Page 1

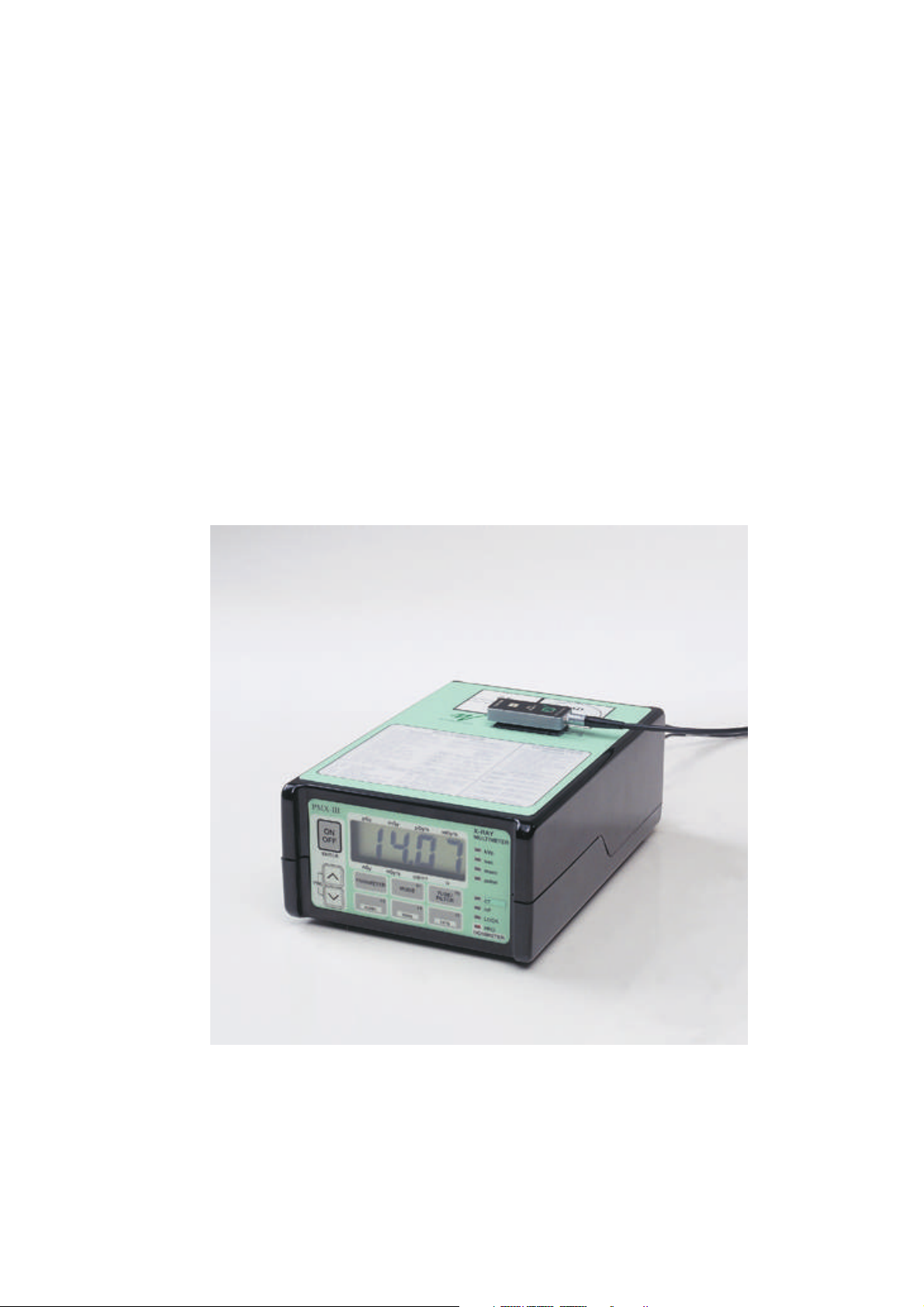

PMX-III

X-ray multimeter version 6.0

oRTIgo version 3.0

Page 2

Page 3

Declaration of conformity

We, RTI Electronics AB, Göteborgsvägen 97 / 50, SE-431 37 MÖLNDAL, Sweden,

declare under our sole responsibility that the product:

Product name:

Type of equipment:

PMX-III

X-ray multimeter; kVp, exposure time, and dose meter

Intended use of this product:

Accessory to diagnostic X-ray equipment, to be used

Model name:

R/M, R/CT, PH

for service and quality control.

is in conformity with the following standards:

Medical electrical equipment

Part 1: General requirements for safety (COUNCIL DIRECTIVE 93/42/EEC, Annexes

V and VII)

Part 2: Collateral standard: Electromagnetic compatibility - Requirements and tests

(EN 60601-1-2: 1993)

following the provisions of the 93/42/EEC Medical Devices Directive.

Mölndal, 1998-11-13, ……………………………………

Lars Herrnsdorf, Vice President

Address: RTI Electronics AB Göteborgsvägen 97 / 50 SE-431 37 MÖLNDAL Sweden

Phone: +46 (0)31 746 36 00 Fax: +46 (0)31 27 05 73 E-mail: info@rti-e.se Web: www.rti-e.se

2-CE-03000-2 Tillverkardeklaration PMX-III.DOC

Page 4

Page 5

NOTICE

NOTICE

RTI Electronics AB reserves all rights to make changes in

the PMX-III family of meters and the information in this document

without notice.

RTI Electronics AB assumes no responsibility for any errors or consequential

damages that may result from the use or misinterpretation of any information

contained in this document.

© Copyright 1999, RTI Electronics AB. All rights reserved.

Contents of this document may not be reproduced in any form without

permission of RTI Electronics AB.

NOTE!

This user manual is valid for PMX-III with the following version: 6.0

IBM is a registered trademark of International Business Machines Corporation.

HP is a registered trademark of Hewlett-Packard Company.

Appletalk and Macintosh are registered trademarks of Apple Computer, Incorporated.

Microsoft, Windows and Windows 95 are registered trademarks of Microsoft Corporation.

Pentium is a registered trademark of Intel Corporation

RTI Electronics AB

Göteborgsvägen 97 / 50

SE-431 37 MÖLNDAL

Sweden

Phone: Int +46 31 746 36 00

Fax: Int +46 31 270 573

E-mail: info@rti-e.se

Web: http://www.rti-e.se

PMX-III Manual 1999-03/6.0B I-1

Page 6

PREFACE

Chapter 1 Gives an introduction to the PMX-III.

Description of ADI, applications and typical use

Chapter 2 Describes general functions and connectors

Chapter 3 Set up the system for measurements

Chapter 4 Learn to make basic QC measurements.

Chapter 5 Service and Maintenance related measurements

II,, Dose/frame, DSI, and light measurements.

PREFACE

Chapter 6 Remote control of the PMX-III using oRTIgo.

Chapter 7 Display code list and kVp correction graph.

Chapter 8 Precautions and maintenance.

Chapter 9 Detector range and detector selection guide,

problem report document.

Chapter 10 Hints and troubleshooting, backup of calibration data

Index Important words are listed in alphabetical order.

It is advisable to read through the user manual at least once to gain

familiarity with the terms used and the capabilities of the PMX-III.

It is possible to make measurements quickly with a minimum of reading.

To do this read the instructions on the top panel of the instrument.

Consult the PMX-III reference manual for more specific information.

Note! The PMX-III is intended for service and quality control of diagnostic X-ray

equipment. It is not intended for for use during or together with

diagnostic examinations of patients.

I-2 1999-03/6.0B PMX-III Manual

Page 7

TABLE OF CONTENTS

I-NOTICE ............................1

I-PREFACE ...........................2

1-INTRODUCTION .......................7

1.1 Overview .........................7

1.2 Package Information and Changes Version 6.0 ....8

1.3 Options and Accessories ................8

1.4 Application Notes ....................8

1.5 About oRTIgo Version 3.0................8

1.6 About ADIs ........................9

1.6.1 What is the Function of an ADI ............9

1.6.2 What to do when Changing an ADI..........9

1.6.3 Any Precautions? ...................9

TOC

1.6.4 How to Choose the Correct ADI Module .......9

1.7 Shortform Detector Selection Guide ..........10

1.8 Typical Use .......................11

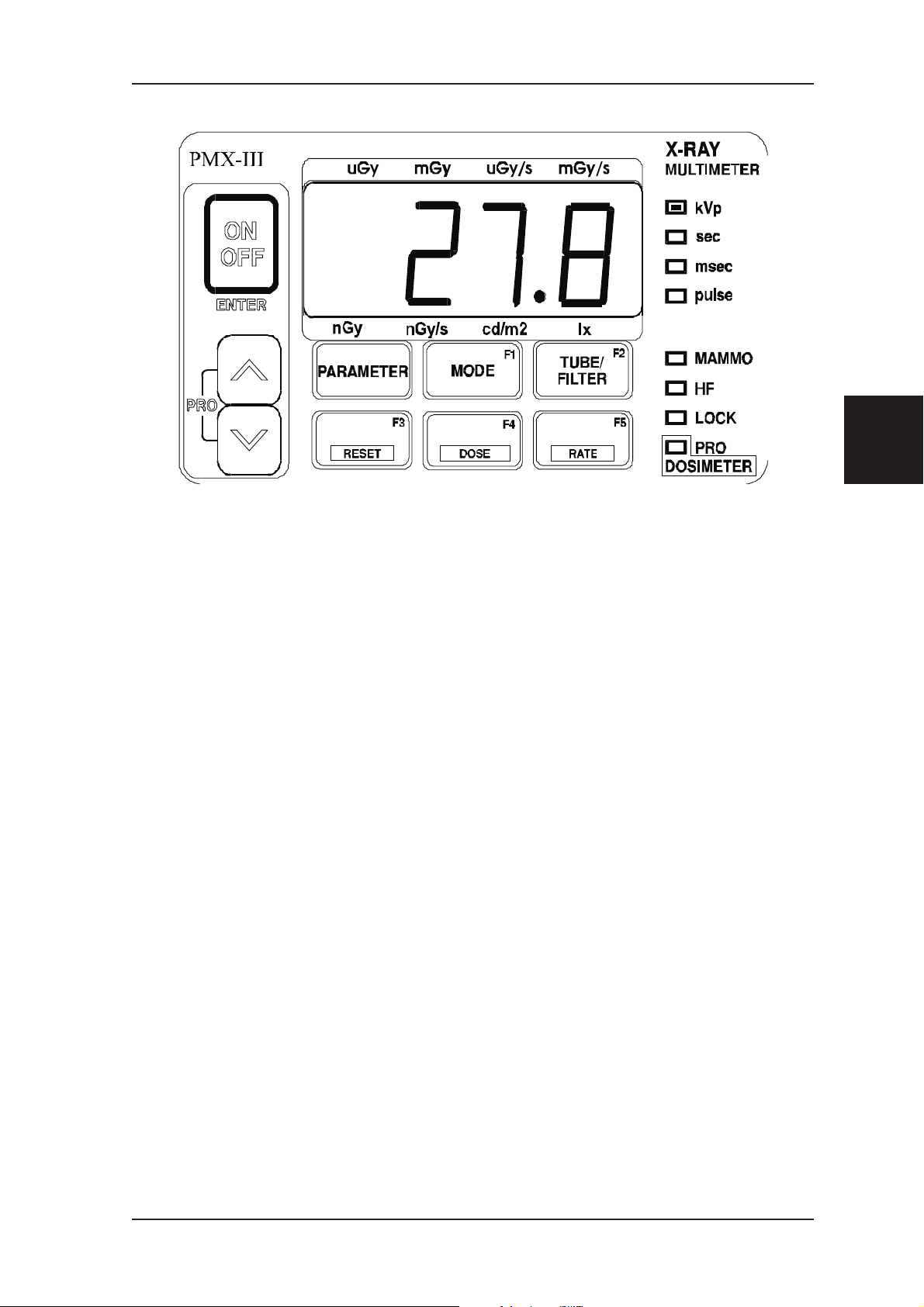

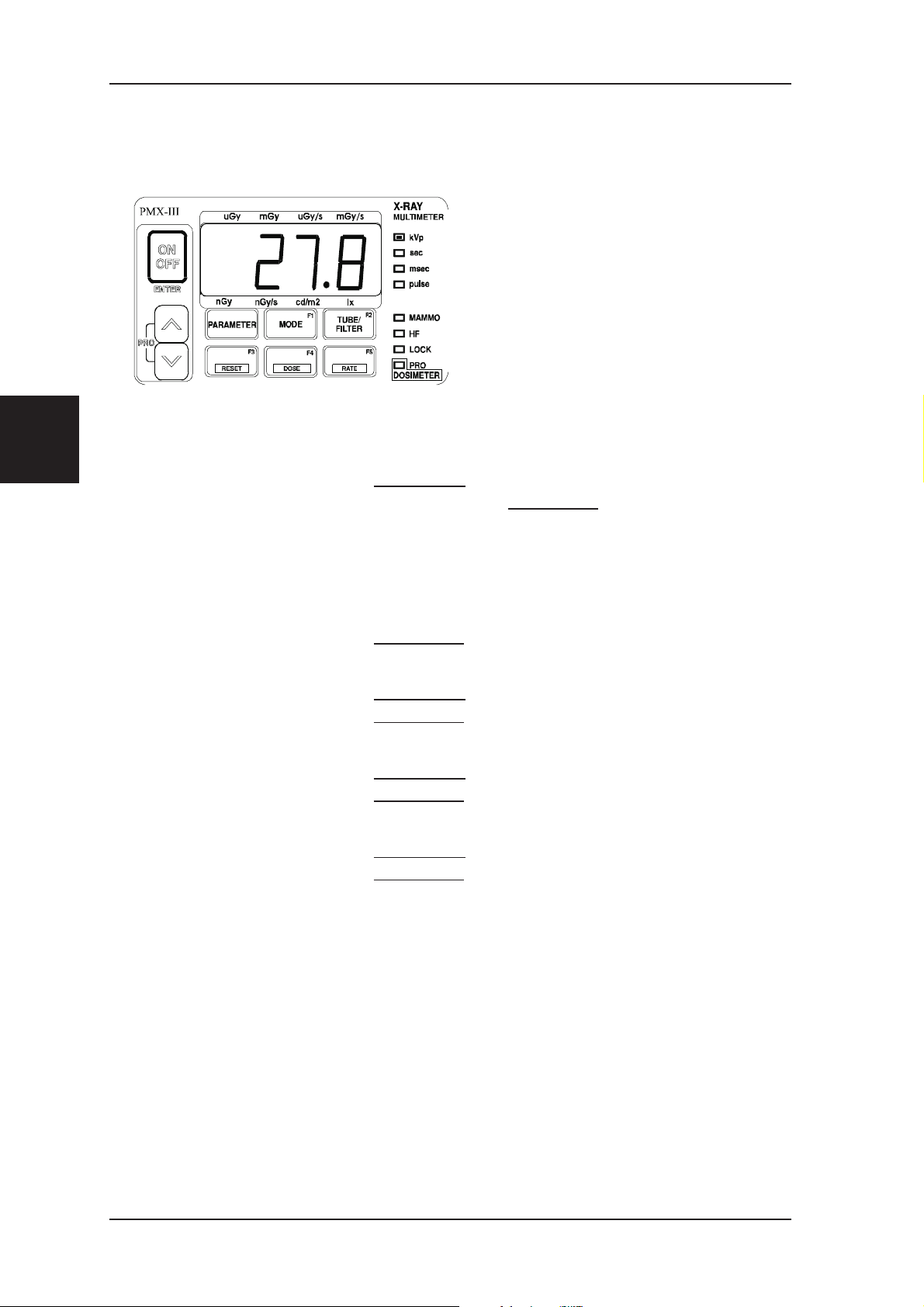

2-DESCRIPTION OF PMX-III ..................13

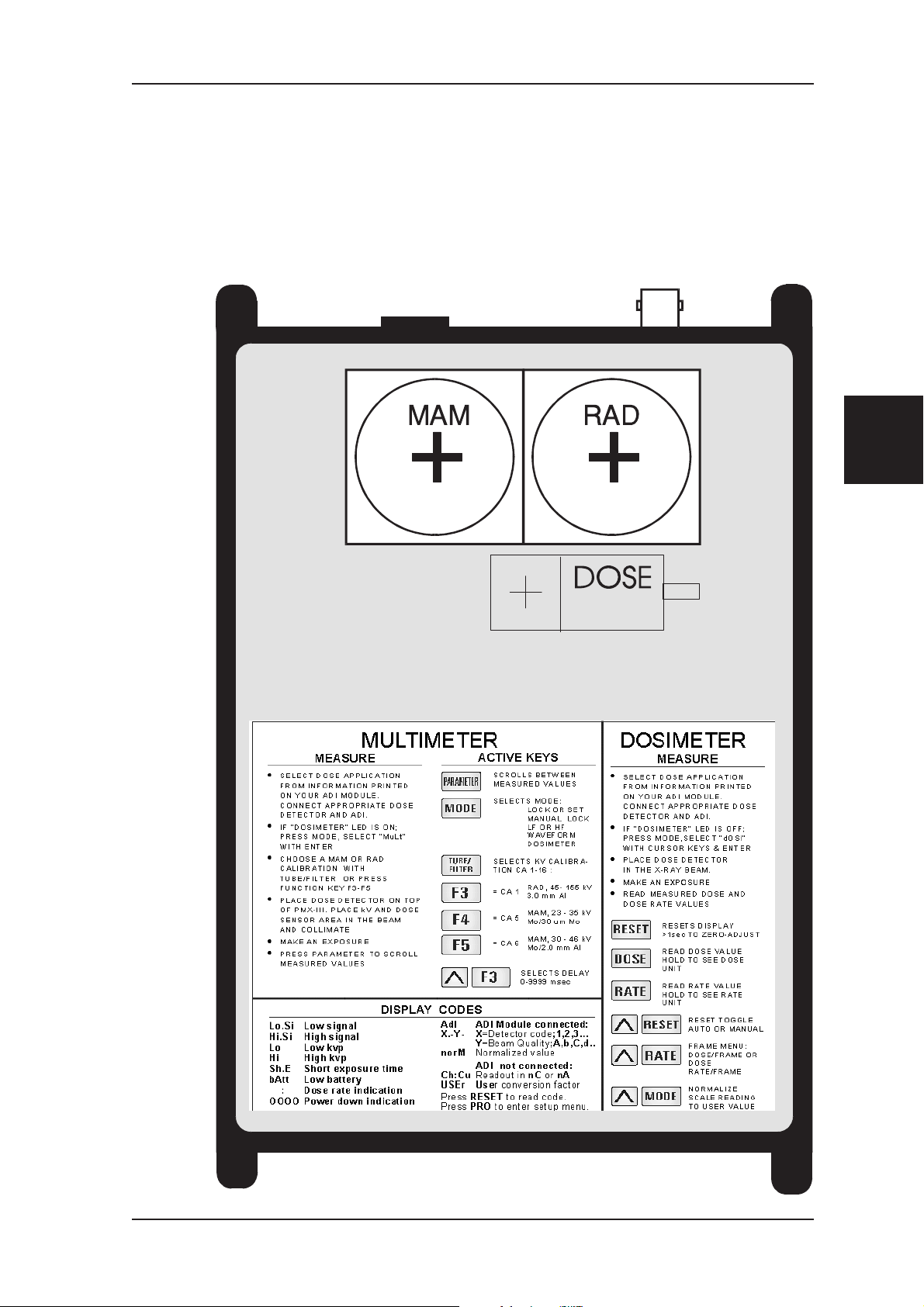

2.1 Front Panel ........................13

2.2 The Display........................13

2.3 The LED Indicators ...................14

2.4 Front Panel Keys ....................16

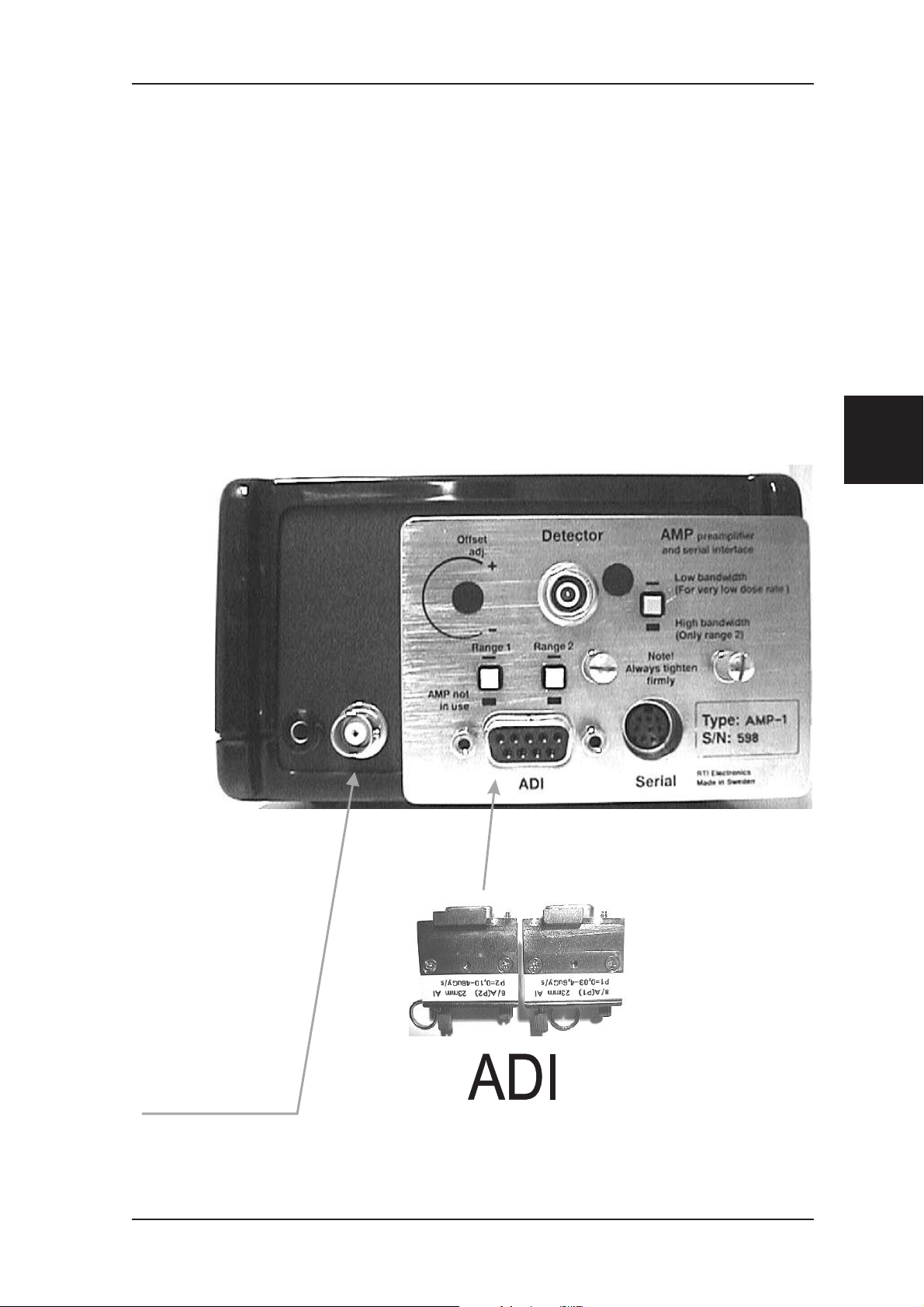

2.5 Back Panel and AMP-1 .................17

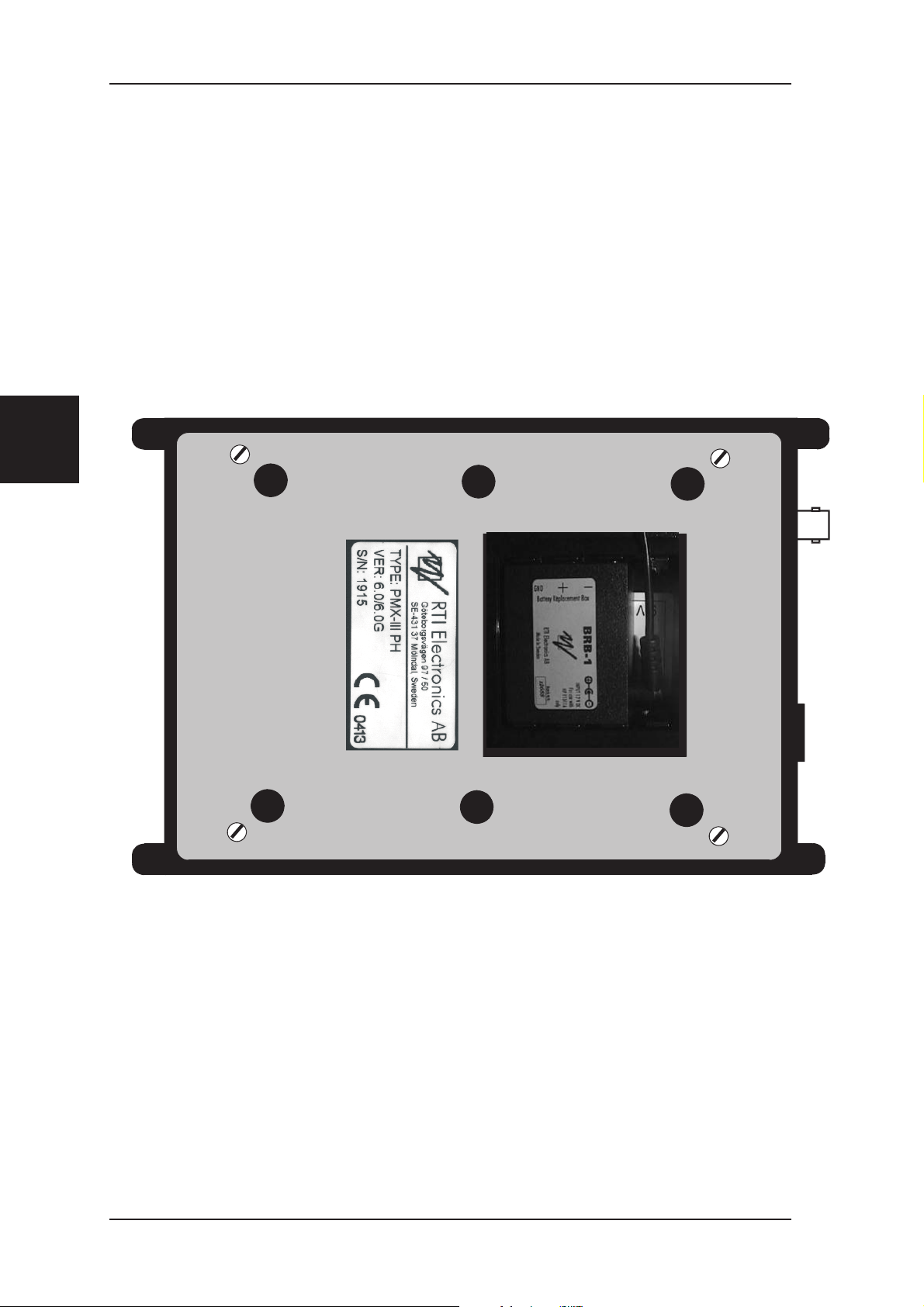

2.6 The Battery Case ....................18

2.7 Top Panel.........................19

2.8 Special Remarks for Use of ADI 8/A(P1) ........20

2.9 AMP-1 Front Panel....................21

2.10 Operation of Principle of the Electrometer .....21

3-HOW TO SET UP THE SYSTEM ..............23

4-BASIC QC MEASUREMENTS ................25

4.1 kVp and Time (Multimeter Mode) ...........25

PMX-III Manual 1999-03/6.0B 3

Page 8

4.1.1 PARAMETER.....................25

4.1.2 MODE ........................25

4.1.3 When to use SET and LOCK modes .........25

TOC

4.1.4 When and how to use manual LOCK mode .....26

4.1.5 When to use LF and HF: ...............26

4.1.6 TUBE/FILTER ....................27

4.1.7 Measurement with the MAM/RAD version ......28

4.1.8 Default values for F3-F5 (MAM/RAD version) ....29

4.1.9 CT kVp Measurement with the CT/RAD version ...29

4.2 Dose and Dose Rate (Dosimeter Mode)........31

4.2.1 When and How to Use Manual LOCK Mode .....32

4.2.2 How to Use Free Run/Trig Mode ...........32

4.2.3 Active Keys ......................33

4.2.4 How to Make a Measurement ............35

4.3 The Waveform Analyzer ................36

4.3.1 Examples of waveforms ...............37

4.3.2 Waveform flowchart .................38

4.4 Using preamplifier AMP-1 ................39

4.5 Measurements with the AMP-1 ............41

4.5.1 General .......................41

4.5.2 Detector Range and Identification Codes ......42

5-SERVICE / MAINTENANCE .................43

5.1 Introduction .......................43

5.1.1 New Version of Firmware for PMX-III. ........43

5.1.2 Extension Cable Added. ...............44

5.1.3 Probe Holder Added. .................44

5.1.4 ADIs Removed from Detector Cables. ........44

5.1.5 Maintenance. .....................44

5.2 Entrance Dose Rate Measurements ..........45

5.2.1 Very Low Entrance Dose Rate to an Image Intensifier 45

5.2.2 Hints .........................47

5.2.3 Example of Dose Rate Waveforms .........48

5.3 Fluoroscopy low mA ..................48

5.3.1 II-Entrance Dose Rate (µGy/s) ............48

4 1999-03/6.0B PMX-III Manual

Page 9

5.4 Exposure Dose .....................49

5.4.1 Fluorography and Radiography............49

5.5 Measurement of kVp...................50

5.5.1 Long Exposure time, Skin Dose, and Dose Rate

(SET MODE) ........................50

5.5.2 Short Exposure Time, Skin Dose and Dose Rate

(MANUAL LOCK MODE) ..................51

5.6 Light Measurements, Detector and Adapters .....52

5.6.1 Introduction ......................52

5.6.2 Measurement of Luminance (cd/m²) .........55

5.6.3 Measurements on CRTs and Film Viewing Boxes . . 56

5.6.4 Ambient Light and Other Sources of Error ......57

5.7.3 Measurement of Illuminance (lx) ...........59

5.7 Examples of Field Measurements ...........60

5.7.1 Check the total Contrast Range for the System,

From the Image Intensifier to the Monitor. .........60

5.7.2 Check that the Dose and Dose Rate Level is within

Specification for all II Formats. ...............61

6-REMOTE CONTROL USING ORTIGO ............63

6.1 Introduction .......................63

TOC

6.2 oRTIgo version 3.0....................64

6.3 Connecting PMX-III to a Computer ...........65

6.4 Start oRTIgo 3.0 .....................66

6.5 What is a Record.....................67

6.6 Application example...................68

6.7 List of Hotkeys and Short Cuts .............76

6.7.1 General ........................76

6.7.2 Waveform Analyzer..................78

6.7.3 Text Editor and NotePad ...............79

7-DISPLAY CODES, SENSITIVITY AND FILTRATION ....81

7.1 Display codes ......................81

7.1.1 Most Common Display Codes ............81

7.1.2 Description of the Display Codes ...........82

7.2 KVp Sensitivity Graph ..................85

PMX-III Manual 1999-03/6.0B 5

Page 10

7.3 Filtration Dependence ..................86

7.4 KVp Correction Graphs .................88

7.4.1 Radiographic - CA-1, 2.0-5.5 mm Al .........88

TOC

7.4.2 Radiographic CA-1, 3.0, 4.0, and

5.0 mm Al+0.1 mm Cu ...................89

8-PRECAUTIONS AND MAINTENANCE............91

8.1 Safety Rules .......................91

8.2 Precautions .......................91

8.3 Maintenance .......................92

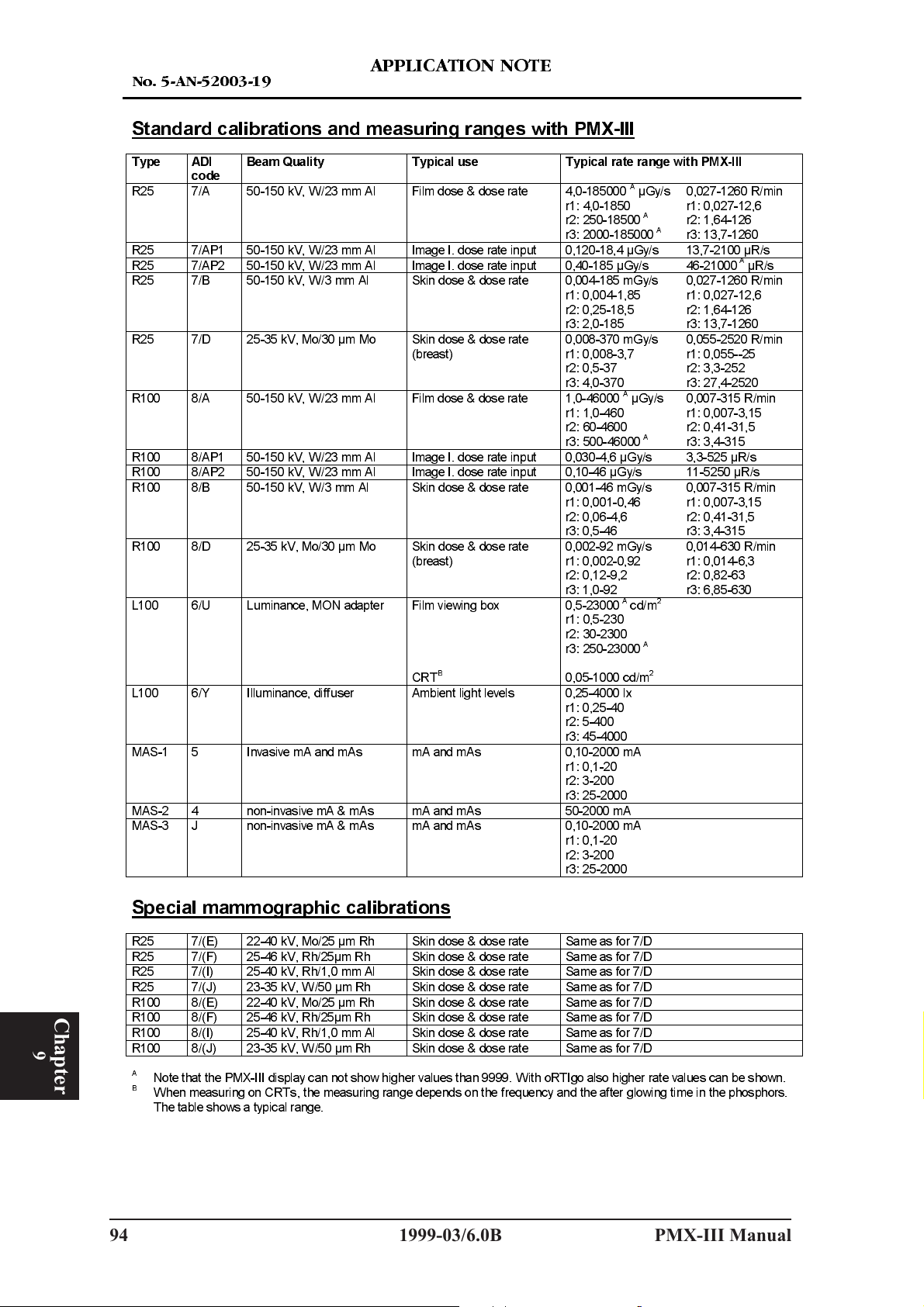

9-Notes and Reports .....................93

9.1 Application Notes Related to PMX-III..........93

9.2 Problem report ......................98

10-HINTS AND TROUBLESHOOTING .............99

10.1 Hints...........................99

10.1.1 General Info .....................99

10.1.2 oRTIgo Measurement ................99

10.2.1 Dose Measurements ................101

10.2.2 Questions on kV Measurements ..........104

10.2.3 Light Measurements.................104

10.2.4 General Questions .................105

10.2 Troubleshooting ....................106

10.3 Save EEPROM and ADI data..............108

10.3.1 Backup of internal EEPROM and ADI Modules . . 108

10.4 Restoring data from backup ..............110

10.4.1 Restore the content of PMX-III internal EEPROM . 110

INDEX ..............................113

6 1999-03/6.0B PMX-III Manual

Page 11

INTRODUCTION Overview

1 INTRODUCTION

1.1 Overview

PMX-III is a combined dosimeter and multimeter with a waveform analyzer

for both stand alone and remote control use.

PMX-III operates in four different main modes:

As a dosimeter, measuring dose and dose rates simultaneously.

•

The PMX-III can be operated from the control room. Functions as hold, normalize,

auto range, and auto reset are available. Use of light detectors or current detectors

makes it possible to measure , cd/m

As a multimeter measuring kVp, time, dose, and dose rate simultaneously.

•

As a waveform analyzer

•

• Remote controlled by the oRTIgo software.

2

, lx , mA, and mAs.

PMX-III can be used to measure the following:

• Dose, dose rate, and

dose/frame

• Light output from monitors

and film viewing boxes

using L100 light detector

• mA and mAs using

optional current probes

1

Chapter

•

Mammo kVp and

diagnostic kVp accuracy

•

Exposure time accuracy

•

Reproducibility of kVp,

time, and output

•

mAs-linearity

•

HVL

•

kV and radiation output waveform

•

Dose rate, mA and light waveforms

•

Dose/frame, frame/s and monitor frequency (Hz) automatically using waveform

analyzer

PMX-III version 6.0 can be programmed to always start up in dosimeter mode

or multimeter mode or what mode was used when last powered off.

PMX-III Manual 1999-03/6.0B 7

Page 12

About oRTIgo Version 3.0 INTRODUCTION

1.2 Package Information and Changes Version 6.0

Please read the addendum to the reference manual.

1.3 Options and Accessories

Please study the RTI’s product catalogue that should be included in the

Chapter

package. The latest information can be found on RTI’s web site www.rti-e.se.

1

1.4 Application Notes

For A list of available application notes, see chapter 9 “Notes and Reports”.

All application notes can be downloaded from our web page . They are stored

as pdf files.

1.5 About oRTIgo Version 3.0

This manual briefly describe oRTIgo version 3.0 in chapter 6, for detail

information please study the oRTIgo user manual.

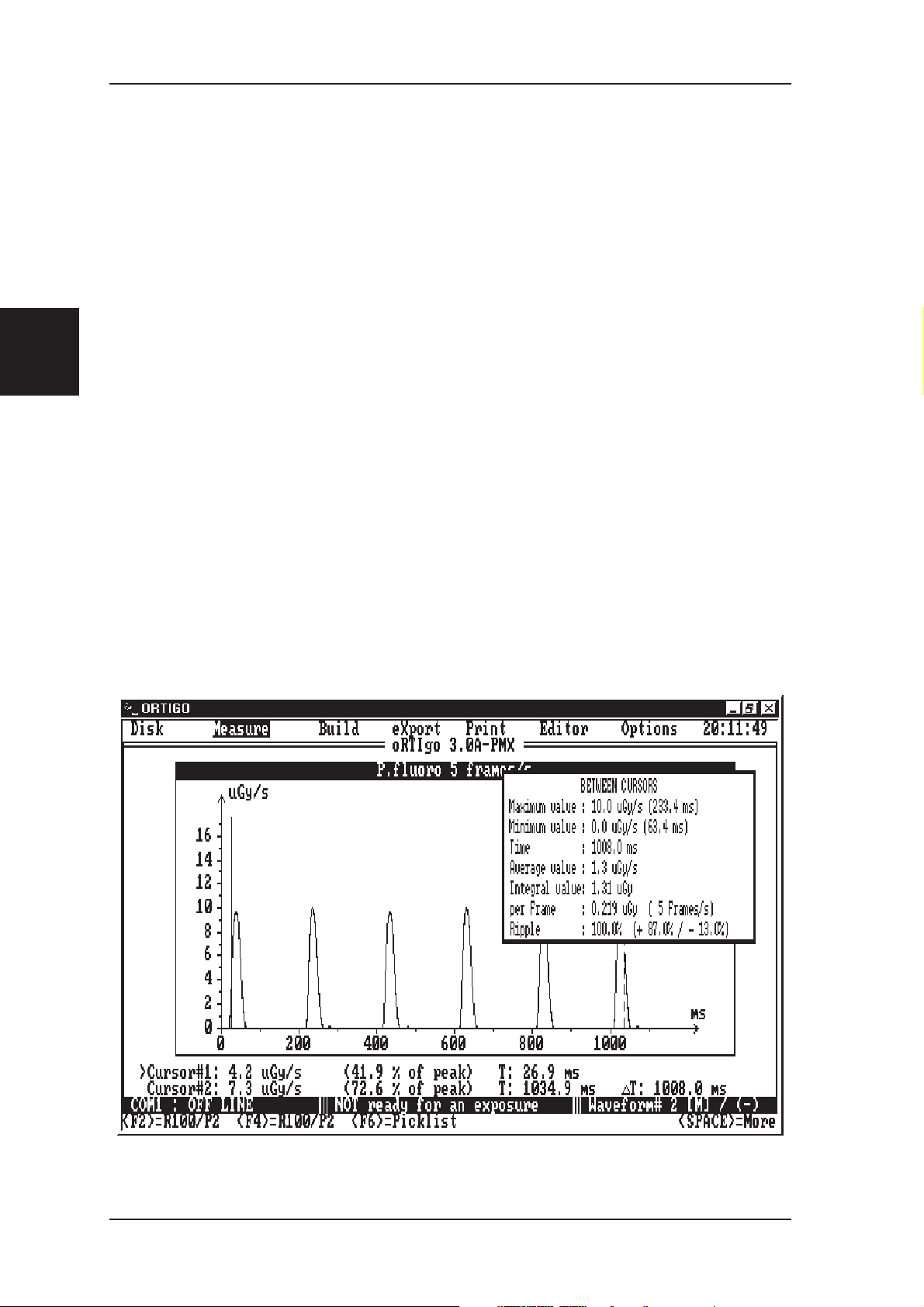

Example of dose rate waveform with automatic calculation of dose/frame and frame/s

8 1999-03/6.0B PMX-III Manual

Page 13

INTRODUCTION About ADIs

1.6 About ADIs

1.6.1 What is the Function of an ADI

The ADI contains the calibration factors for the detector with the same serial

number. It also informs the PMX which detector is being used and transfers

data to PMX-III for optimize the use of the detector.

As an example the selected ADI can inform if PMX-III should display dose

rate or dose values after power on.

1

Chapter

ADI multi module (replaces the need for

up to 5 separate R100 ADIs, option)

1.6.2 What to do when Changing an ADI

The PMX reads the ADI at power on, after each exposure in multimeter mode

and when pressing Reset. The display will indicate the type of ADI. Pressing

reset longer than2sindosimeter mode will make a new offset calibration. A

“c” is displayed after reset to indicate calibration.

Do not expose during the time “c” is displayed.

1.6.3 Any Precautions?

The ADI contains an EEPROM with the probe calibration data. The

calibration data can be downloaded to your PC by the oRTIgo program

delivered with the PMX. In case of deletion (Er.30 message) this data can

then be restored again. Also the internal Eeprom can be restored the same

way. See chapter 10 “Hints and Troubleshooting” for more information.

1.6.4 How to Choose the Correct ADI Module

See the Short form Detector Selection Guide below.

PMX-III Manual 1999-03/6.0B 9

Page 14

Shortform Detector Selection Guide INTRODUCTION

1.7 Shortform Detector Selection Guide

Chapter

1

Type

ADI

Code

R100 8/A

R100 8/A(P1)

R100 8/A(P2)

R25 7/B

R100 8/D

L100 6/U

Beam Quality Typical Use

50-150 kV

W/23 mm Al

50-150 kV

W/23 mm Al

50-150 kV

W/23 mm Al

50-150 kV

W/3mmAl

25-35 kV

Mo/ 30m Mo

Luminance

CIE filter

film dose / rate 0,001-40 mGy/s

II dose rate input 0,03-0,46 µGy/s

II dose rate input 0,10-46 µGy/s

Skin dose / rate 0,004-160 mGy/s

skin dose to breast 0,002-90 mGy/s

Monitor adapter

Film viewing box

Typical Range

(rate)

0,1 cd>1000 cd/ m

0,5 cd>9999 cd/ m

L100 6/Y Illuminance, diffusor LUX adapter 0,25 - 4000 lx

Invasive mA & mAs

MAS-1 5

(use the mA

mA and mAs 0,10-2000 mA

test socket)

2

2

MAS-2 4

MAS-3 J

The R25 and R100 are

ideal for field service

situations. They do not

need corrections for

temperature or pressure

an need no bias voltage.

Non-invasive mA &

mAs

State of the art

non-invasive mA &

mAs

mA and mAs 50-2000 mA

mA and mAs 0,10-2000 mA

10 1999-03/6.0B PMX-III Manual

Page 15

INTRODUCTION Typical Use

1.8 Typical Use

(ADI=Automatic Detector Identification)

Application

Cont. fluoroscopy 3/6

mA

DSI/spotfilm fixed

current

DSI/spotfilm falling

load

Ambient light level 6/Y Illuminance, (lx)

Skin dose

Monitor light output

with test pattern

mA, mAs, and mA

waveform check

ADI

8/A(P1) Dose rate only

8/A(P2)

8/A

7/B

6/U Luminance (cd/m

5

Measurements

Dose rate & dose rate

Dose rate & dose (less

sensitive)

Unfiltered beam (3mm

Al.)

with MAS-1 current

probe

Power on

Display

rate

dose

rate

dose

2

)

rate

dose

PMX

Display

code

8.AP1

8.A.P2

8.-A-

6.-y-

7.-B-

6.-Y-

MAS.1

1

Chapter

Determine dose/frame

and number/frames per

second

Determine monitor

vertical frequency

8/A(P2)

6/U

oRTIgo waveform

analyzer (see record

news1.dta)

oRTIgo waveform

analyzer (see record

news1.dta)

- Not valid

- Not valid

PMX-III Manual 1999-03/6.0B 11

Page 16

Chapter

1

Typical Use INTRODUCTION

This page is intentionally blank.

12 1999-03/6.0B PMX-III Manual

Page 17

DESCRIPTION OF PMX-III The Display

2 DESCRIPTION OF PMX-III

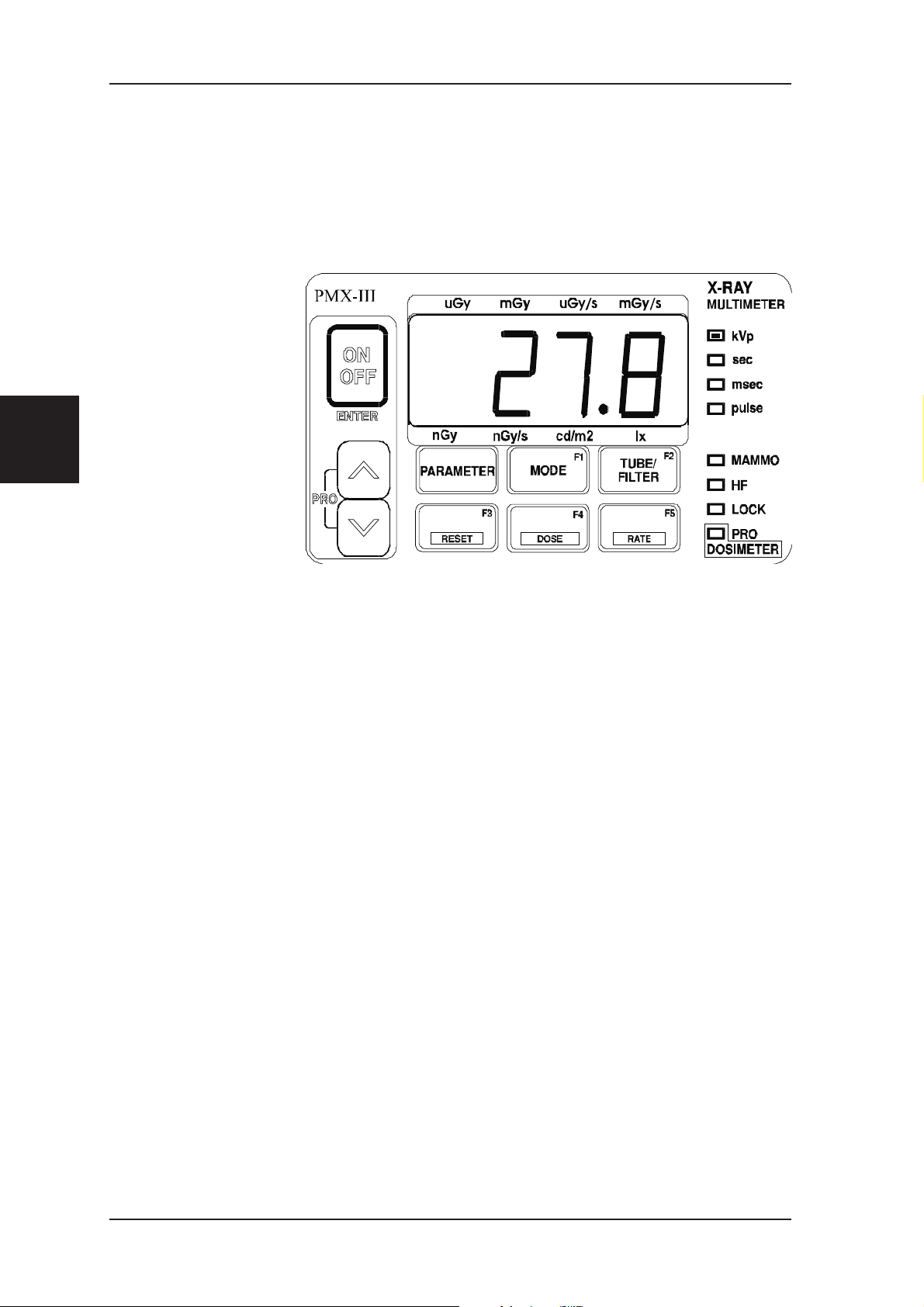

2.1 Front Panel

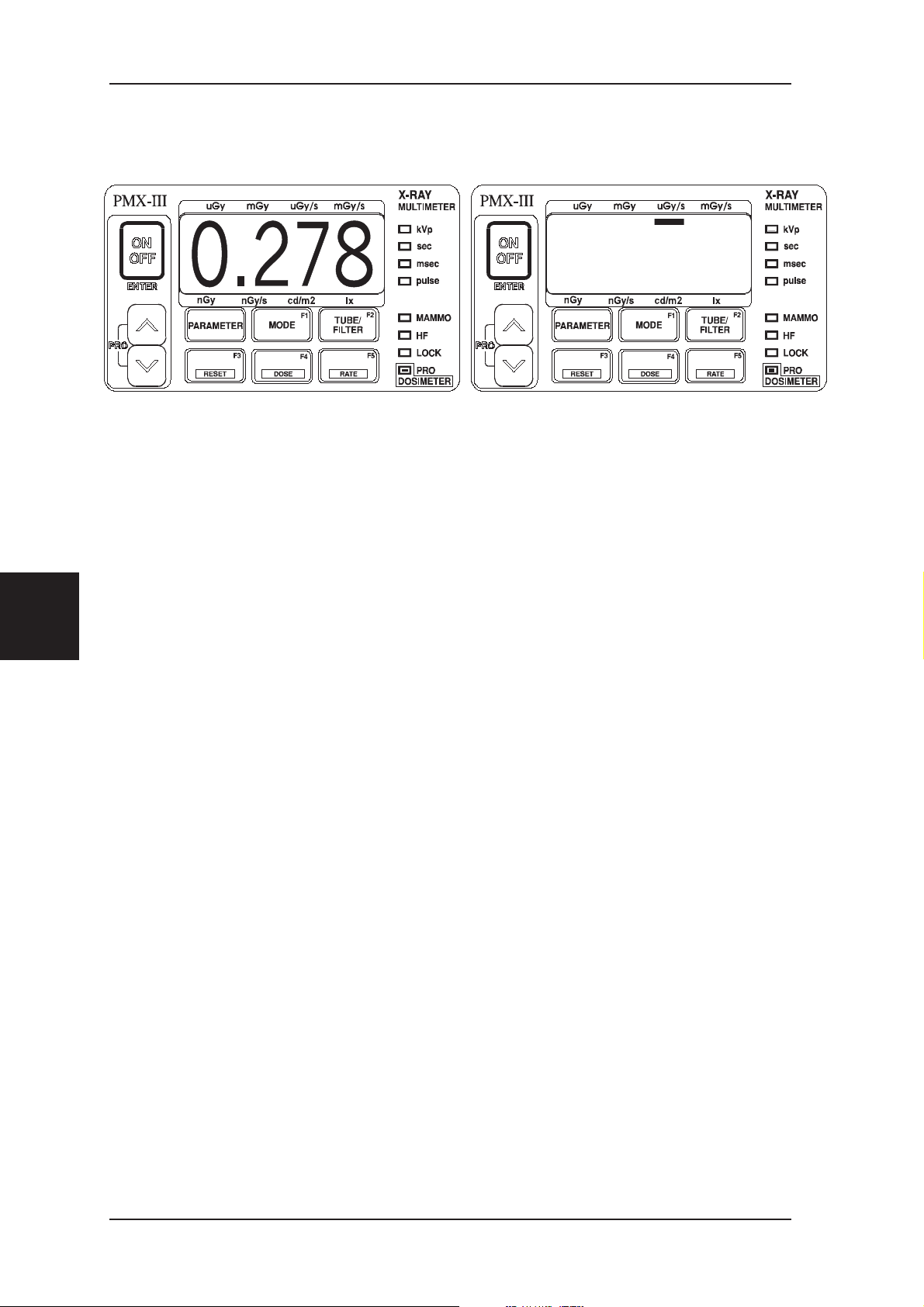

PMX-III is equipped with a membrane switch panel with 9 different switches,

one LCD display, and 8 LED indicators,4. Each time a key is pressed a beep

is generated to indicate that PMX-III has recognized the key.

2

Chapter

2.2 The Display

The display is a four digit LCD (liquid crystal display). The display is used to

show digits and text and to indicate dose and dose rate units. Dose and dose

rate are indicated at the top and bottom of the display.

The character “c” in the first position indicates that PMX-III is performing

internal calibrations. This is done after each exposure in multimeter mode and

when RESET is pressed in dosimeter mode.

When PMX-III operates in multimeter mode and is turned upside-down the

display information is automatically turned around. This function can be

turned off by means of the programming feature.

PMX-III Manual 1999-03/6.0B 13

Page 18

Chapter

2

The LED Indicators DESCRIPTION OF PMX-III

2.3 The LED Indicators

Eight LED indicators are used to indicate different parameters and modes of

operation. The LED indicators are turned on each time a measurement is

performed or a

function is selected.

In multimeter mode

the LEDs are on for

10 seconds and then

turned off to save

power. If the LEDs

are off, they can be

turned on again by

pressing the upper

cursor key.

In dosimeter mode

the LEDs are on

continuously.

The following LED indicators are on the front panel:

kVp Indicates tube voltage.

sec Indicates exposure time, measured in seconds.

msec Indicates exposure time, measured in

milliseconds.

pulse Indicates exposure time, measured in pulses.

14 1999-03/6.0B PMX-III Manual

Page 19

DESCRIPTION OF PMX-III The LED Indicators

2

Chapter

MAMMO ON: Indicates that the selected tube/fil

ter combination corresponds to a

mammo X-ray unit, i.e. the MAM

sensor area is used.

OFF: Indicates that the selected tube/fil-

ter combination corresponds to a

conventional X-ray unit, i.e. the

RAD sensor area is used.

HF ON: Indicates high frequency mode.

OFF: Indicates low frequency mode.

LOCK ON: Indicates LOCK or manual LOCK

mode.

OFF: Indicates SET mode.

-

PRO ON: Indicates PROGRAMMING mode

(the ON/OFF key acts as ENTER

key) or that the dosimeter is acti

vated.

DOSIMETER OFF Indicates multimeter measuring

mode.

PMX-III Manual 1999-03/6.0B 15

-

Page 20

Chapter

2

Front Panel Keys DESCRIPTION OF PMX-III

2.4 Front Panel Keys

The front panel keys are used to

choose different operating modes.

The same key may have different

functions in multimeter and

dosimeter modes.

The following keys are on the

front panel, see figure.

ON/OFF (ENTER) Power on/off and enter key in programming mode.

PARAMETER Multimeter:

ter an exposure.Dosimeter: No function.

MODE Changes operating mode

TUBE/FILTER Multimeter: Selects tube/filter combination.

Dosimeter:

F3/RESET Multimeter: Activates a setup table.

Dosimeter: Performs reset of the electrometer.

F4/DOSE Multimeter:

Dosimeter: Selects dose.

F5/RATE Multimeter: Activates a setup table.

Dosimeter: Selects rate.

Selects parameter to be displayed af

No function

Activates a setup table.

-

UPARR and

DNARR

16 1999-03/6.0B PMX-III Manual

Select different entries when moving around in the

menus.

Page 21

DESCRIPTION OF PMX-III Back Panel and AMP-1

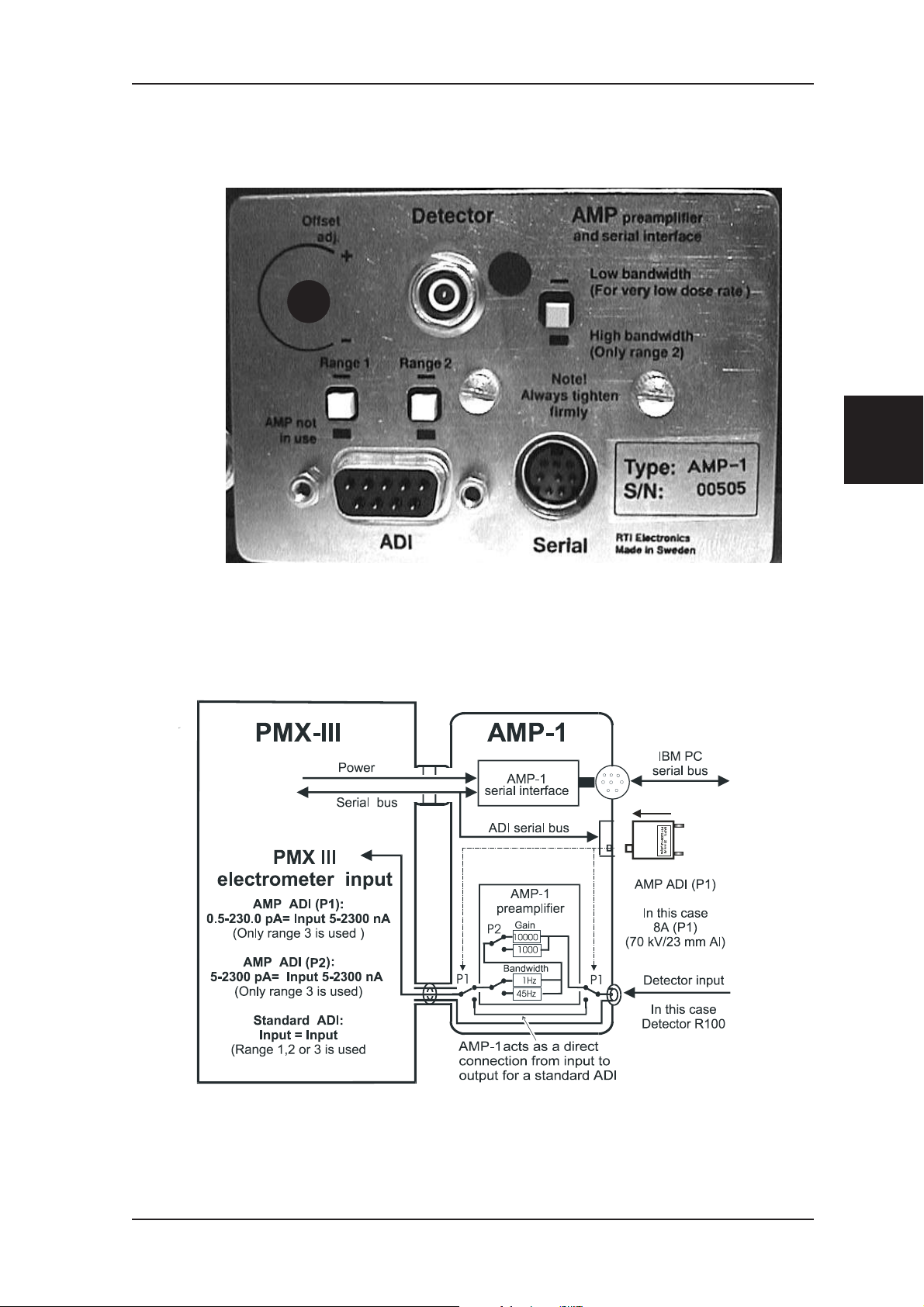

2.5 Back Panel and AMP-1

On the back panel the AMP-1 preamplifier/serial interface, there are four

connectors:

Detector connector input

•

9-pin ADI connector

•

8- pin MINI-DIN serial connector

•

BNC output

•

2

Chapter

A BNC connector

for connection to

an oscilloscope or

voltmeter.

PMX-III Manual 1999-03/6.0B 17

Page 22

Chapter

2

The Battery Case DESCRIPTION OF PMX-III

2.6 The Battery Case

Two high power alkaline “6LR61” 9 V batteries should be used if battery is

used. Preferable a Battery Replacement Box “BRB” for mains power could be

used instead of the two batteries.

18 1999-03/6.0B PMX-III Manual

Page 23

DESCRIPTION OF PMX-III Top Panel

2.7 Top Panel

On the top you will find indications for two sensor areas for MAM and RAD

and indication where to place the dose detector (in multimeter mode), and

user instructions for PMX-III

2

Chapter

PMX-III Manual 1999-03/6.0B 19

Page 24

Chapter

2

Special Remarks for Use of ADI 8/A(P1) DESCRIPTION OF PMX-III

2.8 Special Remarks for Use of ADI 8/A(P1)

The remarks are valid for PMX-III working in dosimeter mode:

Check that the correct ADI and detector is connected and that the detector is not

•

radiated during the time RESET is pressed.

Always press RESET until "c" appears, when a detector has been connected, to read

•

the ADI information. PMX-III then automatically selects Range 3 and then makes a

check that the correct offset level exists before the instrument is ready to measure.

A few picoampere current spike can create a doserate overflow that make the dose

•

display indication show HI.SI. This situation can typically happen when the user

connects or changes detector and ADI with power on, and the preamplifier circuitry

at the same time is activated. Press RESET to clear. This is not seen if the user

selects RATE before changing to 8/A(P1) ADI since the current spike happens only

once, and when the display updates the value is back to zero again. In the new

release of PMX-III version 6.0 PMX-III automatically starts up in dose-rate mode

for 8/A(P1) and therefore the message HI.SI is not seen anymore.

• The offset adjustment potentiometer hole on the back is only for service purposes

for detectors where the detector offset level can change dramatically between

different types. This is not the case for the R100, R25, and L100 detectors. The hole

should normally be sealed.

If the offset value is negative the PMX-III cannot work properly. If the offset value

is to high then the measuring range value will be limited.

A voltmeter have to be connected to BNC output on the back panel to be able to test

the offset level correctly. Normal working levels for R100 using 8/A(P1) is between

100 and 300 mV.

A correct value is 200 ±30 mV after reset and normal working condition .

(Without any ADI connected and after Reset the normal level is 100 ±20 mV.)

Only adjust the potentiometer if you are sure that the real offset level is outside

the accepted range that is valid for the ADI used.

20 1999-03/6.0B PMX-III Manual

Page 25

DESCRIPTION OF PMX-III Operation of Principle of the Electrometer

2.9 AMP-1 Front Panel

2

Chapter

2.10 Operation of Principle of the Electrometer

PMX-III Manual 1999-03/6.0B 21

Page 26

Chapter

2

Operation of Principle of the Electrometer DESCRIPTION OF PMX-III

This page is intentionally blank.

22 1999-03/6.0B PMX-III Manual

Page 27

HOW TO SET UP THE SYSTEM

3 HOW TO SET UP THE SYSTEM

Place PMX-III in the X-ray field for multimeter measurements.

•

For dosimeter measurements place the PMX-III as convenient for you as

•

possible and use the 8 meter extension cable and the probe holder to put

the detector in the measurement field.

If a computer is used, connect the interface cable between your PMX-III

•

AMP-1 and the computer (com l or Com 2), use serial extension cable if

needed.

Connect the ADI-module and detector, use detector extension cable if

•

needed.

Connect the power supply to the BRB-1.

•

• Power on the PMX-III, start oRTIgo or follow instructions on top panel.

3

Chapter

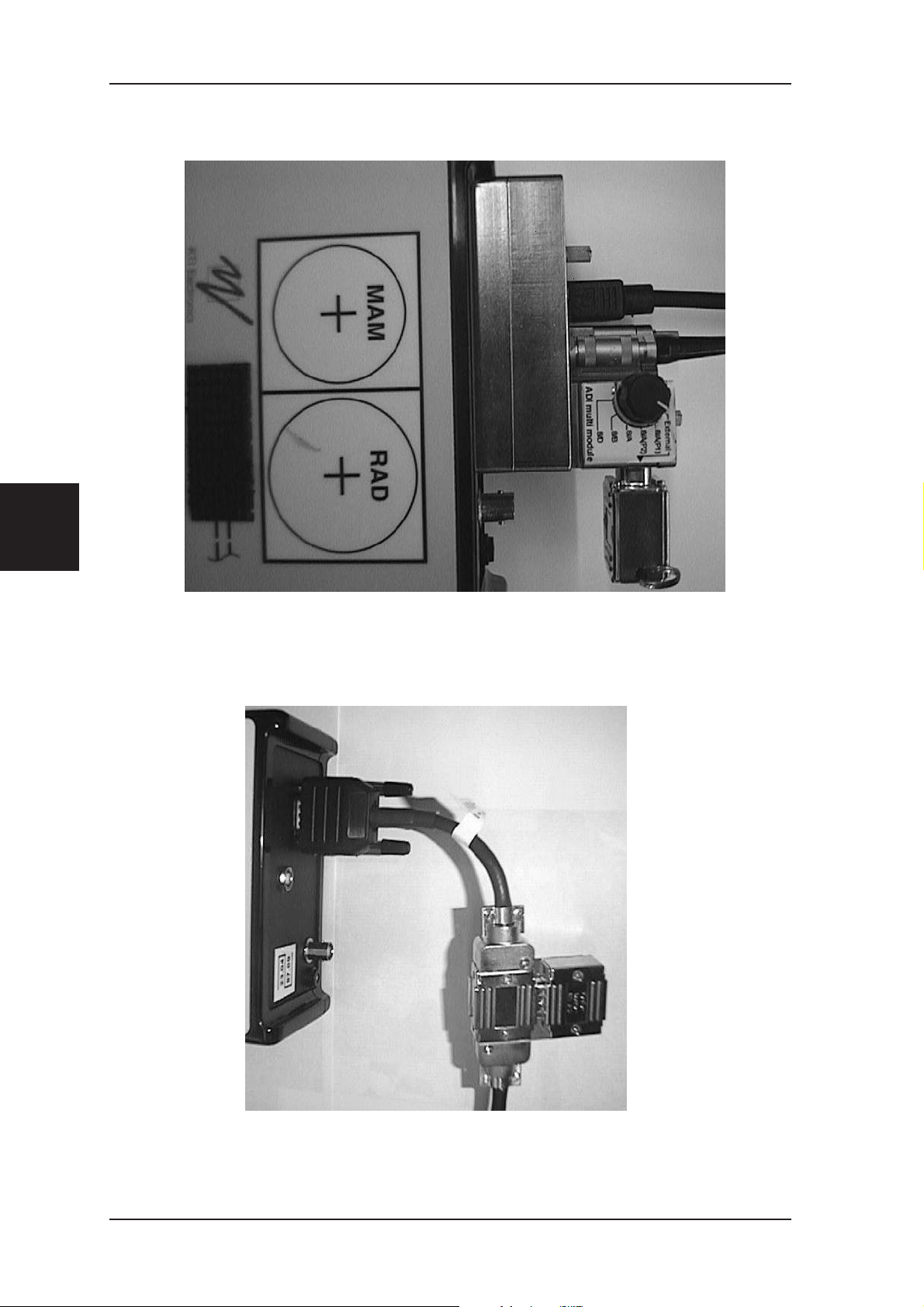

Figure 1. Correct connection of the serial cable, the detector cable, and ADI.

PMX-III Manual 1999-03/6.0B 23

Page 28

Chapter

3

HOW TO SET UP THE SYSTEM

Figure 2. Detail picture of connection of the serial cable, the detector

cable, and ADI Multi module (option).

Figure 3. Correct connection of the serial cable, and ADI for the old

serial interface.

24 1999-03/6.0B PMX-III Manual

Page 29

BASIC QC MEASUREMENTS kVp and Time (Multimeter Mode)

4 BASIC QC MEASUREMENTS

4.1 kVp and Time (Multimeter Mode)

4.1.1 PARAMETER

This key selects the measuring parameter to be displayed.

Each time the key is pressed the display changes between kVp, exposure time,

dose, and dose rate.

4.1.2 MODE

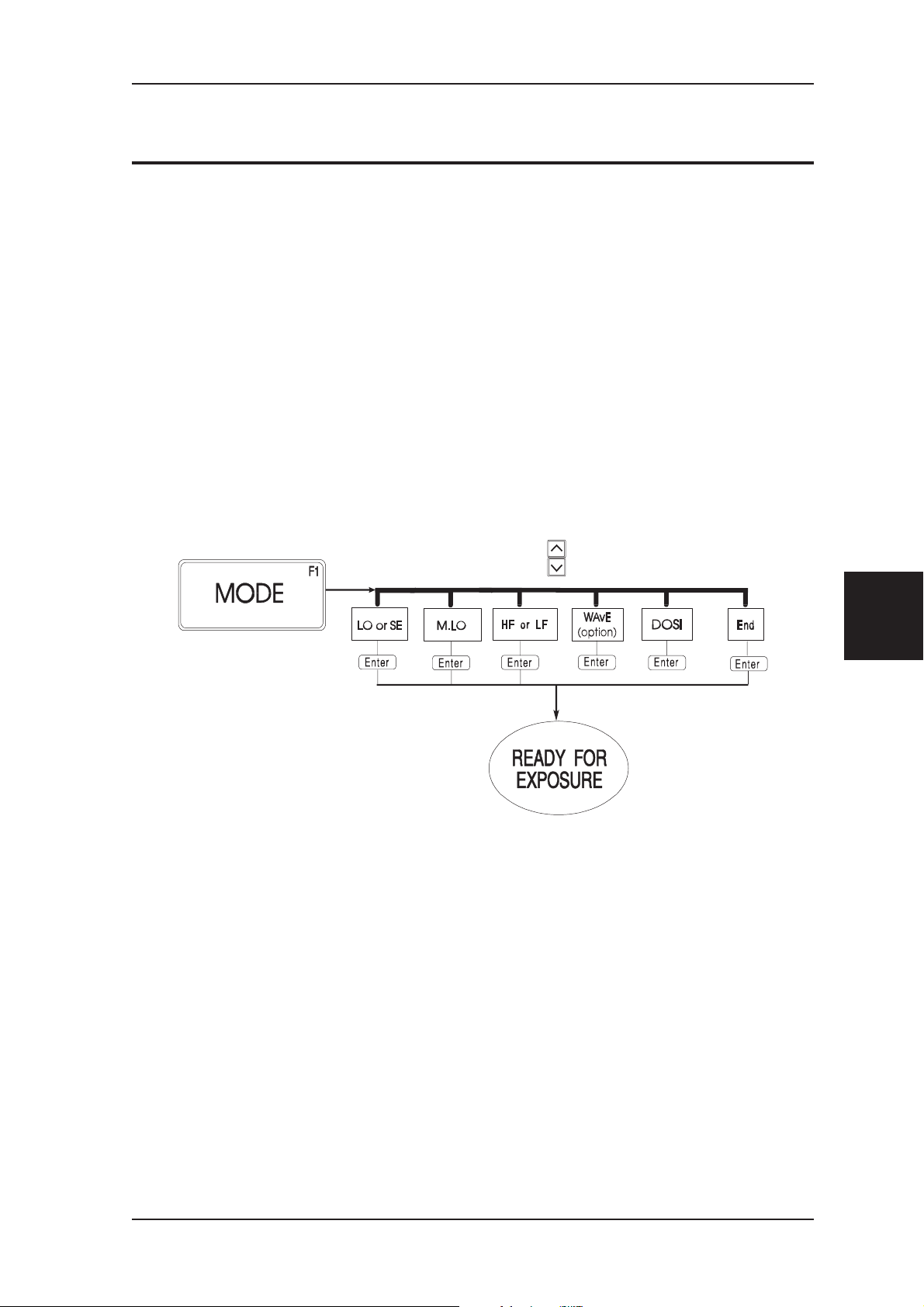

This key selects the type of measuring mode:

SET or LOCK mode, manual LOCK mode, LF or HF mode, waveform

analyzer , or dosimeter mode.

Chap

4.1.3 When to use SET and LOCK modes

SET basic measuring mode (>50 ms exposure times).

LOCK- kVp and time measurements for short exposure

times. (See also manual LOCK mode)

Two exposures must be done when using LOCK Mode. One to set PMX gain

and range and one to get the values.

4

Chapter

Use LOCK Mode to

•

Study the beginning of the exposure waveform using the BNC output

•

Measure exposure time by counting pulses.

PMX-III Manual 1999-03/6.0B 25

Page 30

kVp and Time (Multimeter Mode) BASIC QC MEASUREMENTS

4.1.4 When and how to use manual LOCK mode

Chapter

When it is impossible to make a set exposure because of too short

•

exposure time.

When the user wants to control how PMX-III selects kV-range and gain:

•

Press DNARR to select between:

F1:G1 to F1:G4 - F2:G1 to F2:G4

F1= kV range 45-90 kV

F2= kV range 85-155 kV

G1= Very low X-ray output

G2= Low X-ray output

G3= Average X-ray output

G4= High X-ray output

4

The electrometer always uses range rA:3 .

4.1.5 When to use LF and HF:

LF - single phase

- three phase 6-pulse

- 12-pulse, DC, and mammo units

- HF > 5 kHz and ripple less than 5 %

- Most modern DC/DC X-ray units.

HF - 0.8-5 kHz, only when ripple>5%.

The analog output bandwidth for PMX-III is 800 Hz in LF mode and 10 kHz

in HF mode.

26 1999-03/6.0B PMX-III Manual

Page 31

BASIC QC MEASUREMENTS kVp and Time (Multimeter Mode)

4.1.6 TUBE/FILTER

This button selects valid calibration tables for different tube/filter

combinations.

Up to 16 different calibration tables can be selected.

1-4 are dedicated for the diagnostic 45-155 kV range.

5-12 are dedicated for mammo use. 13-16 for CT.

Calibration table numbers which are stored into PMX-III are indicated after

the text CA in the display (Ex. CA -1). Use cursor keys to select correct

tube/filter combination from the existing calibration table. Store with the

ENTER key.

F3, F4, and F5.

Factory set function keys for direct setup of measuring conditions. The keys

can also be user defined.

y+F3

Press UPARR and while still pressing UPARR, press F3, use cursors to select

delay 0-9999 ms.

Press ENTER to store the new value.

4

Chapter

PMX-III Manual 1999-03/6.0B 27

Page 32

kVp and Time (Multimeter Mode) BASIC QC MEASUREMENTS

4.1.7 Measurement with the MAM/RAD version

Connect the dose detector/ADI module.

•

Each ADI module holds information for one beam quality only (See also

•

the “Detector Selection Guide” chapter 9 if you need additional help).

Power on PMX-III. The “DOSIMETER” indicator must be off. If the

•

indicator is on, press the MODE key and enter “MuLt”.

Choose a calibration table with the TUBE/FILTER key, or press a

•

function key to upload a setup table.

Position the sensor area (MAM or RAD) in the X-ray beam, and

•

collimate the light field.

Put the dose detector on top of the PMX-III, and add desired additional

•

filtration.

Chapter

4

• Set desired generator values and make an exposure.

• Read the measured values from the display.

• After the results have stopped flashing, and the character “c” has

disappeared, PMX-III is ready for another exposure.

• Press the PARAMETER key to alter between kVp, exposure time, dose,

dose rate, or light.

28 1999-03/6.0B PMX-III Manual

Page 33

BASIC QC MEASUREMENTS kVp and Time (Multimeter Mode)

4.1.8 Default values for F3-F5 (MAM/RAD version)

F3 Setup table #1; (CA:1 diagnostic)

W/Al 3.0 mm, 45 - 155 kV

F4 Setup table #4; (CA:5 mammo)

Mo/Mo 30 um, 23 - 35 kV)

F5 Setup table #5; (CA:6 mammo)

Mo/Al 2.0 mm, 30 - 46 kV

Setup table #1 is always uploaded when the

PMX-III is powered on.

4.1.9 CT kVp Measurement with the CT/RAD version

Power on PMX-III. The “DOSIMETER” indicator must be off. If the

•

indicator is on, press the MODE key and enter “MuLt”.

• Choose a calibration table with the TUBE/FILTER key, or press a

function key to upload a setup table.

• Press F4 or F5 according to the table below:

• F4 Setup table #13; (CA:13 CT without comp.filter)

W/see calibration record,75-145 kV

• F5 Setup table #14; (CA:14 CT with comp.filter)

W/see calibration record, 75-145 kV

4

Chapter

PMX-III Manual 1999-03/6.0B 29

Page 34

kVp and Time (Multimeter Mode) BASIC QC MEASUREMENTS

Open the beam width to 10 mm. Use the patient positioning light to

•

align the CT sensor area horisontally within the beam.

Disable the motion of the tube and table. Place the tube in the top

•

position.

Make the exposure, both kVp and time will be displayed after the

•

exposure is finished. Use the PARAMETER key to select kVp and time.

Make corrections of the kVp value for the filtration dependence if

•

needed,

Consult the PMX-III reference manual, Appendix E for more information

how to correct for filtration depencence and how to make kVp measurements

with rotating CT units and oRTIgo

Chapter

4

30 1999-03/6.0B PMX-III Manual

Page 35

BASIC QC MEASUREMENTS Dose and Dose Rate (Dosimeter Mode)

4.2 Dose and Dose Rate (Dosimeter Mode)

PMX-III is normally supplied with two small durable and accurate solid state

detectors for X-ray and light measurements, and a number of ADI modules.

(See the “Detector Selection Guide; Chapter 9” if you need additional help.)

In dosimeter mode dose and dose rate are measured simultaneously. Press the

DOSE key and the measured dose value is displayed. Press the RATE key

and the measured dose rate is displayed. Rate is indicated on the display with

a “:” sign.

MODE The MODE key is used to select manual LOCK,

free run, or trig level, or return to multimeter

mode.

4

Chapter

PMX-III Manual 1999-03/6.0B 31

Page 36

Dose and Dose Rate (Dosimeter Mode) BASIC QC MEASUREMENTS

4.2.1 When and How to Use Manual LOCK Mode

Press DNARR to manually select electrometer range if manual LOCK mode

is selected:

RA:1 This is the most sensitive range for low dose rate

measurements.

RA:2 Middle range.

Chapter

4

RA:3 This range should be used for high dose rate mea

surements.

It is recommended to use the manual LOCK mode when the exposure time is

less than 50 ms.

Press MODE , select Auto to select auto range.

4.2.2 How to Use Free Run/Trig Mode

In the free run mode no trig levels exist. This makes it possible to measure

down to zero signal in the display. In trig run mode, measured dose rate value

is started to be displayed when the signal is above a set trig level determined

by the selected ADI. Please note that PMX-III is not powered down

automatically when “Free run” is activated.

-

32 1999-03/6.0B PMX-III Manual

Page 37

BASIC QC MEASUREMENTS Dose and Dose Rate (Dosimeter Mode)

4.2.3 Active Keys

DOSE Press to read measured dose in specified

dose unit.Press again to display dose unit.

RATE Press to read measured dose rate value

in specified dose unit.

Press again to display dose unit.

RESET Press <1 s to reset display to zero.

Press >1 s for internal zero-adjustment.

The ADI code X.-Y- where

X= Detector identification 1, 2, 3 .6.7.8 .. and

Y= Beam quality A, b, C, d, U,Y.

is displayed for 1 s to indicate valid ADI.

The ADI code for AMP is XY.PZ where

X and Y is defined as above . P indicate AMP-1

Z =1 for range 1 , Z=2 for range 2

y+MODE Press to normalize the display value to a prede-

fined value. Can be used to calculate a ratio between two detector signals. Abort normalize mode

by pressing y+MODE again.

y+RESET Press to toggle between manual and auto-

reset modes.

Manual: Dose values are accumu

lated

Auto: Previous dose value is cleared

y+DOSE Press to hold display value. Abort by pressing

y+DOSE again.

4

Chapter

-

PMX-III Manual 1999-03/6.0B 33

Page 38

Dose and Dose Rate (Dosimeter Mode) BASIC QC MEASUREMENTS

y+RATE Press to select the dose/frame menu:

Use the cursor keys to select:

1.5-63.5

Chapter

4

OFF Normal dose and dose rate measurement

Fr Selects the frame mode.

Press ENTER and current number of frames during the exposure is shown in the display.

Use the cursor keys to select a new value.

Press ENTER to store the new value,measuring

mode is activated again.

The measured and displayed dose is divided with the number of frames.

Fr.: Selects the frames/second mode.

Press ENTER and current number of frames dur

ing one second is shown in the display.

Use the cursor keys to select a new value.

Press ENTER to store the new value,

measuring mode is activated again.

-

The measured and displayed dose rate is divided with the number of frames/s.

It is recommended to use the manual LOCK mode when using the frame

mode.

An alternative method is to use the waveform analyzer and oRTIgo. The number of

pulses, number of frames/s or Hz, and dose/frame are automatically calculated

from the stored dose rate wave form.

34 1999-03/6.0B PMX-III Manual

Page 39

BASIC QC MEASUREMENTS Dose and Dose Rate (Dosimeter Mode)

4.2.4 How to Make a Measurement

Connect the dose detector/ADI module.

•

Each ADI module holds information for one beam quality only.

Power on PMX-III. The “DOSIMETER” indicator must be on. If the

•

indicator is off, press the MODE key, scroll with the cursor keys and

select “dOSI” with the ENTER key.

Position the dose detector in the X-ray beam.

•

Set desired generator values and make an exposure.

•

• Read measured values on the display. Both dose rate and dose value are

stored after the exposure.

4

Chapter

PMX-III Manual 1999-03/6.0B 35

Page 40

The Waveform Analyzer BASIC QC MEASUREMENTS

4.3 The Waveform Analyzer

It is strongly recommended to use oRTIgo to collect waveform if possible

since it is much easier to handle. If used without computer it is recommended

to read sections 6.1 to 6.3 in the reference manual at least once before using

the analyzer:

Chapter

Connect a BNC cable between the connector on the rear of the PMX-III

•

and your oscilloscope (amplification: 0.5 V/div, time: 5 ms/div).

Use the MODE key to enter the mode menu and be able to switch the

•

waveform analyzer on and off.

The waveform analyzer has three main levels indicated on the display:

•

“Set”:

All PMX-III keys are valid. The PMX-III waits for an exposure

to adjust gain and filter to current generator settings.

4

• “SAMP”:

Waiting for an exposure. Gain and filter adjustment are set from an

earlier exposure or by the user if manual lock mode is selected.

The PMX-III samples the detector to be able to measure the initial part

of the exposure.

“PA:1":

Sending sampled kV and radiation waveforms to the oscilloscope.

“RY:1”:

Sending sampled electrometer and radiation waveforms to the

oscilloscope

•

Make exposures, and the PMX-III automatically adapts to the

measurement situation.

•

Use the:

-PARAMETER key to toggle between kV and radiation or electrometer

waveforms.

-cursor keys to select different memory parts of the measured exposure.

-F3 key to calibrate the kV or electrometer rate waveform on the

oscilloscope.

-ENTER key to go to “SEt” level.

36 1999-03/6.0B PMX-III Manual

Page 41

BASIC QC MEASUREMENTS The Waveform Analyzer

Please consult Section 6.3.2 and 6.5 in the reference manual to use the

programming features.

4.3.1 Examples of waveforms

Dose rate response from a dental unit at two bandwidth

60 kV, 3 mA, 23 mm Al, SSD=30cm, 8/A(P2)

45 Hz and 1 Hz are selected using the AMP-1 filter knob.

4

Chapter

Upper: Dental kV, compressed mode

Lower: Dental output, simultaneously sampled

PMX-III/PH Manual 1999-03/6.0B 37

Page 42

The Waveform Analyzer BASIC QC MEASUREMENTS

4.3.2 Waveform flowchart

Sa mp lin g ra te

Chapter

4

The flo w c ha rt is va lid

for PMX-III firmware 6.0

Wa v f lo w 4 . c d r

38 1999-03/6.0B PMX-III/PH Manual

Page 43

BASIC QC MEASUREMENTS Using preamplifier AMP-1

4.4 Using preamplifier AMP-1

AMP-1 consists of a preamplifier

for the PMX-III electrometer and a

serial interface. See Chapter 2 for

an overview of the AMP-1

functions.

AMP-1 makes it possible to

increase the sensitivity 100 times

when used with PMX-III. This

sensitivity is needed for acceptance

test and adjustment of modern

Image Intensifier systems.

AMP-1 should only be used with the PMX-III in Dosimeter mode.

The AMP-1 is specially designed to measure the very low entrance dose rate

levels to an Image Intensifier (II). An optimised range for II of 0.030 µGy/s to

about 46 µGy/s is obtained when the detector R25/R100 is used together with

AMP-1. The preamplifier is simply “piggy backed” directly on the PMX-III

back panel, eliminating connecting cables. The AMP-1 is powered by the

PMX-III.

Furthermore there is no need to disconnect the AMP-1 and the detector from

PMX-III since the AMP-1 only is activated when a special made

AMP-1 ADI is used.

The special AMP-1 ADI (Automatic Detector Identification) combines the

features of storing the detector data in use into the ADI and simultaneously

activate and select range of the AMP-1. The AMP-1 has two measurement

ranges, P1 and P2.

AMP-1 has a built-in second order low-pass filter with two ranges,

DC-1 Hz and DC-45 Hz.

4

Chapter

The special ADI connected to the AMP-1 makes it possible to read directly in

µGy/s (or µR/s) and µGy (µR) on the display depending on AMP-1 range and

detector. The II dose rate waveform can also be collected and displayed using

the oRTIgo wave form analyser or with an oscilloscope.

A handy method to adjust the II entrance dose rate level (typically 0.10-0.50

µGy/s) is to look at the dose rate level with an oscilloscope. The scale factor

is 1 µGy/s / V, if the AMP-1 and R100 is used and the oscilloscope is

connected to PMX-III BNC output.

PMX-III Manual 1999-03/6.0B 39

Page 44

Using preamplifier AMP-1 BASIC QC MEASUREMENTS

Example:

The picture below shows a measurement with a dose rate of 0.13 µGy/s

ocilloscope settings: 0.05 µGy/s /div. 1 s/div.

Chapter

4

Using oRTIgo a certain portion of the dose rate waveform can be selected

using the radiation waveform as reference. This part of the dose rate

waveform is then integrated and the dose/frame, dose rate value and number

of frames/s value is automatically calculated and displayed.

40 1999-03/6.0B PMX-III Manual

Page 45

BASIC QC MEASUREMENTS Measurements with the AMP-1

4.5 Measurements with the AMP-1

4.5.1 General

It is recommended that only dosimeter mode is used with the AMP-1.

Select reading in dose rate by pressing the RATE knob.

Be aware that the limited bandwidth of 1 Hz is optimised for Image

Intensifier measurements measuring the dose rate signal. If pulsed

fluoroscopy should be measured you must select higher bandwidth. Select

range 2 and 45 Hz or deactivate the AMP-1 to get 700 Hz bandwidth to be

able to follow the individual pulses.

The PMX-III starts to measure when the dose rate signal is greater than

approximately 0.050 µGy/s when using the AMP-1 8/A(P1) ADI

(0.030-4.600 µGy/s for R100).

Select “Free” run mode if the AMP-1 should start to measure all the way from

zero.

For short exposure times or pulsed radioscopy please deactivate the AMP-1 by

selecting the appropriate ADI and select multimeter mode or use the waveform

analyzer to be able to measure the individual dose rate pulses.

When selecting multimeter mode you should and must “gate” the dose rate signal

by using the PMX-III kV detector as a trigger. This method makes the

measurement easy to do. You can even combine the dose rate and dose reading with

kVp and exposure time measurements.

4

Chapter

PMX-III Manual 1999-03/6.0B 41

Page 46

Measurements with the AMP-1 BASIC QC MEASUREMENTS

4.5.2 Detector Range and Identification Codes

On the above display the colon indicates that rate mode is selected.

As long as the RATE key is pressed, the sign above µGy/s is shown to

indicate that the unit is µGy/s. The reading is 0.278 µGy/s.

The measuring range and unit is indicated on the ADI.

Chapter

4

An identification code for the selected conversion factor is shown during

approximately one second after reset and zero adjust.

X.-Y- Standard ADI, for detector X and beam quality Y.

XY.PZ AMP ADI, for detector X, beam quality Y,

range Z (1 or 2).

42 1999-03/6.0B PMX-III Manual

Page 47

SERVICE / MAINTENANCE Introduction

5 SERVICE / MAINTENANCE

5.1 Introduction

The default function of PMX-III was earlier to start up with Multimeter or

Dosimeter mode, depending on the mode used when it was powered off. This

is sometimes inconvenient, especially when having specific written

instructions for certain measurements.

You can now program the PMX-III to start up in either Multimeter or

Dosimeter mode. You activate this function by pressing the MODE and

ENTER key when choosing the measuring mode you want to be default after

power on. It is done in the following way:

Activate the measuring mode, Multimeter or Dosimeter, you don’t want to have as

•

default. Use the MODE menu if you have to change measuring mode.

• Press MODE to activate the MODE menu.

• Move to the entry corresponding to the mode you want to have as default, i.e. “Mult”

or “dOSI".

• While keeping the MODE key pressed, press the ENTER key.

• Release both keys.

The PMX-III will now start up with the measuring mode you selected.

To disable the above described function:

• Press the MODE key.

•

Move to the entry End.

•

While pressing the MODE key, press Enter.

5.1.1 New Version of Firmware for PMX-III.

•

Automatically selects dose rate when ADI 7A(P1) or 7A(P2) is detected

•

All dose rate measurements with ADI 7A(P1) and 7A(P2) will be displayed in the

same unit (µGy/sec or µR/sec )

•

The measured dose rate is "freezed" in the display until a new exposure starts or

reset is pressed (not in Free Run mode, without trig level)

5

Chapter

•

Possibility to select half of frame number, for example 12.5 (consequently the

maximum value will be 63.5 instead of 125)

•

The Hi-YES-Lo message related to the offset adjustment (when AD 7A(P1) is used)

is removed (see: "Offset potentiometer" chapter 2)

PMX-III Manual 1999-03/6.0B 43

Page 48

Introduction SERVICE / MAINTENANCE

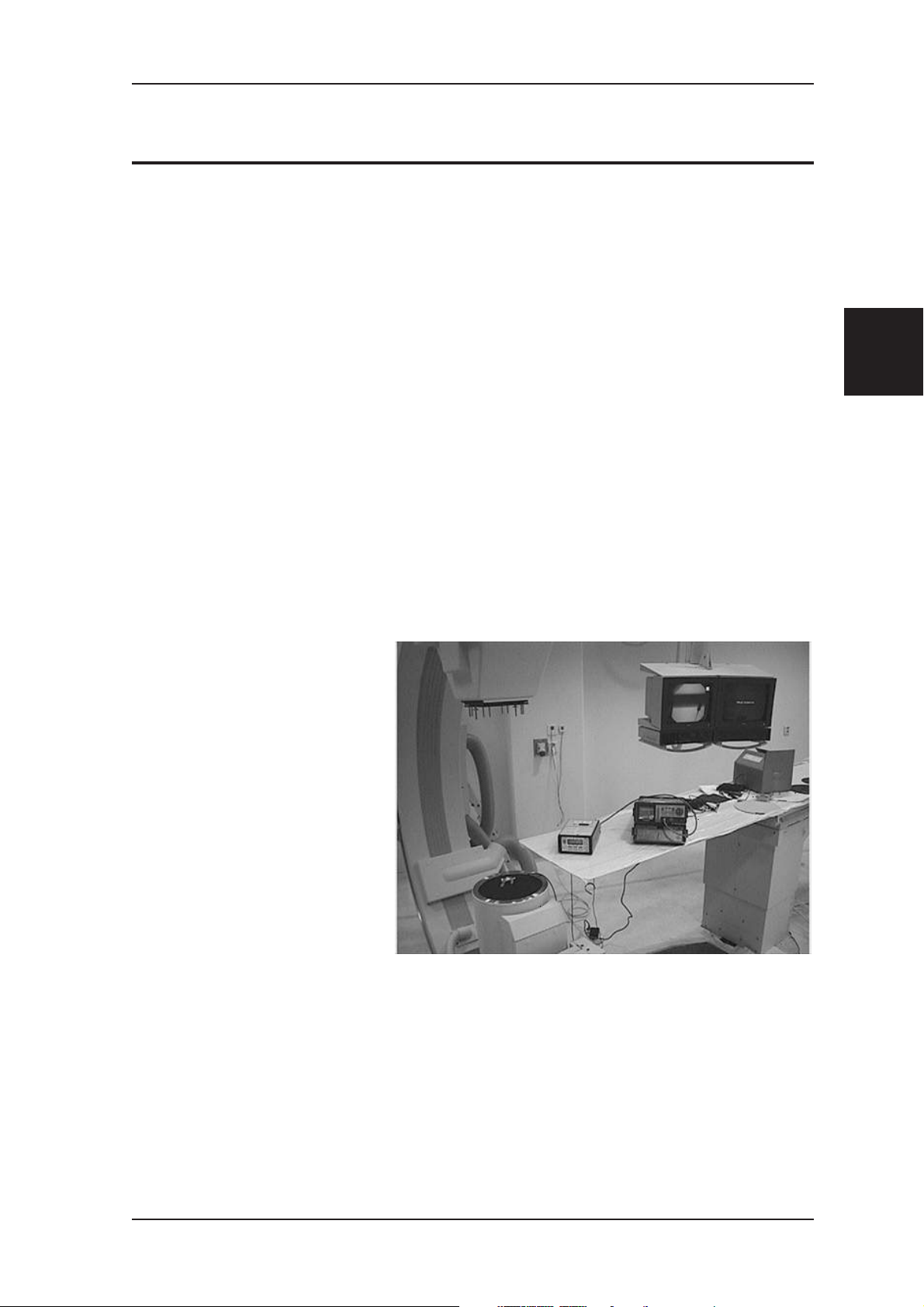

5.1.2 Extension Cable.

An extension cable (8m)

connected to the

R25/R100 probe enables

the engineer to position

the PMX-III at a conve

nient place (i.e. near to

control desk in control

room of the PMS system).

This makes PMX-III

frontpanel operation and

reading of the display eas

ier during testing.

Furthermore the engineers

radiation load is kept as

low as possible. Avoid

work near the radiation field.

-

-

Chapter

5

5.1.3 Probe Holder.

The R25/ R100 probe is

attached to the probe

holder. This support

makes positioning of the

probe in the X-ray beam

much more easy (i.e. in

Scopomat). It also prevents the probe to rotate

by the force of the cable

which can result in consid

erable measuring inaccuracy.

-

5.1.4 ADIs Removed from Detector Cables.

Since there are too many ADIs connected to the cable-chain of the detector

cables (both R100 and L100) they are removed and stored in a separate

storage area in the case.

5.1.5 Maintenance.

In order to prevent damage

to the probes during trans

port a protection cover is

supplied with the

R25/R100 dose probe and

L100 light probe.

44 1999-03/6.0B PMX-III Manual

-

Page 49

SERVICE / MAINTENANCE Entrance Dose Rate Measurements

5.2 Entrance Dose Rate Measurements

5.2.1 Very Low Entrance Dose Rate to an Image Intensifier

See also on top of PMX-III for a very short instructions

Put 20 mm Al or equivalent copper filter (appr. 1.4 -2.1 mm Cu plate) to

•

simulate a patient thickness. Use the probe holder to fixate the R100 so

it is easy to move it over the II input area. Place it on the II so that is not

affecting the feedback system. As a guideline, do not place the detector

in the centre of the field, rather somewhere near a circle with half the the

diameter of the field diameter.

Use the EXT-1 extension cable if needed.

•

Select high dose rate bandwidth with the little tiny red button on the rear

•

panel (the button should be “out”

• For continuos fluoro select ADI 8/A (P1) The range is now 0,030-4,600

µGy/s and the reading is directly in µGy/s, on the PMX-III.

For pulsed fluoro measurements select 8/A (P2) The range is now

0,1-46 µGy/s range instead and also the higher bandwidth (DC to 45

Hz).

• Power on PMX-III and select free run mode (see section 2.3), then select

RATE. By selecting free run mode PMX-III deactivates the trig level so

the user is able to measure all the way down to zero .

•

Verify by pressing RESET that the correct ADI is selected.

•

Start the fluoro exposure. The dose rate is updated on the display during

the exposure. You can freeze the display during the measurements using

the hold mode, see Chapter 4 but since the display values are stored after

the exposure both for dose rate and dose there are normally no need to

use this function anymore.

Pressing the RATE button during or after the measurements displays the

measuring unit.

5

Chapter

Note:

Other detectors and measuring units are also supported.

In this chapter the dose detector R100 and use of Gray units have been used.

See Chapter 9 and the Shortform Detector Selection Guide for use of other units.

PMX-III Manual 1999-03/6.0B 45

Page 50

Entrance Dose Rate Measurements SERVICE / MAINTENANCE

Hints:If the dose rate output also needs to be monitored during adjustment, please

connect an oscilloscope to the PMX-III BNC connector. Select 100 mV/Div. and

1s/Div. on the scope. A change of the dose rate of 0.1µGy/s is then equal to 1 Div.

on the y-axis. The bandwidth is approximately 1 Hz or 45 Hz.

Chapter

5

Dose rate measurement on II fluoro system with PMX-III/AMP-1.

46 1999-03/6.0B PMX-III Manual

Page 51

SERVICE / MAINTENANCE Entrance Dose Rate Measurements

5.2.2 Hints

Use the probe holder

•

together with R25/R100 to

be able to place the detector

in a suitable place on the II

input screen. By observing

the dose rate measured

during slow movement of the

detector above the II you can

check if the detector is

altering the feedback system

or not.

Use the “free” run mode in

•

dosimeter mode to deactivate

the internal trig level. This

makes it possible to measure

linearly all the way down to

The R100 on rod in image intensifier field.

the display reading will not suddenly change to zero or freeze.

zero in the display.

It is therefore easier to adjust

small dose rate values since

• If no dose rate can be measured, please check that the current is greater than 0.05

µGy/s or select “free” run mode.

• The AMP-1 can be mounted all the time on the PMX-III. The AMP-1 is only

activated when the special ADI that “power on” the AMP-1 mechanically is used.

When a normal ADI is used the current signal is passed directly to the PMX-III

electrometer input without using AMP-1’s signal amplification.

•

Use the 8 meter extension cable EXT-1 to be able to place PMX-III in the control

room for easy readout and change of ADI.

•

Use the BRB-1 and AC/DC adapter to avoid battery drain.

•

Select “free” run mode to avoid PMX-III to power off.

It is recommended to use BRB-1 in this situation.

•

Use High bandwidth (45 Hz)allways if possible .

•

Test have been done with R100 8A(P2) 45 Hz on pulsed fluoro/dental system

indicating that measurements with pulse rate of up to approximately 30 pulses/s can

be measured.

•

The AMP-1 ADI automatically selects gain 3 on PMX-III electrometer.

This is indicated by the “Manual Lock” LED. Trying to use gain 1 or gain 2 easily

result in a"HI.Si" message.

5

Chapter

•

If problems should appear with the serial communication transfer, please check that

the PMX-III BRB power supply and the computer power supply is connected to the

same power outlet.

PMX-III Manual 1999-03/6.0B 47

Page 52

Fluoroscopy low mA SERVICE / MAINTENANCE

5.2.3 Example of Dose Rate Waveforms

An oscilloscope was connected to the analog output of the PMX-III.

The external

detector R100 was

placed in the X-ray

field so dose rate

waveform could be

collected using the

PMX-III waveform

analyzer. Only the

dose rate waveform

was displayed on the

oscilloscope. 100

nGy/s was

measured.

(50 nGy/s/div and

1s/div)

Chapter

5

5.3 Fluoroscopy low mA

5.3.1 II-Entrance Dose Rate (µGy/s)

• Connect dose detector R100 and ADI 8/A(P1) to the input on the rear

panel of the PMX . Make sure that the range 1 or 2 switches are

correctly depressed.

•

Select high bandwidth with tiny red button (pull out) on rear panel.

•

Add 1.5 mm Cu or 20 mm Al filtration.

•

Power on the PMX and wait until the internal checks are completed.

•

The dosimeter LED should be on now and PMX-III is ready to measure

dose rate. A “:” in the middle of the display indicates that dose rate is

selected (1).

•

Press select Free run with the cursor keys, and press Enter to

activate “Free”run mode.

•

Give fluoroscopy command, wait for stable reading.

•

Read desired value during or after the exposure

•

The unit of measurement is shown when pressing or .

48 1999-03/6.0B PMX-III Manual

(2)

Page 53

SERVICE / MAINTENANCE Exposure Dose

(1) The lower third dot indicates the deciml dot !

(2) y+RESET

Press to toggle between manual and auto reset modes.

Manual: Dose values are accumulated

Auto: Previous dose value is cleared

y+DOSE

Press to hold display value. Abort by pressing y+DOSE again.

Note: If the display indicates a dash (-) or (Hi Si) ,then press reset longer then 1

second until c appears and now PMX corrects for internal zero-adjustment., It is

normal that the display still indicates a dash(-) after reset sometimes if the drift is

slightly negative.

5.4 Exposure Dose

5.4.1 Fluorography and Radiography

• Connect dose detector R100 and ADI for:

Falling load ADI: 8A

Fixed current ADI: 8A(P2) (1)

• Select high bandwidth by releasing the tiny red button on the rear

panel.

• Add 1.5 mm Cu or 20 mm Al filtration.

•

Select an appropriate exposure time >=50 ms (2)

•

Power on the PMX and wait until the internal checks are completed,

this means the dosimeter LED is on.

•

Make a single exposure

Both the measured dose and dose rate value have been collected and are

available on the display. Use or to move between

measured rate or dose value. By holding down the same key the unit of

measurement is indicated.

5

Chapter

(1) In case of Hi Si display code, take the less sensitive ADI 8A

(2) If exposure time is less than 50 ms, program manual lock mode. (Section 4.2)

PMX-III Manual 1999-03/6.0B 49

Page 54

Measurement of kVp SERVICE / MAINTENANCE

5.5 Measurement of kVp

5.5.1 Long Exposure time, Skin Dose, and Dose Rate

(SET MODE)

Connect dose detector R25 and ADI 7/B (this means no extra filtration

•

in the beam) to the input on the rear panel of the PMX .

Power on the PMX and wait until the internal checks are completed, this

•

means the character “c” has disappeared.

If dosimeter LED stays on after power on, press Mode. The display

•

shows “M.LO”. Select “MuLt” with the cursor keys and press Enter to

activate multi meter mode.

Place dose detector on the velcro strip on top of the PMX and position it

•

in the beam.

Chapter

5

• Select for the RAD sensor area a beam quality of 3 mm( ADI:8/B)

• Set kVp, mA.

• Exposure time (1) may be as low as:

50 ms for good kV measurement.

10 ms for good exposure time measurement.

• Make an exposure.

• Read the values which are displayed automatically in the following

sequence:

kVp

time

unit for dose(rate)

skin-dose(rate)

“c” indicating auto reset performed after each exposure

After this the display returns to one of the values measured .

Press PARAMETER button to scroll measured values.

Note: collimate X-ray field to protect the AMP-1 module at rear of PMX against

direct radiation! It is important to irradiate the complete RAD field on top of the

PMX.

Note: If the total filtration is not 3.0 mm Al, measured kV should be corrected to

achieve maximal accuracy, see chapter 7.

50 1999-03/6.0B PMX-III Manual

Page 55

SERVICE / MAINTENANCE Measurement of kVp

5.5.2 Short Exposure Time, Skin Dose and Dose Rate

(MANUAL LOCK MODE)

Select manual LOCK mode, in

•

this mode the internal filter and

gain range combination are user

selectable.

Make an exposure.

•

Exposure time

•

may be as low

(1)

as:

3 ms for good kV measurement.

0.3 ms for good exposure time

measurement.

In case of over- or under flow the

•

default filter/gain combination

for PMX is not correct.

• Press DNARR to select between:

F1:G1 to F1:G4

F2:G1 to F2:G4

F1= kV range 45-90 kV

F2= kV range 85-155 kV

G1= Very low X-ray output

G2= Low X-ray output

G3= Average X-ray output

G4= High X-ray output

5

Chapter

The electrometer always uses range rA:3 .

(1) Exposure times are specified for HF and DC generators, for 12 pulse (or

lower) generator types see Reference manual page 7-4

If you only want to use the PMX-III as an exposure timer, you can select a display

mode (disp) and parameter (Par) that only display the exposure time after each

exposure, see reference manual chapter 4 section 4.9.4.

PMX-III Manual 1999-03/6.0B 51

.

Page 56

Light Measurements, Detector and Adapters SERVICE / MAINTENANCE

5.6 Light Measurements, Detector and Adapters

5.6.1 Introduction

For more general information about light measurements a separate L100

manual can be ordered from RTI Electronics AB

L100

The L100 detector is the fundamental part of the light meter system from RTI

Electronics AB. On top of the actual detector a filter house is attached. This is

shown in below. The filter house contains the CIE filter that makes the

silicon chip have the same response as the human eye. The purpose of the

filter house is also to fit the different adapters that make the L100 measure the

desired quantity. The actual L100 without any adapters is not calibrated for

any quantity.

Chapter

5

The basic L100 detector which include the CIE filter house

Monitor Adapter

The monitor adapter is intended for luminance measurements on CRTs and

film viewing boxes, i.e. to measure cd/m², and it is referenced to as L100-M.

It consists of two parts: a metal tube with a light shutter and an ambient light

shield made of rubber. This is shown on next page. A luminance meter must

have a limited field of view. In the case of L100-M this is accomplished by

pressing the tube against the surface to be measured.

52 1999-03/6.0B PMX-III Manual

Page 57

SERVICE / MAINTENANCE Light Measurements, Detector and Adapters

The purpose of the ambient light shield is to prevent non-wanted light to

interfere with the measurements. This could otherwise be a problem when

measuring on not so bright sources like e.g. a CRT. Without the ambient light

shield non-wanted light, e.g. from the room, would be reflected via the glass

surface of the CRT and would be added to the measured light. A smaller

shield is also included to make the easier to position the monitor when the

ambient light level

is not a big error

source.This is also a

part of the reason

why

RTI Electronics AB

has chosen not to

design a traditional

luminance meter,

with optics that let

you measure at a

distance. Such a

measurement would

obviously be a

measurement of not

only the source

itself but also of the

ambient light

reflected by e.g. the

The monitor adapter with light shutter and ambient light shield..

glass surface of the

CRT.

5

Chapter

Lux Adapter

To measure illuminance the detector must be able to collect light from every

direction in a half sphere. The contribution from an incidence light beam must

follow the cosine function. This is quite natural if we consider how we

apprehend the surface of a spot on e.g. a desk. Seen from above at an

incidence angle of 0° the projected area of the spot is the same as the real one.

When we increase the angle of incidence to 60° the projected area decreases

by a factor of 0,5, just like cosine 60° equals 0,5. When we have increased the

angle of incidence to 90° we of course cannot see the spot, just as cosine 90°

equals 0.

In theory this sounds easy but in practice there are a few things to consider

when designing a lux detector.

53 1999-03/6.0B PMX-III Manual

Page 58

Chapter

5

Light Measurements, Detector and Adapters SERVICE / MAINTENANCE

First: The surface of the silicon chip will always be shiny. This means

•

that light that hits the detector from a very large angle of incidence will

be reflected by the surface of the silicon chip, thus neglecting the cosine

function.

Second: The actual silicon chip can in most cases not be placed at the

•

surface of the detector. An example of this is the L100 with its CIE

filter.

The solution to these problems is the lux adapter, see figure below. The white

plastic inside the aluminium is called a cosine diffuser.

The surface of the

cosine diffuser is, as

the name implies,

diffuse. Thus

preventing light with a

large angle of

incidence from being

reflected by the

surface. The cosine

diffuser also leads the

light down to the

silicon chip, more or

less in the same way as

an optical fibre can

The Lux adapter with its cosine diffuser

lead light. The lux

adapter is referenced to

as L100-L.

Collimator Adapter

The collimator adapter is a piece of plastic witha1mmhole, and it is

referenced to as L100-C. Its purpose is to allow you to check the contrast ratio

of the edge of the collimator light field. You measure the “light level” just

inside the edge of the light field and divide this value with the “light level”

outside the edge of the light field. This ratio should be sufficiently large.

Since this is a relative measurement there is no need to define what the

quantity “light level” means. You simply measure the current that the L100-C

produces. This also means that there is no need for a calibration of the

collimator adapter.

Contact RTI Electronics AB for further information about the collimator

adapter.

PMX-III Manual 1999-03/6.0B 54

Page 59

SERVICE / MAINTENANCE Light Measurements, Detector and Adapters

5.6.2 Measurement of Luminance (cd/m²)

Connecting the L100-M to the PMX-III

Follow these steps to prepare a measurement.

If it is not already done, attach the monitor adapter tube to the detector

•

housing. It is important that the monitor adapter is pressed all way down

in the detector housing when the screw fixate the tube.

Connect the light detector L100-M to the input on the rear panel of the

•

PMX-III.

Connect the Monitor Adapter ADI module marked 6/U to the connector

•

on the rear panel of the PMX-III

Power on the PMX-III and select DOSIMETER mode, then choose

•

RATE mode. That is normally done automatically for firmware 6.0 and

later.

Make an Reset

•

You have to perform a reset before you can start to measure.

It is VERY IMPORTANT that no light reaches the detector during the

reset procedure. To ensure that the instrument is reset while the detector

is held in complete darkness you must press the light detector to a

completely black surface, e.g. the surface of the ambient light shield,

while pressing the reset key on the instrument.

With the new monitor adapter with light shutter this is a easy task since

the monitor adapter signal is zero until the shutter knob is pressed down.

To perform a reset (actually a zero level adjustment) on the PMX-III you

have to:

•

Press the reset key and keep it pressed until the character “c” is shown

on the display.

•

Wait until the character “c” has disappeared.

•

Start to measure

Move the light detector to the measuring point and open the shutter by

pressing the knob to stop, hold to collect a light value.

After you have released the knob, the PMX-III is stored the value in the

display until next measurement.

5

Chapter

55 1999-03/6.0B PMX-III Manual

Page 60

Light Measurements, Detector and Adapters SERVICE / MAINTENANCE

5.6.3 Measurements on CRTs and Film Viewing Boxes

Attach the ambient light shield to the monitor adapter. You can select

between a small and big shield. Place the light detector on the CRT or the

film viewing box. Make sure the ambient light shield is held flat on to the

surface to prevent ambient light from reaching the detector. Press and hold the

shutter knob. Read the value on the display of the instrument. Two sample

measurements are shown in below.

Chapter

5

Checking the luminance of a

monitor, in this case different

grey-level areas.

SMPTE Test Pattern

A common test pattern used

when testing CRT is the test

pattern specified by the Society

of Motion Picture and

Television Engineers, SMPTE.

This test pattern has, among

other features, 11 different areas

of grey-scale intensity, ranging

from0%to100%.

PMX-III Manual 1999-03/6.0B 56

Page 61

SERVICE / MAINTENANCE Light Measurements, Detector and Adapters

When measuring on these different grey-scale areas you should have in mind

that the luminance of an area NOT is proportional to its grey-scale value.

Instead the luminance (L) is related to the grey-scale level (G) by:

L ∝ G

γ

(Equation 1 )

Equation is equivalent to:

log(L) = γ log(G) + C (Equation 2 )

In equation 2, C is a constant and γ is the gamma value of the monitor that

characterises the relationship between luminance and grey-scale value.

5.6.4 Ambient Light and Other Sources of Error

As mentioned above ambient light will strongly affect the measurement if it is

not taken care of in an appropriate way. To examine how much the ambient

light effects the measurements you could perform a simple experiment and

measure without the ambient light shield. Measure on a CRT that is

completely black, i.e. not powered on, and compare the result with

measurements performed with the ambient light shield attached. Also

measure with and without reduced room illumination. You will notice that the

values achieved without the ambient light shield and with normal room

illumination differ considerably from the ideal value. Imagine the percentage

error you would achieve if you were to measure in this way on the 10 %

grey-scale area!

5

Chapter

Other sources of error are fingerprints and dust on the CRT. Investigations

have shown that these smudges can decrease the luminance by as much as

10 %.

If the CRT is not sufficiently warmed up the luminance can vary during the

measurements. Some monitors need several hours to stabilise. Even if the

monitor has stabilised its output luminance will vary over different areas of

the surface. To exclude this error source from your grey-scale measurements

you can perform the measurements from the same location on the screen.

Zoom the test pattern as large as possible and pan the selected grey-scale area

to the centre of the screen. If necessary you can mark the place to put the

ambient light shield with a piece of adhesive tape. The tape must of course be

placed in such a way that it does not affect the measurements.

57 1999-03/6.0B PMX-III Manual

Page 62

Light Measurements, Detector and Adapters SERVICE / MAINTENANCE

Chapter

5

Example of very compact monitor test system based on oRTIgo.

58 1999-03/6.0B PMX-III Manual

Page 63

SERVICE / MAINTENANCE Light Measurements, Detector and Adapters

5.7.3

Measurement of Illuminance (lx)

Follow these steps to prepare a measurement.

If it is not already done, attach the lux adapter tube to the detector

•

housing. It is important that the lux adapter is pressed all way down in

the detector housing when the screw fixate the lux adapter.

Connect the light detector L100-L to the input on the rear panel of the

•

PMX-III

Connect the LUX Adapter ADI module marked 6/Y to the connector on

•

the rear panel of the PMX-III.

Power on the PMX-III and select DOSIMETER mode, then choose

•

RATE mode. That is normally done automatically for firmware 6.0 and

later.

Make a reset

•

You have to perform a reset before you can start to measure. It

is VERY IMPORTANT that no light reaches the detector during the

reset procedure. To ensure that the instrument is reset while the detector

is held in complete darkness you must press the light detector to a

completely black surface while pressing the reset key on the instrument.

To perform a reset (actually a zero level adjustment) on the PMX-III you

have to:

• Press the reset key and keep it pressed until the character “c” is shown

on the display.

•

Wait until the character “c” has disappeared.

•

Start to measure

Remove the light detector from the black surface , place the detector

where you want to measure and read the value on the display.

5

Chapter

PMX-III/PH Manual 1999-03/6.0B 59

Page 64

Examples of Field Measurements SERVICE / MAINTENANCE

5.7 Examples of Field Measurements

5.7.1 Check the total Contrast Range for the System,

From the Image Intensifier to the Monitor.

Setup:

Chapter

5

Grid mounted

Table-top mounted

SID grid mark ±1 cm

1,5 mm Cu on the X-ray collimator

Contrast phantom is placed in front of II covering the whole entrance screen.

Light is measured on the monitor with the L100 light monitor adapter.

Measuring Results:

Measuring

Field

Phantom

II=17 cm

A1 2,2 3,0 2,7

A2 3,5 4,2 4,0

A3 4,8 5,5 5,4

A4 10,3 10,6 10,7

A5 23,3 22,2 19,9

A6 47,1 49,7 47,8

A7 92,7 98,7 92,5

Continuous

fluoro

IQ APR Low

(cd/m²)

Pulsed fluoro

IQ APR

Normal

(cd/m²)

Exposure

IQ APR

25 frames/s

(cd/m²)

A8 144,6 155,7 144,6

A9 222,6 240,5 221,5

A10 279,5 281,0 273,0

Centre 28,3 28,4 28,7

Continuous fluoro

Measuring field number

Monitor adapter with light shutter to

simplify the collecting of the

luminance values to PMX-III and

oRTIgo.

60 1999-03/6.0B PMX-III/PH Manual

Page 65

SERVICE / MAINTENANCE Examples of Field Measurements

5.7.2 Check that the Dose and Dose Rate Level is within

Specification for all II Formats.

Setup:

Grid not mounted

Table-top mounted

SID grid mark ±1 cm

2.0 mm Cu on the X-ray collimator

R100 detector is placed in front of II outside measuring field.

Please make kV and Cu correction according to calibration

record.

Measuring

results

ADI 8/A(P1) 8/A(P2) 8/A

II Format

cm

Continuous fluoro

IQ APR

Low

(µGy/s)

Pulsed fluoro

IQ APR

Normal

(µGy/frame)

Exposure

IQ APR

25 frames/s

(µGy/frame)

23 0,70 0,026 0,10

5

Chapter

18 1,06 0,040 0,14

13 1,37 0,058 0,22

Example made for Philips MedicalSystem by RTI, Sweden

BasedonprotocolmadebyRolandCarneborn,PMSSweden

PMX-III/PH Manual 1999-03/6.0B 61

Page 66

Examples of Field Measurements SERVICE / MAINTENANCE

This page is intentionally blank.

Chapter

5

62 1999-03/6.0B PMX-III/PH Manual

Page 67

REMOTE CONTROL USING ORTIGO Introduction

6 REMOTE CONTROL USING

ORTIGO

6.1 Introduction

oRTIgo is a Quality Assurance software package which offers

you maximum freedom in managing and documenting X-ray measurements.

Using the software is simple, just choose predefined measurement templates

or create them to suit your own specifications.

Main Features

Customized measurement records with user selected template structure

•

Fully user designable templates.

•

Automatic calculations: % or

•

mGy/mAs, linearity, mean value, and more

• kVp reading are automatically compensated for total filtration

• Dose and dose reading are automatically compensated for the energy response of the

dose detector

• Min/Max acceptance limits for all data, with automatic warnings

• Waveform analysis of kVp, radiation output, and dose rate

• Waveform analysis of light and tube current

• User designable print-out formats

•

Can be run from a DOS shell in WINDOWS

•

Export of data

•

Built-in notepad for adding comments to your measurements

•

Text editor

•

Pull-down menus

•

Context-sensitive help texts

•

Hotkeys for easy access to different functions

∆ error, variation of coefficient, reproducibility, HVL,

6

Chapter

•

DOS file structure for all storage of data

•

Personal password for protection of data and template structure

•

Interface to PMX-III for automatic measurements

PMX-III Manual 1999-03/6.0B 63

Page 68

oRTIgo version 3.0 REMOTE CONTROL USING ORTIGO

6.2 oRTIgo version 3.0

A new version of the DOS based oRTIgo software was released in November

1998.

Major difference, compared to version 2.20:

Improved user interface, Information about the template settings for detector ,

•

detector range, beam quality and PMX-III is now displayed on a “template screen”

to assist the user for the measurement.

Improved communication interface with PC

•

Autoread of dose and dose rate values in dosimeter mode

•

(Pressing INS stores the value in the active template)

Set dose, set dose rate, % dose and % dose rate (mA, Cd/m²..)

•

The display is continuously updated in multimeter mode during exposure

•

(kVp, time, dose, dose-rate (mA, Cd/m²..))

Chapter

6

• Start up of oRTIgo directly from window explorer by double-clicking the

appropriate *.DTA file

• Installation procedure under Windows (W 3.1 / W '95)

• Manual Trig in the waveform analyzer

The possibility to manually trig the waveform analyzer is added. This new function

is available when measuring the electrometer signal (dose, dose rate, light, mA and

mAs) and in combination with MANUAL LOCK mode.

There is sometimes a need for the ability to start the sampling manually, for example

when measuring a very low signal, using the light detector L100, or when the signal

you want to measure need a certain time to stabilize.

You can activate this by changing measuring mode in the build mode before entering

the waveform analyzer. You can also change measuring mode by pressing "M" after

entering the waveform analyzer.

You start the sampling by pressing the INS key.