RST INSTRUMENTS

MEMS Tilt Beam

Instruction Manual

Copyright ©2012 RST Instruments Ltd. All Rights Reserved.

RST Instruments Ltd.

11545 Kingston St.,

Maple Ridge, B.C. Canada V2X 0Z5

Tel: (604) 540-1100

Fax: (604) 540-1005

Email: info@rstinstruments.com

Website: www.rstinstruments.com

LTD.

MEMS Tilt Beam Instruction Manual

i

MEMS Tilt Beam Instruction Manual

Although all efforts have been made to ensure the accuracy and completeness of the information contained

in this document, RST Instruments Inc. reserves the right to change the information at any time and

assumes no liability for its accuracy.

Product: MEMS Tilt Beam Instruction Manual

Document number: ICM0065B

Revision: B

Date: May 10, 2010

RST Instruments

MEMS Tilt Beam Instruction Manual

ii

TABLE OF CONTENTS

1 GENERAL DESCRIPTION .....................................................................................................1

2 MATERIALS ...........................................................................................................................2

2.1 REQUIRED TOOLS/COMPONENTS ..........................................................................................2

3 INSTALLATION .....................................................................................................................2

3.1 ANCHOR INSTALLATION ........................................................................................................2

3.2 SINGLE MEMS TILT BEAM INSTALLATION ..............................................................................5

3.3 MULTIPLE MEMS TILT BEAM INSTALLATION ..........................................................................6

3.4 ELECTRICAL CONNECTIONS .................................................................................................8

4 ANALYZING THE DATA ................................................................................................ ........ 9

5 SPECIFICATIONS ................................................................................................................ 12

5.1 ENVIRONMENTAL ............................................................................................................... 12

5.2 ELECTRICAL ...................................................................................................................... 12

LIST OF FIGURES

Figure 1: MEMS Tilt Beam ............................................................................................................1

Figure 2: MEMS Tilt Beam Details ................................................................................................1

Figure 3: Horizontal & Vertical Tilt Beam Concrete Anchor Orientation ........................................3

Figure 4: MEMSTilt Beam/Meter General Arrangement ...............................................................4

Figure 5: Single Beam Mounting Details .......................................................................................5

Figure 6: Multiple Beam Configurations ........................................................................................ 7

Figure 7: Electrical Connections ...................................................................................................8

Figure 8: Tilt Data Interpretation ................................................................................................. 10

Figure 9: MEMS Tiltbeam Directional Reading ........................................................................... 11

Figure 10: Calibration Certificate ................................................................................................ 13

RST Instruments

MEMS Tilt Beam Instruction Manual

1

COVER PLATE

SCREWS

MEMS TILT BEAM

SERIAL # LABEL

PIVOT REFERENCE

LEFT MOST ANCHOR

CABLE INPUT

(JACKET STRIPPED 15cm)

ADJUSTABLE

END BRACKET

ADJUSTABLE

END BRACKET

CABLE OUTPUT

(BUSSED SYSTEM ONLY)

(JACKET STRIPPED 25cm)

FACE PLATE

FIBERGLASS

BEAM

1 GENERAL DESCRIPTION

RST Instruments MEMS Sensor Tilt Beam is mounted on vertical or horizontal

surfaces and can measure differential angles in the X or Y directions. The Horizontal

or Vertical MEMS Tilt Beam system consists of a fiberglass beam with mounting

brackets, and a uniaxial MEMS sensor. The Vertical Tilt Beam is capable of uniaxial

as well as biaxial MEMS sensors (optional). Because of the excellent zero and range

stability, no separate sensor leveling is required- i.e. the enclosure should be mounted

as close to level as possible, but no secondary level adjustment is required.

Figure 1: MEMS Tilt Beam

Figure 2: MEMS Tilt Beam Details

RST Instruments

MEMS Tilt Beam Instruction Manual

2

2 MATERIALS

2.1 REQUIRED TOOLS/COMPONENTS

Before beginning the installation of the Horizontal or Vertical MEMS Tilt Beam,

ensure that all of the components and tools required for installation are present. See

the list below for tools and equipment required for a typical installation:

MEMS Tilt Beam(s)

(1) Readout (IC6800-V, or FlexDaq 1000/800 Datalogger)

(1) Level

(1) Phillips screw driver

(1) Anchor kit (consisting of (2) 10mm SS anchors, (4) belleville washers, (4) nylon

washers, (2) nylon bushing, (4) 10mm SS nuts

(2) 16mm wrench

3 INSTALLATION

Determine the MEMS Tilt Beam installation location. The location must allow for

access inside the beam to connect the sensors after the unit has been mounted. The

mounting angles should be securely attached with the supplied hardware to a rigid

structure that is free of vibration. Care should be taken to avoid areas of rapid or

extreme changes in temperature such as direct sunlight or near heating or cooling

equipment. For exposed units, a sun shade and or external insulation is

recommended.

The output of the MEMS sensor(s) is in Volts, which can be read with an RST IC6800V Readout or a FlexDaq 1000/800 Datalogger. The MEMS sensors have excellent

zero and full scale stability. As a result, precision sensor zeroing is not necessary.

This is in contrast to electrolytic sensors which have high coefficients of thermal

sensitivity, necessitating precise leveling on the structure.

3.1 ANCHOR INSTALLATION

It is important to install the anchors at a distance equal to the MEMS Tilt Beam

mounting angles pattern (using a level, ensure the anchors are installed inline

horizontally or vertically) (see figure 3).

The anchors should:

1. Protruding horizontally, in all planes, from the structure (not necessarily

perpendicular to the structure)

RST Instruments

MEMS Tilt Beam Instruction Manual

3

FRONT VIEW

10mm CONCRETE

ANCHOR HOLES

TILT BEAM LENGTH

REQURED SPAN

ACCORDING TO

TOP VIEW

10mm CONCRETE

ANCHOR

SIDE VIEW

FRONT VIEW

10mm CONCRETE

ANCHOR HOLES

TILT BEAM LENGTH

REQURED SPAN

ACCORDING TO

SIDE VIEW

2. In plane (i.e. reading level, if a level were placed across both anchors)

3. Allow anchors to set.

Figure 3: Horizontal & Vertical Tilt Beam Concrete Anchor Orientation

RST Instruments

MEMS Tilt Beam Instruction Manual

4

Figure 4: MEMSTilt Beam/Meter General Arrangement

RST Instruments

MEMS Tilt Beam Instruction Manual

5

10mm NUT

10mm NUT

10mm BELLEVILLE WASHER

10mm NYLON WASHER

MOUNTING BRACKET

10mm NYLON WASHER

10mm BELLEVILLE WASHER

MEMS TILT BEAM

10mm CONCRETE ANCHOR

DETAIL A

SCALE 1 : 2

A

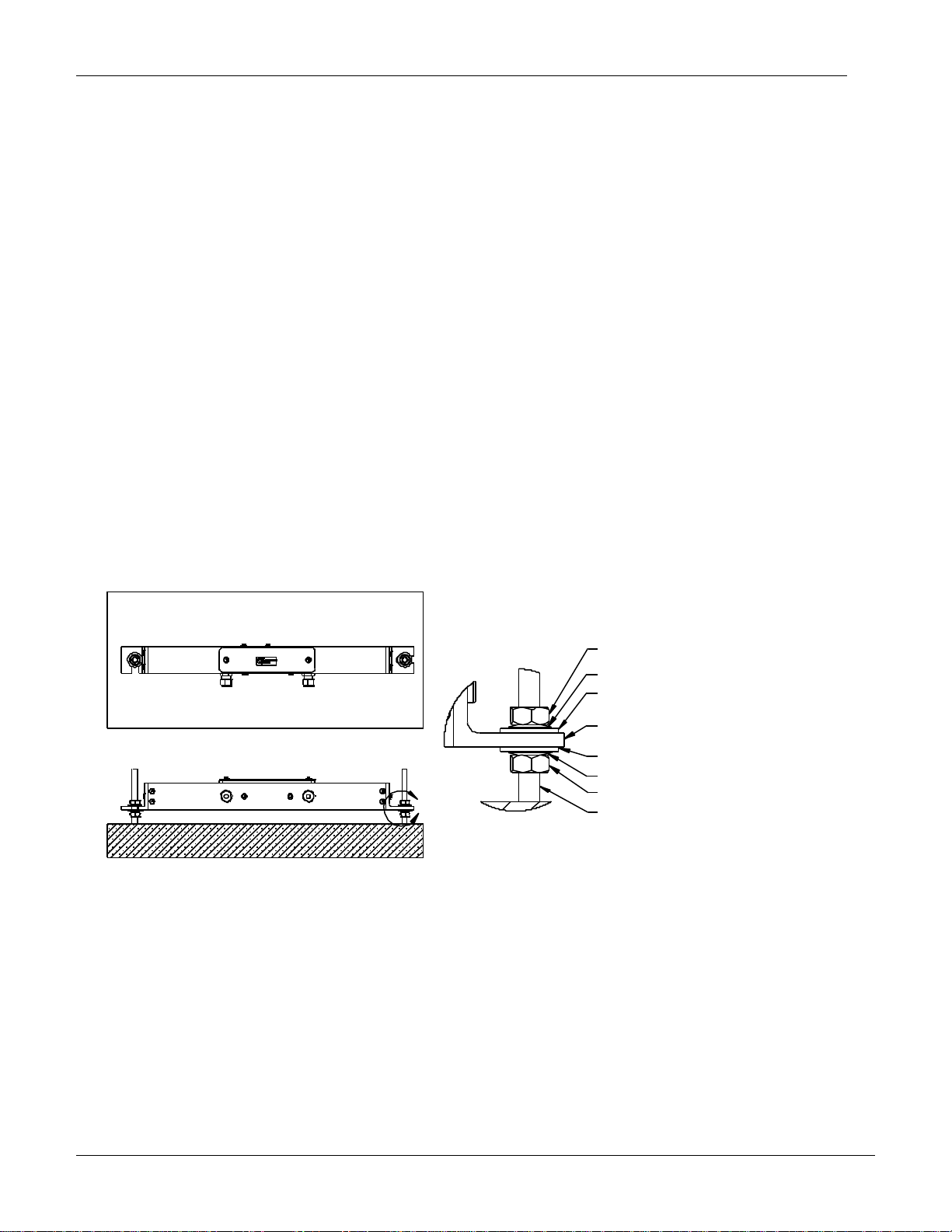

3.2 SINGLE MEMS TILT BEAM INSTALLATION

Determine the MEMS Tilt Beam installation orientation (i.e. Is the Beam to be

installed on the ceiling, wall, or floor). Refer to Figure 4 and adjust mounting

brackets accordingly.

1. Thread a 10mm nut onto each anchor until they reach the desired position

(ensure the nuts are in plane)

2. Place a Belleville washer over each anchor (see Figure 5)

3. Place a Nylon washer over each anchor

4. Place a Nylon bushing over each anchor

5. Slide the MEMS Tilt Beam onto the Nylon Bushings

6. Place a Nylon Washer over each anchor

7. Place a Belleville washer over each anchor (see Figure 5)

8. Thread a 10mm nut onto each anchor, finger tight, and ensure that the Beam is

horizontal or vertical

9. For a single beam installation, where (2) Belleville washers are used per

anchor, turn the nut 2-3 wrench flats (120-180) (see Figure 5)

10. For a double beam installation, where (4) Belleville washers are used per

anchor, turn the nut 4-5 wrench flats (240-300) (see Figure 5)

Figure 5: Single Beam Mounting Details

RST Instruments

MEMS Tilt Beam Instruction Manual

6

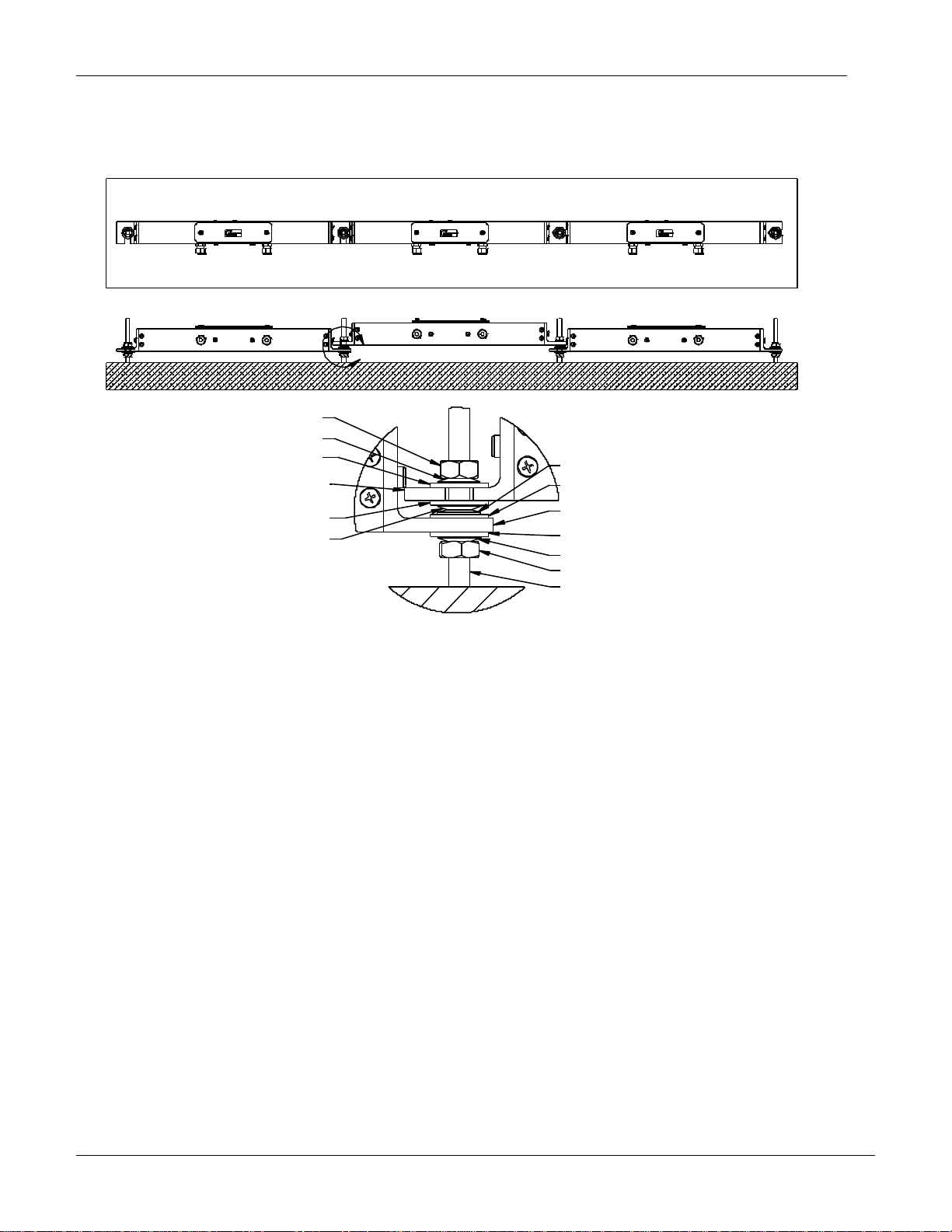

3.3 MULTIPLE MEMS TILT BEAM INSTALLATION

Determine the MEMS Tilt Beam installation orientation (i.e. Is the Beam to be

installed on the ceiling, wall, or floor). Refer to Figure 4 and adjust mounting brackets

accordingly. Ideally, the beams should be staggered (see Figure 6).

There are two ways to complete this installation:

Installing the odd beams first and then the even beams afterwards

Or, install one beam at a time in succession, by placing beams on top

and then in behind.

In either case, you should end up with a staggered installation as shown in Figure 6.

The following installation procedure is for installing one beam at a time in

succession.

1. Thread a 10mm nut onto the first two anchors until they reach the desired

position (ensure the nuts are in plane, not necessarily the same distance from

the wall as the wall may be bowed)

2. Place a Belleville washer over the 1st and 2nd anchors (see Figure 6)

3. Place a Nylon washer over the 1st and 2nd anchors

4. Place a Nylon bushing over the 1st and 2nd anchors

5. Slide the MEMS Tilt Beam onto the Nylon Bushings

6. Place a Nylon Washer over the 1st and 2nd anchors

7. Place a Belleville washer over the 1st and 2nd anchors (see Figure 5 or 6)

8. Thread a 10mm nut onto the 1st anchor, finger tight, and ensure that the Beam

is horizontal or vertical

9. Tighten the nut 2-3 wrench flats (120-180)

10. Thread a 10mm nut onto the 3rd anchor (position nut so that the next beam

when installed will be parallel to the previously installed beam (see Figure 6)

11. Place a Belleville washer and then a Nylon washer and Nylon Bushing over the

nut installed in step 10 (see Figure 6)

12. Place a Belleville washer and then a Nylon washer and Nylon Bushing over the

Belleville washer on the 2nd anchor (see Figure 6 for orientation of washers)

13. Slide the MEMS Tilt Beam onto the 2nd and 3rd anchors, adjust the nut on the 3rd

anchor until the beam is parallel

14. Place a Nylon Washer, and then a Belleville washer over the 2nd and 3rd anchor

15. Place a Nylon bushing over the 2nd and 3rd anchor

16. Thread a 10mm nut onto the 2nd anchor, finger tight, and ensure that the Beam

is horizontal or vertical

17. Tighten the nut 4-5 wrench flats (240-300)

18. Repeat steps 10-17 incrementing anchor references by 1 (i.e. in step 10, the 3rd

anchor would now become the 4th anchor etc.)

RST Instruments

MEMS Tilt Beam Instruction Manual

7

MOUNTING BRACKET

SCALE 1 : 2

DETAIL A

10mm NUT

10mm NYLON WASHER

MOUNTING BRACKET

10mm NYLON WASHER

10mm BELLEVILLE WASHER

10mm NUT

10mm CONCRETE ANCHOR

10mm BELLEVILLE WASHER

10mm BELLEVILLE WASHER

10mm NYLON WASHER

10mm NYLON WASHER

MEMS TILT BEAM

MEMS TILT BEAM

10mm BELLEVILLE WASHER

A

The beams when installed should be staggered and the washers and nuts should be

installed as shown in Figure 6.

Figure 6: Multiple Beam Configurations

RST Instruments

MEMS Tilt Beam Instruction Manual

8

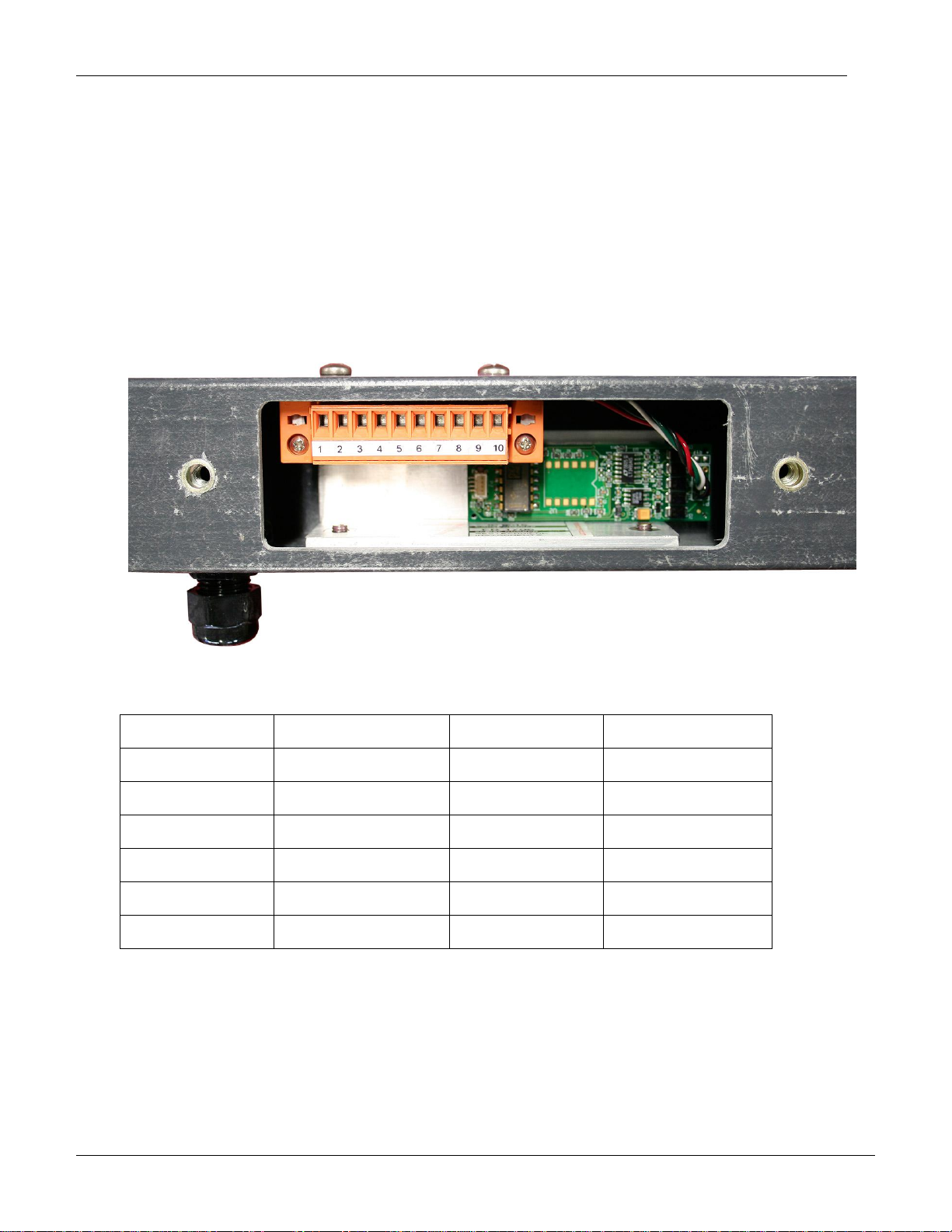

Tiltmeter

Wire Color

Terminal

Datalogger

12V

Red

1

12V

Gnd

Black

2

Gnd

A+

Green

3

xH

A-

White

4

xL

B+

Orange

5

yH

B-

Blue

6

yL

3.4 ELECTRICAL CONNECTIONS

1. Under the Colour Code Table, look up the lead designations for the type of

cable being used.

2. Under the Electrical Connections Table, make the appropriate lead connections,

according to the type of system being used.

3. Horizontal and Vertical Tilt Beam system measure the A-axis (Green & White).

Vertical Tile Beam system is capable of measuring the B-axis (optional) (Orange

& Blue).

Information regarding your sensor configuration and cable type is listed below and on

your Calibration Certificate.

Figure 7: Electrical Connections

Note: For BUSSED Systems only, use the cable with the jacket stripped 25mm back

for the Cable Output.

RST Instruments

MEMS Tilt Beam Instruction Manual

9

4 Analyzing the Data

Each MEMS Tilt Beam is identified by a Serial Number, and has a corresponding

Calibration Certificate (See Sample Calibration Certificate). To convert the sensor

signal into meaningful data, simply substitute the values from the readings and the

Calibration Constants into the following formula:

Sin = m(V-b)

Where

V is the Tiltmeter Output signal.

m is the predetermined Calibration Constant.

b is the predetermined Calibration Constant.

The sensing principle of the MEMS Tilt Beam is that of an accelerometer with the

sensitive axis is oriented horizontally. The measured phenomenon is then the

component of gravity transverse to the sensitive axis, i.e.

a = g sine()

Commonly, MEMS Tilt Beam data are interpreted as linear motion – i.e. rotation about

a presumed radius gives an equivalent motion. In many cases, where the ultimate

variable of interest is lateral displacement at some presumed radius due to rotation,

the accelerometer result can be simply rescaled, i.e.

x = r sine()

r a

= -----

g

In the case of a uniaxial MEMS Tilt Beam, radius (r) is the beam length. For MEMS Tilt

Beam on rigid bodies, the radius must be chosen with some care.

RST Instruments

MEMS Tilt Beam Instruction Manual

10

x

r a g

Figure 8: Tilt Data Interpretation

In cases where the actual angle is sought, the arcsine function or a polynomial

equivalent may be used:

= arcsine(a/g)

It should be noted that measuring “dynamic tilt” may be a concept error: the lateral

dynamic accelerations may exceed the tilt accelerations

RST Instruments

MEMS Tilt Beam Instruction Manual

11

Figure 9: MEMS Tiltbeam Directional Reading

RST Instruments

12

5.1 ENVIRONMENTAL

Operating temperature

-40C to +80C

5.2 ELECTRICAL

Sensor

0ne/Two MEMS Tilt Sensor(s)

Range

15 Degree Standard

Resolution

0.0013 Degree

Null Repeatability

<0.004 Degree

Signal Cable

22 Gauge Shielded Twisted

Datalogger

Analog Readout

FlexDaq 1000/800

IC6800-V

5 Specifications

MEMS Tilt Beam Instruction Manual

RST Instruments

MEMS Tilt Beam Instruction Manual

13

Figure 10: Calibration Certificate

RST Instruments

Loading...

Loading...