Page 1

MCII-e

System Contr oller Car d

User Manual

9350-7734-000 Rev B April / 2007

Page 2

PROPRIETARY NOTICE

SHIPPING TO THE MANUFACTURER

The product information and design disclosed herein were originated by

and are the property of Telex Communications, Inc. Telex reserves all

patent, proprietary design, manufacturing, reproduction, use and sales

rights thereto, and to any article disclosed therein, except to the extent

rights are expressly granted to others.

COPYRIGHT NOTICE

Copyright 2006 by Telex Communications, Inc. All rights reserved.

Reproduction, in whole or in part, without prior written permission from

Telex is prohibited.

WARRANTY NOTICE

See the enclosed warranty card for further details.

CUSTOMER SUPPORT

Te chnical questions should be directed to:

Customer Service Department

RTS/Telex Communications, Inc.

12000 Portland Avenue South

Burnsville, MN 55337 USA

Telephone: 800-392-3497

Fax: 800-323-0498

RETURN SHIPPING INSTRUCTIONS

Customer Service Department

Telex Communications, Inc. (Lincoln, NE)

Telephone: 402-467-5321

Fax: 402-467-3279

Factory Service: 800-553-5992

Please include a note in the box which supplies the company name,

address, phone number, a person to contact regarding the repair , the type

and quantity of equipment, a description of the problem and the serial

number(s).

All shipments of product should be made via UPS Ground, prepaid (you

may request from Factory Service a different shipment method). Any

shipment upgrades will be paid by the customer. The equipment should

be shipped in the original packing carton. If the original carton is not

available, use any suitable container that is rigid and of adequate size. If

a substitute container is used, the equipment should be wrapped in paper

and surrounded with at least four (4) inches of excelsior or similar

shock-absorbing material. All shipments must be sent to the following

address and must include the Proof of Purchase for warranty repair.

Upon completion of any repair the equipment will be returned via

United Parcel Service or specified shipper, collect.

Factory Service Department

Telex Communications, Inc.

8601 East Cornhusker Hwy.

Lincoln, NE 68507 U.S.A.

Attn: Service

This package should include the following:

This package should include the following:

Component Description Qty.

90207734000 MCII-e Front Card Assembly 1

90207734500 MCII-e Back Card Assembly 1

59000240 Screw, M2.5-45x10 PH Pan Head M/S DIN

7985A Zinc

93507734000 Master Controller User Manual 1

38110387 RTS Warranty Lincoln 3 year 1

90207562010 Cable, SCSI-III 10 Ft. Amp 750732-4 1

4

Page 3

Table

of

Contents

Introduction .........................................................3

Introduction .........................................................4

Features ................................................................4

Specifications ......................................................4

System Diagram ..................................................5

Reference View - Front Card ..............................6

Reference View - Back Card ...............................8

DIP Switches .......................................................8

Connector Pinouts .............................................10

Configuring the MCII-e .....................................13

System Requirements ........................................14

Ethernet Setup for MCII-e

System Controller ..............................................14

Set the IP Address for the

MCII-e System Controller .................................14

Download Firmware for the

MCII-e System Controller .................................16

Accessories ........................................................ 19

Accessories ........................................................ 20

XCP-ADAM-MC Master Controller

Breakout Panel ...................................................20

AZedit ................................................................ 20

Trunking Systems ..............................................20

UIO-256 .............................................................20

PAP .................................................................... 21

LCP .................................................................... 21

GPI/O (General Purpose Input/Output) .............21

Trunking and the MCII-e System ......................23

Trunking and the MCII-e System Controller ....24

Page 4

Page 5

In this chapter

CHAPTER 1

Intr oduction

• Introduction

• Features

• Specifications

• Reference View - Front Card

• Reference View - Back Card

• DIP Switches

• Connector Pin-out s

3

Page 6

Introduction

Introduction

The RTS MCII-e System controller card is the third generation controller for the ADAM Intercom System. Designed to

replace the ADAM-MC, it adds a number of key features. Adding Ethernet connectivity between the ADAM Intercom and the

PC running AZedit, the new controller can support up to 35 simultaneous AZedit sessions (32 using Ethernet and up to 3 using

serial ports). Using a pair of MCII-e controller cards will provide full redundancy with seamless automatic change-over upon

failure.

The speed of Ethernet, combined with expanded memory, allows the card to fully support large matrices with reduced setup

file download time.

As with all ADAM™ Intercom family products, the MCII-e card supports all standard, hot-swappable, and configurable

features through the AZedit configuration software. It is fully compatible with existing ADAM systems and cards, including

AIO-8, AIO-16, AES-3, and RVON VOIP interfaces

*The New MCII-e System Controller card is only for use in the ADAM Matrix Intercom System and cannot be intermixed with older ADAM

master controllers in a given frame.

Features

Installation: The MCII-e System Controller card is hot-swappable and installs into slots 19 or 20 in an

ADAM™ Intercom System.

®

Trunk Capable: The MCII-e System Controller card supports ancillary data control for use with Telex

Trunking.

Ethernet Compatible: Fully Ethernet capable. The MCII-e provides a single RJ-45 connection for use with a 10BASE-T

or 100BASE-TX compliant and network. Each system contro ller ha s its own IP address network

access.

AZedit Configurations: The MCII-e can connect to AZedit via Ethernet or Serial (RS-232) connections. Also, the new

Intercom Sizing Wizard in AZedit makes configuring the new system controller card easier than

ever.

Controls: Reset push-button switch, general indicators, an LED module for advanced monitoring features and

for gathering additional card information.

Intelligent

Specifications

Power

7.5W/ 1.5A @ 5V

Physical

5.687” (144.45mm) W x 11.024” (280.01 mm) L

Connectors

SCSI connector via backcard

RJ-45 Ethernet via backcard

Miscellaneous

4 Mbytes of Code Flash

4

Page 7

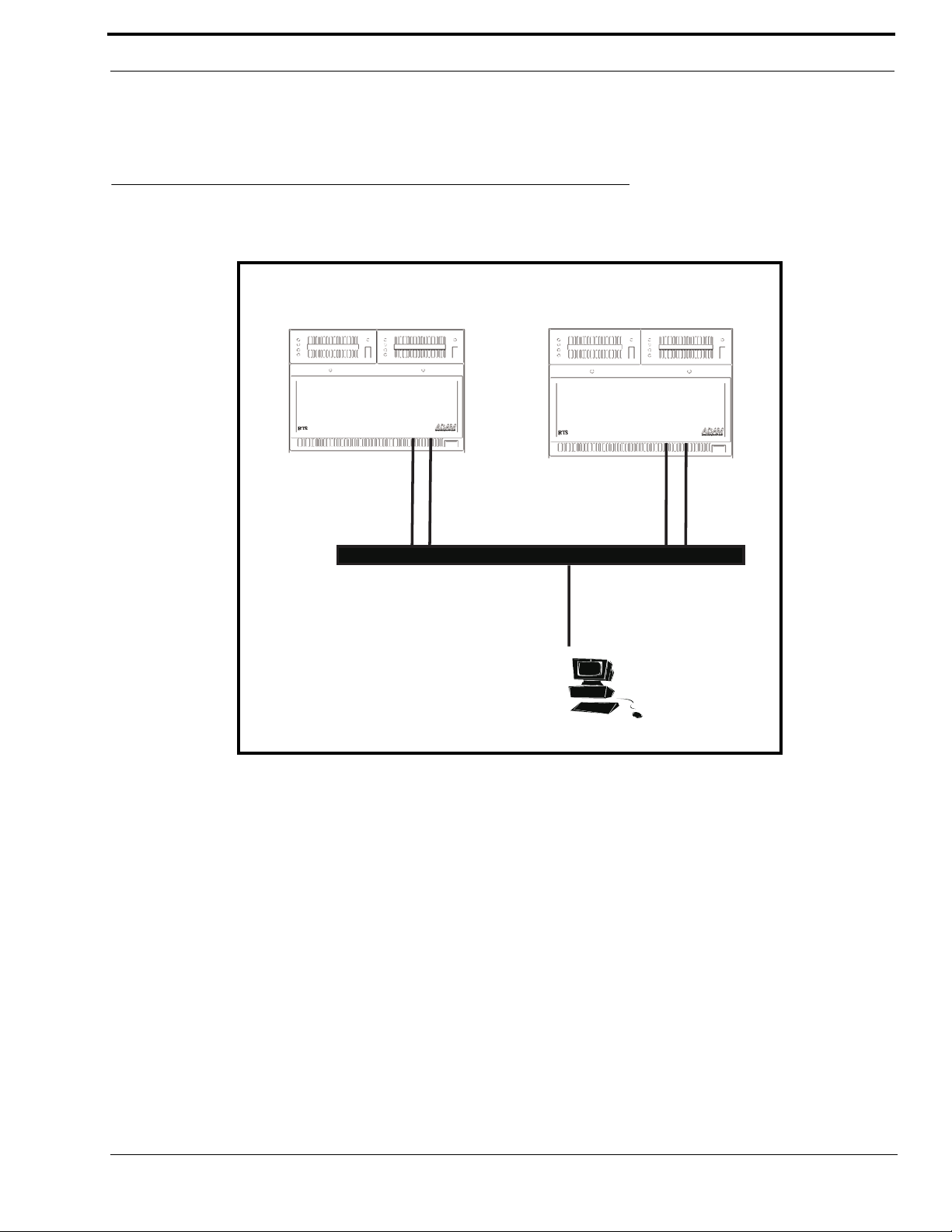

System Diagram

MCII-e

AZedit

A

DAM

MCII-e

A

DAM

LAN

MCII-e

MCII-e

32 MB of SDRAM

8Mbytes Configuration Flash

System Diagram

Figure 1. System Diagram - MCII-e Master Controller

5

Page 8

Introduction

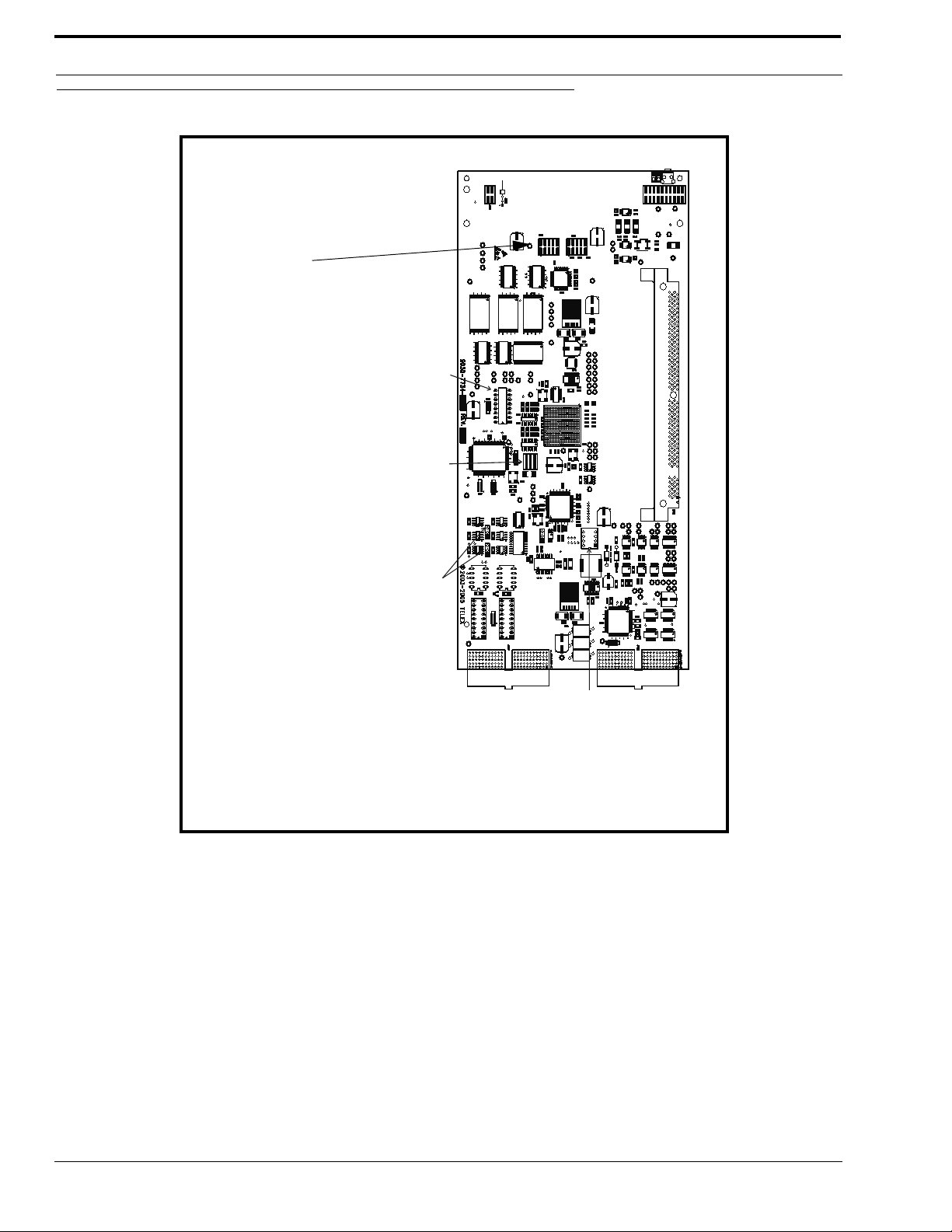

J900

LEDB

SW01

LEDA

SE02

DIP SWITCH BANK

J500 AND J501

RS-232 OR RS-485

FOR J1 AND J2 SERIAL PORTS

J100

DEBUG SERIAL

PORT

J500 (Azedit #1, J1)

J501(Trunking, J2)

RS-232

1 & 2 (default)

2&3

RS-485

2&3

1 & 2 (default)

SE01 -

FOR INTERNAL USE ONLY

ALL DIP SWITCHES MUST BE

IN OFF POSITION

Jumper Settings

For

Programming Use

ONLY!

J801 Pins 1 & 2 must be

shorted.

Pins 3 & 4 must be

shorted.

Reference View - Front Card

Figure 2. MCII-e System Controller Card Board view.

6

Page 9

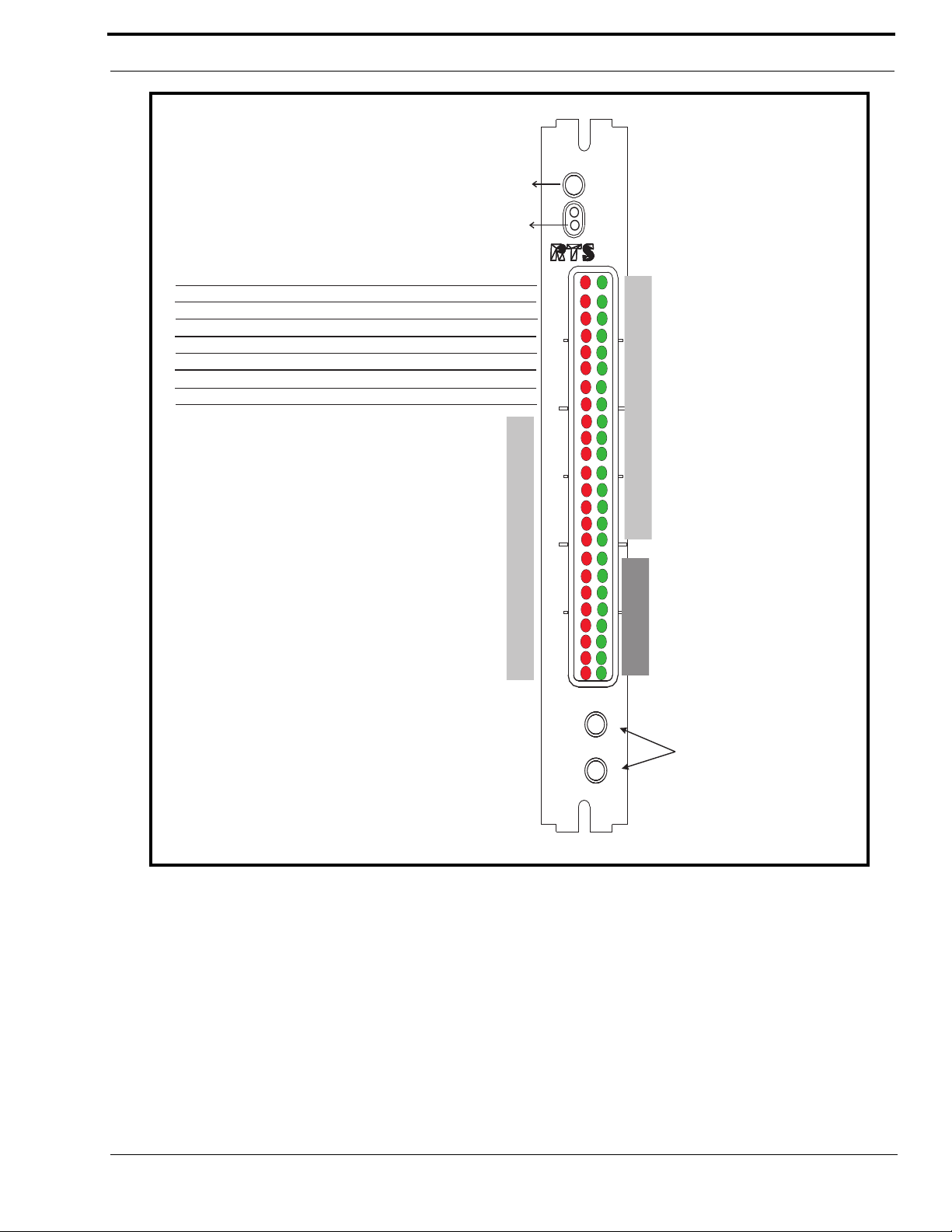

Reference View - Front Card

0

MCIIe

CONTROLLER

SYSTEM

2

1

15

7

1

3

2

5

4

6

11

9

8

10

13

12

14

22

16

18

17

20

19

21

23

TM

RESET

Gives (in binary) the

slot number (1-19) of

the card that the MC

is currently talking with

over the control bus.

Or when all the LEDs are

off, the MC isn’t

talking to a card over

the control bus.

This changes rapidly in

normal operation.

The rest of the green LEDs

show which IO cards are

alive.

For example,

23 = I/O Card in Slot 16 is alive and talking

...

10 = I/O Card in Slot 3 is alive and talking

9 = I/O Card in Slot 2 is alive and talking

8 = I/O Card in Slot 1 is alive and talking

NOTE: There is no LED for I/O card in slot 17.

ON, if acting as the active controller. OFF, if acting as standby.

Flashes while transmitting data on control bus to another card

Flashes while receiving data on control bus from another card

Flashes while transmitting data on private bus to active or standby partner controller

ON, if Trunk Master is alive and connected.

Not used (future)

Not used (future)

Flashes while receiving data on private bus from active or standby partner controller

Illuminated when the corresponding internal task is running

Reset Button

Fail LEDs

Push button 1 Bypass Debug-ONLY

Push Button 2 Unassigned

Figure 3. LED Descriptions for the MCII-e

7

Page 10

Introduction

ETHERNET

J1

J2

LINK

ACT

RJ-45 Ethernet Connection

68-pin SCSI Connection

ON

SE02

1

23

4

5

67

8

Closed

Open

Reference View - Back Card

Figure 4. Back Card

DIP Switches

Figure 5. Dip Switch SE02

DIP Switch 1: Debug Only! Must be in OPEN position.

DIP Switch 2: Sets the baud rate for the AZedit serial connection via J1. By default, AZedit is set for COM 1

and 38,400 kbps (38.4K). The baud rate set in AZedit must match the baud rate setting of the

Master Controllers in ADAM.

DEFAULT = OPEN

OPEN = 9600

CLOSED = 38.4k Baud

DIP Switches 3, 4, and 5: Reserved, keep in OPEN position.

DIP Switch 6: Debug Only! Must be in OPEN position.

DIP Switch 7: Determines Master/Slave Frame in a multi-frame

system.

8

Page 11

DIP Switches

DEFAULT = CLOSED

OPEN = Slave Frame

CLOSED = Master Frame

DIP Switch 8: Debug Only! Must be in OPEN position .

Warning: DIP Switches 1, 6, and 8 should always be left in the OPEN position. These are reserved for debugging

and can have unintended consequences.

9

Page 12

Introduction

Connector Pinouts

68-pin Master

Controller

1 1 RS485 TX/RX3 2 RS232C RX

37 3 RS232C TX

4 4 RS422 TX2 5 Ground

2 6 Ground

38 7 RS422 TX+

35 8 RS485 TX/RX+

68-pin Master

Controller

5 1 RS485 TX/RX36 2 Ground

6 3 RS232C RX

41 5 RS422 TX+

39 6 RS485 TX/RX+

36 7 Ground

40 8 RS232C TX

7 9 RS422 TX-

XCP-ADAM-

Trunking System

XCP-ADAM-

AZedit #1

J-1 of

Assignment 2W

MC

9

J-2 of

Assignment 2W

MC

4Not Used

UIO-256/PAP/LCP

68-pin Master

Controller

8 1 RS485 TX/RX9 2 Ground

44 5 RS422 TX+

42 6 RS485 TX/RX+

9 7 Ground

10 9 RS422 TX-

68-pin Master

Controller

11 1 RS485 TX/RX43 2 Ground

46 5 RS422 TX+

45 6 RS485 TX/RX+

43 7 Ground

12 9 RS422 TX-

J-3 of

XCP-ADAM-MCAssignment 2W

3Not Used

4Not Used

8Not Used

General Purpose

J-4 of

XCP-ADAM-MCAssignment 2W

3Not Used

4Not Used

8Not Used

10

Page 13

Connector Pinouts

General Purpose / Bus Exp.

General Purpose

68-pin Master

Controller

11 1 RS485 TX/RX14 2 Ground

47 6 RS485 TX/RX+

14 7 Ground

General Purpose / Bus Exp.

68-pin Master

Controller

15 1 RS485 TX/RX48 2 Ground

49 6 RS485 TX/RX+

48 7 Ground

J-5 of

XCP-ADAM-

MC

3Not Used

4Not Used

5Not Used

8Not Used

9Not Used

J-6 of

XCP-ADAM-MCAssignment 2W

3Not Used

4Not Used

5Not Used

8Not Used

9Not Used

Assignment 2W

68-pin Master

Controller

16 1 RS485 TX/RX17 2 Ground

50 6 RS485 TX/RX+

17 7 Ground

General Purpose / Bus Exp.

68-pin Master

Controller

18 1 RS485 TX/RX51 2 Ground

52 6 RS485 TX/RX+

51 7 Ground

J-7 of

XCP-ADAM-

MC

3Not Used

4Not Used

5Not Used

8Not Used

9Not Used

J-8 of

XCP-ADAM-

MC

3Not Used

4Not Used

5Not Used

8Not Used

9Not Used

Assignment 2W

Assignment 2W

11

Page 14

Introduction

General Purpose

AZedit #2

68-pin Master

Controller

J-9 of

XCP-ADAM-

MC

Assignment 2W

1Not Used

19 2 Ground

20 3 RS232C RX

4Not Used

5Not Used

6Not Used

19 7 Ground

53 8 RS232C TX

9Not Used

AZedit #3

68-pin Master

Controller

J-10 of

XCP-ADAM-

MC

Assignment 2W

1Not Used

67 2 Ground

21 3 RS232C RX

4Not Used

5Not Used

6Not Used

67 7 Ground

54 8 RS232C TX

9Not Used

J-11 of

Assignment Signal

Controller

68-pin Master

22 1 MI (0) Logical Input (0)

23 2 MI (1) Logical Input (1)

24 3 MI (2) Logical Input (2)

25 4 MI (3) Logical Input (3)

26 5 MI (4) Logical Input (4)

27 6 MI (5) Logical Input (5)

28 7 MI (6) Logical Input (6)

29 8 MI (7) Logical Input (7)

30 9 Ground Ground

31 10 Ground Ground

32 11 Ground Ground

33 12 Ground Ground

34 13 Ground Ground

55 14 MO (0) Logical Output (0)

56 15 MO (1) Logical Output (1)

57 16 MO (2) Logical Output (2)

58 17 MO (3) Logical Output (3)

59 18 MO (4) Logical Output (4)

60 19 MO (5) Logical Output (5)

61 20 MO (6) Logical Output (6)

62 21 MO (7) Logical Output (7)

63 22 Ground Ground

64 23 Ground Ground

65 24 Ground Ground

66 25 Ground Ground

XCP-ADAM-MC

12

Page 15

In this chapter

• System Requirements

• Ethernet Setup for the MCII-e System Controller

• Download Firmware for the MCII-e System Controll er

CHAPTER 2

Configuring the MCII-e

13

Page 16

Configuring the MCII-e

System Requirements

Before you configure your MCII-e System Controller card, verify the following items are updated:

• AZedit v 2.08.01 or later

• AIO-8 v 10.3.4 or later

• AIO-16 v 1.0.0 or later

• Periph-IIe, requires DBX v1.14.0 or later

NOTE: Field upgrade of DBX will requires Boot Code upgrade to version 0.0.3. If the Boot Code is not upgraded, the DBX

card will not work with the MCII-e. Refer to DBX Boot Code Upgrade (pn 38110-472.

Ethernet Setup for MCII-e System Controller

Set the IP Address for the MCII-e System Controller

NOTE: The PC must be running version 2.08.01 or later of AZedit and have an Ethernet card installed. The MCII-e can

support up to 32 concurrent sessions of AZedit on Ethernet.

Verify the MCII-e is connected to the PC using a RS232 (ADAM standard) cable. Connect J1 on the XCP-ADAM-MC to the

COM port on the PC.

NOTE: For more information on Network Basics, see the Basic Networking Guide found at our website

www.telex.com/Intercoms/files.nsf/sitemap#Brochures), under Applications.

If there are two controllers, they must each have their own unique IP Addresses (different from each other and any other

devices sharing the same network).

To connect the Active MCII-e to the PC with a serial cable, do the following:

1. Open AZedit.

The Keypanels/Ports screen appears.

(http://

14

Page 17

Ethernet Setup for MCII-e System Controller

2. From the Option menu, select Ethernet Setup.

The Ethernet Setup screen appears.

3. In the IP Address field, enter the IP Address for the current MCII-e System Controller.

4. In the Network Mask field, enter the Network Mask number for the current MCII-e System Controller.

5. Where appropriate, in the Default Gateway field, enter the Gateway number for the MCII-e System Controller.

NOTE: If the MCII-e will communicate with hosts outside its network, enter the IP address of a host or router which will

serve as the Gateway. Otherwise, if the MCII-e only needs to communicate with the local network, leave the

Default Gateway field at its default setting (0.0.0.0).

The Default Gateway is normally configured the same on both the active and standby MC-II-e System Controller

Cards.

The same screen you use to set the network settings can be used to view the settings as well. You must be

connected using a serial connection via J1 to make changes, but you can view them with any type of AZedit

connection (J1, J9, J10, or Ethernet).

6. Click Apply.

7. Click Close.

The Ethernet Setup window is closed.

8. Connect the MCII-e System Controller to your network with an Ethernet cable.

NOTE: The unique Ethernet MAC address assigned to each MCII-e card during manufacturing is displayed in the field

MAC Address. It is NOT possible to modify this address.

9. Connect the PC to your network with an Ethernet cable.

NOTE: If you do not know these numbers, your system administrator can give you the IP Address and Netmask to use.

Once you have entered the IP Address and Network Mask, do the following:

1. From the Options menu, select Communications.

The Communication screen appears

15

Page 18

Configuring the MCII-e

2. In the Connection area, select the Network radio button.

3. In the IP Address field, either enter the MCII-e IP Address you wish to connect with, or click the Search button .

The search button scans the network for any MCII-e devices. If multiple units are on the network, each will appear in

the list.

4. Select the MCII-e System Controller you wish to work with.

5. Click OK.

The Communications screen closes. The IP Address is configured in AZedit for the MCII-e System Controller.

Download Firmware for the MCII-e System Controller

WARNING: The following procedure will cause one or more brief disruptions in intercom communications. Also, SAVE

your intercom system configuration. From the File menu, select SAVE. Later, if you need to restore the

intercom configuration from disk, use Send File in the Online Menu.

Before you begin, be sure to verify that SERVER mode has been disabled. Also, it is extremely important to take the Standby

Controller card out of the frame, if one is installed.

NOTE: The Active Master Controller will have the topmost red LED (#23) on in the status window lit.

To download master controller firmware, do the following:

16

Page 19

Download Firmware for the MCII-e System Controller

1. From the Status Menu, select Software Versions.

A popup list appears.

2. From the Software Versions popup list, select Master Controllers.

The Master Controller Version Information screen appears.

3. Right-click the active Master Controller, and then select Download Firmware.

The Firmware Download screen appears.

NOTE: You can als o press Ctrl+Shift+D to open the Firmware Download screen once the Master Controller is

highlighted.

4. From the Firmware Download screen, select the firmware update file. Or use the browse button to navigate where

the new file resides.

5. Click Open.

The firmware update appears in the Download Firmware screen.

6. Click Begin Download.

This process can take as little as 30 seconds with “Fast Ethernet” or as long as five minutes when using a serial

connection at 9600 baud.

NOTE: If there is any disruption in the communications link during the download, you wi ll get an error message. In this

case, repeat the download.

7. When the file has been completely downloaded, the MCII-e System Controller will begin processing the update.

IMPORTANT! Any disruption at this point, such as loss of power, removing or resetting cards may result in Master

Controller failure. If this happens, you will have to return the affected unit for replacement or repair.

The AZedit session goes offline for 15-20 seconds when the card performs a reset. It automatically will reconnect when it is

finished.

When the Master Controller is finished, the new software version will appear in the version field of the Version Status screen.

If you do not have a Standby Master Controller Card, you can skip steps eight and nine.

8. Once the Active Master Controller is updated, remove it from the frame.

9. Insert the Standby Master Controller and repeat steps three through eight.

10. When the Standby Master Controller is finished, insert both controllers and resend your system setup file.

17

Page 20

Configuring the MCII-e

18

Page 21

In this chapter

• Accessories

• AZedit

• UIO-256

• PAP

• LCP

• General Purpose

CHAPTER 3

Accessories

19

Page 22

Accessories

Accessories

figure 6. Connection Diagram. The 68-pin SCSI can be attached to the

XCP-ADAM-MC.

NOTE: AZedit sessions are only enabled on J9 or J10 when the advanced communication boxes are enabled from

“communications” screen and the correct baud rates are configured.

XCP-ADAM-MC Master Controller Breakout Panel

The XCP-ADAM-MC Breakout Panel allows many different peripherals to be connected to the master controller of an ADAM

Intercom System, such as AZedit, trunking systems, UIOs, PAPs, LCPs, GPI/Os, etc. For the breakout panel pinouts, see pages

9-15.

AZedit

AZedit is a Windows®-based, full-featured configuration software, providing online and offline configuration capabilities. It

gives you the ability to manage multiple intercom systems, assign and reassign users to dif ferent ports, as well as dynamically

add hardware to your system setup without jumper changes, rewiring, or taking the system offline. AZedit has the capability to

load pre-set configuration files, which means configurations saved to a disk can be uploaded to the “live” application at

anytime, without interruption.

The XCP-ADAM-MC breakout panel has three DB-9 connectors that can be used to connect to AZedit (AZedit #1, #2, and

#3).

Trunking Systems

The RTS™ Trun king System manages intercommunications between separate intercom systems using intercom ports that

have been reserved and interconnected between the intercom systems with devices in other frames. Keypanels or other data

devices can then communicate with devices in other frames.

UIO-256

Each UIO-256 provides 16 GPI inputs and16 GPI outputs. The GPI inputs can be used just like keypanel keys to activate

intercom ports, party lines, relays, etc. Each relay output provides a choice of normal open and normal closed contacts. The

20

Page 23

Accessories

relays can be assigned for activation from keypanel keys, and can be used to control lighting, or to key remote transmitters,

paging systems, etc.

PAP

Program Assist Panels provide a fast and easy method of selecting any of several program sources (connected to input ports of

the intercom system) for use with the IFB outputs feature of the intercom system.

LCP

The LCP panel (Level Control Panel) combines the functionality of three products into one. The LCP allows you to adjust

analog input and output gains, assign sources to IFB outputs and make changes on the fly, and to add members to a party line

on the fly.

GPI/O (General Purpose Input/Output)

J11 provides 8 general purpose control inputs and 8 general purpose control outputs. The control inp ut s ca n be used just like

keypanel keys to activate intercom port s, party lines, relays, etc. The control outputs are open-collector, active-low outputs.

They can be activated by keypanel keys and can be used to control lighting, to key a remote transmitter, to activate a paging

system, etc.

Pin-outs for the digital inputs and outputs are summarized in the table on page 15.

21

Page 24

Accessories

22

Page 25

T runking and the MCII-e System

In this chapter

• Enable Trunk Support for MCII-e System Controller Card

• Connect MCII-e to the Trunk Master (Data)

• Configure TrunkEdit and AZedit to Communicate with the MCII-e System Controller Card

CHAPTER 4

23

Page 26

Trunking and the MCII-e System

Trunking and the MCII-e System Controller

Trunking allows one intercom system to communicate with another remote intercom system with devices in other frames. For

example, a user in New York can talk to a user in Los Angeles if the systems they are using are trunked together. T runking can

be configured to work with cables, fiber optics, voice over internet protocol, or any form of audio/data transfer media, to allow

communication between systems.

To trunk the MCII-e System Controller Card, do the following:

ENABLE TRUNK SUPPORT IN AZEDIT

1. From the AZedit main menu, select Options.

The Options sub-menu appears.

2. From the Options sub-menu, select Preferences.

The Applications Preferences screen appears.

3. On the Applications Preferences screen, click the Advanced tab.

The Advanced screen appear.

4. On the Advanced screen, select Enable trunking support.

5. Click OK to save the change and close the screen. Or, click Apply to save the change and leave the screen open.

When your system has limited bandwidth, you want to set the Allow for Remote T runk Master. By setting this option, the baud

rate is changed to 9600 baud, instead of the default, 38.4K.

To enable the Remote Trunk Master, do the following:

WARNING!: Enabling this option will cause the system to reset. All data will be erased in the frame. Be s ure to save

your system setup to disk before performing this task.

1. Remove the Standby Master Contoller.

2. From the AZedit main menu, select Options.

The Options sub-menu appears.

3. From the Options sub-menu, select Intercom Configuration.

The Intercom Configuration screen appears.

4. On the Intercom Configuration screen, click the Options tab.

The Options screen appears.

5. On the Options screen, select Allow for remote trunk master.

6. Click Test to verify the intercom will accept the new settings.

7. Click Apply.

The intercom will stop communicating with AZedit, reconfigure itself, and then reset.

8. Resend the current setup.

9. Replace the standby contr o ller.

It will automatically reconfigure itself to match the new settings.

CONNECT THE MCII-e TO THE TRUNK MASTER (DATA)

To connect MCII-e to the Trunk Master, do the following:

1. Connect the MCII-e System Controller Card data connecto r to on e of the eight DB-9 connecti ons on the ICP-2000.

CONFIGURE THE TRUNKMASTER TO COMMUNICATE WITH

THE MCII-e SYSTEM CONTROLLER CARD

24

Page 27

Trunking and the MCII-e System Controller

To setup the TrunkMaster to be able to communicate with MCII-e, do the following:

1. Open TrunkEdit.

2. In the left navigation, open the Intercom slide screen.

The Intercom navigation panel displays.

3. From the Intercom navigation, select Setup.

The Intercom Setup screen appears.

4. In the Intercom Setup screen, enter the Intercom System Name (i.e.; ADAM) in the appropriate ICOM port (for

example, if the MCII-e System Controller is cabled to the ICP-2000’s J4 connector, then in the Intercom Setup

screen, enter the MCII-e’s machine name in the line which corresponds with the COM port #4 field).

5. Select the Baud Rate field and enter the baud rate to match the baud setting of the Intercom Trunking port (38.4K or

9600).

6. When you are finished, click the Send button to send the changes to the Trunk Master. When the changes are sent to

the Trunk Master, the MCII-e connects to the Trunk Master and uploads the remote ports. Once the MCII-e has

uploaded this data, it sends its port alphas to the Trunk Master.

In AZedit

1. Open AZedit.

2. On the main screen, select the port you want to make available remotely..

3. In the Scroll Enable field, select Trunk and AZedit.

By enabling Trunk and AZedit on this port, remote users will display in AZedit and remote keypanel users will be able

to see enabled ports.

NOTE: We recommend that you only enable user positions that will be used by remote systems.

4. Send the changes to AZedit.

25

Page 28

Trunking and the MCII-e System

In TrunkEdit - Define the trunk line

NOTE: We recommend you map out your system before defining the trunk lines.

Defining the trunk line shows where a trunk line begins and ends, as well as shows the audio connections between frames.

To define trunk lines, do the following:

1. Open TrunkEdit.

2. In the left navigation, open the Trunk slide screen.

The Trunk Definitions for: All Intercoms panel displays.

3. In the ICOM 1 field, enter the intercom name of one end of the trunk connection (i.e.; ADAM).

4. In the Port Field, enter the port number where ICOM1 is assigned (i.e.; N014). Or, in the Alpha field, enter the

Alpha of the ICOM1 system (i.e.; N014).

5. In the ICOM2 field, enter the name of the system ICOM1 is linked to (i.e.; INT1).

6. In the Port field, enter the port number where ICOM2 is assigned (i.e.; N005). Or , in the Alpha field, enter the alpha

of the ICOM2 system.

7. Once finished with all your definitions, Send the changes to the TrunkMaster.

In AZedit

Once you are finished defining the trunk lines of your system, you can use AZedit to make key assignments for the keypanels.

With Trunking enabled, you will be able to see all trunked system and their ports enabled in AZedit.

26

Loading...

Loading...