Important notes

The 9000TS System described herein operates on a logic voltage of

24VDC and as standard +24VDC is used for the field contact supply

voltage.

External power supplies using higher voltage ac/dc primary sources and

optional high voltage field contact voltages may be present if this is the

case please ensure the necessary precautions are taken

REV DATED DESCRIPTION AUTHOR APPROVED

12 02-10-08 Battery Disposal PC DF

13 27-10-08 Max system size revised and P925TS-R

relay details added

14 12-01-09 Corrected F1 and F2 fuse functions PC DF

15 27-03-09 Relay Address Setting Revised PC DF

16 29-04-09 Watchdog Relay coil state correction PC DF

17 13-06-11 Modified event list, IRIGB section, Trouble

shooting guide, Dual redundant.

18 28-05-13 Watchdog Relay Coil & Contact States

clarified

PC DF

AI DF

PC DF

System 9000TS Event Recorder

© RTK INSTRUMENTS LTD 2005

The copyright in this work is vested in RTK Instruments Ltd and this document is issued for the purpose

only for which it is supplied. No licence is implied for the use of any patented feature. It must not be

reproduced in whole or in part, or used for tendering or manufacturing purposes except under an

agreement or with the consent in writing of RTK Instruments Ltd and then only on the condition that this

notice is included in any such reproduction. Information furnished is believed to be accurate but no

liability in respect of any use of it is accepted by RTK Instruments Ltd.

2

System 9000TS

TABLE OF CONTENTS

System 9000TS Event Recorder ........................................................................................................ 1

SECTION 1 - INTRODUCTION ..................................................................................... 8

SECTION 2 - SYSTEM DESCRIPTION AND FEATURES ........................................... 9

GENERAL ................................................................................................................................................. 9

UNIVERSAL CARD SLOTS ........................................................................................................................ 10

POLARISATION KEYS ............................................................................................................................... 10

SYSTEM CONNECTIONS .......................................................................................................................... 10

CUSTOMER CONNECTIONS ...................................................................................................................... 10

FULLY FIELD CONFIGURABLE .................................................................................................................. 10

PRINT OUTS ........................................................................................................................................... 10

FIRST-UP ALARMS .................................................................................................................................. 11

SYSTEM RELAYS .................................................................................................................................... 11

TIME DELAYS ......................................................................................................................................... 11

AUTO SHELVE ........................................................................................................................................ 11

SLEEP MODE .......................................................................................................................................... 11

SECTION 3 – MECHANICAL DETAILS ..................................................................... 12

LOGIC RACK ........................................................................................................................................... 12

MOUNTING ............................................................................................................................................. 12

EARTHING .............................................................................................................................................. 12

PLUG-IN CARDS ...................................................................................................................................... 12

LAMP / LED DISPLAYS ............................................................................................................................ 12

MULTIPLE RACKS SYSTEMS .................................................................................................................... 13

CHASSIS INTERCONNECTING RIBBON DETAILS ......................................................................................... 13

SECTION 4 – OPERATING INSTRUCTIONS ............................................................ 14

PRE-CHECKS .......................................................................................................................................... 14

STATUS LED .......................................................................................................................................... 14

POWER ON ............................................................................................................................................ 14

SECTION 5 – TECHNICAL SPECIFICATION ............................................................ 15

LOGIC SUPPLY ....................................................................................................................................... 15

SUPPLY CURRENT .................................................................................................................................. 15

INDIVIDUAL REPEAT RELAYS ................................................................................................................... 15

COMMON RELAYS ................................................................................................................................... 15

FUSE RATINGS ........................................................................................................................................ 15

EMC COMPLIANCE ................................................................................................................................. 16

CONDUCTED RFI IMMUNITY ..................................................................................................................... 16

RADIATED EMISSIONS ............................................................................................................................. 16

CONDUCTED EMISSIONS ......................................................................................................................... 16

RADIATED POWER FREQUENCY MAGNETIC FIELD ..................................................................................... 16

ESD EFFECTS ........................................................................................................................................ 16

DIELECTRIC WITHSTAND ......................................................................................................................... 16

SURGE WITHSTAND – OSCILLATORY ........................................................................................................ 16

ELECTRICAL FAST TRANSIENT/BURST IMMUNITY ...................................................................................... 16

SURGE IMMUNITY.................................................................................................................................... 16

ENVIRONMENT ........................................................................................................................................ 16

INPUT SPECIFICATIONS ........................................................................................................................... 17

OUTPUT SPECIFICATIONS ........................................................................................................................ 17

SECTION 6 – ALARM SEQUENCES ......................................................................... 18

SUMMARY .............................................................................................................................................. 18

ISA A – AUTOMATIC RESET – LOCK IN ..................................................................................................... 20

3

ISA A-4 – AUTOMATIC RESET – NON LOCK IN .......................................................................................... 21

ISA A-4-5-6 – STATUS ........................................................................................................................... 22

ISA M – MANUAL RESET – LOCK IN ......................................................................................................... 23

ISA R – RINGBACK ................................................................................................................................. 24

ISA F1A-1 – AUTOMATIC RESET FIRST UP .............................................................................................. 25

ISA F2M-1 – MANUAL RESET FIRST UP .................................................................................................. 26

ISA F3A – AUTOMATIC RESET FIRST UP ................................................................................................. 28

SECTION 7 – P925TS-X INTERFACE CARD ............................................................ 30

INTERFACE CARD FEATURES ................................................................................................................... 30

DIAGNOSTIC LED’S ................................................................................................................................ 30

SERIAL PORTS ........................................................................................................................................ 30

GENERATING REPORTS ........................................................................................................................... 31

BUFFERS ................................................................................................................................................ 31

SORT DELAY PERIOD .............................................................................................................................. 31

SYSTEM RELAY OUTPUTS ....................................................................................................................... 32

AUDIBLE ALARM RELAYS ......................................................................................................................... 32

GROUP RELAYS ...................................................................................................................................... 32

GROUP RELAYS WITH REFLASH ............................................................................................................... 32

DIAGNOSTIC RELAY OUTPUTS ................................................................................................................. 32

WATCHDOG RELAY ................................................................................................................................. 32

TIME SYNCHRONISATION ......................................................................................................................... 33

TIME SYNCHRONISATION JUMPER SETTING .............................................................................................. 33

INTERFACE CARD RELAY OUTPUTS. ........................................................................................................ 34

SYSTEM RELAY SETTINGS:- .................................................................................................................... 35

SETTING RELAY CONTACT STATES .......................................................................................................... 35

HORN RELAY:- RL1 ................................................................................................................................ 36

HORN RELAY:- RL2 ................................................................................................................................ 36

GROUP RELAYS RL3 & RL4:- ................................................................................................................. 37

RELAYS RL5 - RL8:-............................................................................................................................... 38

REFLASH COMMON ALARM RELAYS ......................................................................................................... 38

POWER FAILURE MONITORING:- PF ......................................................................................................... 39

PRINTER FAILURE ALARM ........................................................................................................................ 40

TIME SYNC. FAILURE .............................................................................................................................. 40

BUFFER OVERLOAD ALARM ..................................................................................................................... 40

WATCHDOG RELAY:- WD ........................................................................................................................ 40

SECTION 7A – P925TS-X1/2 DUAL REDUNDANT INTERFACE CARD .................. 41

DUAL INTERFACE CARD FEATURES .......................................................................................................... 41

DIAGNOSTIC LED’S ................................................................................................................................ 41

DUAL REDUNDANT SYSTEM ..................................................................................................................... 41

DOMINANT X1 AND SUBMISSIVE X2 ......................................................................................................... 41

DOMINANT X1 CONTROL FUNCTION ......................................................................................................... 42

SUBMISSIVE X2 CONTROL FUNCTION ...................................................................................................... 42

SWITCHOVER PROTOCOL ........................................................................................................................ 42

SWITCHOVER SCENARIO’S ...................................................................................................................... 42

TABLE BELOW LISTS EVENT TYPE’S SPECIFIC TO A DUAL REDUNDANT 9000TS SYSTEM.

DUAL REDUNDANT SPECIFIC EVENT TYPE’S ............................................................................................. 44

............................... 44

SECTION 8 – INPUTS AND OUTPUTS...................................................................... 46

OPTICALLY COUPLED INPUTS .................................................................................................................. 46

DIGITAL INPUTS ...................................................................................................................................... 46

LOCK IN ................................................................................................................................................. 46

LAMP/LED OUTPUTS .............................................................................................................................. 46

REPEAT RELAY OPTION .......................................................................................................................... 46

DUAL HORN RELAY ................................................................................................................................. 46

GROUP RELAYS ...................................................................................................................................... 47

4

System 9000TS

REFLASH FACILITY .................................................................................................................................. 47

WATCHDOG RELAY ................................................................................................................................. 47

RS485 COMMUNICATION OPTION ............................................................................................................ 47

RS232 PRINTER PORT ........................................................................................................................... 47

RS232 PROGRAMMING PORT ................................................................................................................. 47

CONTROL INPUTS ................................................................................................................................... 47

GROUP INHIBITS ..................................................................................................................................... 47

DATA STORAGE ...................................................................................................................................... 48

SECTION 9 – P925TS-I INPUT CARD ....................................................................... 49

SIGNAL INPUT VOLTAGE SELECTION ........................................................................................................ 49

OPTIONAL HIGH VOLTAGE INPUTS ........................................................................................................... 50

POWER ON / STATUS LED ....................................................................................................................... 50

ALARM STATUS LED’S ............................................................................................................................ 51

INPUT CARD FACE PLATE & WIRING ........................................................................................................ 51

PUSHBUTTON CONNECTIONS .................................................................................................................. 52

SECTION 10 – P925TS-O OUTPUT CARD ................................................................ 53

LAMP PROTECTION .............................................................................................................................. ... 53

OUTPUT DRIVE TYPE .............................................................................................................................. 53

CARD ADDRESS SETTINGS ...................................................................................................................... 53

POWER ON / STATUS LED ...................................................................................................................... 53

LAMP / LED OUTPUT STATUS LED .......................................................................................................... 54

SECTION 11 – P925TS-R RELAY CARD .................................................................. 55

STATUS LED .......................................................................................................................................... 55

RELAY STATUS LED’S ............................................................................................................................ 55

OPERATING MODE .................................................................................................................................. 55

CONTACT STATE .................................................................................................................................... 57

COIL STATE ............................................................................................................................................ 57

SECTION 12 – LOGIC AND SIGNAL POWER OPTIONS ......................................... 59

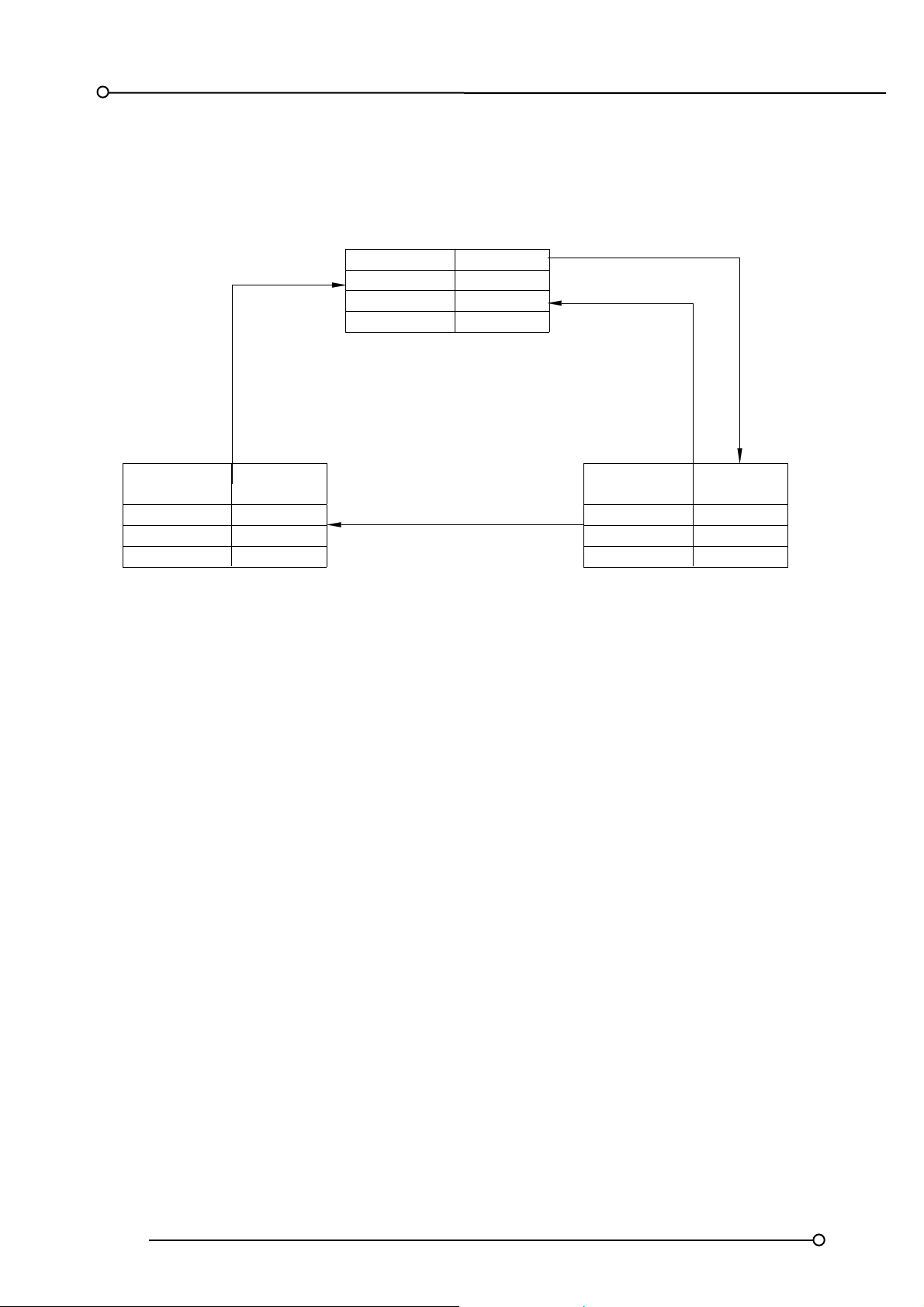

STANDARD SYSTEMS USING 24VDC LOGIC AND SIGNAL POWER ............................................................. 59

LOGIC SUPPLY ....................................................................................................................................... 59

SIGNAL SUPPLY ...................................................................................................................................... 59

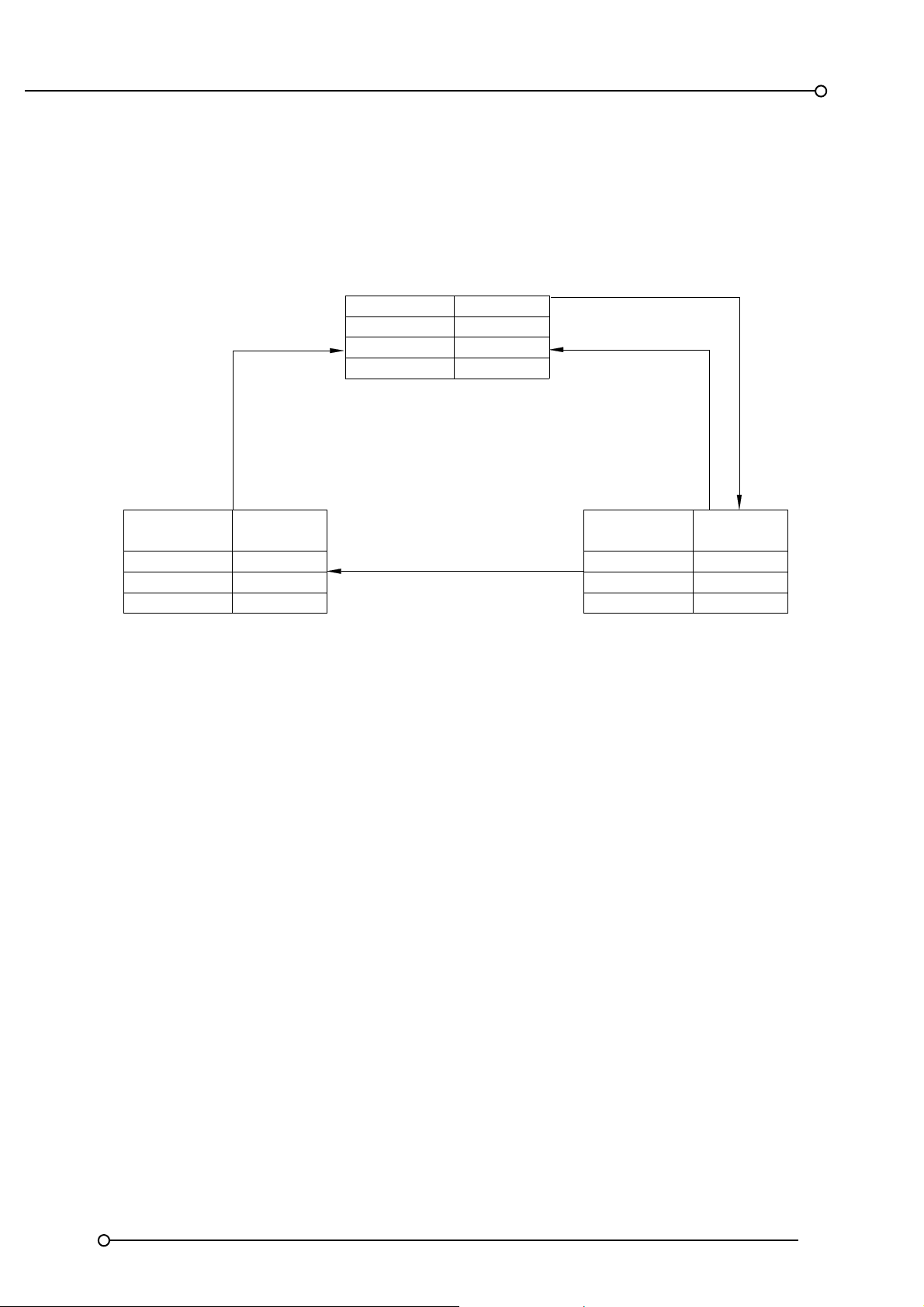

OPTIONAL ISOLATED 24VDC SIGNAL INPUT POWER ................................................................................. 60

LOGIC SUPPLY ....................................................................................................................................... 60

SIGNAL SUPPLY ...................................................................................................................................... 60

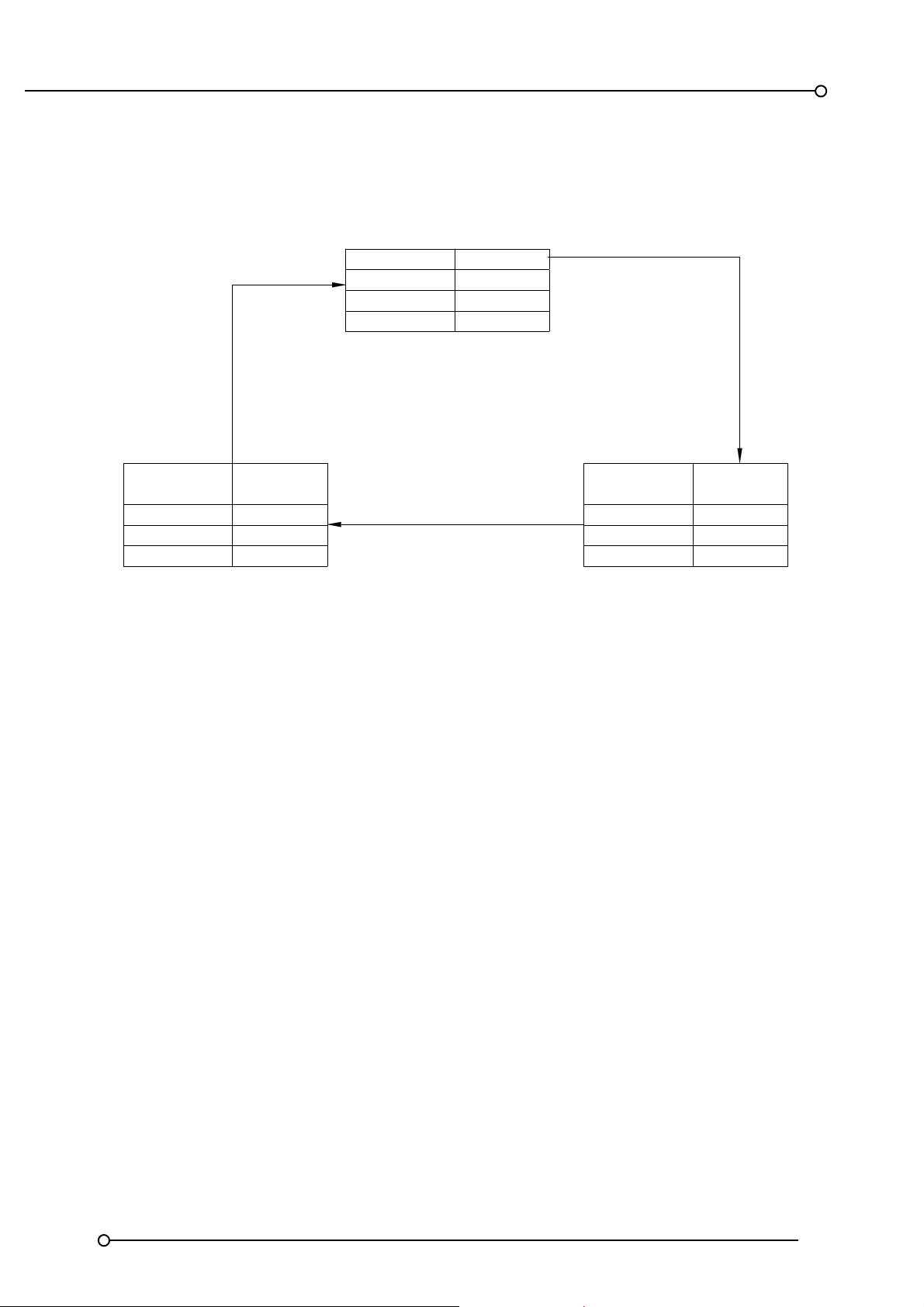

OPTIONAL 125VAC/DC HIGH VOLTAGE SIGNAL INPUTS ........................................................................... 61

LOGIC SUPPLY ....................................................................................................................................... 61

SIGNAL SUPPLY ...................................................................................................................................... 61

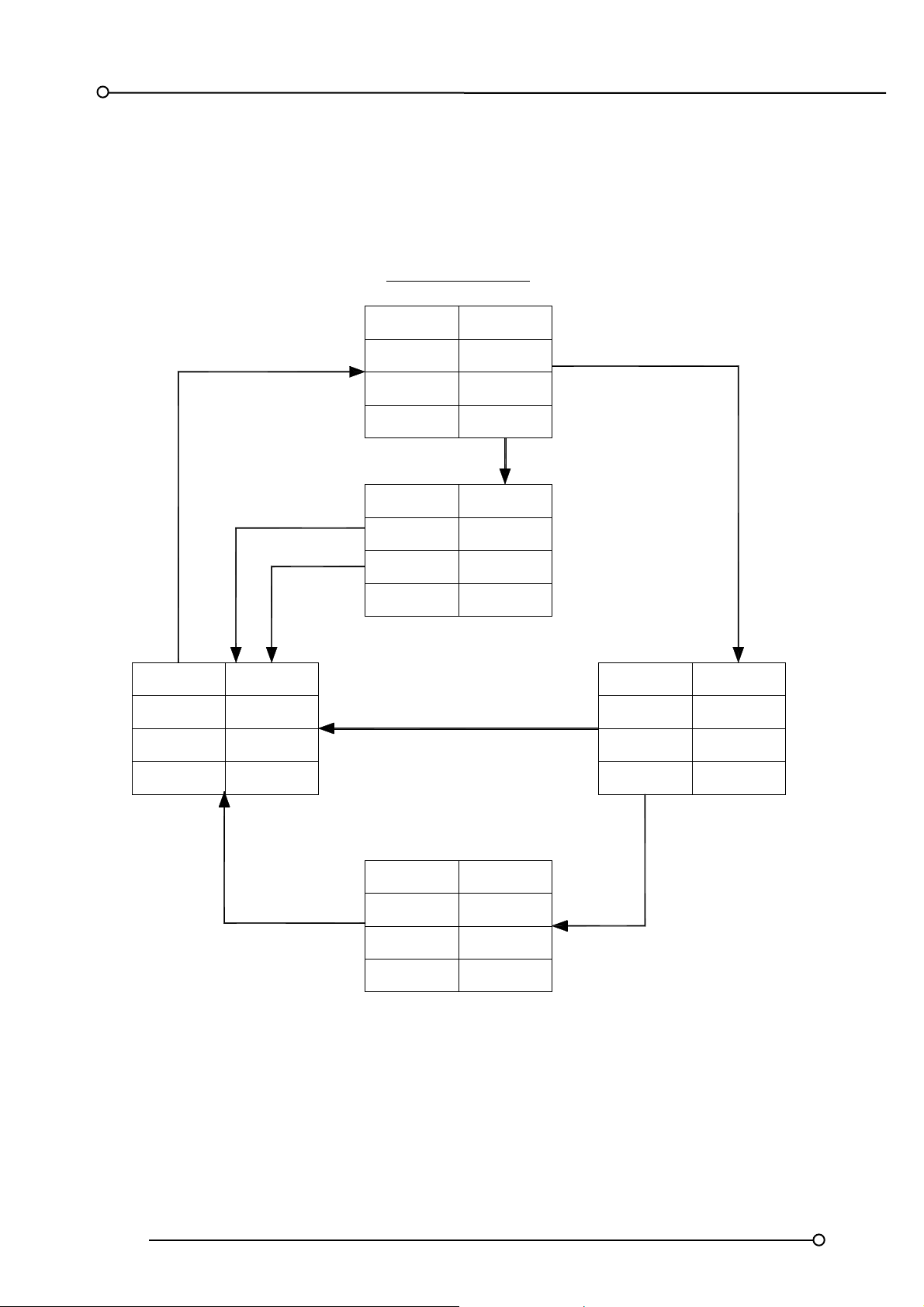

OPTIONAL 48 OR 250VAC/DC HIGH VOLTAGE SIGNAL INPUTS ................................................................. 62

LOGIC SUPPLY ....................................................................................................................................... 62

SIGNAL SUPPLY ...................................................................................................................................... 62

SECTION 13 – CARD ADDRESS SETTINGS ............................................................ 63

P925TS-I INPUT / P925TS-O OR P925TS-R OUTPUT CARD TYPICAL ADDRESSES SETTINGS ................... 64

SECTION 14 – END OF LINE LOAD .......................................................................... 65

SECTION 15 – INTER CARD COMMUNICATIONS ................................................... 66

UNIVERSAL CARD SLOTS ........................................................................................................................ 66

P9000TS LOCAL RTK COMMUNICATION SWITCH LOCATION AND SETTING ................................................ 66

UPPER RACK SWITCH SETTINGS ............................................................................................................. 67

LOWER RACK SWITCH SETTINGS ............................................................................................................. 67

SECTION 16 – EXAMPLES OF 9000TS SYSTEMS .................................................. 68

5

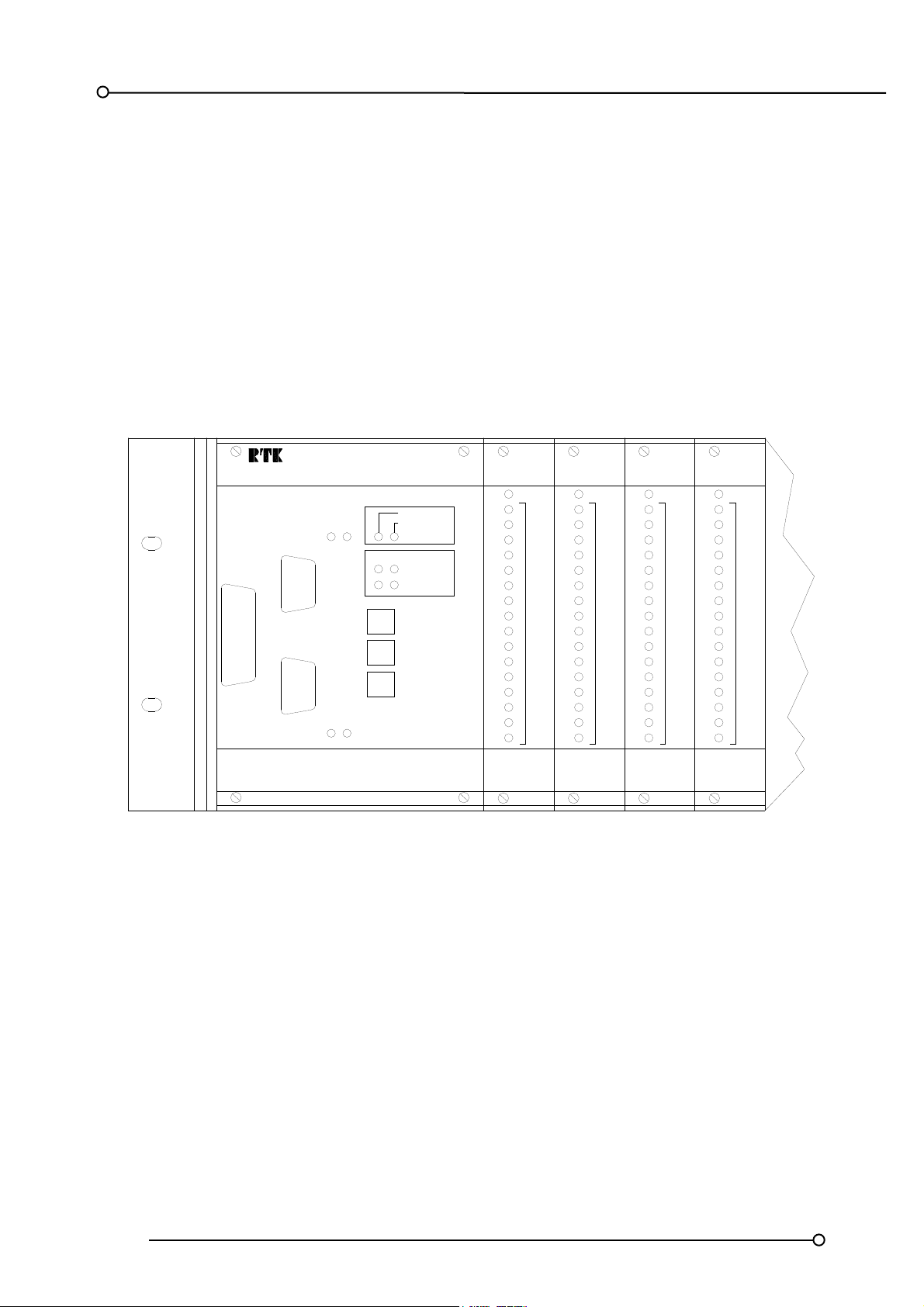

P9000TS SOE ONLY CARD LAYOUT ...................................................................................................... 68

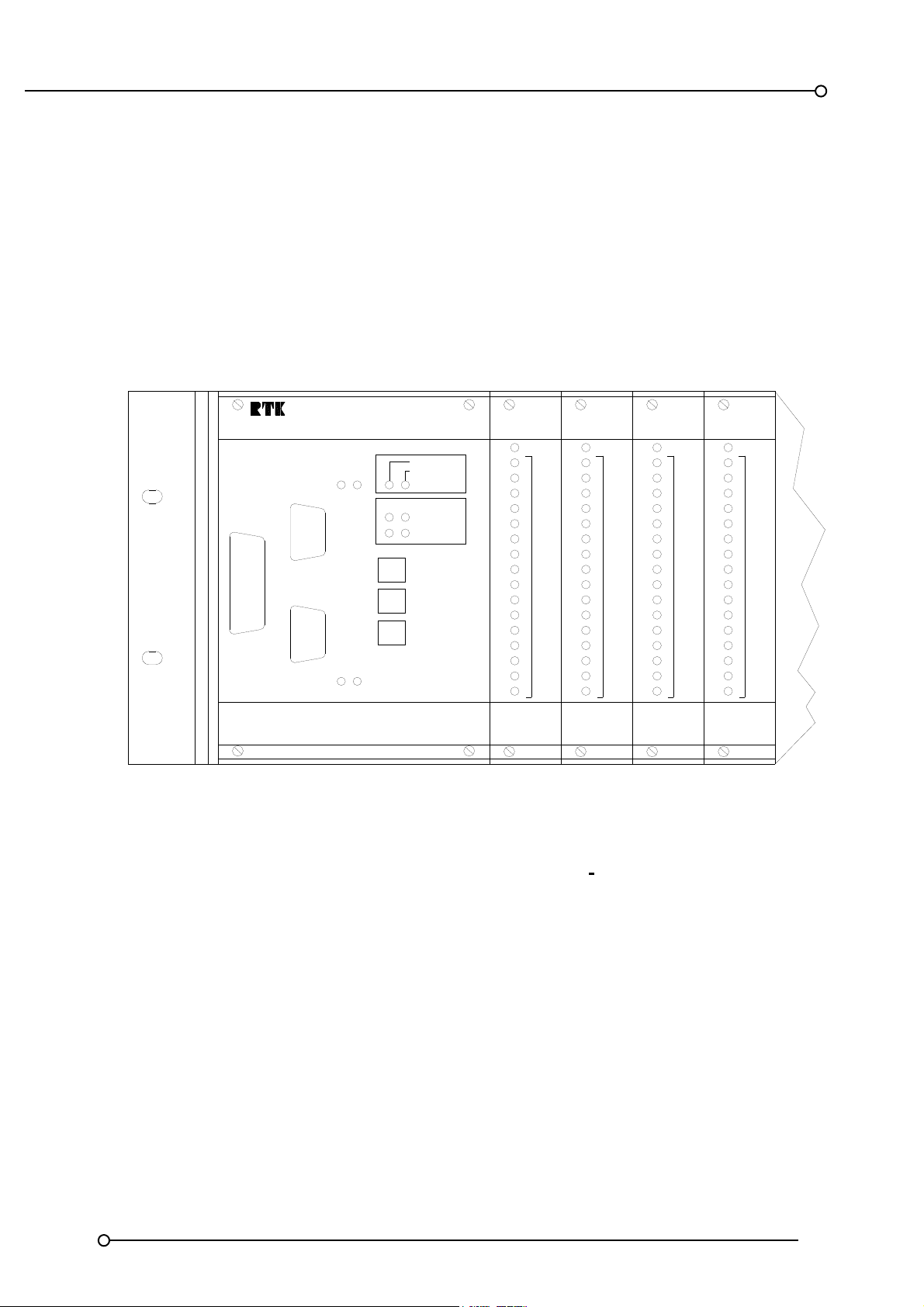

9000TS SOE AND ANNUNCIATOR CARD LAYOUT ..................................................................................... 69

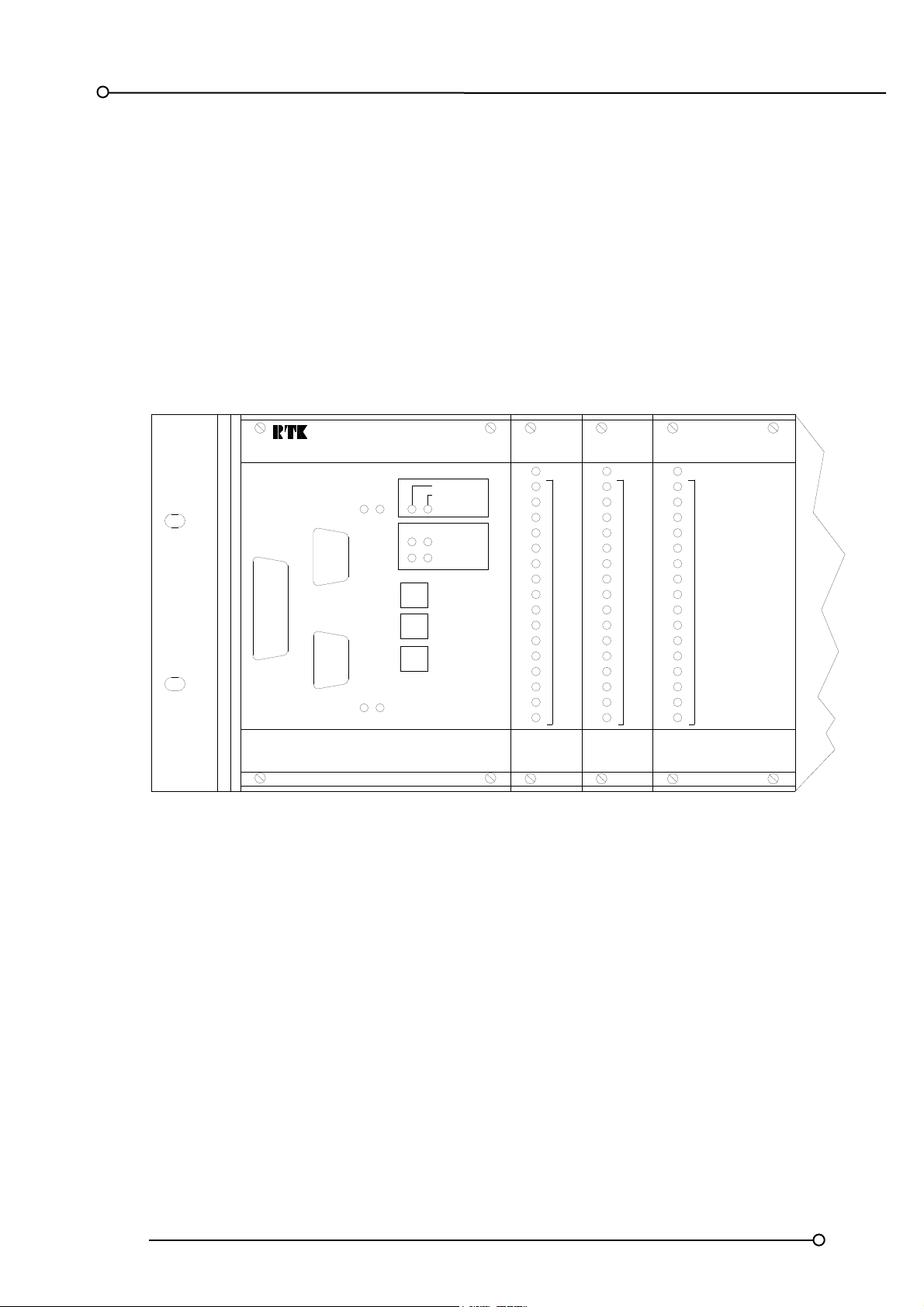

9000TS SOE ANNUNCIATOR AND REPEAT RELAY LAYOUT CARD ............................................................. 70

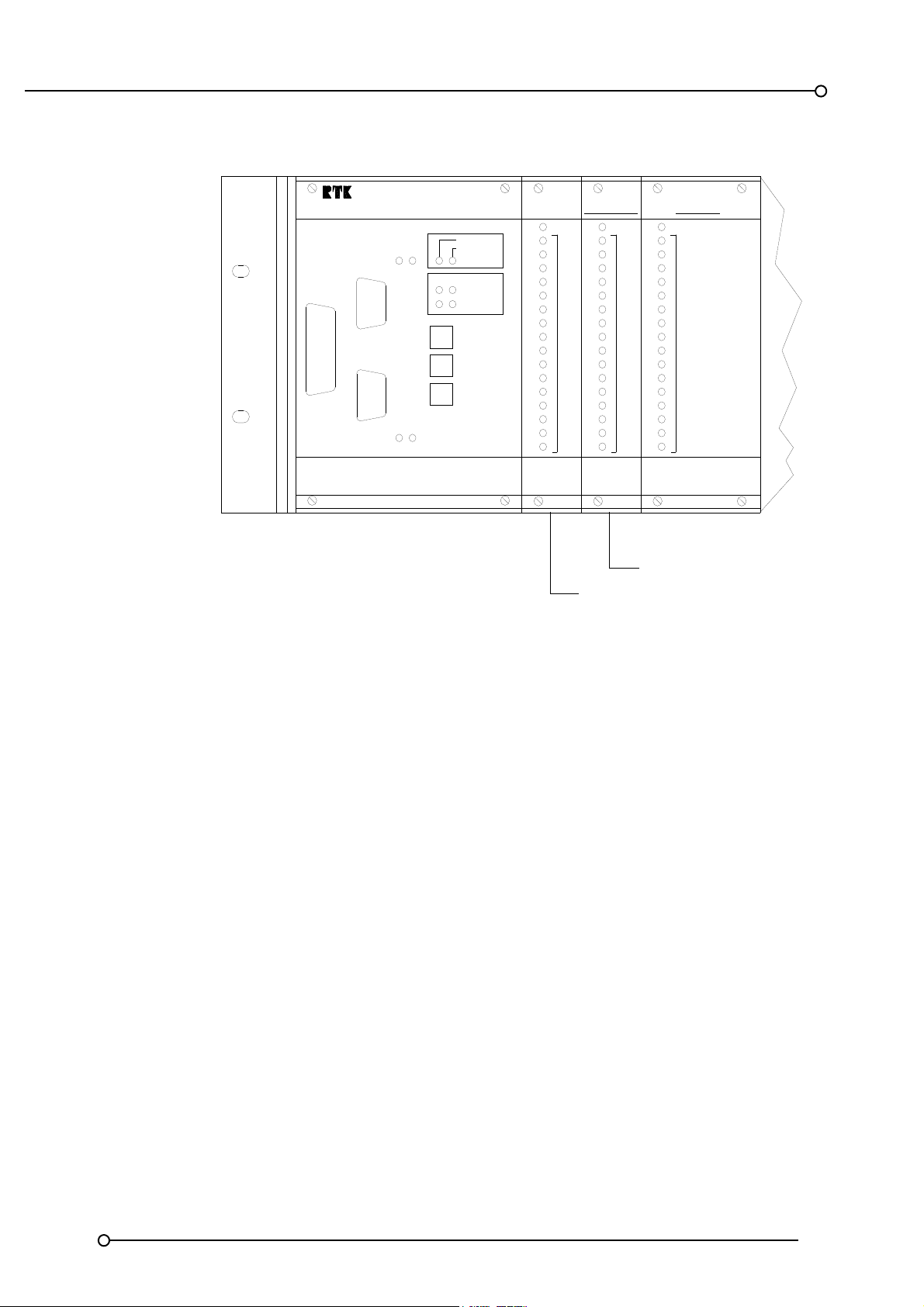

TYPICAL CARD LOCATION AND ADDRESS SETTINGS WITHIN THE P925TS-RK RACK ................................... 71

SECTION 17 – 9000TS EVENT TYPE KEY ............................................................... 74

P925TS-I INPUT CARD EVENT TYPE KEY ................................................................................................ 74

P925TS-0 OUTPUT CARD EVENT TYPE KEY ............................................................................................ 75

P925TS-R RELAY CARD EVENT TYPE KEY ............................................................................................. 75

9000TS SYSTEM INTERNAL EVENT TYPE KEY.......................................................................................... 75

SECTION 18 – PORT 1 SERIAL COMMUNICATIONS .............................................. 78

PORT 1 PROTOCOL FORMATS. ................................................................................................................ 78

AMS TIME STAMPED EVENT PROTOCOL .................................................................................................. 78

MODBUS RTU PROTOCOL ...................................................................................................................... 78

READ REQUEST – MASTER ..................................................................................................................... 78

READ RESPONSE – 9000TS SLAVE ......................................................................................................... 81

WRITE SINGLE REQUEST/RESPONSE – MASTER AND 9000TS SLAVE ....................................................... 81

WRITE MULTIPLE REQUEST – MASTER .................................................................................................... 82

WRITE MULTIPLE RESPONSE – SLAVE ..................................................................................................... 82

EXCEPTION RESPONSE – 9000TS SLAVE ................................................................................................ 83

SECTION 19 – PORT 2 SERIAL COMMUNICATION ................................................ 84

PORT 2 PROTOCOL FORMATS. ................................................................................................................ 84

PROG ................................................................................................................................................... 84

MODBUS RTU ..................................................................................................................................... 84

MODBUS RTU PROTOCOL ...................................................................................................................... 84

READ REQUEST – MASTER ..................................................................................................................... 84

READ RESPONSE – 9000TS SLAVE ......................................................................................................... 87

WRITE SINGLE REQUEST/RESPONSE – MASTER AND 9000TS SLAVE ....................................................... 87

WRITE MULTIPLE REQUEST – MASTER .................................................................................................... 88

WRITE MULTIPLE RESPONSE – SLAVE ..................................................................................................... 88

EXCEPTION RESPONSE – 9000TS SLAVE ................................................................................................ 89

WHARTON PROTOCOL ............................................................................................................................ 89

SECTION 20 – PORT 3 SERIAL COMMUNICATION ................................................ 90

PORT 3 PROTOCOL FORMATS. ................................................................................................................ 90

WHARTON PROTOCOL ............................................................................................................................ 90

HOPF PROTOCOL .................................................................................................................................. 90

FOXBRGH 9600 E 1 8 .......................................................................................................................... 90

AUG CAT, G22, ALM ............................................................................................................................ 90

MODBUS RTU PROTOCOL ...................................................................................................................... 90

READ REQUEST – MASTER ..................................................................................................................... 91

READ RESPONSE – 9000TS SLAVE ......................................................................................................... 93

WRITE SINGLE REQUEST/RESPONSE – MASTER AND 9000TS SLAVE ....................................................... 93

WRITE MULTIPLE REQUEST – MASTER .................................................................................................... 94

WRITE MULTIPLE RESPONSE – SLAVE ..................................................................................................... 94

EXCEPTION RESPONSE – 9000TS SLAVE ................................................................................................ 95

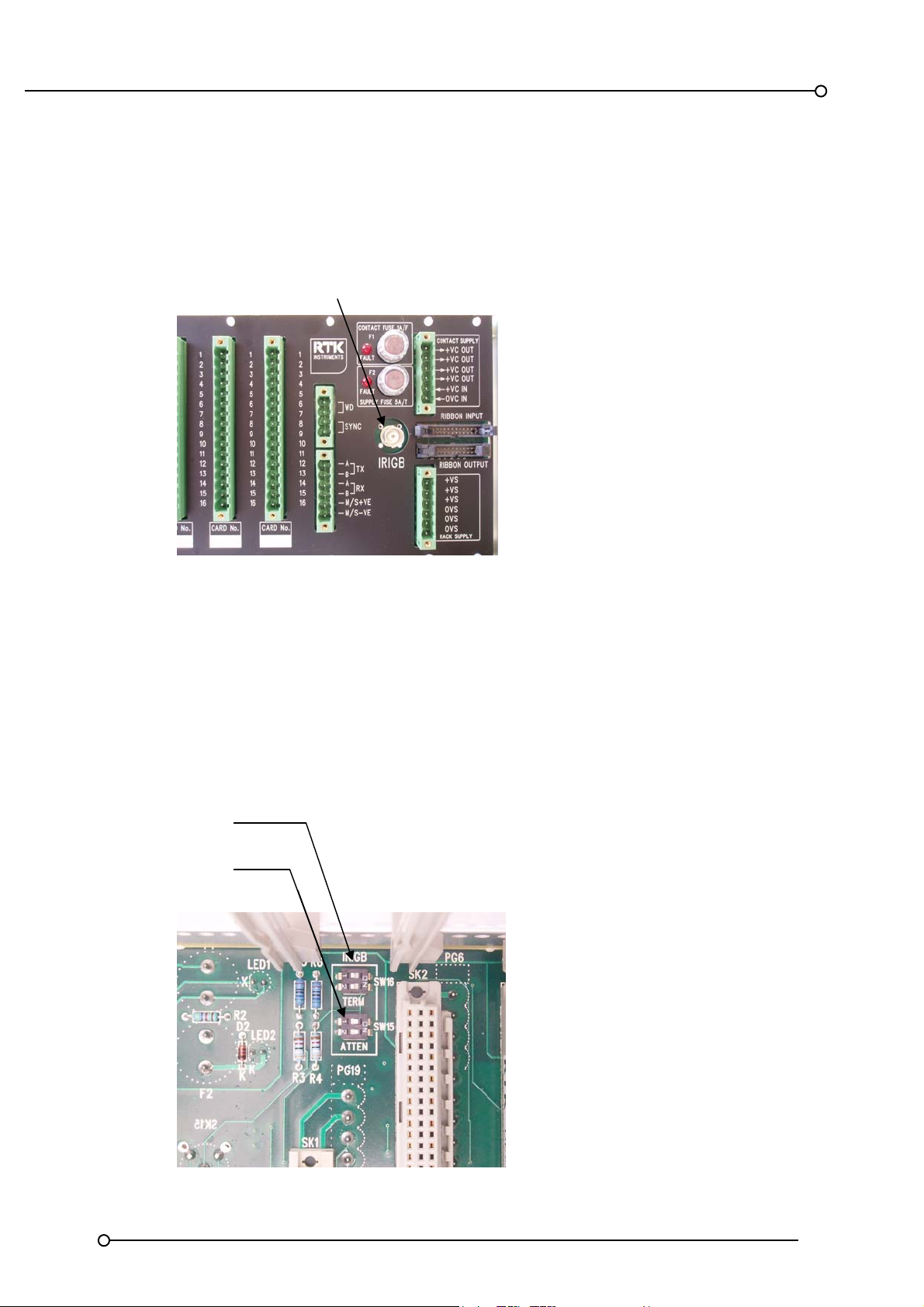

SECTION 21 – IRIGB – OPTION ................................................................................ 96

TIME CODE INPUT SPECIFICATIONS:- ....................................................................................................... 96

CONNECTIONS AND HARDWARE SETTINGS:- .............................................................................................. 97

IRIGB CARD STATUS INDICATION:- .......................................................................................................... 99

IRIGB DATE AND TIME:- ....................................................................................................................... 100

IRIGB SYNC:- ...................................................................................................................................... 101

SECTION 22 – SPARE PARTS LIST ....................................................................... 102

6

System 9000TS

SECTION 23 – SERVICING ...................................................................................... 103

SECTION 24 – TROUBLE SHOOTING GIUDE ........................................................ 106

STATUS LED ON ALL CARDS FAIL TO ILLUMINATE ..................................................................................... 106

STATUS LED ON SOME INPUT CARDS FAIL TO ILLUMINATE ......................................................................... 106

STATUS LED ON SOME OUTPUT CARDS FAIL TO ILLUMINATE ..................................................................... 106

STATUS LED ON SOME RELAY CARDS FAIL TO ILLUMINATE ........................................................................ 107

EVENTS LOST DURING POWER DOWN ..................................................................................................... 108

PORT 2 CONFIGURATION (PROGRAMME) DOES NOT WORK ....................................................................... 109

INPUT CARD CHANNEL DOES NOT RESPOND TO LOCAL INPUT CHANGE ...................................................... 109

OUTPUT CARD CHANNEL DOES NOT RESPOND TO LOCAL INPUT CHANGE ................................................... 109

RELAY CARD CHANNEL DOES NOT RESPOND TO INPUT CHANGE ............................................................... 109

INPUT CARD CHANNEL DOES NOT RESPOND TO REMOTE INPUT CHANGE ................................................... 109

OUTPUT CARD CHANNEL DOES NOT RESPOND TO REMOTE INPUT CHANGE ................................................ 110

INPUT CARD FAILS TO SIGN ON .............................................................................................................. 110

OUTPUT CARD FAILS TO SIGN ON ........................................................................................................... 110

RELAY CARD FAILS TO SIGN ON ............................................................................................................. 110

SUSTAINED WATCHDOG RELAY FAULT .................................................................................................... 110

INTERMITTENT WATCHDOG RELAY FAULT ................................................................................................ 110

SUSTAINED PRINTER WATCHDOG FAULT ................................................................................................. 111

INTERMITTENT PRINTER WATCHDOG FAULT ............................................................................................. 111

SUSTAINED AMS WATCHDOG FAULT ...................................................................................................... 111

INTERMITTENT AMS WATCHDOG FAULT ................................................................................................. 111

UNABLE TO CLEAR STATUS EVENT ......................................................................................................... 111

INTERFACE CARD STATUS LED NOT ILLUMINATED / FLASHING ................................................................... 111

INTERFACE CARD SYNC LED NOT ILLUMINATED / FLASHING ....................................................................... 112

CARD FUNCTIONS INCORRECTLY ............................................................................................................ 112

UNABLE TO SILENCE AUDIBLE / HORN ON INPUT CARD ONLY SYSTEM ........................................................ 112

SILENCE AUDIBLE / HORN ON INPUT CARD ONLY SYSTEM UNRESPONSIVE ................................................. 112

SECTION 25 – CONTACT ........................................................................................ 113

PROCEDURES FOR FACTORY REPAIR AND RETURN WARRANTY ................. 113

7

SECTION 1 - INTRODUCTION

The 9000TS system is modular in design and can be used to display alarms for

immediate action and / or to record and print alarms for later analysis.

Typical systems comprise:-

Stand alone Sequential Event Recorder providing time stamping of events to a

1mS resolution.

Sequential Event Recorder with Combined Alarm Annunciation features and

Remote Displays

Sequential Event Recorder with Combined Alarm Annunciation features,

Remote Displays and Signal Duplicating Relays.

Stand alone Remote Logic Annunciator systems

Optional Alarm Management Software (AMS)

9000TS Systems are fully programmable using RTK’s windows based software utility

which is provided free of charge.

A programming port, RS232, is provided on the front of the Interface Card for

connection to a suitable PC / Laptop and no special programming language skills are

required as the user can simply enable or disable pre-defined features on a per

channel basis and the revisions can be down loaded to the system via the Interface

Card. Configuration data is stored in EEPROM on the individual cards without the

need for battery back-up.

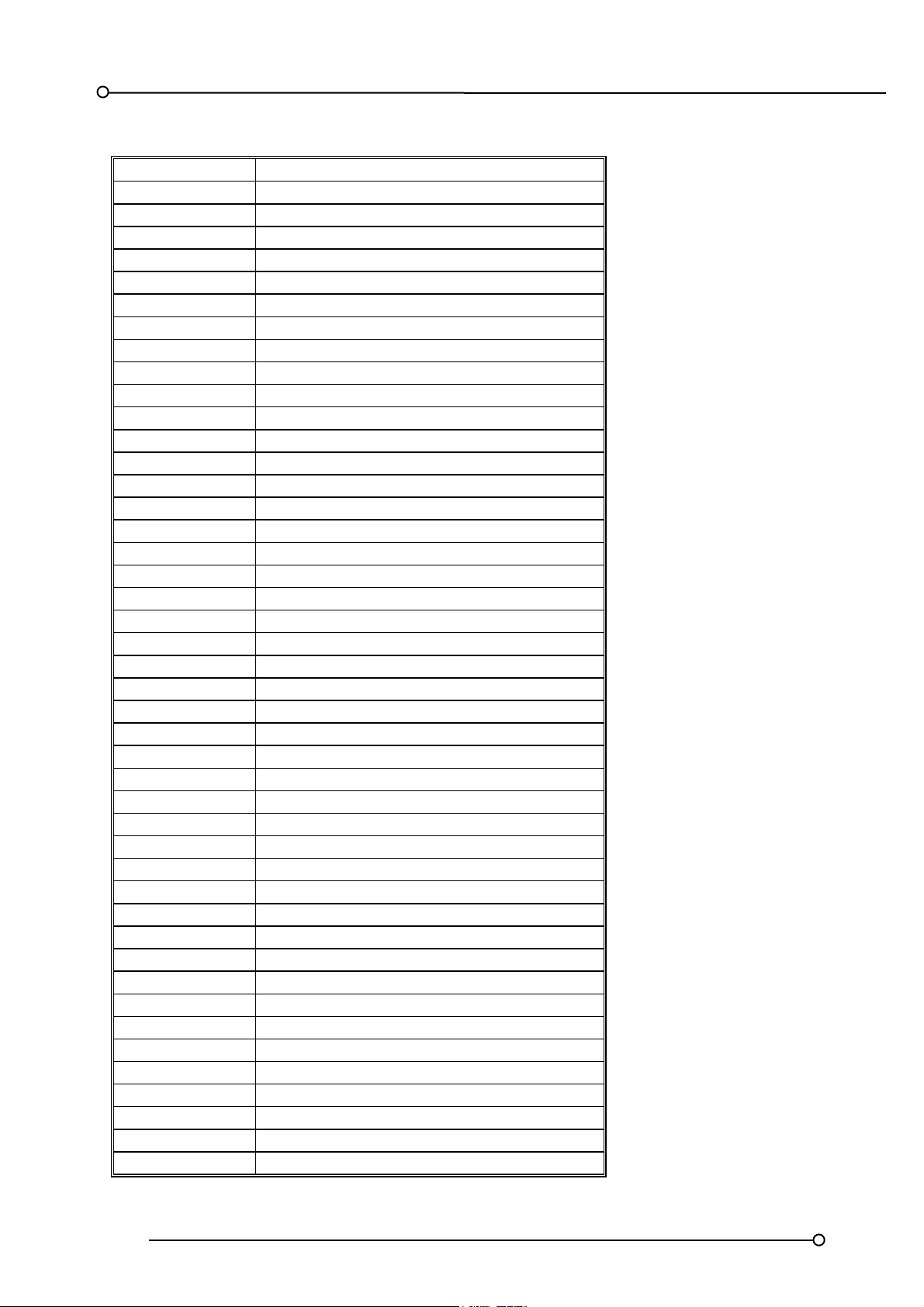

9000TS Systems are constructed using a combination of the following key parts

MODEL NUMBER FUNCTION

P925TS-RK 19” Rack Chassis (Base Unit)

P925TS-RK-ETN 19” Rack Chassis (Expansion Unit)

P925TS-X Interface Card

P925TS-I 16 channel Input Cards

P925TS-O 16 channel Output Cards

P925TS-R 16 channel Repeat Relay Cards

P925TS-BL Blanking Plates (For unused positions)

P925TS-CABLE-1 Rack Interconnection Ribbon Cable 1 metre length (standard)

8

System 9000TS

SECTION 2 - SYSTEM DESCRIPTION AND FEATURES

General

9000TS Systems are constructed using industry standard 19” Racks with front access

to the associated logic cards and rear access to custom terminals. All terminals are of

the rising clamp type suitable for a maximum of 2.5mm sq. wire and each terminal

block can be removed to aid installation. Terminal blocks are provided with locking

screws for increased security during normal operation.

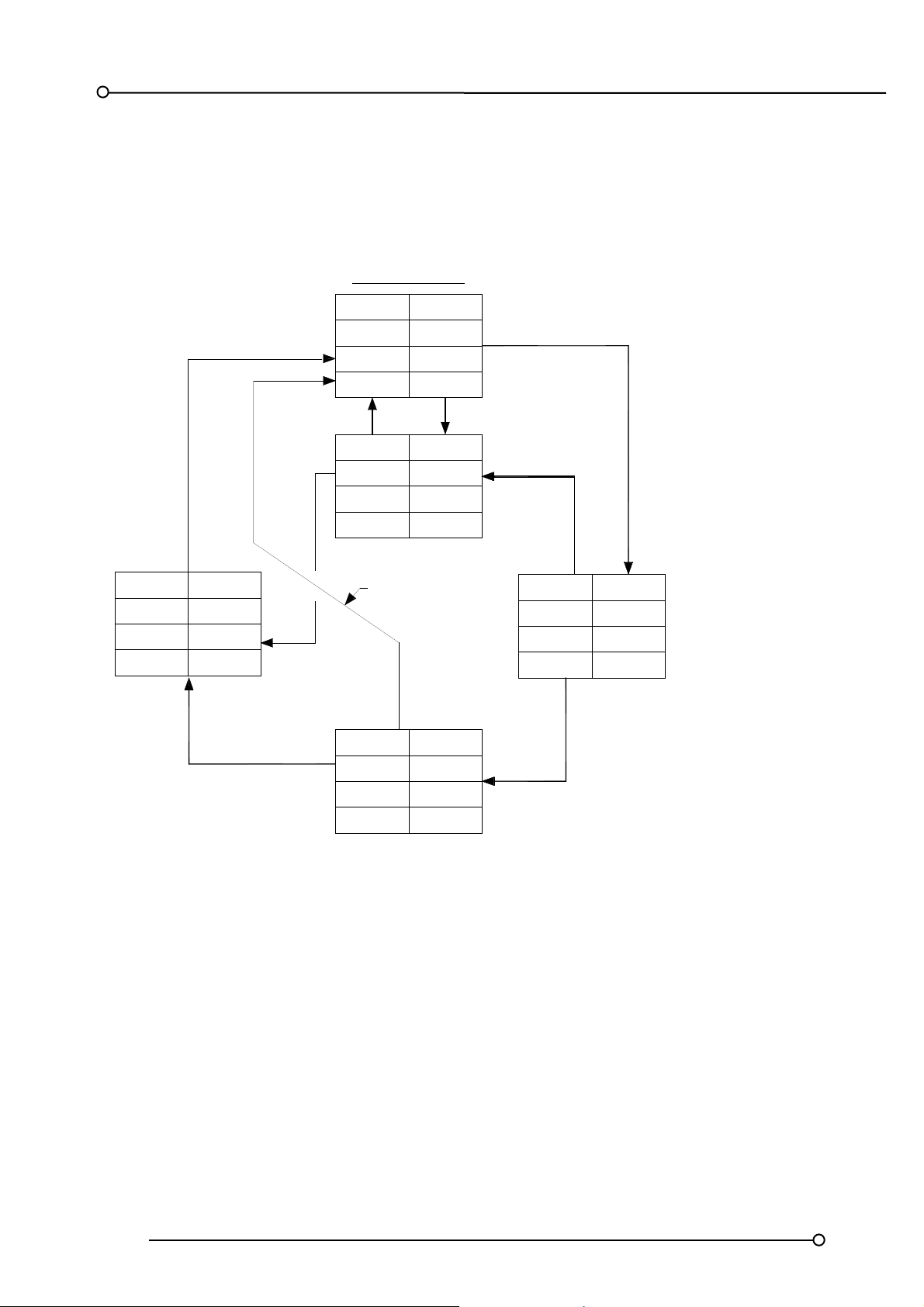

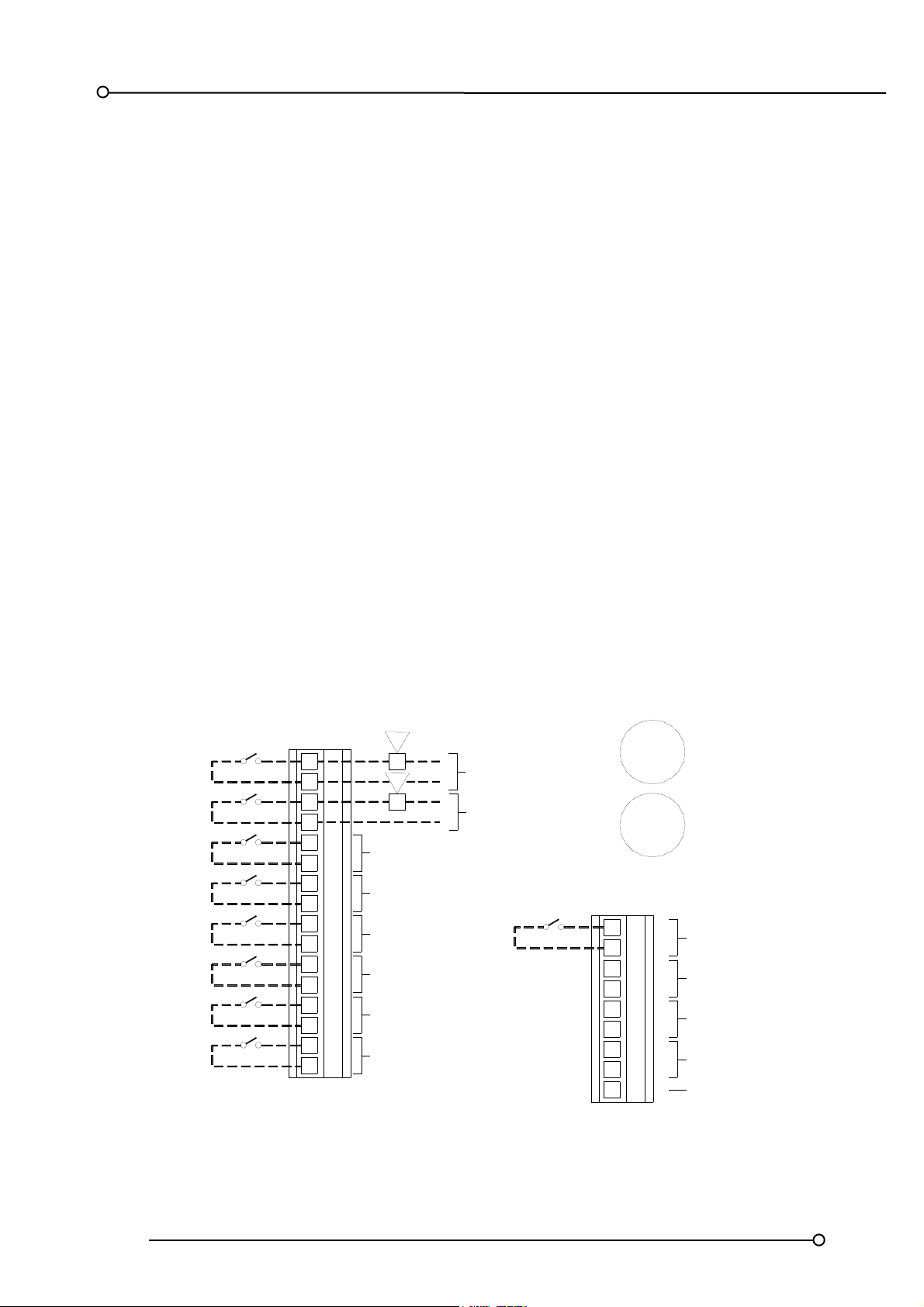

RACK

P925TS-RK

INTERF ACE

PORT 2

PRINTER

PORT 3

RX

TX

PORT 2 (PROG)

PORT 3

RX

TX

P925TS-X

RX

1

2

3

STATUS

SYNC

TX

INTERNAL

PORT 1

INPU T

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

P925TS-I

STATUS

INPUTS 1 TO 16

STATUS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1A1

P925TS-O

OUTPUTS 1 TO 16

RELAYOUTPUT

STATUS

1

2

3

4

RELAYS 1 TO 16

5

6

7

8

9

10

11

12

13

14

15

16

1B

P925TS-R

P925TS-BL

A P925TS-RK 19” 3U Base Rack with 13 card slots is supplied with each system and

the following can be used as required.

P925TS-X Interface Card

P925TS-I Input Cards (16 channel)

P925TS-O Output Cards (16 channel)

P925TS-R Relay Cards (16 channel)

P925TS-BL Blanking Plates to protect and cover unused positions

P925TS-RK-ETN 19” 3U Expansion Racks with 14 card slots

Any combination of Input, Output or Relay Cards can be used to suit individual

applications. Ribbon sockets are provided on the rear of each rack allowing all of the

common system bus to be linked to expansion racks using factory supplied ribbon

cables.

Each Rack is equipped with its own 24VDC Logic and Signal Supply Fuse for added

protection and status LED’s are provided per fuse.

9

Universal Card Slots

All card slots within the racks are universal in application therefore Input, Output or

Relay Cards can be inserted into any available slot. Cards are inserted from the front

of the rack and once inserted automatically connect to the customer terminals located

on the rear of the chassis. Locking screws are provided at the top and bottom of each

card to ensure they are firmly seated at all times.

Polarisation Keys

For added security all cards and slots are supplied with polarisation keys to prevent

accidental insertion into the incorrect position within the racks. The polarisation can be

changed but care must be taken to ensure the associated field wiring is disconnected

and re-wired before cards of a different type are inserted into slots previously occupied

by different card types. For example high voltage inputs may have been used on a

socket that it being upgraded for use with low voltage outputs.

System Connections

In larger applications multiple racks can used to form larger systems and common bus

connections between racks are linked via RTK supplied plug in ribbon cables. These

connect to dedicated ribbon sockets located on the rear of each rack and are labelled

ribbon IN and ribbon OUT. The standard ribbon is 1mtr in length but additional length

cables can be supplied at time of order if required.

Customer Connections

Industry standard rising clamp terminal blocks, capable of accepting a maximum of

2.5mm2 cable are provided on the rear of each rack for connection of logic power,

signal power, signal inputs, lamp and relay outputs. Locking screws are provided at

the top and bottom of each terminal block to allow them to be easily removed during

installation, commissioning or fault finding.

Fully Field Configurable

Each channel within the 9000TS System can be configured by the customer using the

RTK supplied software utility and all programming information is stored in non-volatile

memory on individual cards with a minimum of 20 years retention. Full details of the

software and available features are provided via a separate manual.

Print Outs

A dot matrix printer can be directly connected to the P925TS-X Interface Card to

dynamically print the alarms as they occur or the user can choose to disable the print

function for later analysis. 3 tactile pushbuttons located on the face of the Interface

Card allow the user to trigger predefined reports as detailed later in this manual.

10

System 9000TS

First-Up Alarms

When a group of alarms is initiated, it is often critical to know the first alarm to occur

within the group as it allows the user to quickly identify the primary cause of failure.

This should reduce downtime and allow the plant to be returned to the operational

state in the shortest possible time. A printout of events to a 1mS resolution and or a

First-Up alarm sequences can be used to identify the primary cause of failure.

System Relays

Eight relays are provided within the P925TS-X Interface Card comprising two horn

relays and six common relays, which can be software configured to provide common

alarm group or failure alarm contacts for use with 3rd party devices.

Time Delays

Whilst some of the alarms in the system may require events to be captured to a 1ms

resolution some of the alarms may not need to respond in the same manner. Input

Cards are therefore provided with incremental time delays that allow the user to

configure each channel to activate and / or de-activate after a pre-set time limit has

elapsed. Each channel can be selected between 1 and 65,000ms

Auto Shelve

When high-speed events are being captured and stored in logs a faulty input contact

to an alarm channel can quickly fill the associated event buffers. Each channel can be

software configured to automatically shelve an alarm if the frequency of alarms

exceeds the specified norm within a defined time period. Once the channel returns to

set limits it will be automatically removed from auto shelve and will carry on

responding in the normal way. When auto-shelve occurs the event is stored in memory

and printed as required.

Sleep Mode

In applications where plant areas are not manned on a permanent basis – Sleep Mode

– can be used to disable the output drives to Displays and Audibles. This feature is

used to minimise drain on the primary power source, (typically batteries), and to

prevent unnecessary noise pollution.

Sleep mode is a standard feature of the 9000TS System and it is important to note that

whilst in this mode the logic continues to respond to alarms in the normal manner. The

pushbutton functions are disabled during sleep mode to ensure that once this feature

has been turned off the operator can use the associated pushbuttons to control the

alarms in the normal way.

11

SECTION 3 – MECHANICAL DETAILS

Logic Rack

The 9000TS System is mounted in industry standard 19" Racks manufactured to

IEC297-3 (DIN1494 Pt5). On larger systems multiple racks are supplied and ribbon

cables, which plug into dedicated sockets on the rear of each rack, are used to link

common bus lines.

When mounting the rack care must be taken to ensure that there is sufficient room to

withdraw the cards from the front of the rack and for cable access to the rows of 16

way terminals mounted on the rear of the rack. Customer inputs and outputs are

capable of accepting cable up to a maximum of 2.5mm2 and each terminal block can

be removed for ease of wiring using the locking screws provided at either end of the

block

Mounting

The 19” Rack should be mounted in a location that is free from excessive moisture,

vibration, heat and dust with sufficient clearance at the front to withdraw all cards

without obstruction and space at the rear to connect the associated field wiring. All

spare positions in a rack are fitted with all of the necessary edge connectors and

chassis blanking plates for ease of expansion at a later date. Additional Input, Output

or Relay Cards can therefore be plugged in and connected with ease.

Earthing

To comply with the EMC requirements for electrostatic discharge IEC801-2 it is

essential that each 19" Rack is suitably earthed. A dedicated earth point is supplied on

the right hand side plate of each rack for this purpose.

Plug-in Cards

The first rack in any system is supplied with one P925TS-X Interface Card and thirteen

vacant card slots, which can be used for a combination of :-

CARD TYPE FUNCTION SPACE REQUIRED

P925TS-1 16 Channel Input Card One Card Slot

P925TS-O 16 Channel Output Card One Card Slot

P925TS-R 16 Channel Repeat Relay Card Two Card Slots

P925TS-BL Blanking Plates One Card Slot

Once the cards are plugged into the rack they automatically connect to the

motherboard to link all of the control functions between cards and to provide

connections to the Customer terminals mounted on the rear of the rack.

Lamp / LED Displays

The 9000TS System is able to drive existing displays or RTK can supply the system

with RTK manufactured display units as required.

12

System 9000TS

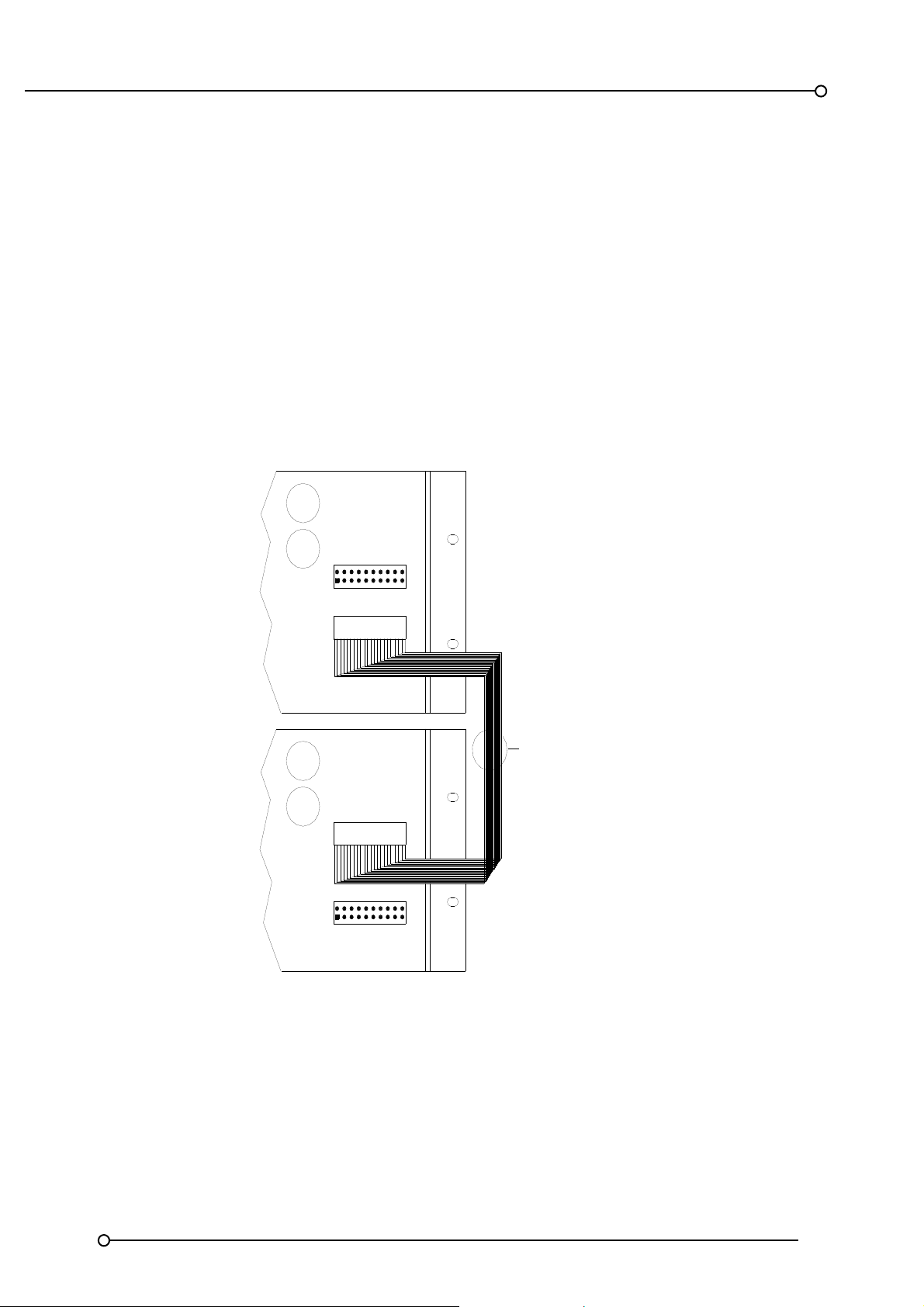

Multiple Racks Systems

In larger SOE or combined SOE / Annunciator schemes multiple racks can be supplied

as required.

These systems still only 1 x P925TS-X Interface Card for communication to the

outside world and to being able to configure the associated cards.

The common signals required between racks are fully buffered and are connected

using RTK supplied plug in ribbon cables which connect into dedicated sockets on the

rear of the associated racks as typically shown below.

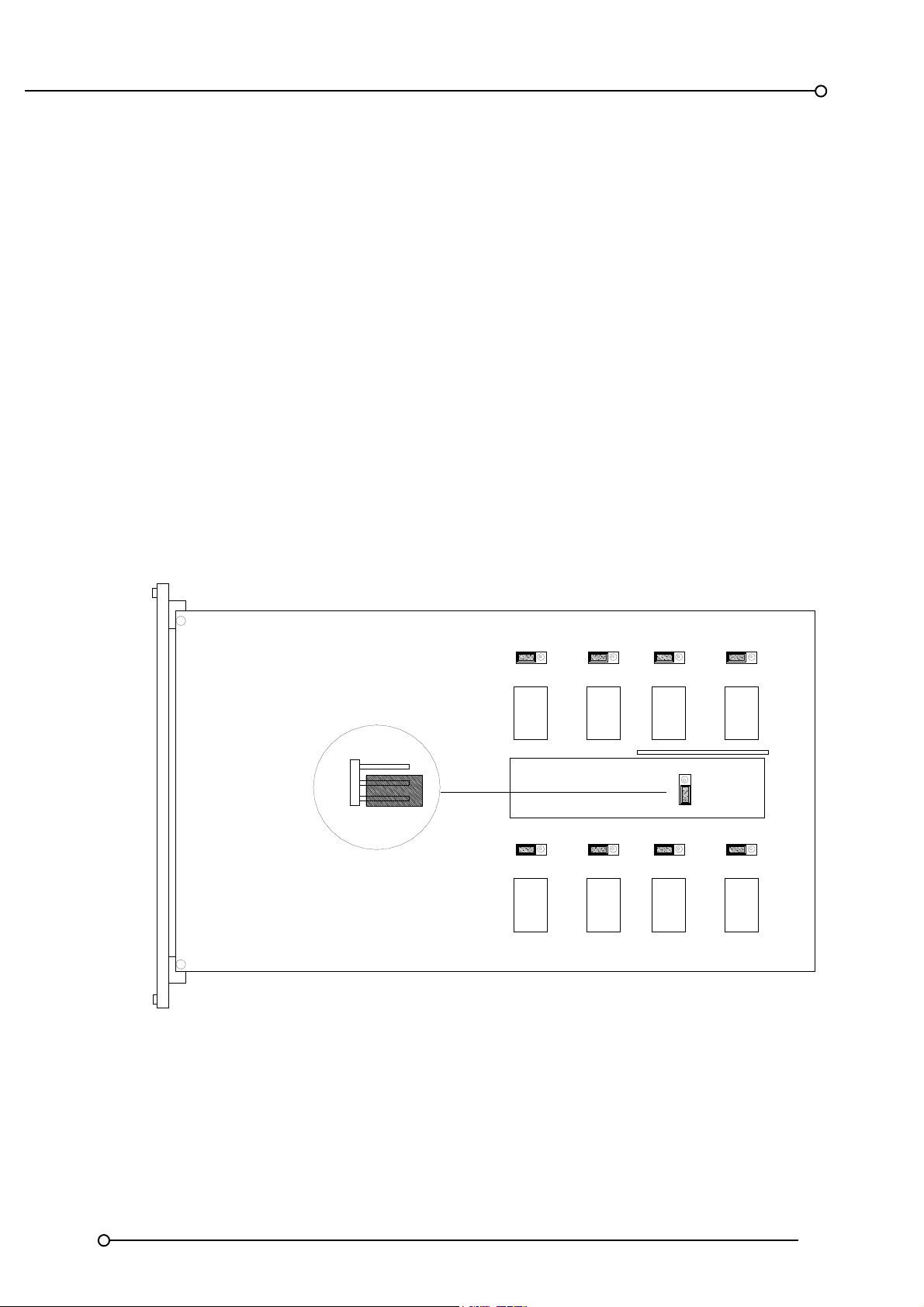

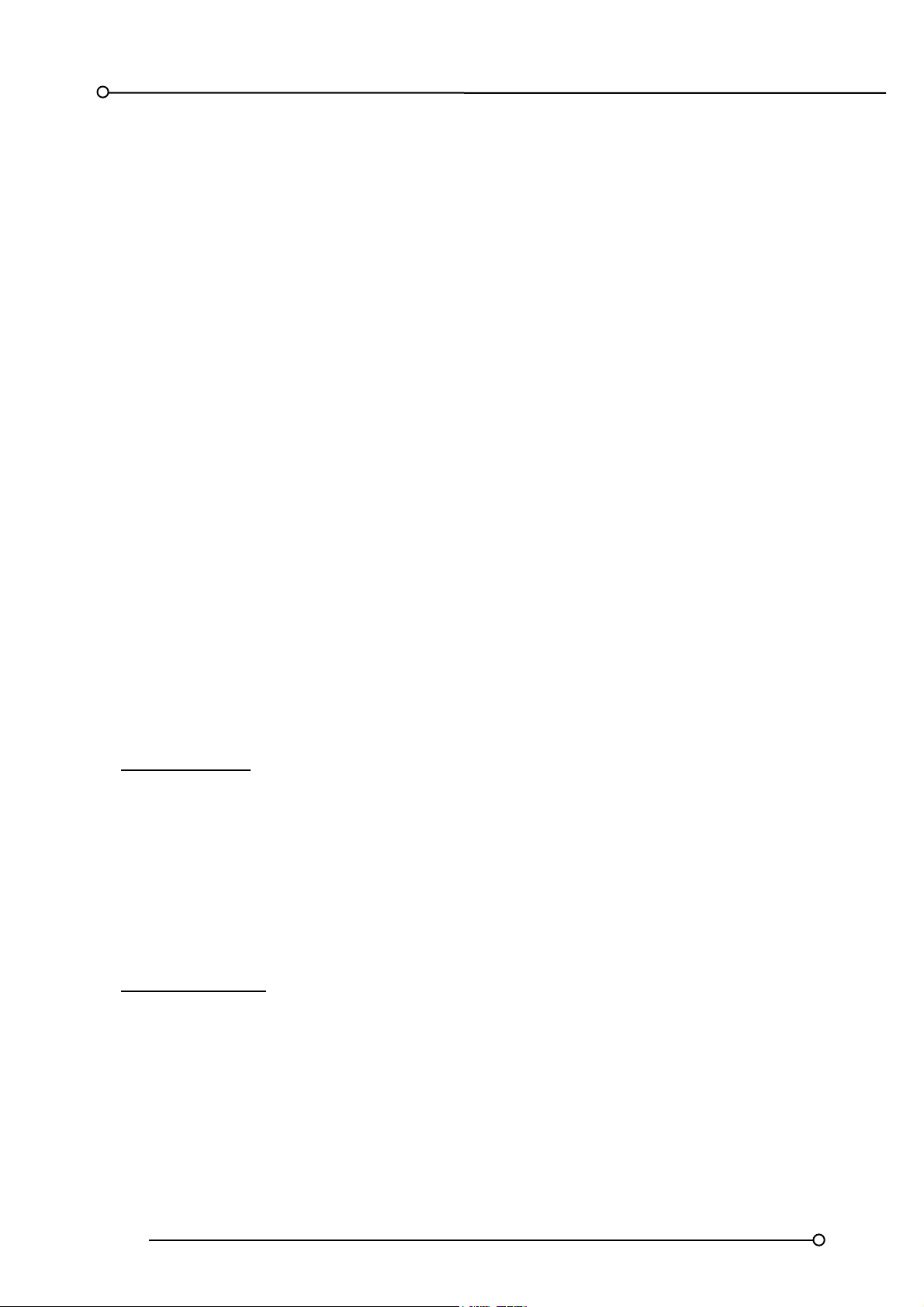

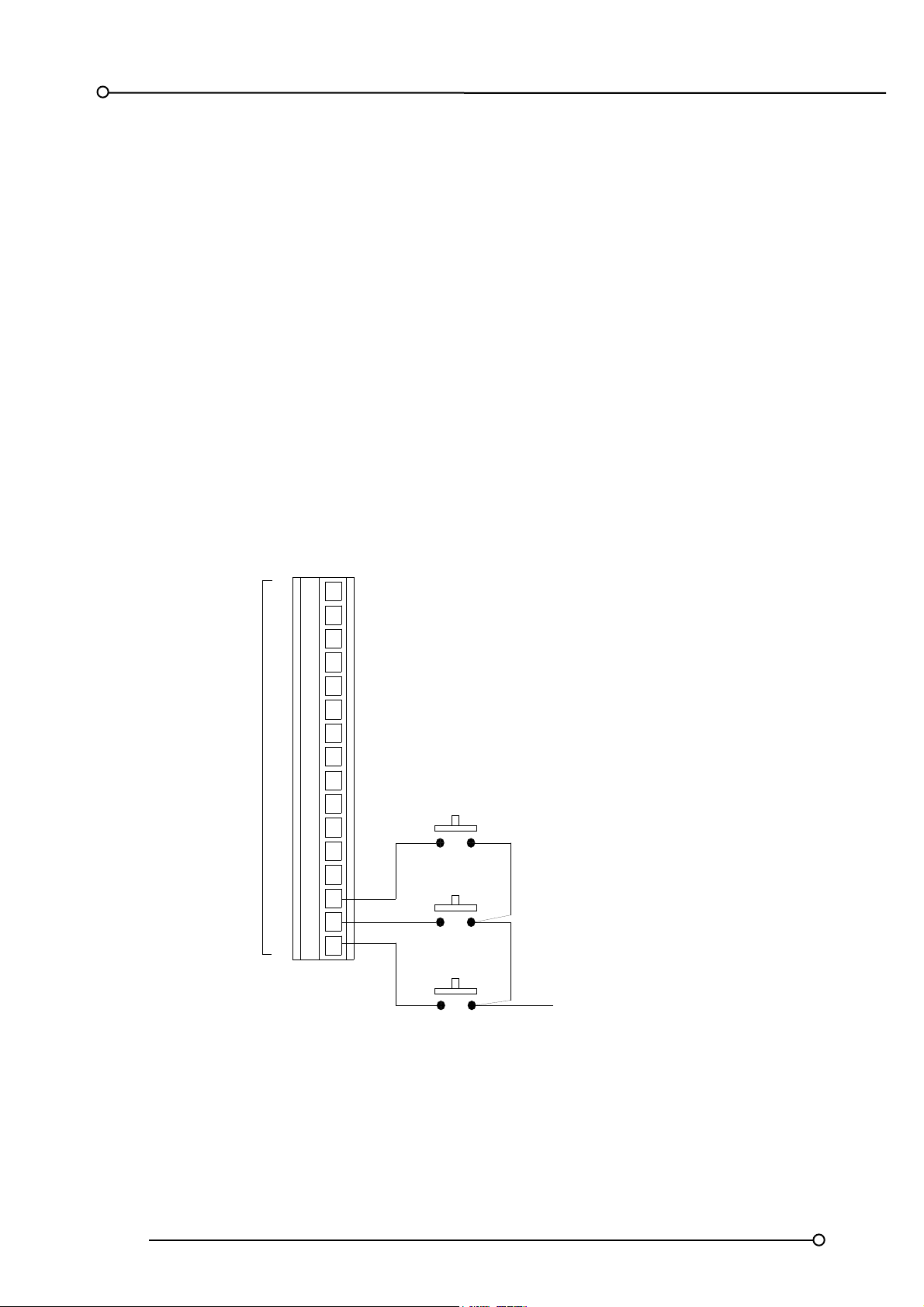

Chassis Interconnecting Ribbon Details

FUSE 1

FUSE 2

FUSE 1

FUSE 2

IN P UT

OUTPUT

IN P UT

OUTPUT

RTK SUPPLIED CHASSIS

INTERCONNECTING RIBBON

PART NO . P925TS-CA BLE -1

(1 Metre supplied as standard)

13

SECTION 4 – OPERATING INSTRUCTIONS

Pre-checks

The system is supplied fully tested and, if requested, pre-configured to suit your

application so detailed on site re-testing should not be necessary.

After connections have been completed the following pre-checks should be made

before applying power.

1. Ensure the equipment is earthed using the specific earth stud on the right-hand

side of the P925TS-RK Euro-rack.

2. Check that the power supply is adequately rated and suitable for the primary

supply available and that the output voltage is suitable for use with the 9000TS

system.

3. The 9000TS System requires a 24VDC logic supply and the 24VDC signal

supply is derived from this supply as standard. (Options exists for high voltage

inputs fed via external power source as detailed within this manual)

4. Check that all cards are fully seated and the retaining screws have been

tightened.

5. Check all alarm contacts are volt-free and correctly wired using the common

voltage +24VDC available on terminal +VC for standard systems (Options

exists for high voltage inputs fed via external power source as detailed within

this manual)

6. Care should be taken with the output wiring to the display to ensure no shorts

occur.

7. Please note a short in the output will not damage the equipment but could give

extremely misleading results.

Status LED

Each card is supplied with a status LED which is used for fault and setup indication as

follows:-

LED STATUS

ON Normal Operation

OFF Faulty card or card not recognised in software

Power ON

After completing the above pre-checks, power can be supplied to the unit. The system

will complete an initial self-test and will search for all of the installed cards. During this

time the status LED on the associated input / output card will illuminate as soon as the

system recognises the card and its settings.

14

SECTION 5 – TECHNICAL SPECIFICATION

Logic Supply 24VDC ( 19 to 36VDC )

A range of power supplies are available to convert from

higher AC or DC primary supply voltages.

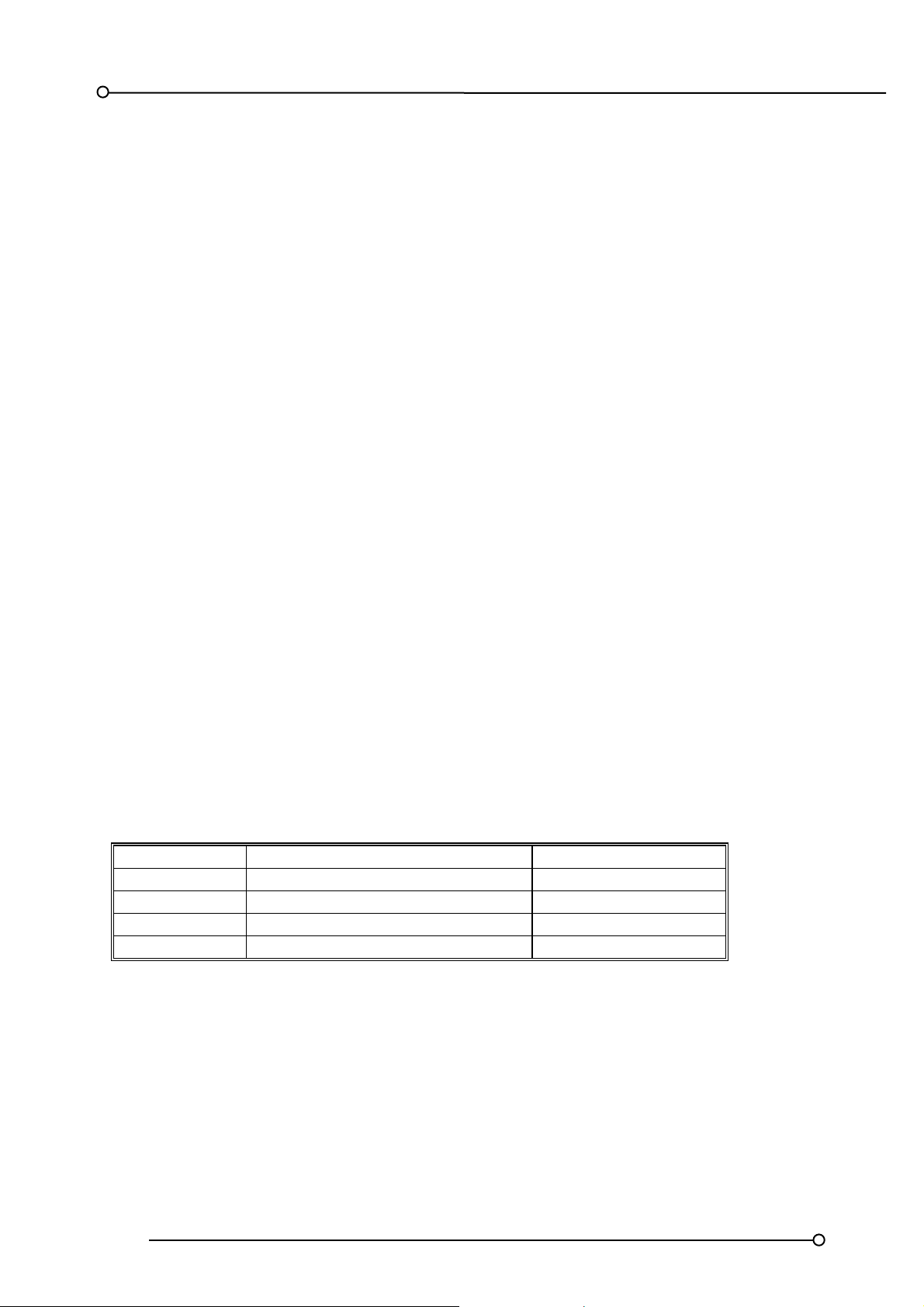

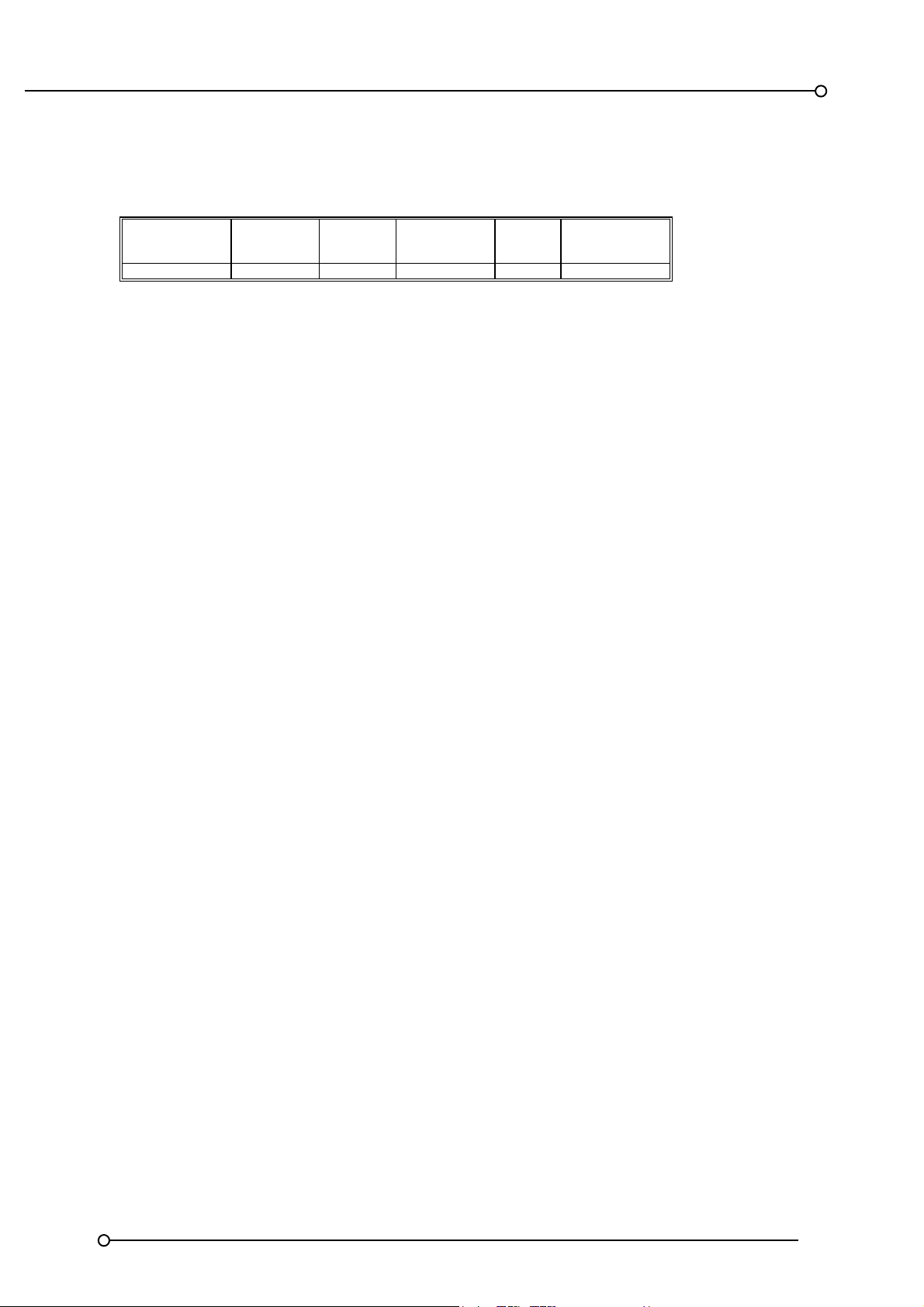

Supply Current @ 24VDC for all card types

MODEL NO TYPE CURRENT

P925TS-X Interface Card 1A

P925TS-I Input Card 100mA

P925TS-O Output Card 100mA plus Lamp / LED load

P925TS-R Relay Card 250mA

RTK LED LED Cluster 20mA each

RTK 28V Lamp 40mA each

Individual Repeat Relays

VOLTAGE RATING (RESISTIVE)

24VDC 2A

125VDC 0.5A

Common Relays

VOLTAGE RATING (RESISTIVE)

24VDC 2A

125VDC 0.5A

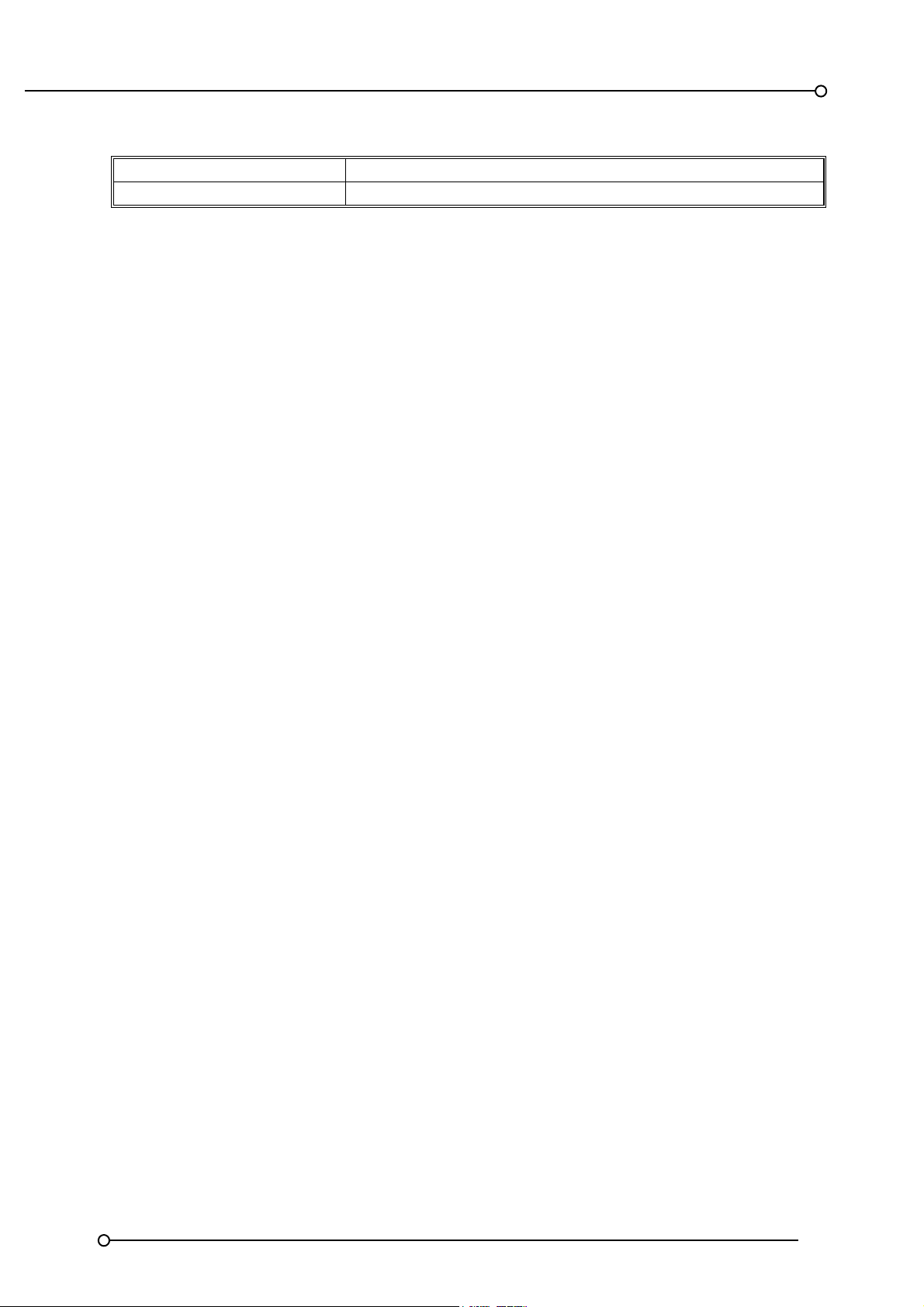

Fuse ratings

FUSE RATINGS PURPOSE

F1 1A/T Protects the +24VDC signal supply from each chassis

System 9000TS

F2 5A/F Protects the main 24VDC logic supply to each chassis

Alarm Sequences Compliant to ISA Standard S18.1 – 1979 (R.1992)

Each channel can be configured to operate in accordance

with the standard ISA sequences detailed in ISA-S18.1

1979.

Terminals Rising clamp type terminals complete with locking screws.

Maximum cable size 2.5 mm Square

15

EMC Compliance

Radiated RFI Immunity

IEC 61000-4-3

Conducted RFI Immunity

IEC 61000-4-6

Radiated Emissions

IEC 61000-6-3

Conducted Emissions

IEC 61000-6-3

Radiated Power Frequency Magnetic Field

IEC 61000-4-8

ESD Effects

IEC 61000-4-2

Dielectric Withstand

1500V RMS

Surge Withstand – Oscillatory

ANSI C37.90.1

Electrical Fast Transient/Burst Immunity

IEC 61000-4-4

Surge Immunity

IEC 61000-4-5

LVD Compliance

Designed and manufactured to BS EN61010-1:1993

Environment

Operating temperature 0oC to 60oC

Storage temperature -20oC to 80oC

Humidity 0-95% RH, non-condensing

16

System 9000TS

Input Specifications

Contact Volt Free contacts that can be software configured to be

either normally open or normally closed.

Voltage 24V AC/DC with selectable option per channel for

125VAC/DC (Options for 48VAC/DC or 250VAC/DC)

Contact resistance N/C series resistance of contact cables 20K Ohm max

Contact resistance N/O parallel resistance of contact cables 200K Ohm min

Alarm contact current Typical loop current 2mA

Input response time Selectable form 1mS to 65,000mS

First up discrimination 1mS

Input protection The equipment is protected against reverse connection of

the supply input.

Pushbuttons Control pushbuttons can be software configured as

required and normally use +24VDC as a common return in

systems using high voltage inputs they use the same return

as the signals (48VAC/DC, 125VAC/DC or 250VAC/DC)

Output Specifications

Output cards Each channel can drive up to 160mA @ 24VDC, making it

suitable for multi bulb / LED displays or multiple repeat

displays.

System relays There are eight systems relays comprising two horn relays

and six common relays, which can be configured as group

or fault relays. A volt free contact is provided per relay,

which can be set to normally open or normally closed as

required.

All contacts are rated at 2A @ 24VDC

Repeat relays As an option 16 channel repeat relay cards are available

which provide a volt free contact per relay, which can be

set to normally open or normally closed as required.

All contacts are rated at 2A @ 24VDC

Communications RS485 Bi-directional modbus communication port, 9 Pin

programming port and 25 Pin printer port.

17

SECTION 6 – ALARM SEQUENCES

On systems supplied with P925TS-O Output Cards each channel can be programmed

to operate to a sequence defined within ISA-S18.1 Alarm Sequences. Full details of

how to set each channel to the required alarm sequence are provided in the 9000TS

Configuration Manual.

The following paragraphs detail the most common features.

Summary

Within the alarm annunciator market a common standard has been adopted by all key

manufacturers and end users with regards to operational sequences. These standards

are used worldwide to define the visual indication, audible alarm and the action the

operator must take to control the annunciator.

The Instrument Society of America provide full details of each alarm sequence within

ISA 18.1-1979 (R1992) and RTK are fully compliant with the stated sequences. The

most common sequences are detailed within this section of the manual.

Pushbuttons

Six pushbutton functions are provided within the 9000TS System to allow the user to

be able to control any of the available sequences.

1. Lamp Test – is used to test the LED assemblies by illuminating them in a

steady state for as long as the pushbutton is pressed

2. Functional Test – is used to simulate an input on all channels and therefore all

windows and horn circuits will operate in accordance with the selected ISA

sequence and additional pushbuttons will need to be pressed to step through

the alarm sequence to return the unit to its normal state

3. Mute – is used to silence the audible alarm whilst allowing the associated alarm

window to continue to operate in accordance with the selected ISA sequence

4. Acknowledge – is used to silence the alarm and change the state of the

associated alarm window in accordance with the selected ISA sequence

5. Reset – is used to return the alarm to the normal off state once the Input has

returned to the normal condition

6. First Reset – is used to reset the flash sequence on the first alarm to occur

within a defined group of alarms. Once first reset has been pressed the next

alarm to occur within the group will flash at the first up alarm rate.

18

System 9000TS

Audible Alarms

Each channel within the annunciator can be set to operate RL1 and RL2 common horn

relays as required and RL5 – 8 can be set as additional horn relays as required.

Automatic Reset

Once a channel has been acknowledged and its input has returned to normal the

alarm can be set to automatically reset without the operator having to press the reset

pushbutton

Non Latch Sequence – (No Lock In)

Alarms can be set to non lock-in, which allows the alarm to automatically return to the

non alarm state as soon as the signal input returns to normal

Ringback Sequence

Ringback sequence is used to inform the operator both visually and audibly that an

alarm condition has cleared and the channel can be reset to its normal off state. When

a contact returns to normal the associated window will flash at approx ½ the speed of

a normal alarm and the audible will sound. This identifies the specific alarm and

informs the operator that the alarm can be reset to its normal off state.

First Up Sequences

When monitoring devices with interlinked functions such as a turbine or compressor it

is often important to know the specific alarm that occurred first, as it will invariably

result in cascade of secondary alarms. This allows the operator to focus on the root

cause of failure and therefore limits the downtime and associated costs. This is

achieved by having the first-up alarm flashing in a different manner compared to the

subsequent alarms. Four different first-up sequences are available F0, F1, F2 and F3

as detailed below and in the following sequence tables.

F0 The standard mode adopted by RTK Instruments, which indicates the first-up alarm

by flashing at twice the rate of subsequent alarms.

F1 In this mode subsequent alarms appear in the acknowledged state, hence they do

not flash. The audible device does not operate when subsequent alarms occur,

unless still operating from the first alarm. The acknowledge pushbutton will reset

the first-up indication.

F2 In this mode all subsequent alarms do not flash, they will however operate the

audible device. The acknowledge pushbutton will reset the first-up indication.

F3 In this mode initial alarms appear with an intermittent flash rate and subsequent

alarms flash at a steady rate. On acknowledge subsequent alarms revert to the

steady on state and only the first alarm continues to flash at a slower rate.

Please note auto reset and non lock- in functions are not recommended when using

first up sequences as the true sequence of events cannot be guaranteed.

The most common sequences are detailed below:-

19

ISA A – Automatic Reset – Lock In

RETURN

TO NORMAL

PROCESS

SEQUENCE

AUDIBLE

NORMAL

NORMAL

OFFVISUAL

SILENT

TO

ABNORMAL

ACKNOWLWDGE

WHILE NORMAL

PROCESS

SEQUENCE

VISUAL

AUDIBLE

ABNORMAL

OR NORMAL

ACKNOW

ON

SILENT

ACKNOWLEDGE

WHILE ABNORMAL

PROCESS

SEQUENCE

VISUAL

AUDIBLE

ABNORMAL

OR NORMAL

ALARM

FLASHING

AUDIBLE

Sequence Features

1. Acknowledge and test pushbuttons.

2. Alarm audible device

3. Lock In of momentary alarms until acknowledged

4. The Audible device is silenced and the flashing stops when acknowledged.

5. Automatic reset of acknowledged alarms when the process has returned to

normal

6. Operational test

20

ISA A-4 – Automatic Reset – Non Lock In

RETURN

TO NORMAL

PROCESS

SEQUENCE

AUDIBLE

NORMAL

NORMAL

OFFVISUAL

SILENT

System 9000TS

TO

ABNORMAL

RETURN

TO NORMAL

PROCESS

SEQUENCE

VISUAL

AUDIBLE

ABNORMAL

OR NORMAL

ACKNOW

ON

SILENT

ACKNOWLEDGE

WHILE ABNORMAL

PROCESS

SEQUENCE

VISUAL

AUDIBLE

ABNORMAL

OR NORMAL

ALARM

FLASHING

AUDIBLE

Sequence Features

1. Acknowledge, and test pushbuttons.

2. Alarm audible device

3. Non Lock In of momentary alarms

4. The audible device is silenced and the flashing stops when acknowledged.

5. Automatic reset of alarms when the process has returned to normal before or

after acknowledge (Non Lock In)

6. Operational test

21

ISA A-4-5-6 – Status

RETURN

TO NORMAL

PROCESS

SEQUENCE

AUDIBLE

PROCESS

SEQUENCE

VISUAL

AUDIBLE

NORMAL

NORMAL

OFFVISUAL

SILENT

ABNORMAL

OR NORMAL

ALARM

ON

SILENT

TO

ABNORMAL

Sequence Features

1. Test pushbutton.

2. No alarm audible

3. The visual alarm does not flash

4. Non Lock In of momentary alarms

5. Automatic reset of alarms when the process has returned to normal before or

after acknowledge (Non Lock In)

6. Operational test

22

ISA M – Manual Reset – Lock In

RESET

WHILE NORMAL

PROCESS

SEQUENCE

AUDIBLE

NORMAL

NORMAL

OFFVISUAL

SILENT

System 9000TS

TO

ABNORMAL

PROCESS

SEQUENCE

VISUAL

AUDIBLE

ABNORMAL

OR NORMAL

ACKNOW.

ON

SILENT

ACKNOWLEDGE

WHILE ABNORMAL

PROCESS

SEQUENCE

VISUAL

AUDIBLE

ABNORMAL

OR NORMAL

ALARM

FLASHING

AUDIBLE

Sequence Features

1. Acknowledge, reset and test pushbuttons.

2. Alarm audible device

3. Lock In of momentary alarms until acknowledged

4. The Audible device is silenced and the flashing visual alarm stops when

acknowledged.

5. Manual reset of acknowledged alarms when the process has returned to normal

6. Operational test

23

ISA R – Ringback

SEQUENCE

VISUAL

AUDIBLE

NORMALPROCESS

RINGBACK

SLOW FLASH

PULSING

RETURN

TO NORMAL

PROCESS

SEQUENCE

AUDIBLE

ACK WHILE ABNORMAL

RETURN TO NORMAL

PROCESS ABNORMAL

SEQUENCE

VISUAL

AUDIBLE

NORMAL

NORMAL

OFFVISUAL

SILENT

ACKNOW

ON

SILENT

TO ABNORMALRESET

PROCESS

SEQUENCE

VISUAL

AUDIBLE

ACKNOW

WHILE NORMAL

ABNORMAL

OR NORMAL

ALARM

FAST FLASH

AUDIBLE

Sequence Features

1. Acknowledge, reset and test pushbuttons.

2. Alarm audible device. (optional Ringback audible device)

3. Lock In of momentary alarms until acknowledged

4. The audible device is silenced and the flashing stops when acknowledged

5. Ringback visual ad audible indications when the process condition returns to

normal

6. Manual reset of Ringback indications

7. Operational test

24

ISA F1A-1 – Automatic Reset First Up

System 9000TS

RETURN

TO NORMAL

SUBSEQUENT

TO ABNORMAL

PROCESS ABNORMAL

SEQUENCE

VISUAL

AUDIBLE

ACKNOW.

ON

SILENT

PROCESS

SEQUENCE

AUDIBLE

ACKNOWLEDGE

WHILE ABNORMAL

(FIRST OUT RESET)

NORMAL

NORMAL

OFFVISUAL

SILENT

FIRST TO

ABNORMAL

PROCESS

SEQUENCE

VISUAL

AUDIBLE

ABNORMAL

OR NORMAL

FIRST ALARM

FLASHING

AUDIBLE

Sequence Features

1. Acknowledge and test pushbuttons.

2. Alarm audible device

3. Lock In of momentary first alarm only, no lock in of momentary subsequent

alarms

4. Flashing and audible indications for first alarm only, new subsequent alarms go

to the acknowledge state.

5. First out indication is reset and the audible is silenced when acknowledged.

6. Automatic Reset of acknowledged alarm indications when the process returns

to normal

7. Silence pushbutton can be used to silence the audible alarm only

25

(

)

ISA F2M-1 – Manual Reset First Up

SEQUENCE DIAGRAM

PROCESS

SEQUENCE

VISUAL

RESET WHILE

NORMAL

SILENCE

ACKNOWLEDGE

ABNORMAL

OR NORMAL

ACKNOWLEDGED

ON

PROCESS

SEQUENCE

VISUAL

AUDIBLE

PROCESS

SEQUENCE

VISUAL

AUDIBLE

NORMAL

NORMAL

SILENT

ABNORMAL

OR NORMAL

SUBSEQUENT

ALARM

ACKNOWLEDGE

(FIRST OUT RESET)

OFF

SUBSEQUENT TO

ABNORMAL

ON

ON

FIRST TO

ABNORMAL

PROCESS

SEQUENCE

VISUAL

ABNORMAL

OR NORMAL

FIRST ALARM

FLASHING

26

AUDIBLE

SILENT

ACKNOWLEDGE

(FIRST OUT RESET)

PROCESS

SEQEUNCE

VISUAL

AUDIBLE

ABNORMAL

OR NORMAL

FIRST SILENCED

FLASHING

SILENT

AUDIBLE

SILENCE

SEQUENCE ISA F2M-1

MANUAL RESET FIRST OUT WITH NO SUBSEQUENT ALARM FLASHING & SILENCED PUSHBUTTON

AUDIBLE

System 9000TS

LINE

1 NORMAL NORMAL OFF SILENT

2 FIRST ABNORMAL FIRST ALARM FLASHING AUDIBLE LOCK-IN

3 SUB. ABNORMAL SUB. ALARM ON AUDIBLE LOCK-IN

4 FIRST

5 SUB.

6 FIRST

7 SUB.

8 FIRST

9 NORMAL RESET NORMAL OFF SILENT

PROCESS

CONDITION

ABNORMAL OR

NORMAL

ABNORMAL OR

NORMAL

ABNORMAL OR

NORMAL

ABNORMAL OR

NORMAL

ABNORMAL OR

NORMAL

PUSHBUTTON

OPERATION

ACKNOWLEDGE

BEFORE SIL

SILENCE FIRST SILENCED FLASHING SILENT

SILENCE ACKNOWLEDGE ON SILENT

ACKNOWLEDGE

AFTER SILENCE

SEQUENCE

STATE

VISUAL

DISPLAY

TO LINE 7

TO LINE 7

SEQUENCE FEATURES

1. Silence, acknowledge, reset and test pushbuttons

2. Alarm audible device

3. Lock-in of momentary alarms until acknowledged.

4. Option1 – silence pushbutton to silence the alarm audible device

while retaining the first out flashing indication

5. Flashing indication for first alarm only. new subsequent alarms have

the same visual indication as acknowledged alarms.

6. First out indication is reset when acknowledged

7. Manual reset of acknowledged alarm indications after process

conditions return to normal.

8. Operational test

ALARM

AUDIBLE

DEVICE

REMARKS

FIRST OUT

RESET

MANUAL

RESET

REQUIRED

FIRST OUT

RESET

MANUAL

RESET

27

ISA F3A – Automatic Reset First Up

SEQUENCE DIAGRAM

PROCESS

SEQUENCE

VISUAL

AUDIBLE

RETURN

TO NORMAL

ABNORMAL

SUBSEQUENT

ACKNOWLEDGE

ON

SILENT

FIRST OUT RESET

WHILE ABNORMAL

SEQUENCE

ACKNOWLEDGE

WHILE NORMAL

ACKNOWLEDGE

WHILE ABNORMAL

SEQUENCE

PROCESS

VISUAL

AUDIBLE

PROCESS

STATE

VISUAL

AUDIBLE

FIRST OUT RESET

WHILE NORMAL

PROCESS

VISUAL

AUDIBLE

NORMAL

NORMAL

OFF

SILENT

SUBSEQUENT TO

ABNORMAL

ABNORMAL

OR NORMAL

SUBSEQUENT

ALARM

FAST FLASHING

ON

ABNORMAL

OR NORMAL

FIRST

ACKOWLEDGED

SLOW FLASHING

SILENT

FIRST OUT RESET

PROCESS

SEQUENCE

VISUAL

AUDIBLE AUDIBLE

ACKNOWLEDGE

FIRST TO

ABNORMAL

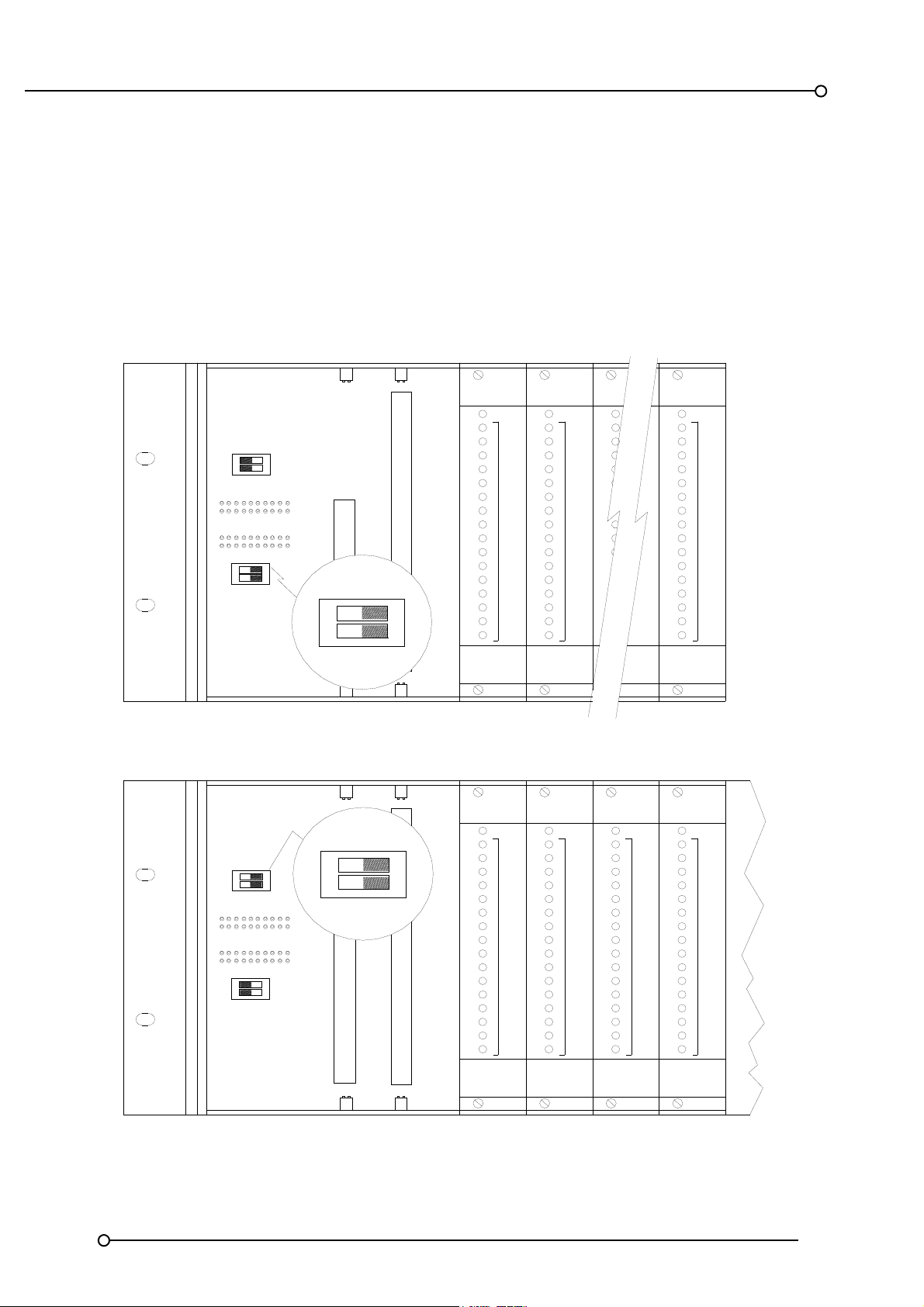

FIRST ALARM

INTERMITTENT

ABNORMAL

OR NORMAL

FLASHING

28

(AUTOMATIC RESET FIRST OUT WITHOUT FLASHING & RESET PUSHBUTTON)

SEQUENCE ISA F3A

System 9000TS

SEQUENCE TABLE

LINE

1 NORMAL NORMAL OFF SILENT

2 FIRST ABNORMAL FIRST ALARM

3 SUB. ABNORMAL SUB. ALARM

4 FIRST

5 FIRST

6A SUB. ABNORMAL

6B SUB. NORMAL TO LINE 8

7A FIRST ABNORMAL

7B FIRST NORMAL TO LINE 8

8 NORMAL NORMAL OFF SILENT

PROCESS

CONDITION

ABNORMAL

OR NORMAL

ABNORMAL

OR NORMAL

PUSHBUTTON

OPERATION

FIRST OUT

RESET BEFORE

ACKNOWLEDGE

ACKNOWLEDGE

FIRST OUT

RESET AFTER

ACKNOWLEDGE

SEQUENCE

STATE

FIRST

ACKNOWLEDGED

SUB.

ACKNOWLEDGE

VISUAL

DISPLAY

INTERMITTENT

FLASHING

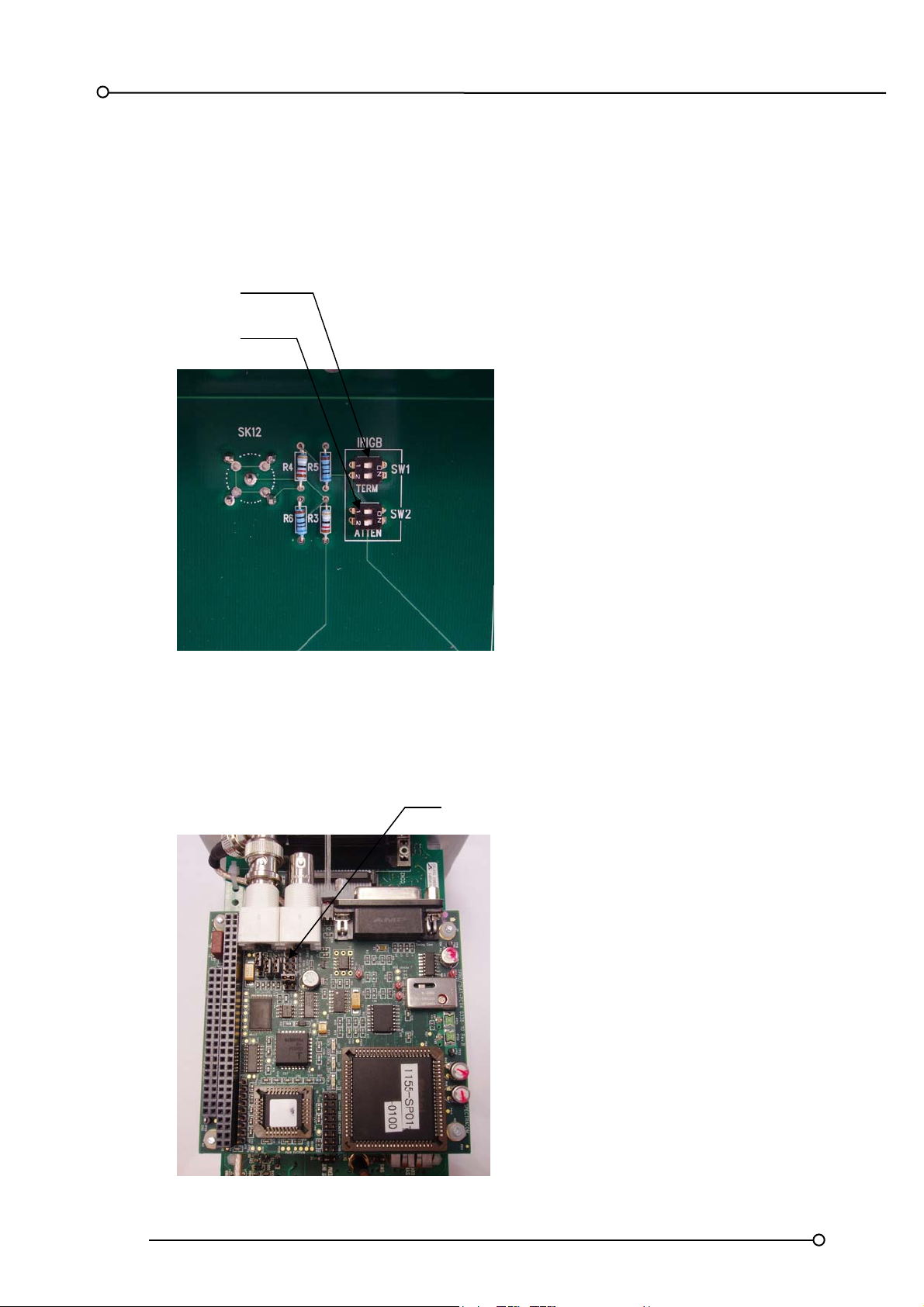

FAST

FLASHING

TO LINE 3

SLOW

FLASHING

ON SILENT

TO LINE 6A

SEQUENCE FEATURES

1. Silence, acknowledge, reset and test pushbuttons

2. Alarm audible device

3. Lock-in of momentary alarms until acknowledged.

4. Flashing indication for first alarm only. New subsequent alarms have the

same visual indication as acknowledged alarms.

5. First out indication is reset when acknowledged

6. Manual reset of acknowledged alarm indications after process conditions

return to normal.

7. Operational test

ALARM

AUDIBLE

DEVICE

AUDIBLE LOCK-IN

AUDIBLE LOCK-IN

SILENT

REMARKS

FIRST OUT

RESET

FIRST OUT

RESET

REQUIRED

MAINTAINED

ALARM

MOMENTARY

ALARM

FIRST OUT

RESET

FIRST OUT

RESET

AUTOMATIC

RESET

29

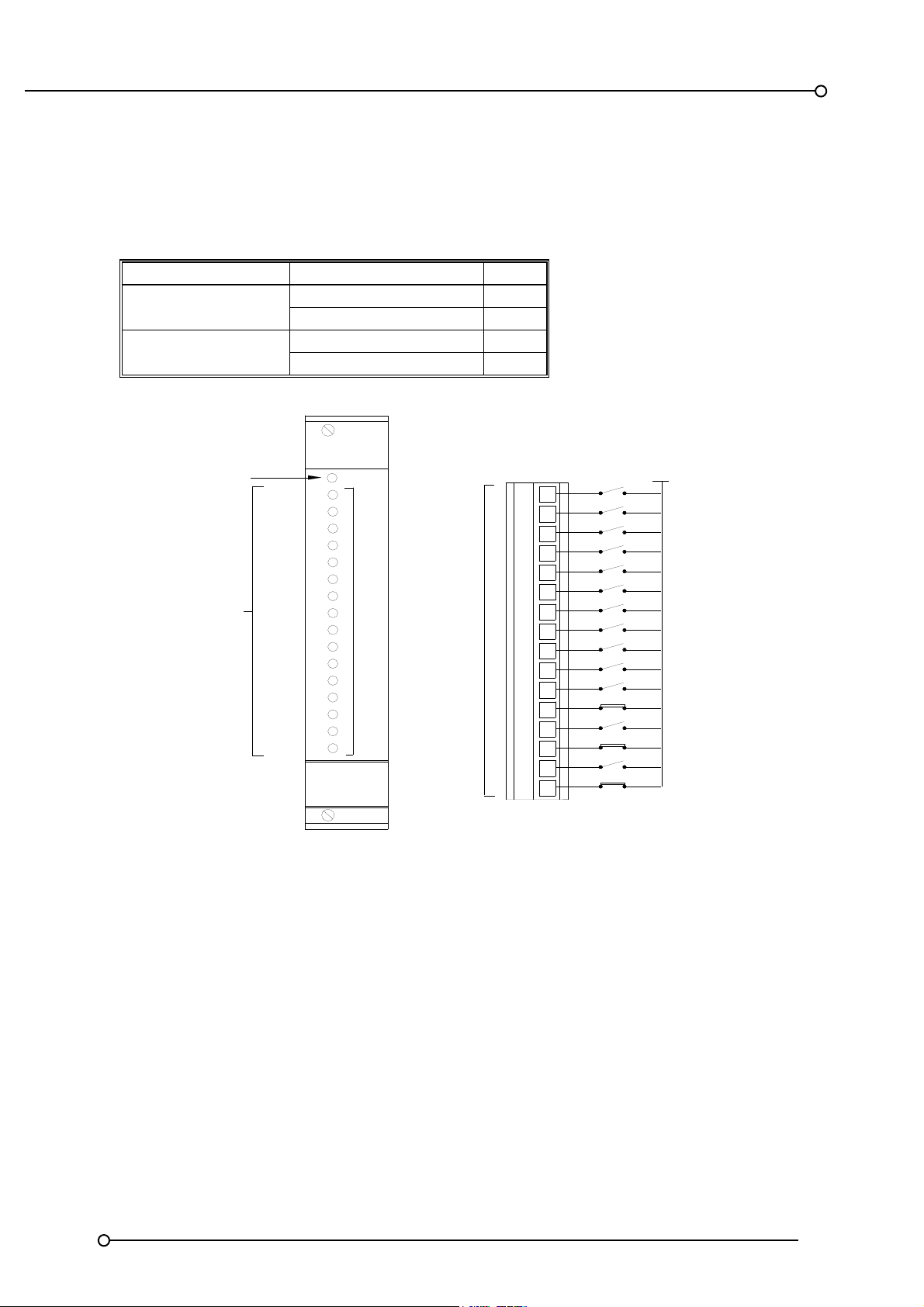

SECTION 7 – P925TS-X INTERFACE CARD

Interface Card Features

INTERFACE

STATUS

RX

SYNC

TX

INTERNAL

PORT 1

PORT 2

RX

TX

PORT 2 (PROG)

PRINTER

PORT 3

RX

PORT 3

1

2

3

TX

P925TS-X

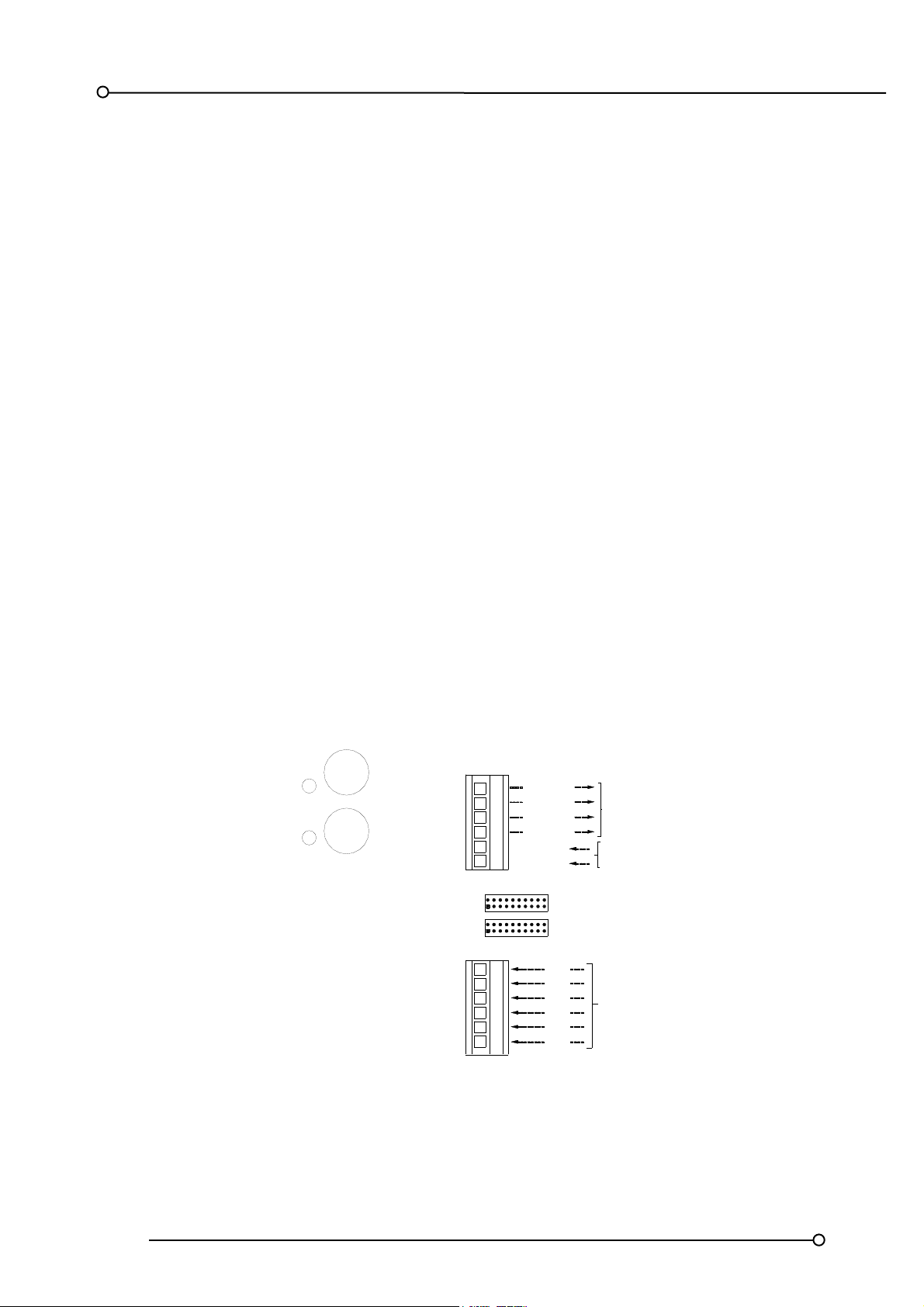

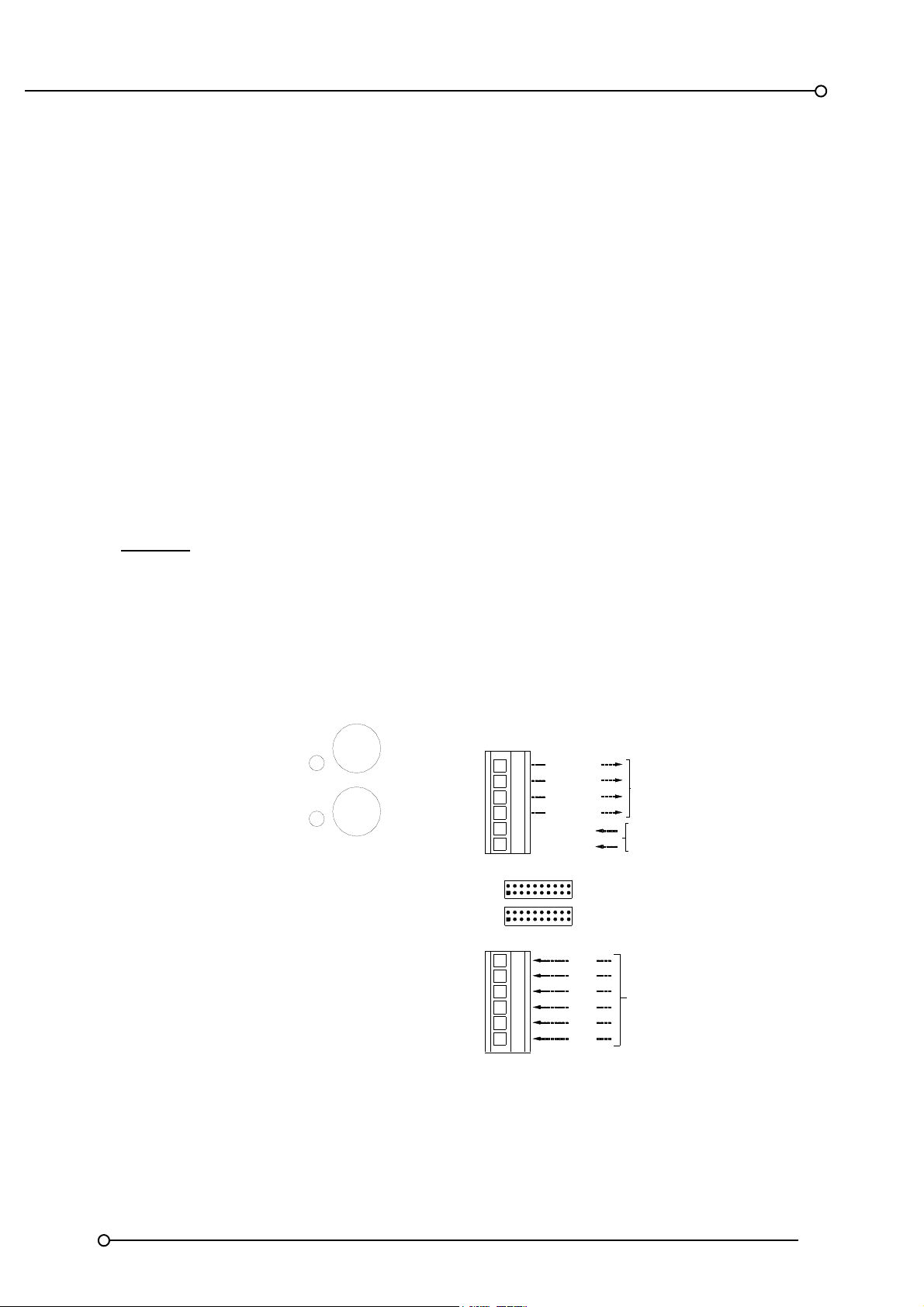

Diagnostic LED’s

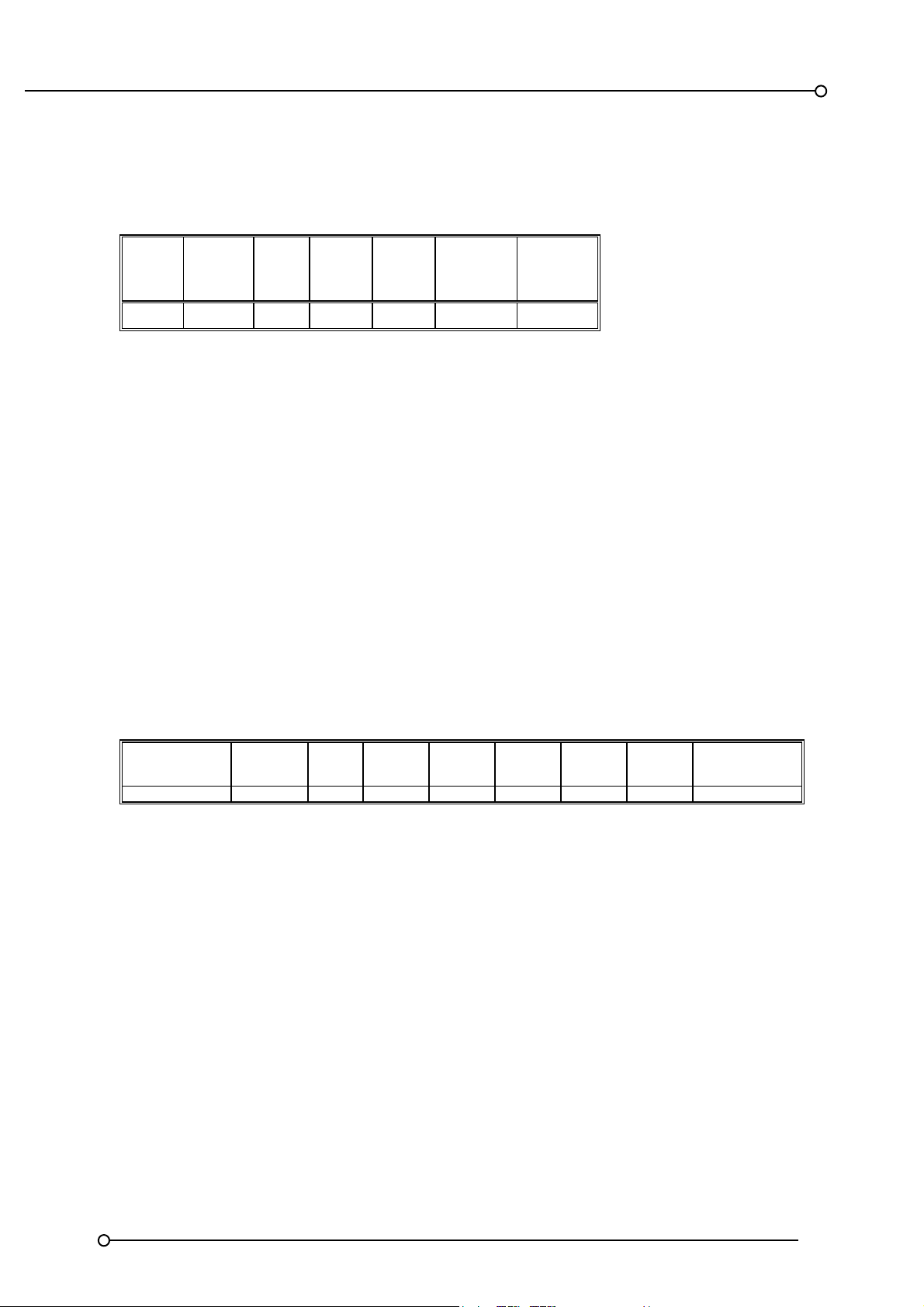

PORT TYPE FUNCTION

1 Modbus Communication Transmit & Receive LED’s

2 Programming Transmit & Receive LED’s

3 Time Synchronisation Transmit & Receive LED’s

System Status Power On LED

Time Sync Status Time Sync LED

Serial Ports

PORT TYPE

1 RS485 Modbus Communication Port

2 RS232 Programming Port

3 RS232 Time Synchronisation Port

RS232 Printer Port (25 Pin)

30

System 9000TS

Generating Reports

Three tactile pushbuttons are provided on the front of the P925TS-X Interface Card to

allow the user to trigger pre-defined reports from a 9000TS System using the

sequential of event feature.

Caution:-

Depending on the type of report required the resulting print out may be several pages

long and therefore the printer will be fully utilised while the print out is in process. To

prevent accidental triggering of reports each pushbutton must be held down for a short

period to confirm that the report should be printed.

Report Print Outs

PUSHBUTTON REPORT TYPE

1 Generates a printed report for ALL channels in the alarm condition.

Generates a printed report indicating any input that has been

2

3

1 & 3

1, 2 & 3

Buffers

The following buffers are available within the interface card.

FUNCTION CAPACITY

Sort Buffer 1,000 Events

AMS Buffer 1,000 Events

Printer Buffer 1,000 Events

Please note these buffers are in addition to the 1,000 event buffers located on each 16

channel card within the system. As an example a 19” rack containing 13 input cards is

capable of storing 13,000 events in addition to the above.

Sort Delay Period

In applications where alarm bursts occur in quick succession the user can software

configure a sort time delay period in seconds to ensure that data remains in strict time

order. Once the sort delay period has elapsed the information is passed onto the AMS

and Printer buffers when requested.

shelved because the number of alarm events within a defined

period has exceeded the programmed parameters for the specific

channel or the channel has been manually shelved in software.

Generates a printed report indicating the events stored within the

event history buffer. Caution:- this can be in excess of 1,000 events.

Pressed simultaneously generates a printed report indicating the

configuration of all alarm legend details

Pressed simultaneously generates a printed report indicating the

configuration of all channels in the system

31

System Relay Outputs

The P925TS-X Interface Card is equipped with eight system relays having the

following functions:-

Audible Alarm Relays

Two systems relays RL1 and RL2 are always factory supplied as horn relays on the

Interface card. Each channel can be configured to activate relay 1 or relay 2. When the

associated channel goes into alarm the horn relay will activate and the relay will

remain in the alarm state until the silence or acknowledge pushbutton has been

pressed.

Group Relays

RL3 and RL4 are factory set as Group Relay 1 and 2 and RL5 to RL8 can be software

configured to operate as group relays. Each channel can be configured to activate any

of the group relays. When the associated channel goes into alarm the group relay will

activate and the relay will remain in the alarm state until all alarms in the group have

returned to normal and the logic has been reset

Group Relays with Reflash

Group Relays can also be configured to include a Reflash function.

In this Mode when an additional alarm occurs within the same group the associated

relay contacts will revert to normal for approx 500mS and then re-alarm.

Diagnostic Relay Outputs

Systems relays RL5 to RL8 can be software configured to provide volt free contact

outputs for the following events:-

EVENT TYPE

Internal Faults

Printer Faults

Sort Log Full

AMS Log Full

Printer Log Full

GPS Lock Fault

GPS Serial Fault

Sync Fault

Watchdog Relay

A Watchdog Relay RL9 is provided as standard, which will change state as soon as

the 9000TS detects an internal communication failure or card fault. The P925TS-X

Interface Card is equipped with 2 x Jumpers LK6 and LK8 which allow the contact and

coil state. LK6 allows selection of EN (Energised) or DE-EN (De-Energised) Coil in the

normal state and LK8 allows selection of the watchdog relay contact to N/O or N/C

32

System 9000TS

Time Synchronisation

Internal Time Synchronisation

The P925TS-X Interface Card generates a time sync pulse, which is broadcast to all of

the associated I/O Cards in the system as a common time base.

External Time Synchronisation

If preferred the 9000TS can be synchronised to an external time source such as IRIGB or GPS

The P925TS-X Interface Card is equipped with a three-way header and two-way

shorting bar, which allows the user to select whether the time synchronisation pulses

are via internal or external sources.

Shorting bar LK4 is used to set the required time synchronisation path as shown

below.

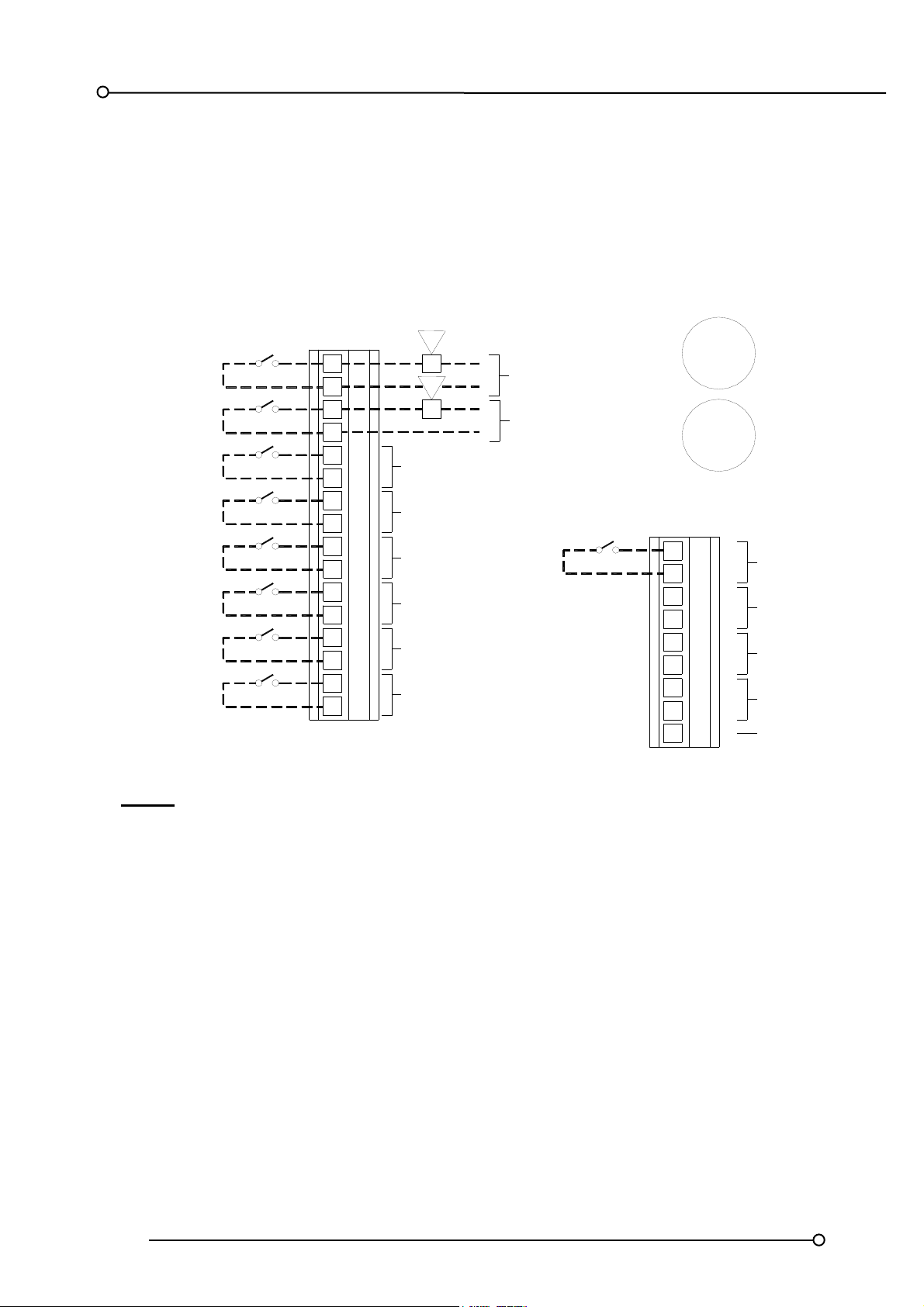

Time Synchronisation Jumper Setting

SET TIME SYNC

TO INTERNAL OR

EXTERNAL SYNC

AS REQUIRED

USING LINK LK4

EXT-SYNC

EXT-SYNC

LK4

INT-SYNC

RL8

RL7

INT-SYNC

RL6

NONCNONCNONCNONC

RL1RL2RL3RL4

NONCNONCNONO NCNC

RL5

33

Interface Card Relay Outputs.

All 9000TS Systems are equipped with eight common relays plus one watchdog relay

as typically shown below.

OPTIONAL EXTERNAL

AUDIBLE ALARMS

SIGNAL SUPPLY 1 AMP

X2

F1

RL1-1

RL2-1

RL3-1

RL4-1

RL5-1

RL6-1

RL7-1

RL8-1

1

2

3

4

5

6

7

8

COMMON ALARM GROUP [GP1]

COMMON ALARM GROUP [GP2]

SYNC.

FAILURE

COMM'S

FAIL

PRINTER

FAILURE

POWER

FAILURE

CRITICAL

HORN [HN1]

NON-CRITICAL

HORN [HN2]

RL9-1

F2

LOGIC SUPPLY 5 AMP

X1

1

2

3

4

5

A

6

B

7

A

8

B

9

Note:-

RL1 and RL2 are factory set as horn relays

RL3 and RL4 are factory set as Group Relay 1 and 2

RL5 to RL8 are software configurable for use as group, horn or fault monitoring

relays. The functions shown for RL5 - RL8 are therefore shown as typical

examples only.

RL9 is factory set as a watchdog relay which will change state if any faults are

detected within the system. The Relay can be set to EN or DE-EN using Link

LK6 and the Contact state can be set to N/O or N/C using Link LK8 as required.

WATCHDOG [WD]

SYNC. I/P

TRANSMIT

RECEIVE

MASTER / SLAVE

34

System 9000TS

System Relay Settings:-

Setting Relay Contact States

Links LK1 to LK8 on the P925TS-X Interface Card allow the user to select the nonalarm state of each of the relays.

The relay contact can be set to be either normally open (NO) or normally closed (NC)

using a 2 way shorting bar on a 3 pin header as detailed in the diagram below.

LK4

LK3 LK2 LK1

NONCNONCNONCNONC

RL1RL2RL3RL4

LK4

HN1HN2

NC NO

RL4

LK8 LK6

SET SYSTEM

RELAY CONTACT

NON ALARM STATE

SHOWN SET FOR

NORMALLY CLOSED

( OPEN TO ALARM )

RL8

P925TS-X Interface Card:- System Relay – “Non Alarm” Contact State Setting

LK7 LK5

RL7

RL6

RL5

NONCNONCNONO NCNC

35

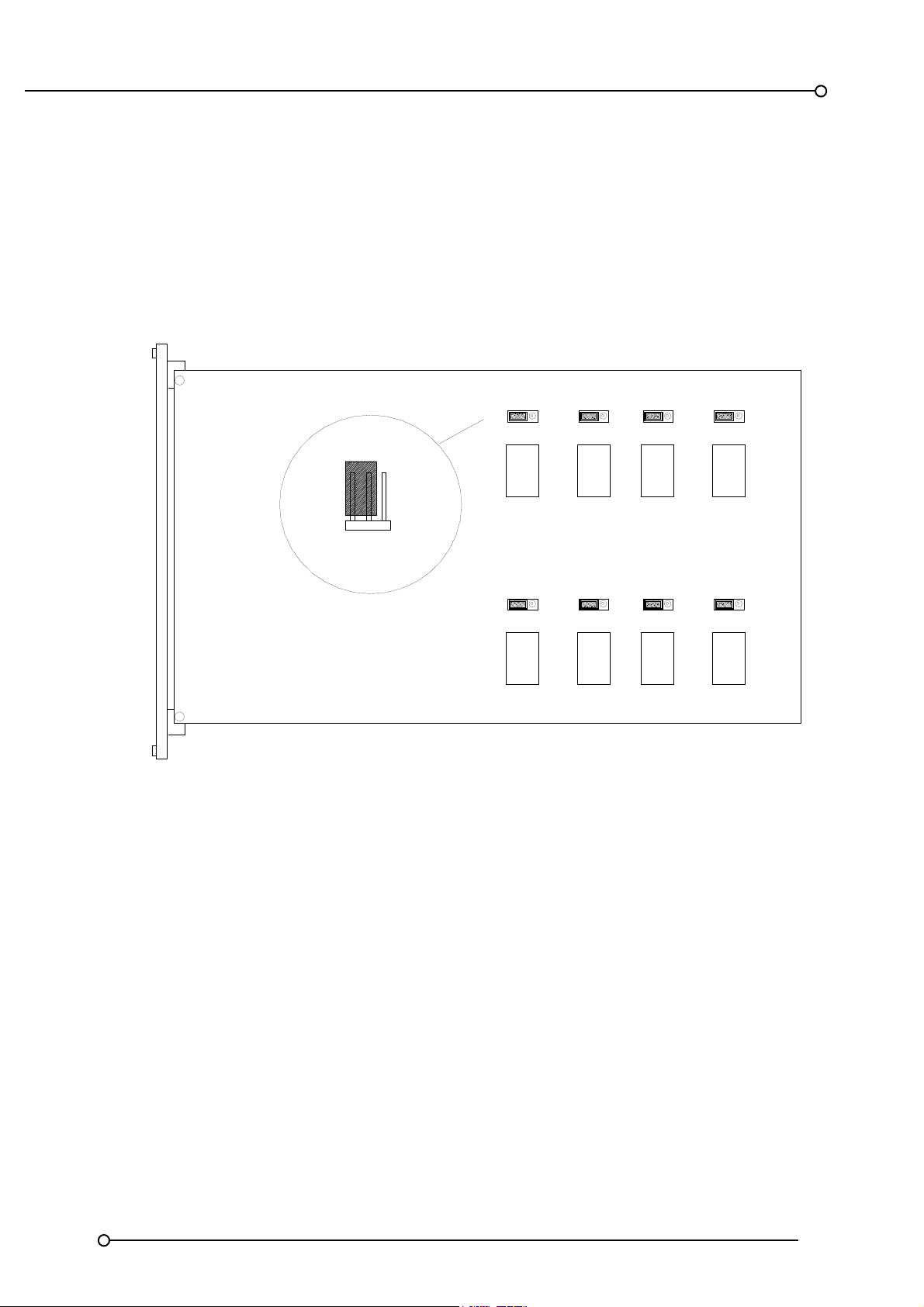

Horn Relay:- RL1

RL1 is factory set as a critical horn relay. This relay will change state when any

channel software configured to operate Horn A (HA) activates and the relay will remain

in the abnormal state until the mute or acknowledge pushbutton has been pressed.

Coil Setting (Non-alarm state)

RELAY SWITCH STATE FUNCTION

RL1 SW1-1

Horn Relay:- RL2

RL2 is factory set as a non critical horn relay. This relay will change state when any

channel software configured to operate Horn B (HB) activates and the relay will remain

in the abnormal state until the mute or acknowledge pushbutton has been pressed.

Coil Setting (Non-alarm state)

RELAY SWITCH STATE FUNCTION

RL2 SW1-2

OFF De-energised

ON Energised

OFF De-energised

ON Energised

SW1-

1

HORN A

SW1

123

24V

110V

ON

OFF

4

LK11 LK10

CONTACT

VOLTAGE

ON

OFF

2

LK9

POWER

FAIL

HORN B

ON

OFF

OFF ON

DE-EN EN

DE-EN EN

36

System 9000TS

Group Relays RL3 & RL4:-

RL3 and RL4 are factory set to operate as group 1 and group 2 common alarm relays.

When an alarm occurs on any within the group the associated relay will change state

and the relay will remain in the abnormal state until the fault has been cleared and the

alarm has been reset.

The coil state of RL3 and RL4 can be set to normally energised or normally deenergised using switch SW1 positions 3 and 4 on the P925TS-X Interface Cards as

detailed below

Coil Setting (Non-alarm state)

RELAY SWITCH STATE FUNCTION

RL3 SW1-3

RL4 SW1-4 OFF De-energised

OFF De-energised

ON Energised

ON Energised

SW1

ON

OFF

1234

LK11 LK10

24V

110V

CONTACT

VOLTAGE

ON

OFF

SW1-

3

4