Page 1

CSD5 Servo Drive

User Manual

Catalog Number(s): CSD5_xxBX1

Page 2

Important User Information

WARNING

IMPORTANT

CAUTION

Solid state equipment has operational characteristics differing from those of electromechanical equipment. There are some important

differences between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will RS Automation Co., Ltd. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements

associated with any particular installation, RS Automation Co., Ltd. cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by RS Automation Co., Ltd. with respect to use of information, circuits, equipment, or software described in

this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of RS Automation Co., Ltd., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances which may lead to serious personal injury or death, properity

damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Idnetifies information about proctives or circumstances that can lead to minor personal injury, properity damage,

ecconomic loss, or product malfuntion. However, depending on the situraiton, failutre to follow the directions

accompanying this symbol may also lead to serious consequences.

Page 3

Summary of Change

You will see change bars to the left or right of a paragraph throughout this

manual to help you quickly indentify revisions.

Manual

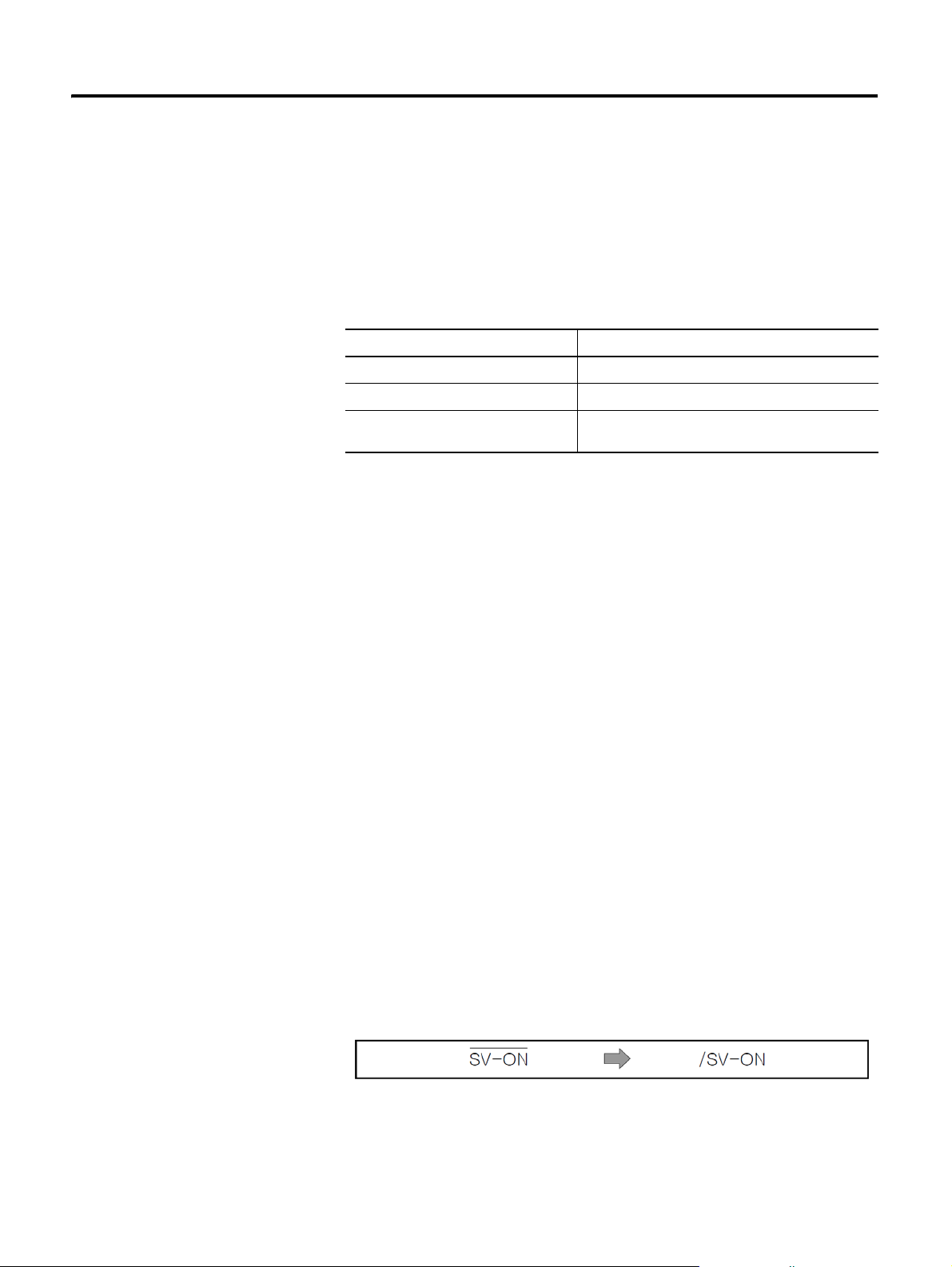

Revision

A N/A Jun 2011

Changes Date

1 CSD5 Servo Drive

Page 4

SOC-2 Summary of Change

CSD5 Servo Drive

Page 5

Summary of Change

Table Of Contents

Preface

Before Using the CSD5 Servo

Drive

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Conventions Used in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Table for Parameter Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Notation Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Manual Description Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Others. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-7

Maintenance and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-7

Chapter 1

Product Type and Each Part Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Model Number of the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Name of Each Motor Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Model Number of the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Installation

Wiring

Chapter 2

Servo Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Servo Motor Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Electric Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Name and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

AC Power Terminal (L1, L2, L3) and Control Power Terminal (L1C, L2C). . . 3-3

Regenerative Register Connection Port . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Electric Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Using the Socket and Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

I/O Signal (I/O). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

I/O Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

(I/O) Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Sequence Input Signal (Allocation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

General Input Signal (Fixed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

(I/O) Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Sequence Output Signal (Allocation) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

General Output Signal (Fixed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

(I/O) Input Circuit and Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

i CSD5 Servo Drive

Page 6

ii

Operator, Basic Setting and

Startup

Pulse Command Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Analog Voltage Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Sequence Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Emergency Stop Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

(I/O) Output Circuit and Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Line Drive Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Photo-Coupler Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Encoder Wiring (Motor Feedback) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Pin Arrangement of Motor Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Terminal Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Encoder Signal Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

General Articles Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Capacity of the Drive and Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Noise Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Wiring when Using Several Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Connection to Peripheral Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Chapter 4

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

About Servo-ON Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Name and Function of Each Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Icons for the Key Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Structure of the Entire Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Status Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Overview of the Parameter Setting Mode . . . . . . . . . . . . . . . . . . . . . . . 4-9

Overview of the Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Overview of the Operation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Basic Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Overview of the Basic Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Control Mode Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Motor Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Before Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Function for Control Mode

Chapter 5

Sequence I/O (Input/Output) Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

What is Sequence I/O Signal?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Function of Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Function of Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Input Signal Allocation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Output Signal Allocation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Notice for Signal Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Position Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Standard Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Page 7

iii

Position Command Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Position Command Pulse Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Electrical Specifications of Position Command Pulse . . . . . . . . . . . . . 5-17

Electronic Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Position Error Clear </PCLR> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Pulse Command Inhibition</INHIB> Input . . . . . . . . . . . . . . . . . . . 5-25

Expansion of Electronic Gear Setting . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

The Second Group of Electronic Gear </GEAR> Input . . . . . . . . . 5-27

Position Completion Signal Detection </P-COM>, Approach Signal

Detection </NEAR> Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Output Width of Allowable Position Error . . . . . . . . . . . . . . . . . . . . . 5-31

Input / Output Signal Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . 5-31

Speed Control Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Standard Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Speed Command Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Zero Clamp </Z-CLP> Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

Rotation Direction Switch Input </C-DIR> . . . . . . . . . . . . . . . . . . . 5-36

Motor Rotation Start/Stop Input</START> . . . . . . . . . . . . . . . . . . . 5-37

Speed Coincidence Output Signal </V-COM> . . . . . . . . . . . . . . . . . 5-38

Rotation Detection </TG-ON> Output . . . . . . . . . . . . . . . . . . . . . . 5-39

Speed Limit Function and Speed Limit Detection </V-LMT> Output . . . 5-41

Torque Control Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Standard Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

Torque Command Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

Torque Limit and Torque Limit Detection </T-LMT> Output . . . . 5-46

Multi-Step Speed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

Standard Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

Multi-Step Speed Command Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

Mixed Control Mode and </C-SEL> Function. . . . . . . . . . . . . . . . . . . . . 5-56

Tuning by Gain Setting

Chapter 6

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Mark Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Gain Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Inertia Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Gain Setting Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Auto Gain Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Auto Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Off-line Auto Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

On-line Auto Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

On-line Vibration Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Online Vibration Suppression Gain Setting . . . . . . . . . . . . . . . . . . . . . 6-13

Manual Gain Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Gain Setting Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Basic Gain Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Position, Speed, Torque Related Gain Setting. . . . . . . . . . . . . . . . . . . . . . . 6-18

Page 8

iv

Applications

Torque Control Related Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Speed Control Related Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Position Control Related Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Tip to get fast response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Feedforward function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Speed Bias Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

P/PI Mode Setting Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Initial Torque Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

</G-SEL> Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

Gain Switching Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Chapter 7

Motor Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Servo Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

OverTravel <P-OT>, <N-OT>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Dynamic Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Motor Brake Contorl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Change the Motor Rotation Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Reneration Resister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Reneration Resister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

External Regenerative Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Regenerative Resistor Selection Standard. . . . . . . . . . . . . . . . . . . . . . . 7-14

Setting for Smooth Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Speed Limiting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Postion Feedback to the Host Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Direction Change of Output Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Pulse Dividing Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Analog Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Use of Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

What is an Absolute Encoder? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Contact with the Host Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Reset of Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Data Transmission of Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . 7-36

Operation Mode Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Things to Know First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Jog Operation (run-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Off-line Auto Tuning Operation (run-01) . . . . . . . . . . . . . . . . . . . . . . 7-43

Auto Adjustment of Speed Command Offset (run-03) . . . . . . . . . . . . 7-44

Auto Adjustment of Torque Command Offset (run-04). . . . . . . . . . . 7-46

Alarm Reset (run-08) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

Absolute Encoder Reset (run-10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

2-Group Gain Storing (run-11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Parameter Initialization (run-12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Monitor Mode Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

Monitor Mode Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Key Button Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

Page 9

Inspection and Protection

Functions

Parameter Group

v

Chapter 8

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Inspection of Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Inspection of Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Part Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Battery Inspection for Absolute Encoder. . . . . . . . . . . . . . . . . . . . . . . . 8-3

Protection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Servo Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Servo Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Confirmation before Requesting for A/S. . . . . . . . . . . . . . . . . . . . . . . . 8-9

Appedix B

Parameter Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Standard Group 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Standard Group 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Standard Group 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Standard Group 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Standard Group 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Standard Group 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Parameter Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Standard Group 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Standard Group 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-25

Standard Group 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-38

Standard Group 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-42

Standard Group 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-47

Standard Group 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-49

Indexing Drive Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-53

Indexing Group 0 - Indexing System . . . . . . . . . . . . . . . . . . . . . . . . . . B-53

Indexing Group 1 - Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-54

Indexing Group 2- Index Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-54

Indexing Gorup 4 - Index Position/Distance . . . . . . . . . . . . . . . . . . . B-55

Indexing Group 7 - Index Dwell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-55

Indexing Gorup 8 - Index Velocity. . . . . . . . . . . . . . . . . . . . . . . . . . . . B-56

Indexing Group 10 - Index Acceleration . . . . . . . . . . . . . . . . . . . . . . . B-56

Indexing Gorup 11 - Index Deceleration . . . . . . . . . . . . . . . . . . . . . . . B-56

Indexing Gorup 12 - Index Next Index . . . . . . . . . . . . . . . . . . . . . . . . B-57

Indexing Parameter Gorup 0 - Indexing System . . . . . . . . . . . . . . . . . B-57

Indexing Parameter Garoup 1 - Homing . . . . . . . . . . . . . . . . . . . . . . . B-59

Indexing Parameter Group 2 - Indexing Options . . . . . . . . . . . . . . . . B-62

Indexing Parameter Group 4 - Index Position/Distance . . . . . . . . . . B-63

Indexing Parameter Group 7 - Index Dwell. . . . . . . . . . . . . . . . . . . . . B-63

Indexing Parameter Group 8 - Index Velocity. . . . . . . . . . . . . . . . . . . B-63

Indexing Parameter Group 10 - Index Acceleration . . . . . . . . . . . . . . B-63

Indexing Parameter Group 10 - Index Deceleration . . . . . . . . . . . . . . B-64

Indexing Parameter Group 12 - Index Next Index . . . . . . . . . . . . . . . B-64

Run Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-64

Display Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-65

Warning and DRive Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-65

Page 10

vi

Specification and Exterior Size

Cable Specification

Appedix C

Drive Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Fuse and Contactor Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Accessaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Drive Size and Exterial View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Appedix D

PC Communication Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Appedix E

I/O Setting and Indexing

Overivew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

I/O Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

I/O Sequence Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Factory Default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

I/O Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

Input Signal Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

Output Signal Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-8

I/O Signal Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

START and IMO (In Motion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

I_SEL0~5 (Index Selection 0~5 Input) . . . . . . . . . . . . . . . . . . . . . . . . E-10

O_ISEL0~5(Index Selection 0~5 Output) . . . . . . . . . . . . . . . . . . . . . E-10

PAUSE(Index Pause). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-11

STOP (Index Stop) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-13

SHOM (Start Home), HOME (Home Sensor), HOMC (Axis Home). . . . E-14

Index Operation Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-15

Operation Setting after Index Movement (Action When Complete) . . E-16

Homing types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-21

Homing Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-26

S/W Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-28

Dwell Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-28

RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-29

Index Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-30

Home Searching Failed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-30

Axis not homed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-30

Index Position Overflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-30

Page 11

Preface

Read this preface to familiarize you with the rest of the manual.

• Who Should Use This Manual

• About This Publication

• Additional Resources

• Conventions Used in This Manual

• Safety Precautions

Who Should Use This

Manual

About This Publication

Additional Resources

This manual is intended for engineers or technicians directly involved in the

installation and wiring of the CSD5 servo drive, and programmers directly

involved in the operation, field maintenance, and integration of the CSD5

servo drive with a Motion Card.

If you do not have a basic understanding of the CSD5 servo drive, contact

your local RS Automation sales representative before using this product, for

information on available training courses.

This manual provides detailed installation instructions for mounting, wiring,

and troubleshooting your CSD5 servo drive, and system integration for your

drive/motor combination with a Motion Card.

The following documents contain additional information concerning related

CSD5 servo drive products.You can view or download publications at

www.rsautomation.biz

To order paper copies of technical documentation, contact your local RS

Automation Korea distributor or sales representative.

For Read This Document

Information on the installation of your

CSD5 servo drive

Information on the motors used together

with CSD5 servo drive

Conventions Used in This

Manual

1 CSD5 Servo Drive

The conventions starting below are used throughout this manual.

• Bulleted lists such as this one provide information, not procedural steps

• Numbered lists provide sequential steps or hierarchical information

CSD5 Servo Drive Installation Instructions

Servo Motor User Manual

Page 12

P-2 Preface

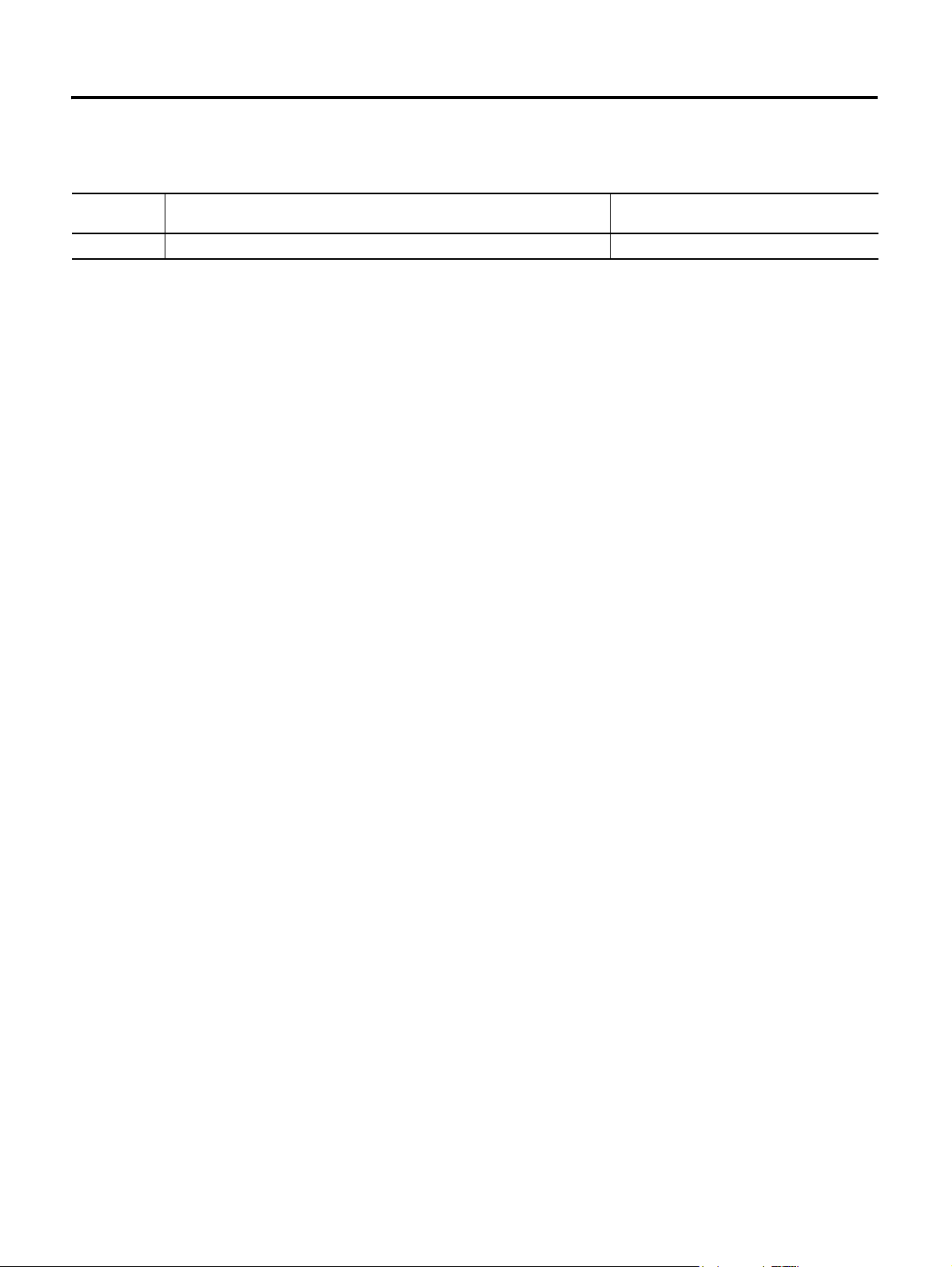

Table for Parameter Setting

This manual uses the following table for parameter description.

Example of Parameter Setting

Parameter

Parameter Name Motor Forward Direction

Description You can choose the rotational direction of the motor

Setting Value • 0: CW

• 1: CCW

Initial Value 0

Applicable Mode All

Others Servo-OFF > Setting > End

Tab le D escr ipt ion

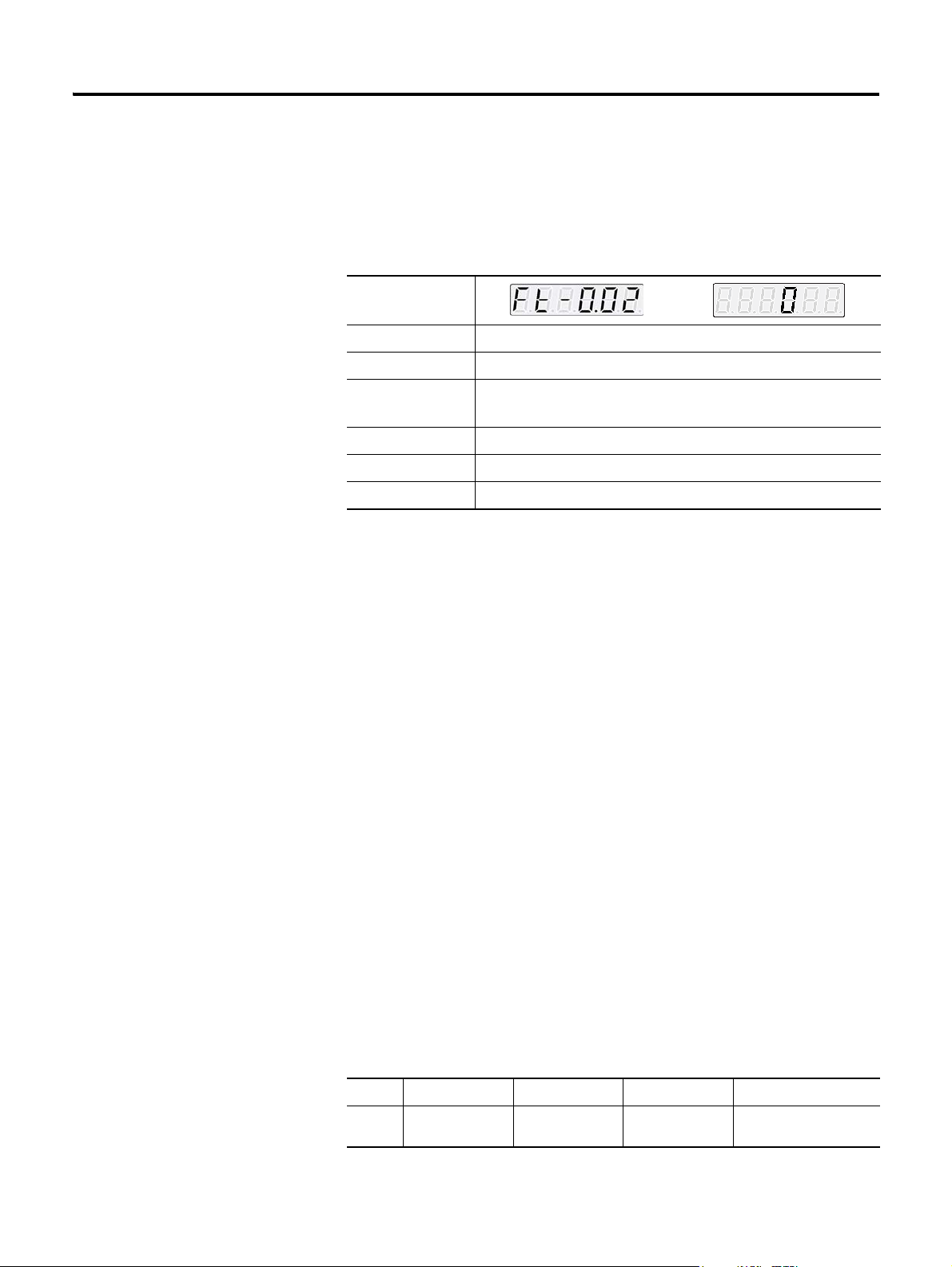

Parameter: at the top-left side shows the parameter being described.

The setting window on the right of the parameter, is entered when the

ENTER key is pressed. The parameter must be set from the digit in black

color and the initial value shows the initial value of the parameter.

It is classified into a parameter selected among already set values (“selected

parameter”) and a parameter, which the users give appropriate value. The

selected parameter, as shown in the example above, displays both parameter

and setting window, and the latter parameter displays only the parameter and

not eh setting window.

Parameter Name: describes the value selectable by the user and the selected

value.

Description: describes the function and usage of parameter.

Setting Value: describes the value selectable by the user and the selected

value.

Initial Value: Initial Value displayed when the parameter is selected.

Applicable Mode: alphabetically displays the corresponding control mode in

setting parameter, and displays (ALL) if all are included.

CSD5 Servo Drive

Mode Position mode Speed mode Torque mode Multi-step speed mode

DisplayFSC

P

Page 13

Preface P-3

Combinational control mode indicates the alphabets of two modes, combined

in a row.

ex) speed + position mode (SF), torque-speed mode (tS).

Others: normally, as described in an example of automobile, the driver cannot

manipulate parking brake of a running automobile, and the servo drive also

should be divided into Servo-ON status and Servo-OFF status when setting

the parameter.

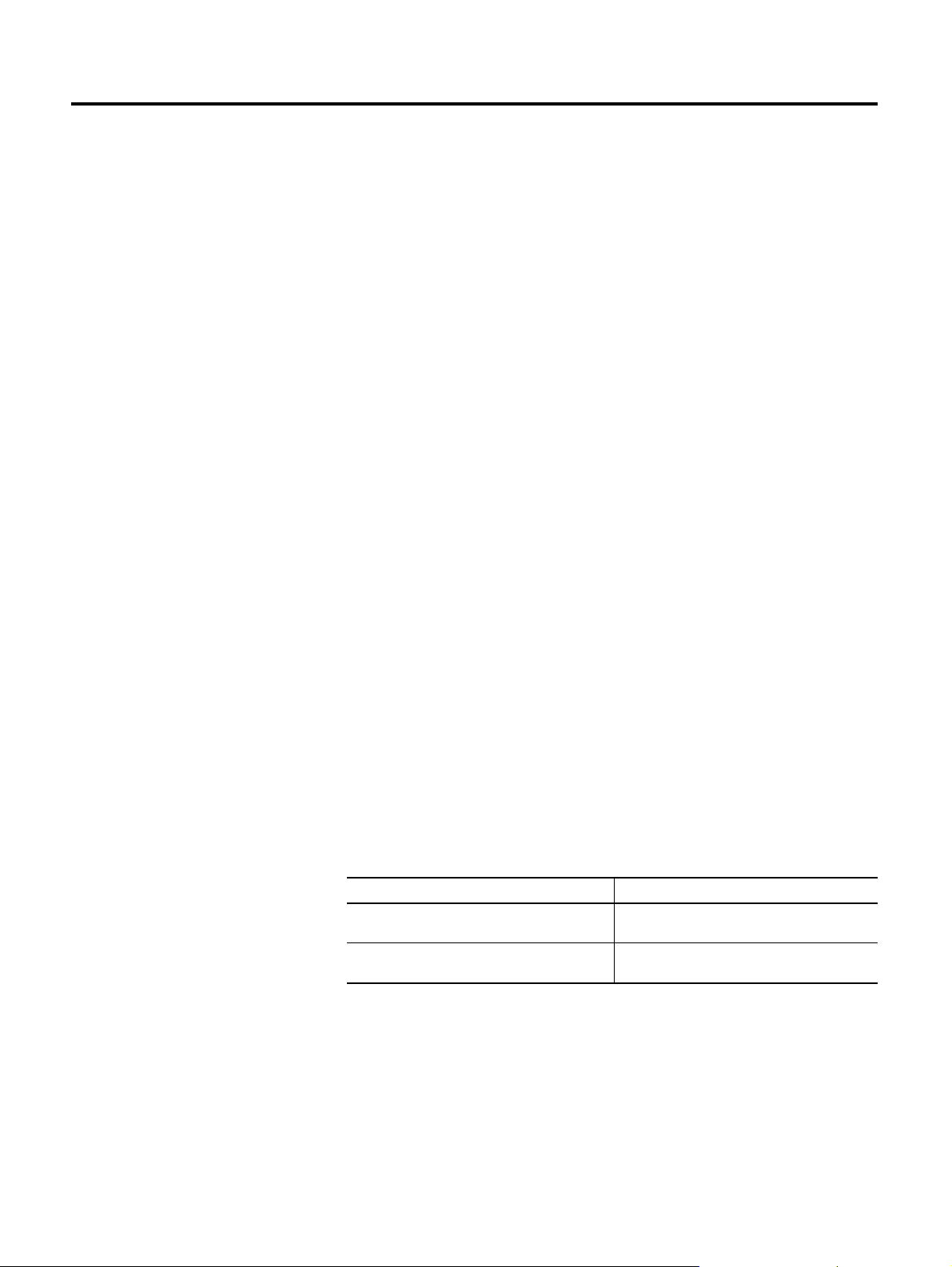

Others Description

Setting > End Set regardless of the drive status.

Servo-OFF > Setting > End Set it in Servo-OFF status

Servo-OFF > Setting > Power Off &

On > End

Set it in Serve-OFF status, and apply the power

again

Terminology

The following describes terminologies used in this manual.

• Servo Drive or Drive: Refer to the CSD5 Servo Drive

• Servo Motor or Motor: Refer to the servo motor exclusively for the

CSD5 drive.

• Host Controller : Refers to a controller or a device that gives

command to the drive and controls it.

• Initial Value: Refer to the value set at the factory before the

shipment.

• Setting Value: Refers to the initial value or the value changed and set

by the users.

• User’s Manual: Simply indicated as ‘manual’.

Notation Description

Within the sentences of this manual, the following is expressed as shown

below. Be fully aware of them when using the servo drive.

1. Use ‘/’ in front of Active Low signal.

3 CSD5 Servo Drive

Page 14

P-4 Preface

I/O

HF_PULS

VCMD+

HF_PULS

VCMD-

I/O

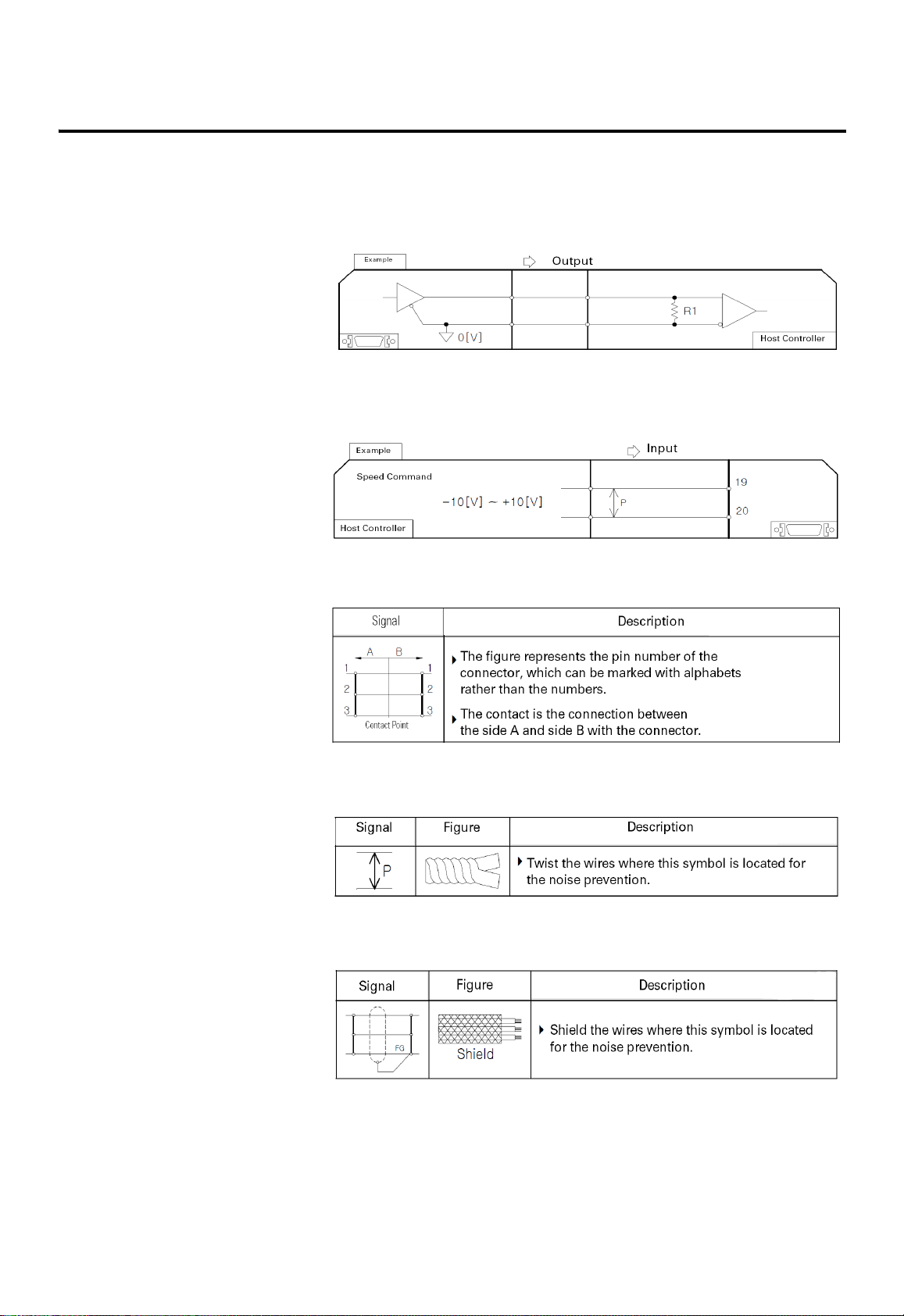

2. A figure box with both the top corners cut off diagonally represents a

circuit diagram. If I/O for I/O signal or a connector attached to the

servo driver is on the left, it is the output of I/O or servo drive.

3. If I/O for I/O signal or a connector attached to servo driver is on

the right, it is the input from the host controller to I/O or servo

drive.

4. The following shows the symbols used on the circuit

diagram.

5. The following figure shows a symbol used to show a twist pair wires

to prevent the noise generation.

6. The following figure shows a symbol used to show a shield pair wire

to prevent the noise generation.

CSD5 Servo Drive

Page 15

Preface P-5

Manual Description Order

This manual is described in the view of users from the purchase to operation.

1. Descripbes things to know before using the product.

2. Describes the outline of product and marking.

3. Describes precations upon product installation.

4. Describes wiring with the host controller and peripheral

equipment.

5. Describes the operator for various settings.

6. Describes brief functions of the product.

7. Describes the basic settings that users should set.

8. Describes the fucntion of the product for each control modes.

9. Describes the tuning to implement optimum performance of load

system.

10.Describes simple supplementary functions.

11.Describes the protective function, fault diagnosis and

troubleshooting.

12.Describes items corresponding to various numerical data in the

Appendix.

Others

Each chapter or paragraph has a page called before you begin before

description. For easier understanding of this manual, be fully aware of the

contents of this page called before you begin in advance.

5 CSD5 Servo Drive

Page 16

P-6 Preface

CAUTION

WARNING

WARNING

WARNING

Safety Precautions

This is CSD5 User Manual describes safety matters using the following marks.

Safety marks deals with the important matters. If the following marks and

contents of each mark are indicated in the contents of this user's manual, you

must be fully aware of them and follow them.

Usage

• Do not touch the inside of servo drive.

• Make sure that the servo drive and the motor are fully

grounded.

• Completely discharged before handling after power

off.

• Do not put excessive stress on the motor power and

encoder cable.

• Never touch the revolving part of the motor during

operation .

• Avoid using the product near wet places or corrosive

and inflammable materials.

• Operate the system with no load during pilot

operation.

• Never touch the heat sink directly.

CSD5 Servo Drive

Storage

• Do not store the product near wet places, rain, toxic

gas or fluid.

• Keep the product out of the direct rays of the sun and

store it within the storage temperature and humidity

ranges.

• Avoid overloading if the product is stored in a

warehouse.

Transportation

• Do not carry the product by holding the cable and the

motor shaft.

Page 17

Installation and Wiring

WARNING

CAUTION

WARNING

• Install a cooling fan to prevent excessive temperature

increase. (Refer to the Chapter 2)

• Be careful not to wiring cables around the heat sink.

• Install drives with regular space (at least 10 mm)

between them.

• Pay attention to the heat sink when wiring. (Refer to

Chapter 2)

Maintenance and Repair

• Do not disassemble or remodel the product. Any

damage caused after the user disassembles or

remodels the product will be excluded from the

company's warranty.

• The company bears no responsibility for injuries or

physical damage caused by remodeling of this

product.

• Life-limited Parts by mechanical friction or heat

requires regular . Refer to the Chapter 8.

• In case of a failure that cannot be dealt with, please

contact the company’ s technical support team or

after-sales service center.

Preface P-7

7 CSD5 Servo Drive

Page 18

P-8 Preface

CSD5 Servo Drive

Page 19

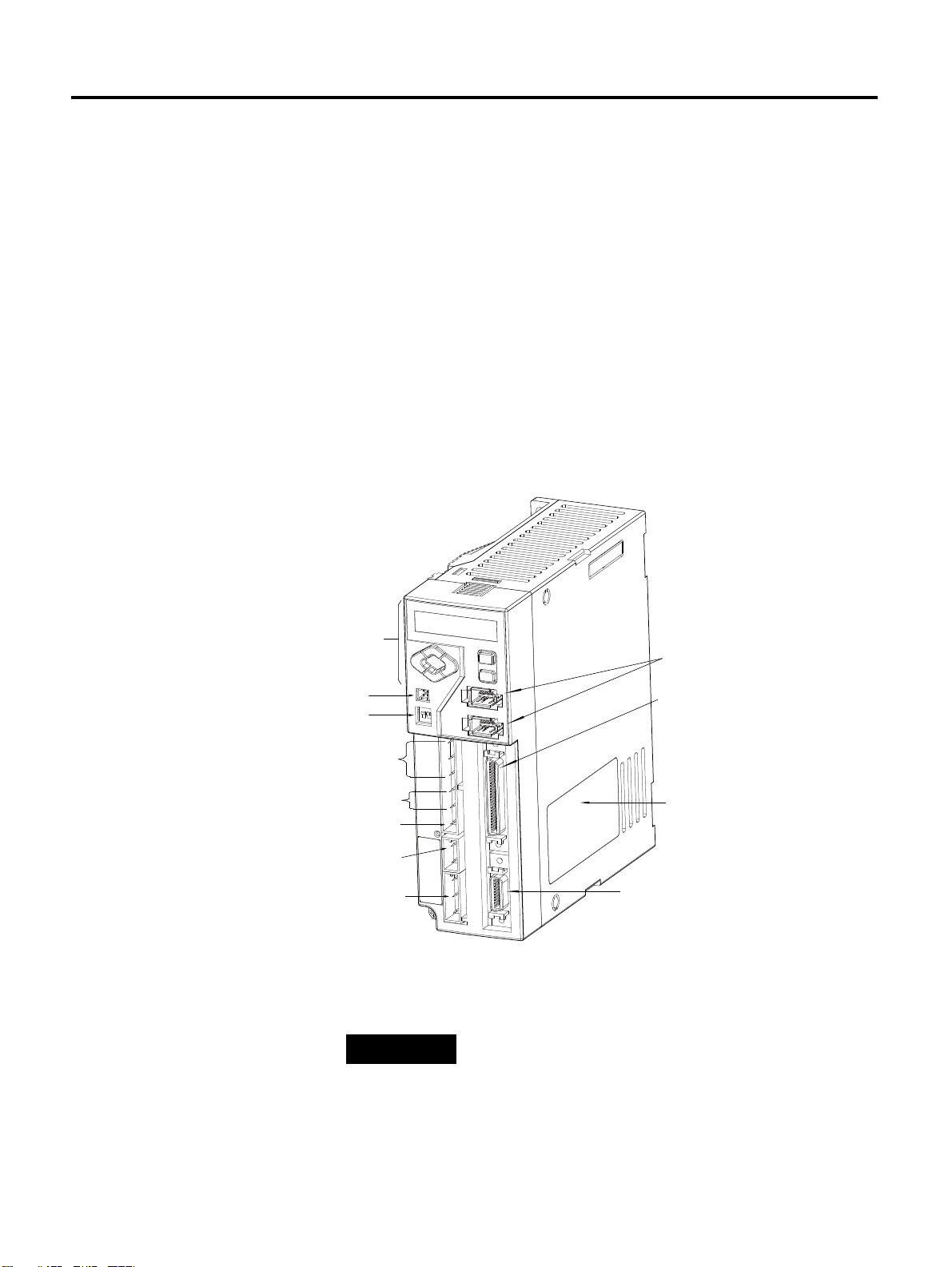

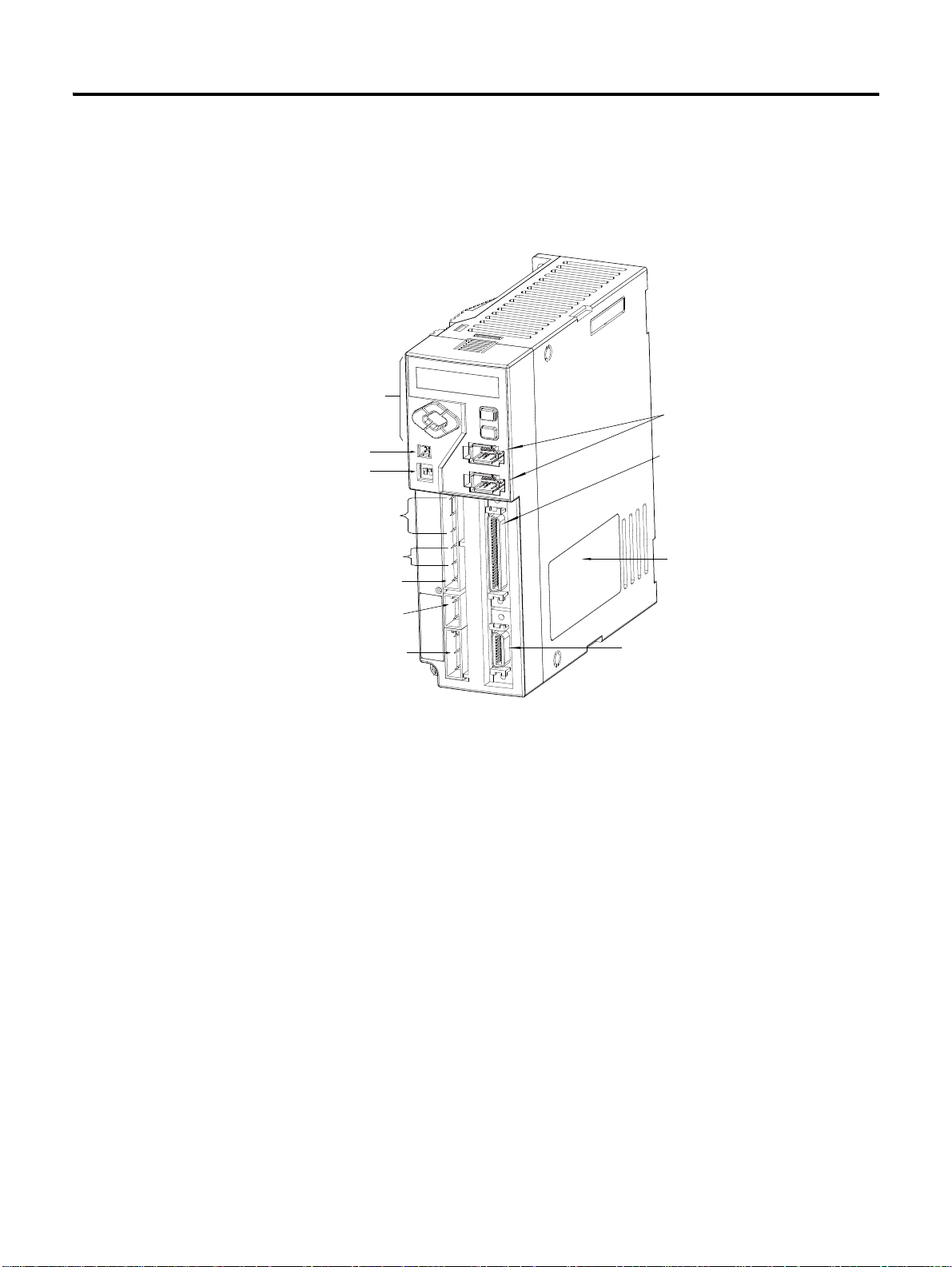

Chapter 1

Drive Nameplate

I/O Signal Connector <I/O>

Encoder Cable Connector <Motor

Feedback>

Communication and Operator

Connector

AC Main Power Input Terminal

Control Power Input Terminal

DC Link Negative Output

Regenerative Resistor Terminal

Motor Cable Terminal

Operator

Analog Output Terminal

Terminating Resistance Setting

TIP

Before Using the CSD5 Servo Drive

This chapter describes the general matters and optional specifications that you

should know before using the CSD5 SERVO DRIVE.

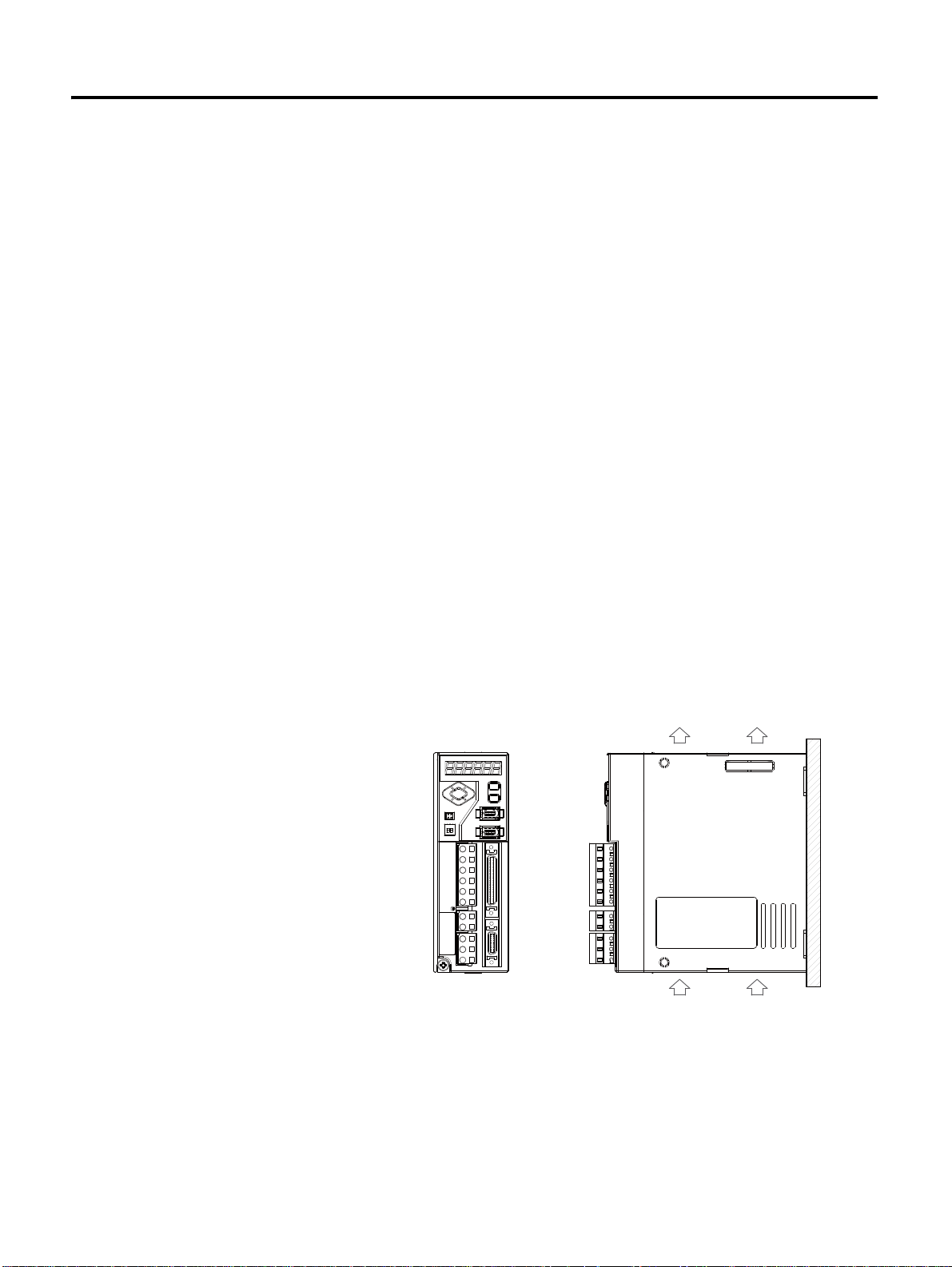

Product Type and Each

Part Name

The following figure introduces the name of each part of the servo drive.

1 CSD5 Servo Drive

For more detail information about Operator, please refer to

“ Chapter 4 Operator, Basic Setting and Startup”.

Page 20

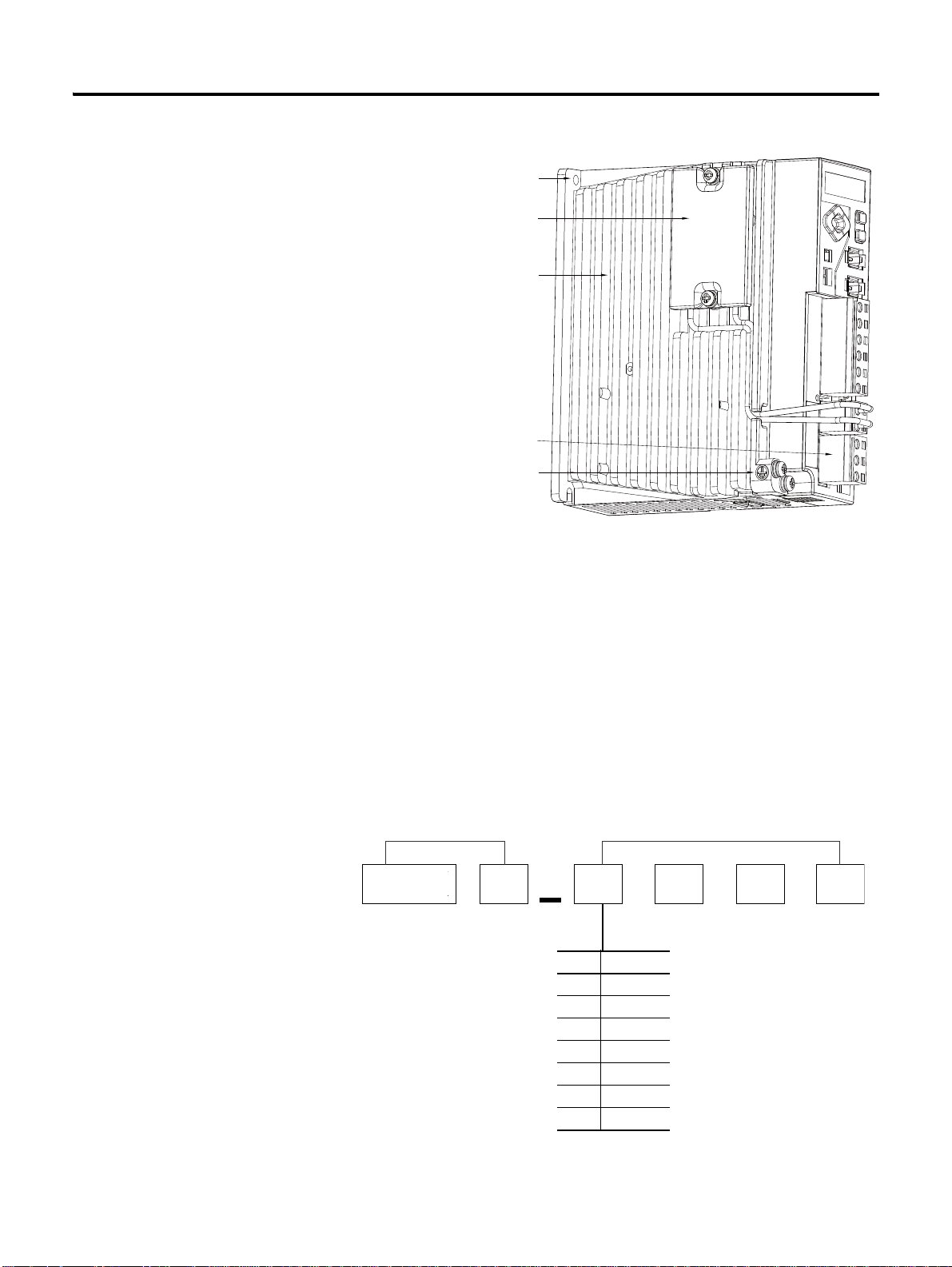

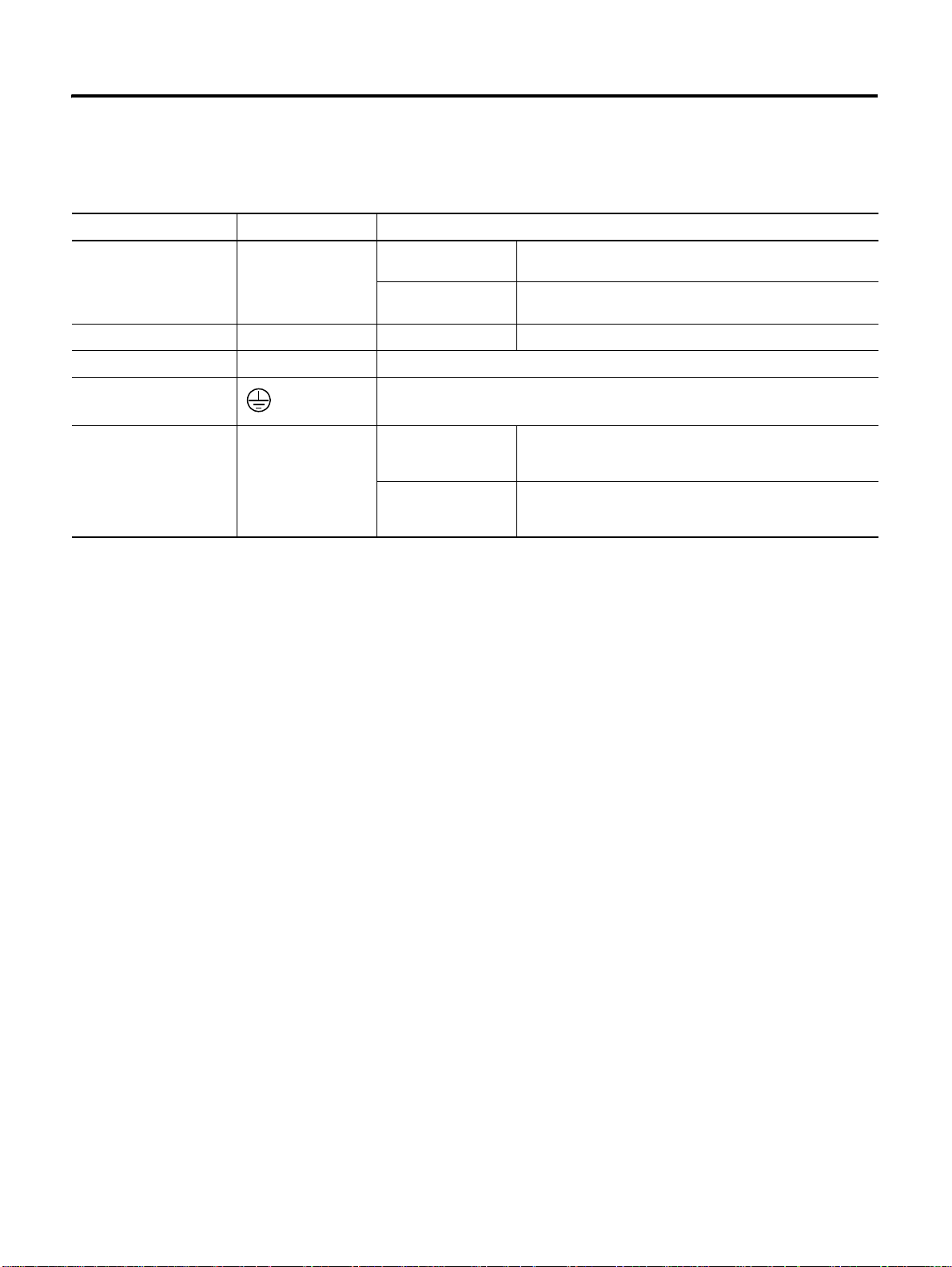

1-2 Before Using the CSD5 Servo Drive

Mounting Hall (Top, Bottom)

Regenerative Resistor

(400 [W] or Higher Attached)

Heat Sink

Wiring Socket (6P, 2P, 3P) 3 PART

Ground T e rminal (Heat Sink)

Drive Type Example of Servo Drvicve Specification

Mask Rated

A5 50 [W]

01 100 [W]

02 200 [W]

04 400 [W]

08 800 [W]

10 1 [kW]

15 1.5 [kW]

CSD

5

A5

BX1

Model Number of the

The following figure describes the model name on the nameplate of the servo

drive.

Drive

• The nameplate is attached on the side of the drive case. Check the

model name on the nameplate, and check if it corresponds to the

product ordered.

• The drive type is RS Automation Servo Drive CSD5 Series.

• The serial number is included on the nameplate. Be careful not to erase

the serial number during the use.

KNX 3 - K A P 0

CSD5 Servo Drive

Page 21

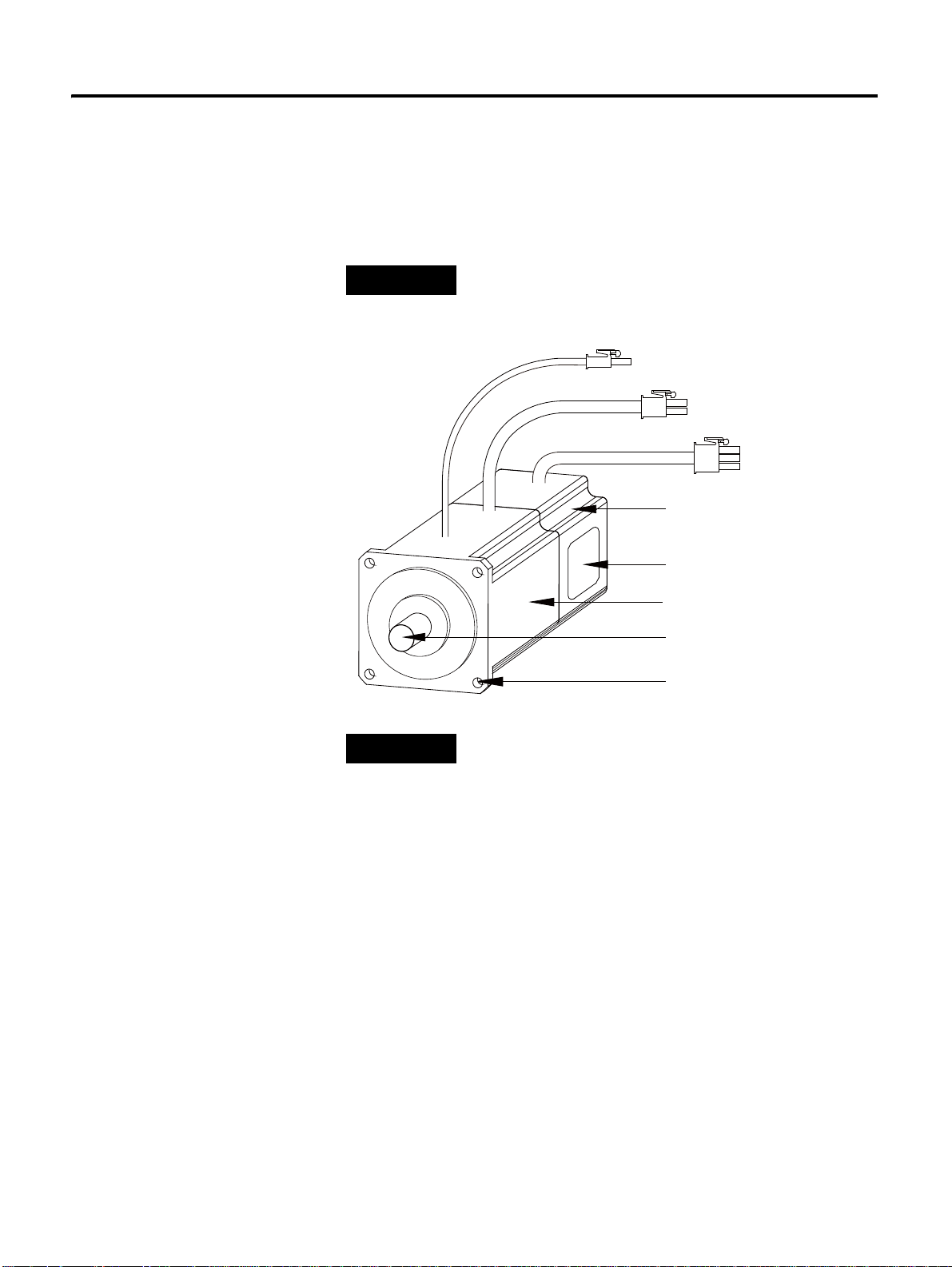

Before Using the CSD5 Servo Drive 1-3

TIP

Break Cable

Motor Cable

Encoder Cable

Encoder

Motor Nameplate

Motor Frame

Motor Shaft

Mounting Hole

TIP

Name of Each Motor Part

The following figure shows the name of each more part.

A motor without a brake does not have a brake cable. The name of each motor

part may differ from the following figure according to the motor type.

For more detailed infroamtion about Servo Motor, please

refer to “ Servo Motor Manual” .

RS Automation does not provide cables. For more

information about specification and order code of cables

below, refer to "Servo Motor Manual (Publication

SMOTOR-UM002)".

• Motor 3 phase Power Cable

• Encoder Cable

• Motor Break Cable

• I/O Cable

• Communication Cable

3 CSD5 Servo Drive

Page 22

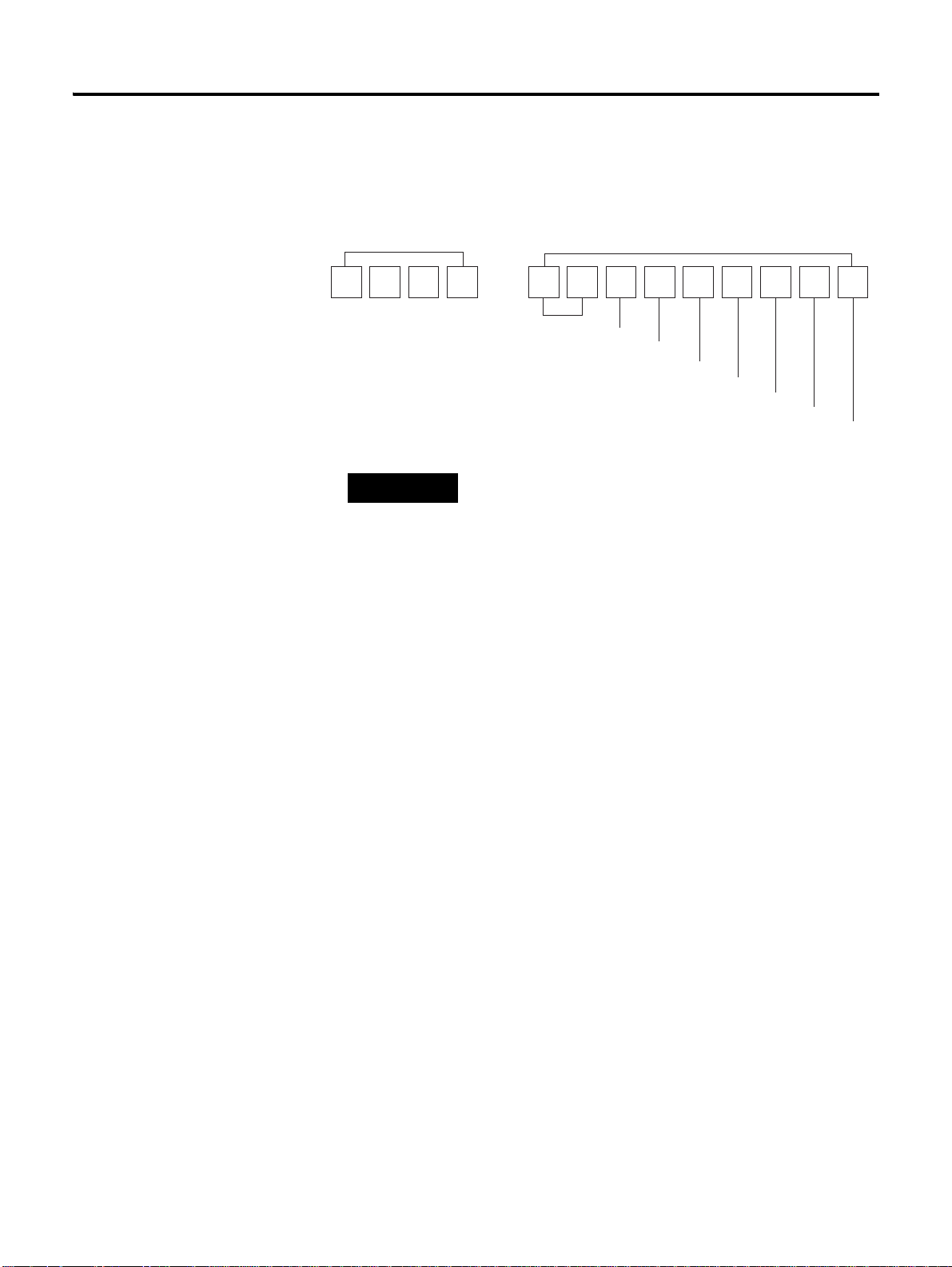

1-4 Before Using the CSD5 Servo Drive

C S M T - 0 1 B B 1 A N T 3

Motor Type Example of Motor Specifcation

Rated Output

Voltage

Encoder Type

Design Sequence

Motor Axis Key

Option

Manufacturer

Shaft Specification

TIP

Model Number of the

Motor

The following figure describes the model name of the motor on the

nameplate.

For more detailed information about each motor name

plate items, refer to Servo Motor Manual.

CSD5 Servo Drive

Page 23

Chapter 2

Natural

Natural

Installation

This chapter describes matters to consider when installing the servo drive and

the motor. Refer to the appendix for numerical data on the drive, motor, and

various peripheral equipments necessary for the installation.

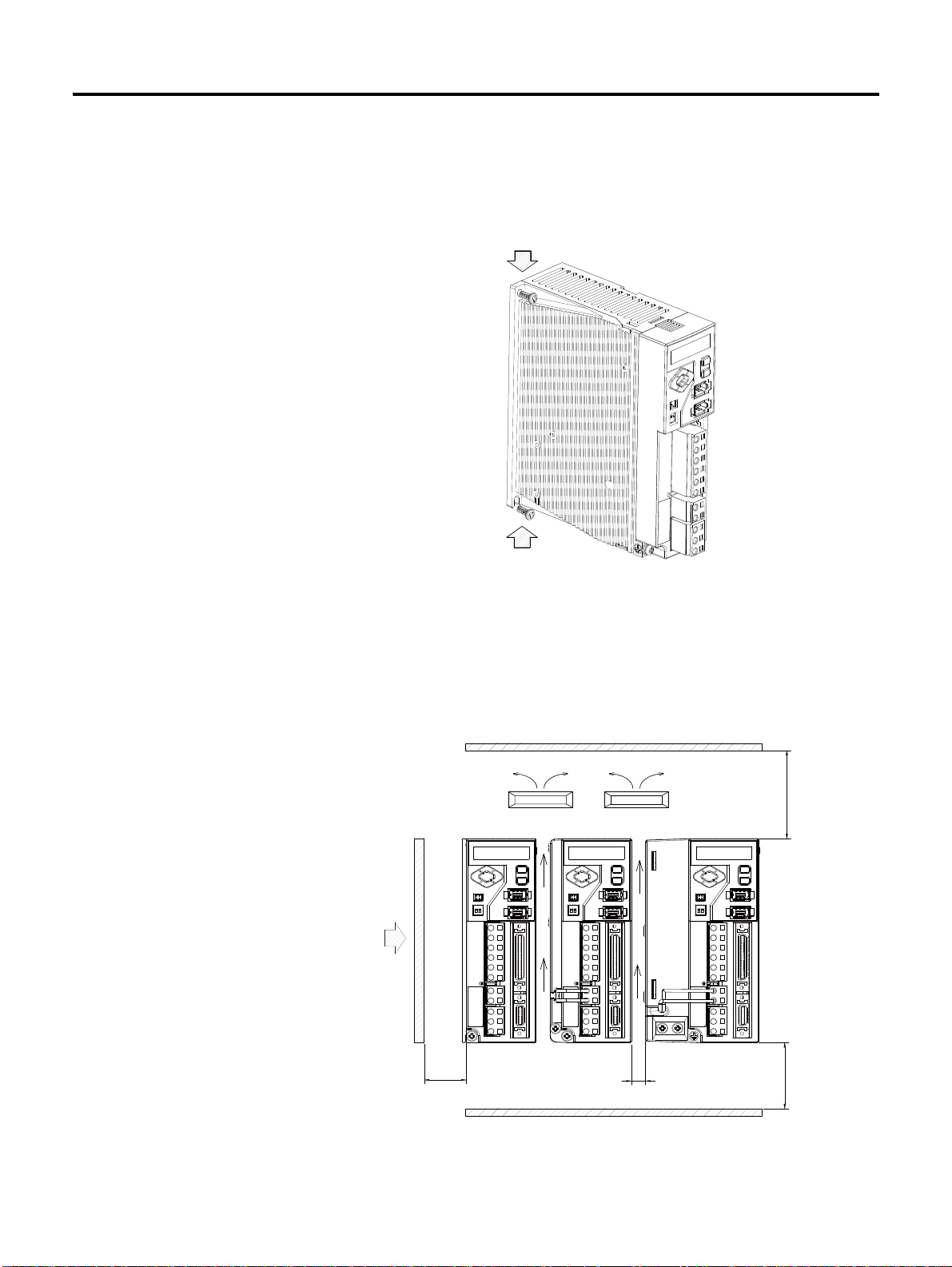

Servo Drive Installation

Precautions

Refer to the following figures when installing the servo drive.

The most important thing to consider when installing the drive is the ambient

temperature. Follow the operational temperature and mount the servo drive

vertically.

Install the Servo Drive Vertically

Servo drive less than 400 [W] applies the natural convective cooling, and the

servo drive with more than 0.8 [kW] uses the cooling fan. To increase the

cooling efficiency, install it vertically.

1 CSD5 Servo Drive

Page 24

2-2 Installation

Fixing Bolt

Fixing Bolt

Cooling Fan

Cooling Fan

Panel

More than

50 [mm]

More than

50 [mm]

More than 10

More than 30 [mm]

Fixing Bolt

• 400 [W] or less: M4xL1 0 mounting holes at the top & bottom

• 0.8 [kW] or more: M5xL10 mounting holes at the top & bottom

Use A Cooling Fan When Installing Several Drives.

When installing several drives, you must the following criteria. Install a cooling

fan to prevent excessive temperature increase.If the surrounding temperature

is higher than the operational temperature, it may reduce the performance.

CSD5 Servo Drive

Page 25

Installation 2-3

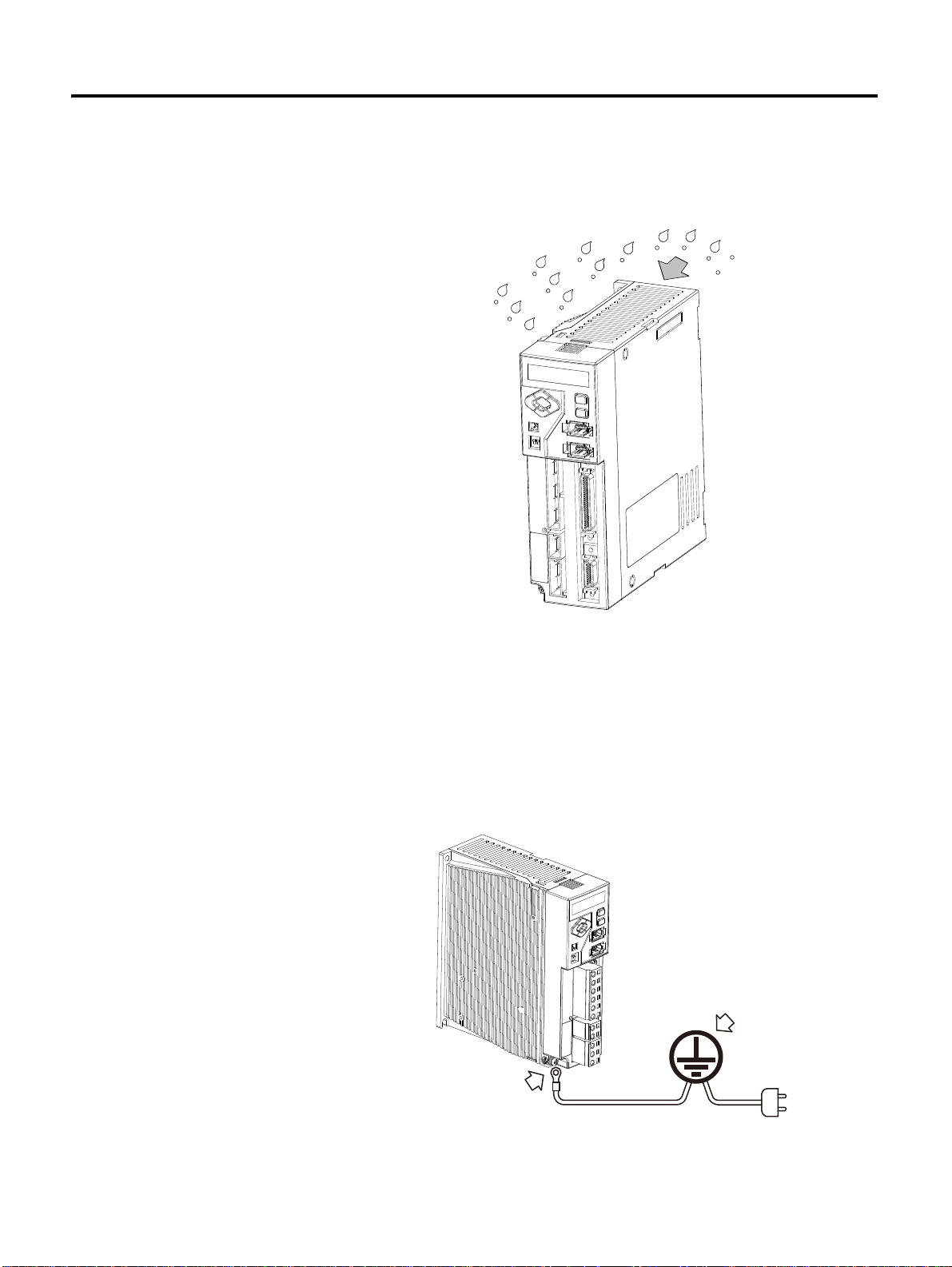

Use the Drive in a Clean Environment

Use the drive in a clean environment where there is no dust or humidity.

Ground

There is a grounding terminal at the bottom of the heat sink.

• 200 [W] or less: 1 mounting hole for M4 BOLT

• 400 [W] or above: 2 mounting holes for M4 BOLT

If not grounded, it may reduce the performance.

3 CSD5 Servo Drive

Page 26

2-4 Installation

IMPORTANT

TIP

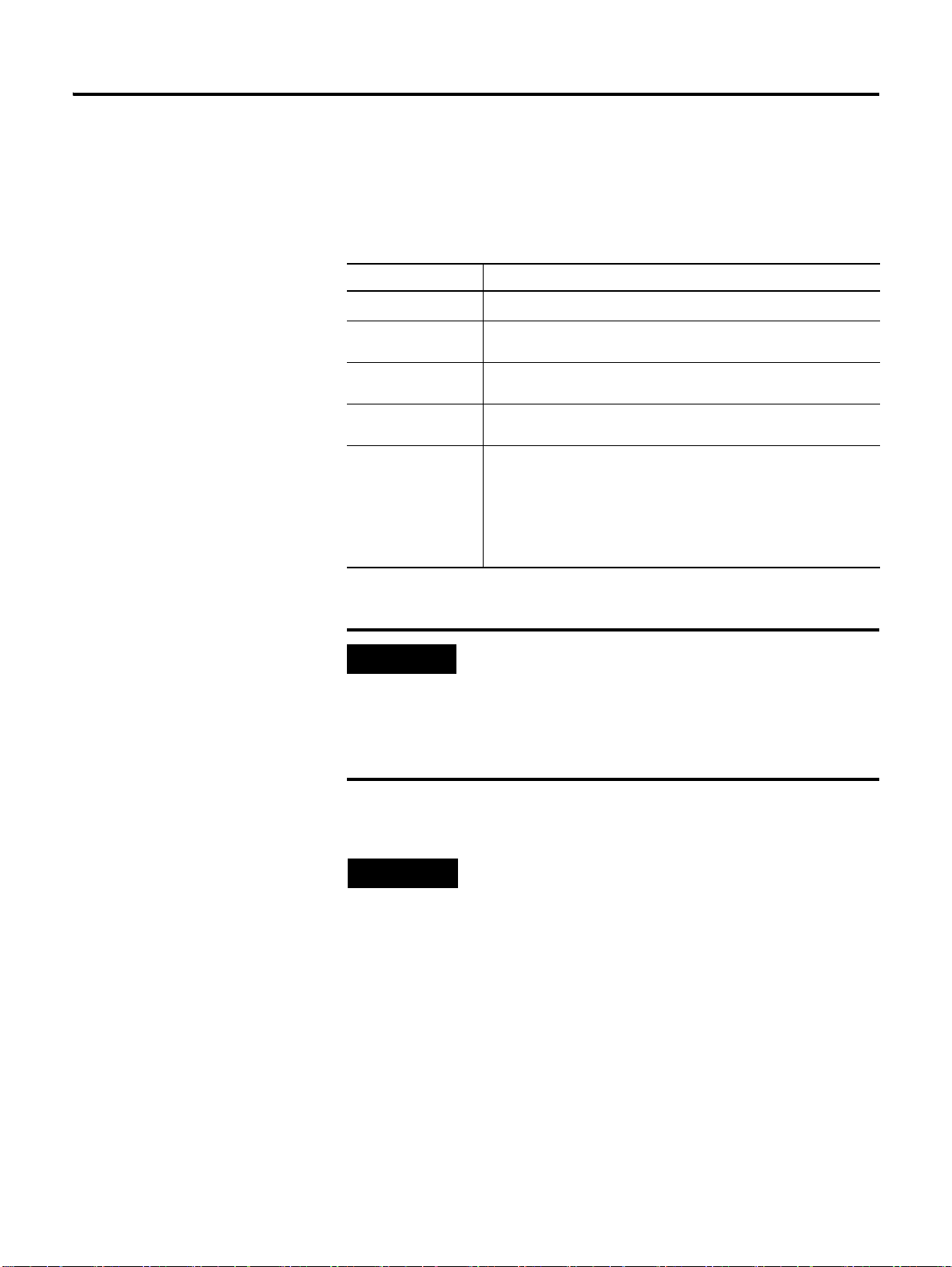

Installation Environment

CSD5 Servo Drive installation environment is like below.

Table 2.1 CSD5 Servo Drive Installation Environment

Item Installation Environment

Storing Temperature

Store it within -25 ~ 85 [

℃]

Operational

Temperature

Operational

Humidity

Vibration 5-55Hz @ 0.35mm(0.014") double amplitude, continuous

Operational Location Installation environment must meet the follwoing conditions:

Use it within 0 ~ 50 [

Use it below 5 ~ 95 [%] RH at a place without condensations

displacement, 55-500Hz @ 2g peak constant acceleration

• Indoors

• Well ventilation

• Easy checkup

• Without explosive gas

℃]

• To maintain reliability for a long time, use it within to

0~35 [℃].

• Install a separate cooling device at a place with high

ambient temperature and use it within the operational

temperature.

Servo Motor Installation

CSD5 Servo Drive

For numerical data related to the installation of the servo

motor, please refer to Servo Motor User Manual.

Page 27

Chapter 3

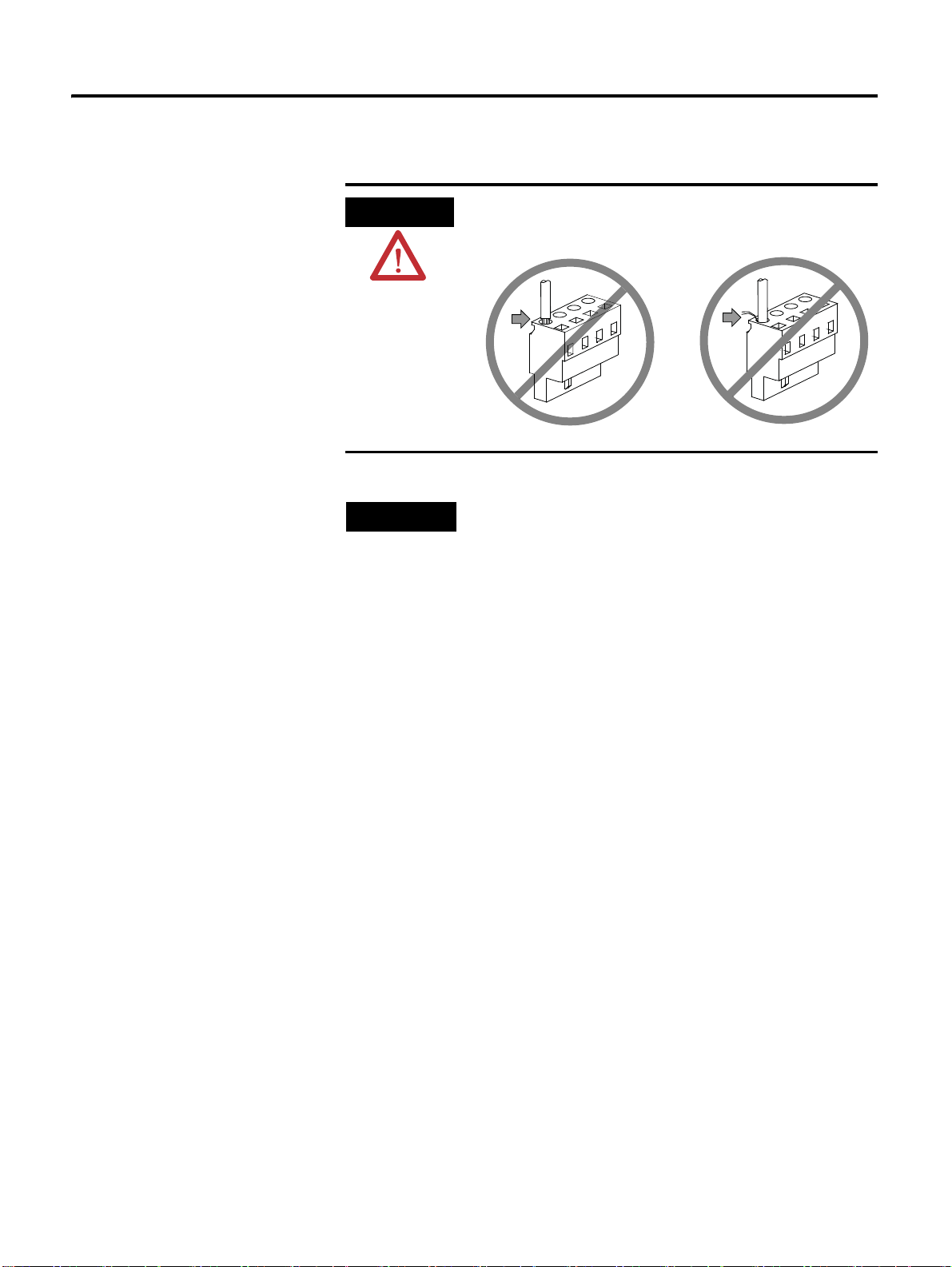

CAUTION

Wiring

This chapter describes the information on motor, host controller and

other wiring connected to the servo drive, along with the circuit

diagram.

Before You Begin

Pay attention to the following precautions when wiring.

• Wiring should be done only by the qualified personal.

• High voltage remains in the drive even through the

power is off. Therefore, do not inspect components

unless inside Charge lamp is off.

• Pay attention to the polarity when wiring.

• The heat sink of the drive generates high heat. Pay

attention to the heat sink when wiring.

1 CSD5 Servo Drive

Page 28

3-2 Wiring

Drive Nameplate

I/O Signal Connector <I/O>

Encoder Cable Connector

<Motor Feedback>

Communication and Operator

Connector

AC Main Power Input Terminal

Contor Power Input Terminal

DC Link Negative Output

Regenerative Resistor Terminal

Motor Cable Terminal

Operator

Analog Output Terminal

RS485 Terminating Resistance Setting

In this chapter, the circuit is divided into electric circuit and signal

circuit for easier and convenient explanation. Be fully aware of the

names of each terminal when reading this user’s manual.

Electric Circuit

CSD5 Servo Drive

The I/O signal connector I/O and encoder cable connector Motor

Feedback are included only in the description of the signal circuit. The

description of other connectors and omitted.

Name and Function

The terminal symbol is printed on the wiring socket at the electric

circuit terminal of the drive. Observe the drive to identify and

understand the terminals on the following table, and then wire

accordingly.

Page 29

Table 3.1 Electric Circuit

Terminal Terminal Symbol Purpose

Wiring 3-3

AC Power Terminal L1, L2, L3 400 [W] or lower Single phase 200 ~ 240 [V] (50/60 [Hz]) (L3 port must not

800 [W] or higher 3 phase 200 ~ 240 [V] (50/60 [Hz]) (800 [W] can be used as

Control Power Te rminal L1C, L2C No output division Single phase 200 ~ 240 [V] (50/60 [Hz])

Motor Cable T e rminal U, V, W Connect the motor cable.

Grounding Terminal

(Heat Sink)

Regenerative Register

Connection Port

B1, B2 200 [W] or lower As the function for regenerative energy consumption is not

Connect the power and motor cable to the grounding terminal.

400 [W] or higher If the capacity of mounted regenerative resistor is

be used)

Single phase )

required, the regenerative resistor does not have to be

mounted.

insufficient, remove it or connect it to the mounted

regenerative resistor in parallel.

AC Power Terminal (L1, L2, L3) and Control Power Terminal

(L1C, L2C)

The main power and control power can be divided when connecting to

the drive. Therefore, the user can configure surrounding circuits when

the main power is cut off in an emergency or when the drive itself

checks the status and cuts off the power.

If the drive independently checks the status and only the main power is

cut off, but not the control power, the drive can display the cause of

cut-off of the main power. The user can take appropriate action after

identifying the cause of cut-off of the main power.

Refer to the 3-5 page "Electric Circuit Diagram"for the Electric Circuit

Diagram of the power separation.

3 CSD5 Servo Drive

Page 30

3-4 Wiring

WARNING

CAUTION

Motor Cable Connectors (U, V, W)

The motor cable connectors (U, V, W) are output terminals.

Do not connect the input power. It may cause of the drive

damage.

Regenerative Register Connection Port

Refer to the 7-12 page "Reneration Resister" for more information the

Regeneration Resistor.

• When wiring the wiring socket, be careful not to expose

the core wire. It may cause an electric shock.

• Completely discharged before handling after power off.

CSD5 Servo Drive

Page 31

Electric Circuit Diagram

Lamp

Relay 1

L1C

L2C

L1

L2

N

L3

1MC

NOISE

FILTER

SW 1 OFF

SW 2 ON

Relay 1

<1>

1 MCCB

1MC

<3>

SUP

<2>

1MC

SERVO DRIVE

B2

B1

<Shield >

CN 2

V

U

W

PG

M

1/2

45

46

Relay 1

CN 1

SALM +

SALM -

24V

+ 24V IN

Power

MCCB (Molded Case Circuit Breaker)

MC (Magnetic Contactor)

<1> For more than one second, press the

Push Button S/W which allows the

current to flow when pressed.

<2> Connect this if the power needs to be

cut-off.

<3> Attach a surge suppressor to the MC

relay coil.

Alarm

Do not connect this to the

drive with less than 400 [W].

Connect this to the

grounding terminal of the

Regenerative

Resistor

Heat Sink

Servo Motor

I/O

Motor Feedback

DC-

CAUTION

Wiring 3-5

Use single-phase power in servo drive whose rated output

(capacity) is 400 [W] or lower. Thus, do not use the

5 CSD5 Servo Drive

terminal L3.

Page 32

3-6 Wiring

+

Prepare the Wires Strip of the

Phenol Terminial

Assemble the Socket

Wire

Terminal

Comress with the Phenol

Terminal Compressor

Socke

Lever

NOTE: Keep the length of the peeled wire less than 8

Using the Socket and Lever

This section describes the usage of wiring socket and lever provided

with servo drive.

• Connect only one wire at wire inlet of the socket.

• If the wire is pulled accidentally with an excessive force, rewire it

properly.

• The peeled wire can be used. (Keep the length of the peeled core wire

less than 8 [mm].)

• The use of phenol terminal is recommended for the reliability of wiring.

• Use a lever for wires provided with the product.

The following figure shows the sequence of assembling wire at the

socket.

1. As shown in the figure, insert lever in the socket and press it.

2. Insert wire into socket and release the lever.

3. Pull it slightly to check if the connection between the socket and wire is

normal.

The thickness of wire allowed by the socket is shown below.

Thickness of Wire

Twist AWG20 ~ AWG14

CSD5 Servo Drive

Page 33

Wiring 3-7

CAUTION

NOTE

Insert the wire completely. If peeled core wire is exposed, it

may cause an electric shock.

The lever is a small tool, used when wiring. Keep it for

other wiring jobs.

7 CSD5 Servo Drive

Page 34

3-8 Wiring

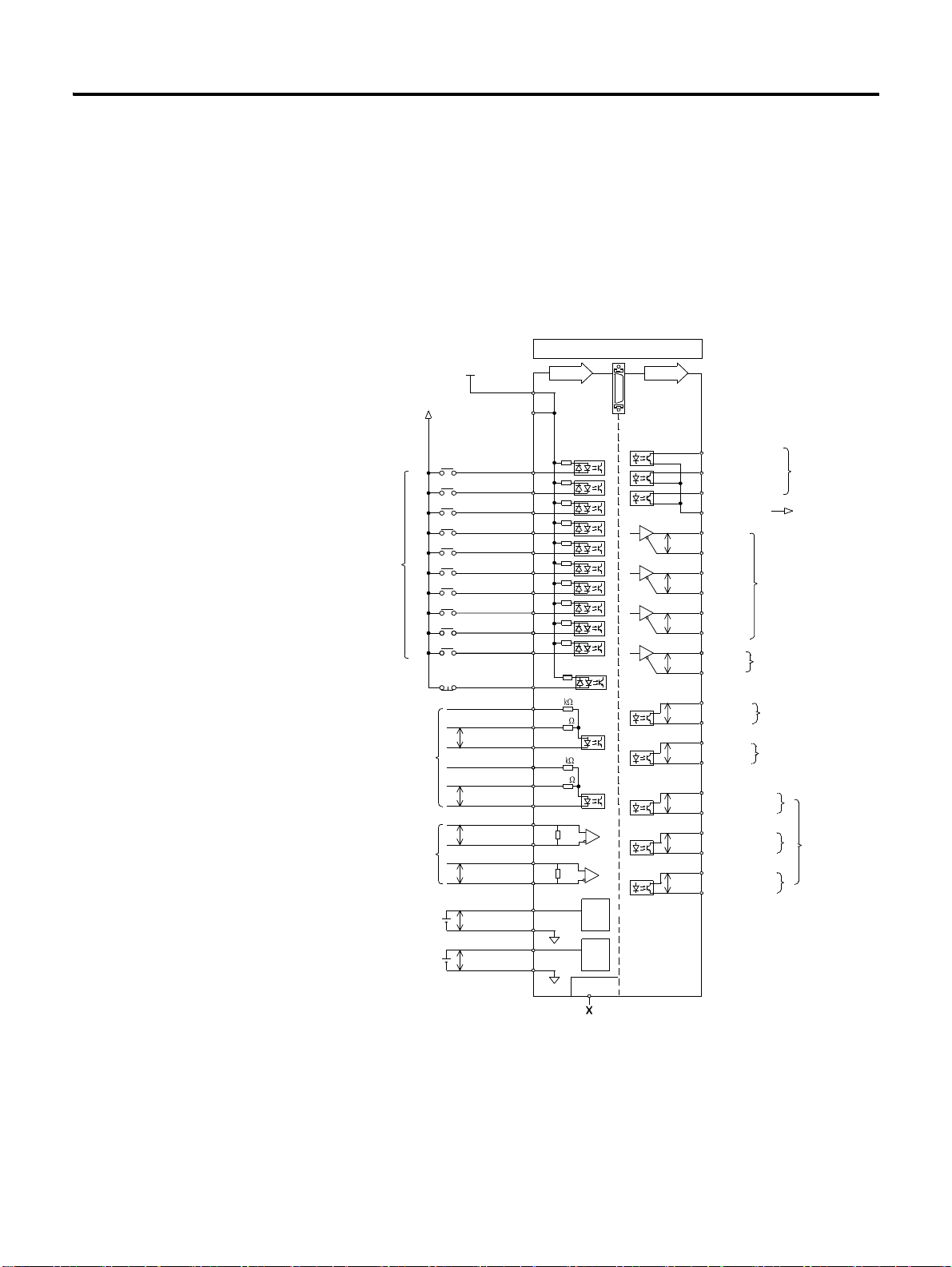

I/O Signal (I/O)

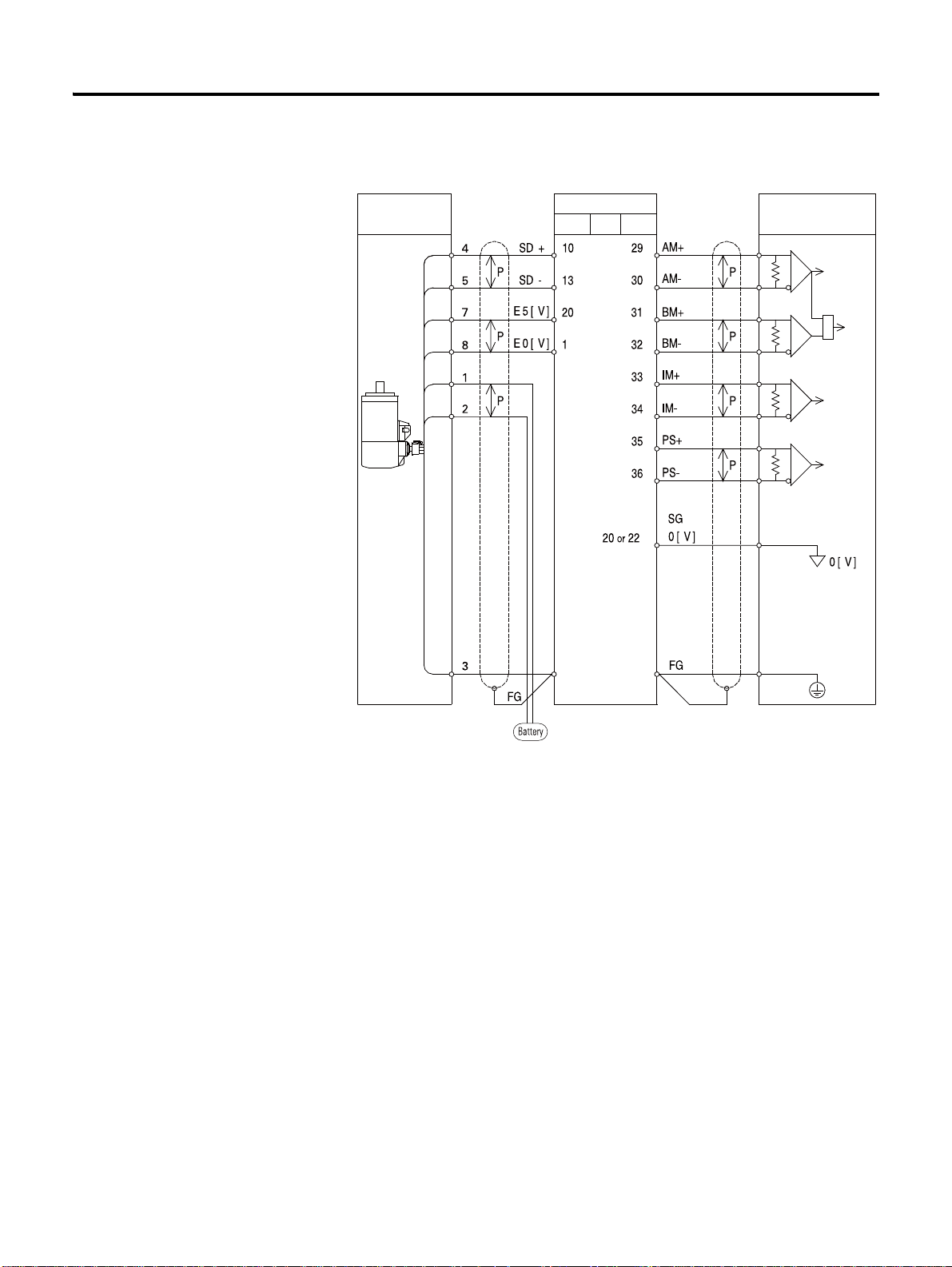

I/O Connection Diagram

This is the circuit diagram of a connector for I/O signal. It is divided

into input on the left and output on the right.

The Backup battery for absolute value encoder does not have the

separate terminal. It must be connected to motor encoder cable.

CN1

I/O

24V

Active Low/High

Programmable

Digital Inputs

Position

Command

High Frequency

Position

Command

Speed Command

-10V to +10V

Current Command

-10V to +10V

GND [or 24V]

24V [or GND]

INPUT1 (/SV-ON)

INPUT2 (P-OT)

INPUT3 (N-OT)

INPUT4 (/P-CON)

INPUT5 (/A-RST)

INPUT6 (/N-TL)

INPUT7 (/P-TL)

INPUT8

INPUT9

INPUT10

E-STOP

24V_PULS+

PULS +

PULS -

24V_SIGN+

SIGN +

SIGN -

HF_PULS +

HF_PULS -

HF_SIGN +

HF_SIGN -

(1)

(1)

INPUT

1

2

(1)

3

4

5

(1)

6

(1)

7

(1)

8

(1)

9

26

27

28

10

2

49

150

11

12

2

25

150

13

14

15

16

23

24

19

20

21

22

16-bit

A/D

12-bit

A/D

50

OUTPUT

37

38

39

40

29

P

30

31

P

32

33

P

34

35

P

36

17

P

18

45

P

46

41

P

42

43

P

44

47

P

48

FAULT 1 / OUTPUT 4

FAULT 2 / OUTPUT 5

FAULT 3 / OUTPUT 6

FCOM/OUTCOM

AM +

AM -

BM +

BM -

IM +

IM -

PS +

PS -

Z-PULSE +

Z-PULSE -

FAULT +

FAULT -

OUTPUT1+ (P_COM+)

OUTPUT1- (P_COM-)

OUTPUT2+ (TG_ON+)

OUTPUT2- (TG_ON-)

OUTPUT3+ (BK+)

OUTPUT3- (BK-)

Binary Fault Code Outputs

/ Digital Outputs

Binary Fault Code Ground

/ Digital Outputs Ground

Buffered

Encoder

Output

Absolute Position

Serial Output

Encoder

Marker

Pulse

Fault

Output

24V

Programmable

Digital

Outputs

CSD5 Servo Drive

(1) Factory Default Value

Page 35

Wiring 3-9

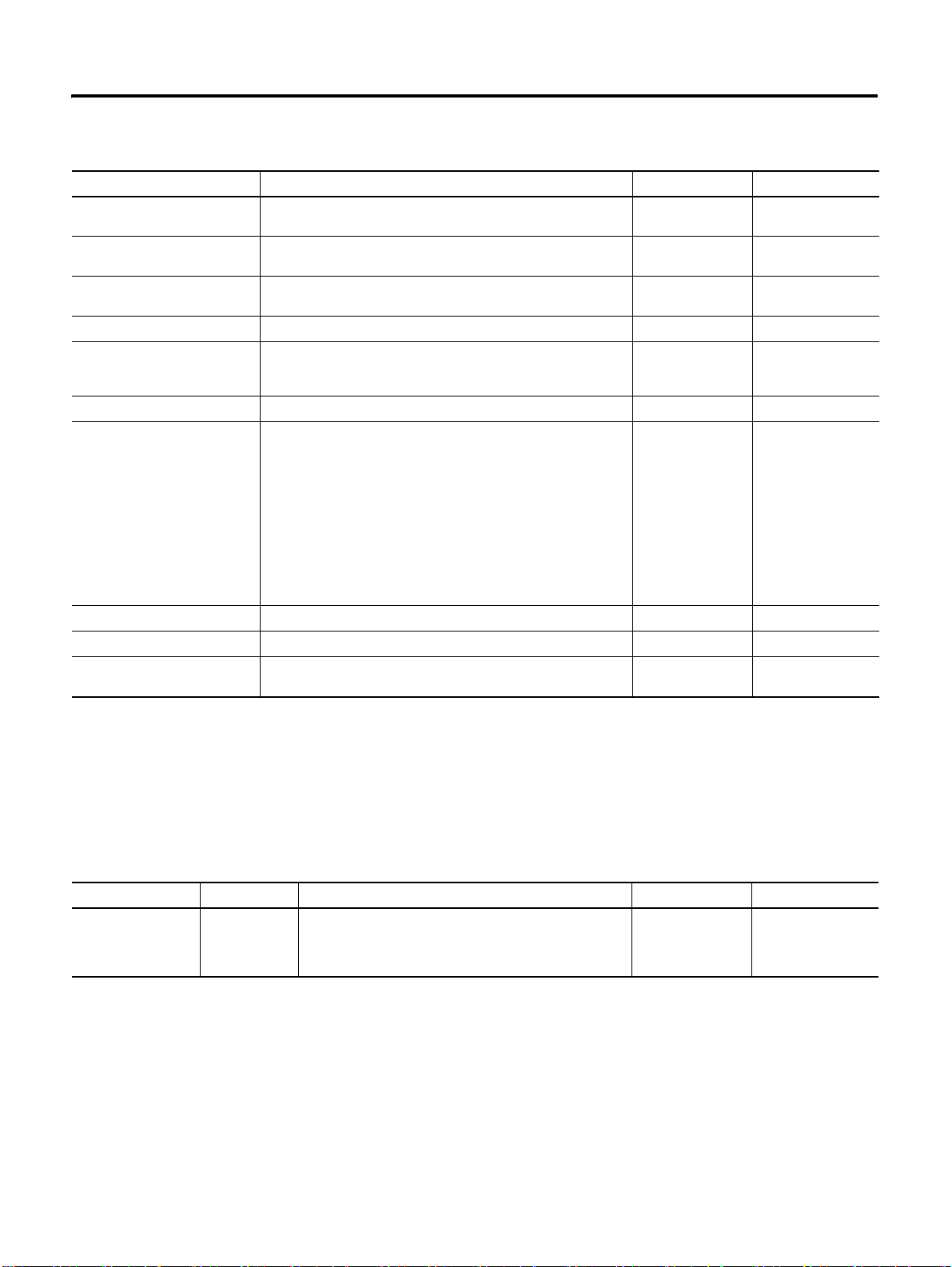

Table 3.2 (I/O) Pin Arrangement for host controller connections

Pin Symbol Description Pin Symbol Description

1 +24V IN External 24 [V] input for contact point

input

2 +24V IN External 24 [V] input for contact point

input

3 INPUT1

4 INPUT2

5 INPUT3

6 INPUT4

7 INPUT5

8 INPUT6

9 INPUT7

Digital input 1(/SV-ON)

Digital input 2(P-OT)

Digital input 3(N-OT)

Digital input 4(/P-CON)

Digital input 5(/A-RST)

Digital input 6(/N-TL)

Digital input 7(/P-TL)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

10 ESTOP ESTOP(Default:Disable) 35 PS+ Absolute Encoder Position data output+

11 PULS+ Position command pulse input+ 36 PS- Absolute Encoder Position data output12 PULS- Position command pulse input- 37 FAULT1/

13 SIGN+ Position command sign input+ 38 FAULT2/

14 SIGN- Position command sign input- 39 FAULT3/

15 HF_PULS+ High frequency position command

pulse input+

16 HF_PULS- High frequency position command

pulse input-

17 Z-PULSE+ Encoder Z-pulse output (Open

collector)

18 Z-PULSE- Encoder Z-pulse output (Open

collector)

19 VCMD+ Speed command input+ 44 OUTPUT220 VCMD- Speed command input- 45 FAULT+ Alarm generation signal output+

21 ICMD+ Current command input+ 46 FAULT- Alarm generation signal output22 ICMD- Current command input- 47 OUTPUT3+

23 HF_SIGN+ High speed position command sign

input+

24 HF_SIGN- High speed position command sign

input-

25 24V_SIGN+ Open collector sign input + for 24 [V]

level

(1)

Factory default values

26 INPUT8 Digital input 8

27 INPUT9 Digital input 9

28 INPUT10 Digital input 10

29 AM+ Encoder signal output A+

30 AM- Encoder signal output A31 BM+ Encoder signal output B+

32 BM- Encoder signal output B33 IM+ Encoder signal output Z+

34 IM- Encoder signal output Z-

Alarm code output 1/Digital output 4

OUTPUT4

Alarm code output 2/Digital output 5

OUTPUT5

Alarm code output 3/Digital output 6

OUTPUT6

40 FCOM/

Alarm code/ Output ground

OUTCOM

41 OUTPUT1+

42 OUTPUT1-

43 OUTPUT2+

48 OUTPUT3-

Digital output 1 +(P_COM+)

Digital output 1 -(P_COM-)

Digital output 2 +(TG_ON+)

Digital output 2 -(TG_ON-)

Digital output 3 +(BK+)

Digital output 3 -(BK-)

(1)

(1)

(1)

(1)

(1)

(1)

49 24V_PULS+ Open collector pulse input + for 24 [V]

level

50 NC Not Available

9 CSD5 Servo Drive

Page 36

3-10 Wiring

(I/O) Input Signal

Sequence Input Signal (Allocation)

Refer to the 5-1 page "Sequence I/O (Input/Output) Signal" for details

of sequence input signal.

Table 3.3 I/O Sequence Input Signal

Type Description Mode Reference

</SV-ON> Servo-ON When the servo is set to ON, voltage is applied to the servo

</A-RST> Alarm Reset It disables the Servo's Alarm. All

</G-SEL> Gain Group

Conversion

</P-CL> Forward Torque

Limit

</N-CL> Reverse Torque

Limit

<P-OT> Prohibit Forward

Rotation

<N-OT> Prohibit Reverse

Rotation

</P-CON> P Control

Conversion

</C-SEL> Control Mode

Conversion

</C-DIR>

</C-SP1>

</C-SP2>

</C-SP3>

</C-SP4>

Contact Speed Command

</Z-CLP> Zero Clamp Ignores the input value in the Speed Control when the

</INHIB> Inhibit Pulse

Command

</ABS-DT> Absolute

Encoder Data Transmission

</PCLR>Position Error Clear Clears position command, position feedback, and position

</ST ART>Start Set to start or stop the motor rotation by using the contact

</GEAR>Electronic Gear

Rate Shift

</R-ABS>Absolute Encoder

Multi-rotation Data Reset

motor; when it is set to OFF, voltage is cut off.

Use 2-group gain where it is set to ON and use current gain

where it is set to OFF. It converts gain of 2 groups.

When it is set to ON, limit the forward torque by the set value

[Ft-4.03].

When it is set to ON, limit the reverse torque by the set value

[Ft-4.04].

It prohibits the motor from rotating forward when the load

device reaches the limit of the available sect ion.

It prohibits the motor from rotating reversely when the load

device reaches the limit of the available sect ion.

It converts the Seed Controller from PI type controller to P

type controller. It is used to suppress the overshoot of the

excessive response and complete a faster response.

It is used to convert Control Mode when using it as

Combination Control Mode.

At the Contact Speed Control Mode, these input combinations

decide the rotation direction of the motor </C-DIR> and the

rotation speed </C-SP1 ~ /C-SP4>. The rotation speed for </

C-SP1~/C-SP3> input is set in [Ft-2.05~Ft-2.11]. The

analogue speed command voltage decides the rotation speed

for </C-SP4>. </C-DIR> is used to change the motor rotation

direction in Speed Control Mode.

command value is lower than the value set in the Speed Zero

Clamp Level [Ft-5.05].

Inhibits the position command pulse where it is ON. F

When it is set to ON, transmits the absolute encoder data to a

higher level through AM, BM signals.

error.

signal in Speed/Contact Speed Control Mode.

In the Position Control Mode, use the 2nd electronic gear

parameter [<:fc 2>Ft<:/fc>-3.05]and [Ft-3.06] where it is ON,

use the basic electronic gear parameter [Ft-3.01]and [Ft-3.02]

where it is OFF. It shifts between two electronic gear ratios.

Reset the multi-rotation data of the absolute motor. All

All

All

All

All

All

All

F, S, P, I

Combinational

Control Mode

Only

P

S

F, I

F, I

S, P

F

4-1 page

7-49 page

6-36 page

5-46 page

5-46 page

7-2 page

7-2 page

6-30 page

5-57 page

5-51 page

5-35 page

5-25 page

7-50 page

5-25 page

5-37 page

5-27 page

7-34 pag

e

CSD5 Servo Drive

Page 37

Wiring 3-11

Table 3.3 I/O Sequence Input Signal

Type Description Mode Reference

</BANK_SEL>Gain Bank

Select

</A-CL>Analog Torque Limit Current Limit Function is activated by the analogue torque

</H_SENS>Home Sensor When activated, the sensor indicates the Return to Home

</SHOME>Start Homing When activated, the system starts returning to home. I .

</PAUSE>Index Pause When activated, it decelerates until stop and pause the index

</STOP>Index Stop When activated, index movement ends. I .

</I-SEL0>

Index Selection 0 Input

</I-SEL1>

Index Selection 1 Input

</I-SEL2>

Index Selection 2 Input

</I-SEL3>

Index Selection 3 Input

</I-SEL4>

Index Selection 4 Input

</I-SEL5>

Index Selection 5 Input

</H_STOP>Homing Stop Stops Homing operation when it is set to ON. I

</START_I>Start Indexing Starts Indexing when it is set to ON. I

</ABS-MD> Absolute

Position Data Transfer Mode

Uses the 3rd and the 4th Gain Bank when it is set to ON. All

command input values when it is set to ON.

sequence that is detected.

sequence. It decides whether to stop or to continue the motion

by constantly monitoring the input status.

Used for the combinations to allocate indexes. I .

Absolute Data transfered to host contoller by photo coupler

output which output Fault Code when it is set to ON.

S, P

I

I.

F

6-38 page

General Input Signal (Fixed)

Power

Table 3.4 Power Input Signal

Signal Name Symbol Function Mode Reference

External power

input

11 CSD5 Servo Drive

+24V IN As control power input for contact point signal, +24 [V]

power should be prepared by users.

Power Specifications: 21.6 ~ 26.4V, 210mA

All

Page 38

3-12 Wiring

Emergency Stop

Table 3.5 Emergency Stop Input Signal

Signal Name Symbol Function Mode Reference

Emergency Stop E-STOP Connect and use an extra emergency stop switch to

quickly act upon emergency situation, users can select

whether to use in [Ft-0.05] constant.

All 3-18 page

Position Command

Table 3.6 Position command input signal

Signal Name Symbol Function Mode Reference

Pulse Command PULS+ Receives position command by pulse input. Can

PULSSIGN+

SIGN-

High Frequency

Pulse Command

Open Collector(24

[V]) Pulse

Command

Speed Command

Input

Torqu e Command

Input

HF_PULSE+ Connect the high frequency pulse input to this terminal.

HF_PULSEHF_SIGN+

HF_SIGN24V_PULSE+ For Open Collector 24 [V] pulse input, connect to this

PULS24V_SIGN+

SIGNVCMD+ Receives analog speed command.

VCMDICMD+ Receives analog torque command.

ICMD-

respond to line drive or 12 [V] & 5 [V] open collector

output of the host controller.

(Line Drive less than 3 [Mpps])

terminal without a pull-up resistance.

(-10 [V] ~ +10 [V])

(-10 [V] ~ +10 [V])

F

F

F

S

C

5-10 page

5-32 page

5-43 page

CSD5 Servo Drive

Page 39

Wiring 3-13

(I/O) Output Signal

Sequence Output Signal (Allocation)

Refer to the 5-1 page "Sequence I/O (Input/Output) Signal" for details

of sequence output signal.

Table 3.7 I/O Sequence Output Signal

Signal Name Description Mode Reference

</S_ALM> Alarm Outputs when Servo Alarm sets off. All

</P-COM (+, -)> Position

Completion Detection

</NEAR (+, -)> Position

Proximity Detection

</V-COM (+, -)> Speed

Match Detection

</TG-ON (+, -)> Rotation

Detection

</T -LMT (+, -)> T orque Limit

Detection

</V-LMT (+, -)> Speed Limit

Detection

<BK (+, -)> Brake Control It is the signal for the brake control installed inside or outside

</A-VLD> Absolute Position

Valid

</RDY> Drive Ready Means getting the operation ready while in the Servo-OFF

</WARN (+, -)> Warning Turns to ON when a Servo warning is detected. All

</HOMC (+,-)> Axis Homing When activated, it shows the completion of the Homing

</IMO (+,-)> In Motion Turns to ON when in motion. I .

</I-DW> In Dwell When activated, it indicates that the motor is on the hold

</O_ISEL0>

Index Selection 0 Input

</O_ISEL1>

Index Selection 1 Input

</O_ISEL2>

Index Selection 2 Input

</O_ISEL3>

Index Selection 3 Input

</O_ISEL4>

Index Selection 4 Input

</O_ISEL5>

Index Selection 5 Input

</E_SEQU> Sequence

Operation Completion

Turns to ON, when the position err or is with in th e set val ue of

the position completion range [Ft-5.00].

Turns to ON, when the position err or is with in th e set val ue of

the position completion range [Ft-5.02].

Turns to ON when the deviation between the speed command

and the motor rotation speed is within the set value of the

speed match decision range [Ft-5.03].

Turns to ON when the motor is rotating above the set value of

the rotation detection level [Ft-5.04].

Turns to ON when torque reaches the set value of the torque

limit.

Turns to ON when speed reaches the set value of the speed

limit.

of the servo motor.

Turns to ON when the absolute position data is valid while

using the absolute motor.

status.

operation.

position in the index movement and on stand-by for the dwell

time assigned.

Used to output the index number in use in the selected

indexing operation.

Turns to ON when the index movement is complete. I

F, I

F, I

F, S, P, I

All

All

All

All

All

All

I.

I.

I.

8-5 page

5-28 page

5-28 page

5-38 page

5-39 page

5-46 page

5-41 page

7-6 page

8-3 page

13 CSD5 Servo Drive

Page 40

3-14 Wiring

NOTE

NOTE

In this manual, < > is applied to the names of sequence I/

O signal. ex) </SV-ON>, </P-COM>

General Output Signal (Fixed)

Alarm Code

Table 3.8 Alarm Code Output Signal

Signal Name Symbol Function Mode Reference

Alarm code FAULT1/OUTPUT4

(Alarm 1/Digital

output 4)

Upon servo alarm generation, it outputs the

types of the servo alarm with the 3-bit.

Maximum rating of open collector: DC 30 [V],

20 [mA]

All

8-3 page

If one or more of Alarm code (FAULT1, 2, and 3) set to

Digital output, Alarm code does not output.

Encoder Signal

Table 3.9 Encoder Signal

Signal Name Symbol Function Mode Reference

Encoder Signal

Output

Absolute Encoder

Position S pulse

AM+ Displays multiplied encoder signal A, B, C pulse in the

AMBM+

BMIM+

IMPS+ Outputs the number of rotation by serial data when the

PS-

form of line drive. According to the parameter setting,

the drive can logically invert output of A, B pulse.

absolute encoder is used.

All

All

7-24 page

7-24 page

Servo Alarm

Table 3.10 Servo Alarm Output Signal

Signal Name Symbol Function Mode Reference

Servo alarm

Monitor Output

CSD5 Servo Drive

FAULT+ It is displayed if the servo alarm is generated. All

FAULT-

7-28 page

Page 41

Wiring 3-15

Encoder Z-pulse Display

Table 3.11 Encoder Z-pulse Output Signal

Signal Name Symbol Function Mode Reference

Encoder Z-pulse Z-PULSE + It is displayed if Z-Pulse of the encoder is detected. All

Z-PULSE -

15 CSD5 Servo Drive

Page 42

3-16 Wiring

Line Drive

SN75174

Host

P

150 [Ω]1 [kΩ ]

2.8 [V] ≤ (H Level) - (L Level) ≤

I/O

Open Collector

Host Controller

P

2 1

VF = 1.5 ~ 1.8

I/O

Vcc

TR1

VF

i

NOTE

(I/O) Input Circuit and

Interface

Describes the connection circuit for input from the host controller to

the servo drive.

Pulse Command Input Circuit

The drive receives the pulse output of host controller by position

command in position control mode.

Host controller can output pulse in line drive or open collector type.

Refer to the 5-10 page "Position Control Mode" for the servo drive

setting according to the selection.

Line drive - Maximum allowable frequency 900 [kpps](Duty ratio: 50:50)

– Input pin number

• PULS+ (11), PULS- (12)

• SIGN+ (13), SIGN- (14)

CSD5 Servo Drive

Open Collector (24 [V])- Maximum Allowable Frequency 250 [kpps]

– Input pin number

• 24V : PULS+ (49) , PULS- (12)

• 24V : SIGN+ (25), SIGN- (14)

For Open Collector 24 [V] input, it does not need the

external resistance.

High Frequency Line Drive - Maximum Allowable Frequency 3 [Mpps]

– Input pin number

Page 43

• PULS+ (15), PULS- (16)

Line Drive

SN75174

Host

P

I/O

NOTE

Analog Input Circuit

390 [Ω] (1/2

Host

P

I/O

Speed

12 [V] 2

1000:1

VCMD+

VCMD-

0 [V]

+

A/D

• SIGN+ (23), SIGN- (24)

Maximum allowable frequency of host controller’s pulse

command is

• 900 [kpps] for the line drive

• 3 [Mpps] for high speed line drive

• 250 [kpps] for the open collector

If the maximum allowable frequency is exceeded,

[E.PoSEr] servo alarm of position command pulse is

generated. Make sure the output of host controller does not

exceed the maximum allowable frequency.

Wiring 3-17

17 CSD5 Servo Drive

Analog Voltage Input Circuit

The drive receives analog voltage output of the host controller with

speed, speed of torque control mode and torque command.

Input impedance of speed and torque commands is about 10 [kΩ].

Maximum allowable voltage range of input signal is -10 [V] to +10 [V].

Input pin of I/O that uses analog voltage output of the host controller:

• Speed Command: VCMD+ (19), VCMD- (20)

• Torque Command: ICMD+ (21), ICMD- (22)

Page 44

3-18 Wiring

Analog Input Circuit

390 [Ω] (1/2

Host

P

I/O

Torque

12 [V] 2

1000:1

ICMD+

ICMD-

0 [V]

+

A/D

Relay Circuit

DC 24 [V] 50 [mA] or

Host

P

+24 [V]

3.3 [kΩ]

Sequence Input

Signal

I/O

i

Open Colletor Circuit

DC 24 [V] 50 [mA] or

Host

P

+24 [V]

3.3 [kΩ]

Sequence Input

Signal

I/O

i

Sequence Input Circuit

Relay or open collector output of the host controller is used for the

sequence input circuit.

Make sure that the input current i is within 7 [mA] to 15 [mA].

CSD5 Servo Drive

Emergency Stop Signal

This drive has a built-in circuit for the emergency stop situation.

To quickly respond to the equipment failure or dangerous situation, it

receives the emergency stop signal from #10 pin of I/O.

Emergency stop input can be done by the relay contact output of host

controller and installing a separate switch.

Page 45

Wiring 3-19

Normal

E-STOP Switch

Install a host

Controller or a

+24 [V]

I/O

External Power 24 [V]

1/2

E-STOP 10

E-Stop

E-STOP Switch

+24 [V]

External Power 24

1/2

E-STOP 10

NOTE

Whether to use the emergency stop input can be set by the parameter

[Ft-0.05]; the initial value is set as not to use.

#10 pin of I/O assigned below is used as the input pin only for the

emergency stop.

• If the emergency stop signal is input, [E.EStoP] servo

alarm is generated.

• Refer to the 8-3 page "Protection Function" more

information on the servo alarm.

• If the emergency stop is released, reset the alarm by

referring to the 7-49 page "Alarm Reset (run-08)".

• You can check the status of emergency stop signal

through the monitor mode describe in the 7-52 page

"Monitor Mode Function".

19 CSD5 Servo Drive

Page 46

3-20 Wiring

Host

P

0 [V]

I/O

R1

Host

P

0 [V]

I/O

DC 5~12 [V]

0 [V]

Photo-Coupler

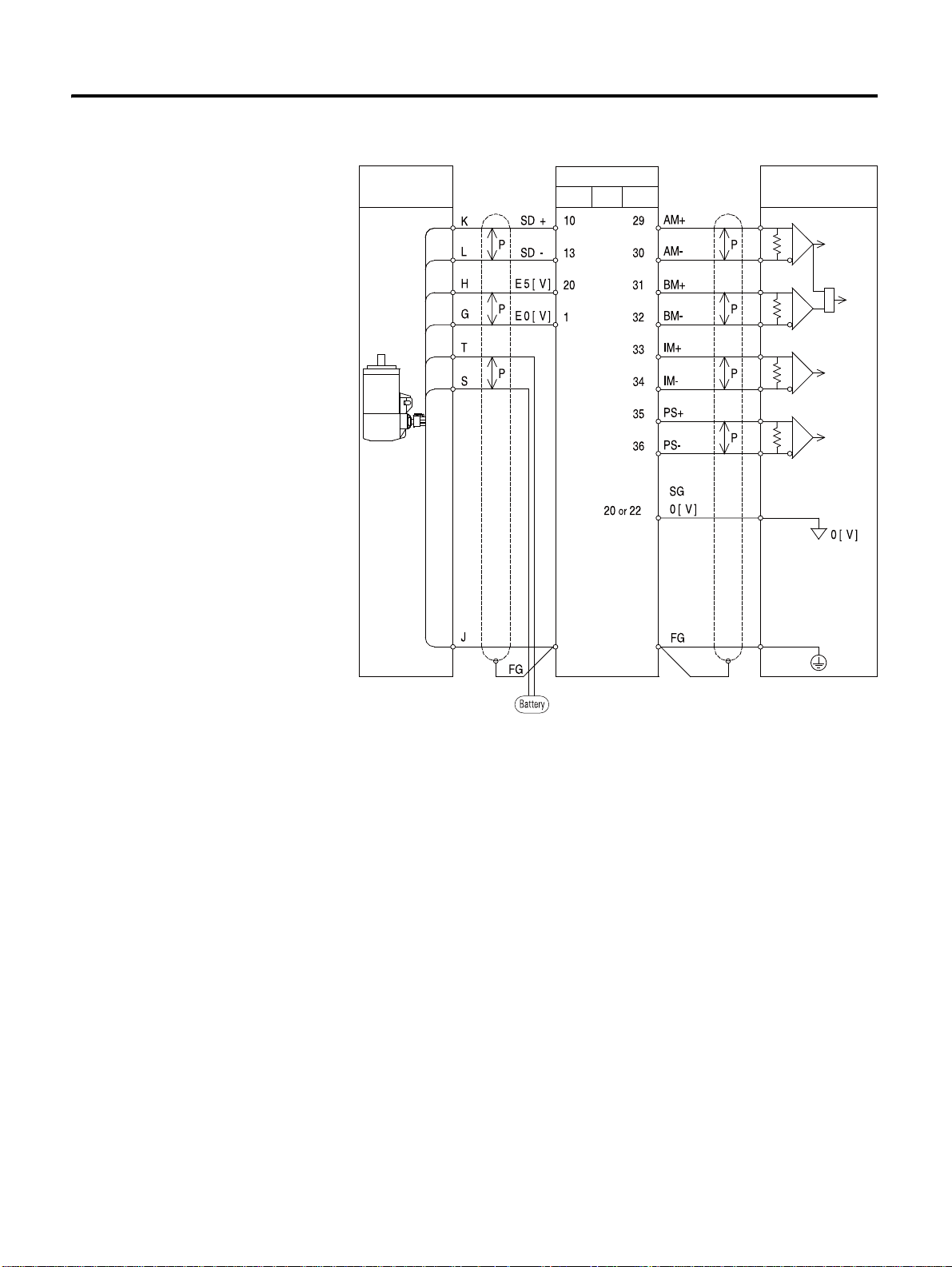

(I/O) Output Circuit and

Interface

There are 2 types for the servo drive output circuits. Design the input

circuit at the host controller suitable for the each output circuit.

• Line Drive Output

• Photo-Coupler output

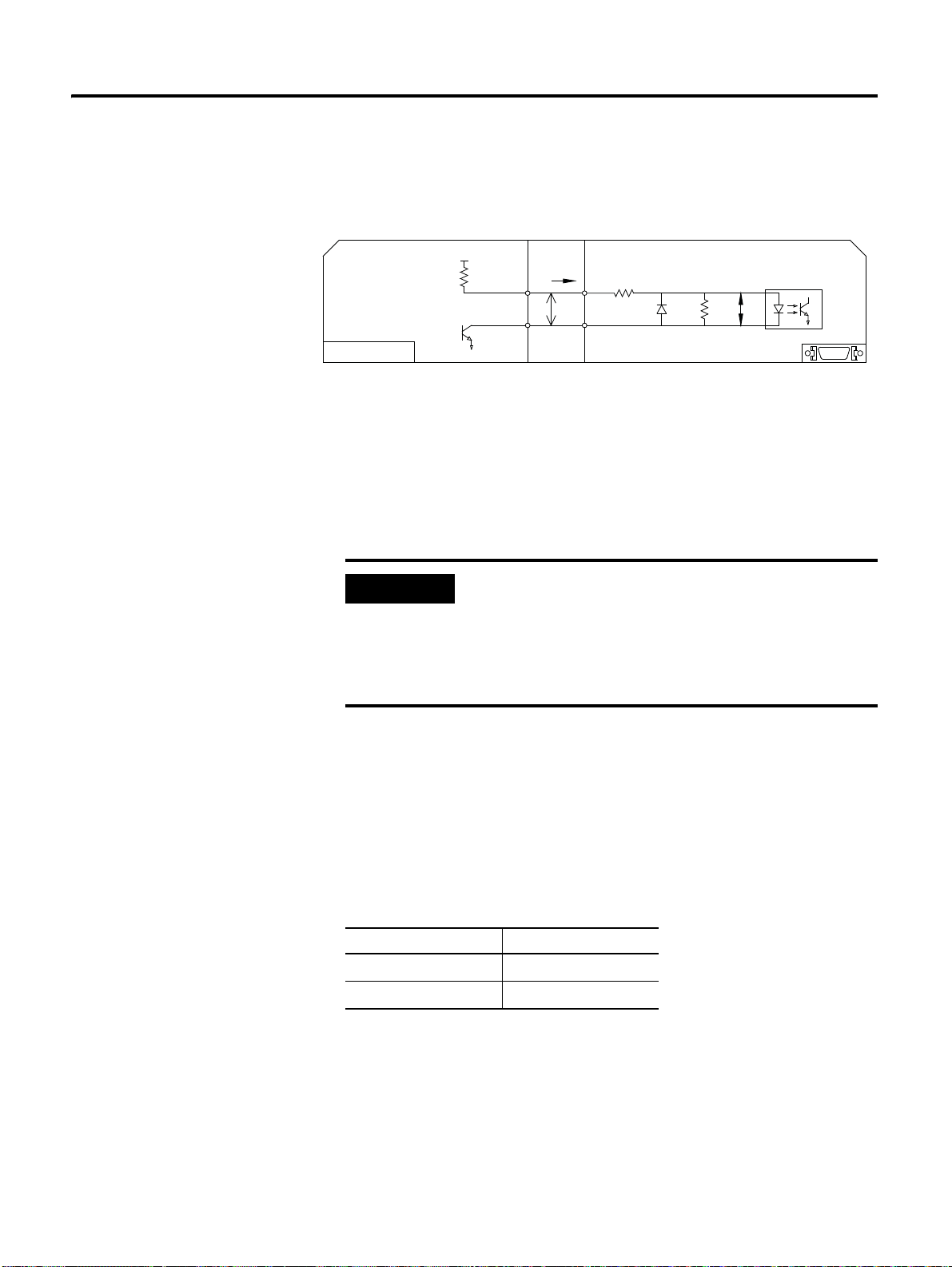

Line Drive Output

Output signal (AM+, AM-, BM+, BM-) that converted the encoder

serial data into 2 phase (A phase and B phase) pulse, zero point pulse

signal (IM+, IM-) and S phase rotation amount signal (PS+, PS-), are

output to line drive circuit. It is used to configure the position control

loop from the host controller. Receive the pulse signal with the line

receiver circuit in the host controller.

Set R1 value to 330 [Ω].

CSD5 Servo Drive

Photo-Coupler Output

Servo alarm, sequence output signal and encoder Z-pulse signal output are the

photo coupler output circuits.

Connect to the photo-coupler circuit of the host controller

:

Page 47

Connect to the relay circuit of the host controller:

Host

P

I/O

DC 5~24 [V]

0 [V]

Relay

Host

P

I/O

DC 5~12 [V]

0 [V]

Line Receiver

Connect to the line receiver circuit of the host controller:

Wiring 3-21

21 CSD5 Servo Drive

Page 48

3-22 Wiring

Encoder Wiring (Motor

Feedback)

Pin Arrangement of Motor Feedback

The table below shows the pin arrangement for each encoder.

Table 3.12 Pin Arrangement for Encoder C onnector (Motor Feedback)

Drive Motors

No. Function CSMT

CSMR

9 wire

Inc.

1EO [V]811G8G

2 - ---- 3 A 11A- 4 /A 22B- 5 B 33C- 6 /B 44D- 7 C 55E- -

RSMQ

RSMZ

9 wire

Inc.

RSMS

RSMD

RSMH

9 wire

Inc.

CSMT

CSMR

RSMQ

RSMZ

17-bit

Serial

(Abs, Inc)

RSMS

RSMD

RSMH

17-bit

Serial

(Abs, Inc)

8 /C 66F- 9 LMT- ---- 10 S1/SD+---4 K

11 - ---- 12 - ---- 13 SD- ---5 L

14 S2 ---- 15 - ---- 16 S3 ---- 17 LMT+ ---- 18 - ---- 19 - ---- 20 E5 [V] 7 10 H 7 H

FG 9 12 J 3 J

CSD5 Servo Drive

Page 49

Wiring 3-23

CON A.

(Connect this to

Moter Feedback )

CON B.

Connect this to the

encoder cable of the

Encoder Cable

1 PIN

2 PIN

NOTE

Terminal Type

The table below shows the terminal type and specifications of the

encoder cable.

Connector CON A for connection to Motor Feedback of servo drive:

One type regardless of motor model and encoder.

Model Number Manufacturer

10120-3000PE

10320-52F0-008(LATCH)

10320-52A0-008(SCREW)

3M

Connector CON B for connection to the encoder cable of servo motor:

Motor Type Housing Terminal Manufacturer

CSMT, CSMR 9 wire Inc.

RSMZ, RSMQ 9 wire Inc. 171162-1

RSMS, RSMD,

RSMH, RSMF, RSMK,

RSML

Serial Absolute

Serial Inc.

9 wire Inc. DMS 3108B20-29S or DMS 3106B 20-29S DDK

172161-1 170361-1

or

70365-1

AMP

Power cable connector for large capacity motor packed with the motor.

Do not connect FG of servo drive to host controller if

GND and FG are common, or if there is no separate FG.

23 CSD5 Servo Drive

Page 50

3-24 Wiring

Host Encoder

Servo Drive

Motor I/O

Host Encoder

Servo Drive

Motor I/O

Encoder Signal Process

Incremental encoder (9 wire Inc.) connection of CSMT/R motors.

Incremental encoder (9 wire Inc.) connection of RSMS/D/F/H/K/L

motors.

CSD5 Servo Drive

Page 51

Serial encoder connection of RSMS/D/F/H/K/L motors.

Host Encoder

Servo Drive

Motor I/O

Serial I/F Circuit