Ruijie RG-S1808, RG-S1818G, RG-S1826G, RG-S1809-P, RG-S1826 Hardware Installation And Reference Manual

...

Hardware Installation and Reference Guide

RG-S1800 Series Switch

RG-S1800G Series Switch

RG-S1800-P Series Switch

RG-S1800G-P Series Switch

Copyright Statement

Ruijie Networks©2017

Ruijie Networks reserves all copyrights of this document. Any reproduction, excerption, backup, modification,

transmission, translation or commercial use of this document or any portion of this document, in any form or by any

means, without the prior written consent of Ruijie Networks is prohibited.

Exemption Statement

This document is provided “as is”. The contents of this document are subject to change without any notice. Please

obtain the latest information through the Ruijie Networks website. Ruijie Networks endeavors to ensure content

accuracy and will not shoulder any responsibility for losses and damages caused due to content omissions,

inaccuracies or errors.

Preface

Thank you for using our products. This manual will guide you through the installation of the device.

This manual describes the functional and physical features and provides the device installation steps, hardware

troubleshooting, module technical specifications, and specifications and usage guidelines for cables and connectors.

Audience

It is intended for the users who have some experience in installing and maintaining network hardware. At the same time,

it is assumed that the users are already familiar with the related terms and concepts.

Obtaining Technical Assistance

Ruijie Networks Website: http://www.ruijienetworks.com/

Service Email: service_rj@ruijienetworks.com

Technical Support: http://www.ruijienetworks.com/service.aspx

Technical Support Hotline: +86-4008-111-000

Symbol Conventions

Means reader take note. Notes contain helpful suggestions or references.

Means reader be careful. In this situation, you might do something that could result in equipment damage or loss

of data.

Hardware Installation and Reference Guide Product Overview

Table of Contents

1 Product Overview................................................................................................................................................... - 6 -

1.1 RG-S1800 Series Switch....................................................................................................................... - 7 -

1.1.1 RG-S1808 ..................................................................................................................................... - 7 -

1.1.2 RG-S1826 ..................................................................................................................................... - 9 -

1.2 RG-S1800G Series Switch .................................................................................................................. - 11 -

1.2.1 RG-S1808G ................................................................................................................................ - 11 -

1.2.2 RG-S1818G ................................................................................................................................ - 14 -

1.2.3 RG-S1826G ................................................................................................................................ - 16 -

1.2.4 Module ........................................................................................................................................ - 19 -

1.3 RG-S1800-P Series Switch ................................................................................................................. - 19 -

1.3.1 RG-S1809-P ............................................................................................................................... - 19 -

1.4 RG-S1800G-P Series Switch .............................................................................................................. - 21 -

1.4.1 RG-S1826G-P ............................................................................................................................ - 21 -

1.4.2 Module ........................................................................................................................................ - 24 -

2 Preparation before Installation ............................................................................................................................. - 25 -

2.1 Safety Suggestions ............................................................................................................................. - 25 -

2.1.1 Safety Precautions for Installing the System ............................................................................... - 25 -

2.1.2 Movement Safety ........................................................................................................................ - 25 -

2.1.3 Electric Safety ............................................................................................................................. - 25 -

2.1.4 Static Discharge Damage Prevention ......................................................................................... - 26 -

2.1.5 Laser Safety ................................................................................................................................ - 26 -

2.2 Installation Site Requirements ............................................................................................................. - 26 -

2.2.1 Ventilation Requirements ............................................................................................................ - 26 -

2.2.2 Temperature and Humidity Requirements .................................................................................. - 26 -

2.2.3 Cleanness Requirements ............................................................................................................ - 27 -

2.2.4 EMI ............................................................................................................................................. - 27 -

2.2.5 System Grounding Requirements ............................................................................................... - 28 -

2.2.6 Lightning Resistance Considerations .......................................................................................... - 29 -

2.2.7 EMI Consideration ...................................................................................................................... - 30 -

2.3 Requirements of Installation Tools ...................................................................................................... - 30 -

3 Product Installation .............................................................................................................................................. - 31 -

3.1 Installation Procedure.......................................................................................................................... - 31 -

3.2 Confirmations before Installation ......................................................................................................... - 31 -

3.3 Precautions ................................................................................................................................ ......... - 31 -

3.4 Installing the RG-S1800 Series ........................................................................................................... - 32 -

3.4.1 Mounting the Switch in the Rack ................................................................................................. - 32 -

3.4.2 Mounting the Switch on the Wall ................................................................................................. - 33 -

3.4.3 Mounting the Switch to a Workbench ................................................................ .......................... - 34 -

3.5 Installing the RG-S1800G Series ........................................................................................................ - 34 -

3.5.1 Mounting the Switch in the Rack ................................................................................................. - 34 -

3.5.2 Mounting the Switch on the Wall ................................................................................................. - 35 -

Hardware Installation and Reference Guide Product Overview

3.5.3 Mounting the Switch to a Workbench ................................................................ .......................... - 36 -

3.6 Installing the RG-S1800-P Series ....................................................................................................... - 37 -

3.6.1 Mounting the Switch to a Workbench ................................................................ .......................... - 37 -

3.6.2 Mounting the Switch on the Wall ................................................................................................. - 38 -

3.7 Installing the RG-S1800G-P Series ..................................................................................................... - 40 -

3.7.1 Mounting the Switch in the Rack ................................................................................................. - 40 -

3.7.2 Mounting the Switch on the Wall ................................................................................................. - 40 -

3.7.3 Mounting the Switch to a Workbench ................................................................ .......................... - 41 -

3.8 Connecting the Power Cord ................................................................................................................ - 42 -

3.9 Checking after Installation ................................................................................................................... - 43 -

4 Maintenance and Troubleshooting ....................................................................................................................... - 44 -

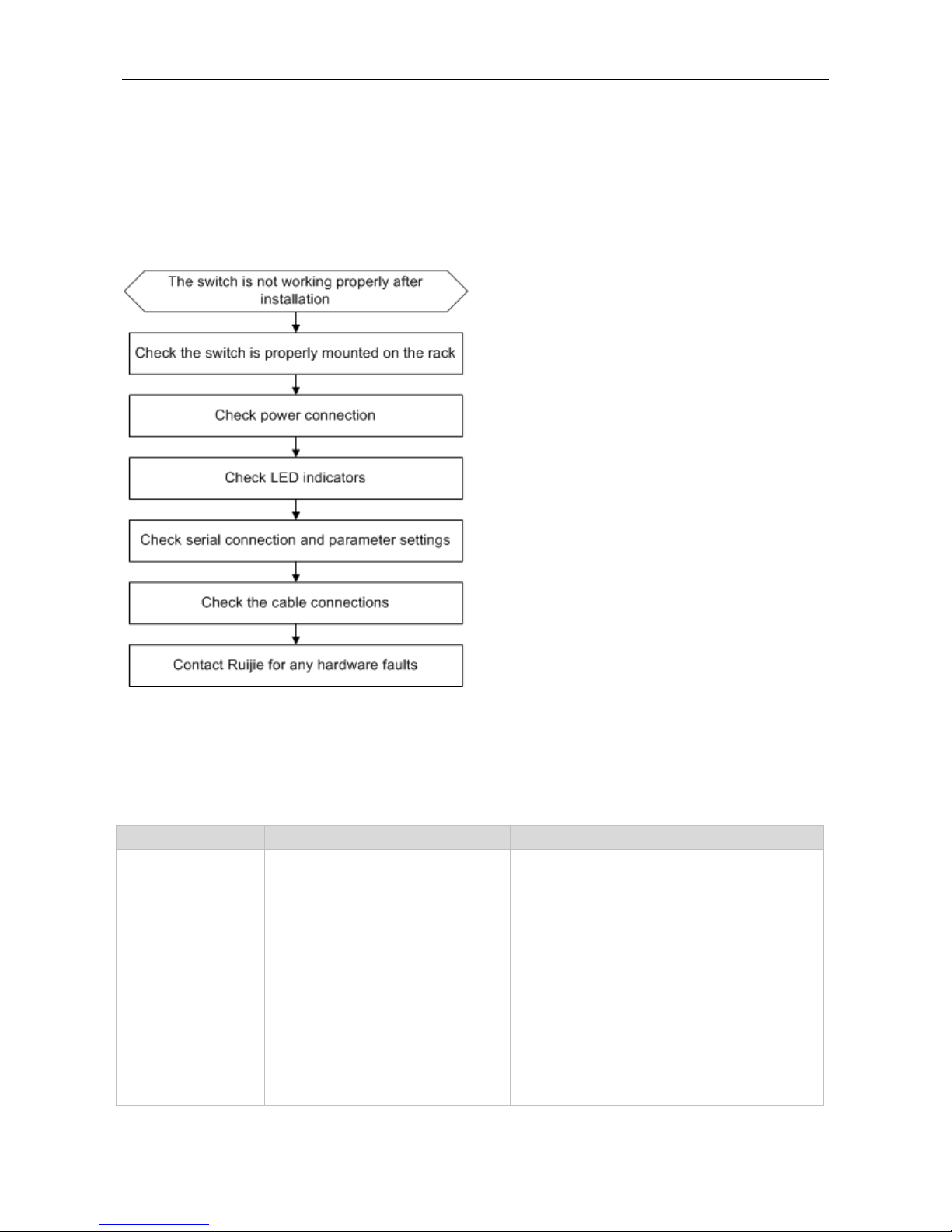

4.1 General Troubleshooting Procedure ................................................................................................... - 44 -

4.2 Common Faults ................................................................................................................................... - 44 -

Appendix A: Connectors and Connection Media .............................................................................................................. 46

Appendix B Mini-GBIC Modules ................................................................................................................................... - 48 -

Hardware Installation and Reference Guide Product Overview

1 Product Overview

Thank you for using Ruijie Networks RG-S18 series Ethernet switches.

The RG-S1800 series switches are unmanaged 100M switches released by Ruijie Networks. Some of the switches

provide GE uplink ports, powerful switching performance, and cost-effective GE port-based uplink capability.

The RG-S1800G series switches are full GE switches released by Ruijie Networks. With powerful switching capability

and cost-effective full GE copper cable ports, the switches fully meet users' requirements for high-bandwidth data

communication, dense high-speed access server clusters, and GE backbone service network construction.

The RG-S1800-P series switches are PoE-capable 100M Ethernet switches released by Ruijie Networks. Some of the

switches provide 100M uplink ports, powerful switching performance, and cost-effective 100M port-based uplink

capability. In addition, some other switches provide GE uplink ports, powerful switching performance, and cost-effective

GE port-based uplink capability. This series of switches are characterized by high performance, high security, support

for multiple services, and ease of use, and provide brand new technical solutions for users. Each port of the switches

can provide high bandwidth and supply power to wireless APs and IP cameras. The switches support full-/half-duplex

mode, and enable low-cost and high-performance network solutions.

The RG-S1800G-P series switches are full GE PoE switches released by Ruijie Networks. The switches are

characterized by high performance, high security, support for multiple services, and ease of use, and enable new

technical solutions for users. Each port of the switches can provide high bandwidth and supply power to wireless APs

and IP cameras. The switches support full-/half-duplex mode, and enable low-cost and high-performance network

solutions.

Some models of the S18 series switches are capable of independent flow control, which prevents data packet loss

during data transmission.

RG-S1800 Series Switch

Model

10/100BASE-T

Auto-sensing Ethernet

Port

Combo Ports

10/100/1000BASE-T

Auto-sensing Ethernet

Port

1000BASE-X SFP Port

RG-S1808

8

N/A

N/A

RG-S1826

24 2 2

Combo port consists of one 1000BASE-X SFP port and one 10/100/1000BASE-T auto-sensing Ethernet port. That

is, only one port of them is available at a particular time.

RG-S1800G Series Switch

Model

10/100/1000BASE-T Auto-sensing Ethernet

Port

1000BASE-X SFP Port

RG-S1808G

8

N/A

RG-S1818G

16

2

Hardware Installation and Reference Guide Product Overview

RG-S1826G

24

2

RG-S1800-P Series Switch

Model

10/100BASE-T Auto-sensing

Ethernet Port

10/100/1000BASE-T

Auto-sensing Ethernet Port

PoE Port

RG-S1809-P

8 1 8

RG-S1800G-P Series Switch

Model

10/100/1000BASE-T

Auto-sensing Ethernet Port

PoE Port

1000BASE -X SFP Port

RG-S1826G-P

24

24

2

1.1 RG-S1800 Series Switch

1.1.1 RG-S1808

Technical Specifications

Model

RG-S1808

Ports

8-port 10/100BASE-T

Power Supply

DC input:

DC 5V/550mA

Rated current: 550mA

Max voltage range: 90V to 290V~

PoE

Not supported

Power Consumption

1.5W(Max)

Operating

Temperature

0ºC to 50ºC (32ºF to 122ºF)

Storage Temperature

-40ºC to +70ºC (-40ºF to 158ºF)

Operating Humidity

10% to 90% RH non-condensing

Storage Humidity

5% to 90% RH non-condensing

Fan

N/A

EMC Standards

EN55032(Class B)

Dimensions (W×D×H)

140 mm x 76 mm x 27 mm

Switching

Capacity(Gbps)

1.6Gbps

Product Appearance

The front panel of RG-S1808 Ethernet switch provides a Power Status LED indicator and Link/ACT Status LED

indicators. The rear panel provides eight 10/100BASE-T Ethernet ports and one DC power input port. Figure 1-1 shows

the appearance of the RG-S1808.

Figure 1-1 Appearance of RG-S1808

Hardware Installation and Reference Guide Product Overview

Front Panel

Figure 1-2 Front Panel of RG-S1808

Note

1. Power status indicator

2. 10/100BASE-T Link/ACT indicator

Rear Panel

Figure1-3 Rear Panel of RG-S1808

Note

1. 10/100BASE-T ports

2. DC power input port

Power Supply

The RG-S1808 switch can be powered with DC power.

DC input: DC 5V/550mA

Heat Dissipation

Hardware Installation and Reference Guide Product Overview

The RG-S1808 switch is designed with no fans. To ensure good dissipation, sufficient space (10 cm distance from both

sides and the back panel of the chassis) should be reserved for ventilation. Dust the device every three months to avoid

blocking the ventilation openings.

LED Indicator

Indicator

Faceplate Marker

Status

Indication

Power indicator

PWR

Off

The switch is powered down.

On

The switch is powered on.

Ethernet port indicator

1-8

Off

The port is NOT connected.

Solid green

The port is connected.

Blinking green

The port is transmitting or receiving data.

1.1.2 RG-S1826

Technical Specifications

Model

RG-S1826

Ports

24-port 10/100BASE-T

2 combo ports

SFP Type

Ethernet Gigabit:

Mini-GBIC-SX

Mini-GBIC-LX

Mini-GBIC-LH40

Mini-GBIC-ZX50

Mini-GBIC-ZX80

Mini-GBIC-ZX100

1000Base-T:

Mini-GBIC-GT

The supported module type may change at any time. Consult us for the detailed change

information.

SFP Ports

Support 1000BASE-X

Power Supply

AC input:

Rated voltage range: 100V to 240V

Max voltage range: 90V to 290V

Frequency: 50/60Hz

Rated current: 0.5A

PoE

Not supported

Hardware Installation and Reference Guide Product Overview

Power Consumption

12W(Max)

Operating

Temperature

0ºC to 50ºC (32ºF to 122ºF)

Storage Temperature

-40ºC to +70ºC (-40ºF to 158ºF)

Operating Humidity

10% to 90% RH non-condensing

Storage Humidity

5% to 90% RH non-condensing

Fan

N/A

EMC Standards

EN55032(Class A)

Dimensions (W×D×H)

440 mm x 205 mm x 44 mm

Switching Capacity

8.8Gbps

Product Appearance

The front panel of RG-S1826 Ethernet switch provides 24 10/100BASE-T Ethernet ports, two Gigabit combo ports. The

rear panel provides an AC power input port and a grounding connector.

Figure 1-4 Appearance of RG-S1826

Front Panel

Figure 1-5 Front Panel of RG-S1826

Note

1. Power status indicator

2. 10/100BASE-T Link/ACT indicator

3.10/100/1000BASE-T Link/ACT

indicator

4. 10/100BASE-T Ethernet port

5. 10/100/1000BASE-T Ethernet port

6. 1000BASE-X SFP port

Rear Panel

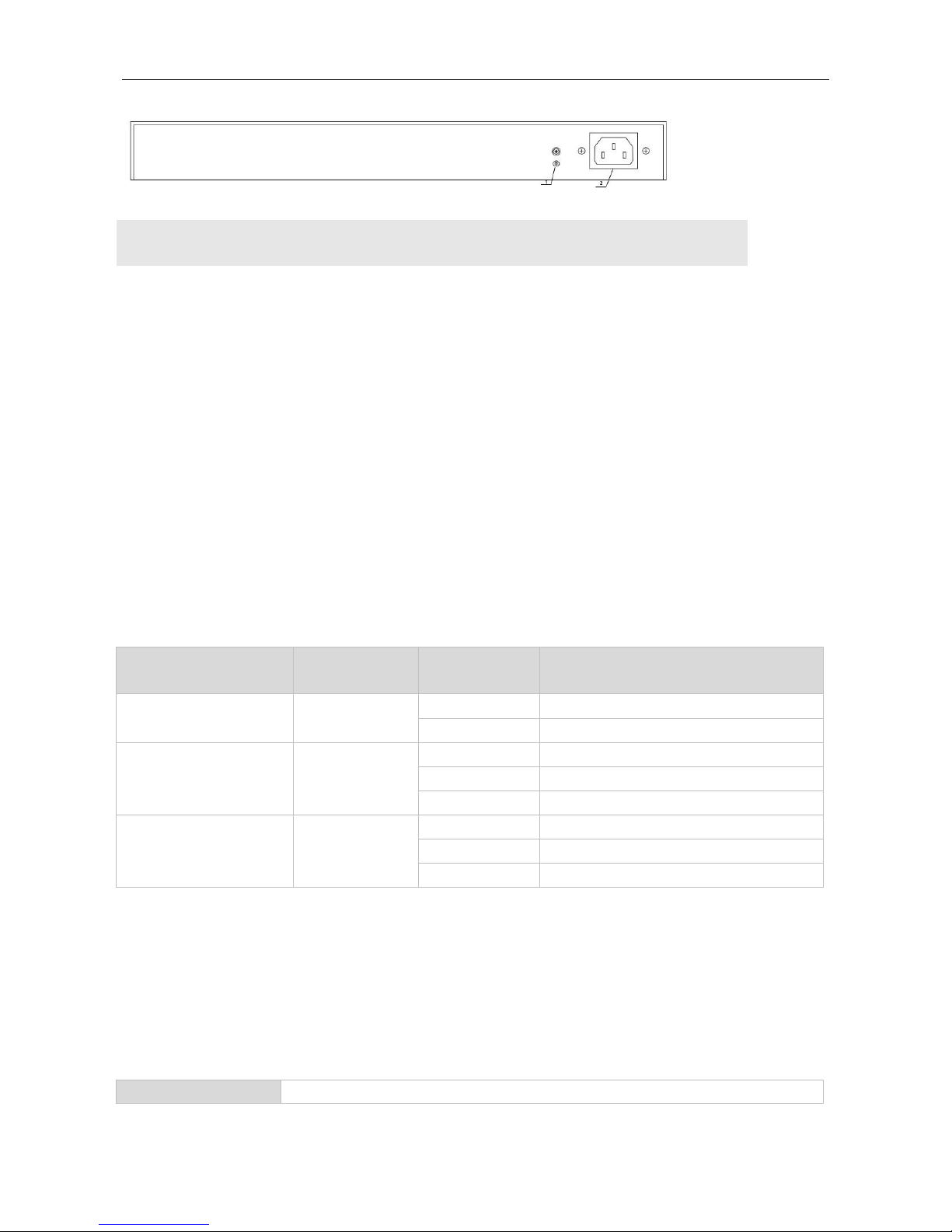

Figure1-6 Rear Panel of RG-S1826

Hardware Installation and Reference Guide Product Overview

Note

1. Grounding connector

2. AC power input port

Power Supply

The RG-S1826 switch can be powered with AC power.

Rated voltage range: 100V to 240V

Max voltage range: 90V to 290V

Frequency: 50/60Hz

Rated current: 0.5A

Power Cord Requirements: 10A

Heat Dissipation

The RG-S1826 switch is designed with no fans. To ensure good dissipation, sufficient space (10 cm distance from both

sides and the back panel of the chassis) should be reserved for ventilation. Dust the device every three months to avoid

blocking the ventilation openings.

LED Indicator

Indicator

Faceplate Marker

Status

Indication

Power indicator

PWR

Off

The switch is powered down.

On

The switch is powered on.

Ethernet port indicator

1-24

Off

The port is NOT connected.

Solid green

The port is connected.

Blinking green

The port is transmitting or receiving data.

Combo port indicator

25 T/S

26 T/S

Off

The port is NOT connected.

Solid green

The port is connected.

Blinking green

The port is transmitting or receiving data.

1.2 RG-S1800G Series Switch

1.2.1 RG-S1808G

Technical Specifications

Model

RG-S1808G

Hardware Installation and Reference Guide Product Overview

Ports

8-port 10/100/1000 BASE-T

Power Supply

AC input:

Rated voltage range: 100V to 240V

Max voltage range: 90V to 290V

Frequency: 50/60Hz

Rated current: 0.3A

PoE

Not supported

Power Consumption

2.5W(Max)

Operating Temperature

0ºC to 50ºC (32ºF to 122ºF)

Storage Temperature

-40ºC to +70ºC (-40ºF to 158ºF)

Operating Humidity

10% to 90% RH non-condensing

Storage Humidity

5% to 90% RH non-condensing

Fan

N/A

EMC Standards

EN55032(Class B)

Dimensions (W×D×H)

220 mm x 160 mm x 44 mm

Switching

Capacity(Gbps)

16Gbps

Product Appearance

The front panel of RG-S1808G Ethernet switch provides eight 10/100/1000Mbps Ethernet ports. The rear panel

provides an AC power input port and a grounding connector.

Figure 1-7 Appearance of RG-S1808G

Front Panel

Figure 1-8 Front Panel of RG-S1808G

Hardware Installation and Reference Guide Product Overview

Note

1. Power status indicator

2. 10/100/1000BASE-T Link/ACT/Speed

indicator

3. Power cord retention clip

Rear Panel

Figure1-9 Rear Panel of RG-S1808G

Note

1. Grounding connector

2. AC power input port

Power Supply

The RG-S1808G switch can be powered with AC power.

Rated voltage range: 100V to 240V

Max voltage range: 90V to 290V

Frequency: 50/60Hz

Rated current: 0.3A

Power cord requirement: 10A

Heat Dissipation

The RG-S1808G switch is designed with no fans. To ensure good dissipation, sufficient space (10 cm distance from

both sides and the back panel of the chassis) should be reserved for ventilation. Dust the device every three months to

avoid blocking the ventilation openings.

LED Indicator

Indicator

Faceplate

Marker

Status

Indication

Power indicator

PWR

Off

The switch is powered down.

On

The switch is powered on.

Ethernet port indicator

1-8

Off

The port is NOT connected.

Solid orange

The port is connected at 10/100 Mbps.

Hardware Installation and Reference Guide Product Overview

Blinking orange

The port is receiving or transmitting

traffic at 10/100 Mbps.

Solid green

The port is connected at 1000 Mbps.

Blinking green

The port is receiving or transmitting

traffic at 1000 Mbps.

1.2.2 RG-S1818G

Technical Specifications

Model

RG-S1818G

Ports

16-port 10/100/1000BASE-T

2-port 1000BASE-X SFP

SFP Type

Ethernet Gigabit:

Mini-GBIC-SX

Mini-GBIC-LX

Mini-GBIC-LH40

Mini-GBIC-ZX50

Mini-GBIC-ZX80

Mini-GBIC-ZX100

1000Base-T:

Mini-GBIC-GT

The supported module type may change at any time. Consult us for the detailed

change information.

SFP Ports

Support 1000Base-X

Power Supply

AC input:

Rated voltage range: 100V to 240V

Max voltage range: 90V to 290V

Frequency: 50/60Hz

Rated current: 0.5A

PoE

Not supported

Power Consumption

9W(max)

Operating

Temperature

0ºC to 50ºC (32ºF to 122ºF)

Storage Temperature

-40ºC to +70ºC (-40ºF to 158ºF)

Operating Humidity

10% to 90% RH non-condensing

Storage Humidity

5% to 90% RH non-condensing

Fan

N/A

EMC Standards

EN55032(Class A)

Dimensions (W×D×H)

440 mm x 205 mm x 44 mm

Hardware Installation and Reference Guide Product Overview

Switching

Capacity(Gbps)

36Gbps

Product Appearance

The front panel of RG-S1818G Ethernet switch provides 16 10/100/1000BASE-T Ethernet ports, two 1000BASE-X SFP

ports. The rear panel provides an AC power input port and a grounding connector.

Figure 1-10 Appearance of RG-S1818G

Front Panel

Figure 1-11 Front Panel of RG-S1818G

Note

1. Power status indicator

2. 10/100/1000BASE-T Link/ACT/Speed

indicator

3.1000BASE-X SFP port indicator

4. 10/100/1000BASE-T Ethernet port

5. 1000BASE-X SFP port

Rear Panel

Figure1-12 Rear Panel of RG-S1818G

Note

1. Grounding connector

2. AC power input port

Power Supply

Hardware Installation and Reference Guide Product Overview

RG-S1818G switch can be powered with AC power.

Rated voltage range: 100V to 240V

Max voltage range: 90V to 290V

Frequency: 50/60Hz

Rated current: 0.5A

Power cord requirement: 10A

Heat Dissipation

The RG-S1818G switch is designed with no fans. To ensure good dissipation, sufficient space (10 cm distance from

both sides and the back panel of the chassis) should be reserved for ventilation. Dust the device every three months to

avoid blocking the ventilation openings.

LED Indicator

Indicator

Faceplate

Marker

Status

Indication

Power indicator

PWR

Off

The switch is powered down.

On

The switch is powered on.

Ethernet port indicator

1-16

Off

The port is NOT connected.

Solid orange

The port is connected.

Blinking orange

The port is connected at 10/100 Mbps.

Solid green

The port is connected at 1000 Mbps.

Blinking green

The port is receiving or transmitting

traffic at 1000 Mbps.

SFP port indicator

SFP1, SFP2

Off

The port is NOT connected.

Solid orange

The port is connected at 100 Mbps.

Blinking orange

The port is receiving or transmitting

traffic at 100 Mbps.

Solid green

The port is connected at 1000 Mbps.

Blinking green

The port is receiving or transmitting

traffic at 1000 Mbps.

1.2.3 RG-S1826G

Technical Specifications

Model

RG-S1826G

Ports

24-port 10/100/1000BASE-T

2-port 1000BASE-X SFP

SFP Type

Ethernet Gigabit:

Mini-GBIC-SX

Mini-GBIC-LX

Mini-GBIC-LH40

Mini-GBIC-ZX50

Hardware Installation and Reference Guide Product Overview

Mini-GBIC-ZX80

Mini-GBIC-ZX100

1000Base-T:

Mini-GBIC-GT

The supported module type may change at any time. Consult us for the detailed change

information.

SFP Ports

Support 1000Base-X

Power Supply

AC input:

Rated voltage range: 100V to 240V

Max voltage range: 90V to 290V

Frequency: 50/60Hz

Rated current: 0.5A

PoE

Not supported

Power Consumption

13W(max)

Operating

Temperature

0ºC to 50ºC (32ºF to 122ºF)

Storage Temperature

-40ºC to +70ºC (-40ºF to 158ºF)

Operating Humidity

10% to 90% RH non-condensing

Storage Humidity

5% to 90% RH non-condensing

Fan

N/A

EMC Standards

EN55032(Class A)

Dimensions (W×D×H)

440 mm x 205 mm x 44 mm

Switching

Capacity(Gbps)

52Gbps

Product Appearance

The front panel of RG-S1826G Ethernet switch provides 24 10/100/1000BASE-T Ethernet ports and two 1000BASE-X

SFP ports. The rear panel provides an AC power input port and a grounding connector

Figure 1-13 Appearance of RG-S1826G

Front Panel

Figure 1-14 Front Panel of RG-S1826G

Hardware Installation and Reference Guide Product Overview

Note

1. Power status indicator

2. 10/100/1000BASE-T Link/ACT/Speed

indicator

3. 1000BASE-T SFP port indicator

4. 10/100/1000BASE-T Ethernet port

5.1000BASE-X SFP port

Rear Panel

Figure1-15 Rear Panel of RG-S1826G

Note

1. Grounding connector

2. AC power input port

Power Supply

RG-S1826G switch can be powered with AC power:

Rated voltage range: 100V to 240V

Max voltage range: 90V to 290V

Frequency: 50/60Hz

Rated current: 0.5A

Power Cord Requirements: 10A

Heat Dissipation

RG-S1826G switch is designed with no fans. To ensure good dissipation, sufficient space (10 cm distance from both

sides and the back panel of the chassis) should be reserved for ventilation. Dust the device every three months to avoid

blocking the ventilation openings.

LED indicator

Indicator

Faceplate

Marker

Status

Indication

Power indicator

PWR

Off

The switch is powered down.

On

The switch is powered on.

Ethernet port indicators

1-24

Off

The port is NOT connected.

Hardware Installation and Reference Guide Product Overview

Solid orange

The port is connected at 10/100 Mbps.

Blinking orange

The port is receiving or transmitting traffic

at 10/100 Mbps.

Solid green

The port is connected at 1000 Mbps.

Blinking green

The port is receiving or transmitting traffic

at 1000 Mbps.

SFP port indicators

SFP1, SFP2

Off

The port is NOT connected.

Solid orange

The port is connected at 100 Mbps.

Blinking orange

The port is receiving or transmitting traffic

at 100 Mbps.

Solid green

The port is connected at 1000 Mbps.

Blinking green

The port is receiving or transmitting traffic

at 1000 Mbps.

1.2.4 Module

The RG-S1800G series switches support the following modules: M3000E-02SFP/GT and M3000E-STACK.

M3000E-02SFP/GT can be used to extend two SFP ports.

1.3 RG-S1800-P Series Switch

1.3.1 RG-S1809-P

Technical Specifications

Model

RG-S1809-P

Ports

8-port 10/100BASE-T

1-port 10/100/1000BASE-T Uplink

Power Supply

DC input:

DC 53.5V/2.3A

Rated current: 2.3A

Max voltage range: 90V to 290V

PoE

Support

Power Consumption

120W(Max)

Operating

Temperature

0ºC to 50ºC (32ºF to 122ºF)

Storage Temperature

-40ºC to +70ºC (-40ºF to 158ºF)

Operating Humidity

10% to 90% RH non-condensing

Storage Humidity

5% to 90% RH non-condensing

Fan

N/A

EMC Standards

EN55032(Class B)

Dimensions (W×D×H)

190 mm x 100 mm x 28 mm

Switching Capacity

3.6Gbps

Hardware Installation and Reference Guide Product Overview

Product Appearance

The front panel of RG-S1809-P Ethernet switch provides a power LED indicator, PoE LED indicators and Link/ACT LED

indicators, 8-port 10/100BASE-T Ethernet ports and one Gigabit uplink port.

Figure 1-16 Appearance of RG-S1809-P

Front Panel

Figure 1-17 Front Panel of RG-S1809-P

Note

1. Power status indicator

2. 10/100BASE-T Link/ACT

indicator(1-8),10/100/1000BASE-T

Link/ACT indicator(Uplink)

3. PoE Status LED indicator

4. 10/100 BASE-T Ethernet port

5.10/100/1000 BASE-T Ethernet port

Rear Panel

Figure1-18 Rear Panel of RG-S1809-P

Note

1. Grounding connector

2. DC power input port

Power Supply

RG-S1809-P switch can be powered with DC power.

Hardware Installation and Reference Guide Product Overview

Rated current: 2.3A

Rated voltage: 53.5V

Heat Dissipation

RG-S1809-P switch is designed with no fans. To ensure good dissipation, sufficient space (10 cm distance from both

sides and the back panel of the chassis) should be reserved for ventilation. Dust the device every three months to avoid

blocking the ventilation openings.

PoE

The PoE power supply of the RG-S1809-P switch is designed to support the IEEE802.3af and 802.3at standards. It

uses Alternative B, that is, uses the idle line pairs (45+, 78-) for power supply.

LED Indicator

Indicator

Faceplate

Marker

Status

Indication

Power indicator

PWR

Off

The switch is powered down.

On

The switch is powered on.

10/100Mbps Ethernet port

indicator

1-8

Off

The port is NOT connected.

Solid green

The port is connected at 10/100 Mbps.

Blinking green

The port is receiving or transmitting traffic

at 10/100 Mbps.

1000Mbps Ethernet port

indicator

Uplink

Off

The port is NOT connected.

Solid green

The port is connected at 10/100/1000

Mbps.

Blinking green

The port is receiving or transmitting traffic

at 10/100/1000 Mbps.

PoE Status indicator

1-8

Off

No PoE power supply.

Solid orange

PoE is operational.

Blinking orange

Abnormal PoE power supply

RG-S1800-P switch supports the dynamic PoE mode, that is, Dynamic-FIFS (Dynamic First In First Service) mode.

This mode enables automatic detection and power-on of PD devices and allocates the PoE port power by the

actual power consumption of the PD device. Device powering will be disabled if the required power is greater than

the available power.

1.4 RG-S1800G-P Series Switch

1.4.1 RG-S1826G-P

Technical Specifications

Hardware Installation and Reference Guide Product Overview

Model

RG-S1826G-P

Ports

24-port 10/100/1000BASE-T

2-port 1000BASE-X SFP

SFP Type

Ethernet Gigabit:

Mini-GBIC-SX

Mini-GBIC-LX

Mini-GBIC-LH40

Mini-GBIC-ZX50

Mini-GBIC-ZX80

Mini-GBIC-ZX100

1000BASE-T:

Mini-GBIC-GT

The supported module type may change at any time. Consult us for the detailed change

information.

SFP Ports

Support 1000BASE-X

Power Supply

AC input:

Rated voltage range: 100V to 240V

Max voltage range: 90V to 285V

Frequency: 50/60Hz

Rated current: 4A

PoE

All the RJ45 ports are PoE-capable with the maximum power output of 30W.

The maximum output power of PoE/PoE+ is 370W.

Power Consumption

400W(max)

Operating

Temperature

0ºC to 50ºC (32ºF to 122ºF)

Storage Temperature

-40ºC to +70ºC (-40ºF to 158ºF)

Operating Humidity

10% to 90% RH non-condensing

Storage Humidity

5% to 90% RH non-condensing

Fan

Support

EMC Standards

EN55032(Class A)

Dimensions (W×D×H)

440 mm x 205 mm x 44 mm

Switching

Capacity(Gbps)

52Gbps

Product Appearance

The front panel of RG-S1826G-P Ethernet switch provides 24 10/100/1000BASE-T ports, two 1000BASE-X SFP ports,

and LED indicators.

Figure 1-22 Appearance of RG-S1826G-P

Hardware Installation and Reference Guide Product Overview

Front Panel

Figure 1-23 Front Panel of RG-S1826G-P

Note

1. Power status indicator

2.10/100/1000 BASE-T

Link/ACT/Speed indicator

3.PoE Status indicator

4.1000BASE-X SFP port indicator

5.10/100/1000 BASE-T port

6.1000BASE-X SFP port

Rear Panel

Figure1-24 Rear Panel of RG-S1826G-P

Note

1. Grounding connector

2. AC power input port

Power Supply

RG-S1826G-P Switch can be powered with AC power.

Rated voltage range: 100V to 240V

Max voltage range: 90V to 285V

Frequency: 50/60Hz

Rated current: 4A

Power cord requirement: 10A

Heat Dissipation

Hardware Installation and Reference Guide Product Overview

The switch adopts turbine fans for heat dissipation, thereby ensuring normal function of the device in the specified

environment. 10 cm distance space should be reserved at both sides and the back plane of the cabinet to allow air

circulation. It is recommended to clean the device once every 3 months to avoid dust from blocking vents.

PoE

The PoE power supply of RG-S1826G-P switch is designed to support the IEEE802.3af and 802.3at standards. It uses

Alternative A, that is, uses UTP/STP category-5/5e cables for power supply.

LED Indicator

Indicator

Faceplate

Marker

Status

Indication

Power indicator

PWR

Off

The switch is powered down.

On

The switch is powered on.

Ethernet port

indicator

1-24

Off

The port is NOT connected.

Solid orange

The port is connected at 10/100 Mbps.

Blinking orange

The port is receiving or transmitting traffic at

10/100 Mbps.

Solid green

The port is connected at 1000 Mbps.

Blinking green

The port is receiving or transmitting traffic at 1000

Mbps.

SFP port indicator

SFP1, SFP2

Off

The port is NOT connected.

Solid green

The port is connected at 1000 Mbps.

Blinking green

The port is receiving or transmitting traffic at 1000

Mbps.

PoE status

indicator

1-24

Off

No PoE power supply.

On

PoE is operational.

Blinking

Abnormal PoE power supply

1.4.2 Module

The RG-S1800G-P series switches support the following modules: M3000E-02SFP/GT, M3000E-STACK.

M3000E-02SFP/GT can be used to extend two SFP ports.

RG-S1800G-P switch supports the dynamic PoE mode, that is, Dynamic-FIFS (Dynamic First In First Service)

mode. This mode enables automatic detection and power-on of PD devices and allocates the PoE port power by

the actual power consumption of the PD device. Device powering will be disabled if the required power is greater

than the available power.

Hardware Installation and Reference Guide Preparation before Installation

2 Preparation before Installation

2.1 Safety Suggestions

To avoid personal injury and equipment damage, please carefully read the safety suggestions before you install

the switch.

The following safety suggestions do not cover all possible dangers.

2.1.1 Safety Precautions for Installing the System

Keep the chassis clean and free from any dust.

Do not place the equipment in a walking area.

The device must be installed and operated in the place that can restrict its movement.

Do not wear loose clothes or accessories that may be hooked or caught by the device during installation and

maintenance.

Turn off all power supplies and remove the power sockets and cables before installing or uninstalling the device.

2.1.2 Movement Safety

Do not frequently move the device.

When moving the device, note the balance and avoid hurting legs and feet or spraining the waist.

Before moving the device, turn off all power supplies and dismantle all power modules.

2.1.3 Electric Safety

Observe local regulations and specifications when performing electric operations. Relevant operators must be

qualified.

Before installing the device, carefully check any potential danger in the surroundings, such as ungrounded power

supply, and damp/wet ground or floor.

Before installing the device, find out the location of the emergency power supply switch in the room. First cut off

the power supply in the case of an accident.

Try to avoid maintaining the switch that is powered-on alone.

Be sure to make a careful check before you shut down the power supply.

Do not place the equipment in a damp location. Do not let any liquid enter the chassis.

Any nonstandard and inaccurate electric operation may cause an accident such as fire or electrical shock, thus

causing severe even fatal damages to human bodies and equipment.

Direct or indirect touch through a wet object on high-voltage and mains supply may bring a fatal danger.

Hardware Installation and Reference Guide Preparation before Installation

2.1.4 Static Discharge Damage Prevention

To prevent damage from static electricity, pay attention to the following:

Proper grounding of grounding screws on the back panel of the device. Use of a three-wire single-phase socket

with protective earth wire (PE) as the AC power socket.

Indoor dust prevention.

Proper humidity conditions.

2.1.5 Laser Safety

When a fiber transceiver works, ensure that the port has been connected with an optical fiber or is covered with a

dust cap, to keep out dust and avoid burning your eyes.

When the optical module is working, do not pull out the fiber cable and stare into the transceiver interface or you

may hurt your eyes.

Do not stare into any optical port under any circumstances, as this may cause permanent damage to your eyes.

2.2 Installation Site Requirements

To ensure the normal working and a prolonged durable life of the equipment, the installation site must meet the

following requirements.

2.2.1 Ventilation Requirements

You must ensure that sufficient space (10 cm distance from both sides and the back panel of the cabinet) is reserved at

the ventilation openings to ensure the normal ventilation. During the jumper process of the device, prevent the cables

from blocking the air intake. Dust the device every three months to avoid blocking the ventilation openings.

2.2.2 Temperature and Humidity Requirements

To ensure the normal operation and prolong the service life of the switch, you should keep proper temperature and

humidity in the equipment room.

If the equipment room has temperature and humidity that do not meet the requirements for a long time, the equipment

may be damaged.

In an environment with high relative humidity, the insulating material may have bad insulation or even leak

electricity. Sometimes the materials may suffer from mechanical performance change and metallic parts may get

rusted.

In an environment with low relative humidity, however, the insulating strip may dry and shrink. Static electricity

may occur easily and endanger the circuit on the equipment.

In an environment with high temperature, the equipment is subject to even greater harm, as its performance may

degrade significantly and various hardware faults may occur. .

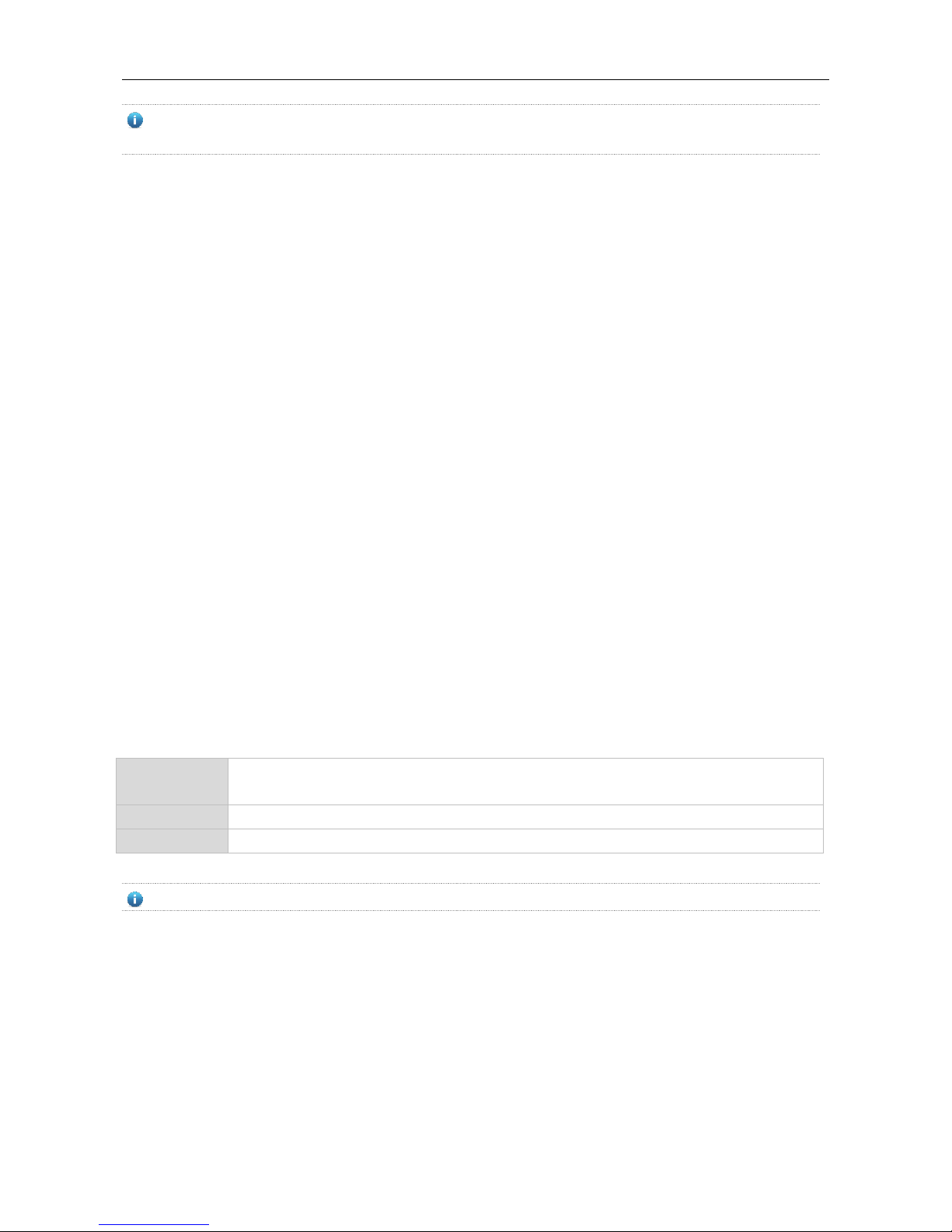

Therefore, the ambient temperature and humidity must meet the requirements listed in Table 2-1:

Hardware Installation and Reference Guide Preparation before Installation

Table 2-1 Temperature and Humidity Requirements

Temperature

Relative Humidity

0ºC to 50ºC (32ºF to 122ºF)

10% to 90% RH

The requirements for the sampling site of the temperature and humidity in the operating environment of the device

are as follows:

There is no protective plate at the front or back of the equipment rack.

The vertical height is 1.5 m above the floor.

The distance from the front panel of the equipment is 0.4 m.

2.2.3 Cleanness Requirements

Dust poses a severe threat to the running of the equipment. The indoor dust falling on the equipment may be adhered

by the static electricity, causing bad contact of the metallic joint. Such electrostatic adherence may occur more easily

when the relative humidity is low, not only affecting the useful life of the equipment, but also causing communication

faults. Table 2-2 shows the requirements for the dust content and granularity in the equipment room.

Table 2-2 Requirements for the Dust Content and Granularity in the Equipment Room

Substance

Concentration Limit (particles/m3)

Dust particles (diameter ≥0.5μm)

≤3.5×106

Dust particles (diameter ≥5μm)

≤3×104

Apart from dust, the salt, acid and sulfide in the air in the equipment room must also meet strict requirements; as such

poisonous substances may accelerate the corrosion of the metal and the aging of some parts. The equipment room

should be protected from the intrusion of harmful gases (for example, SO2, H2S, NO2 and Cl2), whose requirements are

listed in the following table.

Table 2-3 Requirements for Harmful Gases in the Equipment Room

Gas

Average (mg/m3)

Maximum (mg/m3)

SO2

0.3

1.0

H2S

0.1

0.5

NO2

0.5

1.0

Cl2

0.1

0.3

The Average refers to the average limit of harmful gas in one week. The Maximum value is the upper limit of the

harmful gas measured in one week for up to 30 minutes every day.

2.2.4 EMI

During applications, the switch may be subject to external interferences that affect the device through conduction

manners such as capacitance coupling, inductive coupling, electromagnetic wave emission, common impedance

Hardware Installation and Reference Guide Preparation before Installation

(including grounding systems), and wires (power cables, signal cables and outgoing transmission cables). For that

purpose, note that:

For the AC power supply system TN, single-phase three-core power socket with protective earthing conductors

(PE) should be adopted to effectively filter out interference from the power grid through the filtering circuit.

The switch should be located at places free from large power radio launch pad, radar launch pad, and

high-frequency large-current devices.

If necessary, electromagnetic shielding should be adopted. For example, use interface cables to shield cables.

Interface cables should be laid inside the equipment room. Outdoor cabling is prohibited, avoiding damages to

device signal interfaces caused by over-voltage or over-current of lightning.

2.2.5 System Grounding Requirements

A good grounding system is the basis for the stable and reliable operation of the switch. It is the chief condition to

prevent lightning stroke and resist interference. Please carefully check the grounding conditions on the installation site

according to the grounding requirements, and perform grounding operations properly as required.

Effective grounding of the switch is an important guarantee for lightning protection and interference resistance.

Therefore, connect the grounding line of the switch properly.

Safety Grounding

The equipment using AC power supply must be grounded by using the yellow/green safety grounding cable. Otherwise,

when the insulating resistance decreases the power supply and the enclosure in the equipment, electric shock may

occur.

Ensure that a protective earth wire is provided in the building.

A service person should check whether or not the socket-outlet from which the device is to be powered provides a

reliable connection to the building protective earth. If not, the service person should arrange for the installation of a

protective earthing conductor from the separate protective earthing terminal to the protective earth wire in the

building.

The socket-outlet should be installed at a location near the device easy for operation.

During the device installation, always make the ground connected first and disconnected last.

The cross-sectional area of protective earthing conductor should be at least 0.75mm2 (18AWG).

Use three-pin power cord for installation. The cross-sectional area of each pin should be at least 0.75mm2

(18AWG).

Lightning Grounding

The lightning protection system of a facility is an independent system that consists of the lightning rod, downlead

conductor and the connector to the grounding system, which usually shares the power reference ground and

yellow/green safety cable ground. The lightning discharge ground is for the facility only, irrelevant to the equipment.

EMC Grounding

The grounding required for EMC design includes shielding ground, filter ground, noise and interference suppression,

and level reference. All the above constitute the comprehensive grounding requirements. The resistance of earth wires

Hardware Installation and Reference Guide Preparation before Installation

should be less than 1 ohm. The switch backplane is reserved with one grounding pole, as shown in Figure 2-1, Figure

2-2, and Figure 2-3.

Figure 2-1

Figure 2-2

Figure 2-3

2.2.6 Lightning Resistance Considerations

When the AC power cable is imported outdoors and directly connected to the power port of the switch, lightning line

bank should be adopted to prevent the switch from being hit by lightning shocks. Usage of the lightning line bank:

Connect the mains supply AC cable to the lightning line bank. Then, connect the switch to the lightning line bank. This

can help to prevent the current of high-voltage lightning from passing the switch directly through the mains supply cable

to a certain extent.

Hardware Installation and Reference Guide Preparation before Installation

The lightning line banks are not provided and should be purchased by users as required.

For the usage of lightning line banks, refer to their related manuals.

2.2.7 EMI Consideration

Electro-Magnetic Interference (EMI), from either outside or inside the equipment or application system, affects the

system in the conductive ways such as capacitive coupling, inductive coupling, and electromagnetic radiation.

There are two types of electromagnetic interferences: radiated interference and conducted interference, depending on

the type of the transmission path.

When the energy, often RF energy, from a component arrives at a sensitive component via the space, the energy is

known as radiated interference. The interference source can be either a part of the interfered system or a completely

electrically isolated unit. Conducted interference results from the electromagnetic wire or signal cable connection

between the source and the sensitive component, along which cable the interference conducts from one unit to another.

Conducted interference often affects the power supply of the equipment, but can be controlled by a filter. Radiated

interference may affect any signal path in the equipment and is difficult to shield.

Effective measures should be taken for the power system to prevent the interference from the electric grid.

The grounding device of the switch must not be used as the grounding device of the electrical equipment or

anti-lightning grounding device. In addition, the grounding device of the switch must be deployed far away from the

grounding device of the electrical equipment and anti-lightning grounding device.

Keep the equipment away from high-power radio transmitter, radar transmitting station, and high-frequency

large-current device.

Measures must be taken to shield static electricity.

2.3 Requirements of Installation Tools

Table 2-4 List of Installation Tools

Common tools

Philips screwdriver, flathead screwdriver, related electric cables and optical cables, bolts, diagonal

pliers, straps

Special tools

Anti-static tools

Meters

Multimeter

The tool kit is customer supplied.

Hardware Installation and Reference Guide Product Installation

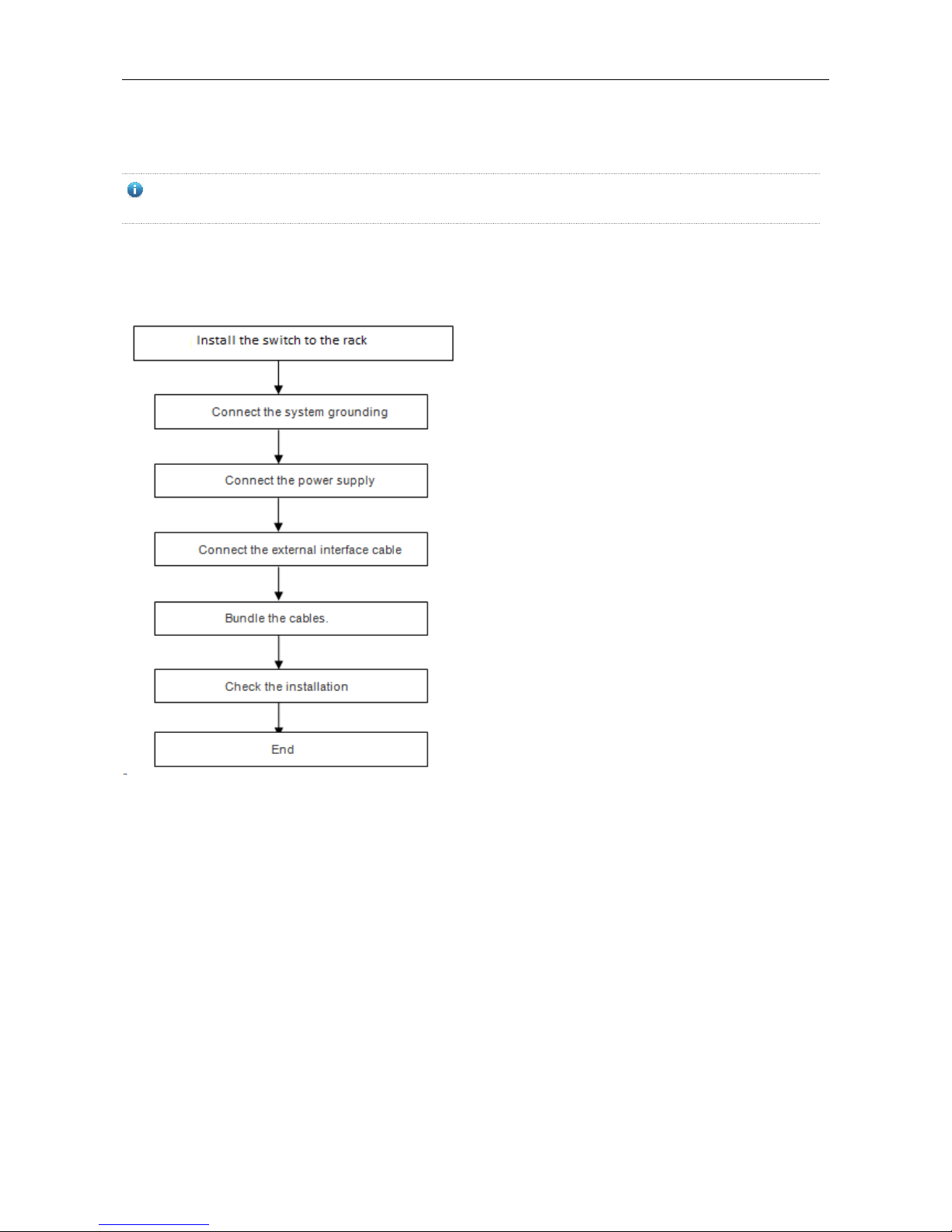

3 Product Installation

Please ensure that you have carefully read the section of “Preparation before Installation”.

Make sure that the requirements set forth in section of “Preparation before Installation” have been met.

3.1 Installation Procedure

3.2 Confirmations before Installation

Before installation, please confirm the following points:

Whether ventilation requirements are met for the switch

Whether the requirements of temperature and humidity are met for the switch

Whether power cables are already laid out and whether the requirements of electrical current are met

Whether related network adaption lines are already laid out

3.3 Precautions

During installation, note the following points:

Hardware Installation and Reference Guide Product Installation

Connect the power cables of different colors to the corresponding grounding posts.

Ensure that the interface of the power supply cable is well connected to the power interface of the device. The

power cables must be protected using power cable retention clips after they are connected to the device.

Do not place any articles on the switch.

Reserve a spacing of at least 10 cm around the chassis for good ventilation. Do not stack the devices.

The switch should be located at places free from the large power radio launch pad, radar launch pad, and

high-frequency large-current devices. If necessary, electromagnetic shielding should be adopted. For example,

use interface cables to shield cables.

100-meter network cables should be laid inside the equipment room and outdoor cabling of such cables is

prohibited. If outdoor cabling is necessary, take relevant measures for lightning protection.

3.4 Installing the RG-S1800 Series

3.4.1 Mounting the Switch in the Rack

The RG-S1800 series switches are designed with the EIA standard dimensions. RG-S1826 can be installed in 19-inch

rack, while RG-S1808 does not support rack mounting.

Step 1: Take out supplied screws and brackets, and then mount the brackets onto left and right sides of the switch.

Figure 3-2 Attaching the Mounting Brackets to the Switch

Step 2: Place the switch into the rack. Fix the other ends of both brakcets onto the suqre hole strips of the rack by using

screws and cage nuts, as shown in Figure 3-3.

Figure 3-3 Fixing the Brackets to the Rack

Hardware Installation and Reference Guide Product Installation

3.4.2 Mounting the Switch on the Wall

The RG-S1800 series switches can be mounted on a wall (RG-S1808 does not support wall mounting).

Step 1: Take out supplied screws and brackets. And then rotate the brackets by 90° when it is mounted on the wall.

Figure 3-4 Fixing the Switch to the Wall

Step 2: Fix the switch onto the wall by using expansion screws.

Hardware Installation and Reference Guide Product Installation

3.4.3 Mounting the Switch to a Workbench

In some cases, users do not have the 19-inch standard cabinet. The common solution is to place the switch on a clean

workbench. The operation is simple as follows:

Step 1: Attach the four rubber pads to the four corners on the switch bottom.

Figure 3-5 Attaching the Pads to the Switch

2) Step 2: Place the switch on the workbench and ensure good ventilation condition around the switch.

Figure 3-6 Placing the Switch on the Workbench

3.5 Installing the RG-S1800G Series

3.5.1 Mounting the Switch in the Rack

The RG-S1800G series switches are designed with the EIA standard dimensions. The switch can be installed in 19-inch

rack.

Step 1: Take out supplied screws and brackets, and then mount the brackets onto left and right sides of the switch.

Figure 3-7 Attaching the Mounting Brackets to the Switch

Hardware Installation and Reference Guide Product Installation

Step 2: Place the switch into the rack. Fix the other ends of both brakcets onto the suqre hole strips of the rack by using

screws and cage nuts, as shown in Figure 3-8.

Figure 3-8 Fixing the Brackets to the Rack

3.5.2 Mounting the Switch on the Wall

The RG-S1800G series switches can be mounted on a wall.

Step 1: Take out supplied screws and brackets. And then rotate the brackets by 90° when it is mounted on the wall.

Figure 3-9 Fixing the Switch to the Wall

Hardware Installation and Reference Guide Product Installation

Step 2: Fix the switch onto the wall by using expansion screws.

3.5.3 Mounting the Switch to a Workbench

In some cases, users do not have the 19-inch standard cabinet. The common solution is to place the switch on a clean

workbench. The operation is simple as follows:

Step 1: Attach the four rubber pads to the four corners on the switch bottom.

Figure 3-10 Attaching the Pads to the Switch

2) Step 2: Place the switch on the workbench and ensure good ventilation condition around the switch.

Hardware Installation and Reference Guide Product Installation

Figure 3-11 Placing the Switch on the Workbench

3.6 Installing the RG-S1800-P Series

3.6.1 Mounting the Switch to a Workbench

In some cases, users do not have the 19-inch standard cabinet. The common solution is to place the switch on a clean

workbench. The operation is simple as follows:

Step 1: Attach the four rubber pads to the four corners on the switch bottom.

Figure 3-12 Attaching the Pads to the Switch

2) Step 2: Place the switch on the workbench and ensure good ventilation condition around the switch.

Figure 3-13 Placing the Switch on the Workbench

Hardware Installation and Reference Guide Product Installation

3.6.2 Mounting the Switch on the Wall

The RG-S1809-P series switches can be mounted on a wall.

Step1: Drill two holes on the wall. Tap wall anchors into the holes.

Figure 3-14

Step 2: Drive screws into the anchors.

Figure 3-15

Step 3: Mount the switch to wall through the screws.

Figure 3-16

Hardware Installation and Reference Guide Product Installation

Step 4: Complete installation.

Figure 3-17

Hardware Installation and Reference Guide Product Installation

3.7 Installing the RG-S1800G-P Series

3.7.1 Mounting the Switch in the Rack

The RG-S1800G-P series switches are designed with the EIA standard dimensions. RG-S1826G-P can be installed in

19-inch rack.

Step 1: Take out supplied screws and brackets, and then mount the brackets onto left and right sides of the switch.

Figure 3-18 Attaching the Mounting Brackets to the Switch

Step 2: Place the switch into the rack. Fix the other ends of both brakcets onto the suqre hole strips of the rack by using

screws and cage nuts, as shown in Figure 3-19.

Figure 3-19 Fixing the Brackets to the Rack

3.7.2 Mounting the Switch on the Wall

The RG-S1800G-P series switches can be mounted on a wall.

Step 1: Take out supplied screws and brackets. And then rotate the brackets by 90° when it is mounted on the wall.

Figure 3-20 Fixing the Switch to the Wall

Hardware Installation and Reference Guide Product Installation

Step 2: Fix the switch onto the wall by using expansion screws.

3.7.3 Mounting the Switch to a Workbench

In some cases, users do not have the 19-inch standard cabinet. The common solution is to place the switch on a clean

workbench. The operation is simple as follows:

Step 1: Attach the four rubber pads to the four corners on the switch bottom.

Figure 3-21 Attaching the Pads to the Switch

2) Step 2: Place the switch on the workbench and ensure good ventilation condition around the switch.

Figure 3-22 Placing the Switch on the Workbench

Hardware Installation and Reference Guide Product Installation

3.8 Connecting the Power Cord

Make sure the socket is powered off and the switch is properly grounded before the power cord is connected.

Connect the AC power cord

1. Insert the AC power plug into the device.

2. Take out the anti-loose buckle.

3. Install the anti-loose buckle on the rear panel of the device

4. Fasten the anti-loose buckle to the power cord.

5. Connect the other end of the power cord to an external power socket.

6. Power on the device and check whether the status indicator is blinking. Blinking indicates the switch is being

initialized.

Figure 3-23 Connecting the Power Cord

Connect the DC power cord

1. Insert the DC power plug into the device.

2. Connect the other end of the power cord to an external power socket.

3. Power on the device and check whether the status indicator is blinking. Blinking indicates the switch is being

initialized.

Hardware Installation and Reference Guide Product Installation

3.9 Checking after Installation

Before checking the installation, switch off the power supply so as to avoid any personal injury or damage to the

component due to connection errors.

Check that the ground line is connected.

Check that the cables and power input cables are correctly connected.

Check that the 100 meter cables are laid out inside the equipment room. In the case of external cabling, check that

the lightning resistance socket or network interface lightning protector is connected.

Check that sufficient ventilation space is available around the device (over 10 cm).

Hardware Installation and Reference Guide Maintenance and Troubleshooting

4 Maintenance and Troubleshooting

4.1 General Troubleshooting Procedure

4.2 Common Faults

Symptom

Possible Causes

Solution

The PWR indicator is

not on after the switch

is started.

The power supply module does not

supply power.

The power cable is in loose contact.

Check whether the power socket at the equipment

room is normal and whether the power cable of the

switch is in good contact.

The RJ45 port is not in

connectivity or it is

erroneous in

receiving/transmitting

frames.

The connected twisted pair cable is

faulty.

The length of the cable exceeds 100 m.

The port has special configuration that

has no common working mode with the

connected switch.

Replace the twisted pair cable.

Check that the port configuration has the common

working mode with the connected switch.

The fiber port cannot

be connected.

The Rx and Tx ends are connected

reversely.

Switch the Rx and Tx ends of the optical fiber.

Replace the optical module with one of the

Hardware Installation and Reference Guide Maintenance and Troubleshooting

Symptom

Possible Causes

Solution

The interconnected optical module type

does not match.

The fiber type is not correct.

The length of the optical fiber exceeds

that rated of the optical module.

matched type.

Replace the optical fiber with one of the

appropriate type.

Replace the optical fiber with one of the

appropriate length.

Hardware Installation and Reference Guide Appendix A: Connectors and Connection Media

Appendix A: Connectors and Connection Media

1000BASE-T/100BASE-TX/10BASE-T Ports

The 1000BASE-T/100BASE-TX/10BASE-T is a port that supports adaptation of three rates, and automatic MDI/MDIX

Crossover at these three rates.

The 1000BASE-T complies with IEEE 802.3ab, and uses the cable of 100-ohm Category-5 or Supper Category-5 UTP or

STP, which can be up to 100 m.

The 1000BASE-T port uses four pairs of wires for transmission, all of which must be connected. Figure A-1 shows the

connections of the twisted pairs used by the 1000BASE-T port.

Figure A-1 Four Twisted Pairs of the 1000BASE-T

In addition to the above cables, the 100BASE-TX/10BASE-T can also use 100-ohm Category-3, 4, 5 cables for 10 Mbps,

and 100-ohm Category-5 cables for 100 Mbps, both of which can be up to 100 m. Figure A-2 shows the pinouts of the

100BASE-TX/10BASE-T.

Figure A-2 Pinouts of the 100BASE-TX/10BASE-T

Figure A-3 shows the straight-through and crossover cable connections for the 100BASE-TX/10BASE-T.

Figure A-3 Connections of the Twisted Pairs of the 100BASE-TX/10BASE-T

Hardware Installation and Reference Guide Appendix A: Connectors and Connection Media

Optical Fiber Connection

For the optical fiber ports, select single-mode or multiple-mode optical fibers for connection according to the fiber module

connected. The connection schematic diagram is shown in Figure A-4:

Figure A-4 Optical Fiber Connections

Hardware Installation and Reference Guide Appendix B Mini-GBIC Modules

Appendix B Mini-GBIC Modules

We provide appropriate SFP modules (Mini-GBIC) modules according to the types of interfaces of the switch modules.

You can select the module to suit your specific needs. The 100M/1000M SFP module supports the following modules

as well as the 100M/1000M fiber/copper conversion SFP module (Mini-GBIC-GT). The following models and technical

specifications of some 100M/1000M SFP modules are listed for your reference.

Models and Technical Specifications of the Mini-GBIC (SFP) Module

Table B-1 Models and Technical Specifications of the 100M SFP Modules

100M Mini-GBIC

(SFP)

Wavelength

(nm)

Media Type

Core

Size

(μm)

Cabling

Distance

Intensity of

Transmitte

d Light

(dBm)

Intensity of

Received

Light

(dBm)

Suppor

t DDM

(Yes/No)

min

max

min

max

FE-SFP-LX-MM1310

1,310

Multi-mode

fiber

62.5/125

2km

-22

-14

-30

-14

Yes

FE-SFP-LH15-SM1310

1,310

Single-mode

fiber

9/125

15km

-15

-8

-28

-8

Yes

Table B-2 Models and Technical Specifications of the 1000M SFP Modules

1000M Mini-GBIC

(SFP)

Wavelength

(nm)

Media Type

Core

Size

(μm)

Cabling

Distance

Intensity of

Transmitte

d Light

(dBm)

Intensity of

Received

Light

(dBm)

Suppor

t DDM

(Yes/No)

min

max

min

max

MINI-GBIC-SX-MM850

850

Multi-mode

fiber

62.5/125

275m

-9.5

-3

-17 0 No

50/125

550m

MINI-GBIC-LX-SM1310

1,310

Single-mode

fiber

9/125

10km

-9.5

-3

-20

-3

No

GE-eSFP-SX-MM850

850

Multi-mode

fiber

62.5/125

275m

-9.5

-3

-17 0 Yes

50/125

550m

GE-eSFP-LX-SM1310

1,310

Single-mode

fiber

9/125

10km

-9.5

-3

-20

-3

Yes

MINI-GBIC-LH40-SM13

10

1,310

Single-mode

fiber

9/125

40km

-2 3 -22

-3

Yes

MINI-GBIC-ZX50-SM15

50

1,550

Single-mode

fiber

9/125

50km

-5 0 -22

-3

Yes

MINI-GBIC-ZX80-SM15

50

1,550

Single-mode

fiber

9/125

80km

0

4.7

-22

-3

Yes

Hardware Installation and Reference Guide Appendix B Mini-GBIC Modules

MINI-GBIC-ZX100-SM1

550

1,550

Single-mode

fiber

9/125

100km

0 5 -30

-9

Yes

For the optical module with transmission distance exceeding 40 km and more, one on-line optical attenuator

should be added on the link to avoid the overload of the optical receiver when short single-mode optical fibers are

used.

Loading...

Loading...