Rubbermaid 1800384 User Manual

Auto Door™

Owner’s Manual

Operating and Maintenance

Instructions

Auto Door™

SAVE THESE INSTRUCTIONS

CONSERVE ESTAS INSTRUCCIONES

VEUILLEZ CONSERVER CES DIRECTIVES

Manual Del Propietario

Instrucciones de Funcionamiento y

de Mantenimiento

Auto Door™

Le Manuel du Propriétaire

Instructions d’Utilisation et d’Entretien

Products manufactured under quality management system registered to ISO 9001:2000

Los productos están fabricados según el sistema de gestión de calidad registrado con la norma ISO 9001:2000

Produits fabriqués selon un système de gestion de la qualité ISO 9001:2000

Printed in China/Impreso en China/Imprimé en Chine

Model no./N.º de modelo/Nº de modèle :

Model No. : 1800381, 1800382, 1800383, 1800384

SKU no./N.º de SKU/Nº SKU :

1788560

FOR COMMERCIAL USE

PARA USO COMMERCIAL

UTILISATION COMMERCIALE

©2011 Rubbermaid Commercial Products LLC

4

Rubbermaid Commercial Products LLC

Winchester, VA 22601 U.S.A.

www.rubbermaidcommercial.com #1788560

Customer Service • Atención al Cliente • Service Clientèle

1-800-347-9800

www.rubbermaidcommercial.com

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

WARNING: TO REDUCE THE RISK

OF SEVERE INJURY OR DEATH:

•Read And Follow All Installation Instructions

•If this product is installed incorrectly or the door is

adjusted incorrectly, the product will not operate

properly and could cause injury and/or equipment

damage. In such cases, the manufacturer’s warranty

becomes void and the manufacturer and seller

decline all liability ensuing from improper installation

or adjustment.

• Installation of this product must be performed by a

licensed and insured professional.

• Permanent wiring is to be employed as required

by local codes.

• DO NOT connect the Auto Door to source of

power until instructed to do so.

• Always disconnect power before removing

Auto Door cover.

• The Auto Door should only be installed in an

opening capable of providing proper structural

support. Install only on a properly operating door.

• The Auto Door must be inspected periodically using

the safety checklist in this manual.

• Ensure power supply is available in ceiling above

door jamb (120 volts; 60 hertz).

• Auto Door is intended for use on interior

pedestrian doors between 34”-42” wide

with a maximum weight of 170 lbs.

• Do not place hands near Auto Door arm when

operating.

Ensure that the existing door meets the

following settings and requirements:

• The door has a UL listed door closer mounted

on the pull side of the door (if not remove and

reinstall).

• Refer to your door closer instruction manual to

adjust the door closer so that the door opening

resistance is less than 7 lbs., measured at the

latching edge of the door. The door should close

no faster than 5 seconds. Adjust the doors closing

speed accordingly.

• Make sure the door hinges are not damaged,

are in proper working condition, and lubricated

regularly.

• The door does not operate with a latch mechanism

and opens simply by pushing or pulling, unless

you use an electric strike (#1800384).

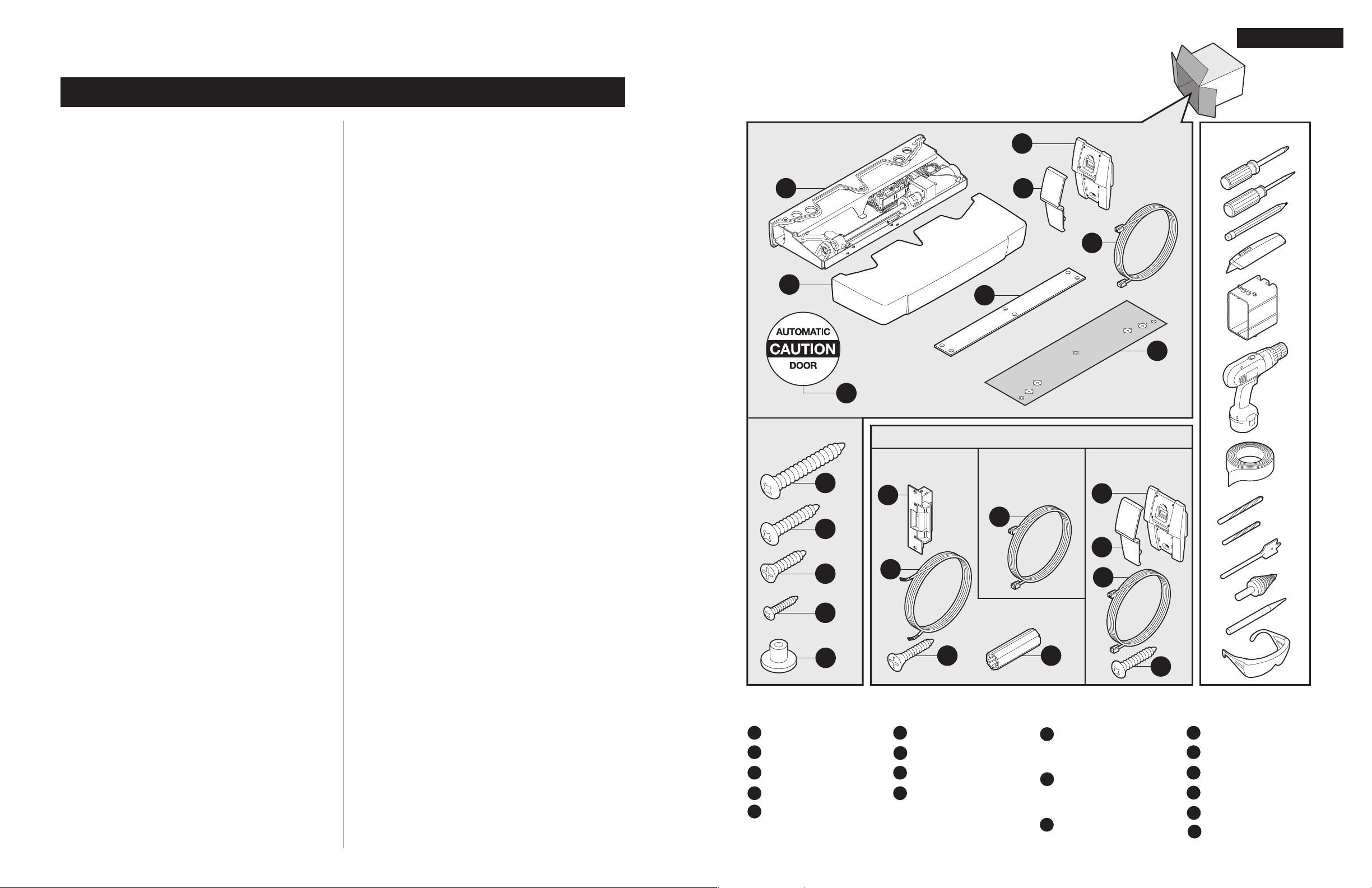

Package Contents

Please confirm that all items shown in the image below are included in the packaging.

If any parts are missing, please call customer service at 1-800-347-9800

B

A

C

D

F

E

D

A

Sensor Extension

Cable Kit

#1800383

Fasteners

x2

G

Optional Accessories

Electric Strike Kit

x3

I

#1800384

N

R

x2

J

x6

K

L

x6

O

.

E

F

B

Entrance Sensor Kit

#1800382

B

C

E

G

C

H

Tools Needed

1/8”

13/64”

1”

1”

• The door must be adjusted as described in this

manual before installation of the Auto Door.

Periodically check the adjustment control

mechanism.

• Check width of top door stop. For normal

mounting, ensure that the width is at least 31/2

”

M

x3

x2 x2

P

wide. If the width is less than 31/2” wide, a spacer

must be used to securely mount. If width is the

less than 15/8”, remove top door stop or do not

Parts List

install unit (adequate mounting requirements not

A

available for secure installation).

1 2

Auto Door main unit

B

sensor plate

C

sensor cover

main unit cover

D

E

20’ sensor cable

F

roller plate

G

caution labels

H

drilling template

I

1/4”-14 x 1-1/2”

Phillips pan head

screw type AB

Q

J

#6-32 x 1“

Phillips pan head

machine scew

K

#8”-18 x 1” Phillips

flat head countersunk

screw type AB

L

#6-20 x 3/4”

Phillips pan head

screw type AB

x2

J

M

spacer

N

electric strike

O

electric strike cable

P

electric strike screws

electric strike anchors

Q

R

sensor extension cable

E

D

A

B

D

F

G

B

ENGLISH

1

E

D

A

B

F

C

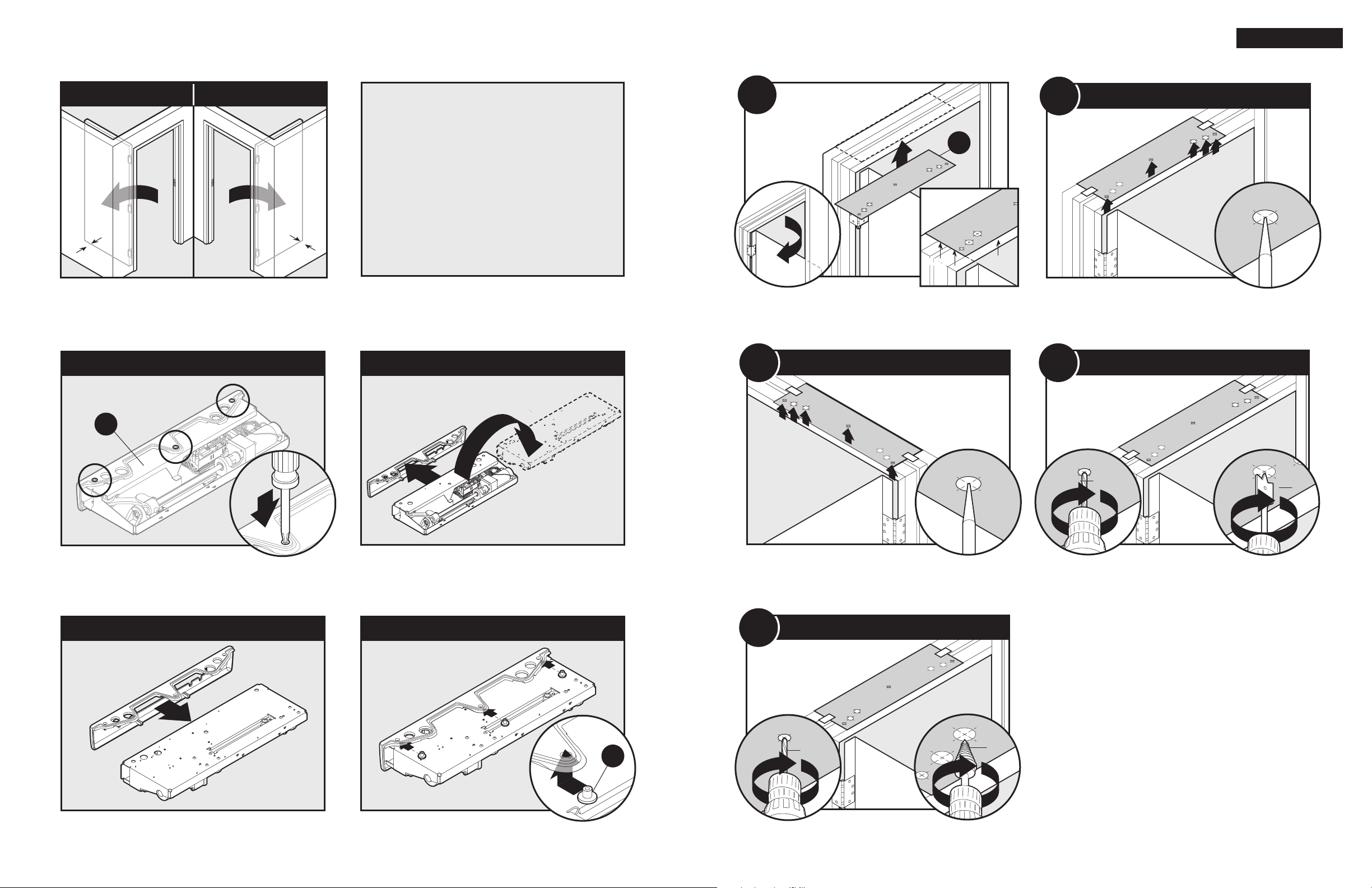

Before Installation

Left hand door Right hand door

90˚

6” min

Determine the correct orientation of the unit (right or left

hand swinging door).

Step A–right hand door only

90˚

6” min

IMPORTANT:

The AutoDoor is supplied in the left hand

configuration. Refer to steps A through D

only if you require a right hand

configuration.

Step B–right hand door only

Installation

1

2

B

E

D

A

Hold the door open 90˚. Place template against the door jamb

aligning front edge of template with face of the door in closed position,

and the side of the template aligned with the face of the 90˚ door.

2b

Right hand door

G

F

Align

Align

H

C

Align

2a

D

Left hand door

B

E

A

G

F

C

Tape template in place. For left hand door, mark hole locations

A, B, C, F and G on the door jamb with an awl or center punch.

Note: Marking letters F and G for identification is recommended.

3a

Wood door fame

A

the main unit.

Step C–Right hand door only

D

A

E

B

2

1

F

G

C

D

A

1/8”

B

E

1

Remove cover and turn main unit over 180 degrees.Using a screwdriver, push three spacers through the inside of

Step D–Right hand door only

Tape template in place. For right hand door, mark hole locations

A, B, C, D, and E on the door jamb with an awl or center punch.

Note: Marking letters D and E for identification is recommended.

3b

Steel door frame

F

B

E

D

A

G

C

For wood door frames use 1/8” drill bit for holes A, B and C

(mounting holes). Use 1” wood drill bit for holes F and G

(D and E for right hand door).

G

F

C

1”

2

Replace cover.

Insert the three spacers from the inside of the unit through

cover into and up in the main unit. Hold spacers in with

adhesive tape.

3

M

13/64”

2

2

For steel door frames use 13/64” drill bit for holes A, B and C

(mounting holes). Use 1” step drill bit for holes D and E

(F and

G for right hand door).

1”

4

Loading...

Loading...