Rubicon Express RE7363 User Manual

RUBICON EXPRESS. 3290 MONIER CIR., RANCHO CORDOVA, CA. 95742 916-473-4600

INSTALLATION INSTRUCTIONS FOR:

RE7353 2 DOOR JK WRANGLER

RE7363 4 DOOR JK WRANGLER

3.5” EXTREME DUTY LONG ARM SYSTEM

Application Notes:

1) The JK long arm system is a complete suspension system designed to replace the stock short arm configuration.

2) Installation of the system will require the removal of the factory rear upper and lower control arm brackets. The front lower

control arm brackets can remain on the frame but we suggest that they are removed for a better visual appearance.

3) This kit does require the removal of the fuel tank for installation. Special tools are not required to remove the fuel tank.

4) 2012 JK’s require modifications to the exhaust system (RE4531 sold separately): it is recommended that the exhaust, from the

transmission cross member back is removed to better access the frame rail during rear bracket installation.

5) The transmission skid plate must be removed and will not be reinstalled due to drive shaft clearance.

6) It is absolutely necessary that a front and rear CV drive shaft be used in conjunction with this suspension system.

7) Shock absorbers are sold separately from the suspension system. It is highly critical that the correct length shock be used with

the system to prevent excessive axle droop. Incorrect length shocks will result in loss of coil springs and/or drive shaft damage.

Rubicon Express Long arm systems are designed around Mono-Tube shocks, using a twin tube shock may cause interference

issues and damage to the shock or suspension. Rubicon Express always recommends using Rubicon Mono-Tube Shock Absorbers

for proper fitment and vehicle specific valving.

Safety Warning:

Suspension systems or components that enhance the off-road performance of your vehicle may cause it to handle differently, on and off-road, than it did

from the factory. Care must be taken to prevent loss of control or vehicle rollover during sudden maneuvers. Failure to drive the vehicle safely may result

in serious injury or death to driver and passengers. We recommend you always wear your seat belt, drive safely and avoid quick turns and other sudden

maneuvers. Constant maintenance is required to keep your vehicle safe. Thoroughly inspect your vehicle before and after every off-road use.

Installation Warning:

All procedures described in these instructions were performed while the vehicle was properly supported on a vehicle lift. Use caution when

supporting the vehicle as removing and installing parts will change the vehicle center weight. Rubicon Express recommends that chassis support

jacks are always used at the front and rear of the vehicle during the installation of a suspension system.

We recommend that certified technicians perform the installations of our products. Attempts to install these products without knowledge or experience

may jeopardize the safety of the vehicle. These instructions only cover the installation of our products and may not include factory procedures for

disassembly and reassembly of factory components. Read instructions from start to finish and be sure all parts are present before disassembling the

vehicle. Included instructions are guidelines only for recommended procedures and in no way are meant to be definitive. Installer is responsible to insure a

safe and controllable vehicle after performing modifications. Do not perform test drives on public roads with partially completed installations. Always

double and triple check your work before use.

ESP WARNING NOTE: The new 2007 Jeep Wrangler JK is equipped an Electric Stability Program (ESP). This system is designed to help

control the vehicle in times of uncertain traction conditions and roll stability. Due to the complex nature of this program Rubicon Express

strongly suggest that after lifting the vehicle it is returned to the dealer for a computer “flash” to re address tire size and proper ESP control

settings. Rubicon Express also recommends that you become familiar with the ESP controls and how the different level of settings can help you to

keep better control of your vehicle.

KIT CONTENTS

RE1370 (2 door JK front 3.5” coil springs) OR RE1371 (4 door JK Front 3.5” Coil Springs)

RE1375 (2 door JK Rear 3.5” coil springs) OR RE1376 (4 door JK Rear 3.5” Coil Springs)

RE1157 Sway Bar End Links

RE1143 Gen2 Sway Bar Disconnects

RE1380 2” Front lower bump stops

RE1387 Rear bump stop pad

RE1530 Front SS brake line set

RE1540 Rear SS brake line set

RE1607 Rear Lower Track Bar Bracket

RE1673 Front Adjustable Track Bar

RE4070 Extreme Duty Control Arm Front Lower Left

RE4080 Extreme Duty Control Arm Front Lower Right

RE4075 Extreme Duty Control Arm Front Upper, pair

RE4085 Extreme Duty Control Arm Rear Lower Left

RE4095 Extreme Duty Control Arm Rear Lower Right

RE4090 Extreme Duty Control Arm Rear Upper, pair

RE4521 3 Piece Extreme Duty front Cross Member

RE4525 Rear Control Arm Bracket kit

Congratulations on purchasing the ultimate suspension package available for the Jeep JK!

RI73537363 Page 1 of 10

TYPICAL TOOLS REQUIRED

1. Basic mechanical hand tools

2. 1” & 1.25” bi-metal hole saws

3. ½” drill motor & drill bits

4. angle drill (for tight locations)

5. angle grinder

6. welder

7. plasma cutter, or reciprocating saw w/metal cutting blades, or cutting wheels for angle or die grinder (to

remove control arm mounts)

PRE INSTALLATION NOTE:

Control arm bushings are pre-lubed during initial assembly at Rubicon Express. As general maintenance the control arm bushings should be

lubed with a silicone base grease as needed. Silicone base grease can be purchased at your local auto parts store.

The Super-flex joints are also pre-lubed during initial assembly at Rubicon Express. As general maintenance the super-flex joints should be

greased as needed and the outer spanner nut tightened on the joint. Any type of grease will work on the Super-flex joints. Spanner nut

tools are available through Rubicon Express (RE3771 & RE3772) if needed for tightening of the joints.

INSTALLATION OVERVIEW

The installation process can be broken down into the following tasks:

1. Vehicle preparation for suspension installation

2. Installation of 3 piece cross member assembly

3. Installation of front control arms, track bar, coil springs and bump stops, shocks, and brake lines, Sway bar discos

4. Installation of rear control arm brackets

5. Installation of rear control arms, track bar bracket, bump stops, coil springs, shocks, brake lines, and sway bar links

6. Final detailing and adjustments.

Step 1 – Vehicle preparation

Prepare the vehicle for the suspension installation by removing the following parts from the vehicle. The transfer case

NOTE: 2 Door JK’s will also require that the exhaust hanger just behind the head pipe to tail pipe connection

FUEL TANK REMOVALL: The fuel tank removal should be done when there is less than 1/8 tank of fuel in the tank to avoid excess fuel

Caution: With the fuel tank removed, there may be fuel vapors present. Use good judgment when drilling,

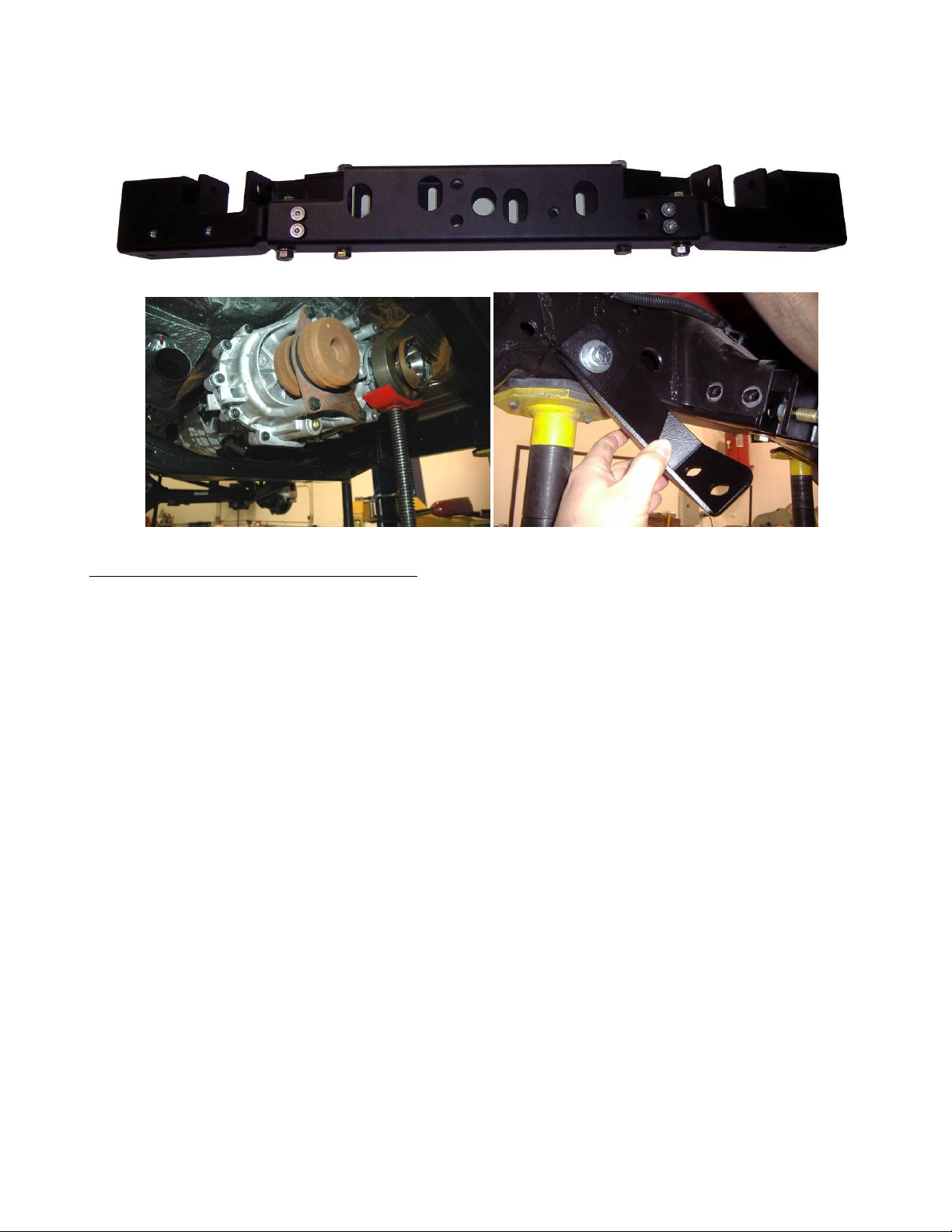

Step 2 – Three Piece cross member installation.

A. Prepare the new cross member, RE4521, by loosely installing the supplied ½” bolts thru all 3 pieces before trying to install into

the vehicle. The shorter of the two ½” bolts install from the front to the back and the longer of the two from the back to the

front. Install the 4, 3/8” flat head bolts into the bottom of the cross member and tighten, then tighten the prior installed ½” bolts

and torque to 80 ft/lbs. Installing the hardware in this fashion will allow the removal of the center cross member section without

removal of the front lower control arms should transmission service become necessary. (photo 1)

B. Support the transmission/transfer case assembly at the rear output shaft.

C. Remove the 3 transmission mount nuts and gently lift the transmission/transfer case assembly to relive the weight off the factory

cross member. Remove the 4 cross member thru bolts and remove the factory cross member. (photo 2)

D. Install the left and right cross member brace’s using the supplied ½” bolt, washer, and nut strip. The nut strip is placed thru the

square hole just forward of the cross member, install hardware and loosely tighten. (Photo 3)

skid plate (4 Door models), fuel tank and exhaust will be re-installed at the end of the installation.

1. Automatic transmission skid plate (if equipped)

2. Transfer case skid plate (not re-installed on 4 door models)

3. Front and rear drive shafts

4. Fuel tank.

5. Exhaust, from the collector at the cross member to the muffler

and the nut plate welded into the bottom of the frame on the drivers side for the t-case skid be removed

for proper fitment of the drivers side rear control arm brackets.

sloshing weight Special tools are not required for the removal of the fuel tank. All plastic clips should come

apart by squeezing the outer portion of the clip and gently pulling apart. The following connections need to

be removed: supply and return at the front of the tank, large plastic line at the charcoal canister, vent hose

at fuel tank, and the fuel filler hose. DO NOT use excessive force, damage to the fittings or seals may result..

Before lowering the tank back out the bolt from the right rear lower control arm to avoid dragging the side of

the tank on the end of the bolt. Do not completely remove the bolt at this time.

cutting, and welding near the fuel system components.

RI73537363 Page 2 of 10

E. Install the new Rubicon Express cross member into the factory mounts with the control arm pockets facing forward. Reinstall the

4 factory cross member bolts thru the factory mounts and brace, tighten to 65 ft/lbs. Once tight, torque the forward cross

member brace bolt to 65 ft/lbs

F. Lower the transmission, install and tighten the transmission mount nuts. Re-check that all new or reused hardware has been

properly tightened.

Photo # 1

Photo #2 Photo#3

Step 3 – Front arm and component installation

NOTE: All of the dimensions listed for set up of the Rubicon Express control arms are base line

measurements for set up only. Due to differences in individual vehicle tolerances each vehicle

will need to be fine tuned for its particular lift height and tire size. Final adjustments should

be checked with the shocks installed and coil springs removed and the suspension cycled

from full compression to full droop including full articulation to the left and right side. Any

areas of contact should be addressed at this point by adjusting the control arms.

A. Prepare for the front end installation by removing the following items, Shocks, sway bar links, and track bar.

B. Remove the brake line attaching screw at the frame, unclip the abs wires from there attaching points for additional length, and

lower the breather hose clip on the shock tower approximately 6”.

Front arm Installation

A. Prepare the new Rubicon Express front lower long arms by pre setting the length to 36 3/4” center to center

B. Remove the passengers side factory upper and lower control arms.

NOTE: It will be necessary to cut the upper control arm bolt off at the frame end to remove the passenger upper front arm.

This is due to the bolt being installed from the inside out prior to the exhaust installation from the factory. Alternatively

the head pipe assembly can be removed to pull the bolt out of the frame bracket. If choosing to unbolt the head pipe

be sure to disconnect all O2 sensors before removal. (photo 4)

NOTE: To identify front left and right lower control arms lay each arm side by side on the ground as they would be installed in

the vehicle. At this point, both upper control arm pockets should be leaning toward each other or the center of the car.

The upper front arms are symmetrical and can be used on either the left or right side. (photo 6) Passenger side

shown.

RI73537363 Page 3 of 10

Loading...

Loading...