Rubicon Express RE7500 User Manual

RUBICON MANUFACTURING INC. 3290 MONIER CIR., RANCHO CORDOVA, CA. 95742 916-473-4600

INSTALLATION INSTRUCTIONS FOR:

RE7500 SERIES TJ EXTREME DUTY LONG ARM

TRI-LINK SYSTEM INCLUDING TJ UNLIMITED

Application Notes:

1) The TJ long arm system was originally designed for 5 .5 ” lif t. T he front track bar may be marginally long for the 4.5” lif t and is too

long for the 3.5” lift. The male thread of the RE1610 bar can be shortened by about 3/8” to allow shortening the bar to better

center the axle. An RE1600 front track bar (

2) It is highly recommended that a slip-yoke eliminator and CV drive shaft be used in conjunction with this lift.

3) This kit requires modifications to the exhaust s ystem. Generally, after the suspension is ins tall ed, plan on a shop installing a

system from the rear of the cat on back with a smaller muffler.

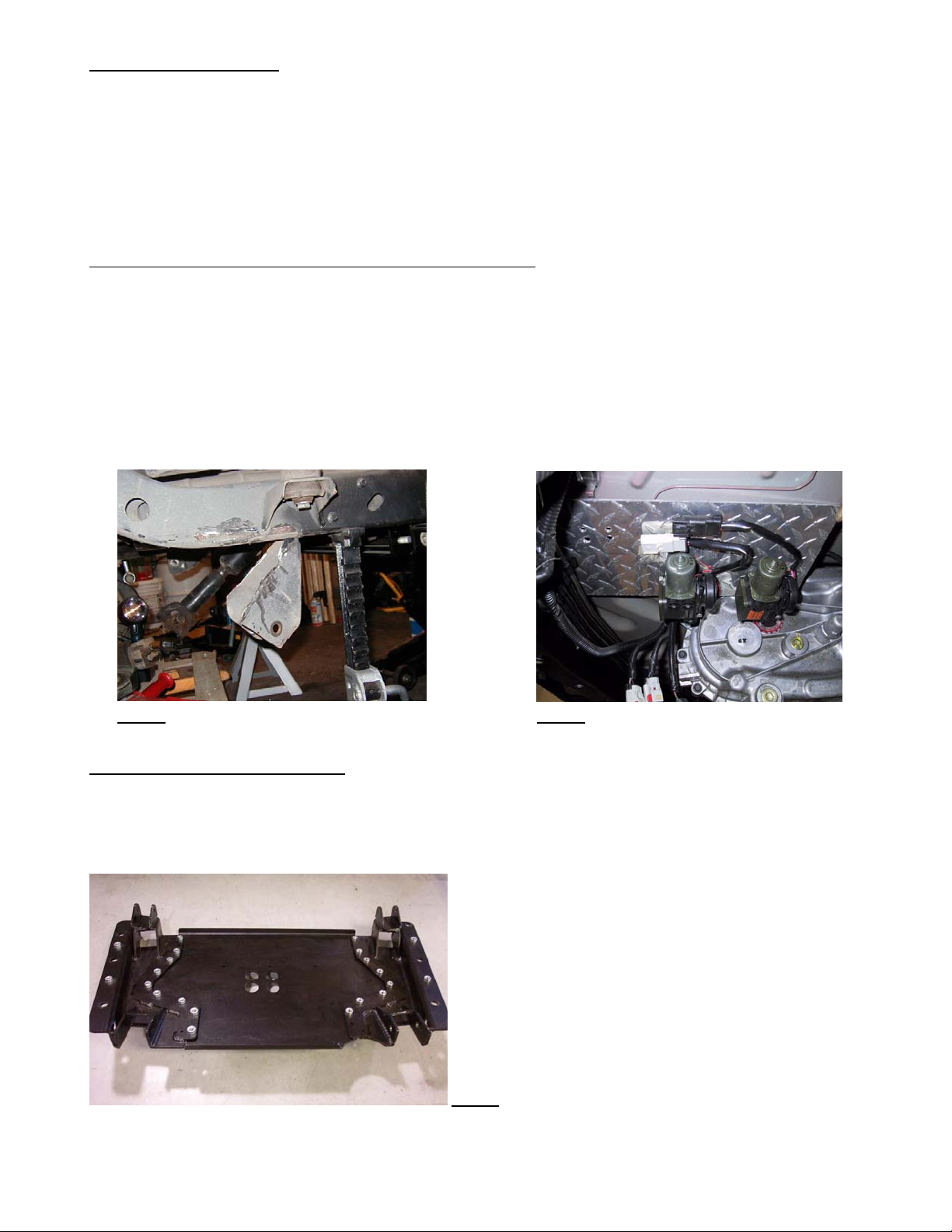

4) The “Rubicon” model TJ’s will require that the installer fabricate a bracket to relocate the compressor (refer to Photo 2 for an

example). Also, “Rubicon” model TJ’s with automatics will have to remove the transmission sk id plate for drive shaft clearance. If

more transmission protection is required, the installer will have to fa bricate it.

5) Atlas transfer cases require a 1” body lift on the ’97-’02 kits and a modified or custom mount.

Safety Warning:

Suspension systems or components that enhance the off-road performance of your vehicle may cause it to handle differently, on and off-road, than it did

from the factory. Care must be taken to prevent loss of control or vehicle rollover during sudden maneuvers. Failure to drive the vehicle safely may result

in serious injury or death to driver and passengers. We recommend you always wear your seat belt, drive safely and avoid quick turns and other sudden

maneuvers. Constant maintenance is required to keep your vehicle safe. Thoroughly inspect your vehicle before and after every off-road use.

Installation Warning:

We recommend that certified technicians perform the installations of our products. Attempts to install these products without knowledge or experience

may jeopardize the safety of the vehicle. These instructions only cover the installation of our products and may not include factory procedures for

disassembly and reassembly of factory components. Read instructions from start to finish and be sure all parts are present before disassembling the

vehicle. Included instructions are guidelines only for recommended procedures and in no way are meant to be definitive. Installer is responsible to insure a

safe and controllable vehicle after performing modifications. Do not perform test drives on public roads with partially completed installations. Always

double and triple check your work before use.

KIT CONTENTS

Front Coil Springs 3.5” Kit: RE1363, 4.5” Kit: RE1355, 5.5” Kit: RE1352

Rear Coil Springs 3.5” Kit: RE1365, 4.5” Kit: RE1360, 5.5” Kit: RE1353

RE1155 Sway Bar End Links

RE1142 Gen2 Sway Bar Disconnects

RE1383 Bump Stops Front3” (5.5” only), RE1380 2” (3.5” & 4.5”)

RE1385 Bump Stop spacers Rear 1.5”

RE1395 Bump Stops Rear 1.5” Extended (5.5”only)

RE1517 Brake Line SS Rear 24”

RE1550 Brake Line SS Front 22”

RE1610 Front Extreme Duty Track Bar (recommend RE1600 for 3.5” and 4.5”)

RE1611 Front Extreme Duty Drop Track Bar Bracket (recommend omitting for 3.5” and 4.5”)

RE2035 Rear Shock Relocation Mount

RE2500 Drop Pitman Arm

RE4000 Extreme Duty Control Arm Front Lower Left

RE4010 Extreme Duty Control Arm Front Lower Right

RE4020 (2) Extreme Duty Control Arm Front Upper

RE4030 (2) Extreme Duty Control Arm Rear Lower

RE4045 (2) Extreme Duty Control Arm Rear Upper Tri-Link

RE4100 (’97-‘02) or RE4200 (’03-‘05) Extreme Duty Three Piece Belly Pan

RE4400 (’97-“02) or RE4405 (’03-“05) Tri-Link Rear Truss Kit

TYPICAL TOOLS REQUIRED

1” hole saw(s) for steel, ½” drill motor & drill b it s (including a high quality 5/8” bit), angle grinder,

Basic mechanical hand tools and T-55 Torx head bit along with standard Torx head wrench set,

Floor jack & jack stands (2 Pair), Pitman arm puller, welder

Plasma cutter, or reciprocating saw w/metal cutting blades, or cutting wheels for angle or die grinder (to remove control arm mounts)

Congratulations on purchasing the ultimate suspension upgrade available for the Jeep TJ.

without

a drop pitman arm) can be used in the factory mounts f or the 3.5” kits.

RE7500A Page 1 of 8

INSTALLATION OVERVIEW

The installation process can be broken down into the following tasks:

1. R em oval of factory lower control arm mounts on frame.

2. 3-piece frame crossmember.

3. Front Control arms.

4. R ear T russ Assembly

5. Rear Control arms

6. Bump stops and coils.

7. Track bars, pitman arm and sway bar links.

8. Brake lines and shocks.

9. Final detailing and adjustments.

Step 1 - Removal of factory lower control arm mounts on frame

A. First, support vehicle by frame (preferably on a lift) and work on a stable level surface. Support axles with jack stands and

remove the following components; shocks, track b a rs, sway b a r end links, coil springs, control arms, bump stops, brake hoses

from axle end (it may be helpful to pinch-off hoses with vise grips to minimize fluid loss until new SS hoses are in stalled in step

6), and exhaust system behind the catalytic converter. N OT E: Coil springs can be removed without compressors i f en ough

distance is generated between the axle and frame). If a lift is not being used, it may be easier to do this one side at a time on

one axle at a time. CAUTION: If using coil spring compressors use extreme care as they will be holding a lot of potential energy

and can release violently.

B. Cut off the (4) factory lower control arm mounts from the frame. Use extreme care as not to damage the frame, or cut into

existing brake, fuel, or electrical lines.

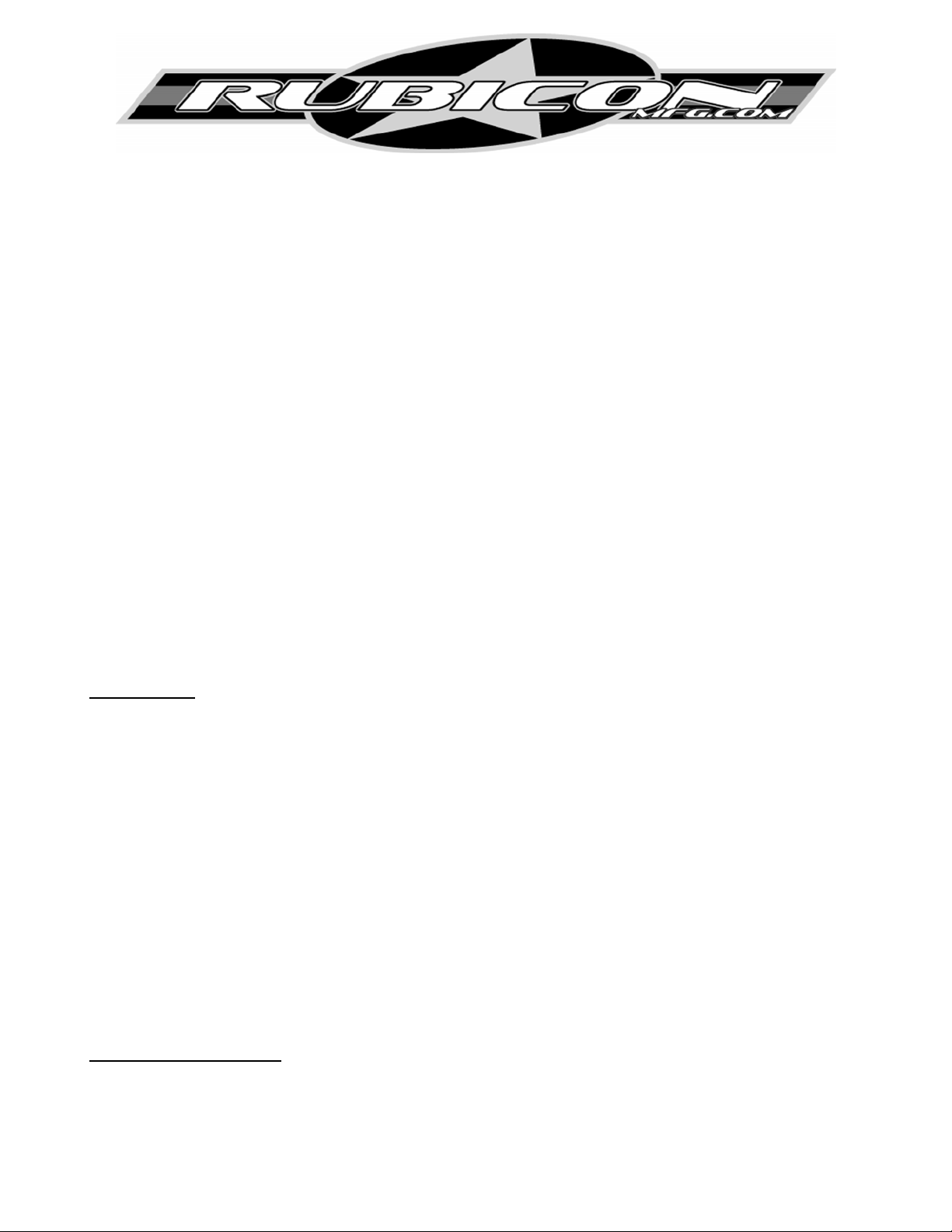

C. Grind rough areas smooth and repaint – refer to Photo 1 for typical bracket removal.

Photo 1

Photo 2

Step 2 - 3-piece frame crossmember

A. Support transmission and tran sfer case and remove stock crossmember. Note that the “R ubicon” model TJ’s will require that the

installer fabricate a bracket to relocate the compressor (refer to Photo 2 for an example).

B. Assemble the right and lef t c ontrol arm mounts to the center section using only a few sup p lied flat head bolts for fitment

purposes – refer to Photo 3 for orientation of parts. We will refer to this assembly from here on out as the “crossmember”.

Photo 3

C. Install the upper control arm mounting brackets from the RE4400 or RE4405 Tri-Link truss kit into the rear upper control arm

pockets using the supplied 10mm bolts and lock nuts. - Refer to photo 1.

RE7500A Page 2 of 8

D. Install crossmember using the six factory mounting bolts. Keep in mind that the two Pem nuts sticking up from each control arm

mount will prevent the crossmember from fitt ing up flat against the frame bottom until the rece ss holes in step ‘F’ are made.

Verify fitment to frame, transmission, tra ns fer case and exhaust. This is the easiest time to ma ke changes and install and remove

the pan. Make note to adjust transfer case linkage and verify clearances.

E. Be sure to pull fuel lines, brake lines, etc. clear of drilling. With crossmember in place, mark with a center punch (thr ough the

Pem nuts) the location of the 2 recess holes required in the b ot tom of each frame rail. You will need to drill a 3/16” pilot hole at

these four center punch marks.

F. Remove pan and drill out the four pilot holes on c enter with a 1” hole saw – refer to Photo 4. Paint all b a re m etal for protection.

G. Attach right and left frame brace to crossmember, only finger tight, using two ½” bolts on each side into the Pem nuts – refer to

Photo 5 for front view of right side assembly (less center section). Note large notch in brace is toward rear for clearance around

body mount. Reinstall entire crossmember/frame brace assembly to frame.

H. With crossmember centered and frame braces tight against frame rails you are now ready to transfer mark the 3 holes on the

side of both frame braces. Use a center punch or other method to accurately mark hole location to frame rail. After marking

remove crossmember/frame brace assembly from frame once again.

I. Use a 3/16” drill bit to run a pilot hole through both side s of frame at all six hole locations. Use care to drill perpendicular to

frame.

J. Use 1” hole saw to enlarge the six pilot holes only

Photo 5

on outside surface of frame rail, and use ½” drill bit to enlarge the six pilot

holes only

refer to Photo 6.

Photo 4

on inside surface of frame rail opposite of 1” hole –

RE7500A Page 3 of 8

Loading...

Loading...