Page 1

User Manual V0.8

Audio Analyzer

User Manual

RTX6001 Audio Analyzer

RTX6001

1

Page 2

User Manual V0.8

General

Information contained in this document is subject to change without notice. RTX A/S

makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties of merchantability and

RTX A/S shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the

Warranty

This instrument is warranted against defects in material a

one year from date of shipment. During the warranty period, RTX A/S will at its option,

either repair or replace products, which prove to be defective. For warranty service or

repair, this product must be returned to a servic

b

uyer shall prepay shipping charges to RTX A/S and RTX A/S shall pay shipping charges,

duties, and taxes for products returned to RTX A/S from another country.

RTX A/S warrants that its software and firmware

instrument will execute its programming instructions when properly installed on that

instrument.

RTX A/S does not warrant that the operation of the instrument or firmware will be

uninterrupted or error free.

Limitati

on of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by Buyer, Buyer

or misuse, operation outside of the environmental specifications

improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

RTX A/S SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND SUITABILITY

FOR A PARTICULAR PURPOSE.

RTX6001 Audio Analyzer

suitability

for a particular purpos

product installation

, performance, or use of this material.

nd w

orkmanship for a period of

e facility designated by RTX A/S.

designated by RTX A/S for use with an

-

supplied software or interfacing, unauthorized modification

for the product, or

2

e.

The

Page 3

User Manual V0.8

General information

This document and the information contained, is property of

Unauthorized copying is not allowed. The information in this document is believed to be

correct at the time of writing.

cont

ent, circuitry and specifications.

The general safety precautions, according to

all phases of operation. RTX

these requirements.

The purpose of the d

ocument is to provide guidance to users of the RTX

Analyzer. It

describes general func

Windows® based interface.

Documentation information

This User

Manual contains essential items of information needed for general

of the RTX6001.

In this document you will find valuable information on how to unpack, install and operate

your RTX6001.

RTX6001 Audio Analyzer

RTX

RTX

A/S reserves the right at any time to change said

this User

Manual, must be observed during

A/S assumes no liability for the Buyers

failure to comply with

tions of the product

and also describes the use of the

3

A/S, Denmark.

6001 Audio

-purpose use

Page 4

User Manual V0.8

Safety information

The following general safety precautions must be observed during all phases of operation

and service of this instrument. Failure to comply with these precautions or with specific

warnings elsewhere in this manual violates safety standards of design, manufa

intended use of the instrument.

comply with these requirements.

WARNING!

This is a Safety Class I instrument (provided with a protective Earth

ground, incorporated in the power cord). T

inserted in a socket outlet provided with a protective earth contact.

Furthermore, any interruption of the protective conductor inside or

outside of the instrument is likely to make the instrument dangerous.

Intentional interrup

DO NOT

defeat the earth

cable, power cable, or autotransformer without a protective ground

connector. If you are using an autotransformer, make sure its common

terminal is connecte

source outlet socket.

DO NOT

operate the product in an explosive atmosphere or in the pre

sence of flammable gasses or fumes.

DO NOT

use repaired fuses or short

continued protection against fire, replace the line fuse(s) only with

fuse(s) of the same voltage and current rating and type.

DO NOT

perform procedures involving cover or shield removal unless

you are qualified to do so

that operating personnel must not remove equipment covers or

shields. Procedures involving the removal of covers and shields

use by service-

trained personnel at

RTX6001 Audio Analyzer

RTX

assumes no liability for the customer’s failure to

he mains plug shall only be

tion is therefore prohibited.

-

grounding protection by using an extension

d to the protective earth contact of the power

-

circuited fuse holders: For

–

it is therefore strongly emphasized here

RTX only.

4

cture, and

-

are for

Page 5

User Manual V0.8

Electrostatic Discharge

Electrostatic discharge (ESD) can damage electronic test equipment. Working with

electronic components or test equipment should always be performed at a static

place.

High Voltage

Some units under test

can generate high voltage

the RTX6001.

To prevent damage to the RTX

External voltages should not be applied to the output terminals of the

The voltage applied to the input terminals should never exceed 150 V peak.

To avoid problems due to DC offsets on the inputs, it is recommended to use the AC

input setting in most cases. AC coupling is especially important when operating the unit

with inputs set to 0 dBV, -

10

Furthermore, the unit should not be operated with excessive overload for extended

periods of time. Doing so may compromise its performance.

RTX6001 Audio Analyzer

s

, which can damage the in/out port of

6001, the following should be observed:

R

dBV or -20 dBV.

5

-safe

TX6001.

Page 6

User Manual V0.8

Table of Contents

1 GETTING STARTED

1.1 Introduction

1.2 Unpacking

the RTX6001 Audio Analyzer

1.2.1

Initial Inspection

1.2.2 Box Contents

1.2.3

Check Voltage Setting and Fuse Rating

1.2.4

Placement/Rack Mounting of the RTX6001

2

DESCRIPTION OF THE R

2.1 General

2.2 Block Diagram

2.3

Front Panel Connectors

2.4

Rear Panel Connectors

2.5

Front Panel LED Indicators and Controls

3

INSTALLING THE PC SO

3.1

Minimum System Requirements

3.2

Installing the RTX6000 Series USB Driver

3.3

Connecting the RTX6001 to a PC USB Port

3.4

Switching the Audio Analyzer on f

3.5

Installing the RTX6001 Attenuation Control Program (optional)

3.6

Installing an Audio Analyzer Program

4

PERFORMING MEASUREME

5

SPECIFICATIONS AND C

6

REGULATORY INFORMATI

6.1

Compliance and Markings

6.2 Safety

7 MAINTENANCE

7.1 Introduction

7.2

General Customer Responsibilities

7.3

Operator Maintenance

7.4

Replacing the Power Line Fuses

7.5 Cleaning

7.6 Contacting RTX

7.6.1

Before calling RTX

7.6.2

Check the Basics

7.6.3

Instrument Serial Numbers

7.7 Calibration

and Service

8

RETURNING YOUR RTX60

RTX6001 Audio Analyzer

TX6001 AUDIO ANALYZER

FTWARE

or the First Time

NTS

HARACTERISTICS

ON

01 AUDIO ANALYZER FO

R SERVICE

6

8

8

8

8

8

9

10

11

11

11

12

13

14

16

16

16

17

17

18

18

19

20

23

23

23

24

24

24

24

24

25

25

26

26

26

27

28

Page 7

User Manual V0.8

8.1

Obtaining an RMA for Service Return

8.2

Packing the RTX6001

RTX6001 Audio Analyzer

for Shipment

7

28

28

Page 8

User Manual V0.8

1 Getting

Started

1.1 Introduction

The RTX6001 is a high-

performance Audio Analyzer with a large degree of flexibility. It

supports a wide

range of audio tests, due to the

PC. Connected to a PC it operates as a USB audio device. This means that a wide range

of audio analyzer software is available

one that provides the

functionality needed in each particular case.

possible to use the RTX6001 in a high

The RTX6001 provides two output channels available as balanced signals on XLR

connectors or

unbalanced signals on BNC connectors. Each channel has a 3

attenuator with 20

dB steps. This allows full range signals (sine wave, balanced) from

100 mV to 10 V.

Two differential input channels are available on XLR connectors. Each channel has a 7

stage attenuator with 10

dB steps.

mV to 100 V.

A 4 mm connector is available on the front. This is intended for connection of ground to

the device under test. In many cases this can reduce problems with

The rear panel has a USB connector for connection to a PC and a power connector for line

power.

1.2 Unpacking

the RTX

1.2.1

Initial Inspection

Please inspect the shipping container for damage. If the shipping container or packaging

material

is damaged, it should be kept until the contents have been checked mecha

nically and electrically. If any mechanical or electrical damage is observed please notify

RTX

. Please refer to the description on how to contact

Pleas

e also keep the damaged shipping materials (if any) for inspection by the carrier

and an RTX representative.

1.2.2 Box Contents

When unpacking the

RTX6001 Audio Analyzer

are included in the box.

• RTX

6001 Audio Analyzer

• Main power cable

•

USB cable (for communication between the

•

Certificate of conformity

• Calibration report

(not for demo units)

RTX6001 Audio Analyzer

standardized and

open interface to the

on the market

, allowing the user to choose the

-

quality audio recording and/or playback system.

This allows full-

range signals (sine wave) from 100

hum.

6001 Audio Analyzer

RTX

provided in this document.

please verify that the items listed below

unit

Analyzer and a PC)

8

It even makes it

-stage

-

-

Page 9

User Manual V0.8

1.2.3 Check V

oltage

IMPORTANT!

Check whether the voltage

setting

main power c

ord (see instructions below).

240 V operation.

The power line fuses are

located within the

picture below

. For 110V to 120V operation the fuse

operation the fuses are T0.325 250V.

Fuse location

If the operating voltage needs to be changed, do the following:

1

Remove the power cord from the

2

Pull out the fuse drawer e.g. with a flat screwdriver.

3

Pull out the grey voltage selector and rotate it 180

voltage.

4 Insert

the correct fuse

5 Replace the fuse

drawer

Fuse drawer

RTX6001 Audio Analyzer

Setting and Fuse Rating

is

compliant to the local region before connecting the

The RTX6001 is delivered prepared for 200V

power entry module o

n the rear panel

s are T0.63

250V. For 220

Analyzer.

°

to select

s as shown in the figure below.

Use two identical fuses.

in the power entry module.

9

–

, see

-240V

a different line

Page 10

User Manual V0.8

1.2.4

Placement/Rack Mounting of the RTX6001

The RTX6001

can be used on the bench top or installed in a 19 inch rack cabinet

optional mounting hardware)

horizontal surface, e.g. a table.

RTX6001 Audio Analyzer

Rack mounting is possible with an optional rack mounting kit. Please contact RTX or

distributor for additional information.

P

lease ensure that the space and airflow requirements

Dimensions of the RTX

6001 Audio Analyzer

RTX6001 Audio Analyzer

. For desktop use, please place the R

TX6001 on a hard

dimensions

within the rack cabinet are met.

are shown in the figure

above

10

(with

.

Page 11

User Manual V0.8

2

Description of the

Analyzer

2.1 General

The

RTX6001 is a flexible tool for testing audio equipment. For operation it must be

connected to a high-s

peed USB port on a PC. It works as a high

card, with sample rates from 44.1 kHz to 192 kHz. To make measurements, a program

should b

e installed on the PC. Since the RTX6001 works as a sound card, a large

selection of analyzer programs is available

preferred one, based on needs and personal preference.

2.2 Block Diagram

The figure below shows

a block diagram of the RTX6001 Audio Analyzer.

1 2

3

+

-

1 2

3

+

-

OSC

OSC

24.576 MHz

22.5792 MHz

0/20/40 dB

Attenuator

0/20/40 dB

Attenuator

1 2

3

+

-

1 2

3

+

-

Buffer

Buffer

Input amp

6/16/26/36 dB

Input amp

6/16/26/36 dB

Attenuator

0/10/20/30 dB

Attenuator

0/10/20/30 dB

BNC

BNC

Knobs + Indicators/

Remote Control

GND

XLR

XLR

XLR

XLR

Generator

Analyzer

The measurement section of the RTX6001 is galvanically isolated from the USB interface.

This ensures that there are no ground loops involving the connected PC.

that

potential issues with noise from the PC, e.g. n

supply of the PC, are virtually eliminated.

RTX6001 Audio Analyzer

RTX6001

Audio

-

performance USB sound

on the market

, allowing the user

ADC

ADC

buffer

ADC

buffer

MCLK

DAC

DAC

filter

DAC

filter

MCLK

MCLK

I2S

PSU

RESET

MCLK

:2

I2C

Transformer

115/

230V

2x15VAC

9VAC

Isolator

oise from the switch

-

11

to select the

USB

Interface

USB

LINE

ON/OFF

FUSES

IEC

USB-B

This ensures

mode power

Page 12

User Manual V0.8

The Analyzer section, shown at the top of the diagram, has two input channels, each with

a differential input. Both inputs are

connectors (shield) is connected to the chassis (ground) of the unit.

Switchable attenuators and gain selections allow full

100 V RMS in 10 dB steps. There are separate level settin

The two-

channel Generator section has two output connectors per channel. Each channel

has a balanced output on an XLR connector and a single

connector. Pin 1 of the XLR connectors (shield) is connected to th

the unit. The ground of the BNC connector is also connected to the chassis (ground) of

the unit. The signals on the BNC connectors are the same signals that are present on pin

2 (+) of the XLR connectors. This means that the single

level of the balanced output level. It also means that the user should be careful not to

load one output heavily in cases where both output connectors are used, since it will

influence the output level

and

The master clock used in the Analyzer is common for the Generator and the Analyzer.

The frequency will be selected based on the sample rate selected on the USB interface.

The USB connector provides the interface to the control PC.

The power s

upply can be set up for either 100 to 120 V or 220 to 240 V operation. The

switch and the fuse must be set for the correct supply voltage available at the given

location.

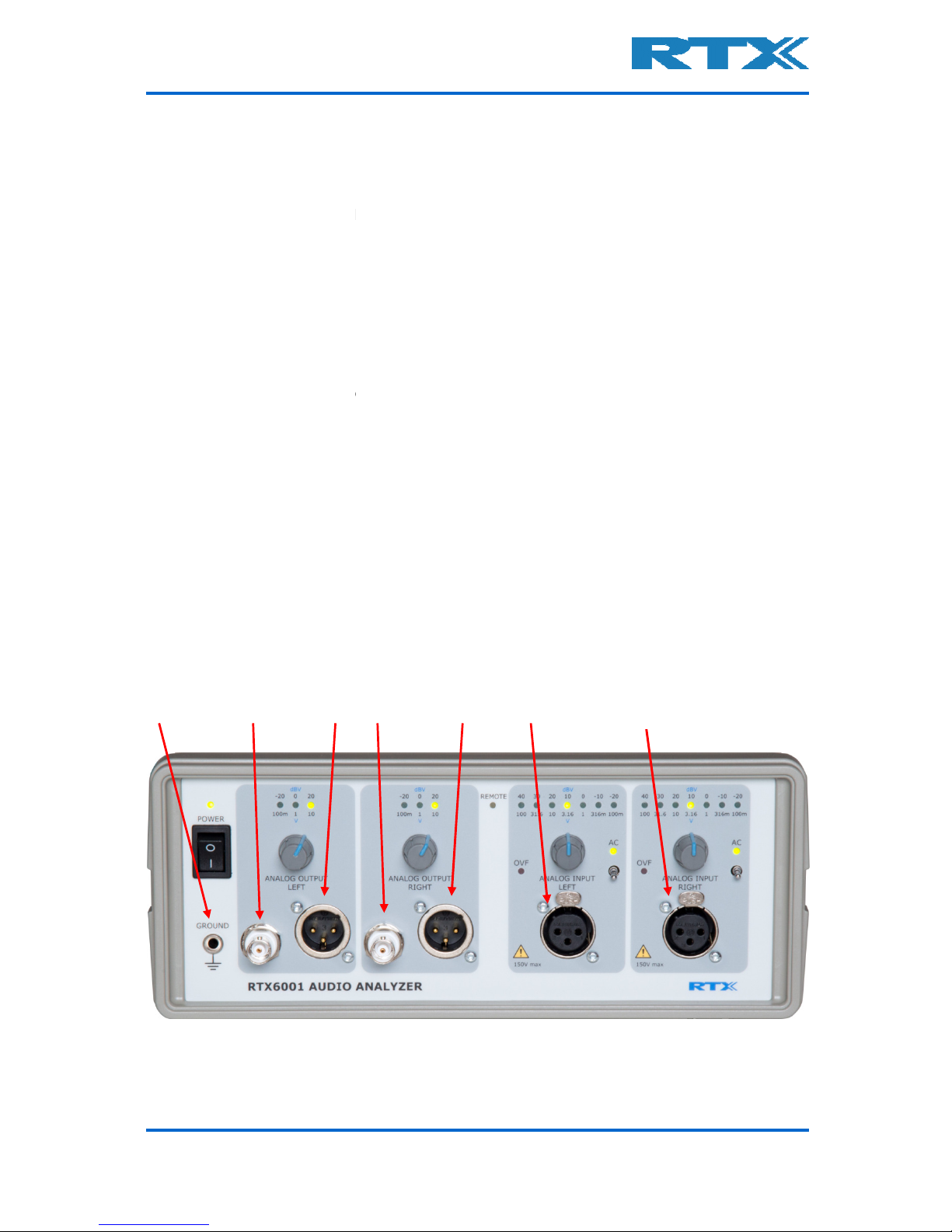

2.3

Front Panel Connectors

The RTX6001 provides

analog

connection. A

brief overview of the available connectors is provided

description of each of the connectors.

Available front panel connector

RTX6001 Audio Analyzer

connected via XLR connectors. Pin 1 of the

-

scale inputs between 100 mV and

gs for the two channels.

-

ended output on a BNC

e chassis (ground) of

-en

ded output level is half the

potentially also the distortion.

inputs/outputs on the front

panel as well as a ground

below

s

12

along with a

Page 13

User Manual V0.8

1. GROUND: Ground

connection (chassis) for 4 mm connector (banana plug).

2. Left Channel Out,

S

is connected to ground.

3. Left Channel Out,

B

is (+) and pin 3 is (-)

4. Right Channel O

ut,

(shield) is connected to ground.

5. Right Channel O

ut,

2 is (+) and pin 3 is (

6. Left Channel In, D

ifferential:

2 is (+) and pin 3 is (

7. Right Channel In,

D

Pin 2 is (+) and pin 3 is (

2.4 Rear

Panel Connectors

The RTX6001

provides rear panel

overview of the available connectors is provided

the connectors.

Available rear panel connectors

1. AC Input:

Power supply (110 / 220V).

2. USB Interface: Th

e USB interface is used for transfer of audio and control

information. It must be used

interface on the

Analyzer

speed

USB cable with Type A

PC.

The connector is isolated from the chassis.

RTX6001 Audio Analyzer

ingle-ended: BNC-connector

. The outer connection (shield)

alanced:

XLR connector. Pin 1 is connected to ground. Pin 2

.

Single-ended: BNC-connector

. The outer connection

Balanced:

XLR connector. Pin 1 is connected to ground. Pin

-).

XLR

connector. Pin 1 is connected to ground. Pin

-).

ifferential:

XLR connector. Pin 1 is connected to ground.

-).

connectors for power and control/audio (USB)

below

along with a description of each of

with a PC in order to control the

Analyzer

is a Type B receptacle, and hence, a standard

-B plugs can

be used to connect the

13

. A brief

. The USB

High-

Analyzer to a

Page 14

User Manual V0.8

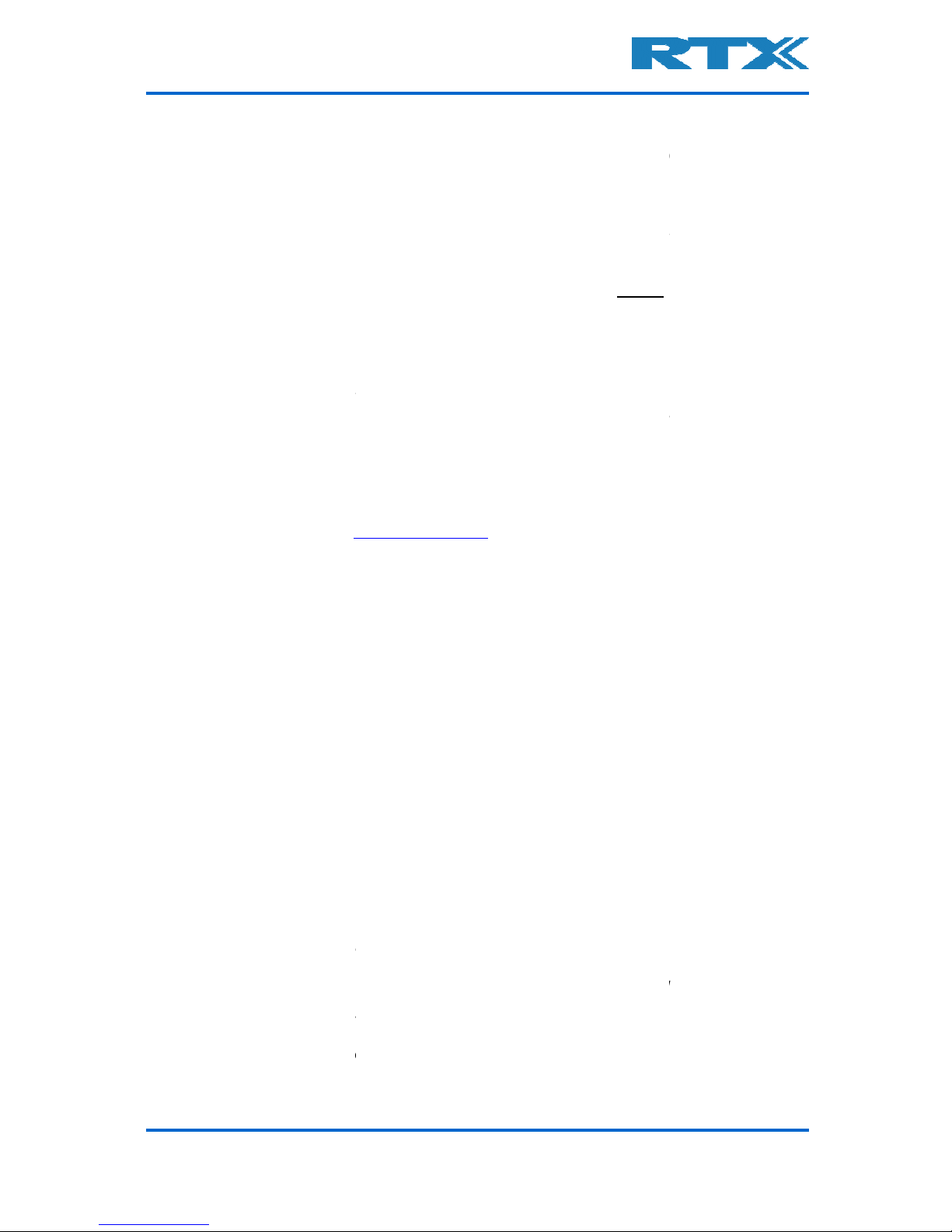

2.5 Front Panel

LED Indicators

On the front panel of the RTX

indicators are

described in more detail below.

Front LED Indicators

and controls

1. Power (Green

LED)

connected to the AC mains and that the power switch is ON.

2. Output Range -

Left

setting for the left channel.

rotary switch below the LED’s.

3. Output Range -

Right

setting for the right channel.

rotary switch below the LED’s.

4. Remote (Yellow

LED)

attached PC. Otherwise the front panel setti

rotary switches and toggle switches.

5. Input Range -

Left

setting for the left channel.

rotary switch below the

6. AC - Left (Green

LED)

of the Audio Analyzer

coupled. With local control

LED.

RTX6001 Audio Analyzer

and Controls

6001 there are in total 26

LED indicators.

– If this LED is lit,

it indicates that the

(3 Green LED’s) - These LED’s

indicate

With local control,

the setting is controlled by the

(3 Green LED’s) - These LED’s

indicate

With local control,

the setting is controlled by the

- If lit

the front panel settings are controlled from the

ngs are controlled by the front panel

(7 Green LED’s) - These LED’s

indicate

With local control,

the setting is controlled by the

LED’s.

– If this LED is lit,

it indicates that the

is AC coupled. Otherwise,

the left channel input is DC

,

the setting is controlled by the toggle switch below the

14

These LED

Audio Analyzer is

the output level

the output level

the input level

left channel input

Page 15

User Manual V0.8

7. Input Range -

Left

setting for the left channel.

rotary switch below the LED’s.

8. AC - Right (Green

LED)

input of the Audio Analyzer

coupled. With local control the setting is controlled by the toggle switch below the

LED.

9. OVF - Left

(Red LED)

left channel.

10. OVF - Right

(Red LED)

the right channel.

RTX6001 Audio Analyzer

(7 Green LED’s) - These LED’s

indicate

With local control,

the setting is controlled by the

– If this LED is lit,

it indicates that the

is AC coupled.

Otherwise the right channel input is DC

– If this LED is lit, it indicates

an overflow condition on the

– If this LED is lit, it indicates

an overflow condition on

15

the input level

right channel

Page 16

User Manual V0.8

3

Installing the PC Software

In this paragraph the installation process

are included:

1. Check

the minimum system requirements to the PC on which the SW must be

installed

2.

Install RTX6000 series PC USB driver

3. Connect the

RTX6001

automatically

4. Switch the RTX6001

on

5. Install the RTX6001

a

6.

Install an audio analyzer software of your choice

7.

Run the analyzer program. Select the RTX6001 as audi

3.1

Minimum System Requirements

For successful operatio

n of the Windows

minimum requirements outlined in the table below.

System Part

CPU

RAM

Available disc space

Monitor resolution

Ports

Operating System

The high-

speed USB port should preferably be a port, which is not behind a USB hub.

USB hub

will increase the probability of

3.2

Installing the RTX6000

When used on a Windows PC

driver for

the RTX6001 must be installed on the PC for proper operation. The drivers

support Windows 7, 8, 8.1 and 10. Both 32 and 64 bit systems are supported.

Download th

e software installation package from the download center on the RTX website

https://www.rtx.dk/en/design

To install the driver run the program

version).

RTX6001 Audio Analyzer

is

outlined. The following items of information

to a PC USB

port. The PC should install

for the first time

ttenuation control program (optional)

o interface

user interface,

your PC must meet at least the

Minimum requirement

1 GHz

processor (Intel© or AMD) or faster

Primarily determined by the Operating

System and the application software

75 MB

1280 x 1024 pixels or higher

recommended

High-speed USB port

Windows 7, 8, 8.1 or 10 (32-

or 64

MAC

Linux

artefacts in the audio stream.

Series USB Driver

, a

driver is needed to support USB Audio Class 2.0. The

-services/contact/download-center/.

RTX_v4.33.0_2017-10-11_setup

.exe

16

the driver

-bit)

A

(or later

Page 17

User Manual V0.8

3.3 Connecting

the RTX6001 to a PC USB

To operate the

Audio Analyzer

controller to the USB port using a standard USB

(supplied together with the

Audio Analyzer

If the RTX6000 series PC driver was installed the

Analyzer and enumerate the unit.

Standard USB cable with Type A

3.4 Switching the

Audio Analyzer

Before switching this instrument

1)

Line voltage selector is set to the voltage of the power supply

2)

Correct fuse is installed

3)

Power supply voltage is in the specified range

Connect the Main Power Cord

Turn on the Analyzer by

toggling

Some of the LED’s on the front should light up.

Depending on the attenuator settings some clicks from relays may be heard at power on

and later during operation

. This is normal.

RTX6001 Audio Analyzer

Port

you must connect a PC (

Windows, MAC

High Speed

cable with Type A

).

Windows

PC should recognize the Audio

-B plugs

on

for the First Time

on please make sure that the:

to the IEC power connector at the back of the unit.

the ON/OFF button on the front.

17

or Linux) system

-B plugs

Page 18

User Manual V0.8

3.5

Installing the RTX600

(optional)

A small utility program is provided with the RTX6001. It allows the user to monitor and

control the status of the front panel settings on the attached Windows PC.

Locate and run the

RTX6001_v1.

software installation package.

After installation the following control panel will be available:

To bring up the control panel later, run the program by clicking the program shortcut.

3.6 Installing an

Aud

To use the RTX6001 for audio measurements a program should be installed.

The list below shows some of the available audio analyzer programs.

Virtins Multi-Instrument -

http://www.virtins.com/multi

Arta, Steps -

http://www.artalabs.hr

HpW Works -

http://www.hpw

MATAA -

http://audioroot.net/mataa

RightMark -

http://audio.rightmark.org

SpectraPlus -

http://www.spectraplus.com

VisualAnalyzer -

http://www.sillanumsoft.org

Audacity -

http://www.audacityteam.org/

Virtins Multi-

Instrument has

control of output and input

settings

ASIO or WASAPI interface is recommended for best performance.

Other SW packages

can also be used.

Refer to the User Manual for the selected analyzer program for further

The RTX6001 can also be used for audio playback and/or recording.

RTX6001 Audio Analyzer

1

Attenuation Control Program

10.exe

(or newer) installation program from the

io Analyzer Program

-

instrument.shtml

/

-works.com/

-mats-audio-analyzer/

/

/

/

an RTX6001 option for

dedicated HW support

from the analyzer SW.

information.

18

, with full

Page 19

User Manual V0.8

4

Performing

The exact operational procedure to use when performing measurements depends on the

analyzer SW used. Refer to

the

for further information.

If very low distortion is to be measured

Audio Analyzer below -

10dBFS, since the distortion will increase slightly when

approaching full scale.

RTX6001 Audio Analyzer

Measurements

supplier’s user manual for the

selected analyzer program

,

it is generally best to operate the RTX6001

19

Page 20

User Manual V0.8

5

Specificatio

Technical Specifications

System

Sample rates

ADC and DAC resolution

Frequency accuracy

PC Interface

Analog Generator

Number of channels

Output connectors

Frequency range

Output impedance

Balanced

Unbalanced

Maximum Level (sine)

Balanced

Unbalanced

Level accuracy

Level flatness

Output attenuator

THD @ 0 dBV

THD 48 kHz sample rate

(1)

fundamental 20 Hz to 20 kHz

THD 192 kHz sample rate

(1)

fundamental 20 Hz to 20 kHz

THD @ 10 dBV

THD 48 kHz sample rate

(1)

fundamental 20 Hz to 10 kHz

THD 192 kHz sample rate

(1)

fundamental 20 Hz to 40 kHz

THD+N, 1 kHz @ 0 dBFS

(1)

THD+N 48 kHz sample rate

THD+N 192 kHz sample rate

Output related crosstalk

(2)

10 Hz to 20 kHz

20 kHz to 80 kHz

DC offset on outputs

Test signals

(

1) System specification, Generator and Analyzer combined

(

2) System specification, Generator and Analyzer combined, one output channel muted

RTX6001 Audio Analyzer

ns and C

haracteristics

44.1 kHz, 48 kHz, 88.2 kHz, 96 kHz, 176.4 kHz,

192 kHz

24 ADC, 32 bit DAC

±30 ppm

USB 2.0 high-speed

2 outputs, 2 inputs

XLR for balanced outputs

BNC for unbalanced outputs

4 mm banana jack (ground)

DC to 90 kHz

100 ohm (±1%)

50 ohm (±1%)

10 V rms, no load

5 V rms, no load

< ±0.1 dB @ 1 kHz

±0.01 dB DC to 20 kHz

±0.2 dB DC to 80 kHz

3 steps, 10 V, 1 V, 100 mV

typical -124 dB @ 1 kHz

< -116 dB

typical -121 dB @ 1 kHz

< -115 dB

typical -119 dB @ 1 kHz

< -115 dB

typical -119 dB @ 1 kHz

< -115 dB

20 kHz BW

typical -107dB

typical -107dB

< -120 dB

< -110 dB

< 1 mV typical

Defined by PC application

20

Page 21

User Manual V0.8

Analog Analyzer

Number of channels

Input connectors

Input bandwidth

Input coupling

Input impedance

Balanced

Unbalanced

Maximum level (sine)

Balanced

Unbalanced

Input ranges

Level measurement accuracy

Level measurement flatness

AC coupling OFF

AC coupling ON

Level measurement residual noise

20 kHz BW A-weighted

20 kHz BW

80 kHz BW

CMRR (10 Hz to 20 kHz) DC coupl.

Input range ≤ 0 dBV

Input range = 10 dBV

Input range = 20 dBV

Analyzer residual THD

1 kHz

fundamental 20 Hz to 20 kHz

Analyzer THD+N, 1 kHz @ -

1 dBFS

THD+N 48 kHz sample rate

THD+N 192 kHz sample rate

Inter-

channel phase accuracy

10 Hz to 20 kHz

20 kHz to 80 kHz

(

3) 20 kHz BW measured at 48 kHz sample rate. 80 kHz BW measured at 192 kHz

sample rate. All measurements done with inputs shorted

dBV. Measured using AudioTester V3.0.

(4)

AC coupling reduces CMRR at low frequencies

capacitors.

RTX6001 Audio Analyzer

2

XLR for balanced inputs

4 mm banana jack (ground)

DC to 90 kHz

AC (-3 dB at 2 Hz)

DC (-3 dB at 1 Hz, -

0.1 dB at 6.5 Hz in ADC)

200 kohm / 20 pF

100 kohm / 37 pF

Input protected in all ranges

100 V rms

100 V rms

7 steps, 100 mVrms

to 100 Vrms, 10 dB steps

< ±0.05 dB @ 1 kHz

±0.01 dB 20 Hz 20 kHz

±0.2 dB 10 Hz to 80 kHz

- 0.1 dB @ 20 Hz, -

0.6 dB at 5 Hz

(3)

0.4 uV typical, ≤ 0.5 uV (-

126 dBV)

0.55 uV typical, ≤ 0.75 uV (-

122 dBV)

1.0 uV typical, ≤ 1.5 uV (-

116 dBV)

(4)

≥ 85 dB

≥ 70 dB

≥ 45 dB

typical -125 dB, < -

120 dB @ 0 dBV

< -115 dB @ 0 dBV

20 kHz BW

typical -105 dB

typical -105 dB

DC coupled

± 0.2°

± 0.5°

to ground, input range =

due to tolerances of the input

21

-20

Page 22

User Manual V0.8

General Data

Power supply

Temperature range

operating conditions

storage

Mechanical dimensions

width

height

depth

Weight

EMC

Safety

Isolation

Specifications may be changed without further notice.

RTX6001 Audio Analyzer

100 –

120 VAC or 220 to 240 VAC 50/60 Hz 40 VA max.

switchable

+15 °C to +35 °C (+59 °F to +95 °F)

-20 °C to +60 °C (-20 °F to +140 °F)

257.5 mm (10.1”)

103 mm (4.1”) excl. feet, 115 mm

(4.5”)

364 mm (14”) excl. connectors.

4.4 kg (9.7 lbs)

European EMC Directive (2014/30/EU)

European Low Voltage Directive (

LVD 2014/35/EU, EN

61010-1:2010)

The measurement section is electrically isolated from the

USB connection.

22

incl. feet.

Page 23

User Manual V0.8

6

Regulatory Information

6.1

Compliance and

Electromagnetic c

ompatibility

Directive (2014/30/EU).

Mechanical resistance s

hock: IEC

6.2 Safety

Electrical safety

complies with the requirements of the European Low Voltage Directive

(LVD 2014/35/EU, EN 6

1010

RTX6001 Audio Analyzer

Markings

c

omplies with the requirements of the European EMC

60068-2-27

bump test 1000 times 40 G in 6 axes.

-1:2010).

23

Page 24

User Manual V0.8

7

Maintenance

7.1 Introduction

This chapter

describes general maintenance of the RTX2012 including central items of

information in relation to calibration and return procedures. It contains the following

sections:

•

General customer responsibilities

• Operator m

aintenance

• Contacting RTX

• Calibration and s

ervice

• Returning your RTX

6001

7.2 General C

ustomer

In general the customer shall:

• R

eplace consumables such as fuses etc.

•

Perform routine operator maintenance and cleaning as specified in the

“Cleaning” below.

7.3

Operator Maintenance

This section describes general responsibilities of the customer. Furthermore, instructions

on how to replace the power line fuse and clean the

section.

7.4

Replacing the Power

The power line fuses are

located within the fuse holder and line switch assembly on the

rear panel. For 110V to 120V operation the fuse

operations the fuses are

T0.3

1

Remove the power cord from the

2

Pull out the fuse drawer e.g. with a flat screwdriver.

3

Install the correct fuse

4 Replace the fuse

drawer

RTX6001 Audio Analyzer

Audio Analyzer for service

Responsibilities

Analyzer

are also provided in this

Line Fuses

s are T0.63

250V. For 220

25 250V. To replace the fuses

do the following:

Analyzer.

s as shown in the picture below.

in the power entry module.

24

paragraph

-240V

Page 25

User Manual V0.8

Fuse location

Fuse drawer

7.5 Cleaning

To clean the test set, disconnect the supply power and wipe the

cloth only and do this regularly.

7.6

Contacting RTX

If you experience problems with your RTX

carefully before contacting

relation to support is outlined here.

If you wish to contact

RTX

problems to ordering i

nformation

Offices”

later in this section.

RTX6001 Audio Analyzer

Analyzer

6001 Audio Analyzer

please read this section

RTX

, since important aspects and items of information in

in relation to any aspect of the

analyzer

- please refer to the paragraph

“Sales and Service

25

with a damp

- from service

Page 26

User Manual V0.8

If you wish to return the

Analyzer

RTX6001 Audio Analyzer

for Service”

7.6.1

Before calling

Before calling RTX

or returning the

to go through the checklist outlined in the paragraph “Check the Basics” later in this

section. The checklist will guide you through some basic checks to rule out some of the

most common problems. Furthermore, i

problem(s).

If this does not solve your problem(s) then please read the warranty printed in the first

pages of this User

Manual. If the problem(s) you experience seem to be covered by the

warranty please state this when contacting

If your analyzer

is covered by a separate maintenance agreement please look into the

terms of the agreement and validate that your problem(

RTX

offers several different maintenance plans to service your

warranty period has expired. Please contact

the paragraph

“Sales and Service Office”

If your RTX6001 analyzer

becomes faulty and you wish to return it please follow the

description on how to return the faulty instrument in the paragraph

Offices” later in this section.

7.6.2

Check the Basics

In order to rule out some of the basic problems that could occur please take a minute to

go through the checklist below.

checks please contact the RTX service office for information and support.

• Che

ck that the line socket has power.

• Check that the

analyzer

• Check that the

analyzer

•

Check that the line fuse

•

Check that the other equipment, cables, and connectors are co

and operating correctly.

•

Check that the PC USB driver is correctly installed and that the analyzer is

recognized as a soundcard by the PC.

•

Check that the test being performed and the expected results are within the

specifications and capab

7.6.3 Instrument S

erial

RTX

service personnel have access to complete records of design changes for each

instrument. This detailed information is based on the serial number of each

Consequently, please have the complete serial number at hand whenever contacting

in relation to your RTX6001

. This way we can ensure that you obtain the most complete

and accurate service information. The serial number can be obtained from the serial

number label (located at the rear of the instrument as indicated in the picture below).

RTX6001 Audio Analyzer

to RTX

please refer to the paragraph

later in this section.

RTX

analyzer

for service please take a couple of minutes

t could help you identify the root cause of your

RTX.

s) is covered by the agreement.

analyzer

RTX for full details –

see contact details in

later in this section.

“Sales and Service

If the Analyzer

is still faulty after performing the above

is plugged into the proper ac power source.

is switched on.

s are in working condition.

ilities of the Analyzer.

Numbers

26

”Returning Your

after the

nnected properly

Analyzer.

RTX

Page 27

User Manual V0.8

Location of Instrument serial number

Sales and Service Office

You can contact one of the following

sales representative. In any correspondence or telephone conversations, please refer to

the RTX6001

by its model number and full serial number. With this information, the

representative can quickly determine whether your unit is still within its warranty period.

Worldwide:

RTX A/S

Stroemmen 6

9400 Noerresundby

Denmark

Tel. +45 96 32 23 00

Fax +45 96 32 23 10

For more information about RTX test and measurement products, applications, services,

and for a current distributor

listing, please visit our web site

7.7 Calibration

and Service

Routine calibration and performance testing of your

out on

a regular basis. If traceable performance is requires it is recommended to

calibrate it on a yearly basis.

For many applications this may not be necessary. Check

voltmeter will ensure basic performance.

The

recalibration is done at

specifications. After each calibration a new “Certificate of Calibration”

verify that the Analyzer

has been calibrated by authorized

Please contact an

RTX Sales and Service office for details on the calibration.

RTX6001 Audio Analyzer

sales o

ffices and ask for a test and measurement

listing, please visit our web site

http://www.rtx.dk

RTX6001

analyzer

ing the levels with a precision AC

RTX by our calibration master

, and in accordance to strict

RTX

personnel.

27

RTX

.

should be carried

report is issued to

Page 28

User Manual V0.8

8

Returning Your

Analyzer

for Service

This section contains important items of information in case

to RTX.

It is strongly emphasized here that all returns to

obtaining a Return Material Authorization (RMA). Any returns without

authorizat

ion cannot be handled in the normal service process and in a timely

manner.

Please read the paragraphs very carefully and follow the instructions closely. The first

step if you want to return your RTX

damages to the

RTX6001

recommendations provided in this section.

8.1

Obtaining an RMA for

In order to obtain an RMA (Return Material Authorization) plea

Service office by E-mail (

rtesupport

information:

–

Any error messages generated by the

–

Any information on the performance of the

– Fault description

– Company name

– Company address

– Contact information

– Serial number of the

unit

– Model Type

– Type of s

ervice agreement, warranty or re

Upon receiving the above information the Service Office will provide an RMA number.

This number

must be placed at a visible location on the shipping box, and furthermore,

the RMA number must be used as a reference in all communication in relation to the

return procedure.

8.2 Packing the

RTX6001

Please note that damage can result from

those specified. Never use styrene pellets in any shape as packaging materials

since they do not adequately cushion the

the box. Furthermore, styrene pellets cause damage by generati

electricity. Consequently, the original packing materials should always be used

when shipping the

Analyzer

Please perform the steps below when packing the

RTX6001 Audio Analyzer

RTX6001 Audio

you need to return

RTX MUST

6001 to RTX

is to obtain an RMA. In order to avoid

when shipping it, please pack it

according to the

Service Return

se contact one of the

@rtx.dk

) or phone with the following items of

Analyzer

Analyzer

-calibration

for Shipment

using packaging materials other than

Analyzer

or prevent it from moving in

.

unit for shipment to

RTX

28

RTX6001

be initialized by

RTX

ng static

for service.

Page 29

User Manual V0.8

1.

Fill in a note and attach it to the

Please be as specific as possible about the nature of the problem in order to give

us the best basis for debugging the problem.

2.

Use the original packaging materials or a

double-

walled, corrugated cardboard with 159 kg (350 lb) bursting strength. The

carton must be both large enough and strong enough to accommodate the

Analyzer

and allow at least 3 to 4 inches on all sides of the

material.

3. Surround the

Analyzer

to prevent the

Analyzer

available,

the best alternative is SD

(Commerce, CA 90001). Air Cap looks like a plastic sheet covered with 1

air filled bubbles. Please use the pink Air Cap to reduce static electricity. Wrap the

Analyzer

several times in the material to both protect the

from movi

ng in the carton.

4.

Seal the shipping container securely with strong nylon adhesive tape.

5.

Mark the shipping container

handling.

6.

Retain copies of all shipping papers.

RTX6001 Audio Analyzer

Analyzer

or place it visible in the shipping box.

strong shipping container made of

Analyzer

with at least 3 to 4 inches of packing material, or enough

from moving around

in the carton. If packing foam is not

-240 Air Cap

TM

from Sealed Air Corporation

Analyzer

“FRAGILE, HANDLE WITH CARE”

29

for packing

-1/4 inch

and prevent it

to ensure careful

Loading...

Loading...