Rubicon Express RE5525 User Manual

RUBICON EXPRESS 3290 MONIER CIR., RANCHO CORDOVA, CA. 95742 916-473-4600

INSTALLATION INSTRUCTIONS FOR:

RE5525 4.5” CJ EXTREME DUTY LEAF SPRING LIFT KIT

Safety Warning:

Suspension systems or components that enhance the off-road performance of

your vehicle may cause it to handle differently, on and off-road, than it did from

the factory. Care must be taken to prevent loss of control or vehicle rollover

during sudden maneuvers. Failure to drive the vehicle safely may result in

serious injury or death to driver and passengers. We recommend you always

wear your seatbelt, drive safely and avoid quick turns and other sudden

maneuvers. Constant maintenance is required to keep your vehicle safe.

Thoroughly inspect your vehicle before and after every off-road use.

Installation Warning:

We recommend that certified technicians perform the installations of our

products. Attempts to install these products without knowledge or experience

may jeopardize the safety of the vehicle. These instructions only cover the

installation of our products and may not include factory procedures for

disassembly and reassembly of factory components. Read instructions from start

to finish and be sure all parts are present before disassembling the vehicle.

Included instructions are guidelines only for recommended procedures and in no

way are meant to be definitive. Installer is responsible to insure a safe and

controllable vehicle after performing modifications. Do not perform test drives on

public roads with partially completed installations. Always double and triple

check your work before use.

KIT CONTENTS:

1 RE1170 Sway bar disconnect kit

2 RE1450 Front 5-leaf springs

2 RE1451 Rear 6-leaf springs

1 RE1465 2* Pair of Aluminum shims

1 RE1513 Rear brake line

1 RE1550 Front brake lines ‘82-86 (RE1552 ‘77-81)

4 RE2050 Spring plates w/ shock mount stud

2 RE2051 Sway bar disconnect mount stud

1 RE2140 Transfer case drop kit

1 RE2435 Front u-bolt kit

1 RE2440 Rear u-bolt kit

1 RE2501 Pitman arm p/s (RE2505 m/s)

1 RE2785 Front CJ conversion shackle kit

1 RE2786 Rear shackle kit

1 RE2790 Main eye greasable bushing kit

REQUIRED TOOLS:

Basic mechanics' tools

Pitman arm puller

Tie rod removal tool

Floor jack

Jack stands (2 pair)

INSTALLATION:

Note: Rear driveline modifications may be required with this lift

(see fixed yoke vibrations in “trouble shooting” before continuing).

1 Block rear wheels of vehicle.

2 Raise front of vehicle and support frame with jack stands.

3 Remove front wheels.

4 Remove front shocks.

5 Support axle with jack stands.

6 Remove u-bolts & spring plates.

7 Remove leaf springs.

8 Remove stock shackles and bushings from frame.

9 Remove brake hoses and replace with new stainless lines.

10 Lightly grease front shackle and main spring eye bushings.

Small shackle bushings go to the frame end and do not use

a steel sleeve. Main spring eyes use the steel sleeves (9/16”

id one at double wrap end). Front conversion shackles have

bent side plates to accommodate the new 2.5” wide leaf

springs and include a cross bar and bolt (see photo 1).

11 Install front shackles and springs into vehicle with double

military wrapped end at the frame (see photo 2). The center

pins may come with spacers installed for use w/ floating type

degree shims (not included). Be sure pins do not bottom out

on axle tube whether using shims or not- remove spacers as

required. DO NOT fully tighten the spring eye or shackle

bolts at this time. Bolts will be tightened to spec once the

vehicle is on the ground (step 14 & 17).

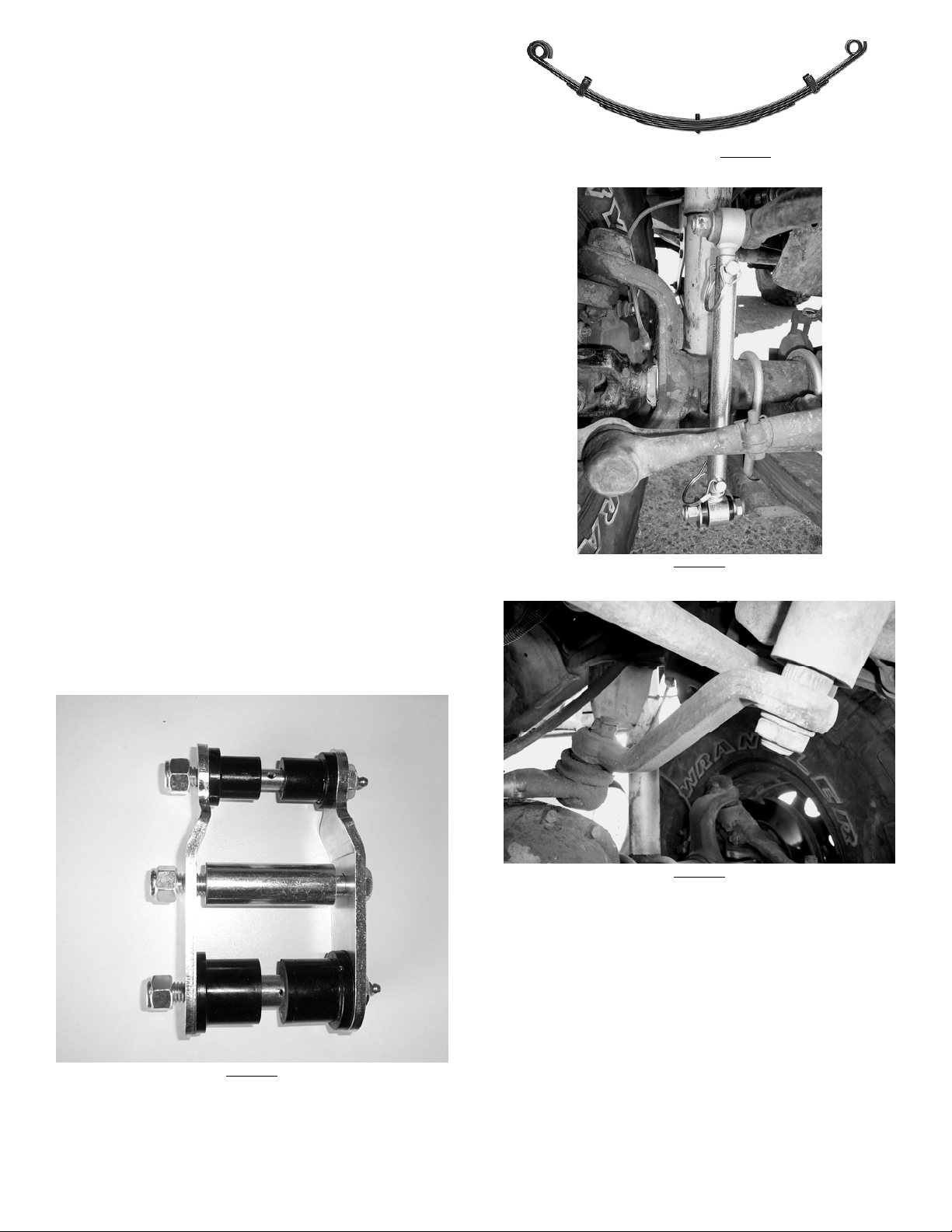

12 (See photo 3 for typical installation of steps 12-14) install

new u-bolts and spring plates with shock and disconnect

studs. Torque u-bolts to 65-80 ft/lbs, or u-bolt specs if

supplied.

13 Install longer front shocks.

14 Install front tires and Lower vehicle to ground.

15 Install front sway bar disconnects.

16 Torque spring eye bolts. ½” bolts 65-80: ft/lbs. 9/16”

bolts: 75-90 ft/lbs.

17 Tighten top shackle bolts (don’t over torque this will crush

bushing).

18 Use tie rod removal tool to remove drag link at pitman arm.

Use puller to remove pitman arm. Install drop pitman arm

and drag link (see photo 4).

-REAR AXLE-

19 Block front wheels of vehicle.

20 Raise rear of vehicle and support frame with jack stands.

21 Remove rear wheels.

22 Support rear axle with jack stands.

23 Remove shocks.

RI5525 Page 1 of 3

24 Remove u-bolts & spring plates.

25 Remove stock rear leaf springs.

26 Remove factory brake hose and replace with new stainless

line.

27 Lightly grease and install rear shackle and main spring eye

bushings. Small shackle bushings go to the frame and do not

use a steel sleeve. Main spring eyes use the steel sleeves

(9/16” id one at double wrap end). Rear shackles have

straight side plates and include a cross bar and bolt (see

photo 5).

28 Install rear shackles and springs into vehicle with double

wrap end at the frame (see photo 6). The center pins may

come with spacers installed for use w/ floating type degree

shims. Be sure pins do not bottom out on axle tube whether

using shims or not- remove spacers as required DO NOT

fully tighten the spring eye or shackle bolts at this time.

Bolts will be tightened to spec once the vehicle is on the

ground If using, insert 2.5” wide shim between spring and

spring pad on axle. Thicker end of shim should be at front

of vehicle (pinion points up).

29 (See photo 7 for typical installation of steps 30-31) install

new u-bolts and spring plates with shock studs. Torque u-

bolts to 65-80 ft/lbs, or u-bolt specs if supplied.

30 Install longer rear shocks.

31 Torque spring eye bolts. ½”: 65-80 ft/lbs. 9/16”: 75-90

ft/lbs.

32 If using, install transfer case drop by supporting one side of

transfer case with floor jack. Remove hardware from one

side of cross member. Install spacers and new hardware.

Tighten to 55 ft/lbs. Repeat on opposite side.

33 Lower axle so that it is at full droop. Rotate the rear drive

shaft to insure the yokes do not bind. If binding occurs and

shims are properly installed, a CV yoke and CV drive shaft

are likely required.

34 Lower vehicle and tighten top shackle bolts (do not over

torque this will crush bushing).

35 Bleed brake system. Inspect all brake hoses and lines for

leaks, kinks or damage.

36 Grease all zerk fittings on new bushings.

37 Lengthen drag link to center steering wheel.

38 Recheck all bolts - use factory torque specs if not given.

Recheck after 50 miles and then after every off road

excursion.

< FRAME END (MILITARY WRAP) – PHOTO 2 – SHACKLE END >

PHOTO 3

PHOTO 4

PHOTO 1

RI5525 Page 2 of 3

Loading...

Loading...