Page 1

1

I

I(,

,'

L.

i

j'

I

4

,

..*,

RTS

SYSTEMS

PROFESSIONAL INTERCOMMUNICATIONS

PROFESSIONAL AUDIO PROOUCTS

1100 WEST CHESTNUT STREET

BURBANK. CALIFORNIA 91506

PHONE 818f843-7022

TELEX 194855

Series

800

MODEL

Master

Station

l.nterc,om

802

.

-

,.

;

Page 2

NOTICE:

''LJ3rfir..ng:

radio frequency energy and

This equipment generates, uses, and can radiate

if

not installed and used In

accordance with the instructions .manual, may cause

interference to radio communications. It has been tested

and found to comply wi'th the limits For

device pursuant to Subpart

J

of Part

15

a

Class A computing

of

FCC

Rules, which

are designed to provide reasonable protection against such

interference when operated in

a

commercial

environment.

Operation of this equipment in a residential area is likely

to.cause interference in which case the user at his own

may

expense will'be required to take whatever measures

be

required to correct the interference."

Page 3

ADDENDUM TO TECHNICAL DATA PACKAGE

Model 802 Intercom Station

Specifications For

RS232

Operation

The following criteria are established as requirements for the RS232 communications

option for the RTS Systems Model 802.

Operate and interrogate all front panel buttons.

Inhibit operation of front panel buttons.

Determine Status of all DIP switches (byte wide).

Read and modify all programmable (RAM) memory.

Operate all relays, talkllisten gates, key lines independently of button

positions.

Initiate a warm or cold start.

Always send out a code upon operator initiation of warm or cold start.

On command, send out a code upon operator initiation of any function, front

panel or DIP switch change.

RS232 software should never cause the 802 to hang or lock up.

Host computer should have the ability to write and execute machine code in

RAM

for diagnostic or other purposes.

,

~

(\-)

RS232

Lanyuaye Implementation

For RS232 commu~cations, the buttons are numbered from 1 to 48.

1

The physical front panel buttons are numbered

to 32. Certain connectibns to the rear

panel are numbered 33 to 48.

Code Definition

1-12

13-24

Top row of front panel buttons.

Second row of front panel buttons.

25-32 Function buttons, front panel, bottom row.

33 External camera iso input.

34 External global reset tally.

35 External

mic.

37-48 Call light inputs (from phase lock loops).

By treating the external contacts as if they were front panel buttons, the external host

computer can turn them on or off, inhibit the function completely (in either the on or off

position), assign a relay to the function, force a chime signal, et cetera.

RTS Systems, Inc.

Burbank,

CA

91506 / FSCM: 60572 TDP3510

/

Rev.B /January 19891

Copyright 1986,1987,1988,1989 by RTS Systems, Inc. All Rights Reserved.

Page 1 of

4

i

I

Page 4

ADDENDUM TO TECHNICAL DATA PACKAGE

Model 802 Intercom Station

Command Structure

All commands will be initiated by a letter, followed by a numeric modifier, followed by an

operator, followed by a terminating carriage return. The command letter indicates the

major functions such as

BUTTON, KEY, RELAY, MEMORY, et cetera. The numeric

modifier usually refers to which button, or relay or memory is associated with that

(+)

particular command. The operator tells the 802 whether to turn something on

or to inquire about its present state

(?).

or off

Some commands have no modifiers or operators such as WARM START or COLD

START or VERSION.

All commands must be terminated in a carriage return before the 802 will act on them.

Command lines must be limited to 128 characters in length. (Only the load memory

command has the capability of exceeding 'this limit.)

()

Error Handling

The 802 cannot stop when it encounters a confusing a command, it will simply ignore the

entire command. Specific errors include a command letter not in its command table, a

numeric modifier that is out of range (for example, relay

12), and unrecognizable operator,

et cetera. Upon detection of an error, the interpreter will normally ignore the remainder

of a command.

The 802 will send out the letter E along with a 2 digit code indicating where the command

interpreter was confused:

Code Definition

EOO Syntax error.

E01 Output buffer overflow.

E03

E04

El0

Unrecognizable command modifier

Number out of range (for example, illegal button number).

RS232

framing or parity error.

(+

,-,

or ? expected).

E20 RS422 framing or parity error.

RTS Systems, Inc. Burbank, CA 91506 / FSCM: 60572 TDP3510

/

Rev.B /January 19891

Copyright 1986, 1987, 1988, 1989 by RTS Systems, Inc. All Rights Reserved.

Page 2 of

4

Page 5

ADDENDUM

Model

TO

TECHNICAL

802

Intercom

DATA

Station

PACKAGE

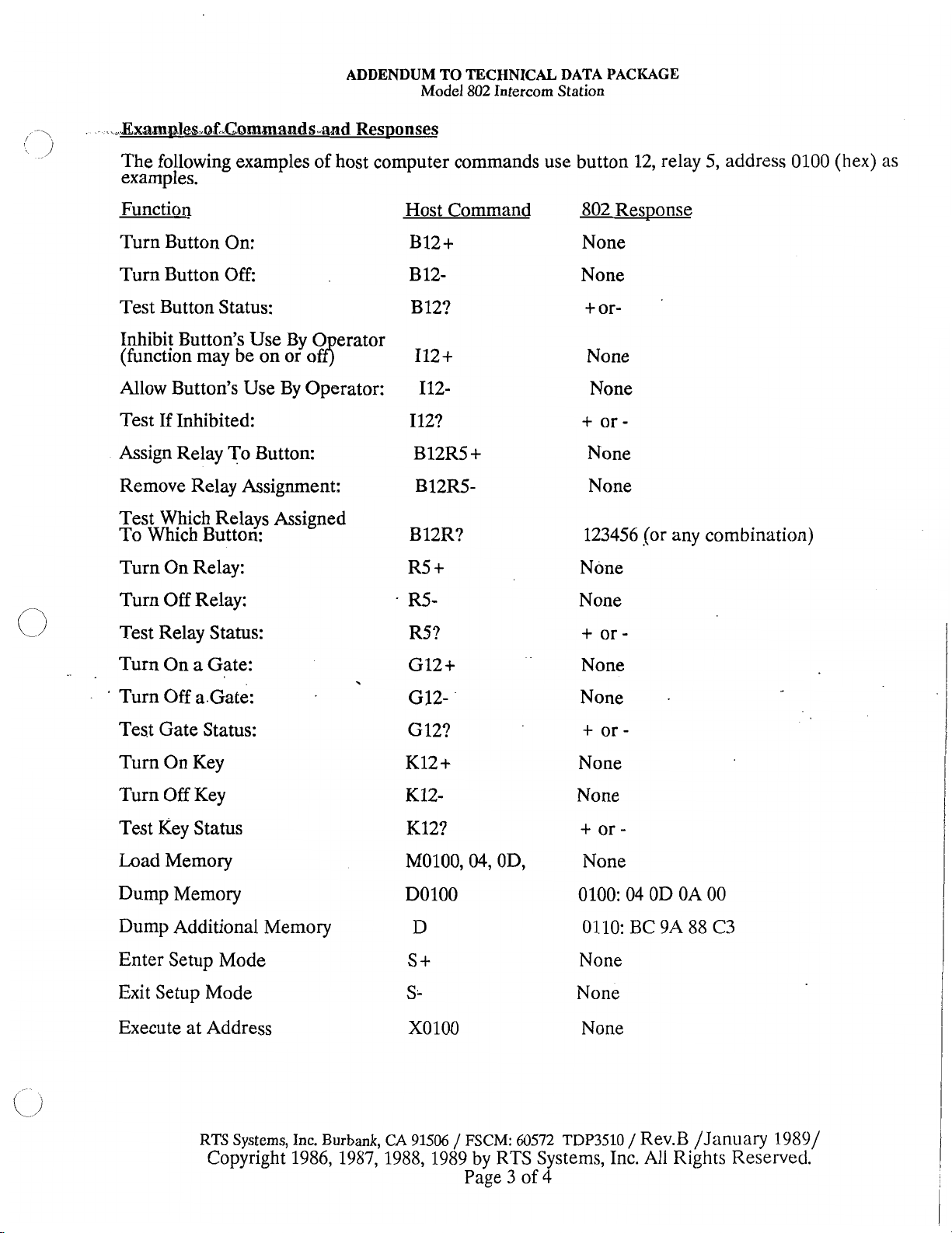

The following examples of host computer commands use button 12, relay 5, address 0100

examples.

Function

Turn Button On:

Turn Button Off:

Test Button Status:

Inhibit Button's Use By

0

erator

(function may be on or off$

Allow Button's Use By Operator:

Test If Inhibited: I12?

Assign Relay To Button: B12R5

Host Command 802 Response

B12+

B 12-

B 12?

I12+

112-

+

None

None

+

or-

None

None

+

or-

None

Remove Relay Assignment: B12R5- None

Test Which Relays Assigned

To Which Button:

Turn On Relay:

Turn Off Relay:

+

R5

R5- None

123456 (or any combination)

None

(hex)

as

Test Relay Status:

R5?

Turn On a Gate: GI2

+

+

or-

None

Turn Off a.Gate: G32- None

Test Gate Status:

Turn On Key

Turn Off Key

Test Key Status

Load Memory

Dump Memory

Dump Additional Memory

Enter Setup Mode

Exit Setup Mode

Execute at Address

G

12?

K12

+

K12-

K12?

M0100,04, OD,

DO100

D

S

t

S.

XOlOO

+

or-

None

None

tor-

None

0100: 04 OD OA 00

0110:

None

None

None

BC

9A 88

C3

RTS Systems, Inc. Burbank, CA

91506

/

FSCM:

60572

TDP3510

Copyright 1986, 1987,1988, 1989 by RTS Systems, Inc.

Page 3 of 4

/

Rev.B /January 1989/

All

Rights Reserved.

Page 6

ADDENDUM TO TECHNICAL DATA PACKAGE

Model

802

Intercom

Station

Eavesdro~

Mode

The eavesdrop mode sends to the host computer an indication of whether the operator has

turned a function on or off. It reflects the status of the panel light under the button.

Function Host Command 802 Response

Turn Eavesdrop Mode On: Et

None until a button pushed by the

operator turns a function on

(B12+) or off (B12-). B12- (if 12

turned off)

Turn Eavesdrop Mode Off: E- None

+

Test Eavesdrop Mode: E?

or-

Warm Start: C C

Version Number:

V

RTS02 1284

Possible problems with relay command: The relays are updated every time a button is

on

a

pushed or released. This means that if the host computer turns

relay, it may be turned

off the next time the operator pushes any button.

Keys and gates have a similar problem, but will only be affected if the operator pushed the

button associated with that particular key or gate.

Rev. B Changes: Page

3,

Host Command, Lines 4,5 6,: Change 112 to 112.

All product information and specifications subject to change without notice.

RTS

Systems,

Copyright 1986, 1987, 1988, 1989 by RTS Systems, Inc.

Inc.

Burbank,

CA 91506 / FSCM: 60572 TDP3510

/

Rev.B /January 19891

All

Rights Reserved.

Page 4 of 4

Page 7

MODEL

TECHNICAL DATA PACKAGE, TDP

OCTOBER 1986

RTS SYSTEMS

1100

802

MASTER STATION

/

I

W.

CHESTNUT ST.

SECOND EDITION/Written

INC

.

BURBANK,

MODEL

3

510

&

Edited by Stan Hubler

CALIFORNIA 91506 U9S.A.

802

MASTER STATION

PROPRIETARY NOTICE

@The informatiori and design disclosed herein

are

the property

patent, propr ie'tary design, manufacturing-, r.eproduction,

sales.

to 'the extent rights

Copyright 1986 by RTS Systems.

without prior written permission from RTS Systems

PATENT NOTICE

The Model 802 contains and

Patent

TERMINAL INTERCOMa. This design employs

operated

NOTE: DETAILED INFORMATION CONCERNING THEORY OF OPERATION

TENANCE , SPARE PARTS

'THE MODEL

OBTA

FACTORY.

rights thereto, and

No.

4,358,644:

as

a

two-wire

802

INm

FROM E I TEER

of,

RTS Systems, Inc.. RTS Sys'te~?s reserves

to

any'

article

.are

expressly granted to others.

Reproduction in whole or in part

uses

a

"BIIATERAL CURRENTSOURCE

to

four-wire converter.

AND

SYSTEM INTERCONNECTION IS AVAILABLE

MASTER STATION TECHNICAL

AN

RTS SYSTEMS' DEALER

a

design embodied in United States

were

disclosed thereibr except

a

bilateral current source

origin'at.ed by, and

is

prohibited.

EDRA

14A10UALn,

OR

DIRECTLY FROM THE

use

MULTI-

,

WHICH

all

and

MAIN-

IN:

MAY

BE

Page 8

TABLE OF CONTENTS PAGE

TABLEOFCONTENTS

WAREiANTY

PROCEDUREFORRETURNS

SEIPPING TO MANUFACTURER FOR REPAIR OR ADJUSTMENT

SECTION

MODEL 802 DESCRIPTION/OPERATION

FRONT PANEL: DESCRIPTSON

ADJUSTMENT BOARD: DESCRIPTION AND OPERATION

REAR PANEL: DESCRIPTION

INTERFACING TO OTHER EQUIPMENT 15

SPECIFICATIONS

SECTION 2: INSTALLATION

MECHANICAL INSTALLATION 17

EI;ECTRICAL INSTALLATION/POCIJER 17

ELECTRICAL

ELECTRICAL INSTALLATION1 S JGNALS/GENERAL 18

ELECTRICAL

ELECTRICAL INSTALLATIONf HEADSETS 28

..HEADSET REQUIREMENTS... 28

..HEADSET CONNECTIONS 2fJ

ELECTRICAL INSTALLATION/ SIGNALS/MODEL 80 2 TQ MODEL

ELECTRICAL

ELECTRICAL

ELECTRICAL

ELECTRICAL

..........e...............m*****.*..**.**

DESCRIPTION.

1:

INSTALLATION/GROUNDING

INSTALLATION1SIGNALSlFEATURES

INSTALLATIONlSIGNALSfMODEL

IMSTRLLATIONISIGNALSlMODEL

INSTALLATIONlSIGNALS1MODEL

INSTALLATIONlSIGNALSlMODEL

....................................

................................

OPERATION. AND SPECIFICATIONS

5

............

........................

AND

OPERATION

.

.

. .

...............

AND

OPERATION

.

.

........................

...................................

. . . .

.

. . .

.

.

.............................

........................

. .

.................

................

......................

............................

..............................

802/TEZEPHONE

8021SERIES 4000 IFB

8021 SERIES 1000 SQUAWK

.

.

.

8021VIDEO IS0 46

.

801/ 860

.

. .

....

.

......

i

....

.

........

.

2

4

5

5

7

7

11

13

14

16

17

18

25

29

33

36

42

SECTION-3:

TABLE

FIGURE

FIGUREl.2. MODEL 802FRONTPANEL

FIGURE 1.3. MODEL 802 ADJUSTMENT BOARD 12

FIGURE 2.1, MODEL 80 2 POWER SUPPLY CONNECTIONS 17

FIGURE 2.2, ALL MASTER STATION SYSTEM

FIGURE2.3, TZRMINATORPLUG

FIGURE 2.4. MASTER STATLON SYSTEM AND MODEL 862 20

FIGURE2.5. TERMINATORPLUGFORMODEL 862

FIGURE2.6. CBANNEL12TERMINATION

FIGURE 2.7. MODEL 80 2/TW INTERCOM SYSTM BLOCK DIAGRAM

TABLE 2.1. CONNECTOR CODE TABLE 23

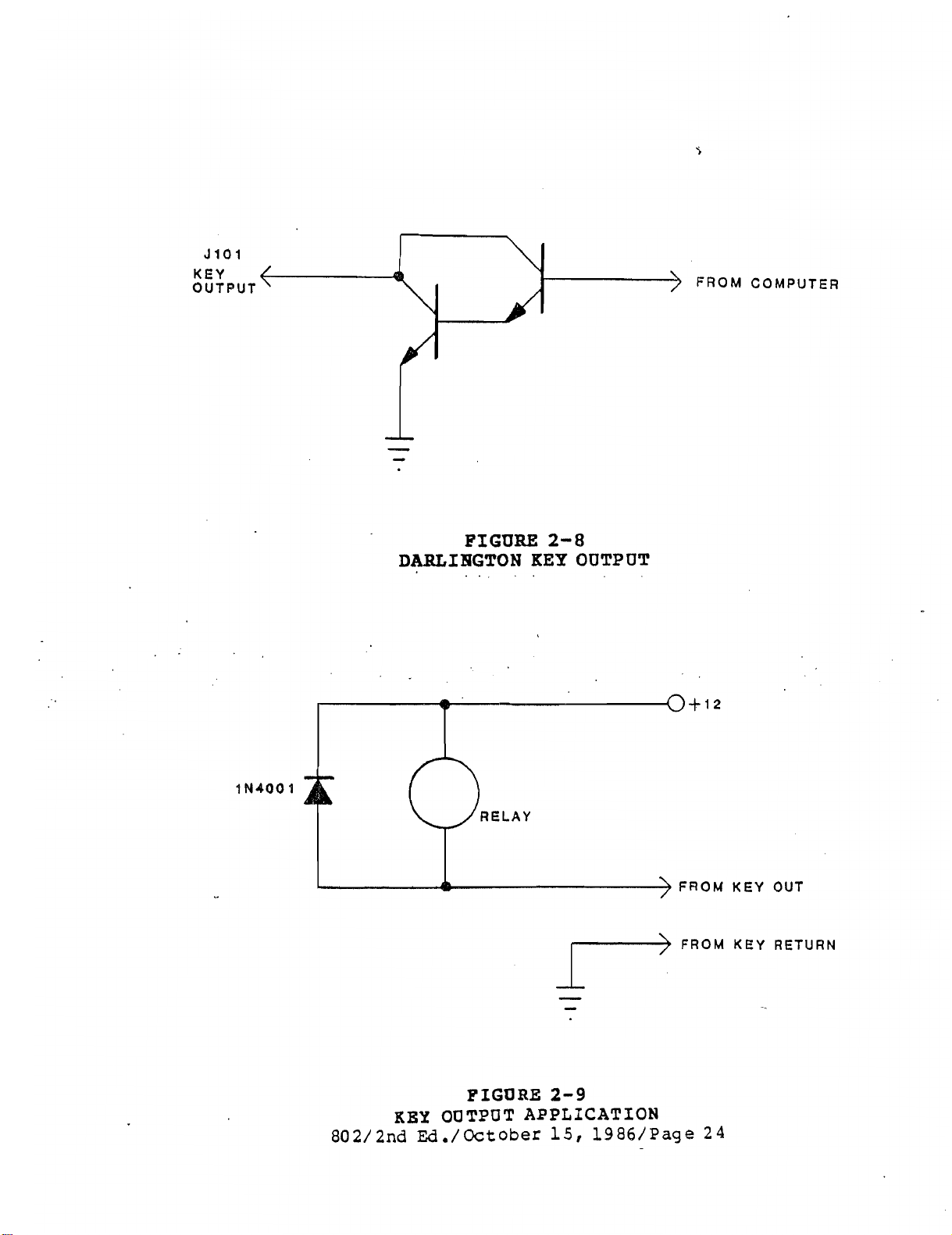

FIGURE2-8!

FIGURE2.9. KEY OUTPUTAPPLICATION

FIGURE

OF

1-1,

2.10.

INSTRUCTIONS

FIGURES

MODEL 802 BLOCK DIAGRAM

.

FOR PROGRAMMING THE MODEL 802 51

......*..............

......................

e.........................

.....................

......................

DARLINGTON KEY OUTPUT

.....................

MODEL 802 REAR PANEL CONNECTIONS

.

.

..................

............

...................

............

...............*

..

0.

l

. .

. . .

..............

.......

PAGE

......

.

6.

10

19

19

20

21

22

24

24

26

8

.

Page 9

TABLE OF FIGURES (CONTINUED)

PAGE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

FIGURE

2-11,

2-12,

2-13

2-14,

2-15,

2-16,

2-17

2-18,

2-19,

2-20A

2-20B

2-21

2-22

2-23

2-24

2-25

2-26

2-27

2-28,

2-29,

2-30,

2-31

2-32,

3-1,

CASE

CASE

,

CASE

CASE

USING A MODEL

METHOD

,

METHOD

METHOD

METBOD

METHOD A : MODEL

METHOD A: MODEL

,

METHOD B: MODEL

,

METHOD B: MODEL

1

FRONT PANEL BUTTON ARRANGEMENT FOR 4 IFB

,

FRONT PANEL BUTTON ARRANGEMENT FOR 8 IFB'

FRONT PANEL BUTTON ARRANGEMENT FOR 6 SQUAWKS

1

FRONT PANEL BUTTON ARRANGEMENT FOR

,

METHOD A: MODEL

METHOD B: MODEL

FRONT PANEL BUTTON ARRANGEMENT FOR ISO(METB0D B)

METHOD A: MODEL

,

METHOD B: MODEL

MO!CEERBOARD DIP SWITCH ASSFBLY

MODEL

1:

SIX CHANNEL

1:

FRONT PANEL LEGEND

2:

TWELVE CHANNEL

2:

FRONT PANEL BUTTON LEGEND

801

1:

MODEL

2:

MODEL

3:

MODEL

4:

MODEL

80 2

FRONT PANEL PROGRAMMING BUTTONS

802

TO SIX CHANNEL

.

. . . .

882

cl'g

SIX

CBANYEE

IN AN MODEL

802

TO TELEPHONE CONNECTION.

802

TO TELEPHONE CONNECTION

802

TO TELEPHONE CONNECTION

80 2

TO TELEPHONE CONNECTION

80 2

TO IFB CONNECTION

802

TO

IFB CONNECTION

802

TO IFB CONNECTION

802

TO IFB CONNECTION

802

TO SQUAWK CONNECTION

802

TO SQUAWK CONNECTION

802

TO

IS0

802

TO

IS0

802

SYSTEM.,

CONNECTION

CONNECTION

801

. . . . . .

. . . . . . . . .

801

.

.

. .

. . . .

. , .

. . . . .

.

.

(

4

IFB ' S)

(

8

IFB 'S)

(4

IFB 'S)

(

8

IFB 'S)

'S.

S.

.

10

SQUAWKS

.

.

.

.

,

.

. . .

.

.

.

. . .

. . . . .

.

.

. .

. . .

.

.

.

. . . .

. . . .

. .

. .

.

. . .

.

.

.

.

.

. .

.

.

.

+.+

O~TC

.

. . .

. .

30

30

31

32

32

34

34

35

3 5

37

3 8

39

40

41

41

43

43

44

45

46

47

48

49

50

DIAGRAMS; DRAWING NUMBER

ASSEMBLY

ASSEMBLY,

ASSEMBLY

ASSEMBLY

ASSEMBLY

ASSEMBLY,

ASSEMBLY,

ASSEMBLY,

ASSEMBLY

SCBEMATIC

8

MODEL

MODEL

,

MODEL

MODEL

,

,

MODEL

MODEL

MODEL

MOD&

p

MODEL

,

MODEL802,

802,

802,

802,

802,

802,

802,

802,

802,

802,

ADJUSTMENTBOARD; AS

CALL LIGHT OPTIONBOARD; AS

CPUBOARD;

FOURWIRE OPTION BOARD; AS

IE'B OPTIONBOARD; AS

MOTHERBOARD;

PIOBOARD; AS

TALK/SQUAWK OPTION BOARD; AS

SWITCH BOARD; AS

SD3000

3000-7.

AS3OOO-5..

AS

3000-1

3000-4o.o

3000-9..

....o.o..........m..o..q.

00......

3000-2.

.

.

..o..o.o.

3000-18

3000-6..

. . .

.

.

3000-3

'

PAGE

.

e'o

...o.

.

.

.

. .

.

.

. . . . . .

.

0.

.

57

59

61

63

65

67

69

71

73

75

Page 10

RTS SYSTEMS' LIMITED WARRAHTY

The products of RTS Systems,

Inc., a California corporation, are

warranted to be free from defects in materials and ;workmanship for a

period of one year from the date of

RTS Systemst sole obligation during the warranty period

sale.

is

to

provide, without charge, parts and labor necessary to remedy

covered defects appearing in products returned prepaid to RTS

Systems

1100

We

Chestnut Street, Burbank , Calif ornia, 91506

I

U.S.A.. This warranty does not cover any defect, malfunction or

failure caused beyond the control of RTS Systems, including

unreasonable or negligent operation, abuse accident, failure to

follow instructions in the Owner's Manual, defective or improper

associated equipment,

attempts at modification and repair not

authorized by RTS Systems, and shipping damage. Products with

their

serial

numbers removed or effaced are not covered by this

warranty.

,

To obtain warranty service

"PROCEDURE FOR RETURNSn and "SHIPPING

follow the procedures entitled

TO

MANUFACTURER FOR REPAIR

OR

ADJUSTMENT" listed below.

This warranty

respect to

user to determine before purchase that this product

is

RTS

the

sole and exclusive express warranty given with

Systems' products,

It

is

the

responsibility of the

is

suitable for

the user intended purpose.

ANY

OF

L

AND

ALL

IMPLIED

MERCHANTABILITY

IM I T.ED W ARRABTY

WARRANTIES I IHCLUDING

ARE

.

NEITHER RTS SYSlfEMS

PRODUCTS

ANY

KXID.

IS

LIABLE FOR PNCIDENTAL

THE

IMPLIED

WARRATITY

LIMITED TO TEE DURATION OF THIS EXPRESS

NOR

TBB:

DEALER

OR

WHO

SELLS

RTS

SYSTEMS'

CONSEQUENTIAL DAMAGES OF

Page 11

3

,

,>,,

,,.

RETU'RF4'.Slil:T'PPING INSTRUCTIONS

PROCEDURE FOR RETURNS

If repair

is

necessary; contact the dealer where this unit was

s

purchased.

If repair through the dealer

Sys

tems

to obtain

Be

prepared to provide your company's name, address, pbne number, a

Order Service Department by telephone, as directed below,

a

Return Authorization Number.

DO

NOT RETURN

W

ITEOOT FIRST

ANY

OBTAINING

EQUIPMENT DIRECTLY TO TEE FACTORY

person to contact regarding

equipment, a description of the defect, and the serial number

is

not possible, contact the RTS

A

RETURN AUTHORIZATION NUMBER,

the

repair, the type and quantity of

(s)

Questions regarding returns for repair, should be directed to:

Customer Service Department

RTS Systems, Inc.

1100

Burbank,

TELEPHONE:

TELEX

TWX:

TELEFAX

W.

Chestnut St.

CA

(

818) 840-7311

:

194855

910-498-4987

:

(

81 8) 846- 51 97

91506

.

SHIPPING TO MANUFACTURER

All

shipments of RTS Systems, Inc. equipment should be made via

REPAIR

OR

ADJUSTMENT

FOR

United Parcel Service or the best available shipper, prepaid. The

equipment should be shipped in the original packing carton; if that

is

not available, use any suitable container that

adequate size. If

should be wrapped in paper and surrounded with

a

substitute container

is

at

of excelsior or similar shock-absorbing material.

is

rigid and of

used, the equipment

least four inches

All

shipments

should be directed to the attention of the Order Service Department

and must include the Return Authorization Number.

Upon completion of repairs equipment

will

be returned via United

Parcel .Service or specified shipper, collect.

Page 12

Page 13

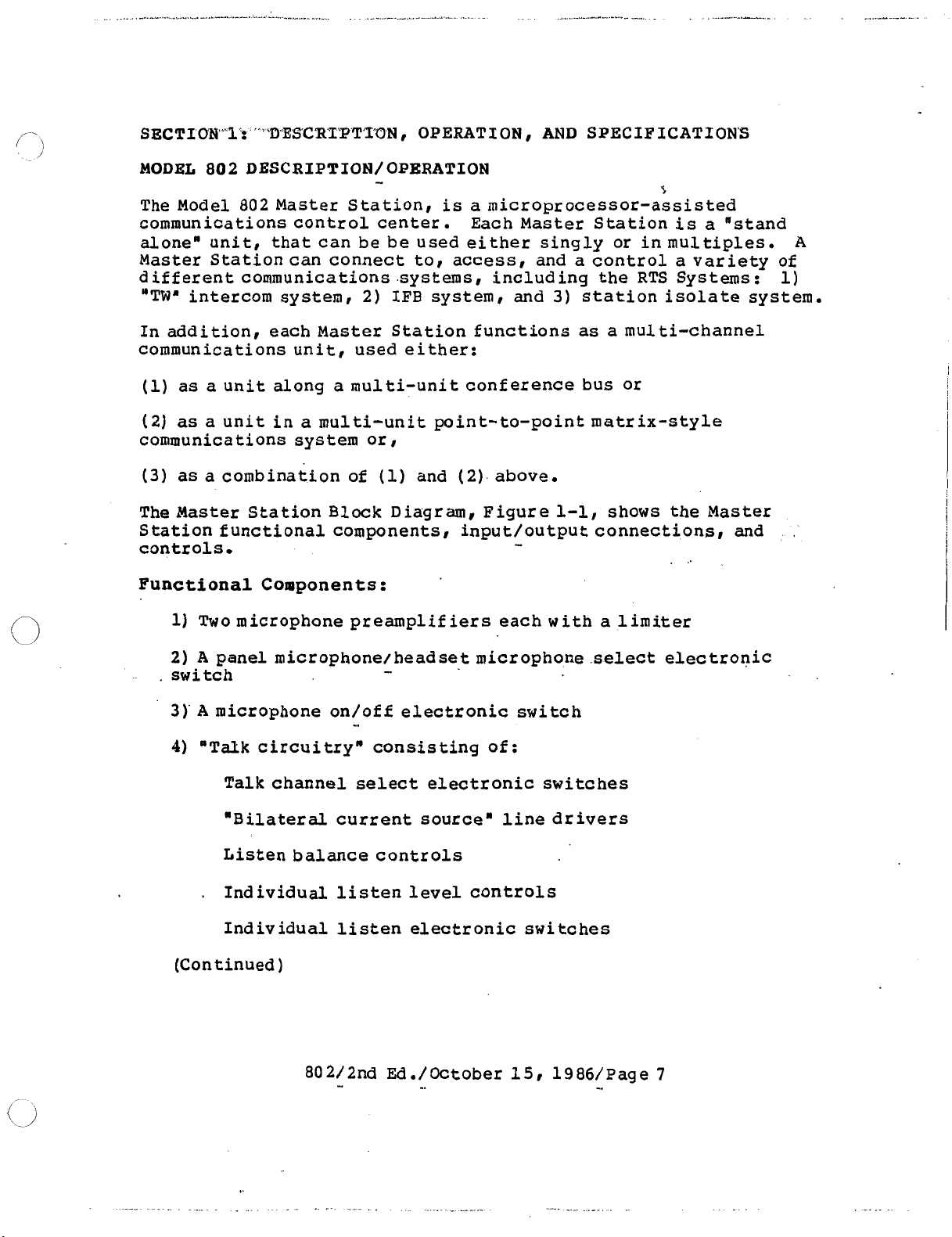

SECTION"1: " "DESC'RXPTTON , OPERATION

,

AND

SPECIFICATION'S

MODEL 802 DESCRIPTION/ OPERATION

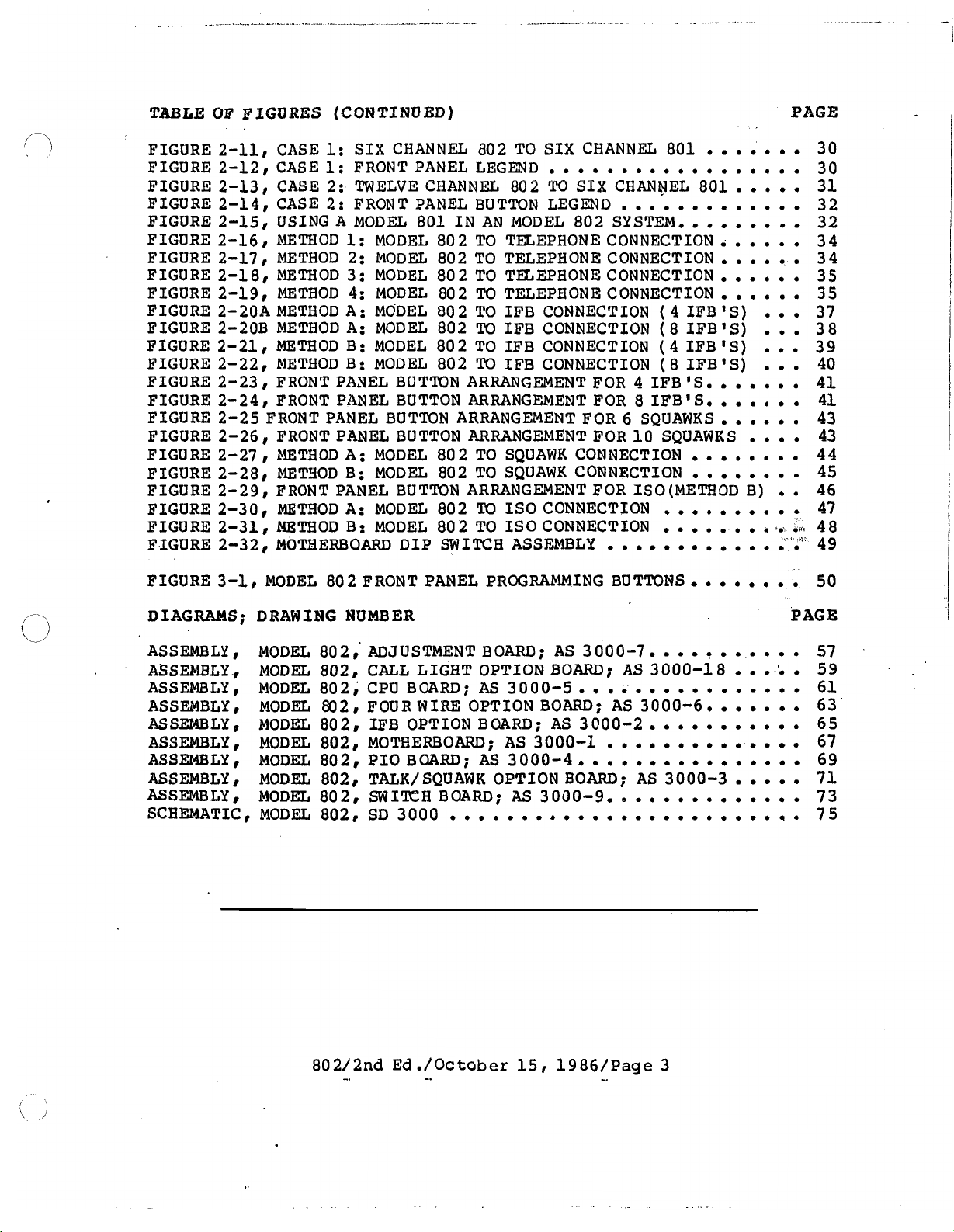

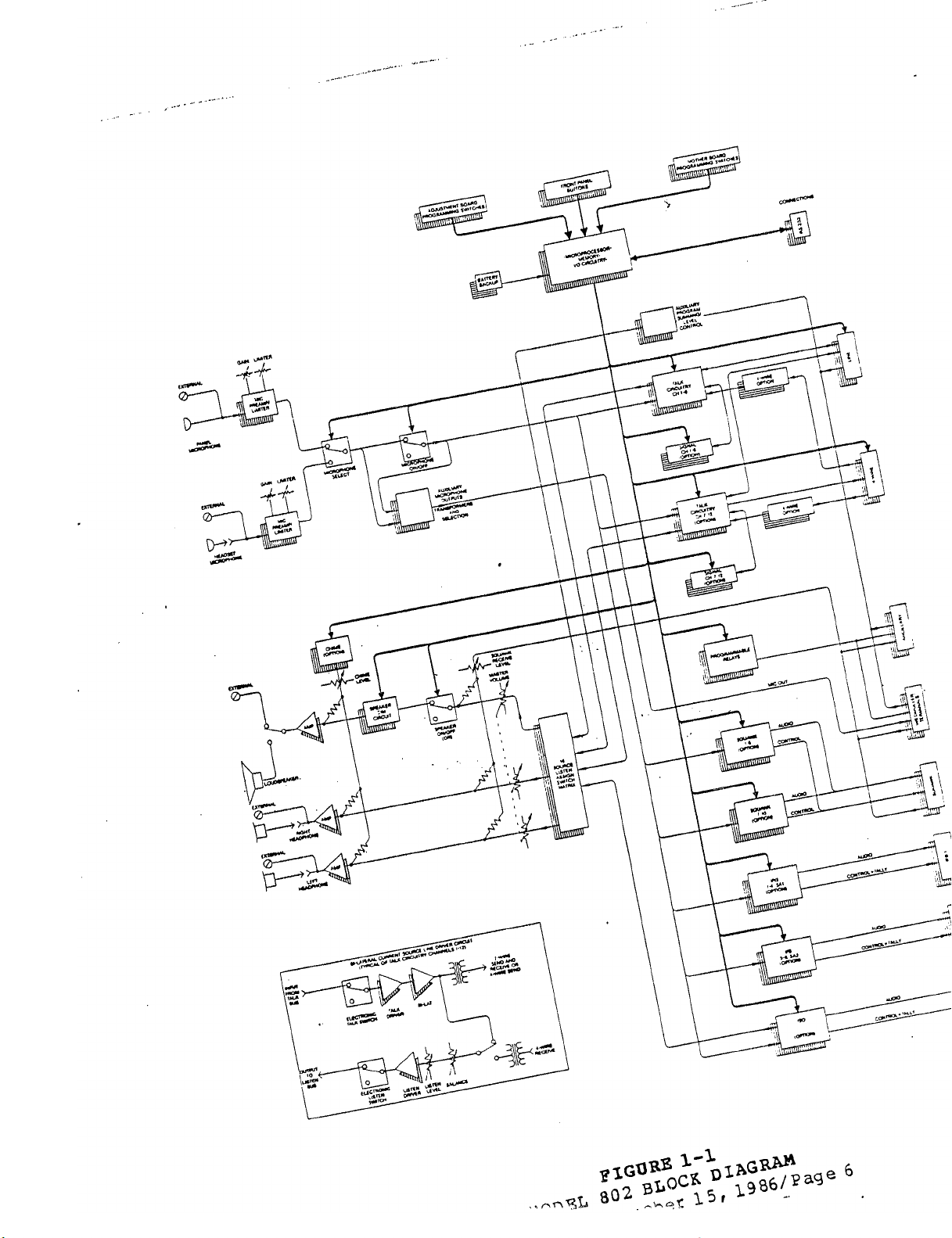

The Model 802 Master Station,

communications control center.

alone" unit, that can be be used either singly or in multiples.

Master Station can connect to, access, and a control a variety of

different communications .systems, including the RTS Systems:

"TWa

In addition, each Master Station functions as a multi-channel

communications unit

communications system or,

The

Station functional components, input/output connections, and

controls.

Functional Components:

intercom system, 2) IFB system, and 3) station isolate system.

(1)

as a unit along a multi-unit conference bus or

(2)

as

a unit in a multi-unit point-to-point matrix-style

(3) as a combination of

Master

1)

Two microphone preamplifiers each with a

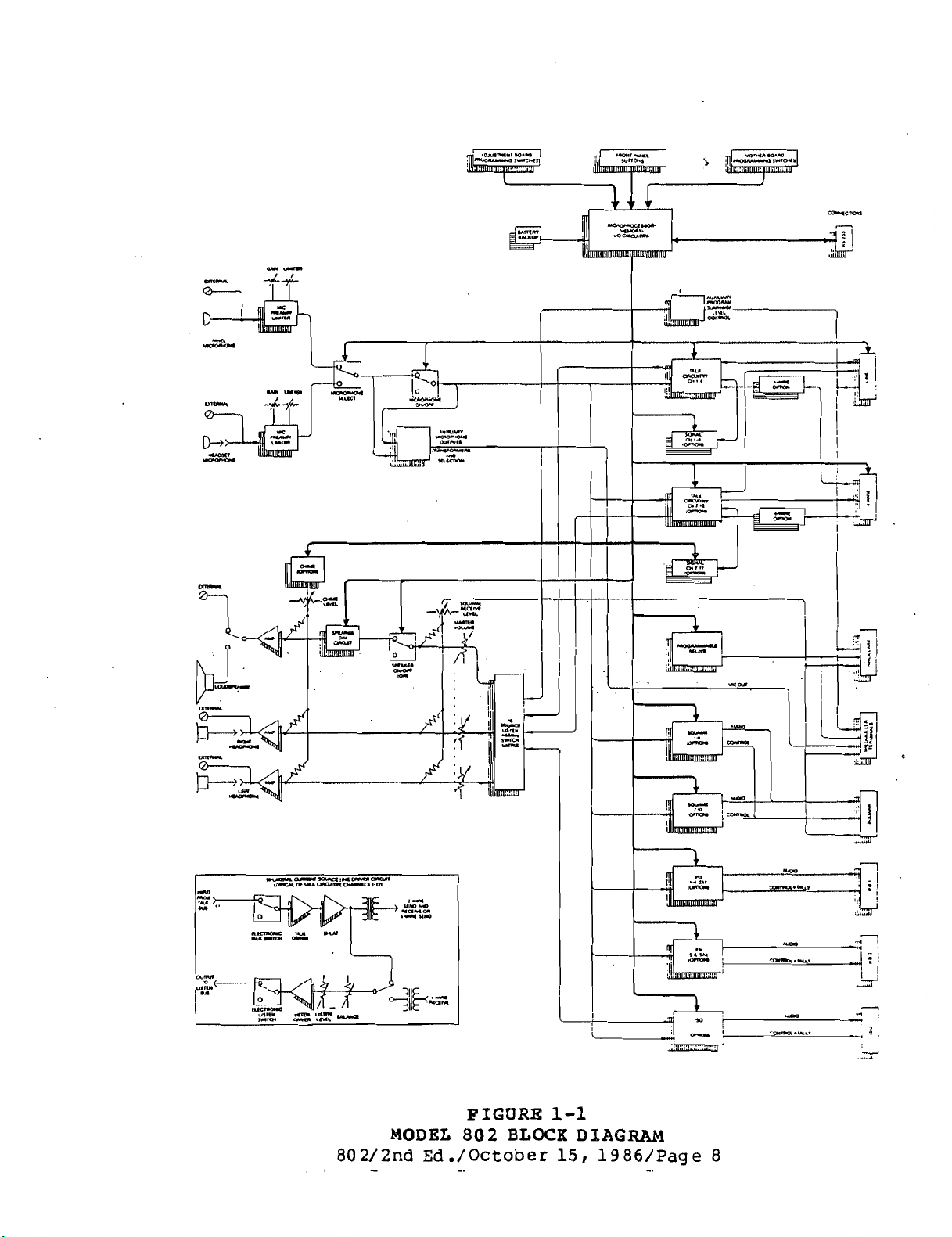

Station Block Diagram, Figure

,

used

-

is

either:

(1)

and (2) above.

s

a microprocessor-assisted

Each

Master

1-1,

Station

shows the

is

a "stand

Master

-

.

..

limiter

1)

A

,

2)

A

panel microphone/headset microphone

.

switch

3)' A microphone on/of f electronic switch

4)

"Talk

.

(Continued)

circuitryn consisting of:

Talk channel

"Bilateral current source" line drivers

Listen balance controls

Individual listen level controls

Individual listen electronic switches

-

-.

select

electronic switches

select

electronic

Page 14

,.

"1

.,i

I.!

-

t----"

rm

-.-.

i

"4

ill

MODEL

802/2nd

-

FIGURE

802

BLOCK

Ed./October

-.

1-1

DIAGRAM

15,

1986/Page 8

-.

Page 15

Functional Components: (Continued)

5)

A

16-source listen assign switch matrix

6)

A

"master" listen volume control

7) A two channel (stereo) headphone amplifier

8)

A

speaker on/of f electronic

switch

9) A speaker "dimo electronic switch

10)

A

speaker amplifier

11)

An internal speaker disable switch

A

.12)

microprocessor control system, which includes:

s

Front panel button inputs

Talk

and listen electronic switch control outputs

(32)

Microphone and speaker electronic switch control outputs

Relay control outputs

(6)

Key outputs (12)

~eadset present ,sense input

User

Adjustment board programming input switches

Mother board programming input switches

programmed memory with battery backup

(8)

(

8)

Additional outputs to control some options

"Resetn switch

(tells

microprocessor to reconfi'gurer

using adjustment and mother board programming inputs)

'

Factory installed "firmware" (operating system for

microprocessor^

.

Page 16

t

t-'

m

9

t-'

U3

a3

cn

\

'd

P,

a

cD

t-

o

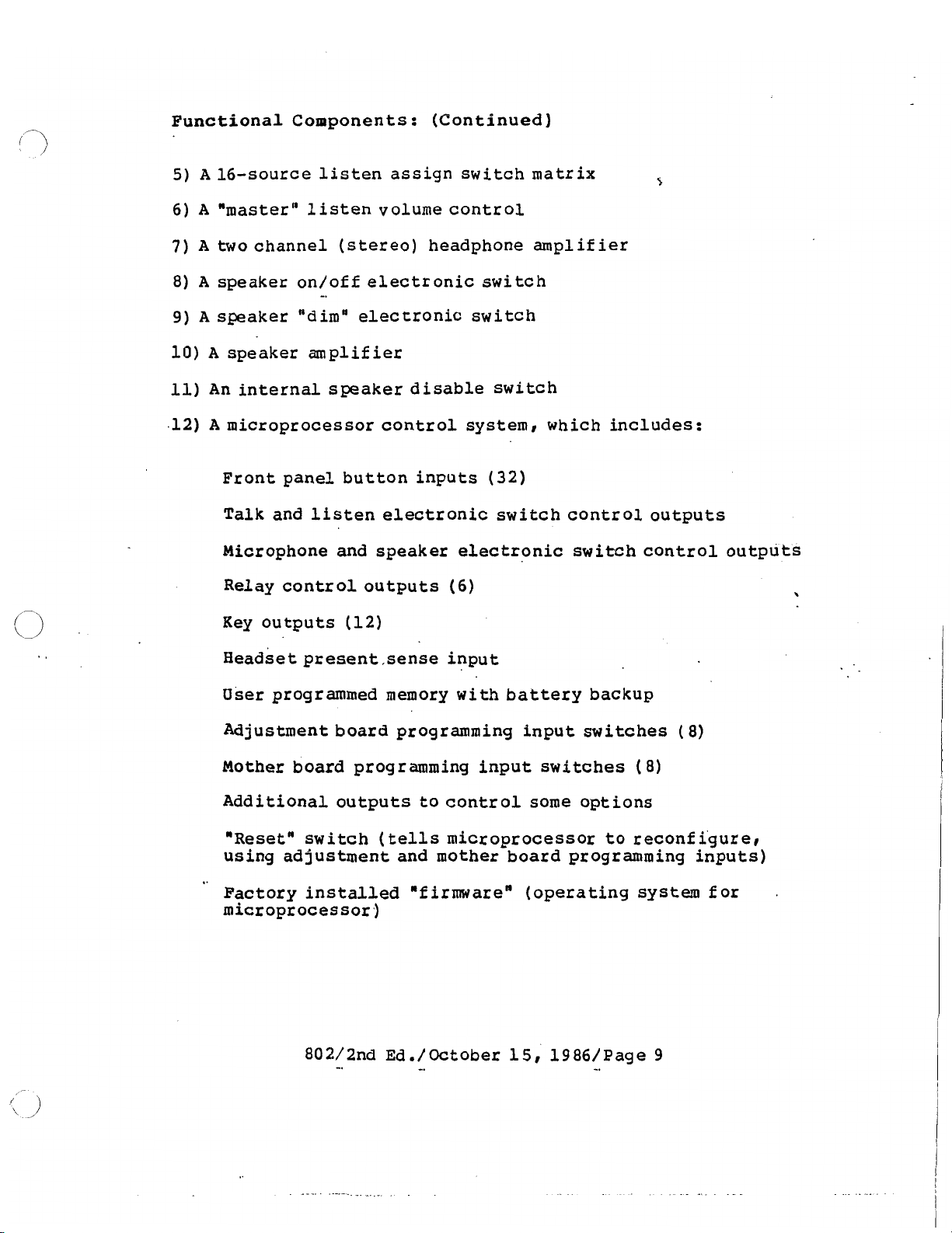

MODEL

FIGURE

802

1-2

FRONT

PANEL

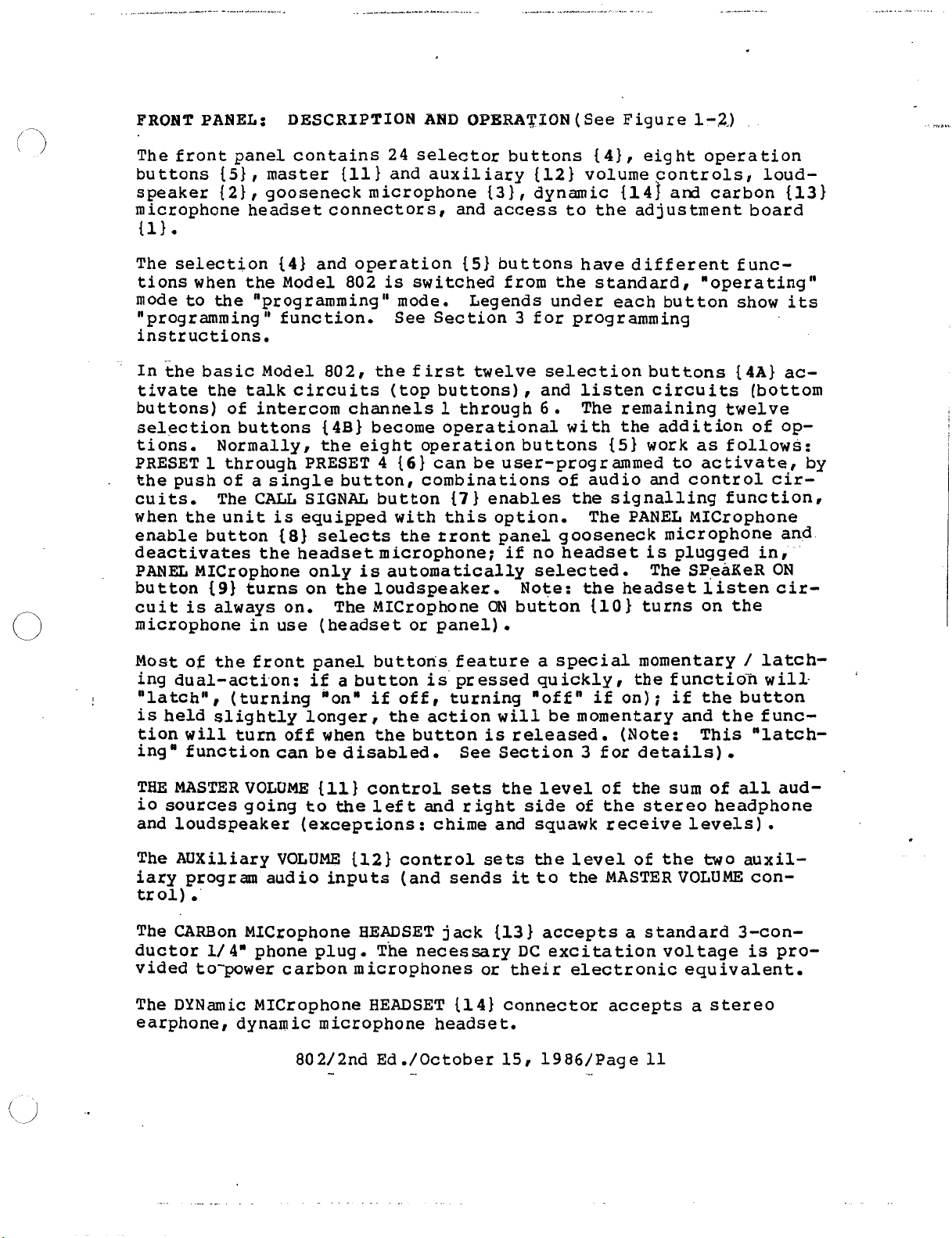

Page 17

0

FRONT

The

buttons

PANEL:

front panel contains

(S),

DESCRIPTION

master {ll) and auxiliary (12) volume ,controls, loud-

AND

BIPERATPON

24

selector buttons

(See

(

41,

Figure

1-2.)

eight opera tion

speaker (21, gooseneck microphone (31, dynamic (141 and carbon (13)

microphone headset connectors, and access to the adjustment board

(1).

(5)

The selection (4) and operation

tions when

Model 802

is

switched from the standard, "operatingn

the

mode to the "programming" mode. Legends under each button show

"programming " function.

See Section

buttons have different f unc-

3

for programming

its

instructions.

In

the

basic Model 802, the

f

irst

twelve selection buttons

(4A)

ac-

tivate the talk circuits (top buttons), and listen circuits (bottom

buttons) of intercom channels

1

through

The remaining twelve

6.

selection buttons (4B) become operational with the addition of op-

tions. Normally, the eight operation buttons

PRESET

the

cuits. The CALL SIGNAL button

when the unit

enable button

1

through PRESET

4

{6)

can be user-programmed to activate, by

push of a single button, combinations of audio and control

(7)

enables the signalling function,

is

equipped with this option.

{8)

selects

the rront panel gooseneck microphone and

deactivates the headset microphone; if no headset

is

PANEL MICrophone only

button

cuit

{9)

turns on the loudspeaker.

is

always on.

The MICrophone

automatically selected. The SPeaKeR

Note: the headset listen

(224

button (10) turns on the

(5)

work

as

follows:

cir-

The PANEL MICrophone

is

plugged in,

ON

cir-

microphone in use (headset or panel).

Most of

ing dual-action: if a button

"latch", (turning 'on" if off, turning "offn if on); if the button

I

is

held slightly longer, the action

tion

ing' function can be disabled.

THE MASTER

io sources going to

the

will

turn off when the button

VOLUME

front panel buttons- feature a special momentary / latch-

is

pressed quickly, the f unctio-n

will

is

be momentary and the f unc-

released.

(Note: This "latch-

See Section 3 for details)

{ll) control

the

left and right side of the stereo headphone

sets

the level of the sum of all aud-

and loudspeaker (exceptions: chime and squawk receive levels)

The Auxiliary VOLUME {12) control

iary program audio inputs (and sends

trol)

,

sets

the

level of the two auxil-

it

to the MASTER

VOLUME

The CARBon MICrophone HEADSET jack (13) accepts a standard 3-con-

ductor

11

4'

phone plug.

d he

necessary

DC

excitation voltage

vided to-power carbon microphones or their electronic equivalent.

The

DYNamic

MICrophone HEADSET (14) connector accepts a stereo

earphone, dynamic microphone headset.

will

,

.

con-

is

pro-

Page 18

Page 19

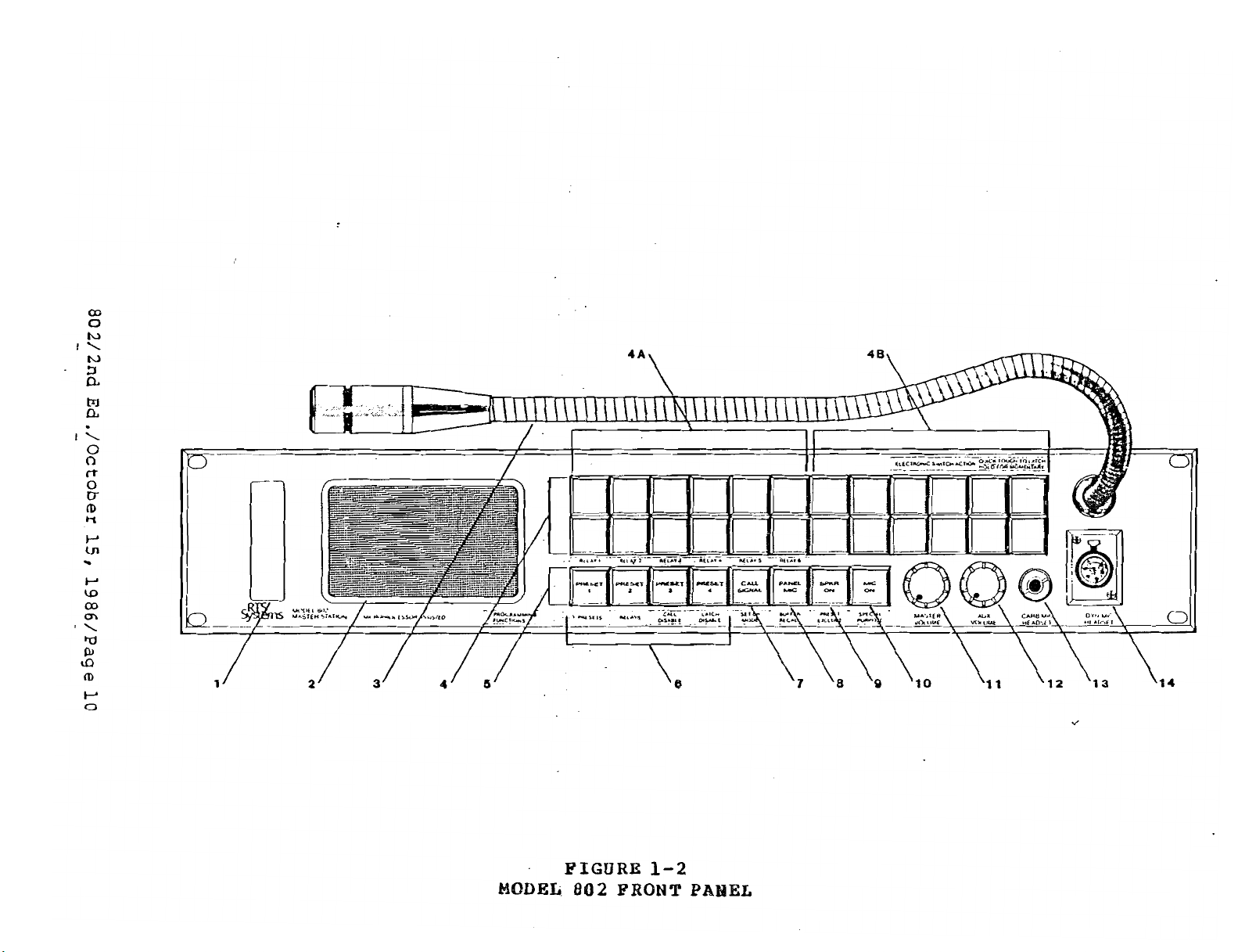

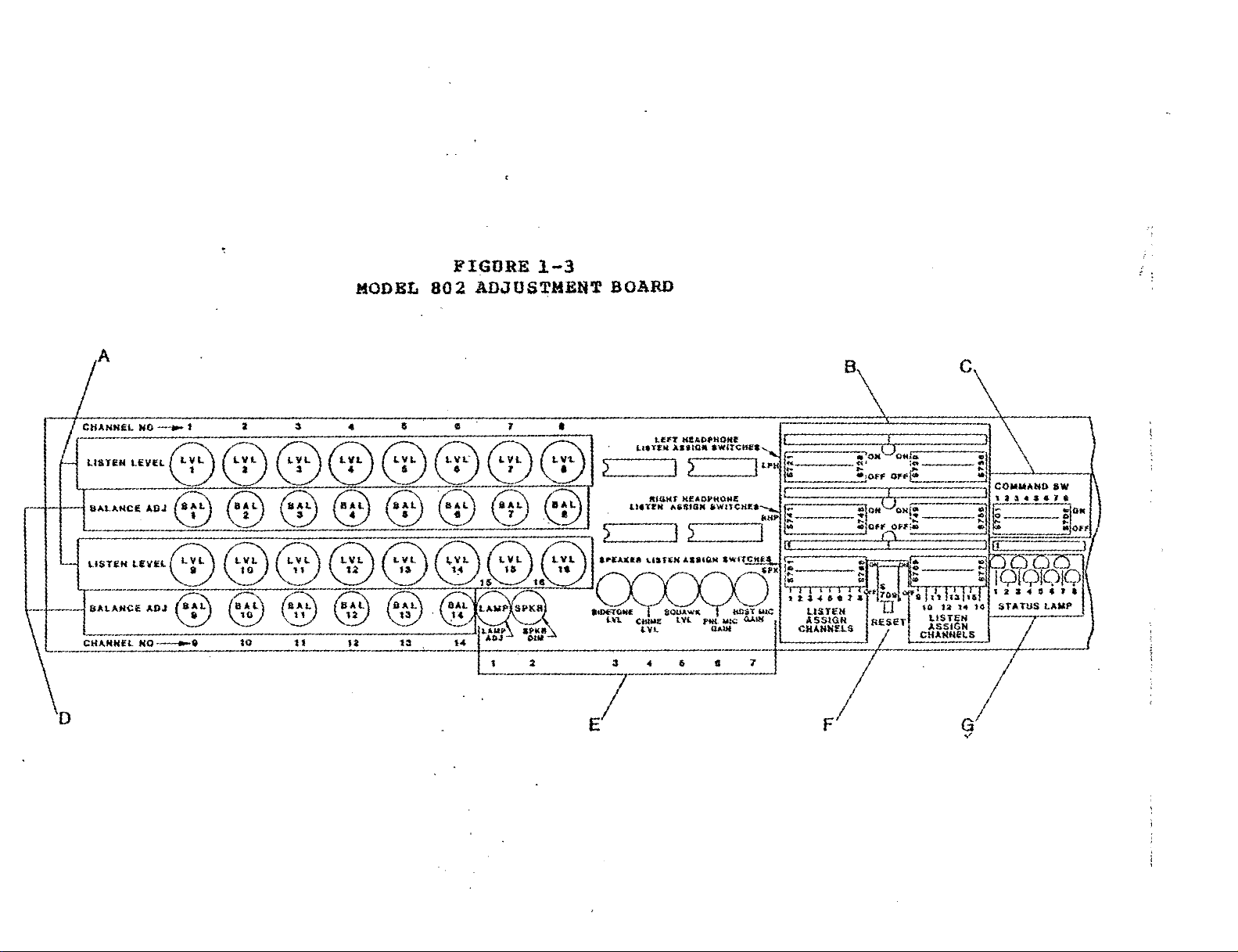

ADJUSTMENT

The

Adjustment Board

Release

rectangular panel

pulling

Located on the board are sixteen individual listen level controls

{A}, fourteen 4-turn 2-wire intercom balance controls {D)

auxiliary function controls {E), three groups of sixteen audio

source assignment switches

microprocessor

{GI

BOARD

the board by fir

it

forward.

reset

DESCRITPTPBN,AHD,..OPERATIC)N

:

is

located to the left of the loudspeaker.

st

pressing and releasing t$e small

(

{I) on the front panel illustration)

{B) , eight programming switches

button {F) , and the status indicator lamps

(Figure ,1-3)

and then

,

,

seven

{c)

I

the.

The LISTEN

the

twelve primary intercom channels.

differences by adjusting these controls.

BALANCE

The

Adjust the BALANCE control on each channel to null your own

microphone signal in the loudspeaker or headphones.

LISTEN and BALANCE controls

14 LISTEN LEVEL and BALANCE controls

LISTEN LEVEL controls 15 and 16 adjust the levels of the AUXILIARY

PROGRAM inputs

In the Auxiliary Control section {E)

adjusts the button illumination brightness; the second control {E2)

adjusts the loudspeaker level change when the microphone

switched on. The SIDETONE LEVEL {E3) adjusts the loudness of your

own microphone signal' heard in your own headset.

{E4)

is

incoming squawk signal (when squawk option

PANEL

the respective microphone preamplifier to compensate for

differences inmicrophone levels or individual's voices.

The ASSIGNMENT SWITCBES

any combination to the left or right side of the stereo headset or

the loudspeaker.

sets

installed)

MIC

LEVEL

controls {D) only function in the 2-wire intercom mode.

controls

1

and 2.

{A}

1-12 adjust the incoming levels of

Compensate for level

Channel 13

are

used in the 'ISOa function. Channel

are

reserved for future use.

,

the f

irst

control

{El)

is

CHIME

The

the volume of the incoming chime signal (when chime option

.

GAIN

The SQUAWK LEVEL

{E6), and HEADSET MIC

{B)

assign the 16 primary audio sources in

These 16 sources are:

{E5)

sets

GAIN

the volume of the

is

installed).

{87}

adjust the gain of

LEVEL

The

to

INTERCOM CBANNELS 1-12

"ISO"

AUXILIARY PROGRAM

AUXILIARY PROGRAM

SPARE

listen

#1

#

2

Page 20

The RESET button

{P}

is

used to

reset

the micsoprocessor.

This

required when initially installing certain options or making

certain programming changes on the Mother Board.

{G}

are used for diagnostic purposes.

The

PROGRAMMING

operating modes. See Figure 2-32A on page

switches

{C}

are used to

set

up various special

44

for illustration.

The STATUS LAMPS

?

is

REAR

PANEL:

The Model 802

DESCRIPTION

is

connected to other Model 802'~~ other systems,

AND

OPERATION

(See Figure 2-10)

external equipment using the connections on the Rear Panel.

The

LINE

terminal strips

The

optional

are

instal1,ed only

{2)

connector,

IFB

ANCILLARY

are

present on a basic Model 802.

{4),

SQUAWK

as

a

part of the various options.

{S}

{3)

I

4-WIRE

connector I and

{6},

and

IS0

18)

screw

17)

connectors

and

Page 21

The

screw terminals

single-pole double-throw (SPDT=form

on/off remote control (momentary action only--not alternate

action), Model VCP

connector, external microphone input, auxiliary program inputs

microphone preamplifier outputs, external loudspeaker, and power

input.

The

LINE

keying circuits for intercom channels 1-12

Auxiliary Program Input $2. In normal 2-wire operation, each audio

pair functions as a full-duplex two-way communication circuit;

while, in the 4-wire mode, the same pairs function as the send

portion of each circuit assigned to 4-wire operation.

connector (2) contains the balanced audio circuits and

18)

,

provide connection to

6

or VCP 12

the

six

sets

C)

relay contacts, microphone

Iso

Control Station, external headset

,

as

well

as connection to

of

,

ANCILLARY

The

programmable relay contacts,

control, 3)

balanced inputs.

IFB

The

compatible with Model 4010 Centr

Central Junction Interconnect, and Model VIE306 Station Isolate,

Electronics, repectively

The 4-WIRE connector

circuits, channels 7-12 4-wire talk (send) circuits

7-12 keying circuits.

The optional

via

IblTERFACIrJG

DIRECT:

connector, the back panel terminals and the ANCILLARY connector.

SYSTEM:

connection of

inputs and outputs, and switching circuits.

the 862 are common to all 802

{4),

an

RS-232 bus, only as a part of custom software applications.

An 802 connects directly to external equipment via the line

The Model 862 System Interconnect provides direct

connector

the squawk receive input, and

SQUAWK

{S)

13)

connects to:

,

and IS0

2) the microphone on/ off remote

{7)

connectors are plug-in

a1

Electronics, Model SQJlOlO

.

f

6)

contains channels 1-12 4-wire receive

AUX

.connector

TO

OTBER EQUIPMENT

up

to 12 channels of

(1)

directly

TW

'

s

in the system.

accesses

Intercom,

1)

six

sets

4)

two auxiliary program

as

Signals interfaced via

of

and

channels

the microprocessor

well

as

audio

<

!

An

DIRECT with

options, can connect with Series 4000 IFB System or the

Station Isolate System.

OPTIONS:

individual 802, equipped with standard

TW

Intercom

Page 22

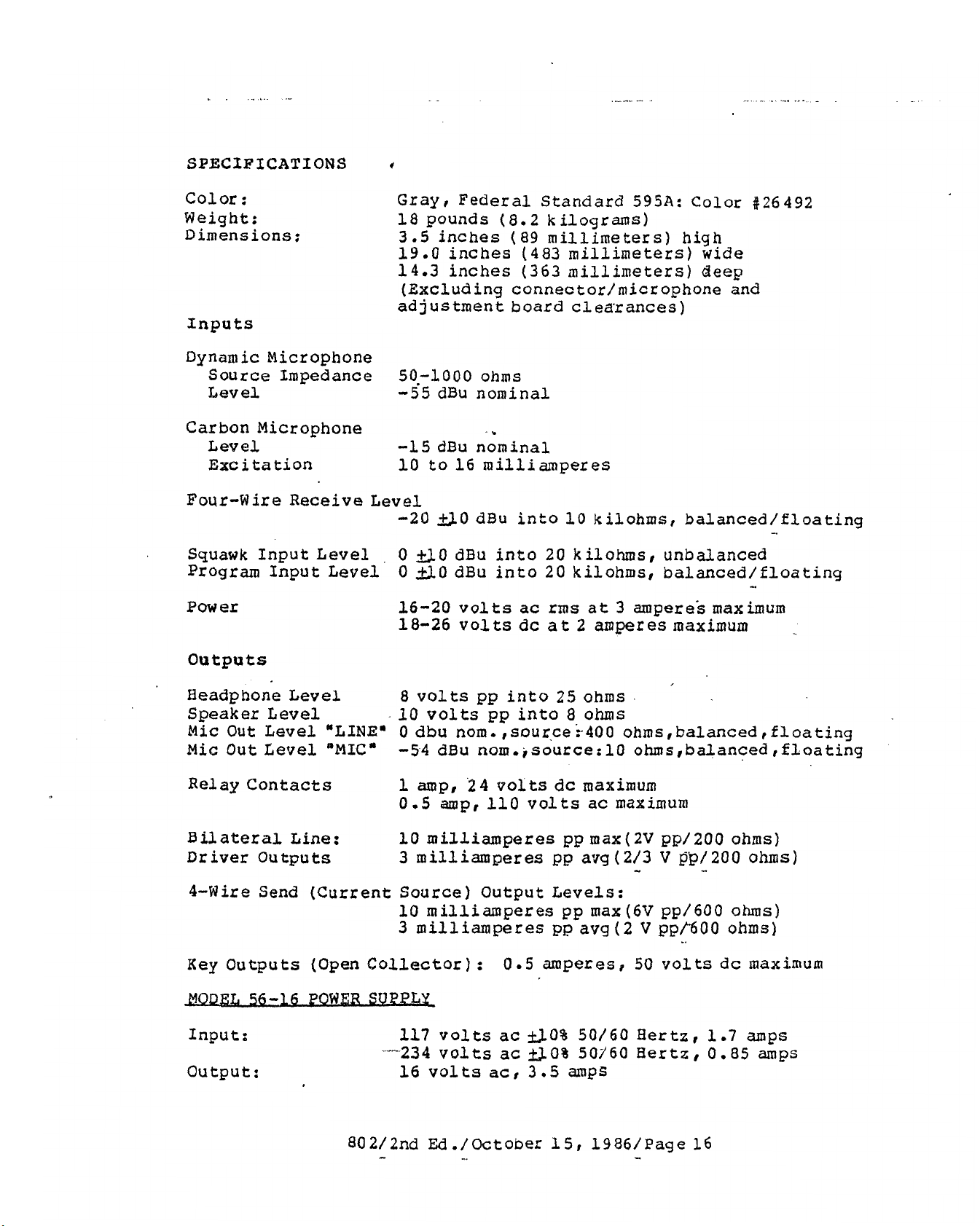

SPECIFICATIONS

f

Color:

Weight: 18 pounds (8.2 kilograms)

Dimensions:

Inputs

Dynamic Microphone

Source Impedance 50.-1000 ohms

Level -55 dBu nominal

Carbon Microphone

Level

Excitation 10 to 16 milliamperes

Four-Wire Receive Level

.

Squawk Input Level , 0 f1.0 dBu into 20 kilohms, unbalanced

Program Input Level 0

Power

Gray

3.5

19.0 inches (483 millimeters) wide

14.3 inches

adjustment board clearances)

-15

-20

16-20 volts ac

18-26

,

Federal Standard

inches (89 millimeters) high

(363

(Excluding connec tor/micr ophone

millimeters) deep

595A:

..

dBu nominal

&).(I

dBu into 10 kilohms, balanced/floating

SO

dBu into 20 kilohms, balanced/floating

rms

at 3 ampere's maximum

volts

dc

at

2

amperes maximum

Color t26492

and

-

Outputs

Headphone Level

Speaker Level

Mic

Out

Level

Mic

Out Level

Relay Contacts

Bilateral Line:

Driver Outputs

4-Wire Send (Current

Key

Outputs

Input:

Output:

"LINE"

"MIC"

(Open

Collector) : 0.5 amperes

8

volts

10 volts

0 dbu

-54

1

amp,

0.5 amp, 110 volts ac maximum

10 milliamperes

3

milliamperes pp

Source)

10 milliamperes pp max

3

milliamperes pp avg

117 volts ac

-..--234 volts

16

volts acI

pp

into

pp

nom.

dBu nom. ,source:lO ohms, balanced ,floating

,source :.400 ohms,balanced ,floating

24

volts

Output Levels:

ac

25

ohms

into 8 ohms

dc

maximum

pp

max(2V pp/200 ohms)

avg(2/3

(2

GO%

SO%

3.5

SO/

60 Hertz,

50160 Hertz

amps

-

(6V

V

50

V

pp/200

-

pp/600 ohms)

ppfi00 ohms)

volts dc maximum

I

1.7

0.85

ohms)

amps

amps

Page 23

MECHANICAL INSTALLATION

(or console) mountable enclosure, 3.5 inches

inches

holes are standard

minimum of 5.0 inches

adjustment board requires

2.0 inches (51

When installing this station, allow space for control access,

cabling and servicing.

connectors, and cables.

located, allow space between this cable and interfering sources

such as

power supplies.

(

483

mm)

wide

mm)

TV

monitors, power supplies and equipment with internal

by

E.I.A.

(127

for the rear panel connectors.

The 802 Speaker Master Station

(

89

mm)

14.3 inches (363

spacing.

mm)

front panel clearance, and the

11

inches (279

Provide space for

If the headset connector

mm)

deep.

The panel micropbne requires a

mm)

:

Allow

.

cab1 ing service loops,

high by 19.0

The mounting

an

.

is

remotely

is

a rack

additional

The Model 56-16 power supply, when used should be mounted at least

to 2 feet away from the Model 802 to minimize hum pickup.

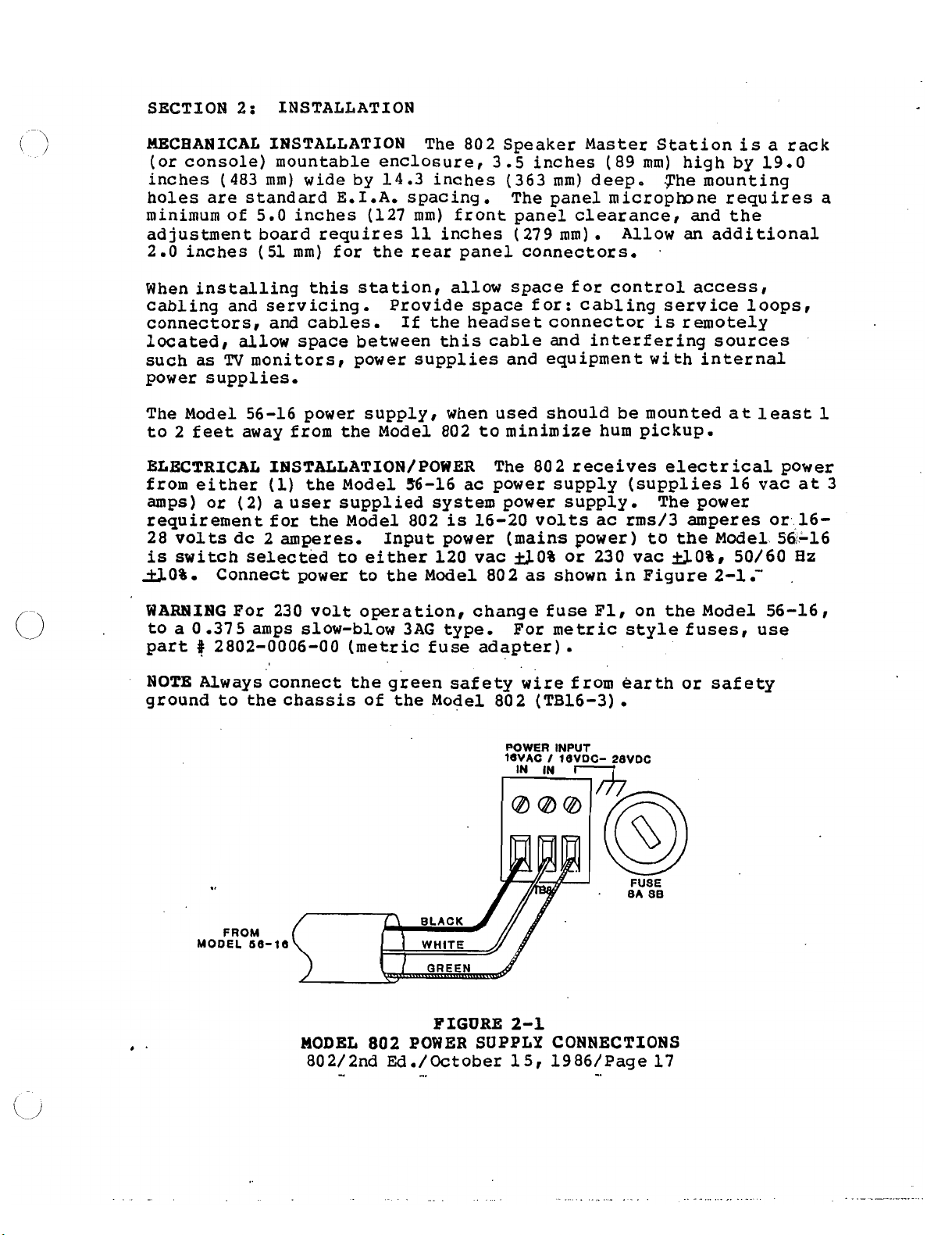

ELECTRICAL IISTALLATION/POWER The 80 2 receives

from either

amps) or

requirement for the Model 802

28 volts dc 2 amperes. Input power (mains power)

is

switch selected to either 120 vac

SO%.

WAEWING

to a 0.375 amps slow-blow 3AG type. For

part

NOTE Always connect the green safety

ground to the chassis of the Model 802 (TB16-3)

Connect power to the Model 802

#

2802-0006-00

(1)

the Model 56-16 ac power supply (supplies 16 vac

(

2) a user supplied system power supply.

is

16-20 volts ac rms/3 amperes or 16-

SO%

For 230 volt operation, change fuse Fl, on the Model 56-16!

(metric

fuse adapter)

or 230 vac

as

shown in Figure 2-1

metric

style fuses, use

.

wire

from earth or safety

.

POWER INPUT

I

IN

IN

1BVDC- 28VDC

ldVAC

electr

The power

to

the Model 56-16

GO%,

ical

50/60

.-

power

at

Hz

/f7

1

3

FROM

MODEL 68-18

@

FUSE

.

BA 88

I

1,

WHITE

\

MODEL

802/2nd Ed./October 15, 1986/Page 17

802

-

GREEN

FIGURE

POWER

-.

//

/

2-1

SUPPLY

CONNECTIONS

-.

Page 24

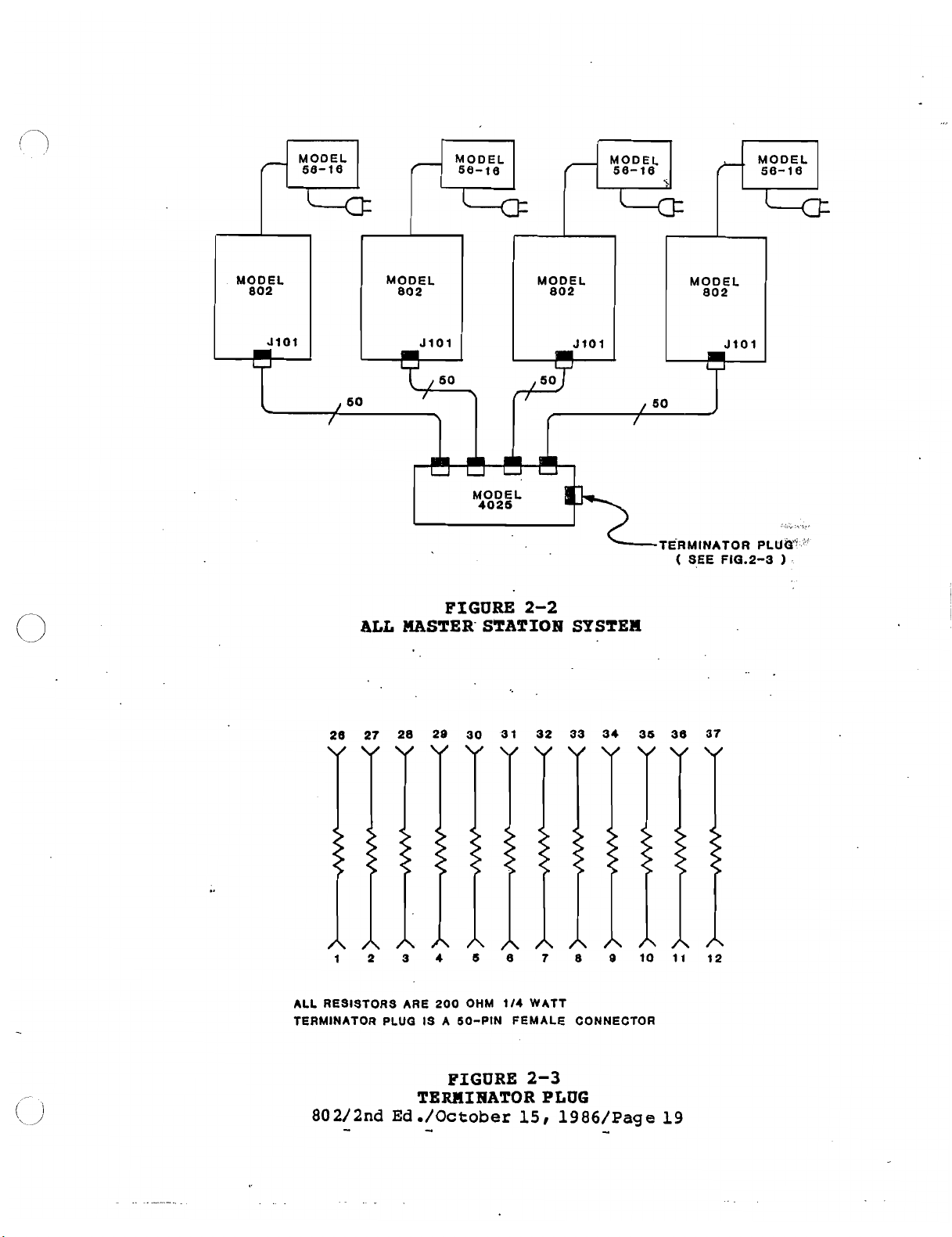

.ELECTRICAL INSTALLATION/GROUNDINC

Master

S tat*ion,.ch,assis

The

should be connected to earth ground or power line safety ground.

Each Master Station

bypassed to

its

own

chassis

via a

is

0.1 microfarad capacitor and 22 kilohm resistor in qarallel to

prevent interference from radio stations.

ELECTRICAL

IBSTALLATION/

SIGNALS/

-

GENERAL

-.

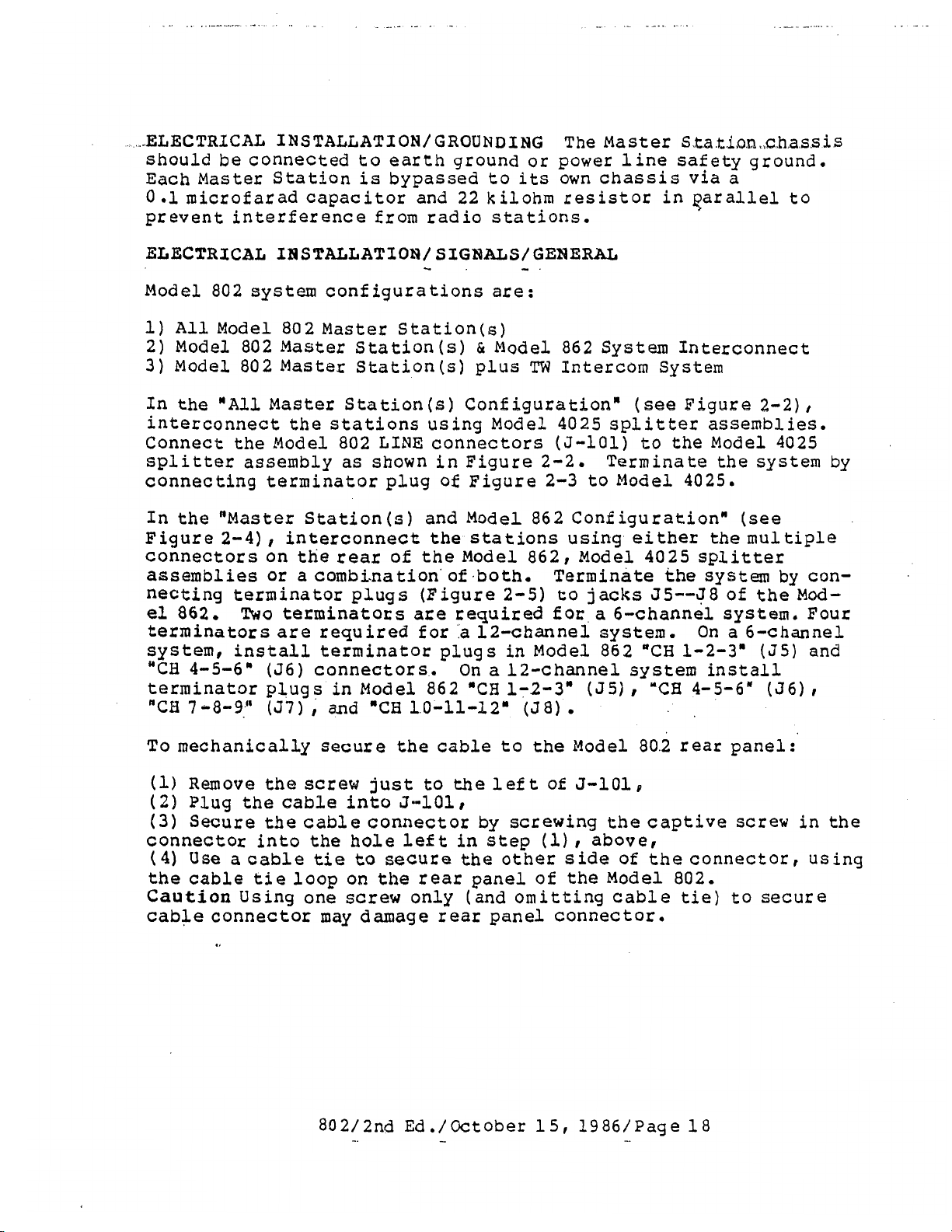

Model 802 system configurations are:

1)

All

Model 802

2) Model

802 Master Station

3) Model 802 Master Station(s) plus

In the "All

Master

Master

Station

Station(s)

(s)

&

Model 862 System Interconnect

(s)

Configuration"

TW

Intercom System

(see

Figure 2-2)

t

interconnect the stations using Model 4025 splittez assemblies.

Connect the Model 802

splitter

assembly as shown in Figure 2-2. Terminate the system by

LINE

connectors (J-101) to the Model 4025

connecting terminator plug of Figure 2-3 to Model 4025.

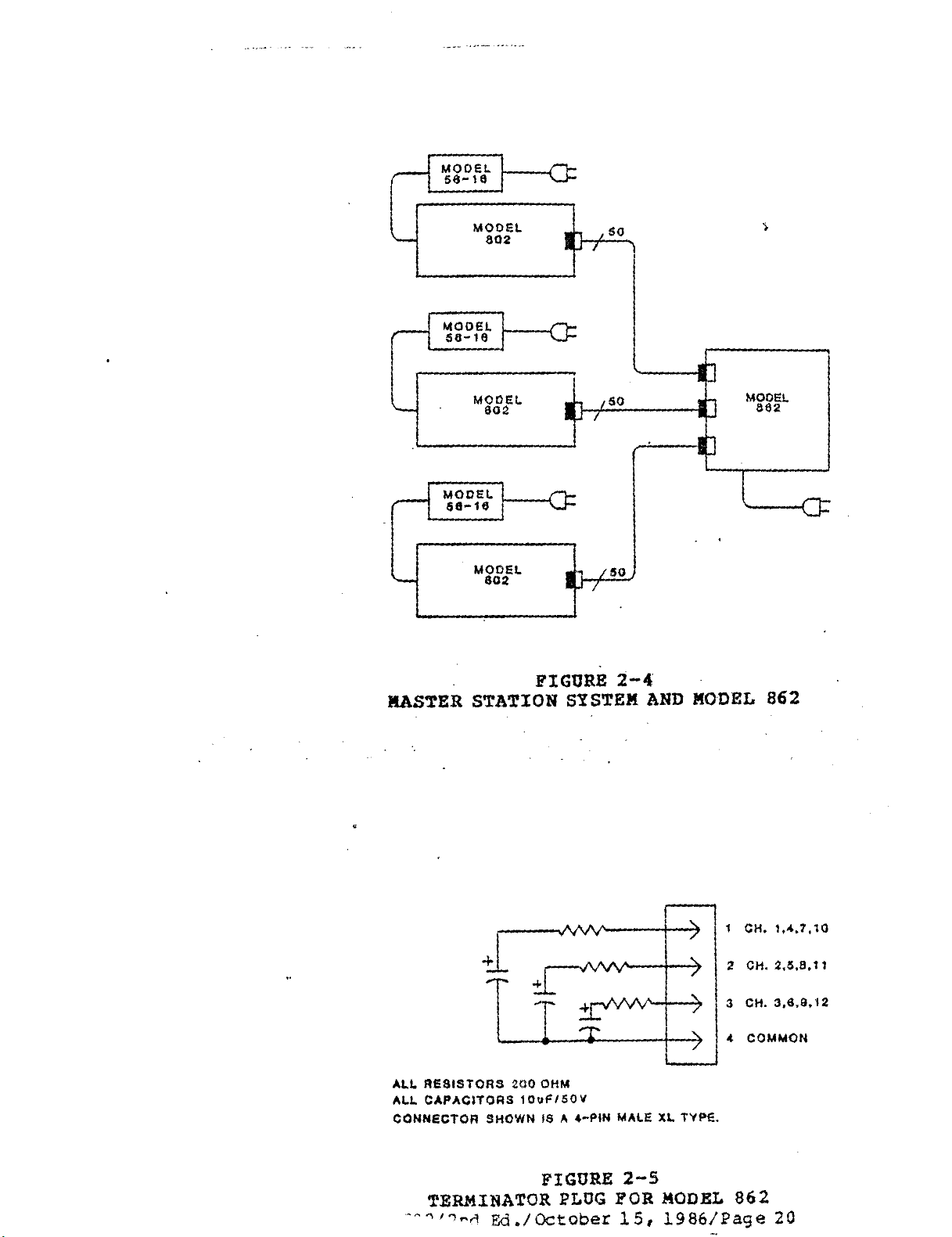

In the

'Master

Figure 2-4)

connectors on the

assemblies or a combi-nation of both.

necting terminator plugs (Figure 2-5) to

el

862,

Two

terminators

system, install terminator plugs in Model 862

'CH

4-5-6* (J6) connectors.

terminator plugs in Model 862

"CH

7-8-9" (57) , and

Station(s) and Model 862 Configurationw

(see

interconnect the stations using either the mu1 tiple

rear

of the Model 862, Model 4025 splitter

Terminate the system by con-

jacks

terminators

are

required for a 12-channel system.

are

required for a 6-channel system. Four

On

"CH

"CB

10-11-12' (J8)

a

12-channel system install

1-2-3" (J5)

.

55-9\18 of the

On a 6-channel

"CB

1-2-3'

I

"CH

4-5-6" (561,

Mod-

(J5)

and

To mechanically secure the cable to the Model 80.2 rear panel:

(1)

Remove the

(2)

Plug

(3)

Secure the cable connector by screwing the captive screw in the

the cable into 5-101

connector into the hole left in step

(4)

Use

a

cable

the cable

Caution

tie

Using one

cable connector may damage

screw

tie

to

loop on

screw

just to

the

left of 5-101

t

(l),

r

above,

secure the other side of the connector, using

the

rear panel of the Model 802.

only (and omitting cable

rear

panel connector.

tie)

to

secure

Page 25

r"9:"h

MODEL

FIGURE

ALL

MASTER' STATIOB SYSTEM

2-2

-TERMINATOR

(

SEE Fla.2-3

PLUW

'

ALL RESISTORS ARE 200 OHM

TERMINATOR PLUG IS A 60-PIN FEMALE CONNECTOR

FIGURE

TERMINATOR PLUG

802/2nd

-

Ed

./October

-

114

WATT

2-3

15,

1986/Page

-

19

Page 26

Page 27

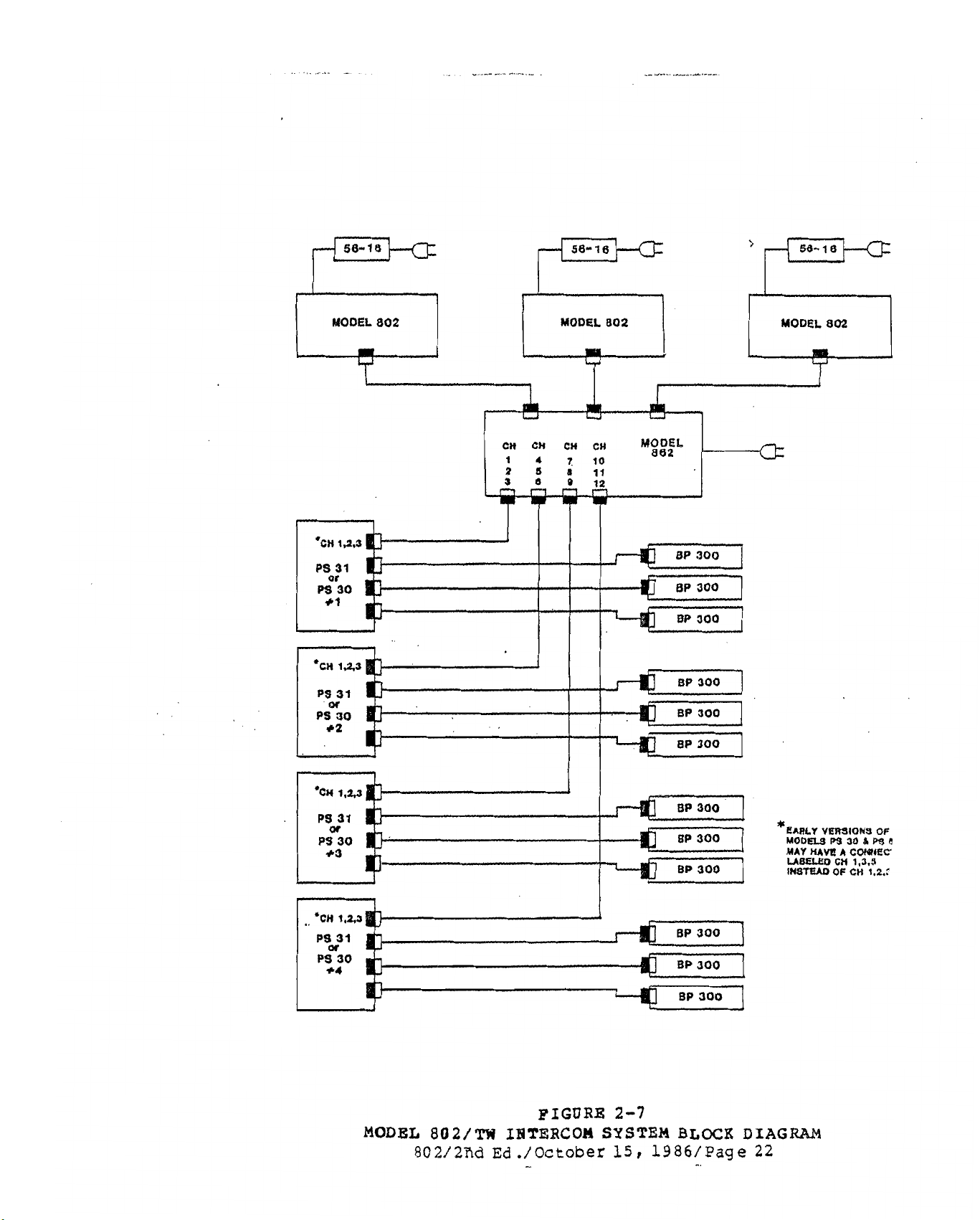

The "Master Station plus

one or more 802Is, a Model 862 System Interconnect, and a

Intercom System

the master stations talk and listen between themselves and the

user stations, The call light (optional) signals are also sent

throughout the system.

This method allows an unrestricted channel assignment switching

system to be used on the

system, (Figure 2-71

supplies and Model BP-300 user stations.

Intercom System to the Model 802 Master Station System, connect PS31

(PS-30) #l output 1-2-3 to 862 input

(PS-30) #2 output 1-2-3 to 862 input

channel master station system

(PS-30) #3 output 1-2-3 to 862 input

#4

30)

output 1-2-3 to 862 input "CH 10-ll-12R (J8).

(see

TW

Intercom System ~onfi~bration" includes

TW

example system, Figure 2-71. In this system

TW

The

TW

TW

Intercom System.

,

consists of four Model PS31 (or PS-30) power

To interface the

"CH

1-2-3" (55). Connect PS31

"CH

4-5-6" (56). If a 12-

is

being interfaced, connect PS31

"CH

7-8-9" (57) and PS31 (PS-

portion of the

TW

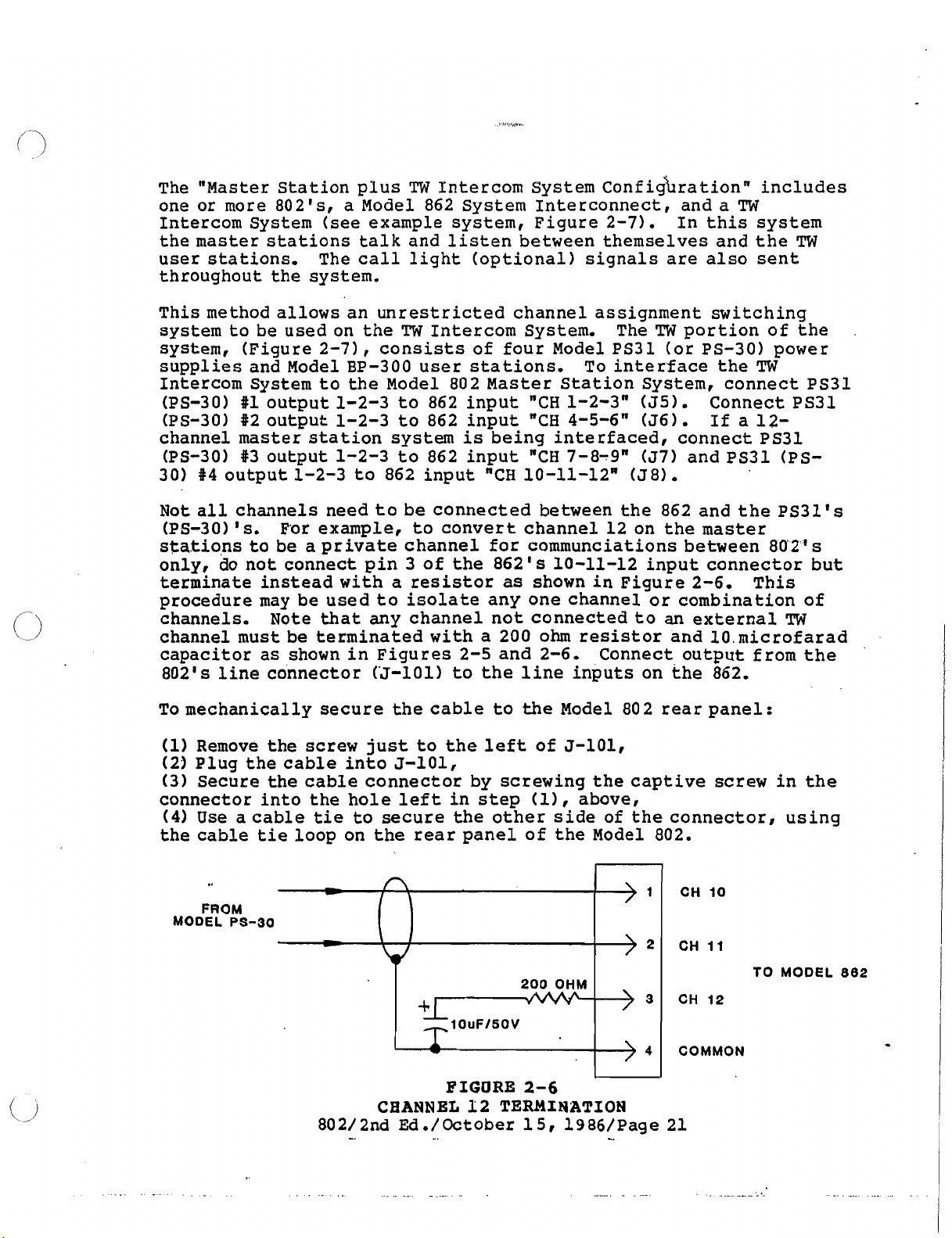

Not all channels need to be connected between the 862 and the PS3l

(PS-30)

stations to be a private channel for communciations between 802Is

only, do not connect pin 3 of the 862's 10-11-12 input connector but

terminate instead with a resistor

procedure may be used to isolate any one channel or combination of

channels,

channel must be terminated with a 200 ohm resistor and 10 microfarad

capacitor as shown in Figures

802's line connector (J-101) to the line inputs on the 862,

To mechanically secure the cable to

1

Remove the

)

Plug the cable into 5-101,

1

Secure the cable connector by screwing the captive

connector into the hole left in step

(4)

Use

the cable

For example, to convert channel 12 on the

Is,

as

shown in Figure 2-6.

Note that any channel not connected to

2-5

and 2-6,

the

Model 80 2 rear panel:

a cable

tie

loop on the rear panel of the Model 802.

screw

tie

just to the

to secure the other side of the connector, using

left

of 5-101,

(11,

above,

Connect output from the

master

an

external

screw

This

TW

in the

s

n

FROM

MODEL

PS-30

-

-

+b

10uFI50V

200

OHM

1

>2

3

4

CH

10

CHI1

CH

12

COMMON

TO

MODEL

-

FIGURE

CHANNEL

802/2nd Eld./October 15, 1986/Page 21

-.

12

2-6

TERMINATION

-

882

-

Page 28

MODEL

802

MODEL

802

MODEL

802/m

802/2nd

FIGURE

IBTERCOI

~d

./October

-

2-7

SYSTEM

15,

1986/Page

BLOCR

'EARLY

MOOUS

MAY

UQELeD

INSTEAD

DIAG

22

V~IONS

PS

30

HAW2

A

CWEC

CH

1,3,8

OF

cn

B

P3

1.2.2

OF

6

Page 29

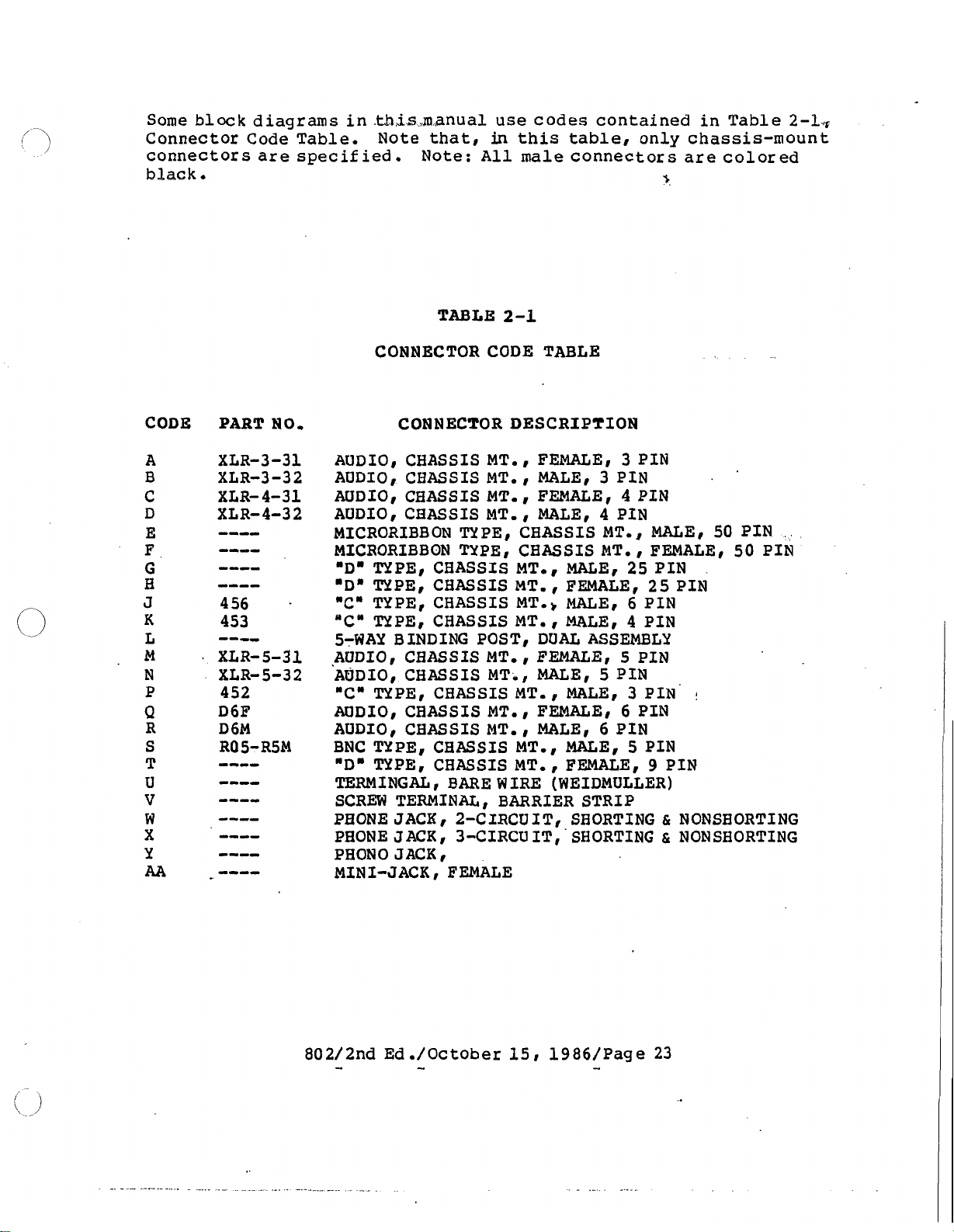

Some block diagrams in .th,is,manual use codes contained in Table

Connector Code Table.

connectors

are

specified.

black.

Note

that,

Note:

in

this table, only chassis-mount

All

male

connectors

are

colored

r

2-1-

TABLE

CONNECTOR CODE TABLE

CODE PART NO. CONNECTOR DESCRIPTION

AUDIO, CHASSIS MT.

AUDIO, CHASSIS MT.

AUDIO, CHASSIS MT.

AUDIO, CHASSIS MT.

MICRORIBBON TYPE, CHASSIS MTo, MALE, 50 PIN

MICRORIBBON TYPE, CHASSIS MTo FEMALE, 50 PIN

"Dm

TYPE, CHASSIS MT., MALE,

"Dm

TYPE, CHASSIS MT.

"C" TYPE, CHASSIS MT.) MALE,

"C" TYPEl CHASSIS MT. MALEl

5-WAY BINDING POST, DUAL ASSEMBLY

.AUDIOI CHASSIS MT.

AUDIO, CHASSIS MT-I MALE, 5 PIN

"C"

TYPE, CHASSIS MT. I MALE,

AUDIO, CBASSIS MT.

AUDIO, CHASSIS MT. MALE,

BNC TYPE, CHASSIS MTm, MALE,

"Dm

TYPE, CHASSIS MTo , FEMALE, 9 PIN

TERMINGAL, BARE WIRE (WEIDMULLER)

SCREW TERMINAL

PHONE JACK, 2-CIRCUIT, SBORTING

PHONE JACK, 3-CIRCU IT

PEON0 JACK

MINI-JACK, FEMALE

2-1

I

FEMALE,

I

MALEl 3 PIN

FEMALE,

,

MALE,

FEMALE, 25 PIN

FEMALE,

I

FEMALE,

,

BARRIER STRIP

I

'

SHORTING & NONSHORTING

4

6

3

4

PIN

5

6

PIN

PIN

PIN

25

6

4

PIN

3

PIN

5

PIN

PIN

PIN

PIN

PIN

61

NONSBORTING

Page 30

JlOl

KEY

OUTPUT

-

-

FROM COMPUTER

i

N400

FIGURE

DABLIBGTON

1

RELAY

I

2-8

KEY

OUTPUT

)

FROM KEY OUT

'

FROM KEY RETURN

KBY

802/2nd

FIGURE

OUTPUT

Ed./October

2-9

APPLICATION

15,

1986/Page

24

Page 31

ELECTRICAL INSTALLATION/ SIGNALS/FEATURES

KEY

OUTPUTS

Twelve logic-type outputs are available

.-

.

-.

at

reear-pankl line

I

I

1

connector, 5101. These outputs control relays in the Model 862

System Interconnect, but if your system does not include a Model

862,

these outputs may be used directly

as

control outputs.

Pressing one of twelve talk buttons on the front panel of the Model

802 activates one of the twelve key outputs (respectively)

Connections to these outputs are shown on

sheet

20 of the Model 802

schematic. Figure 2-8 shows a typical output. The darling ton

transistor output conducts to ground, when activated, and has

a

maximum rating of 50 volts, 50 milliamperes, dc. Figure 2-9 shows

an

application of the key output.

Note:

relays should always have a

diode to protect the transistor in the Model 802.

RELAY

OUTPUTS (See Figure 2-10)

Six form C relay contacts are available on the Model 802 rear panel.

The respective relays are programmable from the front panel to

3)

.

operate with front panel pushbutton(s) (See Section

1

contact ratings are:

ac.

Relay programming

Note: Applying voltages over 32 volts

is

EXTERNAL MICROPRONE SWITCH

an

Connect

external or remote microphone switch to TB7 (using labels

above TB7 for exact connection).

microphone

ON

switch being.brightened.

will

turn on and

action and requires

amp at 24 volts dc, or 0.5 amp

is,not recommended.

discussed in section 3.

(

See Figure 2-10)

When the

will

b.e indicated by

switch

The remote switch

a

maintained. contac

ti

When

is

the

is

not alternate

the

at

front-panel MIC.

remote switch

Maximum

110 volts

closed the

off, the microphone may be turned on locally, but when the remote

is

on,

switch

the microphone may

not

be turned off locally.

is

Page 32

-

MODEL

.-

'802

.

.

FIGURE

REAR

PANEL

2-10

CONNECTIONS

Page 33

VCP

CONNECTOR

(See Figure 2-10)

The rear-panel terminal block,

a

uvideo~'i'sW"

EXTERNAL HEADSET

^system,

CONNECTOR

and,

Connect external headphones to TB9.

headphones connections

are

connections, or oscillations

the

f

ront-panel headset connector; use only one at a

EXTERNAL

MICROPHONE

CONNECTOR

An external microphone may be used in place of

TB8,

has

connections to interface to

also, a "squawkn system.

(See Figure 2-10)

-i

Make

sure that the external

separate from any microphone

TB9

is

will

occur.

paralleled with

time.

(See Figure 2-10)

the

front-panel

gooseneck microphone by connecting the external microphone to rear-

panel terminal block

TB10. When using an external microphone,

disconnect the front-panel microphone by unplugging connector, P1,

from the motherboard.

Electret

wire

electret

microphones may also be used

with

the Model 802. Both 2-

and 3-wire microphones are accomodated.

R3

microphone, install resistor

on the mother board.

To use a 2-wire

PROGRAM INPUTS (See Figure 2-10)

Connect external program inputs to rear-panel terminal blocks

TBll

and TB12. These inputs accept line-level balanced audio. Program

volume level

adjustment board pots 15 and 16, and front-panel MASTER

control.

is

controlled by front-panel

AUX

VOLUME control,

VOLUME

Program may be assigned to left headphone, right

headphone, or speaker by switches on the adjustment board.

Alternatively,

Program

System Interconnect to all

Program input #2 of any Model 80 2

82

audio may

master

be

injected

at

the Model 862

stations, or audio appearing

will

appear on all Model 802

at

's.

MICROPHONE OUTPUT CONNECTORS (See Figure 2-10)

Two microphone outputs are provided via rear-panel terminal blocks

A

TB13

high level

and TB14.

(LINE)

determines whether

EXTERNAL

Connect

SPEAKER OUTPUT (See Figure 2-10)

an

external speaker to rear-panel terminal block TB15.

Since this output

rear-panel

output.

an

is

a

SPEAKER LEAD CONTACT

the

internal speaker

output

bridging-type output,

GROUND.

.

'

LEVEL

A

separate MODE switch for each output

is

switch

selects

controlled by the

DO

NOT

low level (MIC) or

MIC

ON/OFF switch.

-

LET EITBER

The switch next to TB15 turns off

Page 34

ELECTRICAL INSTALLATION: HEADSET(S)

A

HEADSET

Dynamic microphone headset type:

REQUIREMENTS:

wide range of headset types may be used:

Carbon microphone headset type:

s

50 to 1000 ohm microphone

25 to

Use

impedance

good acoustic isolation (20 to 40 dB) improve communication in high

ambient noise environments, and allow the user to use the headphones

at

In the headset connecting cable, prevent coupling between the

microphone and headphone leads by using

the microphone, and

not allow headphone ground to contact microphone ground or shield.

Tie the shield to microphone ground or "mic low".

can be made longer when

physically separated. The

cable length which may be used. Estimated maximum usable headphone

cable

1000 ohm headphone

headphones with an impedance of

8

ohm headphones

a

less tiring , lower volume.

lengths

are

as

(s)

are

a

separate, twisted pair for the headphones. Do

the microphone and headphone pairs are

w

f

oblows:

Standard carbon microphone

25

to 1000 ohm headphone

25

ohms or greater.

not recommended. Headphones with

a

shielded, twisted pair for

The headset cable

ides the separation, the longer the

(s)

Low

.

Single cable, two shielded twisted pair: 10 feet (3.05

Dual ribbed cable, two shielded twisted pair: 30 feet (9.14

Separate cables,

Balanced microphone input: up to

shielded

twisted

pair in each:

LOO

feet (30.48

50 feet (15.24

m)

.

m)

.

m).

m)

.

HEADSET CONNECTIONS

Dynam'ic Microphone headset connector

Input level: -55 dBV nominal

Output level to headphone: 10 volts peak-to-peak open circuit.

1

-

Pin

Pin

Pin

Pin 4

Pin

Carbon Microphone headset connector: Standard

(TRS)

Input level: -15 dBV nominal

Phone Jack

Output to Headphone: 10 volts peak-to-peak open circuit.

Tip

Ring

Sleeve

Microphone low

2

-

Microphone high

3 - Headphone low

-

Left Headphone high

5

-

Right

-

Carbon Microphone

-

Headphone

-

Common/ground

Headphone high

-

:

XLR-5-31 type receptacle

l/

4'

Tip-Ring-Sleeve

-

Page 35

ELECTRICAL INSTALLATION/ SIGNAL/MODEL 802 TO MODEL 801/MODEL

86 0

- -

-

If the Model 802

connector on the rear panel of the Model 802 plugs ,directly into an

"801' type system.

it

is

If

type system, follow the directions below.

Case

Monitor Mute:

six channel "801" system.

channel Model 802 to an 801 system

button legends per Figure 2-12.

Case 2: Six channels of intercom, SA's, IFB1s, Slate, Monitor Mute:

Use

connect using the wiring diagram in Figure 2-13. Install button

legends per Figure 2-14.

860. In a 12-channel 802, program one of

when SLATE

*mic/radio-telephone relay available on J2 of the Model 801.

-

Program another relay to activate when SPKR MUTE

relay

54 on an 801. This relay may also be programmed to activate when an

SA button

studio speaker nearest the 802 may

SA1 button

required that a non-801 emulate type 802 be used in an '801U

1:

Six channels of intercom, no SA1s, no IFB1s, no Slate, no

a 12-channel Model 802 (equipped with the Talk option) and

MIC

is

equivalent to the monitor mute relay contacts available at

is

pressed. Thus if SA1

is

has

Use

a standard six channel Model 802 to connect to a

is

pressed.

pressed.

been equipped with an '801 emulateU option, a

A

This

This

wiring diagram for connecting a

is

shown in Figure 2-11. Install

wiring

This

will

will

relay

is

used as a studio announce, the

be

prevent feedback squeals.

operate all relays in the

the

relays to activate

is

equivalent to the slate-

is

pressed.

muted via the relay when

6-

This

its

.

Model 801

between the systems as shown in-Figure 2-15.

termination

connections

talk and listen channels of the 801 to communicate with the first

six talk and listen channels of the 802. The optional connections

interface the next five channels of the 801 to channels

802. SA and

listen. SLATE

Listen level on the SLATE line

knob. The key connections allow the 801 to oserate relays

the 862.

For more information on 801/860 systems,

manual, TM26 04.

I's

may also be used in an 8021 862 system.

is

provided by only one system. Note that some

are

optional. The standard connections allow the six

IFB

channels on the 801 can only talk and can not

is

a 2-way line and

will

is

work to both talk and listen.

controlled by the

-

see

Make

the 801 technical

connectibns

Be

sure that

7

-

11

of the

MT.

2

7

level

-

11

in

Page 36

CASE

TO J101

MODEL 802

.

1:

SIX

ON

,

CHANNEL

FIGURE

802

TO

2-11

SIX

CBABHEL'

TO MODEL 802

THROUGH

LOOP

TO

86111

.

.

PBTERCONNECTION

0

MODEL 860

J8

R

INPUT

CASE

802/2nd

1:

Ed

FIGURE

FRONT

./October

2-12

PAlEL

15,

BUTTON

1986/Page

-.

LEGEZ4D

30

Page 37

?ROY

YODLL 801

YODEL raa

OR

TO J8 ON

YODLL a01

OR

TO YODEL

880

CASE

2:

TWELVE

FIGURE

CBANNEL

802/2nd Ed./October - 15, 1986/Page

802

TO SIX CBANNEL

2-13

801

-.

INTERCONNECTION

31

Page 38

TO

J101

YODEL

OH

802

CASE

2:

FIGURE

FRONT

2-14

PANEL

BUTTON

LEGEND

TO

MODEL

LOOP THROUGH

TO

MOOEL

OR

800

802

INPUT

J8

USXHG

802/2nd

AB

HODEL

Ed

./October

FIGURE

801

IB

2-15

AH

HODEL

15,

802

1986/Page

SYSTEM

32

Page 39

ELECTRICAL INSTALLATION/ SIGNALS/MODEL 80 2/TELEPHONE

-

...

-

The Model 802 may be interfaced to telephone lines as follows.

Method

from an 862 to either a dry or

transformer as shown in Figure 2-16 (Figure 2-10 in 801 manual).

Terminate the phone line with an 820 ohm resistor across the

transformer secondary (phone line side). The transformer

enough so that

(line with dc current) with negligible ac performance degradation;

the secondary

1

ine

Method 2: Connect a TWI-222T-telco interface unit as in

Figure 2-17.

Method 3: Connect

Note: the 200 ohm resistor termination

(PS-30/60)

Method

OPT802-C3) to

work better than the two methods above. Note: Termination must be

provided.

.

-

1:

Connect a party-line (PL) channel from either one 802 or

wet

it

can be directly connected across

is

low enough resistance so that

a

TWI-326 interface unit using Figure 2-18.

is

also connected.

4:

Connect a Model 802 with 4-wire option (OPT802-C2,. ot

a

TWI-3

26 as shown in Figure 2-19.

phone line via a step-up

is

not required if a PS 31

s

a

*wetu

it

will

This method

"hold* the

is

large

line

kill

Page 40

TRIAD 9-64X

$

-0

TIP

FROM YOOEL 680

XETHOD

1:

XODEL

FIGURE

802

TO

620 OHM

A

-

TO TELEPHONE

0

RlMB

LINE

2-16

TELEPHONE Il!?TERCONBECTXOB

MgTBOD

MODEL

2:

802/2nd

TWC222 TO TELCO

-------------

I

I

I

I

I

I

A4Y

FIGURE

802

Ed

./October

2-17

TO

TELILBEONE

15,

I

L

DETAIL OF TELCO CONNECTIOM

,,--------------

IBTERCONNECTION

1986/Page

TO TELCO

RING

"t

34

-1

I

I

I

I

I

I

I

1

I

Page 41

(

ALSO SEE MODEL TWI-328 MANUAL

TO TELCO

)

XETHOD

TO MODEL 802

3:

<

<

<

<

HODEL

200 OHM

200 OHM

FIGURE

802

-

-

2-18

TO

TELEPHONE INTERCONNECTION

MODEL

TWI-328

4W

IN

4W OUT

. .

TO TELCO

METHOD

4:

MODEL

802/2nd

FIGURE

$02

TO

TBLEPBONE INTERCONNECTION

Ed,/October

2-19

15, 1986/Page

-.

35

Page 42

ELECTRICAL

The Model 802 may be used in either of two ways with the 4000 series

IFB system. Method "A" uses

output from the Model 802 to drive Models 4001, 4002, or 4003 IFB

Control Stations. Method

IFB control station and requires no external parts, but

require:

that mother board programming switch(es) be actuated and 3)

microprocessor

INSTALLATION/SIGNALS/MODEL

1)

the installation of one or two IFB option boards, 2)

reset

be executed.

-

RBU

-

a

line-level unswitched microphone

emulates either a Model 4001 or 4002

802/SERIES 4000

-

IFB

it

does

a

To use Method

MIC

Use

Manual, TM2594. Note that, on the 4000 series control station,

must be removed and a trace cut. Interconnect the IFB system and

configuee the 4001, 4002, or 4003

described in the IFB Technical Manual TM2594 and Figures 2-20A and

2-208, Move the 802's

UNSW. Do not connect the shield

Method

option base

IFB control station option OPT802-Gb must be installed. To emulate

a

options must

priority needs to be changed, consult the IFB Technical Manual,

TM 2594.

OUTPUT 2 to Models 4001, 4002, or 4003 IFB Control Stations.

the instructions for "Line-level inputs" in the IFB Technical

"B*

model 4002 IFB control station, both the OPT802-G1 and OPT802-G5

installed the- "Isom option can not be installed. If the IFB

"An,

IFB (See Figures 21, 22, 23, and 24) requires both an

(OPT802-Al) and IFB option

connect the Model 802 (rear panel)

f.or

power input and priority

LEVEL

be

installed. Note that if both IFB options are

switch to LINE and the MODE switch to

at

the 802 end

(s)

.

of

To emulate a model 4001

MIC

OUTPUT

the cable.

1

ot

R11

as

Page 43

TYPICAL CONFIGURATION

+

1

CENTRAL

METBOD

".Aa

t

802/2nd

-

FIGURE

MODEL 802

Ed

./October

-

TO

2-20A

IPB

CONNECTION

15,

1986/Page

-

37

(

4

IPB

s)

Page 44

TYPICAL CONFlC10RATION

+a

CIMTRAL

ILlCTnOMlf,

METHOD

t

MODEL

.Am

802/2nd

1.4

oCC1TT1n

.

PIGUBX

802

TO

Ed./October

2-20B

IFB

COPJNECTION

15,

1986/Page

!--++=I

(

-

38

MOO.

4010

MOO.

4010

8.

IPB's)

Page 45

CONTROL

YQ0.L 400.

MOO. 4010

w

MBTEOD

FIGURE

.Ba

r

HODEL

802/2nd Ed./October 15, 1986/Page 39

802

tO

2-21

IFB

COQNBCTION

(

4

IFB

'8)

Page 46

TYPICAL

CONfl(lURATl0N +2

w

UOO.

4010

METHOD

.Bar

MODEL

802/2nd

PIGIIRX

802

TO

Ed./October

2-22

IPB

COSINECTIOEI

15,

1986/Page

(8

40

IFB's)

Page 47

I

HODEL

802

PROm

FIGURE

PABEL

2-23

BUTTON

ARRABGEHEBT

..

[

ELECTRONIC SWITCH ACTION:

FOR

-

4

IFB8

s

~~~~~~~~~~~$~~~

I

4

I

MODEL

I

&iikE

1

olsmu 1 uoor 1 aEcrrr 1 ExcLuoE I PuRPosE

802

FRONT

802/2nd Ed

LATCH

SET-UP BUFFER PRESET SPECIAL

FIGURE

PANEL

BUTTON ARRAlDGEHEaT FOR 8 IPB

./October

2-24

15,

1986/Page

MASTER AUX

I

VOLUME

VOLUME HEADSET

'

-.

41

CARE MIC

s

Page 48

ELECTRICAL

The Model 802 may be used in either of two ways with the series 1000

squawk system. Method

squawk station that

in the 802. Method

no

with

For Method

802 to the EXTERNAL

shown in Figure 2-27. Connect the MCP-1010's OUTPUT

LINE to the SQUAWK input at TB8 on the 802.

external parts required.

INSTALLATION/ SIGNALS/ SERIES

is

'A"

squawk, connect

LINE

-

"Aa

requires an external model MCP-1010

connected to use the microphone and speaker

'8"

emulates a model MCP-1010 squawk station

LEVEL MICROPHONE INPUT

-

MIC

OUTPUT 1 or

10 0

0

SQUAWK

MIC

OUTPUT 2 of

of

the MCP-1010 as

TO

CONFERENCE

the

Incoming audio level~from the MCP-1010

Level adjust on the 802's pull-out adjustment boasd only and

affected by

1010'

For Method

squawk options are available. The first option OPT802-F1

emulate only the

option OPT802-F5 adds on to the first option so that all ten

channels on an MCP-LO10

OPT802-A1 option base

Incoming audio level

level pot only and

f

sont-panel speaker switch,

80 2 or MCP-1010

"Ba

squawk, the SQUAWK option must be installed. Two

f

irst

(See

is

is

not affected

f

ront-panel level control or 80 2/MCP-

six channels of an MCP-1010. The second

are

emulated, Either option requires the

Figures 25 I 26 I and 28)

controlled by the adjustment board squawk

by

is

controlled by the SQUAWK

front-panel

.

VOLUME

is

...

will

control.

not

Page 49

I

ELECTRONIC SWITCH ACTION,

~~,"~~~~$,~~~~~~,"

I

--

4

I

HODEL

1

E

802 FROlllT

UTCH SET-UP BUFFER PRESET SPECIAL

1

1

1

MOO.

PANEL

I

RECALL 1 EXCLUDE

FIGURE

BUTTON

I

PUFiPOSE

2-25

I

ARRANGEHEBT

MASTER AUX CARE MIC

VOLUME VOLUME HEADSET

FOR

6

SQUAWK

's

MODEL 802 FRONT

802/2nd Ed

PANEL

./October

FIGURE

BUTTON

ARMGEMEBT

2-26

15,

FOR

1986/Page

MASTER AUX CARE MIC

VOLUME VOLUME HEADSET

10

SQUAWK

43

'

S

Page 50

EXT

LL'

MIC

IN

OUT

TO

CONF. LINE

TBT

/

MODEL

802

METHOD

802/2nd

.A9

-.

FIGURE

MODEL

802

Ed,/Cctober

2-27

TO

SQUAWK

15,

1986/Page

L

CONNECTION

44

Page 51

1 ZOVAC

50160

HZ

INWT POWER

-

MOOEL SdJ- 10 10

SQUAWU JUNCTION

I

NOTES:

METHOD

802/2nd Ed./October

a

THIS STATION MAY BE IN ANY POSITION

MODEL 802's MAY ALSO

FIGURE

..I3

',

t

MODEL

80

(I

BE

USED IN MQRE THAN ONE POSITION.

THROUGH 101

2-28

2

TO

SQUAWK

15,

1986/Page

CONNECTION

45

Page 52

The Model 802 may be used in either of two ways with the VIE-306

video iso electronics, Method

video iso control panel. Method

"A"

requires a model VCP-6 or VCP-12

"B"

will

emulate a model VCP-6

video control panel station and requires no external parts.

Method

control panel. Connect the video control panel

panel

Method

"A"

VB

CONN

"B"

video iso requires an external VCP-6 or VCP-12 video

to

the 802 rear-

terminal block as shown in Figure 2-30.

video iso

will

emulate a model VCP-6.

To use this option

IS0 option OPT802-H1 must be installed along with option base

OPT 80 2-A1.

"B"

Enable IS0 option

(See Figure 2-32) and pushing the RESET button on the adjustment

ON

by moving switch S125-4 on the mother board to

board, Connect output from rear-panel IS0 connector J106 to the

VIE-306 central electronics as showntin Figure 2-31.

With

either IS0 option

enabled. This option wil1,mute

IS0

an

5125-5

case,

channel

the mother board to

on

is

selected. To enable this option, move switch

outgoing party-line channels are disabled during video iso.

REPLACES

MWEL VCP

STATlOH ISOUlT

conmoL

6

STATION

"A"

or

TO UOOEL VIE

STATION ISOLATE

ELECTRONICS

"Bnr

ON

308

IS0

DRIVEN

all

incoming party Line calls when

shown in Figure 2-32,

as

'

TO

TO REMOTE LOCATIONS

VIA 4:WIRE,TELCO CIRCUIT

BNQINEERINQ

*WAY RADIO

TRMSOENE",,~)

LISTEN

KEYING

DISABLE may be

In either

4-WIRE

CYICUITS

TO REMOTE

LOCATIONB

MODEL

802

FRONT

802/2nd Ed./October

PURL

SIX STRANDED

INTERCOM CHANNELS

I

FIGURE

BUTTON

COIHEReHCE

2-WIRE

LW

t

AUDIO VIA MOOEL

I

2-29

ARRAIIGEWBBT

15,

1986/Page

TO TW INTERCOM

INTERCONNECT

FOR

3YSTEM

882

IS0

46

(METHOD

.B"

)

Page 53

MODEL

2/VCP CONNECTOR

4

5

3

2

-130 CONTROL INPUT

AUDIO La

AUOlO HI

GROUND

VCP INTERFACE BOARD

-

3

w

fp,

2

1

-

I

I

T84

'4

8

3

14VAC IN .011500

cs

K

1

ALL CAPACITORS SHOWN ARE IN uFIVOLTS.

METBOD

802/2nd

'Amr

MODEL

Ed./October

FIGURE

2-30

802

.-[r_-L-L-J

TO

IS0

15,

1986/Page

CONNECTION

47

Page 54

MODEL SAP-1026

12

THUMBWHEEL OUTPUTS

I

MODEL

802-A 1 H

PRIORITY

MODEL

VCP-6

-

PRIORITY

-

PRIORITY 3

I

1

1

2

MODEL

VIE-306

@-+-

CAMERAS

6

TO

0

'3

R

R

USER

STNS.

WIRE

TO 6 CAMERAS

TW USER STNS.

j

PLUG IN POWER SIJPPLYnhJ

FIGURE

METHOD

",Bn

r

802/2nd Ed

MODEL

./October

802

2-31

TO

IS0

CONNECTIOM

15, 1986/~age

48

Page 55

FIRMWARE

yb3.0..

CALL ANSWER

INSTANT

IFB on/of f

IFB

8/4

PRESET EXCEUSIV

~ot

Used

COLD START

SET-U

MIC

or IS0

P

DISABLE

ADJUSTMENT

,

ON

1

FIRMWARE

u

FIRMWARE FIRMWARE

-

CALL

Not Used

IFB on/ off 3.

IFB 8/4 or IS01216 4.

PRESET EXCLUSIVE

Not

COLD START 7.

SET-UP DISABLE

FIGURE 2-32A

BOARD

AN

Used

COMMAND

SW

ER

SWITCH

AAdL

1

,

2.

"

"

5

'6

;

8.

Not

Used

Not Used

IFB

on/of f

IFB 4/8

PRESE;T EXCLUSIVE

LISTEN FOLLOW TALK

COLD START

SET-UP DISABLE

or

IS0 6/12

CALL LIGHT TIME

TALK 7 -12 ENABLE

ON=801 emulate

IS0 ENABLE

IS0 LISTEN DISABLE

IFB ENABLE

IFB SELECT

IFB TALK DISABLE

1.

CALL LIGHT TI'ME OUT

2. OFF-1-6 talk ,ON=7-12 talk

3. ON=801 emulate

4.

IS0 ENABLE, OFF=external contact, ONtbuttons

ONtdisable listen buttons when IS0 active

5.

6.

ON=ISO enable

7. ~otUsed

ON=disable talk buttons when IFB

8.

FIRMWARE

8

128

1.

2.

3. ON=801 emulate

4.

5.