;

EN 60950 “Safety of information technology equipment, including electrical business equipment”

The Technical Construction file required by this Directive is maintained at the corporate headquarters of Runco International,

LLC, located at 1195 NW Compton Drive, Beaverton, OR 97006-1992.

Date of Declaration: September 2012

Runco X-200i Series Installation/Operation Manual ix

Page 10

FCC PART 15:

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

INDUSTRY CANADA (ICES-003):

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Y

PRODUCT DISPOSAL:

IMINAR

The Product contains small amounts of tin, lead and/or mercury. Disposal of these materials may be regulated due to

environmental considerations.

IMPORTANT RECYCLE INSTRUCTIONS

Lamp(s) inside this product contain mercury. This product may contain other electronic waste that can be

hazardous if not disposed of properly. Recycle or dispose in accordance with local, state, or federal Laws.

L

PRE

For more information, contact the Electronic Industries Alliance at WWW.EIAE.ORG.

For lamp specific disposal information check WWW.LAMPRECYCLE.ORG.

DISPOSAL OF OLD ELECTRICAL AND ELECTRONIC EQUIPMENT (Applicable throughout the European

Union and other European countries with separate collection programs)

This symbol found on your product or on its packaging, indicates that this product should not be treated as

household waste when you wish to dispose of it. Instead, it should be handed over to an applicable collection

point for the recycling of electrical and electronic equipment. By ensuring this product is disposed of correctly,

you will help prevent potential negative consequences to the environment and human health, which could

otherwise be caused by inappropriate disposal of this product. The recycling of materials will help to conserve

natural resources. This symbol is only valid in the European Union. If you wish to discard this product, please

contact your local authorities or dealer and ask for the correct method of disposal.

x Runco X-200i Series Installation/Operation Manual

Page 11

1Table of Contents

RuncoCare™ Standard Two Year Limited Warranty ................................................... iii

Important Safety Instructions ....................................................................................... vii

Compliance Information ................................................................................................ ix

1. Introduction ............................................................................................................... 1

About This Manual ....................................................................................................... 1

Target Audience ..................................................................................................... 1

If You Have Comments About This Manual... ..........................................................1

Textual and Graphic Conventions ...........................................................................1

Using This Manual ........................................................................................................ 2

Description, Features and Benefits ...............................................................................3

Key Features and Benefits ...................................................................................... 4

Parts List ................................................................................................................4

2. Controls and Functions ............................................................................................ 5

X-200i at a Glance ........................................................................................................ 5

X-200i Rear Panel ........................................................................................................ 7

Controls and Indicators ................................................................................................9

X-200i Remote Control ............................................................................................... 10

X-200i Active 3D Emitter ............................................................................................12

3. Installation ...............................................................................................................13

Remote Control ..........................................................................................................13

IMINAR

L

Y

PRE

Notes on Batteries ................................................................................................ 13

Notes on Remote Control Operation ..................................................................... 13

Quick Setup ...............................................................................................................15

Installation Considerations ..........................................................................................16

Installation Type ....................................................................................................16

Ambient Light .......................................................................................................17

Throw Distance..................................................................................................... 17

Vertical and Horizontal Position ............................................................................. 19

Lens Shift ............................................................................................................. 19

Folded Optics .......................................................................................................22

Other Considerations ............................................................................................22

Runco X-200i Series Installation/Operation Manual xi

Page 12

Table of Contents

Installing the Optional CineWide Lens Mount ..............................................................23

Installing the Lens Motor (X-200i/CineWide with AutoScope) ................................24

Installing the Fixed CineWide Base Plate (Prismatic Anamorphic Lens)..................26

Installing the Fixed CineWide Base Plate (Cylindrical Anamorphic Lens) ................27

Mounting the X-200i ...................................................................................................28

Floor Mounting (Upright) ....................................................................................... 28

Ceiling Mounting (Inverted) .................................................................................... 28

Adjusting the Projection Angle ..............................................................................28

Connections to the X-200i ..........................................................................................29

Connector Panel Access.......................................................................................29

Connecting Source Components to the X-200i..................................................... 30

RS-232 Controller Connection ..............................................................................33

Connecting an External IR Receiver to the Projector ............................................. 34

Connecting 12-Volt Trigger Output to External Theater Equipment ....................... 34

Connecting the Active 3D Emitter to the Projector ................................................35

Connecting to AC Power ...................................................................................... 35

Turning on the Power ................................................................................................. 36

Lens Adjustments ...................................................................................................... 37

Focus and Zoom .................................................................................................. 37

Lens Shift ............................................................................................................. 37

Changing the OSD Language .....................................................................................38

Adjusting the Picture Orientation ................................................................................ 39

Rear Projection ..................................................................................................... 39

Ceiling Mode.........................................................................................................39

PRE

Installing and Adjusting the CineWide Anamorphic Lens ............................................. 39

Cylindrical Anamorphic Lens Installation and Adjustment ......................................40

IMINAR

L

Y

Whitney (Prismatic) Anamorphic Lens Installation and Adjustment.........................45

xii Runco X-200i Series Installation/Operation Manual

Page 13

Table of Contents

4. Operation .................................................................................................................49

Selecting Video Memory ............................................................................................. 49

Selecting an Aspect Ratio ..........................................................................................49

Selecting An Input Source .......................................................................................... 49

Using the On-Screen Menus ......................................................................................50

Main ..................................................................................................................... 52

Image ...................................................................................................................59

Advanced Image................................................................................................... 63

System ................................................................................................................. 68

Control .................................................................................................................70

Service ................................................................................................................. 71

Using the 3D Glasses .................................................................................................73

Key Features.........................................................................................................73

Functional Overview.............................................................................................. 73

Charging the Battery .............................................................................................74

Y

Turning On the Glasses ........................................................................................ 75

Auto Power-Off..................................................................................................... 75

5. Maintenance and Troubleshooting ........................................................................ 77

Lamp Replacement .................................................................................................... 77

Troubleshooting Tips .................................................................................................. 78

6. External Control ......................................................................................................81

Serial Communications ............................................................................................... 81

RS-232 Connection and Port Configuration ..........................................................81

Command Format ................................................................................................ 81

IMINAR

L

PRE

RS-232 Error Codes ............................................................................................. 91

Using Discrete IR Codes ............................................................................................ 92

IR Command Protocol .......................................................................................... 92

Using HDMI CEC Messages ....................................................................................... 93

CEC Command List.............................................................................................. 93

7. Specifications ..........................................................................................................95

X-200i Specifications .................................................................................................. 95

X-200i Dimensions ..................................................................................................... 97

Supported Timings ..................................................................................................... 98

Runco X-200i Series Installation/Operation Manual xiii

Page 14

Table of Contents

Notes:

Y

IMINAR

L

PRE

xiv Runco X-200i Series Installation/Operation Manual

Page 15

1List of Figures

2-1. X-200i Key Functional Components .............................................................................5

2-2. X-200i Rear View (without Door) ................................................................................... 7

3-1. IR Reception Angles ................................................................................................... 14

3-2. Estimating Throw Distance .........................................................................................17

3-3. Projector Placement ................................................................................................... 19

3-4. Vertical Lens Shift (Example Only) ............................................................................... 19

Y

3-5. Horizontal Lens Shift (Example Only)...........................................................................20

3-6. Folded Optics............................................................................................................. 22

3-7. X-200i/CineWide with AutoScope Motor Assembly – Exploded View.......................... 24

3-8. Connecting the AutoScope Lens Transport Motor to the Projector ............................. 25

3-9. Projector with Whitney (Prismatic) Lens Base Plate - Bottom View ............................. 26

3-10. X-200i/CineWide with McKinley (Cylindrical) Lens Base Plate and

Ceiling Mounting Rails - Bottom View ......................................................................... 27

3-11. HDMI/DVI Source Connections ................................................................................ 30

3-12. RGB Connection ...................................................................................................... 31

3-13. Component Video Connections................................................................................32

3-14. RS-232 Control System Connection......................................................................... 33

3-15. External IR Receiver Connection............................................................................... 34

3-16. 12-Volt Trigger Output Connection........................................................................... 34

3-17. Active 3D Emitter Connection ................................................................................... 35

3-18. Cylindrical Anamorphic Lens Mounting Assembly - Exploded View........................... 40

IMINAR

L

PRE

3-19. Attaching the Anamorphic Lens to the Lens Ring ..................................................... 41

3-20. Prismatic Anamorphic Lens Mounting Assembly - Exploded View ............................45

4-1. X-200i OSD Menu Structure ....................................................................................... 51

4-2. X-200i Main Menu ...................................................................................................... 52

4-3. Overscan Examples.................................................................................................... 57

4-4. X-200i Image Menu .................................................................................................... 59

4-5. Typical PLUGE Pattern for Adjusting Brightness ......................................................... 60

4-6. Typical Gray Bar Pattern for Adjusting Contrast .......................................................... 61

4-7. Typical Test Pattern for Adjusting Sharpness..............................................................62

4-8. X-200i Advanced Image Menu ...................................................................................63

4-9. CIE 1931 Color Coordinate Diagram and Effect of PCE Hue and Saturation

Controls ..................................................................................................................... 67

4-10. X-200i System Menu ................................................................................................ 68

Runco X-200i Series Installation/Operation Manual xv

Page 16

List of Figures

4-11. X-200i Service Menu ................................................................................................71

6-1. NEC Protocol Message Format .................................................................................. 92

7-1. X-200i Dimensions ..................................................................................................... 97

Y

IMINAR

L

PRE

xvi Runco X-200i Series Installation/Operation Manual

Page 17

Introduction

1. Introduction

This Owner’s Manual describes how to install, set up and operate the Runco

XtremeProjection™ Series X-200i Active 3D Home Theater Projector.

Throughout this manual, the Runco XtremeProjection™ Series X-200i Active 3D Home

Theater Projector is referred to as the “X-200i.”

most out of the X-200i.

Runco has made every effort to ensure that this manual is accurate as of the date it was

printed. However, because of ongoing product improvements and customer feedback, it

may require updating from time to time. You can always find the latest version of this and

other Runco product manuals on-line, at www.Runco.com.

Runco welcomes your comments about this manual. Send them to info@Runco.com.

Text Conventions: The following conventions are used in this manual, in order to clarify

the information and instructions provided:

• Remote control and keypad button identifiers are set in upper-case bold type; for

example, “Press EXIT to return to the previous menu.”

• Computer input (commands you type) and output (responses that appear on-screen) is

shown in monospace (fixed-width) type; for example: “To change the aspect ratio to

Letterbox, type op

• All keys with functional names are initial-capped, set in bold type and enclosed in angle

brackets. These keys are the following: <Enter>, <Spacebar>, <Control>,

<Esc> and <Tab>.

• <Enter> indicates that you may press either the RETURN or ENTER key on your

keyboard if it has both keys.

In addition to these conventions, underlining, boldface and/or italics are occasionally used

to highlight important information, as in this example:

aspect = 1 <Enter>. ”

PRE

IMINAR

L

Y

1.1 About This Manual

Target AudienceRunco has prepared this manual to help home theater installers and end users get the

If You Have Comments About This Manual...

Textual and Graphic Conventions

Note

Runco X-200i Series Installation/Operation Manual 1

A carriage return must be used after each command or string.

Page 18

Introduction

Graphic Conventions: These symbols appear in numerous places throughout the

manual, to emphasize points that you must keep in mind to avoid problems with your

equipment or injury:

TIPS highlight time-saving short cuts and helpful guidelines for using

Tip

certain features.

1.2

Using This Manual

Note

Caution

NOTES emphasize text with unusual importance or special

significance. They also provide supplemental information.

CAUTIONS alert users that a given action or omitted action can

degrade performance or cause a malfunction.

Y

WARNING

DANGER!

Use the following table to locate the specific information you need in this manual.

WARNINGS appear when a given action or omitted action can result

in damage to the equipment, or possible non-fatal injury to the user.

DANGER appears when a given action can cause severe injury or

death.

IMINAR

If you need... ... Turn to page:

Information about obtaining service iv

General information about the XtremeProjection™ Series X-200i

Active 3D Home Theater Projector

L

3

Installation instructions 13

PRE

First-time configuration instructions 37

Advanced configuration instructions 63

Troubleshooting tips 78

Specifications for the XtremeProjection™ Series X-200i Active 3D

Home Theater Projector

95

2 Runco X-200i Series Installation/Operation Manual

Page 19

Introduction

Runco’s XtremeProjection™ Series X-200i Active 3D Home Theater Projector — the

flagship member of the XtremeProjection series — is a single-chip DLP projector that,

uncalibrated, measures 1,430 ANSI lumens and when calibrated to Runco’s CSMS™

specifications, achieves a light output of 50 Foot-Lamberts (fL). Featuring integrated

processing and multiple lens options, the 3D-capable X-200i comes equipped with three

pairs of active 3D glasses and relies on frame-sequential 3D technology to ensure that

users can enjoy 2D and 3D content on the same screen, with full 1080p HD resolution

delivered to both eyes.

Designed specifically for the custom installer who specializes in high-end theaters and

appreciates craftsmanship and video quality, the X-200i brings big screen experiences to

the home. The X-200i relies on a combination of state-of-the-art, DLP-based

SuperOnyx™ technology and proprietary electronics, processing and optics to deliver

stunning images in both 2D and 3D. The X-200i incorporates the ISF™ (Imaging Science

Foundation) calibration suite for optimal performance, including ISF Day and ISF Night

presets for the ultimate video performance any time of day.

For unparalleled widescreen reproduction of movies originally filmed in the

CinemaScope™ 2.35:1 format, the X-200i can also be paired with Runco’s

award-winning CineWide™ technology. Through an ingenious combination of software,

electronics and precision anamorphic optics, CineWide maintains constant image height

on the screen just as in a movie theater. When a viewer transitions from 1.78:1 (16:9)

program material to superwide 2.35:1, the image simply gets wider while image height is

maintained.

With Runco CineWide, the projection system is able to use the full pixel array, thereby

producing a 2.35:1 image with enhanced resolution and increased brightness. No

resolution or image area is lost to those black bars that contain no picture information.

IMINAR

L

Y

1.3 Description, Features and Benefits

Note

Rounding out this impressive projector are discrete input source, aspect ratio and power

on/off, as well as an RS-232 interface for seamless integration with automation control

systems.

CineWide requires the use of a 2.35:1 (or similar aspect ratio),

“superwide” format screen.

PRE

Runco X-200i Series Installation/Operation Manual 3

Page 20

Introduction

➤

➤

Key Features and Benefits The X-200i offers these key features and benefits:

• Native Resolution: 1920 x 1080 (16:9 Native Aspect Ratio)

• DLP system using high-performance Digital Micromirror Device (DMD)

• Customized color wheel produces wide dynamic range and rich grayscale

• Two (2), HDMI Inputs with High-bandwidth Digital Content Protection (HDCP)

• HDMI 1.4a Full-HD 3D Support

• HDTV Compatible

• Very high optical contrast

• Horizontal and vertical lens shift

Parts List Your X-200i is shipped with the following items. If any items are missing or damaged,

please contact your Runco dealer or Runco Customer Service at (800) 23RUNCO.

• XtremeProjection™ Series X-200i Active 3D Home Theater Projector

• Remote Control Unit and two (2), AA-size batteries

• AC Power Cords (North America, Europe, United Kingdom)

• Cleaning Cloth

• 5.0-mm Hex wrench (for lens shift adjustment)

• Active 3D Emitter and projector interface cable, 3.28 feet (1.0 meters)

• Active 3D Glasses (3 pairs)

• Runco X-200i Quick Setup Guide

Y

Optional Accessories:

• CineWide™ technology (fixed, secondary anamorphic lens)

• CineWide™ with AutoScope™ system (secondary anamorphic lens and motorized

mount)

• Additional 3D glasses

• Ceiling mount kit (part number 956-0074-00)

• Short-throw primary lens, 1.56:1-1.86:1

PRE

• Long-throw primary lens, 2.40:1-4.00:1 (part number 160-0774-00)

• Replacement Lamp

IMINAR

L

4 Runco X-200i Series Installation/Operation Manual

Page 21

Controls and Functions

2. Controls and Functions

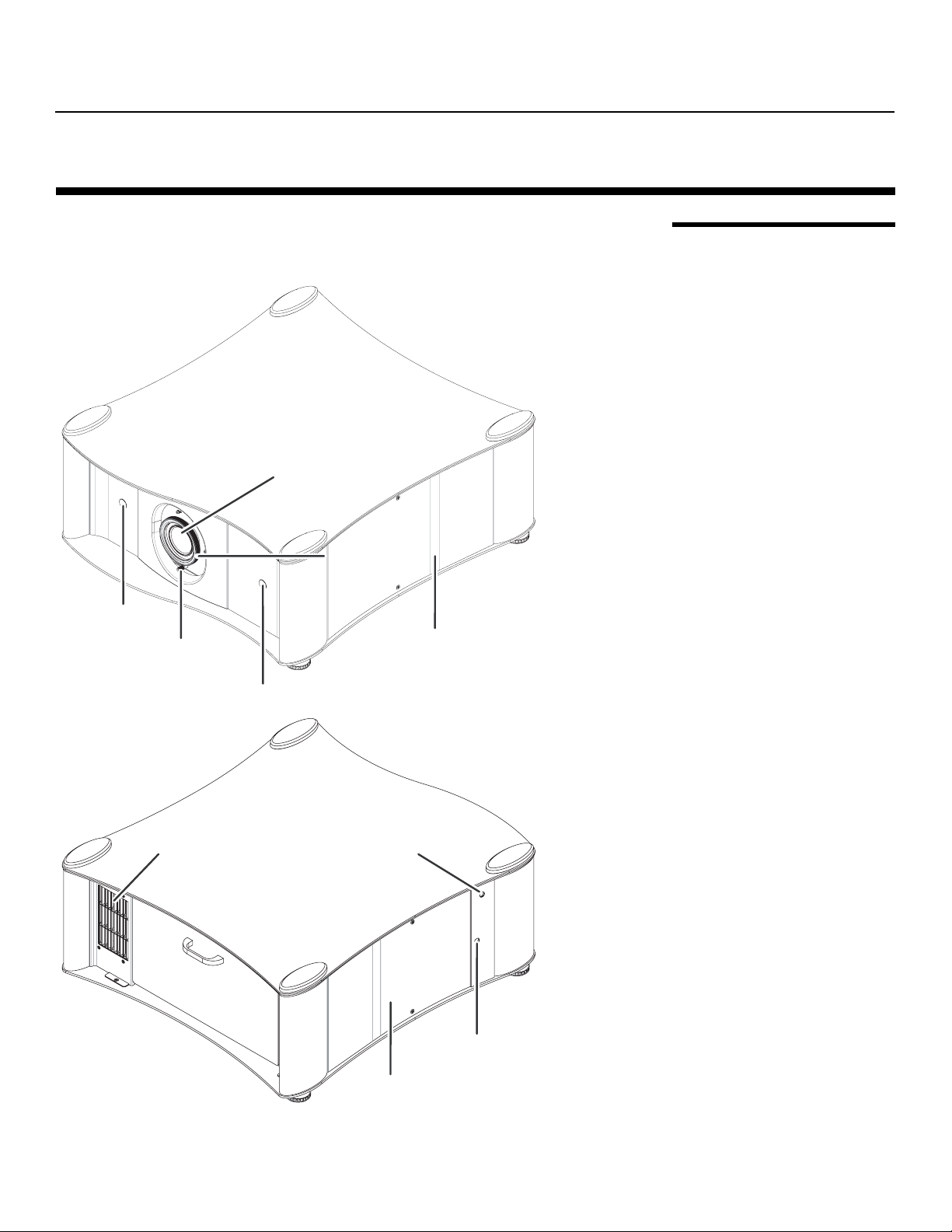

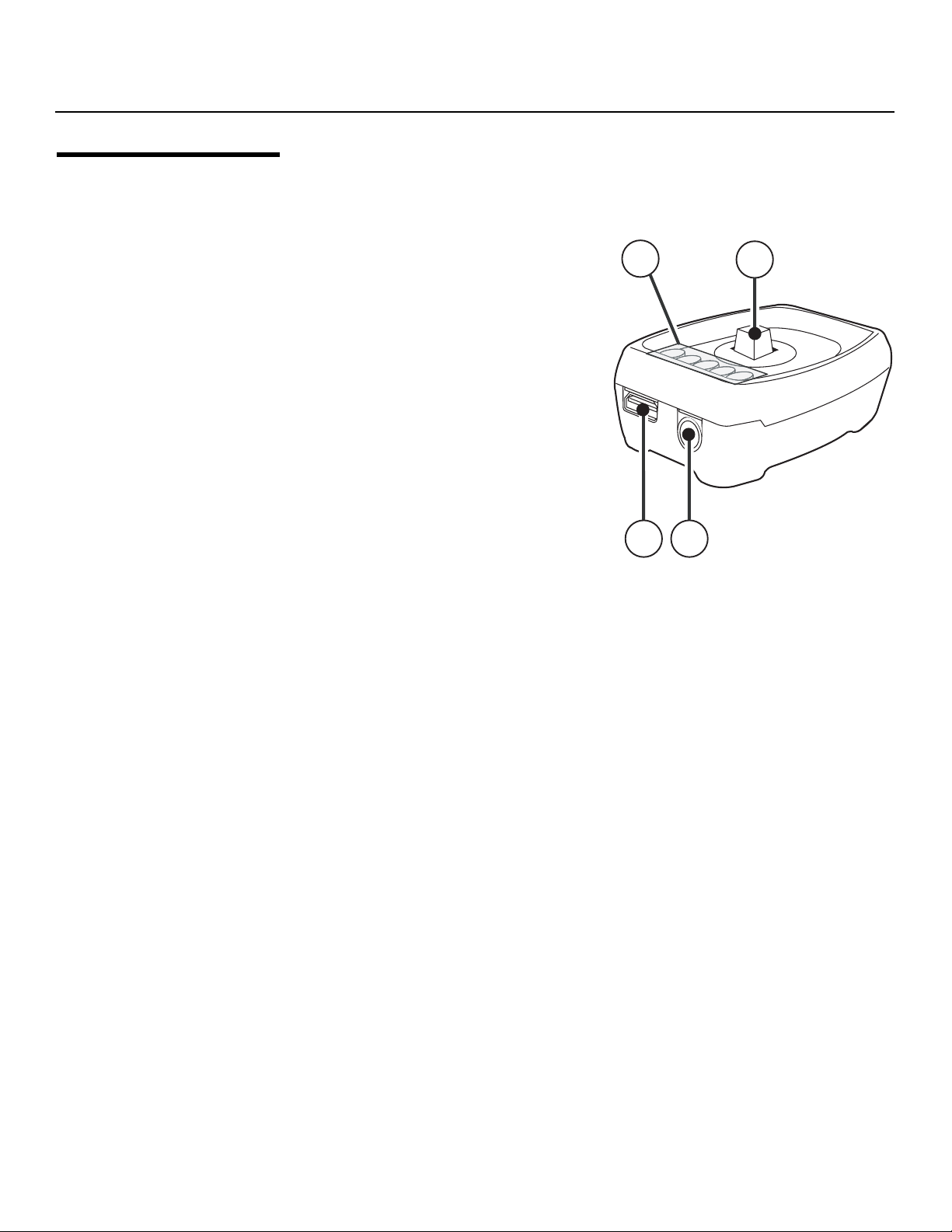

Figure 2-1 shows the key X-200i functional components.

Projection Lens

Focus Ring

IR Sensor

Zoom Control/

Lens Lock

IR Sensor

IMINAR

Exhaust Vent

L

2.1 X-200i at a Glance

Y

PRE

Exhaust Vent

Figure 2-1. X-200i Key Functional Components

Runco X-200i Series Installation/Operation Manual 5

Vertical

Lens Shift

Control

Intake Vent

Horizontal

Lens Shift

Control

Page 22

Controls and Functions

• PROJECTION LENS

Available in three versions: standard throw range (1.85:1 to 2.40:1), short throw range

(1.56:1 to 1.86:1) and long throw range (2.40:1 to 4.00:1).

• IR SENSORS

Two sensors on the front of the projector receive infrared signals from the remote

control unit.

• FOCUS RING

Rotate this to focus the projected image.

• ZOOM CONTROL / LENS LOCK

Move this from side to side to change the projected image size. To lock the position of

the lens, tighten the knob with a flat-blade screwdriver.

• REAR DOOR

Open this door to access the lamp compartment, input panel and system keypad (refer

to

X-200i Rear Panel on page 7).

• HORIZONTAL AND VERTICAL LENS SHIFT CONTROLS

To use the lens shift controls, first ensure that the lens lock is not engaged. Then, insert

the included 5.0-mm Hex wrench into the opening and turn it as needed to shift the

lens in the desired direction (refer to Lens Adjustments on page 37).

Y

Caution

• EXHAUST VENTS

Warm air exits the projector through these vents. Ensure that they are not blocked.

• INTAKE VENT

Internal fans draw cool air into the projector through this vent.

IMINAR

L

PRE

Do not attempt any lens adjustments when the lens lock is

engaged. Doing so may cause damage to the zoom or lens shift

mechanisms.

6 Runco X-200i Series Installation/Operation Manual

Page 23

Controls and Functions

R

SOURC

E

C

R

E

ISSUE

PO

R

LED ST

TUS

LED ST

ATTTUSAA

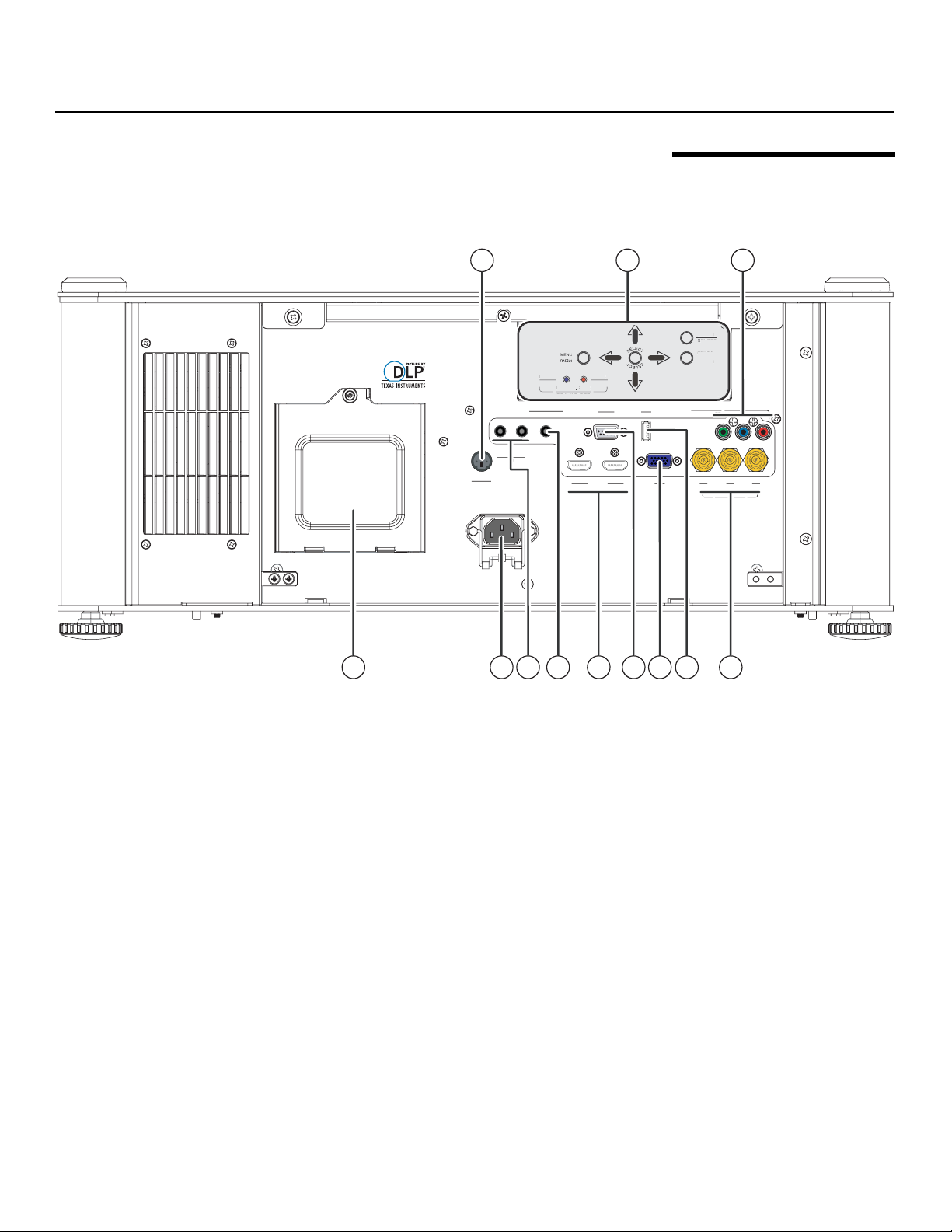

Figure 2-2 shows the X-200i rear panel.

2.2 X-200i Rear Panel

HDMI 1

11

SOURCE

POWER

WER

ISSUE

ISSU

ISSUE

LED STATUS

Y

RS-232

USB

RS-232

HDMI 2

HDMI 2

HDMI

COMPONENT 1

USB

RGB

RGB

YYPbPbPr

12

3D SYNC

III

12V TRIGGER

3D SYNC

WIRED REMOTE

12V TRIGGER

POWER

POWE

POWE

POWER

LED STATUS

WIRED REMOTE

IMINAR

SOURC

SOUR

POWER

POWE

COMPONENT

COMPONENT 2

10

Pr

COMPONENT 2

L

1

2 5 7 86

43 9

Figure 2-2. X-200i Rear View (without Door)

1. LAMP COMPARTMENT COVER

Remove this cover to access the lamp compartment when replacing the lamp.

PRE

2. POWER INPUT (100 to 240 VAC)

Connect the X-200i to power here.

3. TRIGGER 1 (3.5-mm, mini phono jack)

TRIGGER 2 (3.5-mm, mini phono jack)

Provide 12 (+/- 1.5) volt switched output for screen relays with 250mA current

capacity and short protection.

4. WIRED REMOTE

Wired input from a Niles- or Xantech-compatible, infrared (IR) repeater system. It is a

3.5-mm, mini phono jack, wired as follows:

Ring = No connection

Tip = IR Input

Sleeve = Ground

5. HDMI 1 (Digital)

HDMI 2 (Digital)

HDCP-compliant digital video inputs for connecting an HDMI or DVI source.

Runco X-200i Series Installation/Operation Manual 7

Page 24

Controls and Functions

6. RS-232

A female, 9-pin D-sub connector for interfacing with a PC or home theater

automation/control system.

7. RGB

Provides a standard, 15-pin VGA-style connection to either an RGB or component

high-definition source, or to a personal computer. The X-200i automatically detects

the input signal resolution.

8. USB

A standard, Type A USB connector for performing firmware upgrades. Can also

provide power to a 3D emitter.

9. COMPONENT 2

Three BNCs for connecting component (YPbPr) video sources.

10. COMPONENT 1 (RCA connectors)

Standard- or high-definition (480i/480p/576i/576p/720p/1080i/1080p) Component

(YPrPb) input for connecting a DVD/HD-DVD/BD player, HD set-top box or other

SD/HD source.

11. SYSTEM KEYPAD AND LED INDICATORS

Provides an alternative to using the remote control unit to navigate the On-Screen

Display (OSD) controls (refer to

12. 3D SYNC

A 3-pin, VESA standard mini-DIN connector for connecting the Active 3D Emitter to

the projector (see

Figure 3-17).

Controls and Indicators on page 9).

Y

IMINAR

L

PRE

8 Runco X-200i Series Installation/Operation Manual

Page 25

Controls and Functions

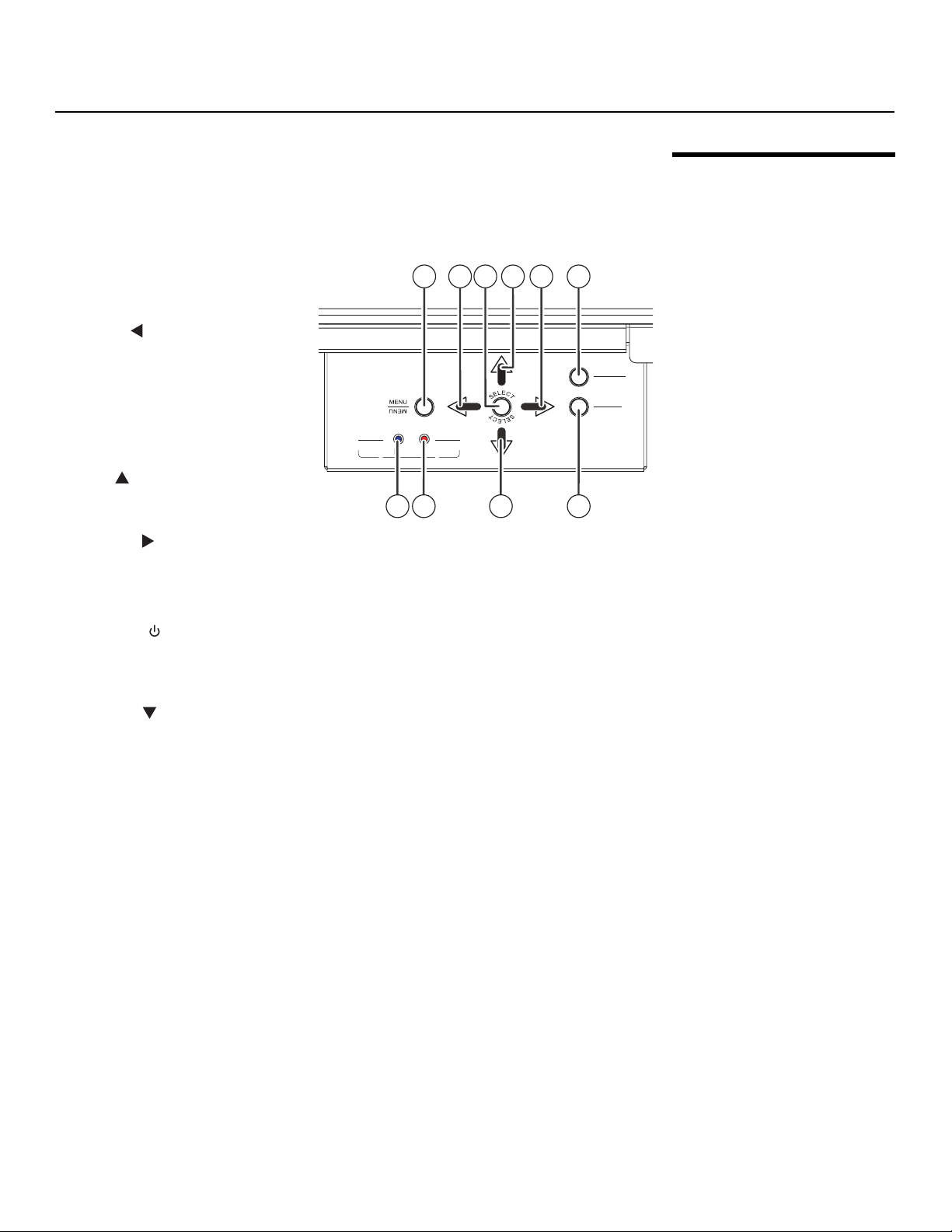

An eight-button keypad on the projector rear panel provides an alternative to the remote

control unit for controlling the projector.

Two LEDs next to the keypad provide visual indications of the current operational state of

the projector. During normal operation, both of these LEDs are off.

1. MENU

Press this button to show or

hide the OSD controls.

2. LEFT ( )

Use this button to move the

cursor left in the OSD.

3. SELECT

Press to select a highlighted

menu item or confirm a

changed setting.

4. UP ( )

Use this button to move the

cursor left in the OSD.

5. RIGHT ( )

Use this button to move the cursor right in the OSD.

6. SOURCE

Press this button repeatedly to select a video source.

7. POWER

Press once to turn on the X-200i. Press it again to put the projector into Standby

mode. For a discrete on or off command, you can use the direct access buttons on

the remote control (see

8. DOWN ( )

Use this button to move the cursor down in the OSD.

X-200i Remote Control on page 10).

POWER

L

1 2 53 4

SOURCE

SOURCE

Y

POWER

POWER

LED STATUS

ISSUE

ISSUE

POWER

LED STATUS

1069 8 7

IMINAR

2.3 Controls and Indicators

9. ISSUE LED (Red)

Indicates various error conditions, as follows:

– Flashes once to indicate a lamp problem (unable to strike, end of life); user

intervention likely to fix problem.

– Flashes twice in quick succession to indicate that the lamp door is open.

– Flashes four times in quick succession to indicate an “over temperature” condition;

user intervention (clear vents, turn on AC) may fix problem.

– Lights solid to indicate an error that requires servicing (fan fail, Power-on self-test fail

etc.).

– During normal operation, this LED is off.

10. POWER LED (Blue)

– Lights solid to indicate that the projector is in standby mode, ready to start.

– Flashes (one half-second on/one half-second off) for approximately 90 seconds

after the system is turned on (warm-up) or turned off (cool-down).

– During normal operation, this LED is off.

Runco X-200i Series Installation/Operation Manual 9

PRE

Page 26

Controls and Functions

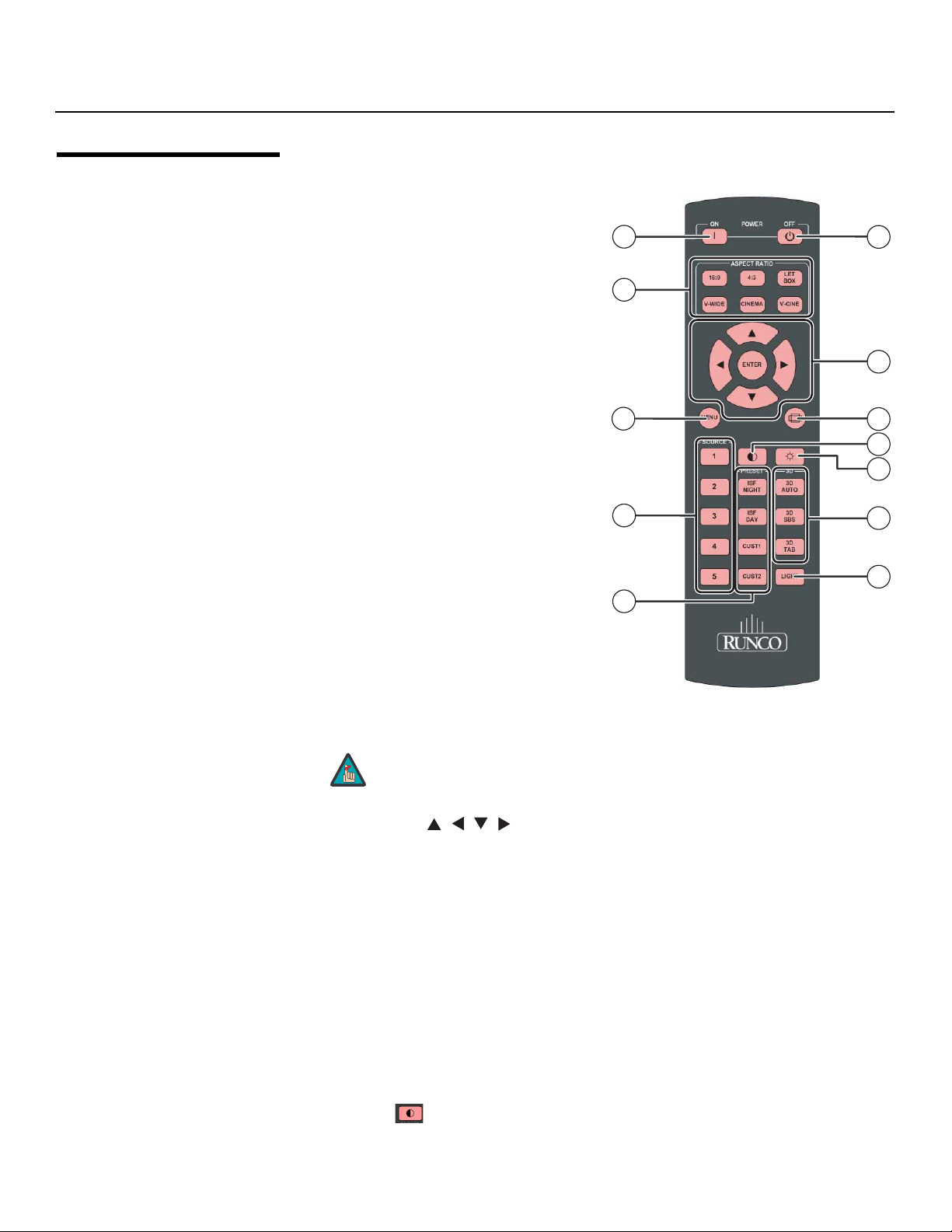

2.4

X-200i Remote Control

1. ON

Use this button to turn the projector

on.

2. OFF

Use this button to turn the projector

off.

3. Aspect Ratio Selection Buttons

Press one of these buttons to select

an aspect ratio:

16 : 9: For viewing 16:9 DVDs or

HDTV programs in their native aspect

ratio.

4 : 3: Scales the input signal to fit 4:3

sources in the center of the screen.

LETBOX (Letterbox): For viewing

non-anamorphic (“full-screen”) DVDs

on a 16:9 screen.

V-WIDE (VirtualWide): Enlarges a

4:3 image horizontally in a non-linear

fashion to fit a 16:9 full screen

display.

CINEMA: For viewing 2.35:1 source

material.

V-CINE (Virtual Cinema): Selects

the Virtual Cinema aspect ratio, used

for viewing 16:9 source material on a

2.35:1 screen.

L

IMINAR

1

3

2

4

Y

5

7

10

6

8

9

11

12

Note

PRE

4. Cursor Keys ( , , , )

Use these buttons to select items or settings, adjust settings or switch display

patterns.

ENTER

Press to select a highlighted menu item or confirm a changed setting.

5. MENU

Press this button to show or hide the OSD controls.

6. Aspect Ratio Selection Button

Press this button repeatedly to select an aspect ratio.

7. Source Selection Buttons (1-5):

Press to select a video source. These buttons are assigned as follows: 1 = HDMI 1;

2 = HDMI 2; 3 = Component 1; 4 = Component 2; 5 = RGB.

8. Contrast

Press to adjust white level.

For more information about aspect ratios, refer to Table 4-1.

10 Runco X-200i Series Installation/Operation Manual

Page 27

9. Brightness

Press to adjust black level.

10. Memory Preset Buttons:

ISF NIGHT

Press to recall settings for the current input from the “ISF Night” memory preset.

ISF DAY

Press to recall settings for the current input from the “ISF Day” memory preset.

CUST 1

Press to recall settings for the current input from the “Custom 1” memory preset.

CUST 2

Press to recall settings for the current input from the “Custom 2” memory preset.

11. 3D Mode Selection Buttons:

3D AUTO

Press to set the 3D Mode to Auto.

3D SBS (Side-by-Side)

Press to set the 3D Mode to 3D Side-by-Side.

3D TAB (Top-and-Bottom)

Press to set the 3D Mode to 3D Top-and-Bottom.

IMINAR

Note

For more information about 3D modes, refer to 3D Mode on

page 58.

L

Controls and Functions

Y

12. LIGHT

Press momentarily to activate remote backlighting.

PRE

Runco X-200i Series Installation/Operation Manual 11

Page 28

Controls and Functions

2.5

X-200i Active 3D Emitter

The Active 3D Emitter, shown below, receives a left/right synchronization signal from the

projector and transmits it to the Active 3D Glasses worn by the viewers. This signal

precisely controls when left and right fields are visible through the glasses.

The Active 3D Emitter has the following

functional components:

1. LED Indicators

Five (5), multi-colored LEDs indicate

modes of operation. During normal

operation, all five LEDs are off.

2. Joystick

Use this to enable various modes and

change settings.

3. USB Port

A USB “Micro B“ port for connecting

to a PC to perform software upgrades.

4. 3D SYNC IN

Connect the 3D SYNC output from

the projector (see

input, using the supplied cable.

For more information configuring the emitter to work with the 3D glasses, refer to Using

the 3D Glasses on page 73.

Figure 2-2) to this

1

Y

3

2

4

IMINAR

L

PRE

12 Runco X-200i Series Installation/Operation Manual

Page 29

Installation

3. Installation

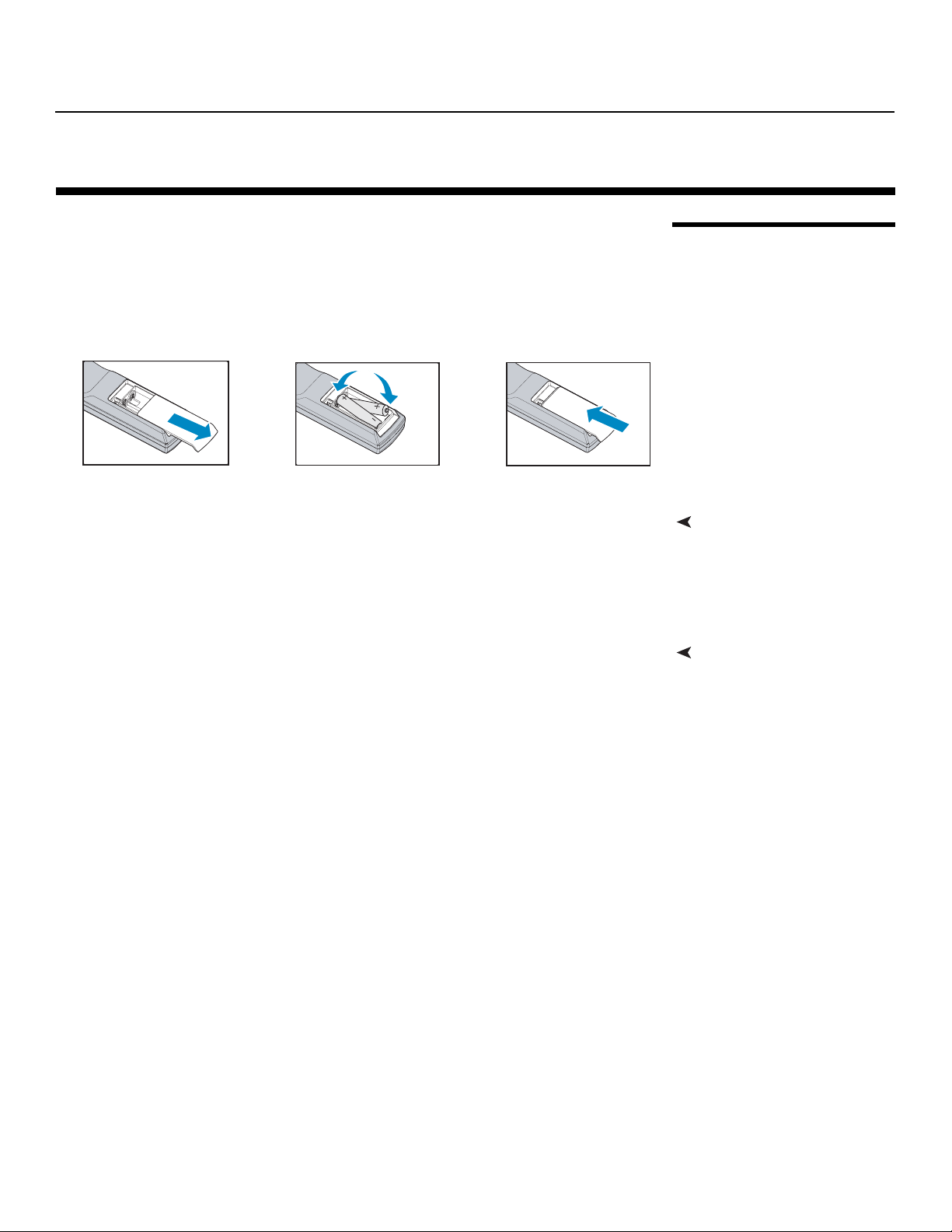

To install batteries in the remote control:

1. Slide the battery compartment cover in the direction of the arrow to remove it.

2. Install two AA batteries with the correct polarity.

3. Replace the cover.

1.

2.

3.

Y

• Do not mix an old battery with a new one or different types of batteries.

• If you will not use the remote control for a long time, remove the batteries to avoid

damage from battery leakage.

• Do not expose batteries to excessive heat such as from sunshine, fire or the like.

• In most situations, you can simply point the remote control at the screen which will

reflect the IR signal from the remote back toward the IR receiver on the projector. In

some cases, however, ambient conditions may prevent this. If so, point the remote

control at the projector and try again.

• If the effective range of the remote control decreases, or it stops working, replace the

batteries with new ones.

• The remote control may fail to operate if the infrared remote sensor is exposed to bright

sunlight or fluorescent lighting.

• During 3D operation, the remote control response may be adversely affected by

interference from the Active

projector during 3D operation. In some cases, it may be better to use the projector

keypad when viewing 3D content.

PRE

3D Emitter. It may help to point the remote directly at the

IMINAR

L

3.1 Remote Control

Notes on Batteries• Make sure that the battery polarities are correct when installing the batteries.

Notes on Remote Control Operation

Runco X-200i Series Installation/Operation Manual 13

Page 30

Installation

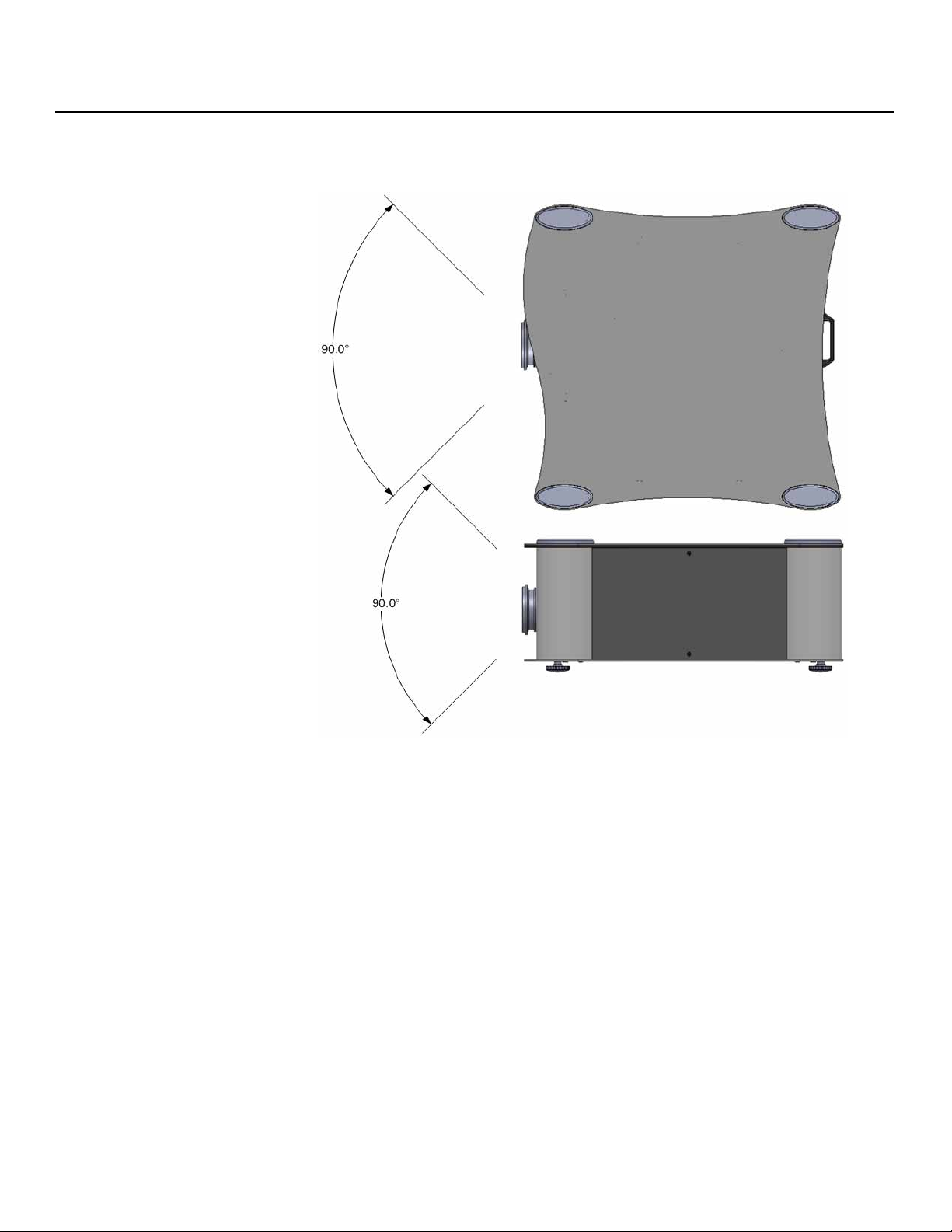

• The projector’s front IR receivers have a range of approximately 40 feet (12.19 meters).

Figure 3-1 shows the reception angles of the IR receivers.

Y

IMINAR

L

PRE

Figure 3-1. IR Reception Angles

14 Runco X-200i Series Installation/Operation Manual

Page 31

Installation

Table 3-1 gives a quick overview of the X-200i installation process. The sections following

this one provide detailed instructions.

Note

Table 3-1. Installation Overview

Step Procedure

Choose a location for the projector 16

1

Install CineWide lens mounting assembly (stationary base plate or

2

AutoScope lens motor – optional)

Mount the projector 28

3

Connect signal sources to the X-200i 30

4

Connect external controller to RS-232 port; connect IR repeater

5

system to wired remote input (optional)

Installation must be performed by a qualified custom video

installation specialist.

For Details, Refer

to page...

23

33

Y

IMINAR

Connect 12-volt trigger output to retractable screen or other,

6

+12V trigger-activated equipment (optional)

L

34

3.2 Quick Setup

7

8

9

10

11

12

13

14

Connect the Active 3D Emitter to the projector 35

Apply power to the projector 35

Primary lens adjustments: projected image size (zoom), position

(shift) and focus

19, 37

PRE

Change the OSD Language (optional) 38

For rear-screen and/or ceiling-mount installations, select the

proper picture orientation

Install and adjust secondary anamorphic lens (optional) 39

Projector calibration: adjust the following for each input; save

settings when finished:

• Aspect ratio

•Brightness

•Contrast

• Color level

•Tint

• Input position

Prepare Active 3D Glasses for use and test with 3D source material

39

52

73

Runco X-200i Series Installation/Operation Manual 15

Page 32

Installation

➤

3.3 Installation Considerations

Installation Type Choose the installation type that best suits your needs: front or rear screen, floor mount or

Proper installation of your projector will ensure the quality of your display. Whether you are

installing a projector temporarily or permanently, you should take the following into

account to ensure your projector performs optimally.

inverted mount.

Table 3-2. Projector Installation Options

Table 3-2 compares these various installation methods.

Advantages Considerations

Front Screen, Floor Mount Installation

Y

• Easy to set up

• Can be moved or changed quickly

• Easy to access

Front Screen, Inverted Mount (ceiling) Installation

• Does not take up audience space

• Projector is unobtrusive

• Projector cannot be accidentally moved

Rear Screen, Floor Mount Installation

• Projector is completely hidden

• Projector is easily accessed

• Usually good ambient light rejection

IMINAR

• Shares floor space with audience

• Installation is more permanent

• Projector access is more difficult

• Requires separate room

• Installation cost is usually higher

L

• Projector is completely hidden

• Usually good ambient light rejection

• Projector is completely hidden

PRE

• Usually good ambient light rejection

• Requires less space behind screen than

other rear screen installations

Rear Screen, Inverted Mount (ceiling) Installation

• Requires separate room

• Installation cost is usually higher

Rear Screen, Floor Mount with Mirror

• Requires separate room

• Installation cost is usually higher

16 Runco X-200i Series Installation/Operation Manual

Page 33

images will be noticeably reduced if light directly strikes the screen, such as when a shaft

T

of light from a window or floodlight falls on the image. Images may then appear washed

out and less vibrant.

This is an important calculation in any projector installation as it determines whether or not

you have enough room to install your projector with a desired screen size and if your

image will be the right size for your screen.

You can quickly estimate the throw distance by taking the width of the screen and

multiplying it by the lens throw ratio; see

roughly how far back the projector should be positioned from the screen in order to

project a focused image large enough to fill the screen.

Figure 3-2. The result of this calculation tells you

Y

Estimating Throw Distance

hrow Distance (TD) =

Screen Width (w) x Lens Throw Ratio

Screen width (w)

Installation

Ambient LightIn general, minimize or eliminate light sources directed at the screen. Contrast ratio in your

Throw DistanceThrow distance is the distance measured from the front of the projector to the screen.

IMINAR

TD

L

PRE

Figure 3-2. Estimating Throw Distance

Runco X-200i Series Installation/Operation Manual 17

Page 34

Installation

Table 3-3 lists the available X-200i Series lens options and their associated throw ratios.

Table 3-3. X-200i Lens Options and Throw Ratios (Note)

Projector Model

X-200i + Standard

Lens

X-200i/CineWide

(Whitney Lens)

X-200i/CineWide

(McKinley Lens)

X-200i/CineWide

with AutoScope +

Standard

X-200i +

Short-Throw

Primary Lens

X-200i/CineWide

(McKinley Lens) +

Short-Throw

Primary Lens

Lens

IMINAR

L

X-200i/CineWide

with AutoScope +

Short-Throw

Primary Lens

Throw Range in

Throw

Ratio with

Primary

Lens Only

1.85 – 2.40 199.80 259.20 (n/a)

inches, with

x 60.75-inch

108

(1.78:1) Screen

Minimum Maximum Minimum Maximum

(n/a) 1.85 – 2.40 266.40 345.60

Throw Ratio

with

Primary

Lens and

Anamorphic

Lens

Throw Range in

inches, with

x 60.75-inch

144

(2.35:1) Screen

Y

(n/a) 1.39 – 1.80 200.16 259.20

1.85 - 2.40 199.80 259.20 1.39 – 1.80 200.16 259.20

1.56 - 1.86 168.48 200.88 (n/a)

(n/a) 1.17 - 1.39 168.48 200.16

1.56 - 1.86 168.48 200.88 1.17 - 1.39 168.48 200.16

X-200i +

PRE

Long-Throw

Primary Lens

X-200i/CineWide

(McKinley Lens) +

Long-Throw

Primary Lens

X-200i/CineWide

with AutoScope +

Long-Throw

Primary Lens

Note: Due to normal manufacturing variances, throw distance can vary by up to +/- 5 percent from

these specifications.

2.40 – 4.00 259.20 432.00 (n/a)

(n/a) 1.80 – 3.00 259.20 432.00

2.40 – 4.00 259.20 432.00 1.80 – 3.00 259.20 432.00

18 Runco X-200i Series Installation/Operation Manual

Page 35

Installation

Proper placement of the projector relative to the screen will yield a rectangular,

perfectly-centered image that completely fills the screen.

Ideally, the projector should be positioned perpendicular to the screen and in such a way

that the lens center is aligned with either the top or bottom edge of the screen area, and

centered horizontally. See

Ceiling Installation

Height

x

Floor Installation

Height

Lens Center

Figure 3-3.

Projection Distance

Lens CenterLens Center

Screen

Screen

Lens Center

Ceiling

Y

Vertical and Horizontal Position

x

Figure 3-3. Projector Placement

Lens shift is generally expressed as a percentage of the screen height or width, as shown

in

Figure 3-4 and Figure 3-5.

Projection Distance

IMINAR

Floor

L

PRE

Screen Center

Note: This is a general example of lens shift. Lenses vary in their shift capabilities. No particular

lens or projector is used in this example.

0%

50% Height

Lens Shift

(0.5 x H)

100% Height

Lens Shift

(1.0 x H)

Lens ShiftYou can use the lens shift controls on the projector to center the image on the screen.

Figure 3-4. Vertical Lens Shift (Example Only)

Runco X-200i Series Installation/Operation Manual 19

Page 36

Installation

100% Width Lens Shift

(1.0 x W)

50% Width Lens Shift

(0.5 x W)

Screen Width (W)

Screen Center

0%

Y

IMINAR

L

Note: This is a general example of lens shift. Lenses vary in their shift capabilities. No particular

lens or projector is used in this example.

PRE

Figure 3-5. Horizontal Lens Shift (Example Only)

20 Runco X-200i Series Installation/Operation Manual

Page 37

Table 3-4 lists the lens shift limits for each available X-200i lens, as percentages and

absolute measurements with a 100 x 56 inch (1.78:1) screen.

Table 3-4. Vertical and Horizontal Lens Shift Limits

Primary Lens Option

Installation

Standard or

Short-Throw Lens

Lens Shift Limits, as Percentages of Screen Height or Width (Note 1)

Vertical

(Note 2)

Horizontal

Lens Shift Limits in Inches, with a 100-by-56 inch (1.78:1) Screen

Vertical

(Note 2)

Horizontal

Notes:

1. Vertical shift limits are percentages of the screen height. Horizontal shift limits are percentages of

the screen width.

2. Vertical lens shift figures are for ceiling mount configurations. For floor installations

(where the projector is upright), reverse the up/down vertical lens shift percentages.

Up 25% 25%

Down 60% 35%

Left 15% 7.5%

Right 15% 7.5%

Up 14.00 14.00

Down 33.60 19.60

Left 15.00 7.50

Right 15.00 7.50

IMINAR

L

Long-Throw Lens

Y

PRE

Runco X-200i Series Installation/Operation Manual 21

Page 38

Installation

➤

➤

Folded Optics In rear-screen applications where space behind the projector is limited, a mirror may be

used to fold the optical path, as shown in

mirror must be accurately set. If you are considering this type of installation, contact your

dealer for assistance.

Figure 3-6. The position of the projector and

Screen

Figure 3-6. Folded Optics

For best performance, always use “first-surface” mirrors in your

Tip

L

rear-projection installation (as opposed to conventional,

“second-surface” mirrors with the reflective surface behind a

transparent substrate such as glass or acrylic).

First-surface mirrors provide a strict reflection without the

IMINAR

“ghosting” effect seen with a second surface mirror, where a faint

secondary reflection could be observed coming from the front

surface of the glass.

Mirror

Y

This is especially critical for 3D viewing; with a conventional

second-surface mirror, the resulting image quality may be

unacceptable.

PRE

Other Considerations Other considerations and tips that can help improve your installation:

• Keep the ambient temperature constant and below 35°C (95°F). Keep the projector

away from heating and/or air conditioning vents. Changes in temperature may cause

drifts in the projector circuitry, which may affect performance.

• Keep the projector away from devices that radiate electromagnetic energy such as

motors and transformers. Common sources of these include slide projectors,

speakers, power amplifiers and elevators.

22 Runco X-200i Series Installation/Operation Manual

Page 39

Installation

If you are installing a standard (non-CineWide) X-200i, skip this step and proceed with

Mounting the X-200i (page 28).

If you are installing an X-200i/CineWide with a “McKinley” (cylindrical)

anamorphic lens, proceed with

Plate (Cylindrical Anamorphic Lens) (page 27).

If you are installing an X-200i/CineWide with a “Whitney” (prismatic)

anamorphic lens, proceed with

Plate (Prismatic Anamorphic Lens) (page 26).

Installing the Fixed CineWide Base

Installing the Fixed CineWide Base

S

U

C

O

F

Y

If you are installing an X-200i/CineWide with AutoScope, proceed as follows to install the

AutoScope lens motor.

Note

1. Do not install the CineWide lens yet, only the fixed CineWide

base plate or AutoScope lens motor. You will install the

CineWide lens after you install the projector and adjust the

primary lens.

2. Some components shipped with your projector may differ slightly

from what is shown in these instructions.

IMINAR

Remove Projector Feet: Place the

projector upside down on a blanket or

other soft surface. Loosen and remove

the two front feet on the projector.

L

3.4 Installing the Optional CineWide Lens Mount

PRE

Runco X-200i Series Installation/Operation Manual 23

Page 40

Installation

➤

Installing the Lens Motor

(X-200i/CineWide with

AutoScope)

Figure 3-7 shows the X-200i/CineWide with AutoScope motor assembly.

CineWide with AutoScope

Ceiling Mt. Adapter/

Projector Stand, Right

Screw, Phillips

Pan-Head,

M6-1.0 x 12mm (14x)

3

2

Y

4

CineWide with

AutoScope

Ceiling Mt. Adapter/

Projector Stand, Left

IMINAR

Lens

Motor

1

L

AutoScope

PRE

Figure 3-7. X-200i/CineWide with AutoScope Motor Assembly – Exploded View

24 Runco X-200i Series Installation/Operation Manual

Page 41

Install Lens Motor:

3D SYNC

3D SYNC

32

USB

COMPO

T

COMPO

T

1

E

O

E

2

RGB

GB

Y

Pb

bPrH

1

COMPO

T

2

1. Position the AutoScope lens motor as shown in Figure 3-7.

2. Line up the mounting holes on the lens motor housing with those on the underside of

the projector.

3. Secure the motor to the projector with the eight (8) supplied M6 x 12mm Pan-Head

Phillips screws.

Install Ceiling Mount Adapters/Projector Stands: For ceiling installations, the

adapters bring the attachment points for the projector mounting rails (included with the

projector ceiling mount kit) from the bottom of the projector above and behind the

AutoScope lens motor housing. For floor installations (where the projector is upright), the

adapters allow the projector to lie flat on the mounting surface.

Installation

Using six (6) each of the supplied, Pan-Head Phillips screws, attach the AutoScope

Ceiling Mount Adapters/Projector Stands to the projector as shown in

Figure 3-7.

Y

DO NOT OVER-TIGHTEN THE SCREWS.

Caution

Connecting the AutoScope Lens Motor to the Projector: Connect the AutoScope

lens transport motor to a 12-volt trigger output on the projector, as shown in Figure 3-8.

COMPONENT 1

WIRED REMOTE

WIRED REMOT

T

WIRED REMOTE

WIRED REM

RS-232

RS-232

RS-232

RS-2

USB

USB

USB

NEN

NEN

COMPONENT 1

IMINAR

3D SYNC

III

12V TRIGGER

3D SYNC

12V TRIGGER

3.5-mm

mini plug

HDMI 1

DMI

HDMI 1

HDMI 2

HDMI 2

HDMI

RGB

RGB

R

L

Y

Y

Pb

PbPrPr

P

COMPONENT 2

COMPONENT

NEN

COMPONENT 2

PRE

+12V

Trigger Input

Power

Switch

AC Input

AuptoScope Lens Transport Motor

Figure 3-8. Connecting the AutoScope Lens Transport Motor to the Projector

After you have installed the AutoScope lens motor, proceed with Mounting the X-200i

(page 28).

Runco X-200i Series Installation/Operation Manual 25

Page 42

Installation

➤

Installing the Fixed

CineWide Base Plate

(Prismatic Anamorphic

Lens)