SmartAlarm Instruction Manual Rev 2

Page 1 of 115

Warning

The SmartAlarm Annunciator described herein operates on a logic voltage of

24VDC and as standard 24VDC is used for the field contact supply voltage.

Internal or external power supplies using higher voltage AC/DC primary

sources and optional high voltage field contact voltages may be present.

If this is the case please ensure the necessary precautions are taken.

REV

DATED

DESCRIPTION

AUTHOR

APPROVED

0

28-08-13

First Issue

P. Cartmell

A. Ibbetson

1

04-09-13

Added details for Watchdog LED1 & 2

A Ibbetson

P. Cartmell

2

06-09-13

Updated field contact supply options

A Ibbetson

D Fishkin

SmartAlarm Alarm Annunciator

SmartAlarm Instruction Manual Rev 2

Page 2 of 115

Annunciator Model Code Definition ......................................................... 6

SECTION 1 - INTRODUCTION .................................................................... 8

General ............................................................................................................................. 8

Available Versions ............................................................................................................ 8

Card Locations .................................................................................................................. 9

Common Services Card .................................................................................................. 10

Alarm Cards (8 Channel) ................................................................................................ 10

Pluggable LED’s ............................................................................................................. 11

Input Isolation .................................................................................................................. 12

Bi-Polar Inputs ................................................................................................................ 12

Standard Input Version ................................................................................................... 12

Optional Powered Input Versions ................................................................................... 12

Integral Pushbuttons ....................................................................................................... 12

Customer Terminals ........................................................................................................ 12

Terminals For Use With External Pushbutton Inputs ...................................................... 13

Internal Audible Alarm ..................................................................................................... 14

HNA & HNB Horn Relays ................................................................................................ 15

GPA & GPB Common Alarm Group Relays ................................................................... 15

WD Watchdog Relay ....................................................................................................... 16

Watchdog Monitoring LED’s ........................................................................................... 17

Standard Mode - LED indication ..................................................................................... 17

Diagnostic / Program mode - .......................................................................................... 18

Dynamic Contact Status ................................................................................................. 18

Diagnostic / Program mode - Manually changing the input type .................................... 19

Diagnostic / Program mode - Communication Monitoring .............................................. 20

Programmable Features ................................................................................................. 21

Film Legends .................................................................................................................. 22

Window Numbering System............................................................................................ 23

USB Programming Port .................................................................................................. 24

SECTION 2 – PRIMARY POWER ............................................................. 25

Primary Power – PS1 ...................................................................................................... 25

SECTION 3 – AUX POWER (Future) ....................................................... 26

Aux Power – PS2 ............................................................................................................ 26

SECTION 4 – SIGNAL INPUT TYPES ...................................................... 27

Internally Powered 24VDC Signal Inputs ........................................................................ 27

Signal Supply Fuse Location and FCV Link Details ....................................................... 28

24 or 48 VDC/AC Customer Powered Inputs ................................................................. 29

Alternative Connection Method ....................................................................................... 29

Signal Supply Fuse Location and FCV Link Details ....................................................... 30

125VDC/AC or 250VDC/AC Customer Powered Inputs ................................................. 31

Alternative Connection Method ....................................................................................... 31

Signal Supply Fuse Location and FCV Link Details ....................................................... 32

SECTION 5 – HORN RELAYS .................................................................. 33

HNA & HNB Horn Relays ................................................................................................ 33

SECTION 6 - COMMON ALARM GROUP RELAYS ................................. 34

GPA & GPB Group Relays ............................................................................................. 34

SECTION 7 - REMOTE PUSHBUTTON INPUTS ...................................... 35

Pushbutton Functions ..................................................................................................... 35

Group Inhibit Function ..................................................................................................... 36

Sleep Mode Function ...................................................................................................... 37

SECTION 8 - INDIVIDUAL CHANNEL REPEAT RELAYS ....................... 38

SmartAlarm Instruction Manual Rev 2

Page 3 of 115

Input Follower ................................................................................................................. 38

Logic Follower ................................................................................................................. 38

Display Follower .............................................................................................................. 38

Contact Rating ................................................................................................................ 38

SECTION 9 - TYPICAL SMARTALARM REAR VIEW .............................. 39

SECTION 10 - INSTALLATION ................................................................. 40

Unpacking ....................................................................................................................... 40

Mounting ......................................................................................................................... 40

Dimensions for panel mounting versions ........................................................................ 40

19” Rack Mounting .......................................................................................................... 41

Wall Mounting ................................................................................................................. 41

Floor Standing ................................................................................................................. 41

SECTION 11 - SOFTWARE INSTALLATION ............................................ 42

SECTION 12 – AUTO DETECT HARDWARE. ......................................... 44

SECTION 13 – IMPORT CSV FILE ........................................................... 45

Open Configuration ......................................................................................................... 45

SECTION 14 – EXPORT CSV FILE ........................................................... 46

Save Configuration ......................................................................................................... 46

SECTION 15 – CREATE A NEW SYSTEM ............................................... 47

SECTION 16 – SYSTEM SETTINGS ......................................................... 48

Auto Detect ..................................................................................................................... 48

View ................................................................................................................................ 49

Advanced ........................................................................................................................ 49

Front View of Annunciator............................................................................................... 49

Tools ............................................................................................................................... 50

Send Settings .................................................................................................................. 50

Receive Settings ............................................................................................................. 50

Restore Default Settings ................................................................................................. 50

Diagnostics ..................................................................................................................... 51

Set Structure ................................................................................................................... 51

Scan Unit......................................................................................................................... 51

Test Tools ....................................................................................................................... 51

General Tab .................................................................................................................... 52

Plant Name ..................................................................................................................... 52

Description ...................................................................................................................... 52

Tag No. ........................................................................................................................... 53

Serial No. ........................................................................................................................ 53

Address Offset ................................................................................................................ 53

Sleep Without Indication ................................................................................................. 53

CS Relays (Common Service Relays) ............................................................................ 54

Horn A - HNA .................................................................................................................. 54

Horn B - HNB .................................................................................................................. 55

Group A - GPA ................................................................................................................ 55

Group B - GPB ................................................................................................................ 55

Optional Settings ............................................................................................................. 55

Assigning Relays to Groups ........................................................................................... 55

Reflash Function ............................................................................................................. 56

Disable in System Test ................................................................................................... 56

Disable in Sleep Mode .................................................................................................... 56

Reflash Pulse Length ...................................................................................................... 56

Alternative Functions for any Relay ................................................................................ 56

Local Pushbuttons .......................................................................................................... 57

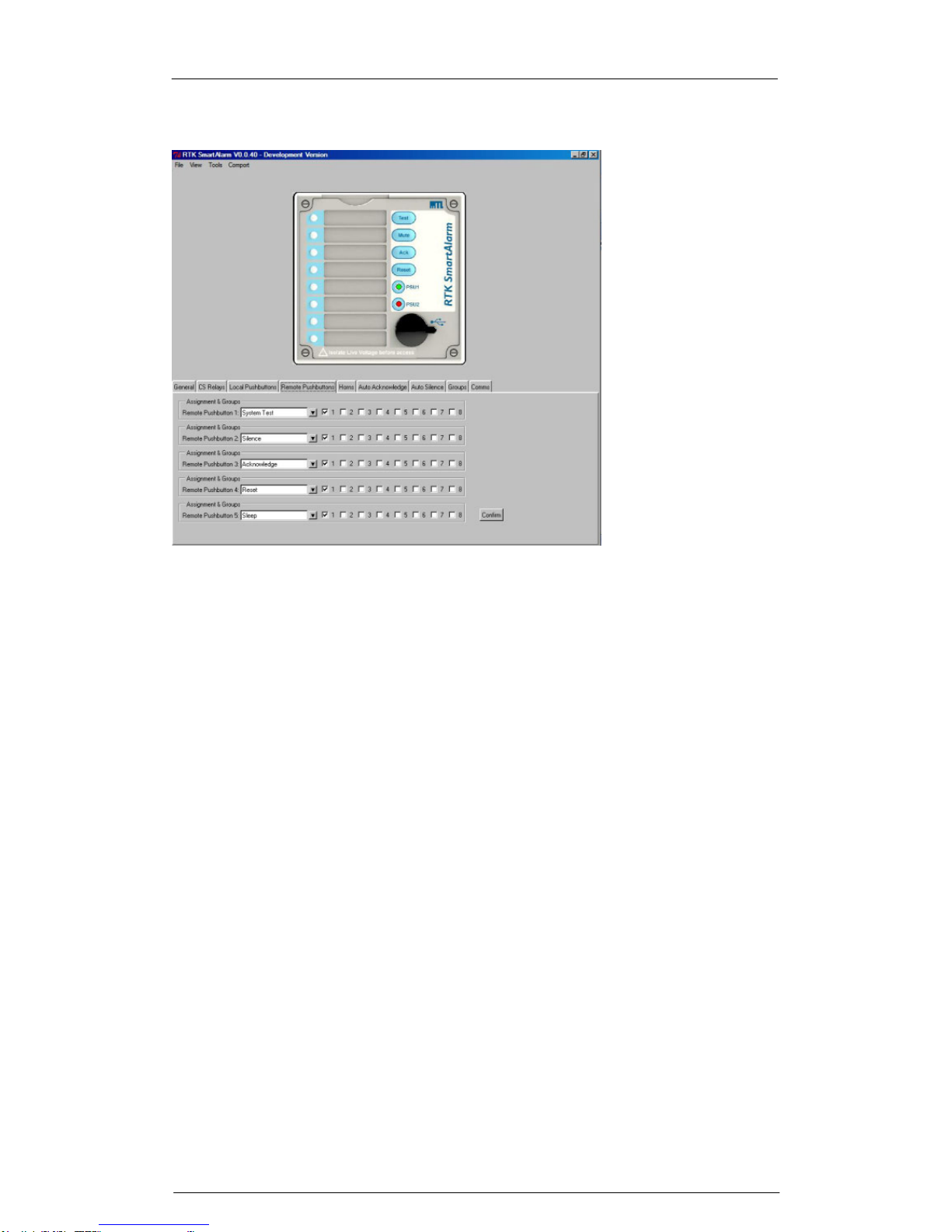

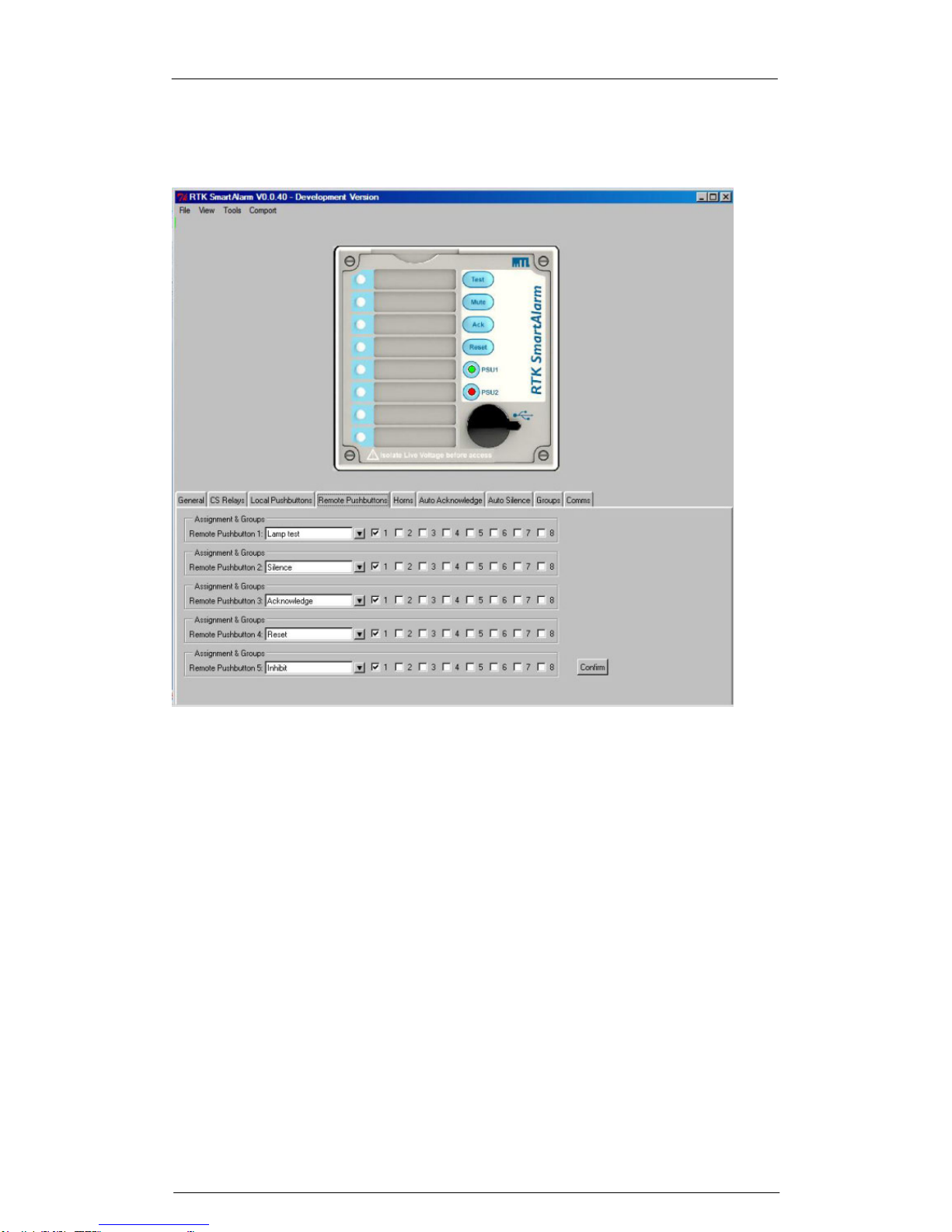

Remote Pushbuttons ...................................................................................................... 58

Inhibit Function ................................................................................................................ 59

SmartAlarm Instruction Manual Rev 2

Page 4 of 115

Assigning Channel to Inhibit Groups .............................................................................. 59

Assigning a Remote Pushbutton Input to Inhibit ............................................................. 60

Sleep Mode ..................................................................................................................... 61

Assigning a Remote Pushbutton Input to Sleep Mode ................................................... 61

Common Relay Operating In Sleep Mode ...................................................................... 63

Inhibiting Common Relays During Sleep Mode .............................................................. 63

Sleep Mode Heartbeat .................................................................................................... 64

Disabling Sleep Mode Heartbeat .................................................................................... 64

Horn ................................................................................................................................ 64

Auto Acknowledge .......................................................................................................... 66

Auto Silence .................................................................................................................... 67

Groups ............................................................................................................................ 68

Group Types ................................................................................................................... 68

First-Up Group ................................................................................................................ 68

Input Group ..................................................................................................................... 68

Audible Group ................................................................................................................. 69

Ring back Audible Group ................................................................................................ 69

Grouping Example .......................................................................................................... 70

........................................................................................................................................ 70

........................................................................................................................................ 70

........................................................................................................................................ 71

........................................................................................................................................ 71

Comm’s ........................................................................................................................... 72

SECTION 17 – INDIVIDUAL CHANNEL SETTINGS ................................. 73

Configuring Individual Channels ..................................................................................... 73

Configuring Selective channels ...................................................................................... 73

Configuring Multiple channels ......................................................................................... 73

Channel ........................................................................................................................... 74

Alarm Legend .................................................................................................................. 74

Manual Inhibit .................................................................................................................. 74

Group Inhibit ................................................................................................................... 74

Auto Shelving .................................................................................................................. 75

Input ................................................................................................................................ 76

Contact Type ................................................................................................................... 76

Delay Timers ................................................................................................................... 76

Abnormal Delay (mS) ...................................................................................................... 76

Normal Delay (mS) ......................................................................................................... 76

Remote............................................................................................................................ 77

Relay ............................................................................................................................... 78

Coil Status ....................................................................................................................... 78

Relay Function ................................................................................................................ 78

Abnormal Delay .............................................................................................................. 79

Normal Delay .................................................................................................................. 79

Sequence ........................................................................................................................ 80

ISA Sequences ............................................................................................................... 80

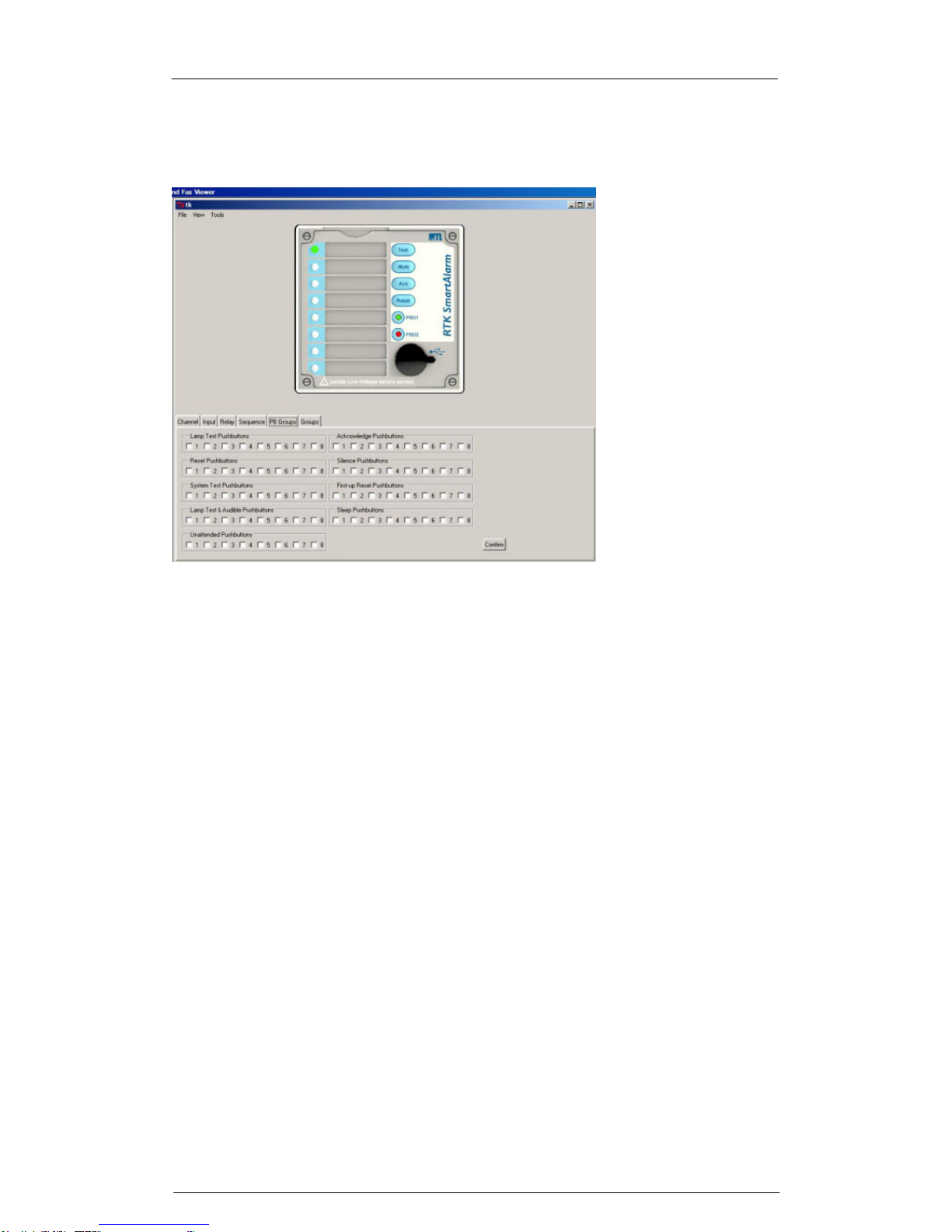

PB Groups ...................................................................................................................... 81

Global Pushbutton Group ............................................................................................... 81

Multiple Pushbutton Groups ........................................................................................... 81

Groups ............................................................................................................................ 82

SECTION 18 – ALARM SEQUENCES ...................................................... 83

ISA A – Automatic Reset – Lock In ................................................................................. 85

ISA A-1-2 – Automatic Reset – Silence Pushbutton Interlock ........................................ 86

ISA A-4 – Automatic Reset – Non Lock In ...................................................................... 87

ISA A-4-5 – Automatic Reset – No Flashing................................................................... 88

ISA A-4-5-6 – Status ....................................................................................................... 89

ISA A-5 – Automatic Reset – No Flash ........................................................................... 91

ISA M – Manual Reset – Lock In .................................................................................... 92

ISA M-1-2 – Manual Reset – Silence Pushbutton Interlock ............................................ 93

ISA R – Ringback ............................................................................................................ 94

SmartAlarm Instruction Manual Rev 2

Page 5 of 115

ISA F1A-1 – Automatic Reset First Up ........................................................................... 95

ISA F2M-1 – Manual Reset First Up ............................................................................... 96

ISA F2A-1 – Automatic Reset First Up ........................................................................... 97

ISA F3A – Automatic Reset First Up .............................................................................. 98

ISA F3A-3 – First Out Reset Interlock .......................................................................... 100

ISA F3M – Manual Reset First Out ............................................................................... 100

ISA F3M-1-2 – Manual Reset First Out with Silence Interlock ..................................... 100

SECTION 19 – COMMUNICATIONS ....................................................... 101

Connection Details ........................................................................................................ 101

Port 1 Connection Details – Smart Alarm ..................................................................... 101

MODBUS RTU .............................................................................................................. 102

Modbus Slave – Standard Communications................................................................. 104

Read Coil Status – Function 01 – Read Request – Master .......................................... 104

Read Coil Status – Function 01 – Read Response - Slave .......................................... 104

Read Status – Function 03 – Read Request – Master ................................................. 105

Read Status – Function 03 – Read Response - Slave ................................................ 105

Write Multiple Coils – Function 15 - Read Request – Master ....................................... 107

Write Multiple Coils – Function 15 – Read Response - Slave ...................................... 107

SECTION 20 - SPECIFICATIONS ........................................................... 108

Primary power supply ................................................................................................... 108

Aux power supplies (Future) ......................................................................................... 108

Quiescent current .......................................................................................................... 108

Signal Inputs ................................................................................................................. 108

Input response time ...................................................................................................... 108

First-Up discrimination .................................................................................................. 108

Individual channel repeat relays ................................................................................... 109

HNA & HNB Horn Relays .............................................................................................. 109

GPA & GPB Common Alarm Group Relays ................................................................. 109

Audible alarms .............................................................................................................. 109

Communications ........................................................................................................... 109

Environmental Specifications ........................................................................................ 110

Temperature ................................................................................................................. 110

Protection ...................................................................................................................... 110

Radiated RFI Immunity ................................................................................................. 110

Conducted RFI Immunity .............................................................................................. 110

Radiated Emissions ...................................................................................................... 110

Conducted Emissions ................................................................................................... 110

Radiated Power Frequency Magnetic Field .................................................................. 110

ESD Effects ................................................................................................................... 110

Dielectric Withstand ...................................................................................................... 110

Surge Withstand – Oscillatory ...................................................................................... 110

Electrical Fast Transient/Burst Immunity ...................................................................... 110

Surge Immunity ............................................................................................................. 110

LVD ............................................................................................................................... 110

SECTION 21- SPARE PARTS LIST ........................................................ 112

Common Services Card ................................................................................................ 112

Standard (8) Channel Alarm Card ................................................................................ 112

Spare LED assemblies ................................................................................................. 112

SECTION 22 - SERVICING ..................................................................... 113

Module Removal ........................................................................................................... 113

SECTION 23 – CONTACT ....................................................................... 114

Procedures for Factory Repair and Return Warranty ................................................... 114

RMA FORM .................................................................................................................. 115

SmartAlarm Instruction Manual Rev 2

Page 6 of 115

Annunciator Model Code Definition

Model No

SM

SmartAlarm

Type

A

Standard Annunciator

B

8 Way Basic Annunciator

C

Future

Alarm Ways

08

08 Way

16

16 Way

24

24 Way

Individual Channel Repeat Relays

X

No Individual Channel Repeat Relays Fitted

R

Individual Channel Repeat Relay Fitted

Primary Supply – Internal PSU-1

A

Universal Input 85-263VAC & 88-360VDC

OR as an option which must be specified at time of order

D

18-58VDC (Must Be Specified At Time Of Order)

Aux Supply – Internal PSU-2 (Future)

X

Not Fitted

A

Universal Input 85-263VAC or 88-360VDC

OR as an option which must be specified at time of order

D

18-58VDC (Must Be Specified At Time Of Order)

Field Contact (Signal Supply) Internal / External

A

Int Generated 24VDC / Ext Supplied 24VAC/DC & 125VAC/DC (Future)

B

Int Generated 48VDC / Ext Supplied 48VAC/DC & 250VACVDC (Future)

C

Int Generated 125VDC / Ext Supplied 24VAC/DC & 125VAC/DC (Future)

D

Int Generated None / Ext Supplied 24VAC/DC & 125VAC/DC

E

Int Generated None / Ext Supplied 48VAC/DC & 125VAC/DC (Future)

F

24VDC / 24 VDC/VAC (Special)

G

24VDC / 48 VDC/VAC

H

24VDC / 125 VDC/VAC

I

Not Fitted / 24 VDC/VAC (Special)

J

Not Fitted / 48 VDC/VAC (Special)

K

Not Fitted / 125 VDC/VAC (Special)

L

Not Fitted / 250 VDC/VAC

LED Colour

R

Red

Y

Yellow

G

Green

B

Blue

SmartAlarm Instruction Manual Rev 2

Page 7 of 115

W

White

I

Intermixed

Communications

X

Not Fitted

S

RS485 Serial Communications Fitted

Time Stamping (Future)

X

Not Fitted

T

Time Stamping Fitted

Ethernet (Future)

X

Not Fitted

I

IEC61850 Fitted

D

DNP3 Fitted

Tropicalisation

X

Not Fitted

C

Tropicalised

IP Rating

4

IP40 Rated

5

Optional IP54

Special Options

X

Not Fitted

(Future)- Indicates not currently available but scheduled as future option

SmartAlarm Instruction Manual Rev 2

Page 8 of 115

SECTION 1 - INTRODUCTION

General

The SmartAlarm is a panel mounting alarm annunciator used to inform the

operator that a process has gone beyond set limits using visual and audible

alarms.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

6

7

8

The system comprises the following key elements

1 x Face plate.

Laser printed film legend sheet/sheets.

1 x DIN sized flush mounting cabinet.

1 x Rear mounting motherboard complete with customer terminals.

1 x Common Services Card.

** x 8 Channel alarm card / cards (** qty depends on annunciator

size).

Available Versions

8, 16 or 24 Way versions are available using industry standard DIN Size

enclosures.

SmartAlarm Instruction Manual Rev 2

Page 9 of 115

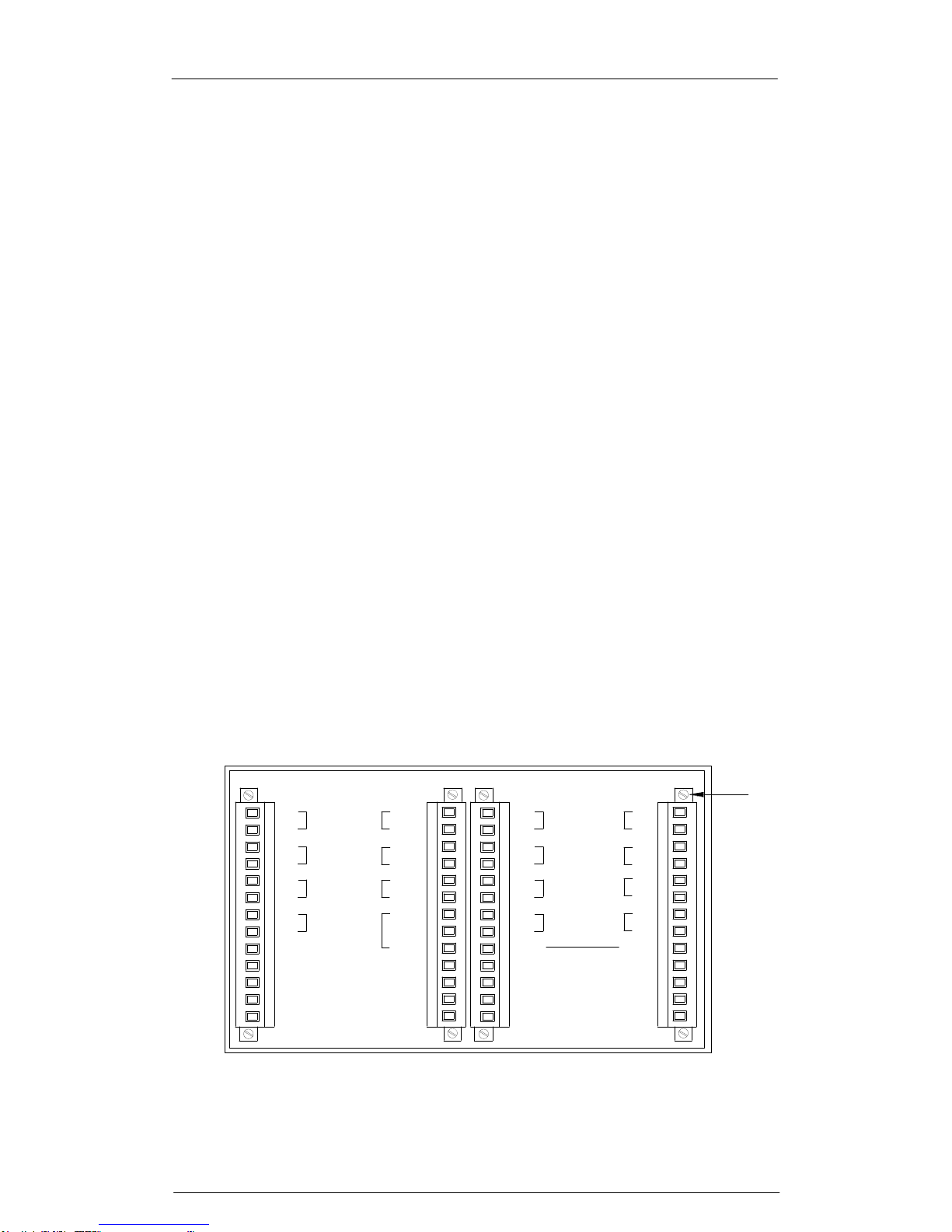

Card Locations

Four screws are provided on the face plate of the annunciator to allow access

to the internal cards.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

6

7

8

FACEPLATE RETAINING

SCREWS (x 4)

FACEPLATE RETAINING

SCREWS (x 4)

USING SCREW DRIVER

LEVER FACE PLATE HERE

Once the Faceplate has been undone access is available to the two types of

card used within the SmartAlarm.

ALARM CARD

COMMON

SERVICES

CARD

SmartAlarm Instruction Manual Rev 2

Page 10 of 115

Common Services Card

The Common Services Card is located in the right hand card slot of the

enclosure, (Position 0), when viewed from the front.

As Common Service cards can be powered from 85-263VAC/DC or 88

to 360VDC for safety reasons please ensure the supply is fully isolated

before removing the associated card.

Alarm Cards (8 Channel)

Alarm cards are located to the left of the Common Service card.

On 16 and 24 way versions multiple alarm cards are used.

The alarm cards are interchangeable however as the associated

configuration settings are stored on the individual cards if a card is

placed in the incorrect slot the setting may not match the monitored

process.

The Common Services card and Alarm card are polarised to prevent

insertion into the incorrect card slot.

SmartAlarm Instruction Manual Rev 2

Page 11 of 115

Pluggable LED’s

Each channel is illuminated by a pluggable LED located on the front of each 8

channel alarm card.

The LED assembly is held in place by 2 pins and the assembly can be

removed by pulling gently towards you.

ALARM CARD

COMMON

SERVICES

CARD

LED assemblies are available in the following colours:-

White .........(W).

Red ............(R).

Yellow ........(Y).

Green .........(G).

Blue ............(B).

Intermixed …….(I). (Specify colour required per channel).

Each LED requires 16mA max.

SmartAlarm Instruction Manual Rev 2

Page 12 of 115

Input Isolation

All signal inputs are optically isolated for use in harsh electrical environments.

Bi-Polar Inputs

All signal inputs are bi-polar and therefore capable of accepting AC or DC

voltages.

Standard Input Version

The standard version uses a fully isolated +24VDC supply as a signal voltage,

(fused at 160mA), which can be fed via a normally open (N/O) or normally

closed (N/C) field contact to trigger each alarm as required.

Optional Powered Input Versions

As an alternative Customer powered Inputs can be used:-

Option D = 24VAC/DC & 125VAC/DC or

Option E = 48VAC/DC & 250VAC/DC.

The signal supply voltage level must be specified at the time of order to

ensure the correct type alarm card is supplied.

Integral Pushbuttons

Four Integral Tactile Pushbuttons are provided as standard designated as

Test, Mute, Ack., (Acknowledge), and Reset.

Customer Terminals

Industry standard rising clamp terminals capable of accepting up to 2.5mm sq

cable are provided for customer use on the rear of the annunciator and each

terminal is held in place by retaining screws located at the top and bottom of

each terminal block for additional security.

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

X2X1

a

HNB

GPB

GPA

b

a

b

b

a

HNA

b

a

PB2

PB1

PB3

PB4

PB5

a

+VFC

IP3

IP1

IP2

b

b

a

a

b

RL7

RL3

RL4

RL8

RL2

RL6

a

b

X3

RL1

RL5

a

+VFC

IP7

IP8

IP5

IP6

b

b

a

a

b

a

b

X4

IP4

LOCKING

SCREWS

Typical Annunciator Rear View

SmartAlarm Instruction Manual Rev 2

Page 13 of 115

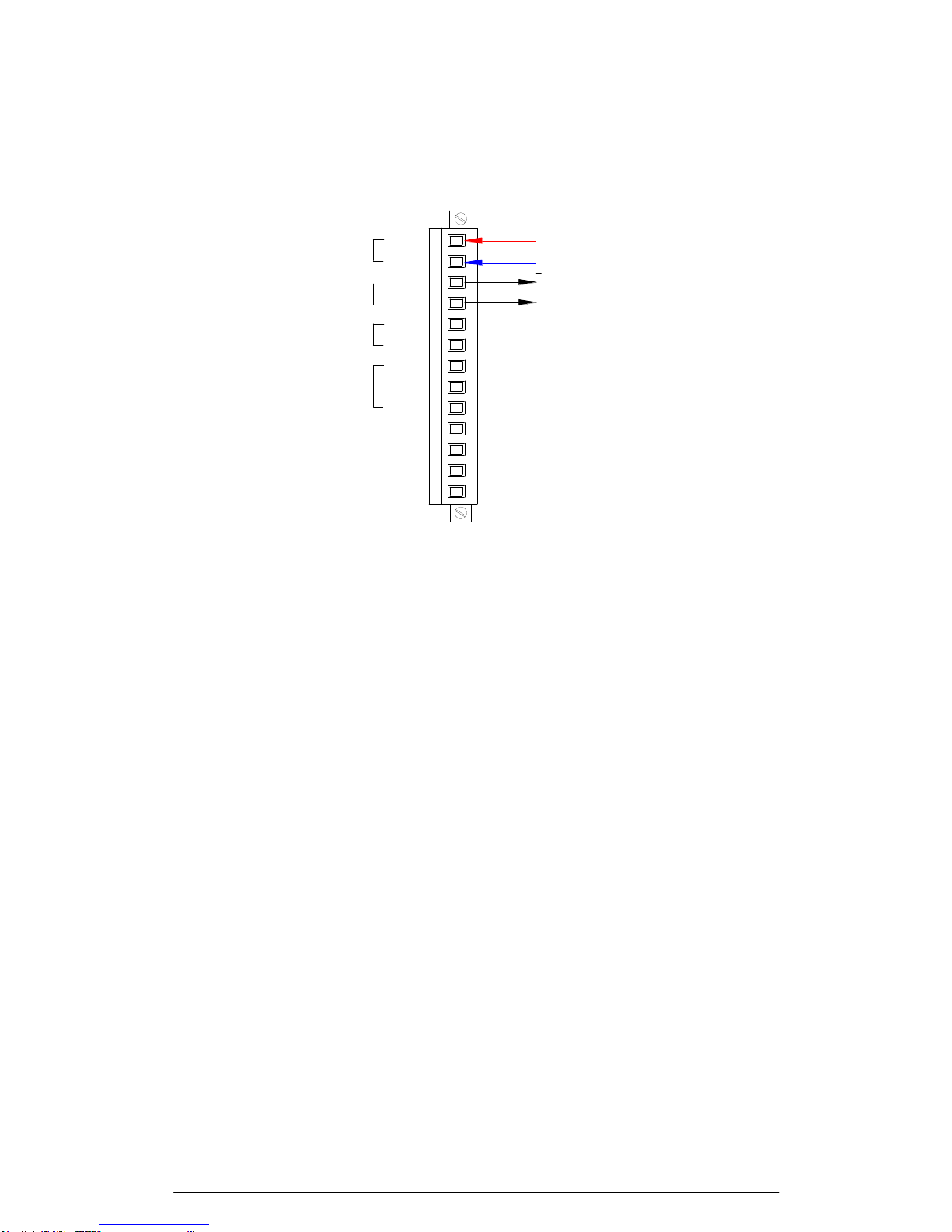

Terminals For Use With External Pushbutton Inputs

Five additional optically coupled inputs , PB1 to PB5, are available on the rear

of the annunciator for use with external pushbuttons, group inhibit or a sleep

mode switch as required.

The common return for the remote inputs is +VB.

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

X2X1

a

HNB

GPB

GPA

b

a

b

b

a

HNA

b

a

PB2

PB1

PB3

PB4

PB5

a

+VFC

IP3

IP1

IP2

b

b

a

a

b

RL7

RL3

RL4

RL8

RL2

RL6

a

b

X3

RL1

RL5

a

+VFC

IP7

IP8

IP5

IP6

b

b

a

a

b

a

b

X4

IP4

REMOTE

PUSHBUTTON

INPUTS

Please note: +VB is the same voltage source as the internally generated field

contact supply. Depending on the model the pushbutton control voltage could

be +24VDC or 125VDC (Future).

SmartAlarm Instruction Manual Rev 2

Page 14 of 115

Internal Audible Alarm

An integrally mounted 2.4Khz piezo horn is located on the common services

card and a potentiometer is provided to allow the user to adjust the volume as

required.

To access the potentiometer remove the 4 x retaining screws on annunciator

face plate and allow the plate to hinge to the left on the pushbutton ribbon

cable.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

6

7

8

FACEPLATE RETAINING

SCREWS (x 4)

To increase volume adjust the potentiometer in a clockwise direction.

ALARM CARD

COMMON

SERVICES

CARD

HORN

VOLUME

ADJUSTMENT

(Clockwise to

increase)

SmartAlarm Instruction Manual Rev 2

Page 15 of 115

HNA & HNB Horn Relays

Common Relay – HNA & HNB are used as Horn Relays and the following

options are software selectable:-

Any channel within the annunciator can be set to operate either relay

as required.

The relay coil state can be set to Normally Energised or Normally De-

Energised.

The relay can be disabled to prevent it operating on System Test.

The relay can be disabled to prevent it operating during Sleep Mode.

Relay mode is set to horn as default but can be modified to other

modes using the configuration software.

GPA & GPB Common Alarm Group Relays

Common Relay – GPA & GPB are used as Group Relays and the following

options are software selectable:-

Any channel within the annunciator can be set to a common alarm

group.

The group function can be set to “alarm” which keeps the signal active

until the alarm has been cleared.

Any “alarm” group within the annunciator can be linked to either relay

as required.

A reflash function can be selected per group which allows the contacts

to revert to normal and re-alarm each time a new alarm occurs within

the same group. The reflash pulse duration can be set between 1mS

and 65,000mS.

The relay state can be set to Normally Open or Normally Closed.

The relay can be disabled to prevent it operating on System Test.

The relay can be disabled to prevent it operating during Sleep Mode.

Relay mode is set to group as default but can be modified to other

modes using the configuration software.

SmartAlarm Instruction Manual Rev 2

Page 16 of 115

WD Watchdog Relay

A Watchdog Relay is available as standard to provide a signal to a 3rd party

device to indicate a fault has been detected within the annunciator. The

following options can be configured in software.

All faults.

Field contact fault.

System fault.

Comm’s fault.

Card fault.

LED fault.

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

X2X1

a

HNB

GPB

GPA

b

a

b

b

a

HNA

b

a

PB2

PB1

PB3

PB4

PB5

REMOTE

PUSHBUTTON

INPUTS

GROUP A

OUTPUT

GROUP B

OUTPUT

HORN B

OUTPUT

HORN A

OUTPUT

WATCHDOG

OUTPUT

Typical Volt Free Relay Contact Outputs

SmartAlarm Instruction Manual Rev 2

Page 17 of 115

Watchdog Monitoring LED’s

As alarm annunciators are used in safety critical applications it is important

that the functions of the annunciator are monitored and the SmartAlarm is

equipped with an extensive self-diagnostic facility including two green status

LED’s, in standard mode they provide dynamic monitoring of the logic supply,

field contact supply, and system status. In diagnostic / program mode the

LED’s allow real time contact status monitoring, manual input type

programming and communications Tx & Rx monitoring.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

6

7

8

WATCHDOG LED'S

Standard Mode

LED 1 Steady – Indicates PSU 1 ok and no system faults.

LED 1 Fast flash - Indicates general system fault. System fault combines

card, contact, communication and structure faults.

LED 2 Steady - Indicates PSU 2 ok.

LED 2 fast flash – Indicates Field contact fault.

SmartAlarm Instruction Manual Rev 2

Page 18 of 115

Diagnostic / Program mode - Dynamic Contact Status

The internal pushbuttons can be used to view the dynamic state of all signal

inputs by pressing and holding the internal Test pushbutton for 10 seconds.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

8

PRESS AND HOLD FOR 10 SEC'S

7

6

LED-1, located above the test pushbutton, slow flashes to indicate the

Annunciator is in monitor mode.

Whilst in this mode the individual channel LED provides the dynamic status of

the associated field contacts.

If the LED is ON the field contact is CLOSED.

If the LED is OFF the field contact is OPEN.

This is a quick method of verifying the dynamic state of the field contact and is

typically used during commissioning or fault finding.

The contact monitoring function times out after 1 minute and the unit

automatically returns to the normal run mode and LED-1 reverts to steady

ON.

SmartAlarm Instruction Manual Rev 2

Page 19 of 115

Diagnostic / Program mode - Manually changing the input type

The internal pushbuttons can be used to change the input state for each

channel from normally open (N/O) to normally closed (N/C) by pressing and

holding the internal Test pushbutton for 10 seconds.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

8

PRESS AND HOLD FOR 10 SEC'S

PRESS ONCE

PRESS TO NAVIGATE BETWEEN CHANNELS

PRESS TO INVERT INPUT STATE

7

6

LED-1, located above the test pushbutton, slow flashes to indicate the

Annunciator is in the monitor mode.

Press the Mute pushbutton once and note LED-2 and Channel-1 LED slow

flash to indicate that you are now able to invert the state of Channel-1 as

required.

Pressing the Ack. pushbutton navigates to the next channel in sequence and

once the last channel has been configured the cycle repeats.

Pressing the Reset pushbutton toggles between N/O or N/C

Note: As you navigate away from each channel .

If the LED remains ON the input is set to normally closed .

If the LED is OFF the input is set to normally open .

The “input state function” times out and the unit automatically returns to the

normal run mode after 1 minute and LED-1 reverts to steady ON.

SmartAlarm Instruction Manual Rev 2

Page 20 of 115

Diagnostic / Program mode - Communication Monitoring

The internal pushbuttons can be used to monitor communication activity

between the SmartAlarm and 3rd Party devices by pressing and holding the

internal Test pushbutton for 10 seconds.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

8

PRESS AND HOLD FOR 10 SEC'S

7

6

PRESS TWICE

LED-1, located above the test pushbutton, slow flashes to indicate the

Annunciator is in monitor mode.

Press the Mute pushbutton twice and note LED-1 and LED-2 go OFF and

then act as Rx & Tx for communication between devices.

The communication monitoring function times out and the unit automatically

returns to the normal run mode after 1 minute and LED-1 reverts to steady

ON.

SmartAlarm Instruction Manual Rev 2

Page 21 of 115

Programmable Features

The SmartAlarm is equipped with a host of customer selectable features

which can be accessed via a USB programming port located behind a rubber

bung on the face of the annunciator.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

6

7

8

USB PROGRAMMING PORT

Once connected to a PC running the RTK supplied configuration software the

user can enable or disable pre-defined functions as required.

Selection of features is on a per channel basis with no special tools or

programming knowledge required.

SmartAlarm Instruction Manual Rev 2

Page 22 of 115

Film Legends

Laser printed alarm legends are used within the SmartAlarm allowing the

Customer to easily change the legends on site as required.

Film legends can be created in a style, size, font and language using

Microsoft Excel and RTK can provide a blank Microsoft Excel template locked

to the correct size viewing area if requested.

Once the legend details have been entered into the excel spreadsheet they

can be laser printed onto A4 overhead transparency film.

Each set of 8 legends can be inserted via the top of the face plate using the ½

circle indent to install the acetate sheet behind the face plate as shown below.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

PROTECTION OPERATED

MAIN-1

TRIP CIRCUIT-1

FAULTY

MAIN-2

PROTECTION OPERATED

BREAKER FAIL

PROTECTION-1 OPERATED

BREAKER FAIL

PROTECTION-2 OPERATED

TRIP CIRCUIT-2

FAULTY

SmartAlarm Instruction Manual Rev 2

Page 23 of 115

Window Numbering System

RTK have adopted the following window numbering system to aid with the

location of the film legend and the associated alarm cards.

This method is used to ensure that the legend matches the functions selected

for the designated alarm.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

6

7

8

SmartAlarm Instruction Manual Rev 2

Page 24 of 115

USB Programming Port

A rubber bung is used to maintain the IP rating of the annunciator and this can

be unplugged to access the USB programming port.

Test

Mute

Ack

Reset

PSU

WD

1

2

RTK SmartAlarm

Isolate Live Voltage before access

!

1

2

3

4

5

6

7

8

USB PROGRAMMING PORT

USB RX and TX Led's

The USB Port is used to:-

1. Upload a configuration from an existing SmartAlarm.

2. Download a configuration to the SmartAlarm.

3. View diagnostic data whilst fault finding.

Once the user connects the RTK supplied USB cable between a PC/Laptop

and the USB programming port USB Led’s located just inside the face plate

aperture indicate data exchange.

Full details of programming are provided in later sections of this manual.

SmartAlarm Instruction Manual Rev 2

Page 25 of 115

SECTION 2 – PRIMARY POWER

Primary Power – PS1

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

PRIMARY SUPPLY

85-263VAC or 88 to 360VDC

WATCHDOG

CONTACT 0/P

X2

Primary power is connected to terminal X2 - PS1 – (+VE) and (–VE) as

indicated above.

On the standard version the supply input is universal capable of

accepting 85-263VAC or 88 to 360VDC.

As an option, which must be specified at the time of order, the primary

supply can be 18-58VDC.

A watchdog relay, WD, is fitted as standard providing a volt free

changeover contact for use with 3rd party devices to indicate loss or

primary power or internal failure.

SmartAlarm Instruction Manual Rev 2

Page 26 of 115

SECTION 3 – AUX POWER (Future)

Aux Power – PS2

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

AUX SUPPLY

VOLT FREE POWER

FAILURE CONTACT 0/P

85-263VAC or 88 to 360VDC

X2

Aux power is connected to terminal X2 - PS2 - (+VE) and (–VE) as

indicated above.

On the standard version the supply input is universal capable of

accepting 85-263VAC or 88 to 360VDC.

As an option, which must be specified at the time of order, the aux

supply can be 18-58VDC.

A normally energised power failure relay, PS2 RLY, is fitted as

standard providing a configurable N/O or N/C volt free contact for use

with 3rd party devices.

SmartAlarm Instruction Manual Rev 2

Page 27 of 115

SECTION 4 – SIGNAL INPUT TYPES

Internally Powered 24VDC Signal Inputs

IP1

RL1

b

a

RL2

a

b

RL3

a

b

RL4

a

b

+VFC

IP2

IP3

IP4

RL6

a

RL7

RL8

+VFC

IP8

IP7

IP6

IP5

b

b

a

a

b

RL5

a

b

TYPICAL INPUTS

X3

X4

On standard SmartAlarm annunciators a fully isolated +24VDC supply

is provided for use as a signal supply voltage.

This output is available on all +VFC terminals which are internally

linked and protected by fuse.

An internal 160mA glass quick blow fuse, 5mm x 20mm, located on the

Common Services Card is used to protect the output from field wiring

errors.

SmartAlarm Instruction Manual Rev 2

Page 28 of 115

Signal Supply Fuse Location and FCV Link Details

A 160mA quick blow glass fuse 5 x 20mm is located on the Common

Services Card to protect the signal supply voltage.

VFC, (Voltage Field Contacts), Links LK1 and LK2 must be in the

internal position.

F2

INT

EXT

LK1

VFC

VFC

LK2

EXT INT

JUMPER

POSITIONS FOR

INTERNAL 24VDC

SIGNAL SUPPLY

160 mA

QUICK BLOW

5 X 20 MM

SIGNAL SUPPLY FUSE DETAILS

AND FCV JUMPER SETTINGS

SmartAlarm Instruction Manual Rev 2

Page 29 of 115

24 or 48 VDC/AC Customer Powered Inputs

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

+VB

X2

X4

X3

a

IP3

IP2

IP4

IP1

b

b

a

a

b

a

b

+VFC

a

b

a

b

b

a

b

a

+VFC

IP8

IP7

IP6

IP5

RL1

RL2

RL3

RL4

RL7

RL8

RL6

RL5

TYPICAL

INPUTS

CUSTOMER +24 or +48 VDC/AC

CUSTOMER 0VDC/AC

0VCHI

0VCLO

Alternative Connection Method

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

X2

X4

X3

a

IP3

IP2

IP4

IP1

b

b

a

a

b

a

b

+VFC

a

b

a

b

b

a

b

a

+VFC

IP8

IP7

IP6

IP5

RL1

RL2

RL3

RL4

RL7

RL8

RL6

RL5

CUSTOMER +24 or +48 VAC/DC

TYPICAL

INPUTS

CUSTOMER 0VDC/AC

If the Customer is providing a signal supply voltage in the range

24/48VAC/DC this supply is connected to terminal X2 +VFC and

OVCLO. If 24 or 48VAC/DC Customer Powered Inputs are required

this must be specified at the time of order as unique alarm cards are

used for each version.

SmartAlarm Instruction Manual Rev 2

Page 30 of 115

Once the supply has been connected the signal supply voltage is

internally distributed to the signal common terminal +VFC for

distribution to the field contacts. An internal 160mA glass quick blow

fuse, 5mm x 20mm, located on the Common Services Card is used to

protect the output from field wiring errors.

Signal Supply Fuse Location and FCV Link Details

A 160mA quick blow glass fuse 5 x 20mm is located on the Common

Services Card to protect the signal supply voltage.

VFC, (Voltage Field Contacts), Links LK1 and LK2 must be in the

external position.

F2

INT

EXT

LK1

VFC

VFC

LK2

EXT INT

JUMPER

POSITIONS FOR

EXTERNAL

SIGNAL SUPPLY

160mA

Quick Blow

5 x 20mm

SIGNAL SUPPLY FUSE DETAILS

AND FCV JUMPER SETTINGS

SmartAlarm Instruction Manual Rev 2

Page 31 of 115

125VDC/AC or 250VDC/AC Customer Powered Inputs

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

X2

X4

X3

a

IP3

IP2

IP4

IP1

b

b

a

a

b

a

b

+VFC

a

b

a

b

b

a

b

a

+VFC

IP8

IP7

IP6

IP5

RL1

RL2

RL3

RL4

RL7

RL8

RL6

RL5

TYPICAL

INPUTS

CUSTOMER 0VDC/AC

Alternative Connection Method

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

X2

X4

X3

a

IP3

IP2

IP4

IP1

b

b

a

a

b

a

b

+VFC

a

b

a

b

b

a

b

a

+VFC

IP8

IP7

IP6

IP5

RL1

RL2

RL3

RL4

RL7

RL8

RL6

RL5

TYPICAL

INPUTS

CUSTOMER 0VDC/AC

If the Customer is providing the signal supply voltage of 125VAC/DC

or 250VAC/DC this supply is connected to terminal X2 +VFC and

OVCHI. If 125VAC/DC or 250VAC/DC Signal Inputs are required this

must be specified at the time of order as unique alarm cards are used

for each version.

Once the supply has been connected the signal supply voltage is

internally distributed to the signal common terminal +VFC for

distribution to the field contacts. An internal 160mA glass quick blow

SmartAlarm Instruction Manual Rev 2

Page 32 of 115

fuse, 5mm x 20mm, located on the Common Services Card is used to

protect the output from field wiring errors.

Signal Supply Fuse Location and FCV Link Details

A 160mA quick blow glass fuse 5 x 20mm is located on the Common

Services Card to protect the signal supply voltage.

VFC, (Voltage Field Contacts), Links LK1 and LK2 must be in the

external position.

F2

INT

EXT

LK1

VFC

VFC

LK2

EXT INT

JUMPER

POSITIONS FOR

EXTERNAL

SIGNAL SUPPLY

160mA

Quick Blow

5 x 20mm

SIGNAL SUPPLY FUSE DETAILS

AND FCV JUMPER SETTINGS

SmartAlarm Instruction Manual Rev 2

Page 33 of 115

SECTION 5 – HORN RELAYS

HNA & HNB Horn Relays

a

b

a

b

a

b

a

b

PB1

PB2

PB3

PB4

PB5

HNA

HNB

GPA

GPB

HORN SUPPLY

(-) N1

(+) L1

HORN SUPPLY

(-) N1

(+) L1

X1

Two horn relays are provided as standard HNA & HNB.

Any channel within the annunciator can be software configured to

operate the HNA or HNB relay as required.

A volt free contact is available from each relay to switch an external

audible or 3rd party device.

The relay is normally de-energised providing a N/O contact to activate

the horn when an alarm occurs.

Contact rating 4A 24VDC (2A 120VAC).

If horn relays are not required the relays can be software selected to an

alternative function. (Group Relay, Pushbutton Follower, Watchdog

Function)

SmartAlarm Instruction Manual Rev 2

Page 34 of 115

SECTION 6 - COMMON ALARM GROUP RELAYS

GPA & GPB Group Relays

a

b

a

b

a

b

a

b

PB1

PB2

PB3

PB4

PB5

HNA

HNB

GPA

GPB

X1

Two common alarm group relays are provided as standard GPA &

GPB.

Any channel within the annunciator can be software configured to

operate the GPA or GPB relay as required.

A volt free contact is available from each relay for use with 3rd party

devices.

The Contact is configurable to N/O of N/C.

Contact rating 1A 24VDC (0.5A 120VAC)

A reflash function can be used to interrupt the common alarm contacts

each time a new alarm in the group occurs.

If Group Relays are not required the relays can be software selected to

an alternative function. (Horn Relay, Pushbutton Follower, Watchdog

Function)

SmartAlarm Instruction Manual Rev 2

Page 35 of 115

SECTION 7 - REMOTE PUSHBUTTON INPUTS

a

b

a

b

a

b

a

b

PB1

PB2

PB3

PB4

PB5

HNA

HNB

GPA

GPB

+VB

TEST

ACK

RESET

1ST RESET

X1

MUTE

Five optically coupled digital inputs are provided as standard for use

with external N/O momentary pushbuttons.

Pushbutton Functions

PB1 = System Test.

PB2 = Mute.

PB3 = Acknowledge.

PB4 = Manual Reset.

PB5 = First Reset.

The above functions can be changed in software if required .

CAUTION

The common return for the external pushbuttons is terminal +VB and

this terminal will provide the same voltage level as the internally

generated signal contact supply.

On standard systems +24VDC is used, however 125VDC may be

present if HV signal inputs were specified at the time of order.

SmartAlarm Instruction Manual Rev 2

Page 36 of 115

Group Inhibit Function

As an option any of the remote pushbutton inputs, PB1 to PB5, can be

software configured to change their use to a group inhibit function.

Any alarm can be assigned to a inhibit group and an external switch can be

used to inhibit the alarms in the group during prolonged maintenance periods

to prevent nuisance alarms.

a

b

a

b

a

b

a

b

PB1

PB2

PB3

PB4

PB5

HNA

HNB

GPA

GPB

X1

+VB

GROUP INHIBIT

The above example shows the PB1input being used with a remote group

inhibit switch. PB1 must be software configured to “Inhibit” for the function to

work and individual channels must be software configured to the inhibit group.

CAUTION

The common return for the external pushbuttons is terminal +VB and

this terminal will provide the same voltage level as the internally

generated signal contact supply.

On standard systems +24VDC is used, however 125VDC may be

present if HV signal inputs were specified at the time of order.

SmartAlarm Instruction Manual Rev 2

Page 37 of 115

Sleep Mode Function

Sleep Mode is used in applications where the installation is not manned 100%

of the time. During unmanned periods the annunciator can be placed in the

unattended mode which disables the alarm LED’s and Audible alarms to save

power and prevent noise pollution.

a

b

a

b

a

b

a

b

PB1

PB2

PB3

PB4

PB5

HNA

HNB

GPA

GPB

+VB

X1

ATTENDED / UNATTENDED

SWITCH

The above example shows PB1 input software configured for use with a

remote Attended / Unattended switch. PB1 must be software configured to

“Sleep” for the function to work.

When “Sleep Mode” is activated, by maintaining the switch in the closed

position, the alarm LED’s and audibles will be disabled to save power and

reduce noise pollution during unmanned periods. Alarms will still be captured

in the normal way and once the switch is returned to the attended position,

(open), the annunciator will function as normal.

Whilst in sleep mode the alarm LED’s pulse in unison periodically to indicate

that the annunciator is in sleep mode. The pulse can be disabled in software

under the “General” Tab by selecting the check box “Sleep Without Indication”

followed by “Confirm” . The SmartAlarm can be updated using the Tools menu

“Send Settings” to download the changes.

CAUTION

The common return for the external pushbuttons is terminal +VB and

this terminal will provide the same voltage level as the internally

generated signal contact supply.

On standard systems +24VDC is used, however 125VDC may be

present if HV signal inputs were specified at the time of order.

SmartAlarm Instruction Manual Rev 2

Page 38 of 115

SECTION 8 - INDIVIDUAL CHANNEL REPEAT RELAYS

As an option a low power magnetically latched pulse relay can be provided on

a per channel basis to repeat the alarm signal to 3rd party devices.

a

IP3

IP2

IP4

IP1

b

b

a

a

b

a

b

+VFC

a

b

a

b

b

a

b

a

+VFC

IP8

IP7

IP6

IP5

RL1

RL2

RL3

RL4

RL7

RL8

RL6

RL5

X3

X4

Each relay can be configured in software to operate in accordance with one of

the following:-

Input Follower

The relay changes state each time there is a change to the associated signal

input contact.

Logic Follower

The relay changes state on alarm and remains in the abnormal state until the

input has returned to normal and the logic has been reset using the

pushbuttons associated with the ISA sequence set for this channel.

Display Follower

The relay changes state on alarm and faithfully follows the display window i.e.

Flashing, Steady or Off depending on the alarm sequence selected for this

channel.

Contact Rating

1A @ 24VDC (0.5A 120VAC)

SmartAlarm Instruction Manual Rev 2

Page 39 of 115

SECTION 9 - TYPICAL SMARTALARM REAR VIEW

+VE

-VE

a

b

-VE

+VE

NO

C

NC

+VFC

PS2

PS2

RLY

PS1

WD

OVCHI

OVCLO

+VB

X2

X4

X3

a

IP3

IP2

IP1

b

b

a

a

b

a

b

+VFC

a

b

a

b

b

a

b

a

+VFC

IP8

IP7

IP6

IP5

RL1

RL2

RL3

RL4

RL7

RL8

RL6

RL5

X1

a

HNB

GPB

GPA

b

a

b

b

a

HNA

b

a

PB2

PB1

PB3

PB4

PB5

a

+VFC

IP3

IP1

IP2

b

b

a

a

b

RL7

RL3

RL4

RL8

RL2

RL6

a

b

X5

RL1

RL5

a

+VFC

IP7

IP8

IP5

IP6

b

b

a

a

b

a

b

X6

IP4 IP4

Typical Rear View 16 Way SmartAlarm with repeat relays

SmartAlarm Instruction Manual Rev 2

Page 40 of 115

SECTION 10 - INSTALLATION

Unpacking

Once the item has been unpacked please visually examine the unit for any

signs of transit damage before installing the unit into the control system. If any

damage has occurred please report the damage to the freight forwarder and

copy RTK. The alarm annunciator is supplied with panel mounting clamps

locked in place, however please check all packages to ensure that no

additional pieces are left in the box as any auxiliary items like horns,

pushbuttons or spares kits will be packed separately.

Please double check that all items listed on the packing list have been

unpacked before disposing of any packing material.

Mounting

SmartAlarm annunciators are designed for panel mounting and therefore a

suitable cut-out must be provided to securely locate them using the RTK

panel mounting clamps provided on either side of the annunciator. Each

clamp can be tightened using a phillips screwdriver.

Dimensions for panel mounting versions

8 Way

Overall:- 96mm H x 96mm W x 125mm D

Cut-Out :- 91.5mm H x 91.5mm W

16 Way

Overall:- 96mm H x 144mm W x 125mm D

Cut-Out:- 91.5mm H x 139.5mm W

24 Way

Overall:- 96mm H x 192mm W x 125mm D

Cut-Out:- 91.5mm H x 187.5mm W

Please note:-

The cut out tolerance should be with ±1mm.

SmartAlarm Instruction Manual Rev 2

Page 41 of 115

19” Rack Mounting

SmartAlarms are suitable for mounting within 19” racks using suitable filler

plates which can be supplied by RTK as optional items.

Wall Mounting

RTK offer a full integration service where panel mounted annunciators are

supplied within an industry standard Wall mounting Enclosure, with all

customer connections typically wired to Weidmuller terminals for ease of

connection to the field device.

Floor Standing

RTK offer a full integration service where panel mounted annunciators are

supplied within an industry standard Floor Standing Enclosures, with all

customer connections typically wired to Weidmuller terminals for ease of

connection to the field device.

SmartAlarm Instruction Manual Rev 2

Page 42 of 115

SECTION 11 - SOFTWARE INSTALLATION

.

Configuration Software is provided free of charge on a conventional CD or the

software can be downloaded from our Website:-

www.rtkinstruments.com/downloads in the section labelled SmartAlarm

To install the software Click on the RTKSmartAlarmInstallerV***

(*** = Version Number)

Please select “Run” to start the install process.

Select “Run” which will list the components to be installed

Select “Next” which will show the default destination folder

SmartAlarm Instruction Manual Rev 2

Page 43 of 115

Select “Install” to install the application and once complete select

“Close”

The desk top will show a quick launch icon showing “RTK” within a red

shield – please select this Icon to open the application.

Select the “File” menu which will prompt the user with the following

options.

SmartAlarm Instruction Manual Rev 2

Page 44 of 115

SECTION 12 – AUTO DETECT HARDWARE.

To Auto Detect the settings within a SmartAlarm.

Open the RTK SmartAlarm configuration software using the “RTK”

quick launch icon located on the desktop.

Apply primary power to the SmartAlarm.

Remove the rubber bung on the front of the SmartAlarm to access the

USB programming port.

Connect the RTK supplied USB cable between the PC/Laptop and the

SmartAlarm.

When you initially plug-in the USB cable to the SmartAlarm you will

notice a green LED near the USB port flash to indicate communication.

From the “Comport” tool bar select the USB Com. port you will be using

to communicate with the SmartAlarm. Note the Comport No varies

depending on the devices connected to each PC and the USB port

being used therefore more than one com port may be identified in the

list.

Use the “”File” menu to select “Auto Detect” and note the green

progress bar increases whilst installation is in progress and once

complete an Auto Detect Complete message appears on the desk top

- please select “OK”.

Once Auto Detect is complete all of the settings shown will be an exact

copy of those held in the associated SmartAlarm.

You are now ready to use the software as required.

Before any configuration changes take place RTK recommend a Master copy

is saved to the PC/Laptop using the “File” menu – “Export CSV File” this

ensures a master copy is available if you wish to revert back to the initial

settings.

SmartAlarm Instruction Manual Rev 2

Page 45 of 115

SECTION 13 – IMPORT CSV FILE

Open Configuration

Configurations are saved in CSV format and can be re-installed as required.

From the “File” menu select “Import CSV File” which will allow standard

windows navigation to locate the saved configuration.

Once located select “Open” to install the previously saved configuration

settings.

Please note this will overwrite all existing settings.

SmartAlarm Instruction Manual Rev 2

Page 46 of 115

SECTION 14 – EXPORT CSV FILE

Save Configuration

Configurations are saved in CSV format and can be saved as required.

From the “File” menu select “Export CSV File” which will allow standard

windows navigation to save the configuration.

Once saved the configuration can be viewed in Microsoft Excel format and

edited as required.

After changes have been made the CSV file can be imported as described in

the previous section.

RTK recommend a copy of each SmartAlarm configuration is saved for future

reference as required.

SmartAlarm Instruction Manual Rev 2

Page 47 of 115

SECTION 15 – CREATE A NEW SYSTEM

Select “Create New SmartAlarm” is only used during manufacturing to select

the order specific features required per SmartAlarm

This function is not used by customers

SmartAlarm Instruction Manual Rev 2

Page 48 of 115

SECTION 16 – SYSTEM SETTINGS

Auto Detect

The user is able to Auto Detect the configurations of an existing SmartAlarm

once they have loaded the RTK configuration software onto a suitable PC and

connected the USB Cable to the communication port located behind the

rubber bung on the front of the SmartAlarm.

The auto detect facility is accessed via the “File” menu as shown above.

Once selected all of the settings stored within the SmartAlarm are read into

the software allowing the user to view, save or modify the configuration as

required.

SmartAlarm Instruction Manual Rev 2

Page 49 of 115

View

The following settings are available under the “View” menu.

Advanced

As standard the configuration software restricts some of the features to

simplify selection of features. In more complex applications additional menus

are available for example. Increased number of groups or custom sequences

and these are accessed via the “View Advanced” menu.

Front View of Annunciator

Selecting the “View” menu – “Front” menu provides a graphic of the alarm

fascia to aid programming.

Rear

Selecting the “View” menu – “Rear” menu provides a graphic of the rear of the

SmartAlarm showing customer terminals and designations for reference

purposes.

SmartAlarm Instruction Manual Rev 2

Page 50 of 115

Tools

The following settings are available under the “Tools” menu

Send Settings

Once the SmartAlarm has been connected to a suitable PC/Laptop via the

RTK supplied USB Cable the user is able to download any configuration

changes to the unit as required. RTK recommend that before downloading the

customer uploads the original settings and saves them on the PC/Laptop for

future reference or as a backup.

Receive Settings

Once the SmartAlarm has been connected to a suitable PC/Laptop via the

RTK supplied USB Cable the user is able to upload the configuration settings

from the unit as required. Before any changes are made RTK recommend that

a copy of the original settings are saved for future reference or as a backup.

Restore Default Settings

If required the user is able to return the unit to the factory default settings,

however please note this will revert ALL settings within the Annunciator so

should only performed with caution.

SmartAlarm Instruction Manual Rev 2

Page 51 of 115

Diagnostics

Once the SmartAlarm has been connected to a suitable PC/Laptop via the

RTK supplied USB Cable the user is able to select Diagnostics to check the

dynamic status of the SmartAlarm.

Set Structure

Please consult factory before modifying the structure of a supplied

Annunciator.

Scan Unit

This allows the user to identify the address, card type, software version and

software revision number for the cards within the SmartAlarm. This will aid

fault finding or spare parts identification.

Test Tools

Production use only.

SmartAlarm Instruction Manual Rev 2

Page 52 of 115

General Tab

The fields listed under the “General” tab allow the user to uniquely identify

each Alarm Annunciator System to aid with the storage and retrieval of

configuration data.

The user can update any of the fields within the software but the changes will

only be saved after the “Confirm Settings” control button is pressed using a

left mouse click. Any changes will need to be sent to the annunciator via the

Tools menu “Send Settings”.

Plant Name

Allows the user to allocate a unique name to define the location of the device.

Description

This field is used to identify the specific plant area or annunciator function

within the plant.

SmartAlarm Instruction Manual Rev 2

Page 53 of 115

Tag No.

This field allows a Customer assigned number to be used to identify a unique

alarm annunciator.

Serial No.

A serial number is automatically provided once the software is communicating

with the alarm annunciator.

Address Offset

This allows the user to offset the Node address to match the application.

Sleep Without Indication

Selecting this feature inhibits the heart-beat pulse which cyclically pulses the

alarm LED’s whilst the unit is in Sleep Mode (Full details of Sleep Mode are

provided within this manual).

SmartAlarm Instruction Manual Rev 2

Page 54 of 115

CS Relays (Common Service Relays)

Each channel within the annunciator can be assigned to a single or multiple

groups. The group can be software linked to any of the common relays to

provide contact outputs for use with 3rd Party devices.

The fields listed under the “CS Relays” tab allow the user to configure the

common system relays to follow groups as required.

Horn A - HNA

The default setting for this relay is Horn A / HNA, the relay is normally deenegised and provides a N/O contact for use with external audibles / 3rd party

devices. The relay will activate on alarm and will return to normal after Mute or

Acknowledge have been pressed. The relay must be assigned to a group and

the group type needs to be set as “Audible” for the relay to operate correctly.

The coil state can be set to Normally Energised or Normally De-

Energised, by selecting the required feature using the Drop-down

menu shown next to the coil status field.

SmartAlarm Instruction Manual Rev 2

Page 55 of 115

Horn B - HNB

The default setting for this relay is Horn B / HNB, the relay is normally deenergised and provides a N/O contact for use with external audibles / 3rd party