Page 1

R&S®FPC

Spectrum Analyzer

User Manual

(;ÜYN2)

1178413002

User Manual

Version 07

Page 2

This document describes the following R&S®FPC models and options:

●

R&S®FPC1000 (1328.6660.02)

●

R&S®FPC1500 (1328.6660.03)

●

R&S®FPC-B22 Preamplifier (1328.6690.02)

●

R&S®FPC-B200 Wi-Fi Support (1328.6990.02)

●

R&S®FPC-K7 AM, FM, ASK, FSK demodulation (1328.6748.02)

●

R&S®FPC-K42 Vector Network Analysis (1328.7396.02)

●

R&S®FPC-K43 Receiver (1328.6754.02)

●

R&S®FPC-K55 Advanced Measurements (1328.6760.02)

The contents of this manual correspond to firmware version 1.40 and later.

Page 3

1

Risk of injury and instrument damage

The instrument must be used in an appropriate manner to prevent

personal injury or instrument damage.

● Do not open the instrument casing.

● Read and observe the "Basic Safety Instructions" delivered as

printed brochure with the instrument.

● Read and observe the safety instructions in the following sections.

Note that the data sheet may specify additional operating conditions.

● Keep the "Basic Safety Instructions" and the product documentation

in a safe place and pass them on to the subsequent users.

Riesgo de lesiones y daños en el instrumento

El instrumento se debe usar de manera adecuada para prevenir

descargas eléctricas, incendios, lesiones o daños materiales.

● No abrir la carcasa del instrumento.

● Lea y cumpla las "Instrucciones de seguridad elementales"

suministradas con el instrumento como folleto impreso.

● Lea y cumpla las instrucciones de seguridad incluidas en las

siguientes secciones. Se debe tener en cuenta que las

especificaciones técnicas pueden contener condiciones adicionales

para su uso.

● Guarde bien las instrucciones de seguridad elementales, así como

la documentación del producto, y entréguelas a usuarios

posteriores.

Safety Instructions

Instrucciones de seguridad

Sicherheitshinweise

Consignes de sécurité

1171.1307.42 - 05

Page 4

2

Gefahr von Verletzungen und Schäden am Gerät

Betreiben Sie das Gerät immer ordnungsgemäß, um elektrischen

Schlag, Brand, Verletzungen von Personen oder Geräteschäden zu

verhindern.

● Öffnen Sie das Gerätegehäuse nicht.

● Lesen und beachten Sie die "Grundlegenden Sicherheitshinweise",

die als gedruckte Broschüre dem Gerät beiliegen.

● Lesen und beachten Sie die Sicherheitshinweise in den folgenden

Abschnitten; möglicherweise enthält das Datenblatt weitere

Hinweise zu speziellen Betriebsbedingungen.

● Bewahren Sie die "Grundlegenden Sicherheitshinweise" und die

Produktdokumentation gut auf und geben Sie diese an weitere

Benutzer des Produkts weiter.

Risque de blessures et d'endommagement de l'appareil

L'appareil doit être utilisé conformément aux prescriptions afin d'éviter

les électrocutions, incendies, dommages corporels et matériels.

● N'ouvrez pas le boîtier de l'appareil.

● Lisez et respectez les "consignes de sécurité fondamentales"

fournies avec l’appareil sous forme de brochure imprimée.

● Lisez et respectez les instructions de sécurité dans les sections

suivantes. Il ne faut pas oublier que la fiche technique peut indiquer

des conditions d’exploitation supplémentaires.

● Gardez les consignes de sécurité fondamentales et la

documentation produit dans un lieu sûr et transmettez ces

documents aux autres utilisateurs.

1171.1307.42 - 05

Page 5

Customer Support

Technical support – where and when you need it

For quick, expert help with any Rohde & Schwarz equipment, contact one of our Customer Support

Centers. A team of highly qualified engineers provides telephone support and will work with you to find a

solution to your query on any aspect of the operation, programming or applications of Rohde & Schwarz

equipment.

Up-to-date information and upgrades

To keep your instrument up-to-date and to be informed about new application notes related to your

instrument, please send an e-mail to the Customer Support Center stating your instrument and your wish.

We will take care that you will get the right information.

1171.0200.22-06.00

Page 6

R&S®FPC

Contents

Contents

1 Documentation Overview......................................................................7

2 Regulatory Information..........................................................................9

3 Preparing for Use.................................................................................10

3.1 Unpacking and Checking the Instrument................................................................. 11

3.2 Placing or Mounting the Instrument..........................................................................12

3.3 Connecting AC Power................................................................................................ 13

3.4 Turning the R&S FPC on and off................................................................................13

4 Instrument Tour....................................................................................15

4.1 Front Panel.................................................................................................................. 15

4.2 Rear Panel....................................................................................................................17

5 Operation.............................................................................................. 19

5.1 Manual Operation........................................................................................................19

5.2 Screen Layout............................................................................................................. 22

5.3 Remote Operation....................................................................................................... 25

6 Firmware Update..................................................................................32

7 Firmware Options.................................................................................34

8 Preset.................................................................................................... 37

9 Instrument Setup..................................................................................39

9.1 BNC Connector Usage................................................................................................39

9.2 Network Configuration............................................................................................... 39

9.3 Date and Time..............................................................................................................41

9.4 Regional Settings........................................................................................................42

9.5 Display Settings.......................................................................................................... 43

9.6 Audio Settings.............................................................................................................43

9.7 Power Settings............................................................................................................ 44

10 Data Management................................................................................ 46

11 Signal Source Configuration...............................................................52

12 Calibration............................................................................................ 54

3User Manual 1178.4130.02 ─ 07

Page 7

R&S®FPC

Contents

13 Measurement Wizard........................................................................... 59

14 The Spectrum Application...................................................................66

14.1 Configuration Overview..............................................................................................66

14.2 Measurements and Result Displays..........................................................................68

14.3 Frequency Configuration........................................................................................... 93

14.4 Amplitude Configuration............................................................................................ 98

14.5 Bandwidth Configuration......................................................................................... 106

14.6 Sweep Configuration................................................................................................ 109

14.7 Trigger Configuration................................................................................................112

14.8 Trace Configuration.................................................................................................. 113

14.9 Marker Configuration................................................................................................ 119

14.10 Marker Functions...................................................................................................... 125

14.11 Display Lines.............................................................................................................129

14.12 Limit Lines................................................................................................................. 130

15 The Receiver Application.................................................................. 134

15.1 Measurements and Result Displays........................................................................134

15.2 Frequency Configuration......................................................................................... 138

15.3 Amplitude Configuration.......................................................................................... 142

15.4 Bandwidth Configuration......................................................................................... 143

15.5 Sweep Configuration................................................................................................ 144

15.6 Trace Configuration.................................................................................................. 144

15.7 Limit Lines................................................................................................................. 145

15.8 Marker Configuration................................................................................................145

16 Analog Demodulation........................................................................147

16.1 Measurements and Result Displays........................................................................147

16.2 Frequency Configuration......................................................................................... 150

16.3 Amplitude Configuration.......................................................................................... 150

16.4 Bandwidth Configuration......................................................................................... 151

16.5 Sweep Configuration................................................................................................ 155

16.6 Limits..........................................................................................................................156

17 Digital Demodulation......................................................................... 158

17.1 Measurements and Result Displays........................................................................158

4User Manual 1178.4130.02 ─ 07

Page 8

R&S®FPC

Contents

17.2 Measurement Configuration.................................................................................... 163

17.3 Frequency Configuration......................................................................................... 166

17.4 Amplitude Configuration.......................................................................................... 167

17.5 Sweep Configuration................................................................................................ 168

17.6 Trigger Configuration............................................................................................... 169

18 Vector Network Analyzer...................................................................170

18.1 Measurements and Result Displays........................................................................170

18.2 Frequency Configuration......................................................................................... 179

18.3 Amplitude Configuration.......................................................................................... 181

18.4 Bandwidth Configuration......................................................................................... 182

18.5 Sweep Configuration................................................................................................ 183

18.6 Trace Configuration.................................................................................................. 184

18.7 Marker Configuration................................................................................................184

18.8 Limit Line Configuration...........................................................................................186

19 Remote Control.................................................................................. 187

19.1 Remote Control Basics.............................................................................................187

19.2 Common Commands................................................................................................ 202

19.3 Preset......................................................................................................................... 206

19.4 Network Connection................................................................................................. 207

19.5 System Configuration...............................................................................................209

19.6 Display Settings........................................................................................................ 215

19.7 Audio Settings...........................................................................................................215

19.8 Data Management..................................................................................................... 216

19.9 Signal Source Configuartion....................................................................................226

19.10 Calibration................................................................................................................. 228

19.11 Applications...............................................................................................................231

19.12 Remote Commands of the Spectrum Application................................................. 232

19.13 Remote Commands of the Receiver Application................................................... 295

19.14 Remote Commands of the Analog Demodulation................................................. 303

19.15 Remote Commands of the Digital Demodulation...................................................313

19.16 Remote Commands of the VNA Application.......................................................... 323

19.17 Status Reporting System......................................................................................... 341

5User Manual 1178.4130.02 ─ 07

Page 9

R&S®FPC

Contents

20 Function Reference............................................................................355

20.1 Function Reference: Setup...................................................................................... 355

20.2 Function Reference: Data Management..................................................................358

20.3 Function Reference: Mode Selection...................................................................... 359

20.4 Function Reference: Spectrum Application........................................................... 360

20.5 Function Reference: Receiver Application.............................................................377

20.6 Function Reference: Analog Demodulation........................................................... 387

20.7 Function Reference: Digital Demodulation............................................................ 391

20.8 Function Reference: Vector Network Analyzer...................................................... 395

List of Commands..............................................................................406

Index....................................................................................................413

6User Manual 1178.4130.02 ─ 07

Page 10

R&S®FPC

Documentation Overview

1 Documentation Overview

This section provides an overview of the R&S FPC user documentation. You can find it

on the product page at:

www.rohde-schwarz.com/manual/fpc

Getting started manual

Introduces the R&S FPC and describes how to set up and start working with the product. A printed version is included in the delivery.

User manual

The user manual contains the description of all instrument modes and functions. It also

provides an introduction to remote control, a complete description of the remote control

commands with programming examples, and information on maintenance, instrument

interfaces and error messages.

In addition to the R&S FPC user manual, there is a separate user manual for the

R&S InstrumentView software package. This manual contains a description of all features of the R&S InstrumentView software package.

The online version (html format) of the user manual provides the complete contents for

immediate display on the internet.

The user manual is also integrated into the firmware (.chm format). You can export the

file to a memory stick ("Setup" > "User Preferences" > "Export Documentation". After

the export, you can connect the memory stick to a PC and read the .chm file.

Service manual

Describes the performance test for checking the rated specifications, module replacement and repair, firmware update, troubleshooting and fault elimination, and contains

mechanical drawings and spare part lists.

The service manual is available for registered users on the global Rohde & Schwarz

information system (GLORIS, https://gloris.rohde-schwarz.com).

Basic safety instructions

Contains safety instructions, operating conditions and further important information.

The printed document is included in the delivery.

Data sheet and brochure

The data sheet contains the technical specifications of the R&S FPC. It also lists the

options and their order numbers as well as optional accessories.

The brochure provides an overview of the R&S FPC and shows its specific characteristics.

7User Manual 1178.4130.02 ─ 07

Page 11

R&S®FPC

Documentation Overview

Release notes and open source acknowledgment

The release notes list new features, improvements and known issues of the current

firmware version, and describe the firmware installation.

The open source acknowledgment document provides verbatim license texts of the

used open source software.

www.rohde-schwarz.com/manual/fpc

The open source acknowledgement is also integrated into the firmware (.chm format).

You can export the file to a memory stick ("Setup" > "User Preferences" > "Export Documentation". After the export, you can connect the memory stick to a PC and read

the .chm file.

Application notes, application cards, white papers, etc.

These documents contain information about possible applications and background

information on various topics, see www.rohde-schwarz.com/appnotes.

Calibration certificates

The calibration certificates of your device are available online. Visit the R&S FPC product page and select the item to download the calibration certificate. You will be forwarded to a Gloris page.

https://gloris.rohde-schwarz.com/calcert

Enter the device ID of your R&S FPC and download the certificate. You can find the

device ID either in the "Setup" menu or on the label on the rear panel.

8User Manual 1178.4130.02 ─ 07

Page 12

R&S®FPC

Regulatory Information

2 Regulatory Information

You can access the regulatory information in the firmware of the R&S FPC.

1. Press the "Setup" key.

The R&S FPC opens the "Instrument Setup" menu.

2. Select the "Regulatory Information" menu item in the "WiFi" category with the

"Enter" key.

The R&S FPC shows the regulations it complies with.

9User Manual 1178.4130.02 ─ 07

Page 13

R&S®FPC

Preparing for Use

3 Preparing for Use

The R&S FPC is designated for use in industrial, administrative and laboratory environments. Use the R&S FPC only for its designated purpose. Observe the safety and

usage instructions documented in the operating manual, as well as the operating conditions and performance limits stated in the data sheet.

Make sure to consider the following information before using the R&S FPC for the first

time.

Risk of injury due to disregarding safety information

Observe the information on appropriate operating conditions provided in the data sheet

to prevent personal injury or damage to the instrument. Read and observe the basic

safety instructions provided with the instrument, in addition to the safety instructions in

the following sections. In particular:

●

Do not open the instrument casing.

Risk of instrument damage due to inappropriate operating conditions

Specific operating conditions are required to ensure accurate measurements and to

avoid damage to the instrument. Observe the information on appropriate operating

conditions provided in the basic safety instructions and the instrument's data sheet.

Instrument damage caused by electrostatic discharge

Electrostatic discharge (ESD) can damage the electronic components of the instrument

and the device under test (DUT). Electrostatic discharge is most likely to occur when

you connect or disconnect a DUT or test fixture to the instrument's test ports. To prevent electrostatic discharge, use a wrist strap and cord and connect yourself to the

ground, or use a conductive floor mat and heel strap combination.

10User Manual 1178.4130.02 ─ 07

Page 14

R&S®FPC

Preparing for Use

Unpacking and Checking the Instrument

Risk of instrument damage during operation

An unsuitable operating site or test setup can damage the instrument and connected

devices. Ensure the following operating conditions before you switch on the instrument:

●

The instrument is dry and shows no sign of condensation.

●

The instrument is positioned as described in the following sections.

●

The ambient temperature does not exceed the range specified in the data sheet.

●

Signal levels at the input connectors are all within the specified ranges.

●

Signal outputs are correctly connected and are not overloaded.

EMI impact on measurement results

Electromagnetic interference (EMI) may affect the measurement results.

To suppress generated electromagnetic interference (EMI):

●

Use suitable shielded cables of high quality. For example, use double-shielded RF

and LAN cables.

●

Always terminate open cable ends.

●

Note the EMC classification in the data sheet.

3.1 Unpacking and Checking the Instrument

Unpack the R&S FPC carefully and check the contents of the package.

●

Check if all items listed on the delivery note, including the getting started manual,

are included in the delivery.

●

Check the R&S FPC for any damage.

If the contents are damaged, immediately contact the carrier who delivered the

package.

●

Keep the box and packing material.

11User Manual 1178.4130.02 ─ 07

Page 15

R&S®FPC

Preparing for Use

Placing or Mounting the Instrument

Risk of instrument damage during transportation and shipment

Insufficient protection against mechanical and electrostatic effects during transportation

and shipment can damage the instrument.

●

Always make sure that sufficient mechanical and electrostatic protection is provided.

●

When shipping an instrument, use the original packaging. If it is not available, allow

for sufficient padding to prevent the instrument from moving around inside the box.

Pack the instrument in antistatic wrap to protect it from electrostatic charging.

●

Secure the instrument to prevent any movement and other mechanical effects during transportation.

Packing material

Retain the original packing material. If the instrument needs to be transported or shipped later, you can use the material to protect the control elements and connectors.

3.2 Placing or Mounting the Instrument

The R&S FPC is designed for use under laboratory conditions, either on a bench top or

in a rack.

Benchtop operation

If the R&S FPC is operated on a bench top, the surface should be flat. The instrument

can be used in horizontal position, standing on its feet, or with the support feet on the

bottom extended.

Mounting the R&S FPC in a rack

The R&S FPC can be installed in the 19" rack mount kit R&S ZZA-FPC1 (order no.

1328.7080.02). The installation instructions are part of the adapter kit.

12User Manual 1178.4130.02 ─ 07

Page 16

R&S®FPC

Preparing for Use

Turning the R&S

Risk of injury if feet are folded out

The feet can fold in if they are not folded out completely or if the instrument is shifted.

This can cause damage or injury.

●

Fold the feet completely in or out to ensure stability of the instrument. Never shift

the instrument when the feet are folded out.

●

When the feet are folded out, do not work under the instrument or place anything

underneath.

●

The feet can break if they are overloaded. The overall load on the folded-out feet

must not exceed 200 N.

F

max

FPC on and off

3.3 Connecting AC Power

The AC power connector on the rear panel of the R&S FPC allows you to connect it to

the primary power supply.

Included in the delivery of the R&S FPC are several common power plug types.

1. Select the cable with the plug type you need and firmly connect it to the R&S FPC.

2. Connect the AC plug to the power outlet to supply the R&S FPC with power.

The R&S FPC is assembled in line with the specifications for safety class

EN61010. Therefore, it may only be connected to an outlet that has a ground contact.

The AC power supply has the following characteristics.

● Line voltage: 100 V AC to 240 V AC

● Line frequency: 50 Hz to 60 Hz; 400 Hz

● Current: 0.6 A to 0.4 A

3.4 Turning the R&S FPC on and off

After you have established a connection to the power supply, you can turn on the

R&S FPC.

13User Manual 1178.4130.02 ─ 07

Page 17

R&S®FPC

Preparing for Use

Turning the R&S FPC on and off

Turning on the R&S FPC

► Turn on the main AC power switch on the rear panel of the R&S FPC (position "I").

The instrument is now supplied with AC power.

● "Power" key is highlighted orange: R&S FPC is in standby mode (main AC

power switch is in position "I").

● "Power" key is highlighted green: R&S FPC is running and ready for operation.

Turning off the R&S FPC

► Turn off the main AC power switch on the rear panel of the R&S FPC (position

"O").

The instrument is no longer supplied with AC power.

Changing the AC supply fuse

Only fuses of the type 2A T IEC60127-2/V should be used.

1. Disconnect the power cable.

2. Open the flap covering the voltage selector using a small screwdriver (or similar).

3. Remove the cylinder labeled with the nominal voltages. Remove the fuse and

install the new one. Reinsert the cylinder so that the value visible through the hole

in the cover flap is the same nominal voltage as before.

4. Close the flap.

14User Manual 1178.4130.02 ─ 07

Page 18

R&S®FPC

Instrument Tour

Front Panel

4 Instrument Tour

The R&S FPC has various connectors on the front and rear panel.

4.1 Front Panel

1 632 5 74

Figure 4-1: Front panel of the R&S FPC

1 = USB ports (type A)

2 = Headphone jack

3 = Softkeys

4 = Signal source output

5 = Function keys and alphanumeric keypad

6 = RF input

7 = Power switch

Instrument damage caused by cleaning agents

Cleaning agents contain substances such as solvents (thinners, acetone, etc.), acids,

bases, or other substances. Solvents can damage the front panel labeling, plastic

parts, or screens, for example.

Never use cleaning agents to clean the outside of the instrument. Use a soft, dry, lintfree dust cloth instead.

Power switch

The power switch turns the R&S FPC on and off when it is supplied with power.

For more information, see Chapter 3.4, "Turning the R&S FPC on and off", on page 13.

15User Manual 1178.4130.02 ─ 07

Page 19

R&S®FPC

Instrument Tour

Front Panel

RF input

The RF input with an impedance of 50 Ω allows you to connect a DUT to the

R&S FPC. Typically, you connect the DUT with a cable and an appropriate connector

(for example a male N connector).

The frequency range of the RF input is specified in the datasheet.

The attenuation range is between 0 dB and 40 dB.

Risk of instrument damage

Make sure not to overload the RF input and keep within the maximum allowed signal

levels. Refer to the datasheet for the maximum allowed signal levels.

A DC input voltage of 50 V must never be exceeded.

Signal source output

Available on the R&S FPC1500.

The "Signal Source" output allows you to generate a signal that can be fed into the

DUT or other external accessories like frequency dividers or amplifiers. You can connect the DUT or accessories with a cable that has a male N connector.

Risk of instrument damage

The maximum supported reverse power is 23 dBm. Make sure that this value is not

exceeded to avoid damage to the R&S FPC.

Headphone jack

The female headphone jack allows you to connect headphones (or external speakers)

with a miniature jack plug.

You can control the output voltage with the volume control integrated into the firmware.

Refer to the user manual for details.

If you connect headphones or external speakers, the R&S FPC automatically turns off

the internal speaker.

Risk of hearing damage

Before putting on the headphones, make sure that the volume setting is not too high to

protect your hearing.

16User Manual 1178.4130.02 ─ 07

Page 20

R&S®FPC

Instrument Tour

Rear Panel

USB ports (type A)

The two USB 2.0 ports on the front panel (type A) allow you to connect devices like

memory sticks.

Function keys and alphanumeric keypad

The function keys provide access to the measurement settings and functions. The

alphanumeric keypad allows you to enter alphanumeric data if necessary.

Refer to the user manual for a comprehensive description of the function keys.

Softkeys

The softkeys allow you to access measurement settings and functions.

Softkeys are dynamic. A different list of softkeys is displayed depending on the

selected function key. A list of softkeys for a certain function key is also called a menu.

Softkeys can either perform a specific function or open a dialog box.

Refer to the user manual for a comprehensive description of the function keys.

4.2 Rear Panel

Figure 4-2: Rear panel of the R&S

1 = Trigger input / external reference

2 = LAN

3 = USB port (type B)

4 = Power supply

FPC

1 432

17User Manual 1178.4130.02 ─ 07

Page 21

R&S®FPC

Instrument Tour

Rear Panel

Power supply

The AC power supply and main power switch are located in a unit on the rear panel of

the instrument.

The main power switch has the following states.

●

Position "1": The instrument is supplied with power.

●

Position "0": The instrument is disconnected from the power supply.

Trigger input / external reference

This female BNC connector allows you to connect an external trigger signal or an

external reference signal.

When you are using the connector as a trigger input, you can trigger measurements

with an external trigger. For more information about triggered measurements, refer to

the user manual.

Alternatively, you can use the connector to connect a 10 MHz reference signal to synchronize the frequency with the external reference. Note that the reference signal must

be stronger than 0 dBm.

LAN

The LAN interface allows you to connect the R&S FPC to a local network for remote

control, printouts or data transfer. The assignment of the RJ-45 connector supports

twisted-pair category 5 UTP/STP cables in a star configuration (UTP stands for

unshielded twisted pair, and STP for shielded twisted pair).

USB port (type B)

The USB port (type B) allows you to connect the R&S FPC to a computer and establish

a remote control connection.

18User Manual 1178.4130.02 ─ 07

Page 22

R&S®FPC

Operation

Manual Operation

5 Operation

You can operate the R&S FPC manually with the keys available on its front panel, or

remotely from another computer.

● Manual Operation....................................................................................................19

● Screen Layout.........................................................................................................22

● Remote Operation...................................................................................................25

5.1 Manual Operation

The front panel of the R&S FPC provides various types of buttons (or keys) on its front

panel that allow you operate it manually.

Using function keys

Function keys are the group of keys with a light grey background.

Figure 5-1: Function keys

Pressing one of the function keys opens a list of parameters on the display that contains settings that thematically belong together. This list of parameters is also referred

to as a menu.

For example, pressing the "Freq" key opens the "Frequency" menu that contains

parameters to configure the frequency characteristics of the measurement.

The contents of the menu depend on the measurement application that you are using.

For example, the "Frequency" menu in the spectrum application looks different than the

"Frequency" menu of the analog demodulation application.

Exceptions are the "Preset" key and the camera key. These do not open a menu, but

initiate an action (performing a preset and taking a screenshot, respectively).

You can modify a specific parameter (menu item) with one of the softkeys.

Using softkeys

Softkeys are the group of keys to the right of the display.

Pressing one of the softkeys allows you to modify the properties of the parameter that

is displayed next to it. The parameter assigned to each softkey is variable and depends

on the function key that you pressed last.

For example, when you press the "Freq" function key in the spectrum application, the

first item in the menu is the "Center Frequency". When you press the softkey next to

19User Manual 1178.4130.02 ─ 07

Page 23

R&S®FPC

Operation

Manual Operation

that menu item, the R&S FPC opens an input field that allows you to change the center

frequency.

Depending on the parameter, pressing a softkey has one of the following effects.

●

It opens an input field that allows you to modify a parameter by entering a specific

value. When an input field is open, the corresponding menu item turns orange.

Example: Pressing the "Freq" key and selecting the "Center Frequency" menu item

opens an input field.

Figure 5-2: Softkey turns orange when an input field is open

Pressing the softkey again, closes the input field. If you have changed the value in

the input field, the new value is adopted.

Figure 5-3: Softkey turns grey when the input field is closed

●

It opens a submenu which contains another list of parameters that thematically

belong together.

A softkey that opens a submenu shows an arrow (">") in its label.

Example: Pressing the "Freq" key opens the "Frequency" menu. The second softkey in the list ("Center Freq Step Size") opens a submenu.

Figure 5-4: Softkey with an arrow opens a submenu

●

It initiates some kind of action.

Example: Pressing the "Span" key and selecting the "Full Span" menu item

restores the full frequency span.

●

It changes the state of something (like a toggle button).

The corresponding menu item turns light blue when its state is "on".

Example: Pressing the "BW" key and selecting the "RBW: Auto" menu item turns

automatic selection of the resolution bandwidth on and off.

Figure 5-5: Softkey in the "on" (left) and "off" (right) state

●

It opens a dialog box that contains additional settings.

Example: Pressing the "Setup" key and selecting the "Instrument Setup" menu item

opens a dialog box to configure general instrument properties like date and time.

Using input keys

Input keys are the group of keys with a dark grey background.

20User Manual 1178.4130.02 ─ 07

Page 24

R&S®FPC

Operation

Manual Operation

Figure 5-6: Input keys

The input keys only have an effect when any kind of input field is active on the display.

There are several types of input keys.

●

Alphanumeric keys

The alphanumeric keys allow you to enter numeric values or characters: the numbers from 0 to 9, the alphabet, a minus and plus sign and a dot. Pressing the number 0 repeatedly allows you to enter an empty space and an underscore.

Press the corresponding key to enter a numeric value. In case of numeric values,

each key covers just the number that is printed on it. You can enter negative values

with the minus sign key and enter values that contain decimal places with the dot

key.

Example: Press the "Freq" key and select the "Center Frequency" menu item.

Enter a number with the alphanumeric keys.

If you need to enter a character (for example for file names), the key assignment

changes. Each key covers one number and more than one character with the first

choice being a lower case character. If you need to enter a character, press the key

several times until the character you require is selected.

Example: Press the "Freq" key and select the "User Preference" menu item. In the

dialog box, select the "Site Name" menu item and enter some characters (for

"Home", for example, press 6x"4", 3x"6", 1x"6" and 2x"9").

An empty space or special characters like _ ! @ # $ % ^ & * = ? are available by

pressing the "0" key several times.

●

Unit keys

The unit keys confirm entries of values that have a unit. The units assigned to each

key are indicated on the key itself or next to the key.

Example: Press the "Freq" key and select the "Center Frequency" menu item. To

define a center frequency of 100 MHz, enter "100" and confirm with the [MHz] key.

●

Escape key

The "Esc" key cancels entries and closes the input field. The firmware does not

adopt the entry you have made.

●

Backspace key

The "Backspace" key ( ) moves the cursor one position backwards and deletes

the character / number that was in that place.

Tip: If an input field is visible, the backspace key toggles between the last two

entries. Using this feature, you can, for example, quickly toggle between two center

frequencies.

●

"Enter" key ("✓")

The "✓" key confirms an entry you have made.

21User Manual 1178.4130.02 ─ 07

Page 25

R&S®FPC

Operation

Screen Layout

If you confirm a value that has a unit with the "✓" key, the R&S FPC always uses

the highest possible unit (for example GHz or s).

In addition, the group of input keys also contains cursor keys and the rotary knob.

Using the cursor keys

The cursor keys do several things, depending on the situation when you use them.

●

The cursor keys navigate through dialog boxes.

●

The up and down keys increase or decrease any kind of numeric value if an input

field is active.

The cursor keys change numeric values with a fix step size.

●

The up and down keys move markers around.

The step size is fix.

●

The left and right keys move the cursor in an input field in the corresponding direction.

Using the rotary knob

The rotary knob does several things, depending on the situation when you use it.

●

The rotary knob works like a cursor key in dialog boxes. In that case, you can navigate to one of the items with the rotary knob. If the dialog box covers more than

one screen page, it also scrolls through the dialog box.

Turning it to the right corresponds to a downward movement. Moving it to the left to

an upward movement.

●

The rotary knob increases or decreases any kind of numeric value if an input field

is active.

Turning it to the right corresponds to an increase, turning it to the left to a decrease

of a numeric value.

The rotary knob changes numeric values with a fix step size.

●

The rotary knob moves markers around in the diagram area.

To do so, you have to select a marker first. The step size is fix.

●

Pressing the rotary knob has the same effect as pressing the "✓" key and confirms

an entry or selection.

5.2 Screen Layout

The following image shows the screen layout in the spectrum application. It shows all

elements that are the same in all applications of the R&S FPC. If an application or

measurement has a completely different layout or elements, the differences are noted

in the description of those.

22User Manual 1178.4130.02 ─ 07

Page 26

R&S®FPC

Operation

Screen Layout

1 2 3

4

5

6

7

8

9

10 11 12 13 14 10

Figure 5-7: Screen layout in the spectrum application

1 = Title bar

2 = Input field

3 = Softkeys

4 = Measurement settings

5 = Trace information

6 = Marker information

7 = Limit line information

8 = Diagram area

9 = X-axis information

10 = Sweep count

11 = Trace

12 = Delta marker

13 = Limit line

14 = Marker

15 = Star icon

Title bar

The title bar shows the application that you are currently using as well as the date and

time.

Input field

An input field opens when you select a feature that requires you to enter a value. The

header of the input field shows the name of the softkey menu you have currently

selected. If no input field is open, the R&S FPC just shows the name of the softkey

menu you have currently selected.

Softkey menu

Softkeys provide access to measurement settings and functions. They are dynamic: a

different list of softkeys is displayed depending on the selected function key. A list of

softkeys for a certain function key is also called a menu.

23User Manual 1178.4130.02 ─ 07

Page 27

R&S®FPC

Operation

Screen Layout

Softkeys can either perform a specific function or open an input field or dialog box.

Measurement settings bar

The measurement settings bar contains information about the current measurement

settings. A blue dot in front of a setting indicates that automatic selection for that setting has been turned off.

Trace information

The trace information indicates the current trace configuration for each active trace

(trace color, trace number, trace mode and detector).

Table 5-1: Overview of trace modes

Abbreviation Detector

Clrw Clear / write trace mode

Max Max hold trace mode

Min Min hold trace mode

Avg Average trace mode

View View trace mode

No label Blank trace mode (trace is off)

Table 5-2: Overview of detectors

Abbreviation Detector

AP Auto peak detector

Pk Max peak detector

Mi Min peak detector

Rm RMS detector

Sa Sample detector

QP Quasipeak detector (receiver only)

Marker information

The marker information indicates the position of each active marker. If a marker function is active, it also shows the result for that marker function.

Limit line information

The limit line information indicates the characteristics of any active limit line (type of

limit line, name of limit line etc.), including the result of a limit check (pass or fail).

Diagram area

The diagram area contains the graphical representation of the measurement results.

24User Manual 1178.4130.02 ─ 07

Page 28

R&S®FPC

Operation

Remote Operation

The diagram area can contain additional information.

●

The sweep count indicates the process of trace averaging. The first number is the

current measurement, the second number the total number of measurements included in the trace averaging.

●

The trace indicates the characteristics of the measured spectrum.

●

The position of markers or delta markers is indicated by a straight horizontal line

(markers) or a dotted line (delta markers). In addition, the marker position is also

indicated by an icon at the bottom of the diagram area.

●

The position and shape of a limit line is indicated by a red vertical line.

●

The star icon (

current measurement settings. The star will appear, for example, when you change

settings after a single measurement is done.

X-axis information

The x-axis information indicates the current scale and range of the x-axis.

) indicates that the displayed results no longer correspond to the

5.3 Remote Operation

There are various tools that allow you to operate the R&S FPC remotely from another

computer (for example PC or tablet).

To use the R&S FPC this way, you have to establish a connection between both devices via the LAN, Wi-Fi or USB interfaces of the R&S FPC.

Remote desktop (R&S InstrumentView)

R&S InstrumentView is a software that contains various useful tools, including a

remote desktop application. You can download the software, including a user manual,

from the Rohde & Schwarz website.

1. Install the software on a desktop PC or notebook.

2. Connect the R&S FPC to the computer with a LAN cable or a USB cable.

3. Start the software on the computer (use the desktop icon, or search for "InstrumentView" in the start menu).

4. Establish a connection to the R&S FPC in the "Connection Manager".

a) Select the "LAN" tab to configure the LAN properties.

b)

Select the pencil icon ( ).

c) Enter the IP address of the R&S FPC you want to connect to.

d) Confirm with the "Connect" button.

You can connect to as many instruments as you like (including other supported

instruments like R&S FSH or R&S FPH). To do so, simply "Add Another

Device" and define the network properties for them.

25User Manual 1178.4130.02 ─ 07

Page 29

R&S®FPC

Operation

Remote Operation

Alternatively, you can establish a connection via USB in the "USB" tab of the "Connection Manager".

5. Select "Instrument" > "Remote Display".

The software shows a live simulation of the R&S FPC, including all keys available

on the front panel.

Everything you do in the remote desktop application is also done on the connected

R&S FPC.

For a comprehensive description of the R&S InstrumentView software, refer to its

user manual.

Tip: Lab display. The lab display allows you to access several instruments at the

same time via the remote desktop. For more information, refer to the documentation of the R&S InstrumentView software.

Remote desktop (R&S MobileView)

R&S MobileView is an app that allows you to remote control the R&S FPC from a tablet or smartphone. It basically works like the remote desktop application built into the

R&S InstrumentView software.

You can download the app from the Google Play Store (Android based devices) or the

AppStore (iOS devices). A search for "Rohde Schwarz MobileView" should find the

app.

1. Start the R&S FPC.

2. Configure your tablet or phone as a hotspot for an ad-hoc connection (usually in

the phone settings).

3. Connect the R&S FPC to the mobile device.

a) Press the "Setup" key to open the instrument setup menu.

b) Select "WiFi": "On" to turn on the Wi-Fi functionality.

c) Select the "Connect" menu item to start a search for Wi-Fi networks in the

area.

The R&S FPC starts a search for all Wi-Fi networks it can find (mobile devices,

routers etc.).

d) Select the network you want to connect to.

e) Enter the password of the network with the alphanumeric keys. The network

password should be displayed in the hotspot settings of the mobile device.

The R&S FPC establishes the connection.

4. Start the R&S MobileView app on your mobile device.

The app shows a list of all R&S FPC devices that are connected to the hotspot.

5. Select the R&S FPC you want to connect to.

The app shows a live simulation of the R&S FPC, including all keys available on

the front panel.

Everything you do in the app is also done on the connected R&S FPC.

26User Manual 1178.4130.02 ─ 07

Page 30

R&S®FPC

Operation

Remote Operation

Note: If you have a device that does not support ad-hoc connections, you have to

connect both devices to an existing wireless infrastructure (for example through a

router). When you connect both the mobile device and the R&S FPC to the infrastructure, you can use the app just like with an ad-hoc connection.

Remote operation (SCPI commands)

Remote operation with SCPI commands is a method to automate measurements by

writing scripts or programs that contain all instructions required for the measurement.

When you start the program, the measurement is done automatically from start to finish. Manual configuration of a measurement with function keys, softkeys or apps is no

longer necessary.

Remote operation is thus a useful tool for measurements that you perform repeatedly

and for which you know the configuration and for which the configuration is always the

same. Testing devices during production is an example for such measurement tasks.

Each device needs to be tested under the same conditions.

You can operate an instrument remotely using SCPI commands (Standard Commands

for Programmable Instruments). Sending a SCPI command initiates one or more

actions on the instrument, for example change the state of a parameter or start a measurement. Usually, each parameter available in the firmware has a corresponding SCPI

command.

Example: The SCPI command to change the center frequency is

[SENSe:]FREQuency:CENTer.

When you send a succession of these commands, you can configure and perform

complete measurements.

There are several tools that allow you to connect to an instrument, send an individual

(or more) command(s) and compile automated test sequences.

One of these tools is delivered with the R&S VISA library that is available for download

on the Rohde & Schwarz website (search term: "r&s visa"). The VISA library itself provides input and output functions that are required to communicate with the instrument.

Another tool with more complex scripting functions is R&S Forum, also available for

download on the Rohde & Schwarz website (search term: "forum"). It allows you to run

and edit example script sequences and to write your own script files, as well as on-thefly remote control of instruments. Script files can range from simple command sequences (Winbatch syntax) to complex programs using the programming language Python.

User documentation and background information is available for both tools. If you want

to learn more about their features, refer to the corresponding user manuals and application notes.

The following basic introduction to remote control is based on the tool that is delivered

with the R&S VISA.

1. Install R&S VISA on a desktop PC or notebook.

2. Connect the R&S FPC to the computer with a LAN cable or a USB cable.

3. Start the RsVisaTester software (search for "tester" in the start menu). Use the 32bit or 64-bit version, depending on your operating system.

27User Manual 1178.4130.02 ─ 07

Page 31

R&S®FPC

Operation

Remote Operation

The user interface of the RsVisaTester opens.

4. Establish a connection to the R&S FPC.

a) In the "Resource" field, enter the IP address of the R&S FPC you want to con-

nect to.

The form is tcpip::<ipaddress>[::protocol][::instrument], you

can leave out the parts in brackets for now. Just enter tcpip::<ipaddress>.

b) Confirm the entry with the "Connect" button.

After a successful connection, you can see in the left pane that the software

already sent the commands necessary to open the connection.

5. Enter a command in the input field in the "Basics" tab, for example *idn? (make

sure to add the question mark). Then select the "Query" button.

The *IDN? (identity) command queries information about the connected product.

In this case, it should return a string similar to this:

Rohde&Schwarz,FPC1000,1328.6660K02/111111,1.00.

"Query" button: whenever you want to retrieve information from the instrument

(query), use this button.

Tip: See Chapter 19.1, "Remote Control Basics", on page 187 for a comprehen-

sive description about the remote command syntax and the ways you can send a

command.

6. For the following command sequence, make sure that the spectrum application is

the active one.

Enter the command instrument:select spec. Then select the "Write" button.

The command selects the spectrum application.

7. At the beginning of a command sequence, you should always preset the instrument settings to their default values. You can do a preset with the *RST command.

Enter the command in the input field and select the "Write" button.

28User Manual 1178.4130.02 ─ 07

Page 32

R&S®FPC

Operation

Remote Operation

The R&S FPC resets the settings to their default value.

"Write" button: whenever you want to send information to the instrument, use this

button.

8. Enter another command, one that changes an instrument setting, for example

sense:frequency:center 100mhz or the short form freq:cent 100MHZ.

Then select the "Write" button.

The new state of the setting you want to change is defined by a parameter that you

add behind the command.

The SENSe:FREQuency:CENTer command changes the center frequency of the

R&S FPC.

After a preset, the center frequency is half of the supported frequency range

(500 MHz for 1 GHz instruments).

When you send the command, the center frequency changes to 100 MHz. You can

observe this change on the instrument display.

9. Send the command again, this time as a query. To query the state of a setting, add

a question mark instead of a parameter (sense:frequency:center?). Then

select the "Query" button.

The command returns the current state of the parameter you have queried (in this

example the return value should be 100 MHz as you have just changed it to that

value).

29User Manual 1178.4130.02 ─ 07

Page 33

R&S®FPC

Operation

Remote Operation

Note that unless stated otherwise, a query always returns a numeric value in the SI

derived unit (Hz in case of a frequency, not in kHz, MHz or GHz) and with several

decimal places (usually six).

Commands like SENSe:FREQuency:CENTer work a setting and a query. Other

commands do not work both ways. *IDN, for example, is only allowed as a query

(setting anything is not possible). *RST, for example, is only allowed as a setting (a

query is not possible). Information about how you can use command is included in

the command description.

10. Send a succession of commands to measure the spectrum around the center frequency of 100 MHz.

initiate:continuous off

a)

This command selects single sweep mode, recommended for remote measurements.

initiate:immediate;*wai

b)

You can write two commands into one command line, but have to separate

them with a semicolon (;). The first command (INITiate:IMMediate) initiates the measurement. The second command (*wai) instructs the program to

wait until the preceding command (INITiate:IMMediate) has been executed before any subsequent commands are sent. This synchronization to the

end of the measurement is important, because it makes sure that the measurement is done before taking another action.

11. When the measurement is done, you can query the measurement results (trace

data).

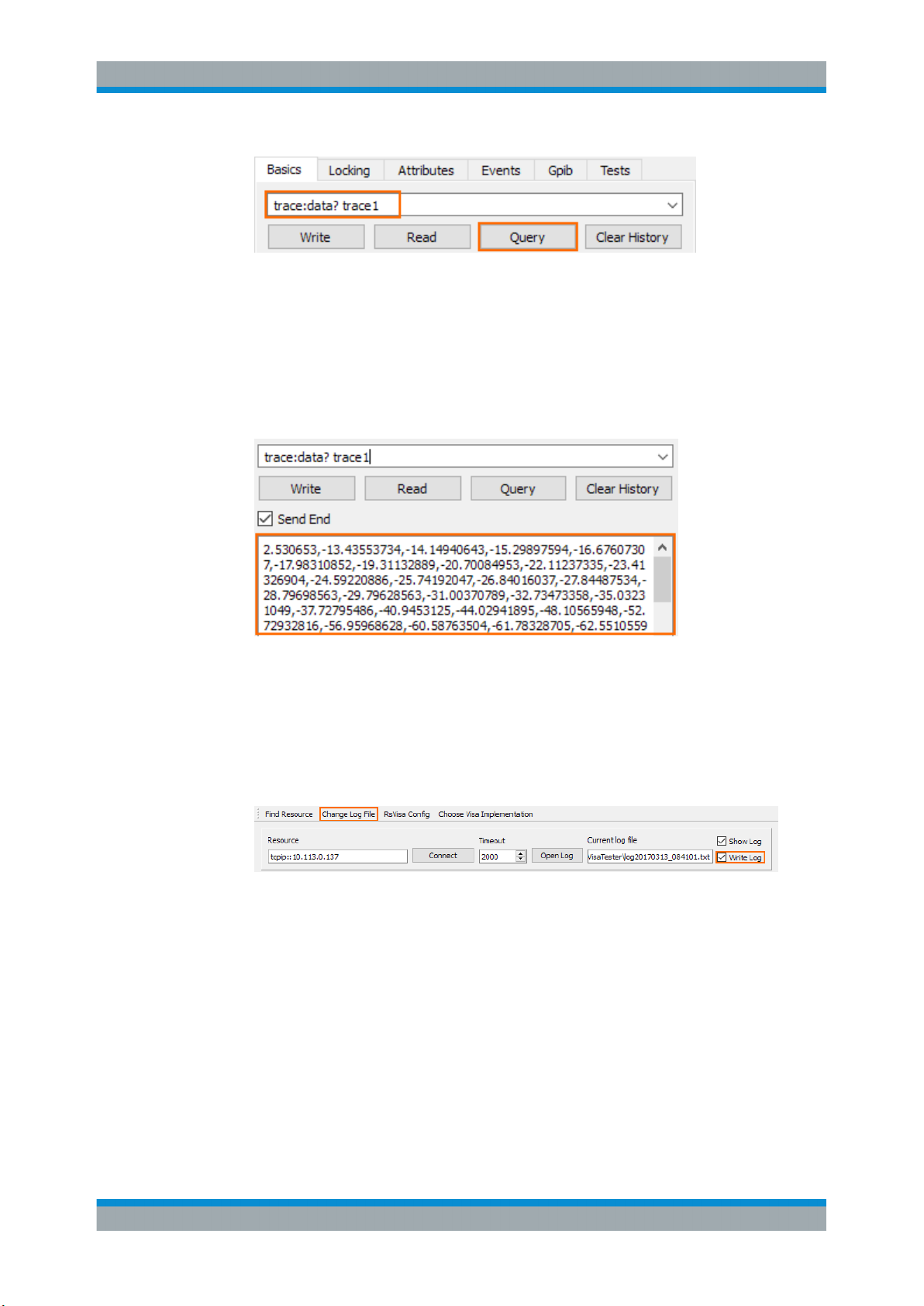

Send the query trace:data? trace1 to do so.

30User Manual 1178.4130.02 ─ 07

Page 34

R&S®FPC

Operation

Remote Operation

TRACe:DATA is a query, but you have to state a parameter in that case. The

parameter defines which data is returned (in this case, the data of trace 1; you

could also display a second trace whose data you could query with TRACe:DATA

TRACE2).

The trace data contains 1183 level values (one value for each pixel of the display).

The unit of the values is dBm. The values are shown in the message box of the

user interface.

You can copy the trace data from the message box and paste it into a text file,

spreadsheet etc. for further evaluation. (There are also SCPI commands that automatically copy that data into a file, so you do not have to do that manually.)

Tip: Logging commands. You can save all commands you have sent with RsVisaTester into a log file (.txt file type) and reuse it later on.

To do so, turn on the "Write Log" feature and select a folder to save the file in

("Change Log File" menu item).

Figure 5-8: Logging feature in the VISA tester application

This was a short example of how to use SCPI commands to measure a signal.

Depending on your measurement task you can expand the succession of commands as you like, write it into a script and automate a measurement.

31User Manual 1178.4130.02 ─ 07

Page 35

R&S®FPC

Firmware Update

6 Firmware Update

New firmware versions usually contain new features, improvements of existing functionality, bug fixes etc. When a new firmware version is available, it is recommended to

replace the old firmware with the new one.

Updating the firmware

The latest firmware version is available for download on the internet:

www.rohde-schwarz.com/firmware/fpc

Before you update the firmware, you should make a backup of the data that you have

stored on the R&S FPC (datasets, screenshots, transducer factors etc.). You can make

a backup with the tools available in the R&S InstrumentView software package.

The firmware update itself does not delete or modify that data, but it is recommended

to perform a factory reset after the firmware update to update predefined limit lines,

channel tables etc. The factory reset, however, does delete user data.

1. Download the firmware installer from the internet.

The firmware comes in a single .exe file.

2. Save the file to the root directory of a memory stick.

3. Run the .exe file to unpack the self-extracting zip archive.

The following files are extracted.

FPC_bootloader_<version>.bin

●

FPC_osimage_<version>.bin

●

FPC_updater_<version>.bin

●

FPC_xmegaloadfiles_<version>.bin

●

Make sure that only these files are present in the root directory of the memory

stick.

4. Turn off the R&S FPC.

5. Connect the memory stick to one of the USB interfaces of the R&S FPC.

6. Press the "Preset" key and the number "8" key simultaneously.

7. Turn on the R&S FPC and keep pressing the two keys for at least 5 seconds after

the startup screen appears.

8. Release the keys.

32User Manual 1178.4130.02 ─ 07

Page 36

R&S®FPC

Firmware Update

The booting process continues. After a couple of seconds, the R&S FPC asks you

if you really want to update the firmware.

9. Press the "Enter" ("✓") key to update the firmware.

(You can cancel the firmware update with the "Esc" key.)

The firmware update takes several minutes. The R&S FPC shows a message

when the firmware update is done.

Note: Do not turn off the R&S FPC during the firmware update.

10. Turn off the R&S FPC.

11. Turn on the R&S FPC.

The R&S FPC boots with the new firmware version.

12. Optional: It is recommended to perform a factory reset after a firmware update to

replace the predefined limit lines, channel tables and other data with the latest

updates.

Note: Before you start a factory rest, make sure to make a backup of your data that

you have saved on the R&S FPC. Otherwise that data is deleted.

33User Manual 1178.4130.02 ─ 07

Page 37

R&S®FPC

Firmware Options

7 Firmware Options

You can equip the R&S FPC with optional functionality or firmware options like the analog demodulation application or the receiver application. These firmware options

expand the functionality of the R&S FPC with new measurement functions settings etc.

Installing firmware options

To install a new firmware option, you have to enter a license key for validation.

The license key is included in the delivery of the firmware option.

1. Press the "Setup" key to enter the instrument setup menu.

2. Select the "Installed Options" menu item.

The R&S FPC shows a list of all options that are currently installed on your

R&S FPC.

3. Select the "Install Option" button and press the "Enter" key.

The R&S FPC opens an input field.

4. Enter the license key with the alphanumeric keys and confirm the entry with the

"Enter" key.

The license key is a 32-digit number.

The R&S FPC confirms a successful installation.

If the R&S FPC shows an "Invalid Key Code" message, try to enter the license key

again.

Using the R&S LicenseManager (online registration)

You can use the R&S License Manager to manage options with a web browser (Microsoft Internet Explorer, Mozilla Firefox etc.) from a PC.

To use the R&S License Manager, you have to connect the R&S FPC to a local area

network (LAN). See Chapter 9.2, "Network Configuration", on page 39 for more information about how to connect the R&S FPC to a LAN.

After you have connected the R&S FPC, open the web browser.

Make sure to allow the execution of mixed-mode scripts, for example allow in Google

Chrome the loading of scripts from unsafe sources.

► Enter the IP address of the R&S FPC in the address bar of the web browser.

The web browser opens the R&S License Manager. In this part of the

R&S License Manager, you can install, activate and register licenses on the

R&S FPC.

34User Manual 1178.4130.02 ─ 07

Page 38

R&S®FPC

Firmware Options

This page contains three areas.

●

The first area shows the details of the connected device, including the device ID

and the IP address.

●

The second area provides functionality to install and activate licenses.

– "Install Registered License Keys And Activate License"

Follow this link if you have purchased a registered license. Registered licenses

only work in a combination with a specific device ID.

– "Register License, Install License Keys and Activate Licenses"

Follow this link if you have purchased an unregistered license. Unregistered

licenses are not linked to a specific device ID.

– "Reboot Device"

Follow this link to reboot the R&S FPC.

–

Opens an online help of the corresponding topic.

●

The third area provides hints on using the license manager when you move the

mouse over one of the options.

The R&S License Manager also provides functionality to managed licenses of options

that you have already installed on a R&S FPC.

► Select the "Manage Licenses" button.

The web browser opens another part of the R&S License Manager. In this part of

the R&S License Manager, you can manage licenses already installed on your

R&S FPC.

This page contains two areas.

●

The first area provides functionality to manage licenses.

– "Register Licenses"

35User Manual 1178.4130.02 ─ 07

Page 39

R&S®FPC

Firmware Options

Follow this link if you have purchased an unregistered license and want to register it.

– "Unregister License"

Follow this link if you have installed a portable license. Portable licenses can be

used with several device IDs. However, you have to unregister it on one device

before you can use it on another.

– "Move Portable License"

Follow this link if you want to move a portable license. Moving a portable

license is possible without unregistering the license.

–

Opens an online help of the corresponding topic.

●

The second area provides hints on using the license manager when you move the

mouse over one of the options.

After you have followed one of the links, follow the instructions displayed in the web

browser. If you encounter any issues during the licensing procedure, you can access

the online help at any time with the icon. The online help contains an extensive

description of all functionality that the license manager features.

36User Manual 1178.4130.02 ─ 07

Page 40

R&S®FPC

8 Preset

Access: "Preset"

Access (preset configuration): "Setup" > "User Preference"

Access (factory reset): "Setup" > "Instrument Setup"

Remote commands required to preset the system:

●

Chapter 19.3, "Preset", on page 206

Before you prepare a measurement, it is recommended to preset the R&S FPC. During

a preset, the R&S FPC resets all settings to their default state. Restoring the default

configuration has the advantage that old settings do not affect measurements.

The default setup depends on the application you are using.

Presetting the system

1. Press the "Preset" key to restore the default instrument configuration.

Preset

You can also define your own default settings via a dataset. The R&S FPC restores

the configuration stored in the dataset after you press the "Preset" key instead of

the factory defaults.

2. Press the "Setup" key to open the setup menu.

3. Select the "User Preference" menu item to open the user preference dialog box.

4. Select the "Preset Mode" menu item to select the preset mode.

● "Default"

Restores the factory default configuration.

● "User"

Restores custom default values taken from a dataset. In that case, you have to

select a dataset that contains the default values.

5. Select the "Preset Dataset" menu item to select a dataset.

When you preset the R&S FPC, it applies the configuration of the dataset.

For more information about the "Discard Calibration Data" menu item, see "Per-

forming a default calibration" on page 56.

In addition to the preset, you can also reset the system to the condition it had when it

was delivered (factory reset).

Potential data loss

Note that when you reset the R&S FPC to the factory state, all files you have saved on

the internal memory of the R&S FPC will be deleted. Only the files that were included

in the delivery will be kept.

Resetting the system

1. Press the "Setup" key to open the setup menu.

37User Manual 1178.4130.02 ─ 07

Page 41

R&S®FPC

Preset

2. Select the "Instrument Setup" menu item to open the setup menu.

3. Select the "Reset To Factory Settings" menu item.

The R&S FPC initiates the reset process and will ask you to confirm the reset.

When you select "Yes", the system will be reset.

38User Manual 1178.4130.02 ─ 07

Page 42

R&S®FPC

Instrument Setup

Network Configuration

9 Instrument Setup

Access: "Setup" > "Instrument Setup"

The "Instrument Setup" dialog box contains general properties of the R&S FPC that

are independent of the measurement application you are using.

● BNC Connector Usage............................................................................................39

● Network Configuration.............................................................................................39

● Date and Time.........................................................................................................41

● Regional Settings....................................................................................................42

● Display Settings...................................................................................................... 43

● Audio Settings.........................................................................................................43

● Power Settings........................................................................................................44

9.1 BNC Connector Usage

Remote commands required to configure the BNC connector:

●

Chapter 19.5, "System Configuration", on page 209

You can use the BNC connector on the rear panel of the R&S FPC for several applications. Before you can use it in the corresponding way, you have to configure it accordingly.

Selecting the BNC connector usage

1. Press the "Setup" key to open the setup menu.

2. Select the "Instrument Setup" menu item to open the instrument setup dialog box.

3. Select the "BNC" menu item in the "Hardware" category.

4. Select one of the menu items.

● "Trigger Input"

You can connect an external trigger source and trigger measurements.

● "Reference Input"

You can connect an external frequency reference and synchronize the frequency of the R&S FPC with the external reference.

9.2 Network Configuration

Remote commands required to configure the network properties:

●

Chapter 19.4, "Network Connection", on page 207

You can connect the R&S FPC to a local area network (LAN) with a standard LAN

cable. Alternatively, you can connect the R&S FPC to a wireless LAN (WLAN or WiFi).

This is useful, for example, for remote control operation or if you would like to control

the R&S FPC with the R&S InstrumentView software package.

39User Manual 1178.4130.02 ─ 07

Page 43

R&S®FPC

Instrument Setup

Network Configuration

LAN

When you are connecting the R&S FPC to a wired network (LAN), connect the

R&S FPC with a standard LAN cable to a LAN port. The LAN port of the R&S FPC is

on its rear panel.

In case of a wired connection, you have to define several network properties to establish a network connection.

You can either fetch the R&S FPC network properties automatically from a DHCP

server (Dynamic Host Configuration Protocol) or manually assign a fixed address. With

manual allocation, a fixed IP address and subnet mask must be assigned to the

R&S FPC.

MAC address

The MAC address is the unique identifier of the network adapter built into the

R&S FPC.

You can see the MAC address of your R&S FPC in a read-only field in the "LAN" category of the "Instrument Setup" dialog box.

Using a DHCP server

In networks with a DHCP server, the network automatically allocates the network properties (IP address, subnet mask and gateway).

1. Press the "Setup" key to open the setup menu.

2. Select the "Instrument Setup" menu item to open the instrument setup dialog box.

3. Select the "DHCP" menu item in the "LAN" category.

4. Select "On" to activate DHCP.

The R&S FPC automatically writes the network properties in the corresponding

fields ("IP Address", "Subnet Mask" and "Gateway"). This can take several seconds.

Connecting the R&S FPC to a LAN

If you want to configure the network properties manually, you need a free IP address in

your network that you can assign to your R&S FPC. Kindly ask your IT system administrator to provide you with an unused IP address (and the other network information

you need).

1. Press the "Setup" key to open the setup menu.

2. Select the "Instrument Setup" menu item to open the instrument setup dialog box.

3. Select the "DHCP" menu item from the "LAN" category.

4. Select "Off" to deactivate DHCP.

When you turn off DHCP, you can define the "IP Address", "Subnet Mask" and

"Gateway" in the corresponding input fields.

40User Manual 1178.4130.02 ─ 07

Page 44

R&S®FPC

Instrument Setup

Date and Time

Connecting the R&S FPC to a WLAN

Instead of connecting to a LAN, you can also connect the R&S FPC to a Wi-Fi network.

You can use the Wi-Fi functionality to connect the R&S FPC to a hotspot (for example

a router or mobile device configured as a hotspot) and operate it remotely.

1. Press the "Setup" key to open the setup menu.

2. Select the "Instrument Setup" menu item to open the instrument setup dialog box.

3. Turn on the Wi-Fi functionality with the "WiFi" menu item in the "WiFi" category.

4. Select the "Scan WiFi Networks" menu item from the "WiFi" category.

The R&S FPC opens a dialog box that contains a list of all available Wi-Fi net-

works.

5. Select the network you would like to connect to.

The R&S FPC asks you to enter a password to access the network.

(In case of an open or public Wi-Fi, a password is not required. Using an open WiFi poses security risks, however, so be cautious when connecting to an open WiFi.)

6. Enter the password of the Wi-Fi network.

Tip: Regulatory information. You can view all regulations the R&S FPC complies

with by selecting the "Regulatory Information" menu item.

9.3 Date and Time

Remote commands required to configure the date and time:

●

Chapter 19.5, "System Configuration", on page 209

The R&S FPC has an internal system clock. A time stamp is added to various applications (for example when you create a file like a screenshot).

Setting the date

1. Press the "Setup" key to open the setup menu.

2. Select the "Instrument Setup" menu item to open the instrument setup dialog box.

3. Select the "Set Date" menu item in the "Date and Time" category.

4. Enter the date you want with the numeric keys.

The sequence depends on the date format you have selected.

If you enter an invalid date, the R&S FPC highlights the invalid part and does not

accept the input until you enter a valid date.

Setting the system time

1. Press the "Setup" key to open the setup menu.

41User Manual 1178.4130.02 ─ 07

Page 45

R&S®FPC

Instrument Setup

Regional Settings

2. Select the "Instrument Setup" menu item to open the instrument setup dialog box.

3. Select the "Set Time" menu item in the "Date and Time" category.

4. Enter the time you want with the numeric keys.

If you enter an invalid time, the R&S FPC highlights the invalid part and does not

accept the input until you enter a valid time.

Selecting a time zone

The displayed time represents the system time (UTC by default). If you need to create

a different time stamp without changing the system time, you can define an offset that

is added or subtracted to the system time.

1. Press the "Setup" key to open the setup menu.

2. Select the "Instrument Setup" menu item to open the instrument setup dialog box.

3. Select the "Time Zone" menu item in the "Date and Time" category.

4. Enter the time offset you want with the numeric keys.