Page 1

®

R&S

OSP

Open Switch and Control

Platform

Getting Started

(;ÜÕA2)

1178711702

Version 03

Getting Started

Page 2

The R&S®OSP is a high-performance switch platform from Rohde & Schwarz. It

facilitates RF tests by eliminating the need to rearrange coaxial cable connections

repeatedly during measurements. Instead, the application-specific modules in the

base unit automatically switch the required signal paths.

This document describes the following R&S®OSP base units:

●

R&S®OSP220 Base Unit 2HU without Touchscreen (order no. 1528.3105.02)

●

R&S®OSP230 Base Unit 2HU with Touchscreen (order no. 1528.3105.03)

●

R&S®OSP320 Base Unit 3HU without Touchscreen (order no. 1528.3111.02)

●

R&S®OSP-B200S2 Satellite 2HU for Base Units (order no. 1528.3134.02/.04)

For all optionally available standard switch modules, refer to the User Manual,

which is available for download at https://www.rohde-schwarz.com/product/osp >

Manuals

The software contained in this product uses several valuable open source software packages. For information, see the "Open Source Acknowledgment" document, which is available for download from the

R&S OSP product page at https://www.rohde-schwarz.com/product/osp > Firmware.

Rohde & Schwarz would like to thank the open source community for their valuable contribution to embedded computing.

© 2019 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

Email: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1178.7117.02 | Version 03 | R&S®OSP

In this manual, products from Rohde & Schwarz are indicated without the ® symbol, e.g. R&S®OSP is indicated as R&S OSP.

Page 3

R&S®OSP

Contents

1 For Your Safety...................................................................... 5

1.1 SSR Failsafe Concept...........................................................................8

2 Key Features.......................................................................... 9

3 Documentation Overview....................................................11

3.1 Getting Started Manual.......................................................................11

3.2 User Manual.........................................................................................11

3.3 Tutorials............................................................................................... 11

3.4 Service Manual....................................................................................12

Contents

3.5 Basic Safety Instructions................................................................... 12

3.6 Data Sheets and Brochures............................................................... 12

3.7 Release Notes, Open Source Acknowledgment.............................. 12

3.8 Application Notes & Cards, White Papers, etc.................................12

4 Preparing for Use.................................................................13

4.1 Unpacking and Checking the Switch Unit........................................ 13

4.2 Accessory List.................................................................................... 14

4.3 Placing or Mounting the Instrument................................................. 15

4.4 Connecting AC Power........................................................................ 17

4.5 Switching the Instrument On and Off............................................... 17

4.6 Checking the Installed Modules........................................................ 19

4.7 Configuring the Initial Instrument Settings...................................... 19

5 Instrument Tour................................................................... 20

5.1 Front Panel View................................................................................. 20

5.1.1 Front Panel of the R&S OSP220.......................................................... 20

5.1.2 Front Panel of the R&S OSP230.......................................................... 21

3Getting Started 1178.7117.02 ─ 03

Page 4

R&S®OSP

5.1.3 Front Panel of the R&S OSP320.......................................................... 21

5.1.4 Front Panel of the R&S OSP-B200S2 Satellite Unit............................. 22

5.1.5 Touchscreen..........................................................................................23

5.2 Rear Panel View.................................................................................. 25

5.2.1 Rear Panel of the R&S OSP220........................................................... 25

5.2.2 Rear Panel of the R&S OSP230........................................................... 25

5.2.3 Rear Panel of the R&S OSP320........................................................... 26

5.2.4 Rear Panel of the R&S OSP-B200S2 Satellite Unit..............................27

Contents

6 Trying Out the Switch Unit..................................................29

6.1 Manual and Remote Modes of Operation......................................... 29

6.1.1 Direct Manual Operation....................................................................... 29

6.1.2 Manual Remote Operation....................................................................30

6.1.3 Remote Operation by SCPI Commands............................................... 30

6.2 User Interface and Functional Elements.......................................... 31

6.3 Main Action Buttons........................................................................... 34

6.4 Elements of the Status Line...............................................................34

6.5 Manual Module Operation.................................................................. 35

6.5.1 Switching Mode.....................................................................................35

6.5.2 Selection Mode..................................................................................... 36

4Getting Started 1178.7117.02 ─ 03

Page 5

R&S®OSP

For Your Safety

1 For Your Safety

The R&S OSP is designated for use in industrial, administrative, and laboratory

environments. Use the R&S OSP only for its designated purpose. Observe the

safety and usage instructions documented in the user manual, as well as operating conditions and performance limits stated in the data sheet.

The product documentation helps you to use the R&S OSP safely and efficiently.

Keep the product documentation in a safe place and pass it on to the subsequent

users.

Safety information is part of the product documentation. It warns you about the

potential dangers and gives instructions how to prevent personal injury or damage caused by dangerous situations. Safety information is provided as follows:

●

In the "Basic Safety Instructions", safety issues are grouped according to subjects. For example, one subject is electrical safety. The "Basic Safety Instructions" are delivered with the R&S OSP in different languages in print.

●

Throughout the documentation, safety instructions are provided when you

need to take care during setup or operation. Always read the safety instructions carefully. Make sure to comply fully with them. Do not take risks and do

not underestimate the potential danger of small details such as a damaged

power cable.

Restrictions on opening a switch unit

Opening an R&S OSP switch unit can lead to personal injury and instrument damage.

To avoid these risks, do not open your switch unit.

If opening is required for mounting a module, let Rohde & Schwarz service

personnel mount this module.

If opening is not required for mounting a module, follow the mounting

instruction in the User Manual.

5Getting Started 1178.7117.02 ─ 03

Page 6

R&S®OSP

Risk of injury due to disregarding safety information

Observe the information on appropriate operating conditions provided in the

data sheet to prevent personal injury or damage to the instrument. Read

and observe the basic safety instructions provided with the instrument, in

addition to the safety instructions in the following sections.

Do not open the instrument casing, except for exchanging a hardware

option module, as described in the User Manual.

Risk of instrument damage due to inappropriate operating conditions

Specific operating conditions are required to ensure accurate measurements and to avoid damage to the instrument. Observe the information on

appropriate operating conditions provided in the basic safety instructions

and the instrument's data sheet.

For Your Safety

Risk of electrostatic discharge (ESD)

Electrostatic discharge (ESD) can damage the electronic components of the

instrument and the device under test (DUT).

A risk of damage due to ESD is typically limited to switch units that are

equipped with hardware options with one or more of the following features:

●

Digital input or output ports (I/O ports)

●

Solid-state relays (SSR)

●

Integrated amplifiers in special modules that are delivered as part of a

test system

ESD is most likely to occur when you connect or disconnect a cable to one

of the switch unit's connectors. To prevent ESD, use a wrist strap and cord

and connect yourself to the ground, or use a conductive floor mat and heel

strap combination.

For details, refer to the basic safety instructions delivered as a printed brochure with the instrument.

6Getting Started 1178.7117.02 ─ 03

Page 7

R&S®OSP

Risk of instrument damage during operation

An unsuitable operating site or test setup can damage the switch unit and

connected devices. Ensure the following operating conditions before you

switch on the switch unit:

●

All fan openings are unobstructed and the airflow perforations are unimpeded. The minimum distance from the wall is 10 cm.

●

The instrument is dry and shows no sign of condensation.

●

The instrument is positioned as described in the following sections.

●

The ambient temperature does not exceed the range specified in the

data sheet.

For Your Safety

Risk of instrument damage due to insufficient airflow in a rack

If you mount several instruments in a rack, you need an efficient ventilation

concept to ensure that the instruments do not overheat. Insufficient airflow

for a longer period can disturb the operation and even cause damage.

EMI impact on measurement results

Electromagnetic interference (EMI) may affect the measurement results.

To suppress generated electromagnetic interference (EMI):

●

Use suitable shielded cables of high quality. For example, use doubleshielded RF, LAN and HDMI cables.

Note: USB cables are of varying and often poor quality. Therefore, consider the quality of each individual USB cable.

●

Always terminate open cable ends.

●

Note the EMC classification in the data sheet.

7Getting Started 1178.7117.02 ─ 03

Page 8

R&S®OSP

SSR Failsafe Concept

For Your Safety

1.1 SSR Failsafe Concept

SSRs are intended for high-frequency and high-speed switching, but their semiconductor elements are damaged easily by excess current, voltage peaks or a

short circuit. If there is a malfunction, the SSR cannot switch off a connected load.

Hence, inappropriate conditions or usage can damage SSRs or connected components and lead to associated problems.

Risk of injury and damage due to inappropriate SSR relay usage

Solid-state relays (SSRs) require a dedicated concept for failsafe operation.

If you do not implement such a concept in a competent manner, the relay

can fail in securely switching off the load. This failure can lead to a risk of

personal injury and damage of equipment.

To prevent this risk, avoid excess current, voltage peaks and short circuits.

Monostable vs. failsafe

The term "monostable relay" is often considered to be equivalent with the

term "failsafe relay", but this interpretation is misleading:

●

Failsafe means, that the relay is designed to cause minimum or no harm

if there is a failure. To realize this goal, the relay must switch off a load

connected to its NO terminal (normally open), when the control voltage

is lost.

●

Monostable means, that with no control voltage applied, the relay automatically falls back to its "stable" default state. In this state, the C terminal (common) is either connected to the NC terminal (normally connected, typically in SPDT switches) or not connected to any terminal (typically in drum switches).

– Monostable electromechanical relays are failsafe by their mechanical

design: With no voltage applied, a spring load brings back the switch

to its default NC state (or to no connection at all).

– On the contrary, monostable solid-state relays are not inherently

failsafe: Without any voltage applied, the relay quits functioning.

Hence, if the control voltage is lost, SSRs still require the presence

of a supply voltage for switching to the default sate.

8Getting Started 1178.7117.02 ─ 03

Page 9

R&S®OSP

Key Features

2 Key Features

The R&S OSP is a highly flexible, modular switch and control platform. Each

switch unit can be equipped with several application-specific switch modules.

The platform meets the requirements of diverse test scenarios in production, labs

and development environments. Scenarios range from desktop configurations for

laboratory measurements to complex, rack-integrated test systems.

The R&S OSP220/230/320 described in this manual are the second generation of

switch units from Rohde & Schwarz, replacing the R&S OSP120/130/150.

Outstanding key features are:

●

5 to 10 module slots and up to 16 module buses provide maximum flexibility

●

Fast setup of test and measurement configurations

●

Replace complex wirings by a single switch and control platform

●

Easy master/slave configuration

●

Optional installation of several remotely controlled satellite units (see p. 22)

●

Reliable measurements and reproducible tests

●

Automation for cost-efficient test sequences

●

Electromechanical relay modules up to 67 GHz

●

Solid-state relay modules with switching and settling times down to the µs

range

●

Backward compatible to all standard modules of the previous switch unit generation R&S OSP120/130/150

9Getting Started 1178.7117.02 ─ 03

Page 10

R&S®OSP

Backward compatibility details

●

The new switch units R&S OSP220/230/320 are mechanically and electrically fully compatible with all legacy standard hardware modules and

new modules, described in the User Manual

●

The new firmware is also compatible with all these modules

However, the following limitations in compatibility apply:

●

In a master-slave setup, you cannot mix legacy switch units with new

switch units. Differences in communication prevent a combination of the

two generations: The legacy switch units were interconnected by a

CAN-bus system, while the new switch units are interconnected via

Ethernet (LAN).

●

Consequently, also the commands for configuring a master-slave setup

of new switch units differ from the commands for the legacy units.

Key Features

●

The new firmware addresses the modules by their connectors M01 to

M16 in a switch unit.

– In setting commands, the firmware alternatively accepts addressing

the modules by A11 A12 or A13, according to the 3 module connector buses in a legacy switch unit.

– In query commands, the firmware per default returns module num-

bers in Mxx format. However, you can use the command

CONFigure:COMPatible[:MODE] to let the firmware return module numbers in A1x format, according to the legacy syntax. Refer to

the User Manual for details on this command.

As the legacy units had 3 module connectors, only, numbers beyond

A11, A12 and A13 make no sense, although the new module (connector) numbers run up to M16.

The available switch modules are described in the User Manual.

For a detailed specification of the R&S OSP, refer to the data sheet, available for

download at www.rohde-schwarz.com/brochure-datasheet/osp.

Note that switch units are no measurement instruments. They support efficient working with test and measurement setups, but switch units never display any measurement results or power levels.

10Getting Started 1178.7117.02 ─ 03

Page 11

R&S®OSP

Documentation Overview

Tutorials

3 Documentation Overview

This section provides an overview of the R&S OSP user documentation. Unless

specified otherwise, you find the documents on the R&S OSP product page at:

www.rohde-schwarz.com/product/osp

3.1 Getting Started Manual

Introduces the R&S OSP and describes how to set up and start working with the

product. Includes, e.g., basic operations and safety instructions. A printed version

is delivered with the switch unit.

3.2 User Manual

Contains the description of all switch unit modes and functions. It also provides

an introduction to remote control, a complete description of the remote control

commands with programming examples, and information on maintenance, switch

unit interfaces and error messages. Includes the contents of the Getting Started

manual.

A separate R&S OSP-B200R/B200S2 Satellite System User Manual is also available for download at www.rohde-schwarz.com/manual/osp.

3.3 Tutorials

Tutorials offer guided examples and demonstrations on operating the R&S OSP.

They are provided on the product page of the internet.

11Getting Started 1178.7117.02 ─ 03

Page 12

R&S®OSP

Application Notes & Cards, White Papers, etc.

Documentation Overview

3.4 Service Manual

Describes handling failed modules, module replacement, troubleshooting and

special remote control commands for service purposes. The document also contains spare part lists and mechanical drawings. The service manual ("Classified

Service Document") is available for Rohde & Schwarz personnel, only.

3.5 Basic Safety Instructions

Contains safety instructions, operating conditions and further important information. The printed document is delivered with the switch unit.

3.6 Data Sheets and Brochures

The data sheet contains the technical specifications of the R&S OSP. It also lists

the firmware applications and their order numbers, and optional accessories.

The brochure provides an overview of the instrument and deals with the specific

characteristics. See www.rohde-schwarz.com/brochure-datasheet/osp

3.7 Release Notes, Open Source Acknowledgment

The release notes list new features, improvements and known issues of the current firmware version, and describe the firmware installation. The open-source

acknowledgment document (OSA) provides verbatim license texts of the used

open-source software. See www.rohde-schwarz.com/firmware/osp

3.8 Application Notes & Cards, White Papers, etc.

These documents deal with special applications or background information on

particular topics. See www.rohde-schwarz.com/application/osp

12Getting Started 1178.7117.02 ─ 03

Page 13

R&S®OSP

Unpacking and Checking the Switch Unit

Preparing for Use

4 Preparing for Use

This section describes the basic steps to be taken when setting up the R&S OSP

for the first time and putting it into operation.

4.1 Unpacking and Checking the Switch Unit........................................... 13

4.2 Accessory List........................................................................................14

4.3 Placing or Mounting the Instrument.....................................................15

4.4 Connecting AC Power........................................................................... 17

4.5 Switching the Instrument On and Off...................................................17

4.6 Checking the Installed Modules........................................................... 19

4.7 Configuring the Initial Instrument Settings......................................... 19

4.1 Unpacking and Checking the Switch Unit

Check the equipment for completeness using the delivery note and the accessory

lists for the various items. Check the equipment for any damage. If parts of the

equipment are missing or if there is damage, immediately contact the carrier who

delivered the equipment.

Packing material

Retain the original packing material. If the instrument needs to be transported or shipped later, you can use the material to protect the control elements and connectors.

13Getting Started 1178.7117.02 ─ 03

Page 14

R&S®OSP

Preparing for Use

Accessory List

Risk of damage during transportation and shipment

Insufficient protection against mechanical and electrostatic effects during

transportation and shipment can damage the instrument.

●

Always make sure that sufficient mechanical and electrostatic protection

is provided.

●

When shipping an instrument, we recommend using the original packaging. If you do not have the original packaging, use sufficient padding to

prevent the instrument from moving around inside the box. Pack the

instrument in antistatic wrap to protect it from electrostatic charging.

●

Secure the instrument to prevent any movement and other mechanical

effects during transportation.

4.2 Accessory List

The R&S OSP base unit comes with the following accessories:

●

Printed "Getting Started" manual, English (order no. 1178.7117.02)

●

Ethernet (LAN) cable, 2 m, RJ45 (1:1), category 6 (order no. 0041.9748.00)

●

Power supply cable, delivered country-specific to fit your local wall outlet format, see Table 4-1

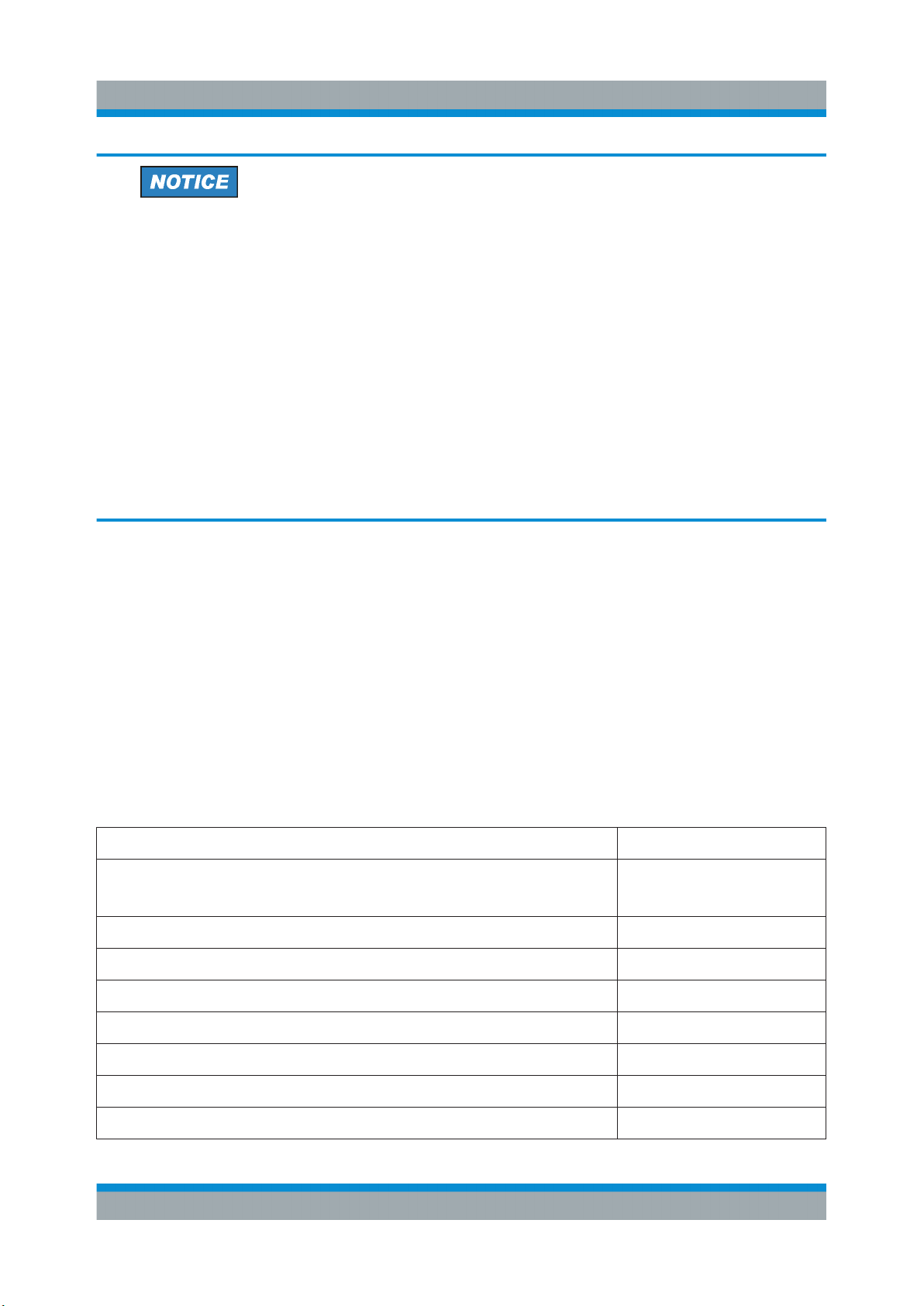

Table 4-1: Power cords

Power supply cables according to country-specific standards Order no.

European standard

Angular adapter for European standard

British standard 0006.7013.00

Swiss standard 0006.7020.00

US American standard 0006.7036.00

Australian standard 0006.7107.00

0025.2365.00

0086.4400.44

Chinese standard 0041.4752.00

Japanese standard 0041.6232.00

Brazilian standard 3587.8102.00

14Getting Started 1178.7117.02 ─ 03

Page 15

R&S®OSP

Placing or Mounting the Instrument

Preparing for Use

4.3 Placing or Mounting the Instrument

The R&S OSP is designed for use either on a bench top or in a standard 19"

rack.

Bench-top positioning

If the R&S OSP is operated on a bench top, the surface must be flat.

Risk of injury when stacking instruments

A stack of instruments can tilt over and cause injury if not stacked correctly.

Furthermore, the instruments at the bottom of the stack can be damaged

due to the load imposed by the instruments on top.

Observe the following instructions when stacking instruments:

●

Never stack more than three instruments. If you need to stack more

than three instruments, install them in a rack.

●

The overall load imposed on the lowest instrument must not exceed

500 N.

●

It is best if all instruments have the same dimensions (width and length).

If you need to stack smaller instruments on the top, the overall load

imposed on the lowest instrument must not exceed 250 N.

●

If the instruments have foldable feet, fold them in completely.

You can use the instrument in horizontal position, standing on its feet, or with the

support feet folded out from underneath.

15Getting Started 1178.7117.02 ─ 03

Page 16

R&S®OSP

Preparing for Use

Placing or Mounting the Instrument

Risk of injury if feet are folded out

The feet can fold in if they are not folded out completely or if the instrument

is shifted, which can cause damage or injury.

●

Fold the feet completely in or out to ensure stability of the instrument.

Never shift the instrument when the feet are folded out.

●

When the feet are folded out, do not work under the instrument or place

anything underneath.

●

The feet can break if they are overloaded. The overall load on the folded-out feet must not exceed 500 N.

F

max

Rack mounting

You can install the R&S OSP in a 19'' rack, using one of the following optional

rack adapter kits:

●

For 2 HU (R&S OSP220 and R&S OSP230), use R&S ZZA-211 (order no.

1096.3260.00)

●

For 3 HU (R&S OSP320), use R&S ZZA-311 (order no. 1096.3277.00)

The installation instructions for the adapter kit are included in its delivery.

The satellite unit R&S OSP-B200S2 is not designed for rack-mounting.

Risk of instrument damage due to insufficient airflow in a rack

If you mount several instruments in a rack, you need an efficient ventilation

concept to ensure that the instruments do not overheat. Insufficient airflow

for a longer period can disturb the operation and even cause damage.

16Getting Started 1178.7117.02 ─ 03

Page 17

R&S®OSP

Switching the Instrument On and Off

Preparing for Use

4.4 Connecting AC Power

The switch unit is equipped with an AC power supply connector and can be used

with different AC voltages. The R&S OSP adapts itself automatically to the voltage. Refer to the data sheet for the voltage and frequency requirements. The AC

power connector is on the rear panel of the instrument.

► Connect the R&S OSP to an AC power supply using the supplied power

cable.

As the instrument's assembly is in line with the specifications for safety class

EN61010, you must connect it only to an outlet that has a ground contact.

For replacing the fuses, refer to the maintenance chapter in the User Manual.

4.5 Switching the Instrument On and Off

Switching on

► Set the AC power switch on the rear panel to position "I".

The instrument is supplied with AC power. After booting, the instrument is

ready for operation. A green LED above the [Pwr] key on the front panel indicates the operating mode.

Switching off

1. If the LED above the [Pwr] key on the front panel emits green light, set the

R&S OSP to standby mode by pressing the [Pwr] key.

The LED changes from green to orange light, indicating sleep mode. The

switch unit is now unavailable via LAN, even if connected.

Otherwise, if the R&S OSP is already in standby mode, do not press the [Pwr]

key.

2. Set the AC power switch on the rear panel to position "O".

The R&S OSP changes into off mode.

17Getting Started 1178.7117.02 ─ 03

Page 18

R&S®OSP

Switching the Instrument On and Off

Display timeout

The OLED mini display of a switch unit R&S OSP220 or R&S OSP320

serves for showing you the network connection. It is switched off automatically, 30 minutes after specifying this LAN connection. Setting or changing

the LAN connection typically happens at power-up. Without a network connection, the OLED mini display is switched off 30 minutes after power-up.

This feature helps to prevent burn-in effects often seen in OLED displays.

When the switch unit is connected via a new network address, the mini display is switched on again for the next 30 minutes. (Your server can assign a

new network address, for example, when you change the switch unit's network settings from static IP to DHCP, as described in the User Manual.)

The RGB-LED touchscreen display in the R&S OSP230 and in the module R&S OSP-B300M needs no burn-in protection. Thus, it has no timeout.

Preparing for Use

Risk of losing settings

While the R&S OSP is in operating mode, if you switch it off using the rear

panel switch or by disconnecting the power cord, the instrument loses its

current settings. (Operating mode is indicated by a green LED above the

[Pwr] key.)

For example, if you have selected signal paths previously, you must select

and enable these paths again, when you restart the switch unit.

To avoid a loss of settings, press the [Pwr] key first to set the switch unit

into standby mode. Then shut it down properly by setting the rear AC power

switch to position "O".

●

If "Configuration" > "General" > "Switch-On Reset" is activated, the

R&S OSP resets all internal latching switches during the startup procedure.

●

If "Configuration" > "General" > "Switch-On Action" is set to "Switch

Path", the R&S OSP loads the previously set path while booting. The

switch unit then activates this path when the startup procedure is completed.

Configuring a master-slave setup of switch units is described in the User Manual.

18Getting Started 1178.7117.02 ─ 03

Page 19

R&S®OSP

Configuring the Initial Instrument Settings

Preparing for Use

4.6 Checking the Installed Modules

The instrument is typically equipped with one or more optional switch modules.

You can visually check whether the modules listed on your delivery note correspond with the installed modules. Each module's name is printed on its panel.

You can also view the installed modules in the "Module Operation" dialog (touchscreen display or "WebGUI", see Chapter 6.2, "User Interface

and Functional Elements", on page 31):

Figure 4-1: The module operation dialog, here with a master switch unit and 5 modules

The information in this dialog is updated during the booting process, when the

R&S OSP automatically detects the installed modules.

4.7 Configuring the Initial Instrument Settings

After startup, the switch unit is fully configured automatically, and ready for use.

However, you have many options to change the configuration, for example:

●

Edit the network settings

●

Define or modify a master-slave setup

●

Restore a previous setting

●

Define switching paths and output channels

These configuration settings and many more are described in the User Manual.

19Getting Started 1178.7117.02 ─ 03

Page 20

R&S®OSP

Instrument Tour

Front Panel View

5 Instrument Tour

5.1 Front Panel View

The following chapters describe the front panels of all models of the R&S OSP

switch unit family. For the functional elements, refer to Chapter 6.2.

5.1.1 Front Panel of the R&S OSP220........................................................... 20

5.1.2 Front Panel of the R&S OSP230........................................................... 21

5.1.3 Front Panel of the R&S OSP320........................................................... 21

5.1.4 Front Panel of the R&S OSP-B200S2 Satellite Unit.............................. 22

5.1.5 Touchscreen.......................................................................................... 23

5.1.1 Front Panel of the R&S OSP220

The front panel of the R&S OSP220 features 3 module slots, a monochrome nontouch mini display, a power switch and various connectors.

The R&S OSP220 occupies 2 height units (2HU) in a standard 19" rack. You can

insert 1-slot, 2-slot or 3-slot modules into the 3 front slots:

Figure 5-1: Front view of the R&S OSP220 (2HU)

FS01 = Front slot 01, here with a blind plate

FS02 = Front slot 02, here with a 1-slot switch module

FS03 = Front slot 03, here with a blind plate

F Int = Front interfaces and mini OLED display (128 x 64 pixels), see Figure 6-4

20Getting Started 1178.7117.02 ─ 03

Page 21

R&S®OSP

Instrument Tour

Front Panel View

5.1.2 Front Panel of the R&S OSP230

The front panel of the R&S OSP230 features 2 module slots, an integrated touchscreen display, a power switch and various connectors.

The R&S OSP230 occupies 2 height units (2HU) in a standard 19" rack. You can

insert two 1-slot modules or one 2-slot module into the 2 front slots:

Figure 5-2: Front view of the R&S OSP230 (2HU)

FS01 = Front slot 01, here with a blind plate

FS02 = Front slot 02, here with a 1-slot switch module

Disp. = Integrated touchscreen display

F Int = Front interfaces, see Figure 6-4

5.1.3 Front Panel of the R&S OSP320

The R&S OSP320 is higher than all other switch units from Rohde & Schwarz.

With its 3 height units (3HU), it enables a more dense fitting of 1-slot switch modules within the same instrument width. Hence, its front panel features 5 module

slots, along with a power switch, a mini display and various connectors.

2 of the 5 front slots (labeled FS04 and FS05 in Figure 5-3) can hold the factorymounted optional touchscreen display module R&S OSP-B300M:

21Getting Started 1178.7117.02 ─ 03

Page 22

R&S®OSP

Instrument Tour

Front Panel View

Figure 5-3: Front view of the R&S OSP320 (3HU)

FS01 = Front slot 01, here with a 1-slot switch module

FS02 = Front slot 02, here with a 1-slot switch module

FS03 = Front slot 03, here with a 1-slot switch module

FS04 + FS05 = Front slot 04 and 05, here with mounted touchscreen display module

F Int = Front interfaces and mini OLED display (128 x 64 pixels), see Figure 6-4

The dedicated touchscreen display module R&S OSP-B300M shown in Fig-

ure 5-3 is optional (see p. 23). It can only be factory-mounted in the

R&S OSP320 with 3 height units (3HU) in position FS04 + FS05.

You cannot insert any modules into the R&S OSP320 that are designed as 2-slot

or 3-slot modules for a switch unit with 2 height units (2HU, see above).

5.1.4 Front Panel of the R&S OSP-B200S2 Satellite Unit

For a comprehensive description of this unit, also refer to the R&S OSP-

B200R/B200S2 Satellite System User Manual, available for download at

www.rohde-schwarz.com/manual/osp.

The R&S OSP-B200S2 is a standalone device, only, not to be mounted into a 19"

rack. The front panel of satellite unit the features 2 module slots, into which you

can insert 1-slot or 2-slot modules:

22Getting Started 1178.7117.02 ─ 03

Page 23

R&S®OSP

Figure 5-4: Front view of the R&S OSP-B200S2 (2HU)

SlotA = Front slot A, here with a 1-slot switch module

SlotB = Front slot B, here with a 1-slot switch module

Instrument Tour

Front Panel View

This unit is designed to serve as a satellite with up to 2 switch modules, controlled

from a base switch unit with remote control module R&S OSP-B200R.

For example, you can use the satellite unit inside a shielded chamber for EMC

tests that do not tolerate electrical wiring. In this scenario, use the satellite with

local battery power supply, and control the switch modules fitted in the unit via a

fiber-optic link. See also Chapter 5.2.4.1, "Wired Link versus Fiber-Optic Link",

on page 28.

5.1.5 Touchscreen

Figure 5-5: Touchscreen display, here showing the Main menu

●

The R&S OSP230 is equipped with an integrated touchscreen display on the

front panel.

23Getting Started 1178.7117.02 ─ 03

Page 24

R&S®OSP

Instrument Tour

Front Panel View

●

The R&S OSP320 can be equipped with the touchscreen display module

R&S OSP-B300M.

Both the integrated display and the display module are based on a touch-sensitive RGB LCD with a resolution of 800 x 480 pixels.

The touchscreen display offers one out of several means of user interaction for

easily handling the switch unit. It shows the relay and switch-path settings, provides status information and allows configuring and controlling your measurement

tasks.

The touchscreen reacts in a defined way when you tap a particular

element on the screen with a finger or with a pointing device, for

example an external USB mouse. Any user interface element that

reacts to a click by a mouse pointer also reacts to a tap on the screen, and vice

versa. Using the touchscreen, you can perform all tasks by the tap of your finger.

For the remainder of this manual, all interactions are described for a "click" action.

These descriptions also mean the equivalent "tap" action using the touchscreen.

On-screen keyboard

The on-screen keyboard is an additional means of direct interaction with the

switch unit R&S OSP230 or R&S OSP320, the latter if equipped with touchscreen

module R&S OSP-B300M.

Figure 5-6: Different versions of the on-screen keyboard

Left = Numbers and characters allowed

Center = Decimal numbers, only

Right = Hexadecimal numbers

The touchscreen automatically opens an on-screen keyboard, if your current

action requires entering numbers or characters. The cancel button or the OK button closes the on-screen keyboard.

Instead of using the on-screen keyboard, you can enter data with a connected

external keyboard (Figure 6-1) or via the user interface in a browser (Figure 6-2).

24Getting Started 1178.7117.02 ─ 03

Page 25

R&S®OSP

Instrument Tour

Rear Panel View

5.2 Rear Panel View

The following chapters describe the rear panels of all models of the R&S OSP

switch unit family. For the functional elements, refer to Chapter 6.2.

5.2.1 Rear Panel of the R&S OSP220............................................................25

5.2.2 Rear Panel of the R&S OSP230............................................................25

5.2.3 Rear Panel of the R&S OSP320............................................................26

5.2.4 Rear Panel of the R&S OSP-B200S2 Satellite Unit...............................27

5.2.4.1 Wired Link versus Fiber-Optic Link........................................................28

5.2.1 Rear Panel of the R&S OSP220

The rear panel of the R&S OSP220 features 3 module slots, an on/off switch,

fuses, power supply connector, LAN and USB connectors and a micro SD card

slot. You can insert 1-slot, 2-slot or 3-slot modules into the 3 rear slots:

Figure 5-7: Rear view of the R&S OSP220 (2HU)

R Int = Rear interfaces, see Figure 6-4

RS01 = Rear slot 01, here with a blind plate

RS02 = Rear slot 02, here with a blind plate

RS03 = Rear slot 03, here with a blind plate

5.2.2 Rear Panel of the R&S OSP230

The rear panel of the R&S OSP230 features 3 module slots, an on/off switch,

fuses, power supply connector, LAN and USB connectors and a micro SD card

slot. You can insert 1-slot, 2-slot or 3-slot modules into the 3 rear slots:

25Getting Started 1178.7117.02 ─ 03

Page 26

R&S®OSP

Figure 5-8: Rear view of the R&S OSP230 (2HU)

R Int = Rear interfaces, see Figure 6-4

RS01 = Rear slot 01, here with a 1-slot switch module

RS02 = Rear slot 02, here with a 1-slot switch module

RS03 = Rear slot 03, here with a 1-slot switch module

5.2.3 Rear Panel of the R&S OSP320

Instrument Tour

Rear Panel View

The rear panel of the R&S OSP320 features 5 module slots, an on/off switch,

fuses, power supply connector, LAN and USB connectors and a micro SD card

slot:

Figure 5-9: Rear view of the R&S OSP320 (3HU)

R Int = Rear interfaces, see Figure 6-4, with an additional D-Sub 9 trigger connector

RS01 = Rear slot 01, here with a 1-slot switch module

RS02 = Rear slot 02, here with a 1-slot switch module

RS03 = Rear slot 03, here with a 1-slot switch module

RS04 = Rear slot 04, here with a 1-slot switch module

RS05 = Rear slot 05, here with a 1-slot switch module

You cannot insert any modules into the R&S OSP320 that are designed as 2-slot

or 3-slot modules for a switch unit with 2 height units (2HU, see above).

26Getting Started 1178.7117.02 ─ 03

Page 27

R&S®OSP

Instrument Tour

Rear Panel View

The D-Sub 9 trigger connector (next to the label "R Int" in Figure 5-9) is only

available in the rear interface panel of the R&S OSP320, not in any other

switch unit. However, triggering is not yet supported by the firmware. The

hardware trigger feature will be added as option R&S OSP-K100 in the

future.

5.2.4 Rear Panel of the R&S OSP-B200S2 Satellite Unit

For a comprehensive description of this unit, also refer to the R&S OSP-

B200R/B200S2 Satellite System User Manual, available for download at

www.rohde-schwarz.com/manual/osp.

The rear panel of the R&S OSP-B200S2 features various connectors and LEDs.

You cannot insert any modules into the rear panel of the R&S OSP-B200S2.

Figure 5-10: Rear view of the R&S OSP-B200S2 (2HU)

1 = DC power supply connector

2 = Fiber-optic link (FOL) connector for optical remote control

3 = Wired link connector for electrical remote control

4 = Status LEDs for indicating [Power] and [Overheat]

5 = Status LED for indicating [Link / Busy]

27Getting Started 1178.7117.02 ─ 03

Page 28

R&S®OSP

5.2.4.1 Wired Link versus Fiber-Optic Link

The link connectors (labeled (2) and (3) in Figure 5-10) allow choosing either an

electrical or an optical control connection.

●

Wired link

For remote operation of the satellite unit R&S OSP-B200S2 across distances

up to 10 m, use the D-Sub cable R&S OSP-Z200x.

Connect this cable exclusively to the remote control interface module

R&S OSP-B200R in your base switch unit. Connecting it to any other device

or module can harm your equipment.

The wired link cable supplies power from the base switch unit to the satellite.

●

Fiber-optic link

For remote operation of the satellite unit R&S OSP-B200S2 across larger distances up to 20 m, or inside a shielded room, use the fiber-optic cable

R&S OSP-Z201x or R&S OSP-Z202x.

As the fiber-optic link cable does not supply power to the satellite unit, you

must also use the 28 V DC power supply R&S OSP-B200P.

Instrument Tour

Rear Panel View

28Getting Started 1178.7117.02 ─ 03

Page 29

R&S®OSP

Manual and Remote Modes of Operation

Trying Out the Switch Unit

6 Trying Out the Switch Unit

This chapter introduces the most important basic operations and settings of the

R&S OSP step by step. For a complete overview, see the User Manual (p. 11).

Prerequisite: the instrument is set up, connected to mains power supply and started up, as described in Chapter 4 on page 13. The next sections describe:

● Manual and Remote Modes of Operation....................................................... 29

● User Interface and Functional Elements......................................................... 31

● Main Action Buttons........................................................................................ 34

● Elements of the Status Line............................................................................ 34

● Manual Module Operation...............................................................................35

6.1 Manual and Remote Modes of Operation

You can operate the switch unit by any of the following modes:

● Direct Manual Operation................................................................................. 29

● Manual Remote Operation.............................................................................. 30

● Remote Operation by SCPI Commands......................................................... 30

6.1.1 Direct Manual Operation

If you use an R&S OSP230 or an R&S OSP320 with display module R&S OSPB300M, you can control your switch unit by the user interface on the integrated

touchscreen display.

Alternatively, with any of the R&S OSP models, you can control your switch unit

via an external mouse and keyboard, connected to the USB interfaces (see (4) in

Figure 6-4). Optionally (especially without integrated touchscreen), you can con-

nect an external monitor to the switch unit's HDMI interface (see (5)).

Figure 6-1: Operation by integrated touchscreen (1) or by external USB / HDMI devices (2)

29Getting Started 1178.7117.02 ─ 03

Page 30

R&S®OSP

Trying Out the Switch Unit

Manual and Remote Modes of Operation

For connecting external devices, see Figure 6-4.

6.1.2 Manual Remote Operation

You can control one or more switch units by working with the user interface in a

web browser ("Web GUI") on a remote computer that is connected via LAN.

Figure 6-2: Manual remote operation via "WebGUI" and LAN

RJ45 = Ethernet (LAN) connector on the rear panel of each switch unit

Refer to the User Manual for more information, also regarding the combination of

several switch units in a master-slave setup.

Note that the legacy software R&S OSP Panel is not compatible with the

switch units R&S OSP220, R&S OSP230 and R&S OSP320.

6.1.3 Remote Operation by SCPI Commands

You can control the R&S OSP by SCPI commands sent from a remote computer

that is connected via LAN. Refer to the User Manual.

Figure 6-3: Remote operation by SCPI commands

RJ45 = Ethernet (LAN) connector on the rear panel of each switch unit

Far left = Two switch units integrated in a test system like R&S CEMS

30Getting Started 1178.7117.02 ─ 03

Page 31

R&S®OSP

Trying Out the Switch Unit

User Interface and Functional Elements

To do so, you have two options:

●

For SCPI command communication, use a terminal program like R&S Forum

or similar programming interface (for example with R&S VISA driver). Remote

operation and RC commands are described in the User Manual.

●

Let a test system software like R&S EMC32 or R&S ELEKTRA send the

required commands. Refer to www.rohde-schwarz.com/product/emc32 and

www.rohde-schwarz.com/product/elektra.

6.2 User Interface and Functional Elements

The switch units R&S OSP220 and

The switch unit R&S OSP230 and the display

module R&S OSP-B300M have a touch-

screen display.

Its functions are described in the User Manual.

R&S OSP320 have a micro display.

Use it to find the IP address in the first

2 lines and the subnet mask in the last

2 lines.

You cannot operate the switch units R&S OSP220 ‒ and the R&S OSP320 without display module R&S OSP-B300M ‒ by their micro displays. To operate these

switch units without the graphical user interface of a built-in full touchscreen display, use one of the following alternatives:

●

As on the right-hand side in Figure 6-1, connect an external monitor to the

HDMI connector on the unit's front panel (labeled (5) in Figure 6-4). Also connect a mouse and keyboard to the USB connectors, labeled (4).

●

Use the switch unit as a slave device in a master-slave setup, as described in

the User Manual.

●

Connect the switch unit to a local area network (LAN) by the RJ45 connector

on the unit's rear panel. The connector is labeled (1) in Figure 6-4. Read the

unit's IP address from the micro display and proceed as described in Chap-

ter 6.1.2, "Manual Remote Operation", on page 30, or Chapter 6.1.3, "Remote

Operation by SCPI Commands", on page 30.

31Getting Started 1178.7117.02 ─ 03

Page 32

R&S®OSP

Trying Out the Switch Unit

User Interface and Functional Elements

Figure 6-4: Connectors and functional elements on the switch unit's rear and front panel

R = Rear interfaces (where the R&S OSP320 has an additional trigger port, see Figure 5-9)

F = Front interfaces (where the R&S OSP220 has no OLED micro display)

I/0 = Main power switch with fuse holder and power connector

1 = LAN connector (RJ45)

2 = Slot for the micro SD card that holds the switch unit's operating system

3 = USB 3.1 connector

4 = Two USB 2.0 connectors (for external mouse and keyboard)

5 = HDMI connector (for an external monitor)

6 = Two BNC trigger input connectors (A and B) with two trigger status LEDs

7 = Front power switch with [Pwr] and LAN status LEDs

If you connect an external monitor to the HDMI connector (5), use a monitor

that is compatible with this port’s DVI signal, which has the touchscreen's

resolution of 800 x 480 pixels. Incompatible monitors cannot display the

graphical user interface.

The trigger connectors (6) are not yet supported by the firmware. The hardware trigger feature will be added as option R&S OSP-K100 in the future.

Note that the rear interface panel of the R&S OSP320 has an additional DSub 9 trigger connector, shown in Rear view of the R&S OSP320 (3HU) on

page 26.

In any of these configurations, you can operate a switch unit by its user interface:

either in a browser window or on an external monitor. The same holds true for the

R&S OSP230 and R&S OSP320 with integrated display module R&S OSPB300M, which provide touchscreen operation.

Using any of these options, you get access to the graphical user interface (GUI):

32Getting Started 1178.7117.02 ─ 03

Page 33

R&S®OSP

User Interface and Functional Elements

Figure 6-5: Main menu of the graphical user interface

In the "Main" menu of the user interface, clicking the "Help" icon in the

top right area opens an overview of the available functions:

Trying Out the Switch Unit

Figure 6-6: Main elements of the graphical user interface (GUI)

1 = Main menu

2 = Module operation

3 = Path switching

4 = Device configuration

5 = Context menu, always used together with one of the menu buttons above

6 = Status line with varying elements, see Chapter 6.4

The main GUI elements listed above are briefly described in Chapter 6.3, "Main

Action Buttons", on page 34, and Chapter 6.4, "Elements of the Status Line",

on page 34. For more information, refer to the User Manual.

33Getting Started 1178.7117.02 ─ 03

Page 34

R&S®OSP

Trying Out the Switch Unit

Elements of the Status Line

6.3 Main Action Buttons

The user interface includes the following main action buttons:

The "Main" menu provides status and network information. Its context

menu (1)+(5) gives additional device info and messages.

The "Module Operation" dialog allows immediate interaction with the

relays. For a brief overview, see Chapter 6.5.

The "Path Switching" dialog allows defining, editing and activating

paths. You can also export and import paths.

The "Configuration" dialog provides general settings, settings for network connectivity and for master/slave operation.

Context Menu

The "Context Menu" button calls specific functionality for any of the

menu items shown above and listed as (1) to (4) in Figure 6-6. Hence,

this button is always used together with one of the other buttons.

For more information, refer to the User Manual.

6.4 Elements of the Status Line

The status line is shown on top in Figure 6-5 and Figure 6-6. The various indicator icons have the following meanings:

Left: the R&S OSP is controlled by its graphical user interface

(locally or via LAN). Right: the R&S OSP is controlled

remotely by SCPI commands or a master. See Chapter 6.1,

"Manual and Remote Modes of Operation", on page 29.

If this label is displayed in the status line, the R&S OSP is in virtual

mode (see User Manual).

If the lock icon is highlighted (right), it indicates the locked mode (see

User Manual).

If the selection indicator icon is highlighted (right), at least one

relay or output channel is selected (see Chapter 6.5.2).

34Getting Started 1178.7117.02 ─ 03

Page 35

R&S®OSP

Trying Out the Switch Unit

Manual Module Operation

6.5 Manual Module Operation

This chapter outlines only the most basic features of the dialogs for manual "Module Operation" that allow immediate interaction with the relays.

Click to either see a list of all installed switch modules or to see the

interaction dialog of one switch module:

Table 6-1: List of installed modules (left), interaction dialog of one switch module (right)

If you see the interaction dialog of one switch module, click to see the list of

installed modules. Then click the name of any module to see its interaction dialog.

6.5.1 Switching Mode

As long as the selection mode (see Chapter 6.5.2) is deactivated, click the icon of

a relay or channel to change its state:

Figure 6-7: Various relay types and the effect of clicking them

●

(A) SPDT relays, and (B) DPDT relays: Clicking toggles the state

●

(C) SP6T relays, and (D) SP8T relays:

Clicking a terminal port selects it to be connected to the common port

●

(E) Output channels: Clicking toggles the state

35Getting Started 1178.7117.02 ─ 03

Page 36

R&S®OSP

Trying Out the Switch Unit

Manual Module Operation

For switching relays and output channels, the "Toggle select mode" button

(orange, described below) must not be active.

6.5.2 Selection Mode

The "Toggle select mode" button switches the "Selection Mode" on or off. This

button (marked by a red circle in Figure 6-8) is only available in a view that shows

at least one module and its details.

Figure 6-8: Relay or channel selection dialog

Red circle = "Toggle select mode" button. If the button is orange, the "Selection Mode" is

activated.

Green circle = "Items selected" indicator. The icon is highlighted, if at least one relay or output

channel in any module is selected.

Orange frames = Selected relays and output channels are highlighted in the module's interaction

dialog

While the "Selection Mode" is active, tapping or clicking the icon of a relay or output channel does not change its state, but only selects or deselects the relay

or channel. This selection is indicated by the color of the icon's frame changing

from gray to orange.

Use the selection mode for defining paths and output patterns.

To select or deselect all relays and output channels, go to "Module Operation" (or "Path Switching") > "Context Menu" > "Path Selection" > "Select

All" or "Deselect All".

36Getting Started 1178.7117.02 ─ 03

Page 37

R&S®OSP

Trying Out the Switch Unit

Manual Module Operation

In a full-screen window of your web browser, the module interaction dialog

can display several modules at the same time:

Figure 6-9: Full-screen representation of several modules in a browser window

On the contrary, to reproduce the original size of the touchscreen display,

set your browser window to 800 × 480 pixels. Optionally, hit [F12] to enter

this setting.

For a comprehensive description of module operation and all other functions,

including the definition and switching of paths, refer to the User Manual.

37Getting Started 1178.7117.02 ─ 03

Loading...

Loading...